Patents

Literature

81 results about "Compressed air filters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compressed air filters, often referred to as line filters, are used to remove contaminants from compressed air after compression has taken place. When the filer is combined with a regulator and an oiler, it is called an air set.

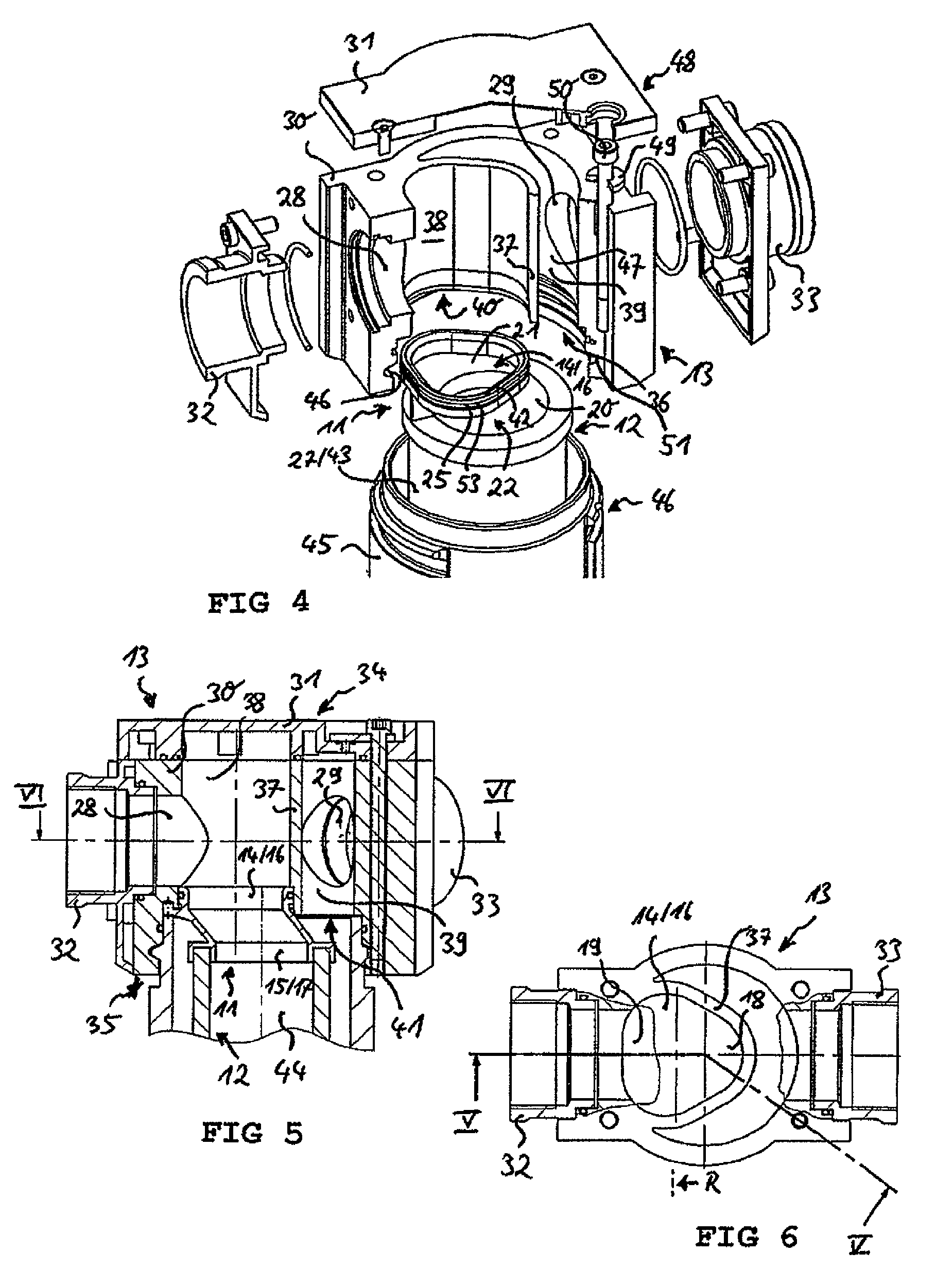

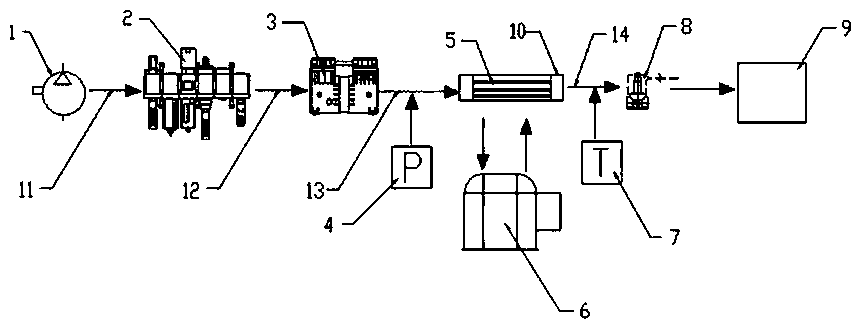

Cooling device for cutting process

InactiveCN101209528AReduce the temperatureSimple and fast operationPipeline systemsPressure vesselsMicrocontrollerControl signal

