Preparation method of porous silicon carbide nanofiber

A technology of porous silicon carbide and nanofibers, applied in the fields of fiber chemical characteristics, rayon chemical post-treatment, textiles and papermaking, etc., can solve the problem of low yield of very dilute solution spinning fibers, difficulty in porous silicon carbide nanofibers, discomfort Due to problems such as large-scale preparation, it can achieve the effects of easy adjustment of diameter and shape, good spinnability, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

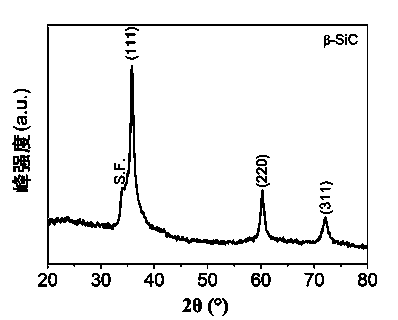

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps:

[0024] (1) Preparation of spinning solution: Add polyacrylonitrile powder to DMF, the mass ratio of polyacrylonitrile powder to DMF is 1:10 (that is, the mass concentration of polyacrylonitrile is 9.1wt%), stir to make polyacrylonitrile completely dissolved to obtain a homogeneous spinning solution;

[0025] (2) Electrospinning: The homogeneous spinning solution obtained in step (1) is subjected to electrospinning. The nozzle used for electrospinning is a metal needle with an inner diameter of 0.8mm, the spinning voltage is 16kV, and the receiving distance is 20cm. The speed is 10 μl / min, the spinning temperature is 20°C, the relative air humidity is 60RH%, and a flat aluminum foil receiver is used to prepare nano-polyacrylonitrile fibrils;

[0026] (3) Pre-oxidation crosslinking: Place the polymer nano-polyacrylonitrile fibrils obtained in step (2) in an oxidation furnace, raise the temperature at a rate of 5°C / min, keep...

Embodiment 2

[0031] This embodiment includes the following steps:

[0032] (1) Preparation of spinning solution: Add polyacrylonitrile powder to DMF, the mass ratio of polyacrylonitrile powder to DMF is 1.2:10 (that is, the mass concentration of polyacrylonitrile is 10.7wt%), stir to make polyacrylonitrile completely Dissolve and prepare a homogeneous spinning solution;

[0033] (2) Electrospinning: The homogeneous spinning solution obtained in step (1) is subjected to electrospinning. The nozzle used for electrospinning is a metal needle with an inner diameter of 0.8mm, the spinning voltage is 16kV, and the receiving distance is 20cm. The rate is 10 μl / min, the spinning temperature is 20°C, the relative air humidity is 60RH%, and parallel electrodes are used as receivers to prepare ordered nano-polyacrylonitrile fibrils;

[0034](3) Pre-oxidation cross-linking: place the polymer nano-polyacrylonitrile fibrils obtained in step (2) in an oxidation furnace, raise the temperature at a rate o...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] (1) Preparation of spinning solution: Add polyacrylonitrile powder to DMF, the mass ratio of polyacrylonitrile powder to DMF is 1.2:10 (that is, the mass concentration of polyacrylonitrile is 10.7wt%), stir to make polyacrylonitrile completely Dissolve and prepare a homogeneous spinning solution;

[0041] (2) Electrospinning: The homogeneous spinning solution obtained in step (1) is subjected to electrospinning. The nozzle used for electrospinning is a metal needle with an inner diameter of 0.8mm, the spinning voltage is 16kV, and the receiving distance is 20cm. The speed is 15 μl / min, the spinning temperature is 25°C, the relative air humidity is 60RH%, and a flat aluminum foil receiver is used to prepare nano-polyacrylonitrile fibrils;

[0042] (3) Pre-oxidation crosslinking: Place the polymer nano-polyacrylonitrile fibrils obtained in step (2) in an oxidation furnace, raise the temperature at a rate of 3°C / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com