Electrostatic spinning device

An electrospinning and collecting device technology, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of industrialization, cumbersome cleaning and maintenance, and easy blockage of needles, etc. , to achieve the effect of wide choice of viscosity, fine diameter and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

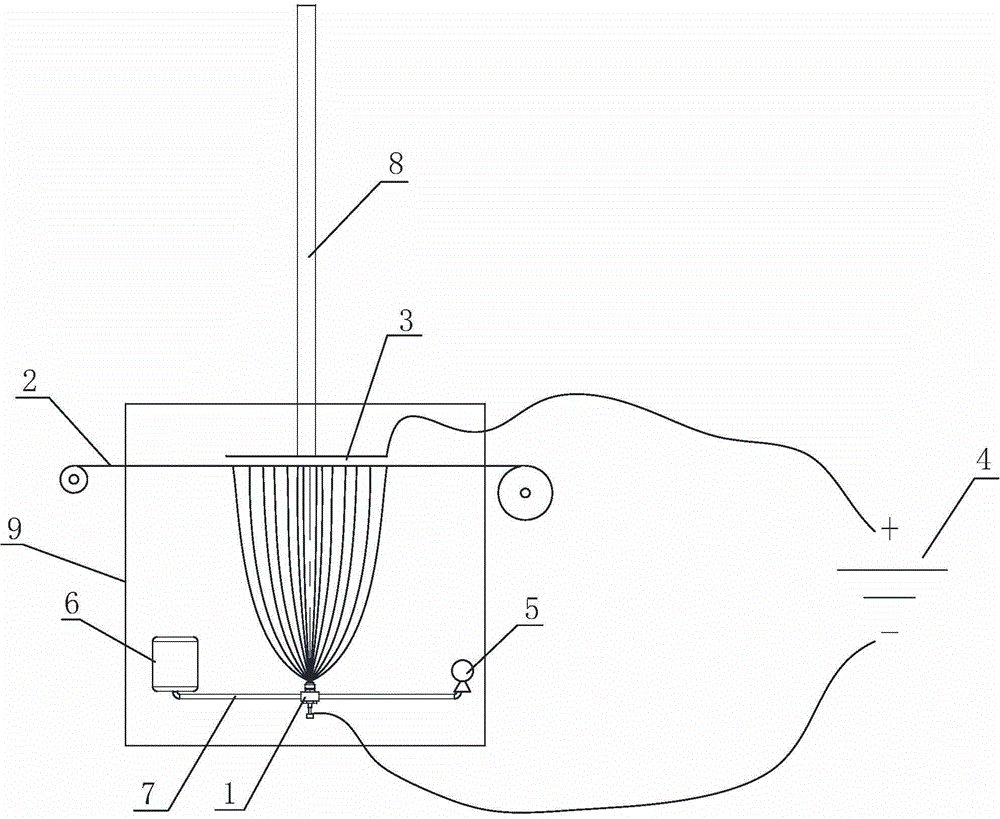

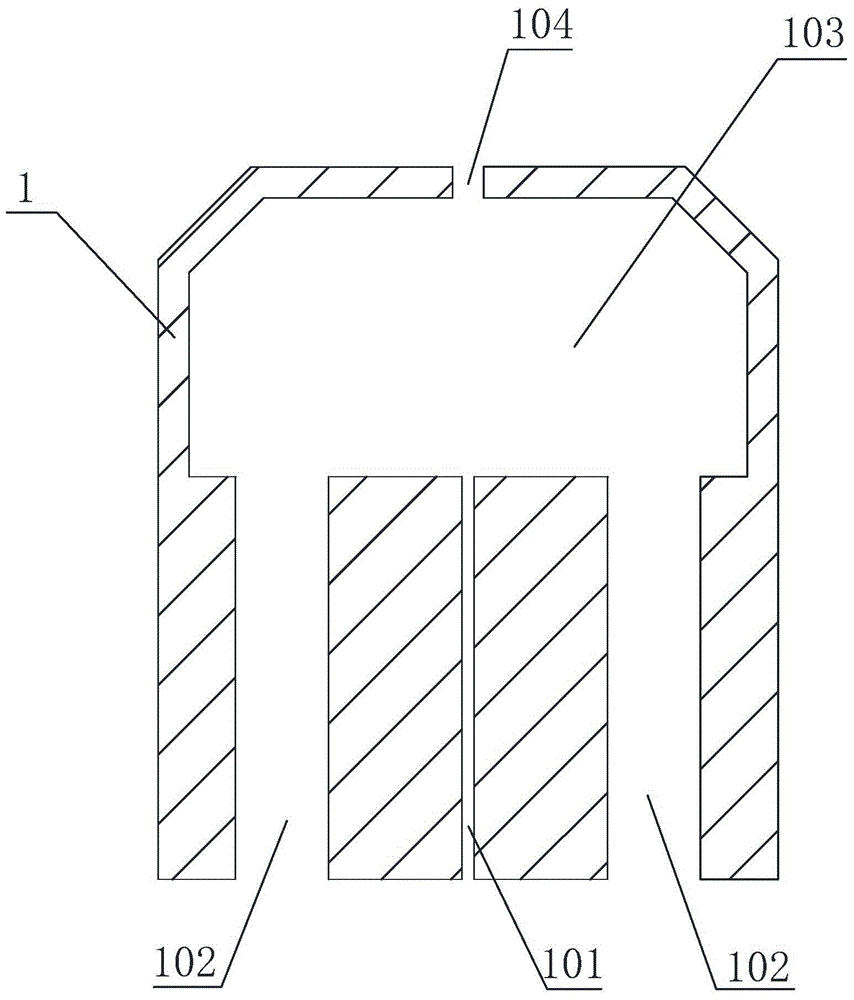

[0025] With reference to the accompanying drawings, an electrospinning device includes a nozzle 1 , a collecting device 2 , an electrode 3 and a high-voltage power supply 4 . The nozzle 1 is provided with a gas flow channel 101 along the central axis direction, and two or three liquid flow channels 102 are arranged in parallel around the gas flow channel 101. The diameter of the gas flow channel 101 is 0.1-0.6mm, as specifically It can be 0.1 mm, 0.3 mm, 0.5 mm or 0.6 mm, etc., and the diameter of the liquid channel 102 is 2-3 mm, for example, it can be 2 mm, 2.5 mm, or 3 mm. The inlet of the gas channel 101 is connected to the gas pump 5 through a gas delivery pipeline, and a gas purification and drying device and / or a heating device are arranged on the gas delivery pipeline. The inlet of the liquid channel 102 is connected to the spinning liquid storage tank 6 through a liquid delivery pipeline. An atomizing chamber 103 is provided inside the nozzle 1 , and the outlet of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com