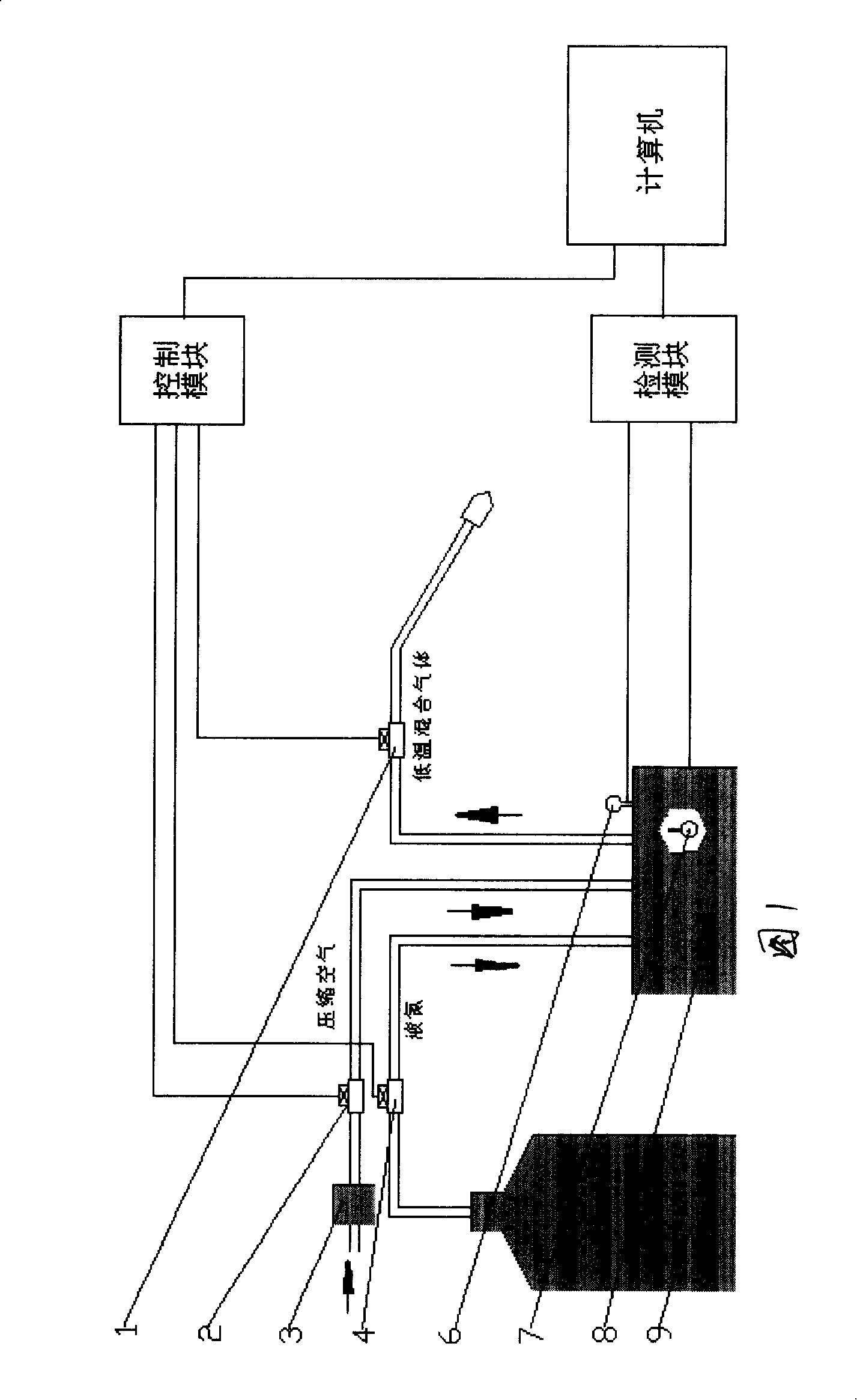

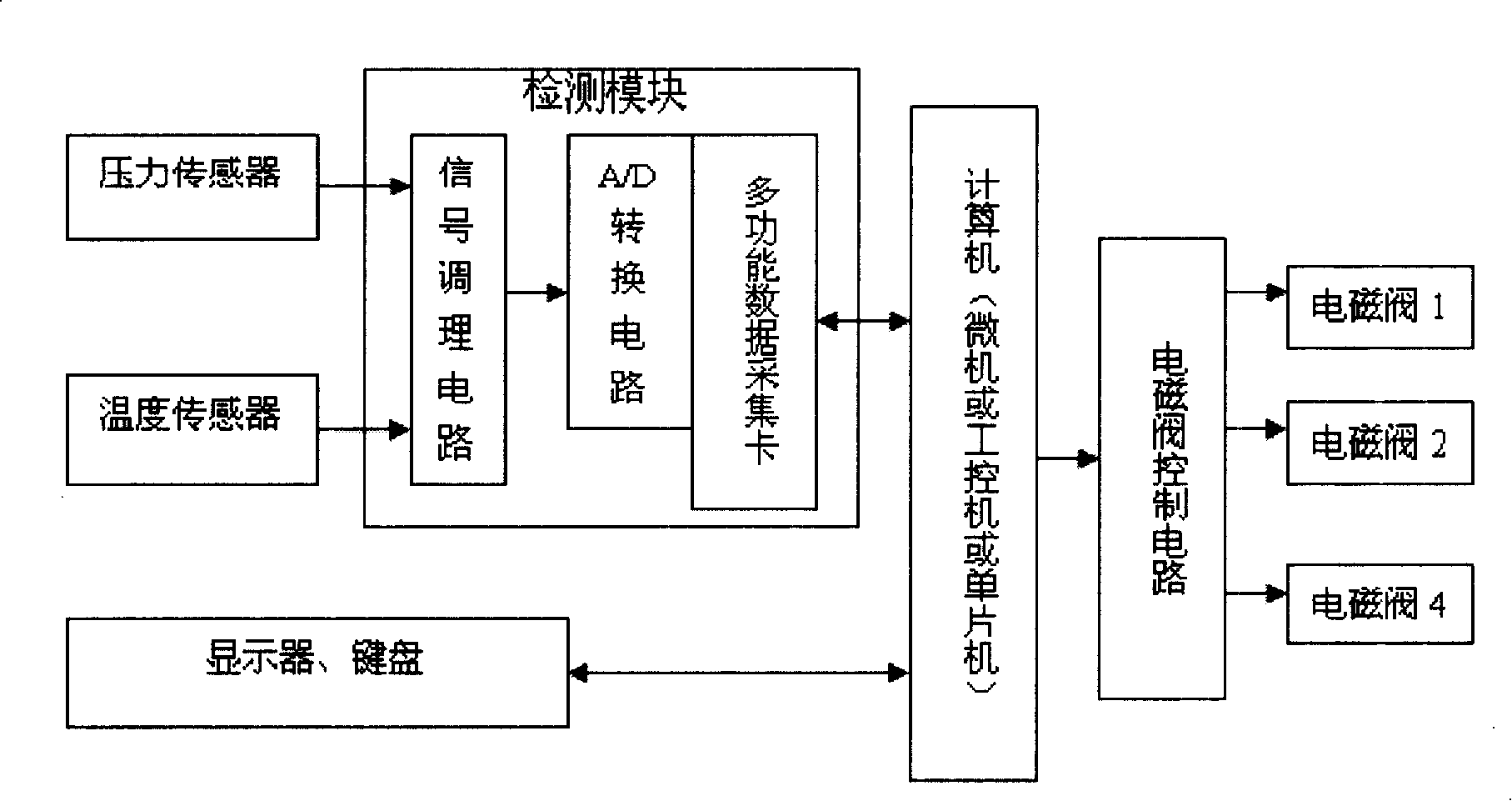

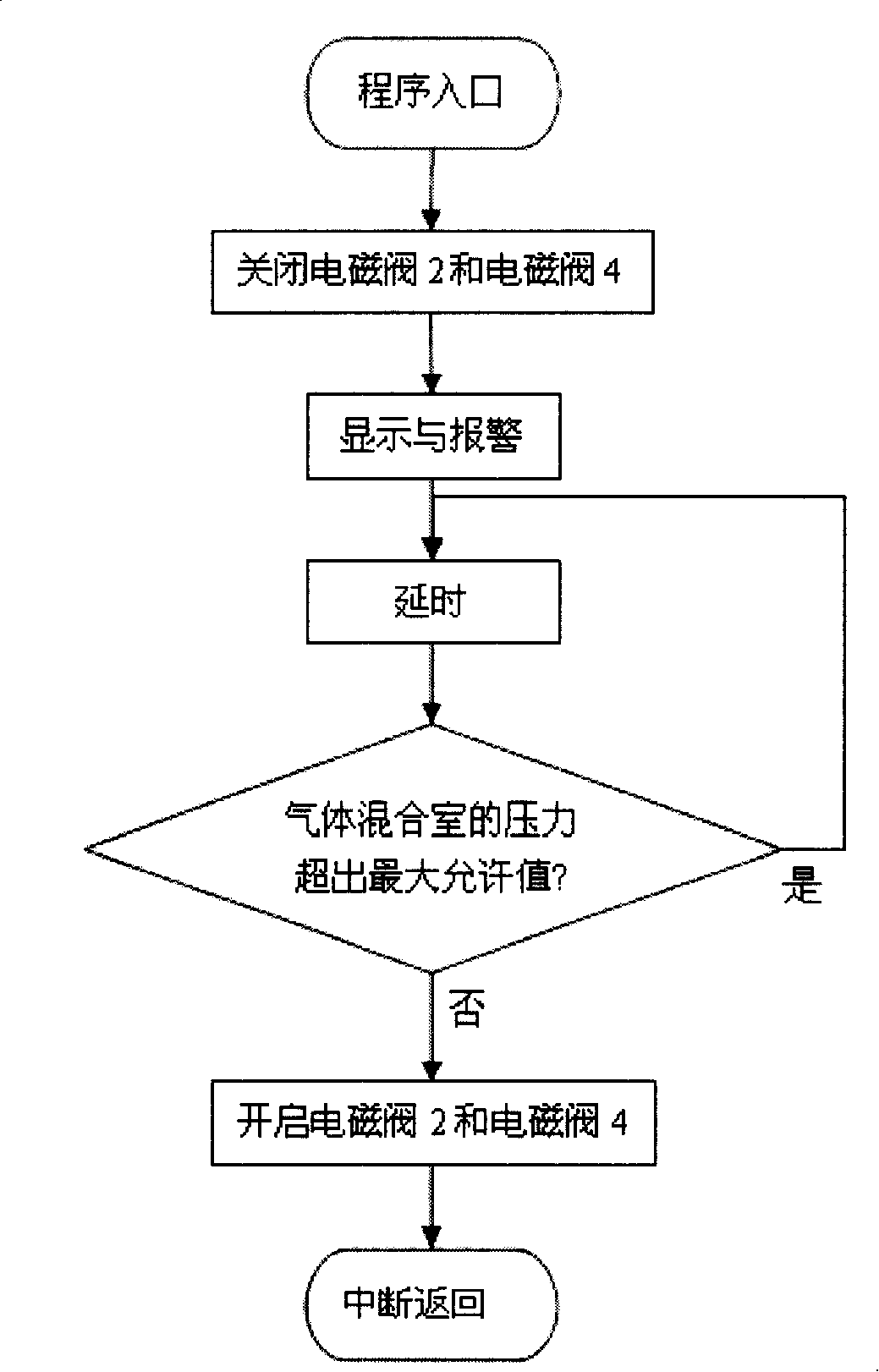

The invention provides a cutting processing cooling device, comprising a low-temperature liquid storage tank 9, a gas mixing room 8, a compressed air filter 3, a pipe joint, a liquid nitrogen conveying pipe, electromagnetic valves 1, 2, 4, a pressure sensor 6, a temperature sensor 7, a control module, a detection module, a computer (industrial computer, micro-computer or singlechip), a display, a keyboard, and a signal line. The low-temperature liquid storage tank 9 is connected with the gas mixing room 8 through a gas conveying pipe and the electromagnetic valve 4; the compressed air is connected with the gas mixing room 8 through the gas conveying pipe, the filter 3 and the electromagnetic valve 2; the low-temperature gas and the normal-temperature gas are mixed in the mixing room; the output of the gas mixing room 8 passes through the gas conveying pipe and the electromagnetic valve 1; the temperature sensor 7 and the pressure sensor 6 in the gas mixing room 8 are connected with the detection module through the signal line; the electromagnetic valve 1, the electromagnetic valve 2 and the electromagnetic valve 4 are connected with the control module through the control signal line; the control module and the detection module are connected with the computer through communication lines.

Owner:ZHEJIANG UNIV OF TECH

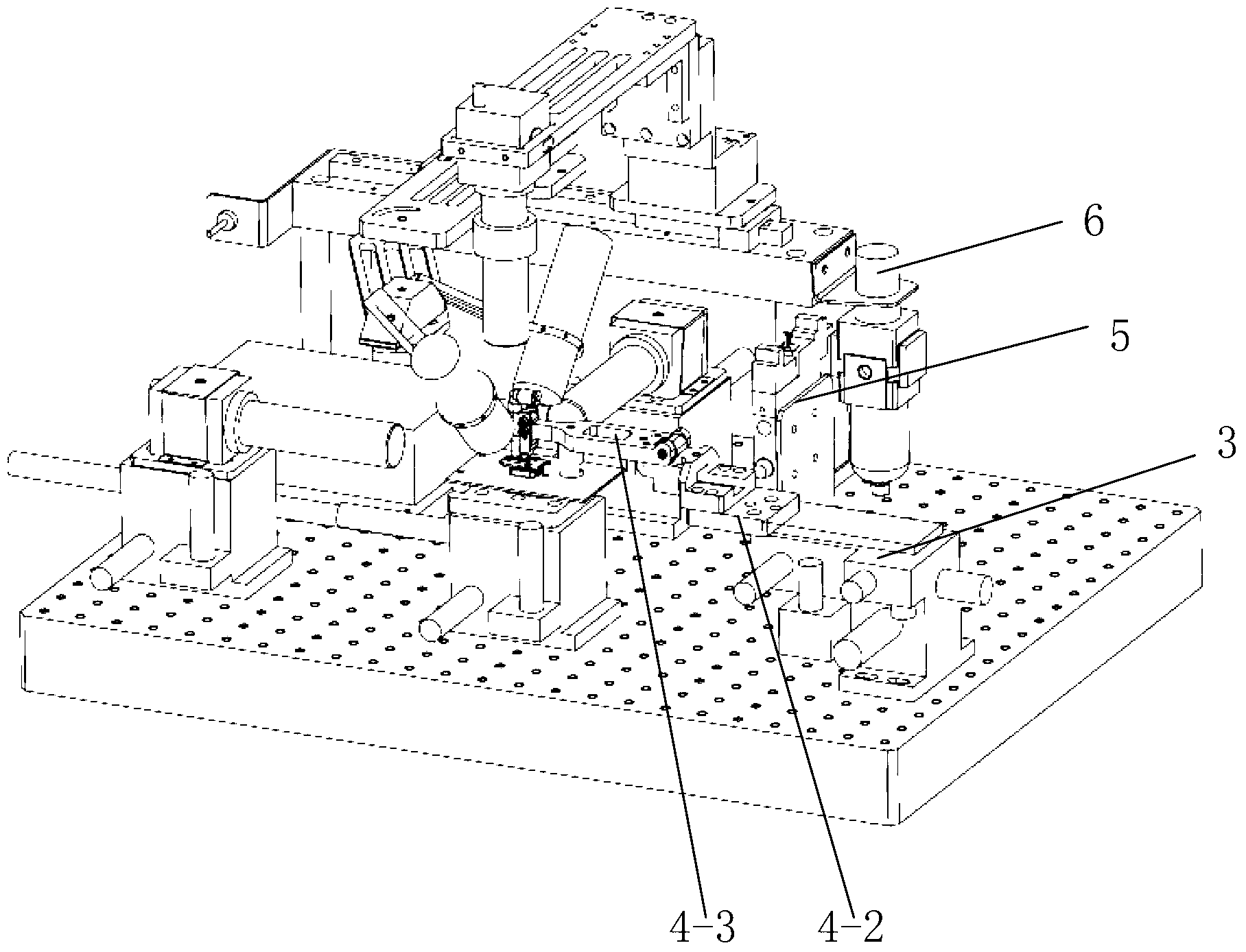

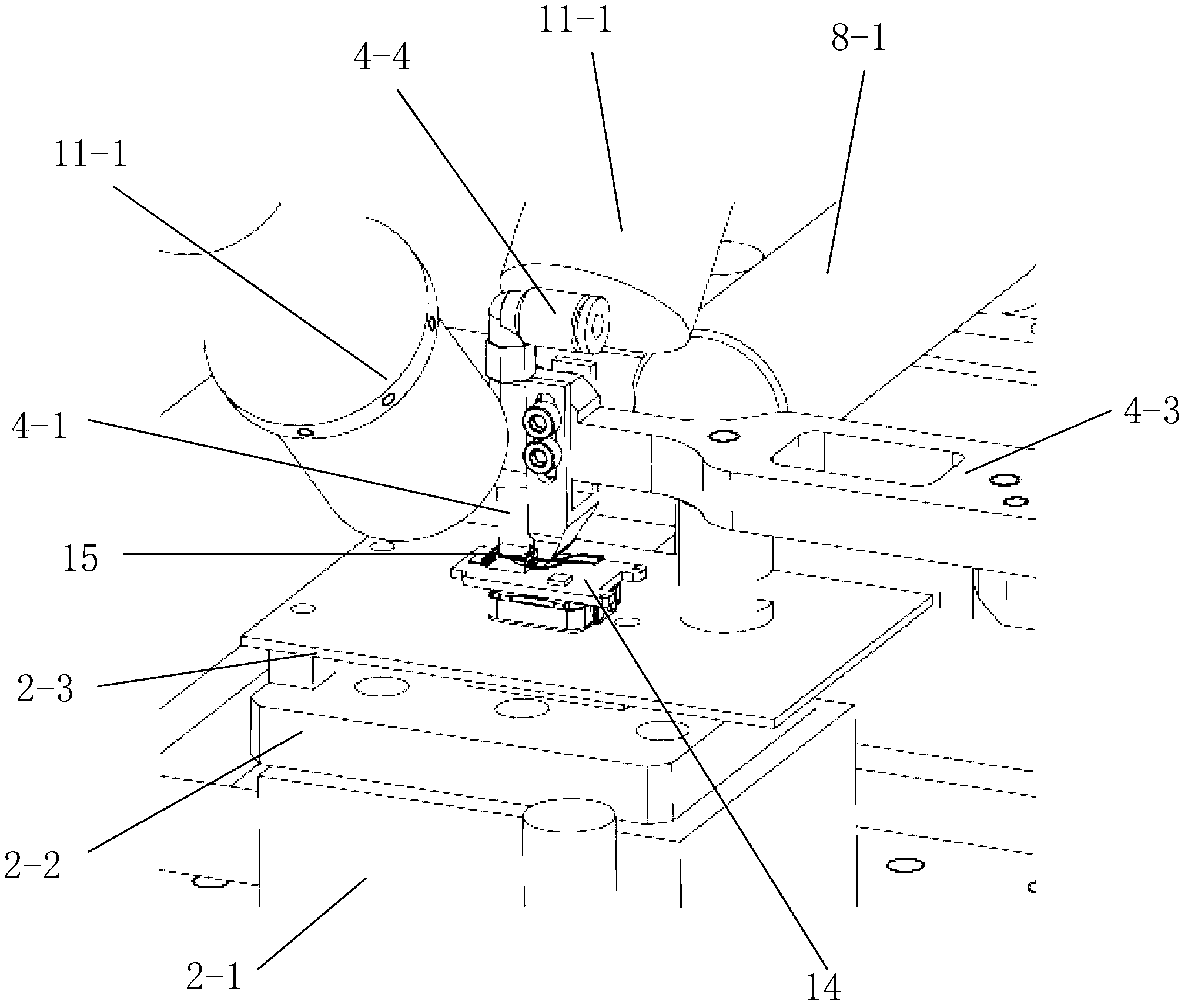

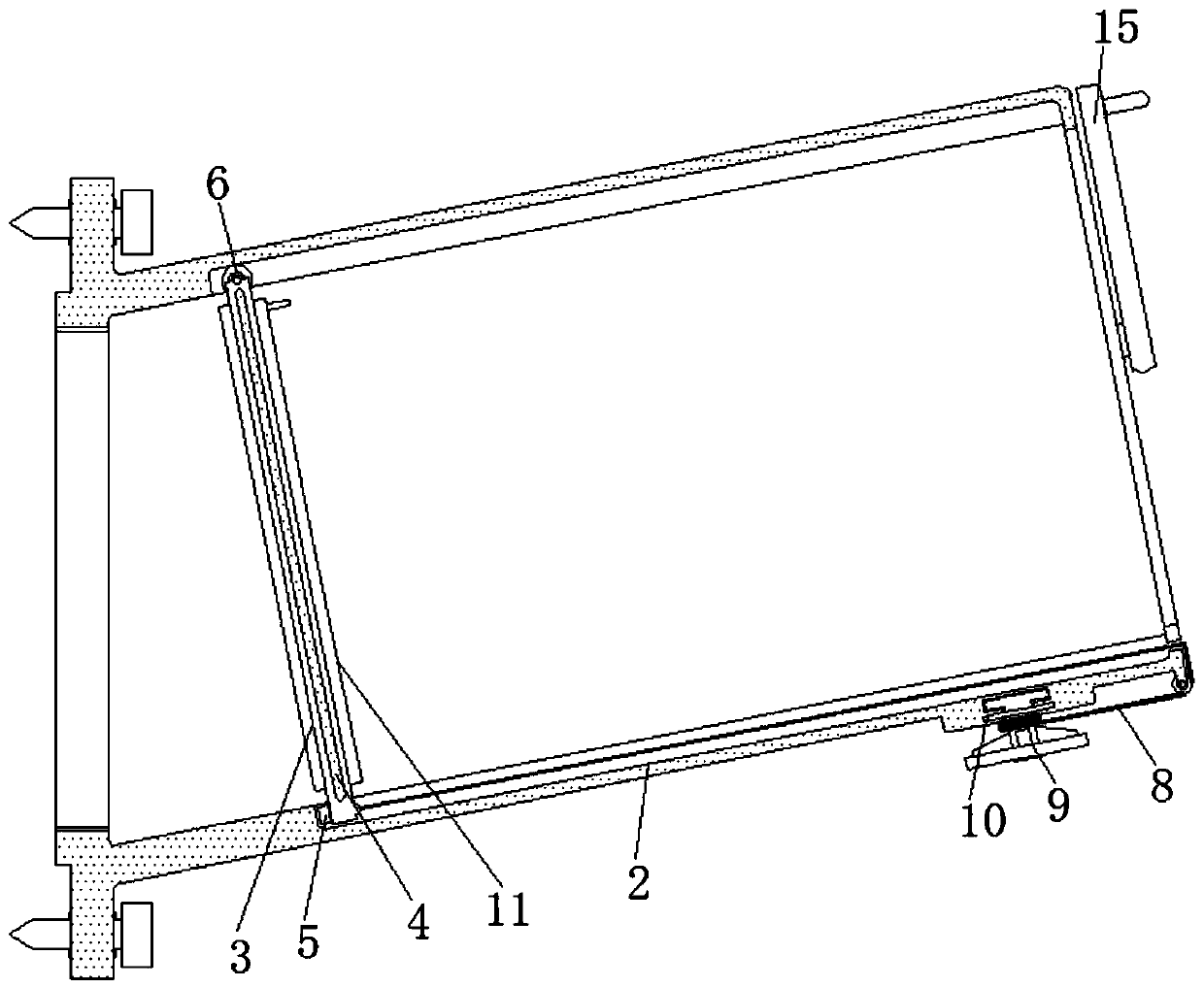

Full-vision semi-automatic coupling platform

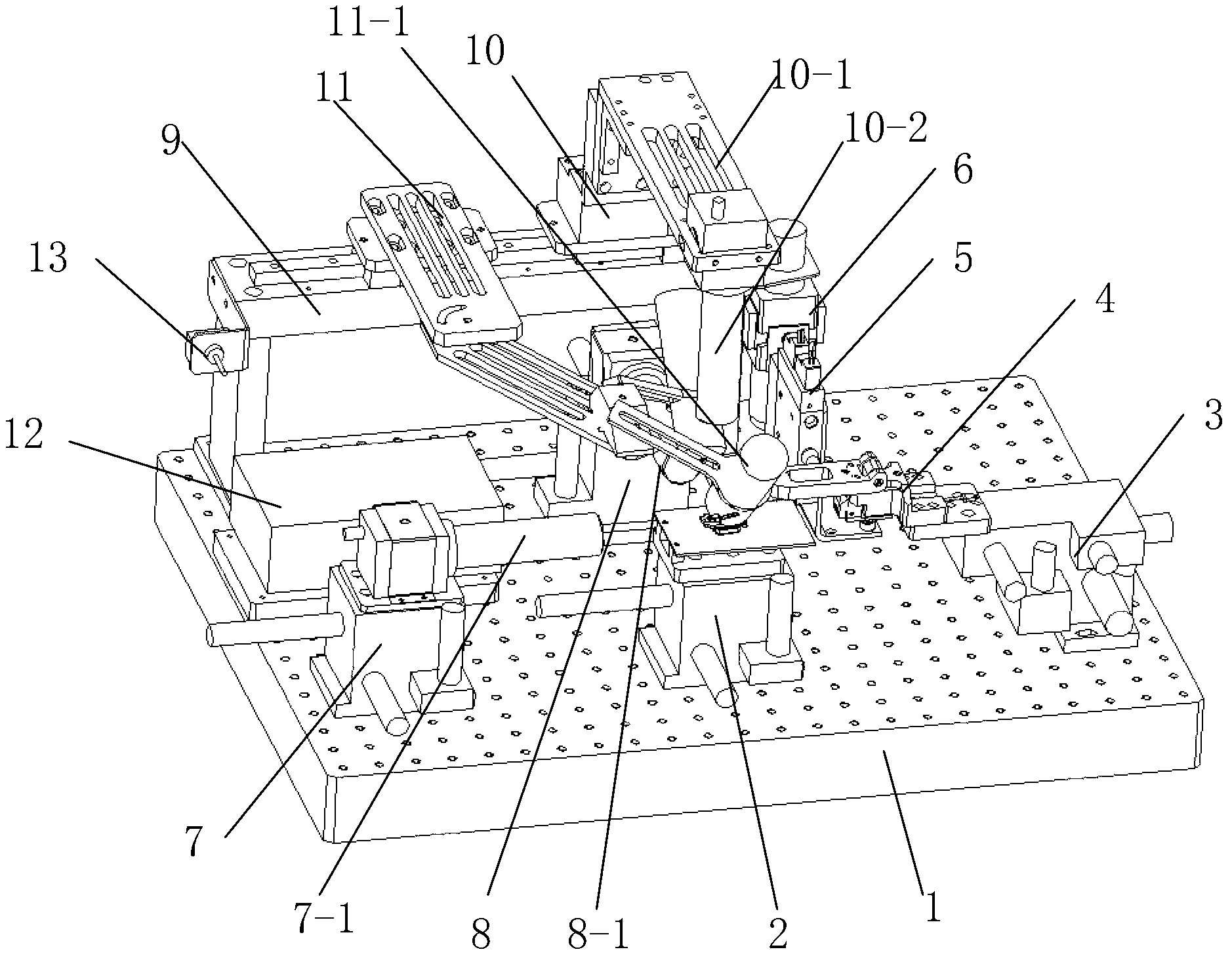

The invention relates to a full-vision semi-automatic coupling platform which comprises an optical surface covering plate anti-vibration platform, an object mounting adjusting bracket, a six-dimensional adjusting bracket, a vacuum nozzle mounting rotating mechanism, a compressed air filter valve, a vacuum valve, a side-view camera mounting adjusting bracket, a rear-view camera mounting adjusting bracket, a translation slide platform, an overhead-view camera mounting adjusting bracket and a UV (ultraviolet) irradiation system mounting rack; the object mounting adjusting bracket, the six-dimensional adjusting bracket, the vacuum nozzle mounting rotating mechanism, the compressed air filter valve, the vacuum valve, the side-view camera mounting adjusting bracket, the rear-view camera mounting adjusting bracket, the translation slide platform, the overhead-view camera mounting adjusting bracket and the UV irradiation system mounting rack are fixed to the upper surface of the optical surface covering plate anti-vibration platform. The full-vision semi-automatic coupling platform has the advantages that various components are fixed onto the optical surface covering plate anti-vibration platform, so that influence of slight vibration on display parameters is prevented; one of two to-be-coupled object can be repositioned by the six-dimensional adjusting bracket, so that non-blind area adjustment is implemented; the two to-be-coupled objects can be conveniently mounted and fetched owing to the vacuum nozzle mounting rotating mechanism; the two to-be-coupled objects at opposite positions can be monitored by automatic focusing cameras from three directions, so that adjustment by the aid of the six-dimensional adjusting bracket and observation for the two to-be-coupled objects at the opposite positions can be carried out simultaneously.

Owner:武汉钧恒科技有限公司

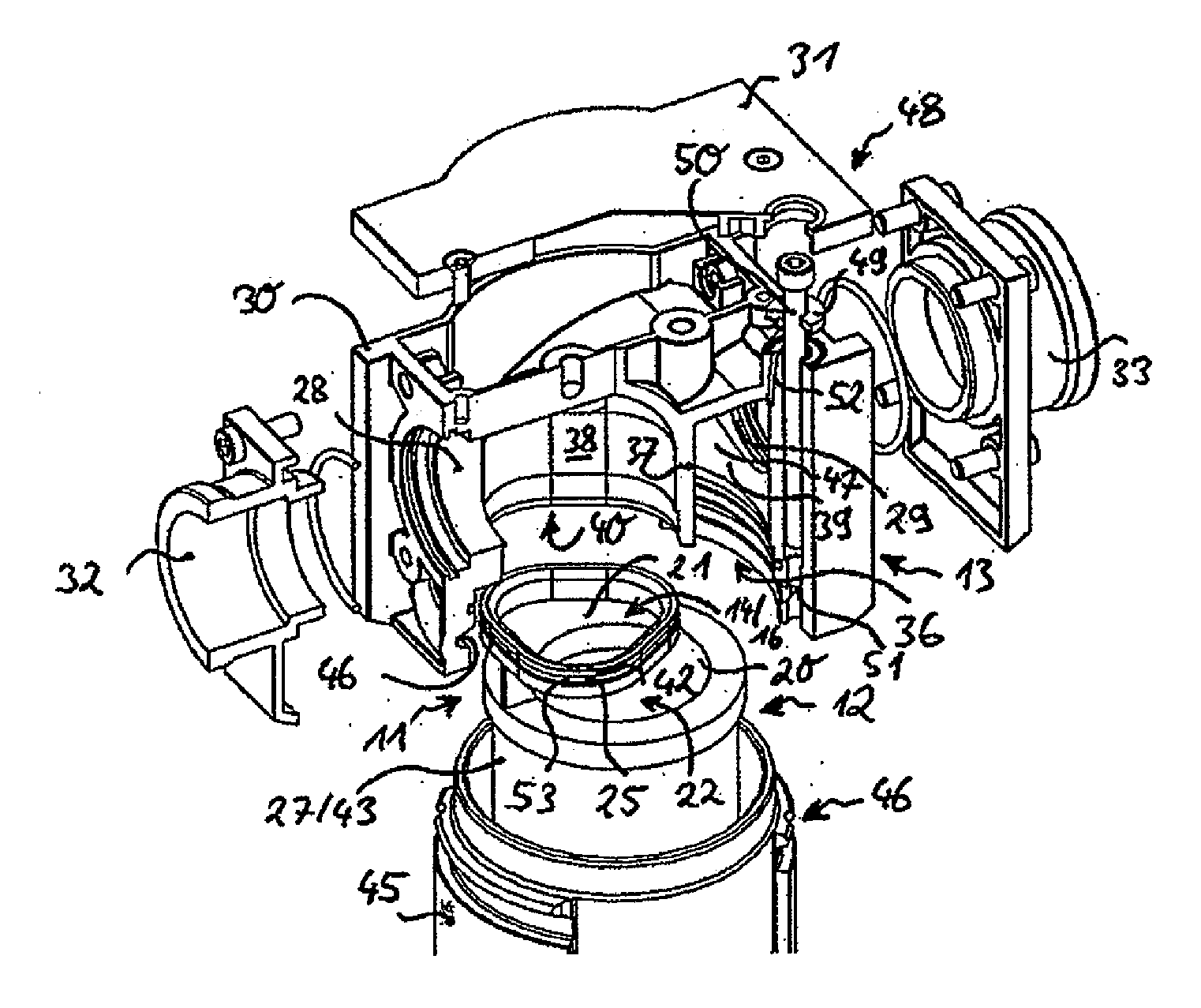

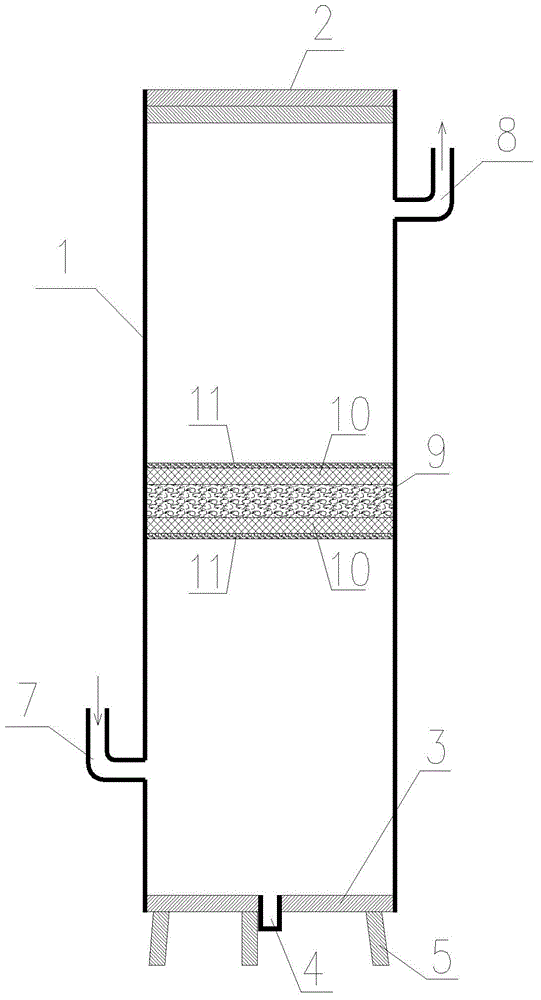

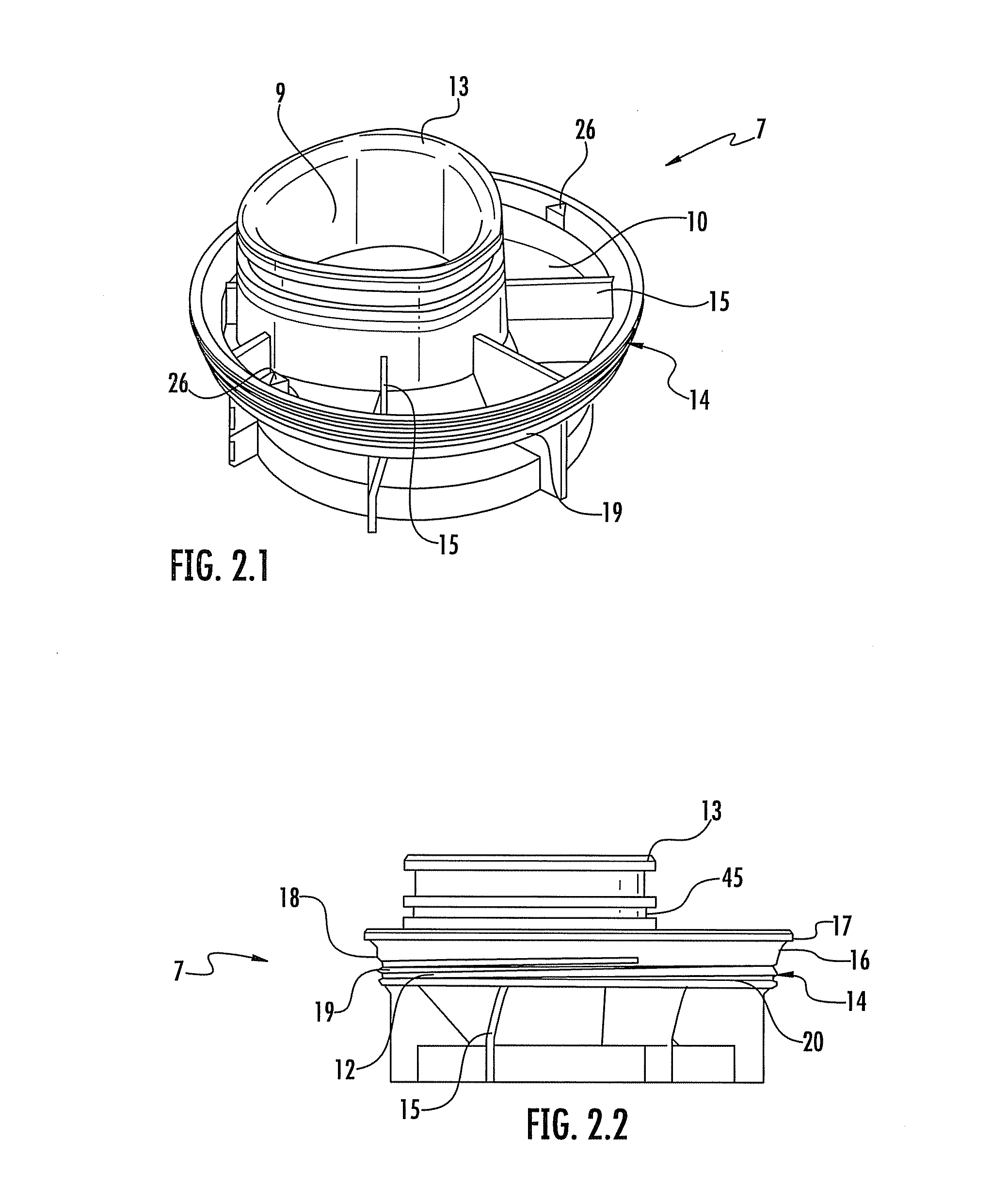

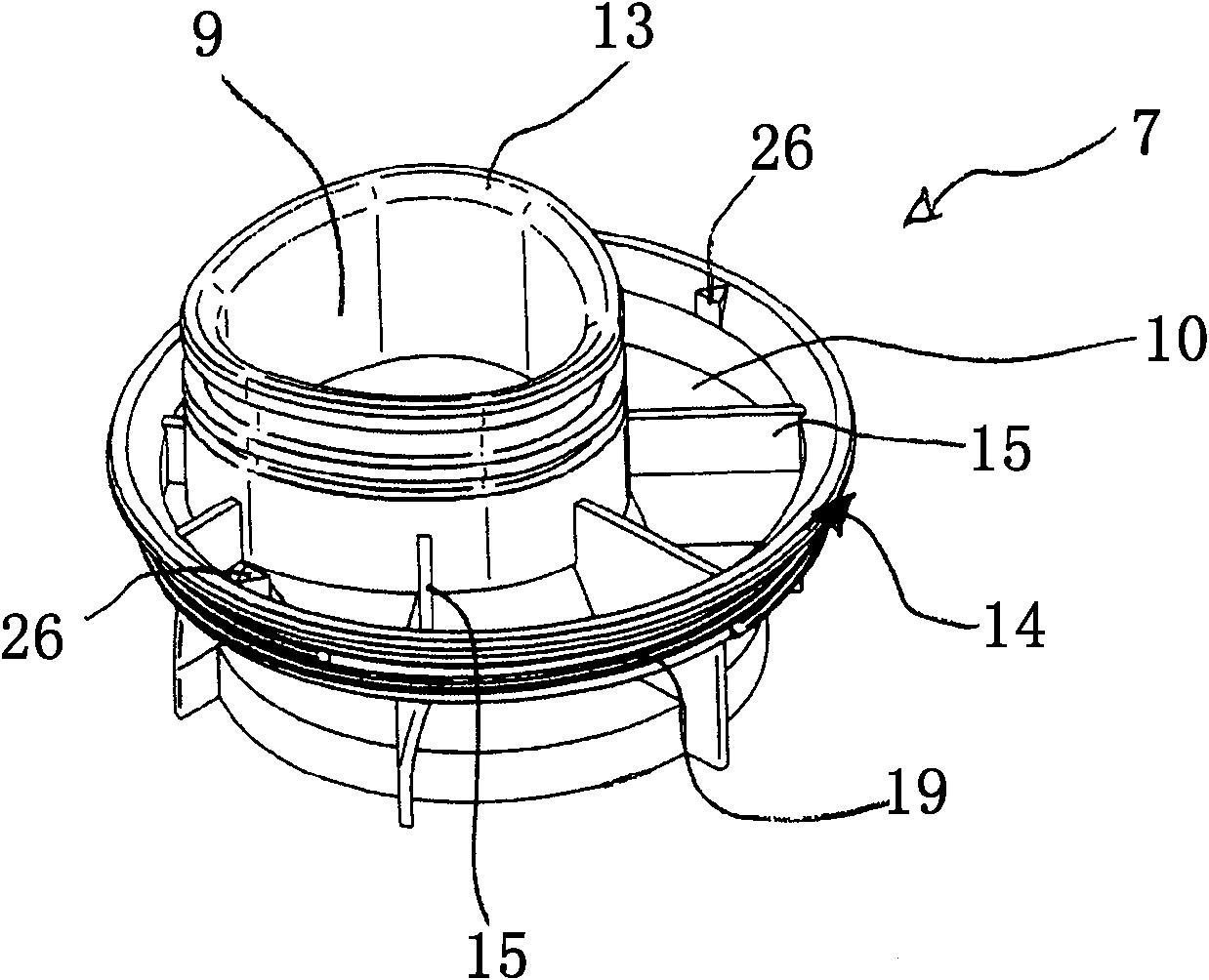

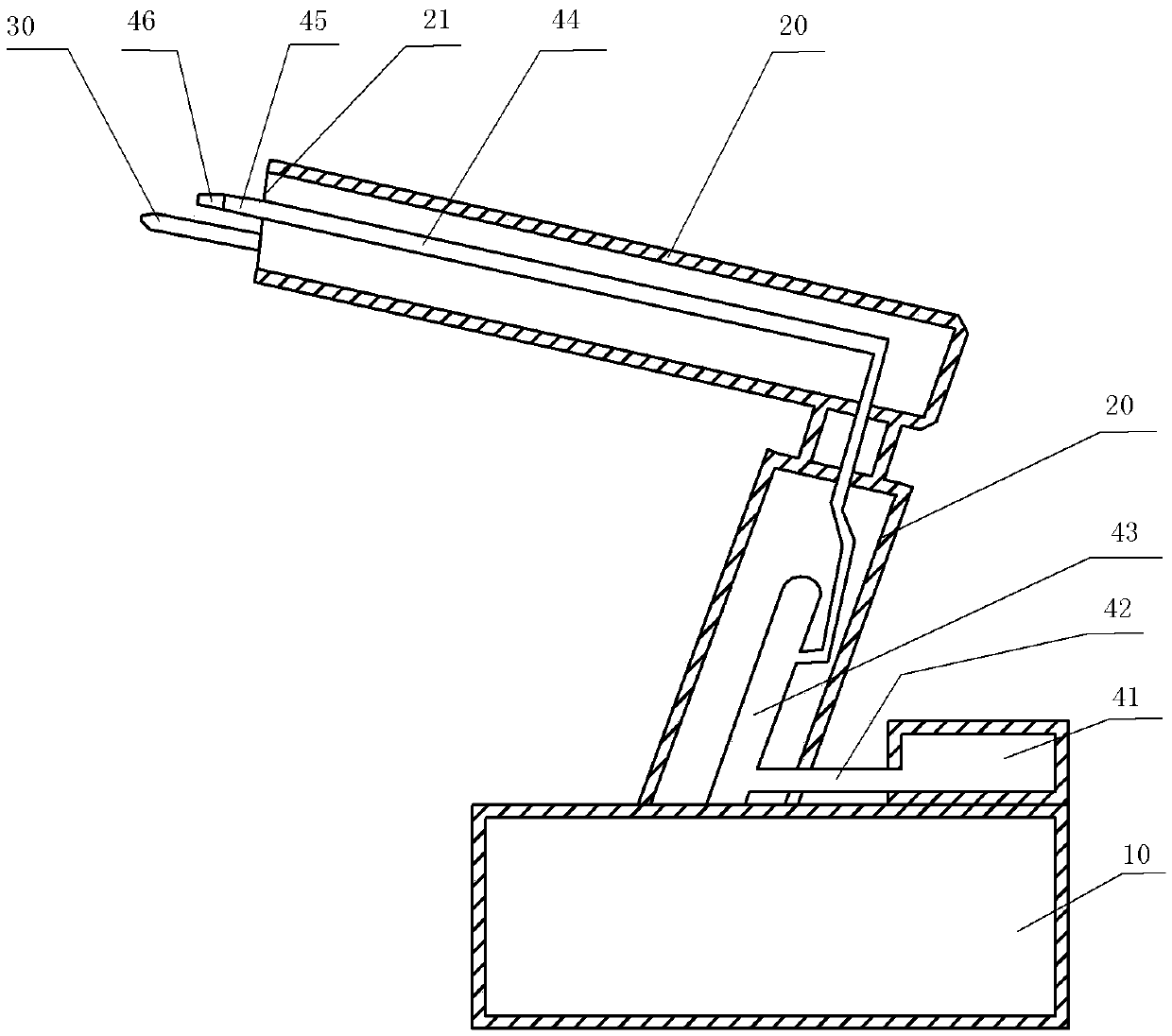

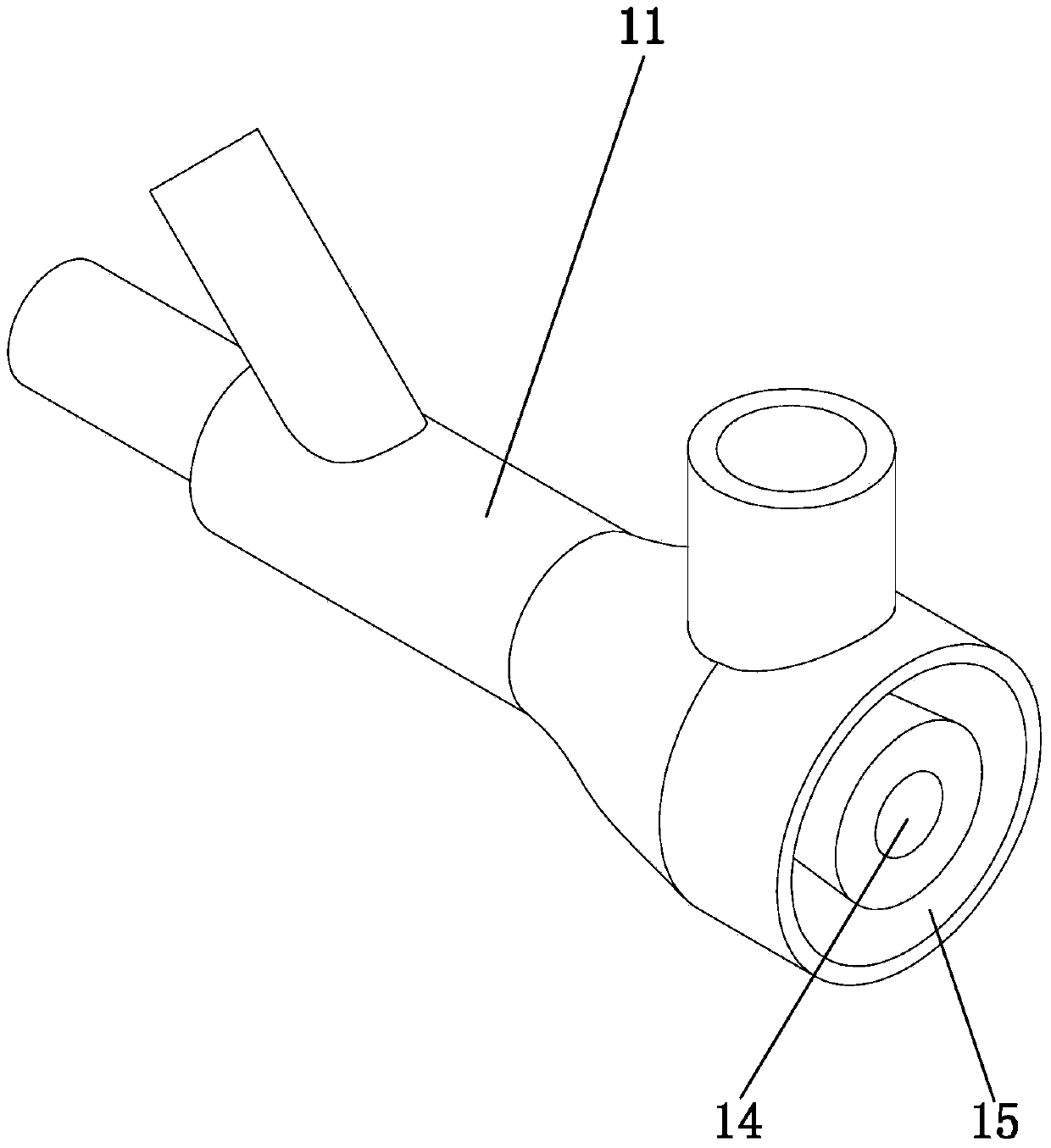

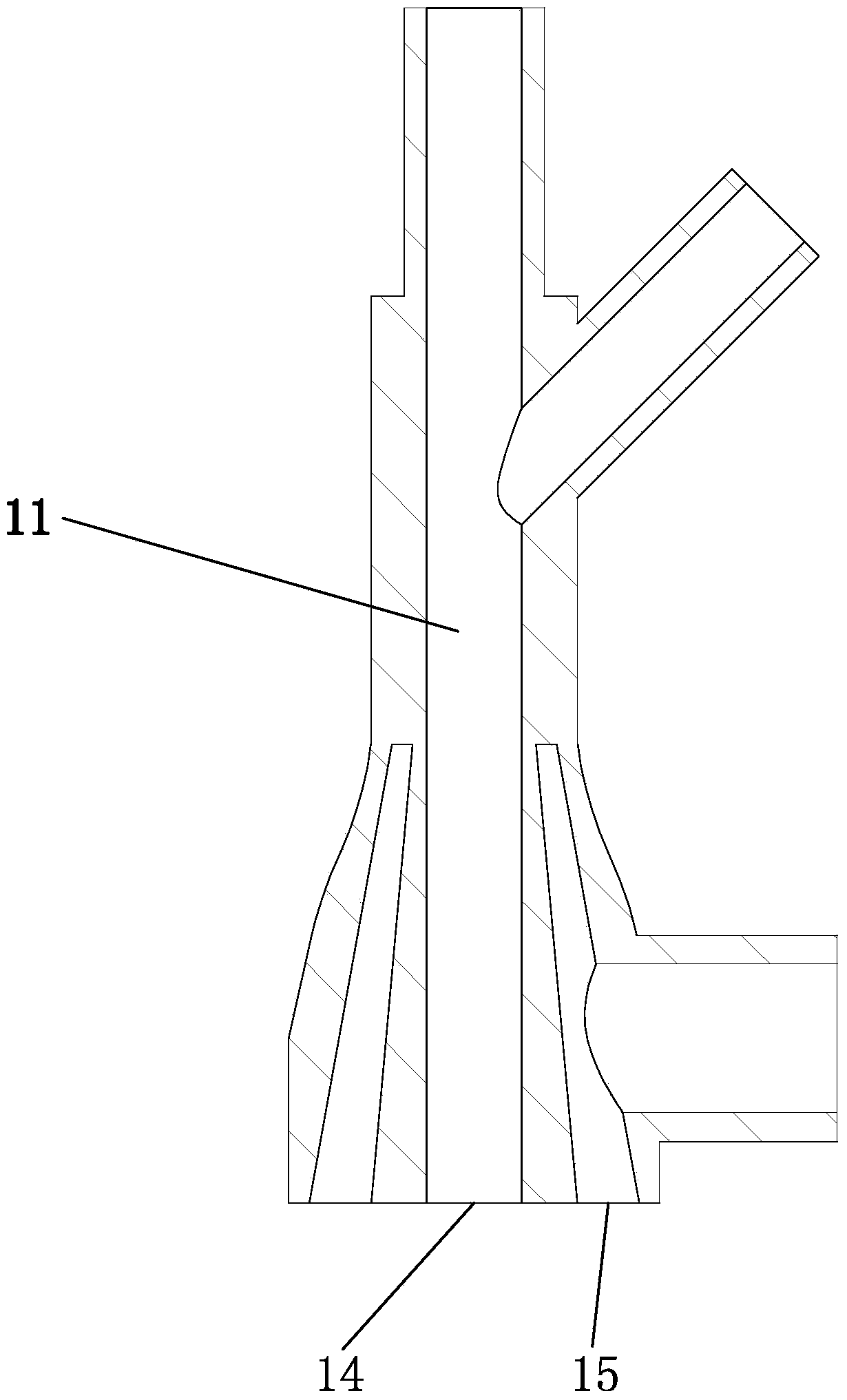

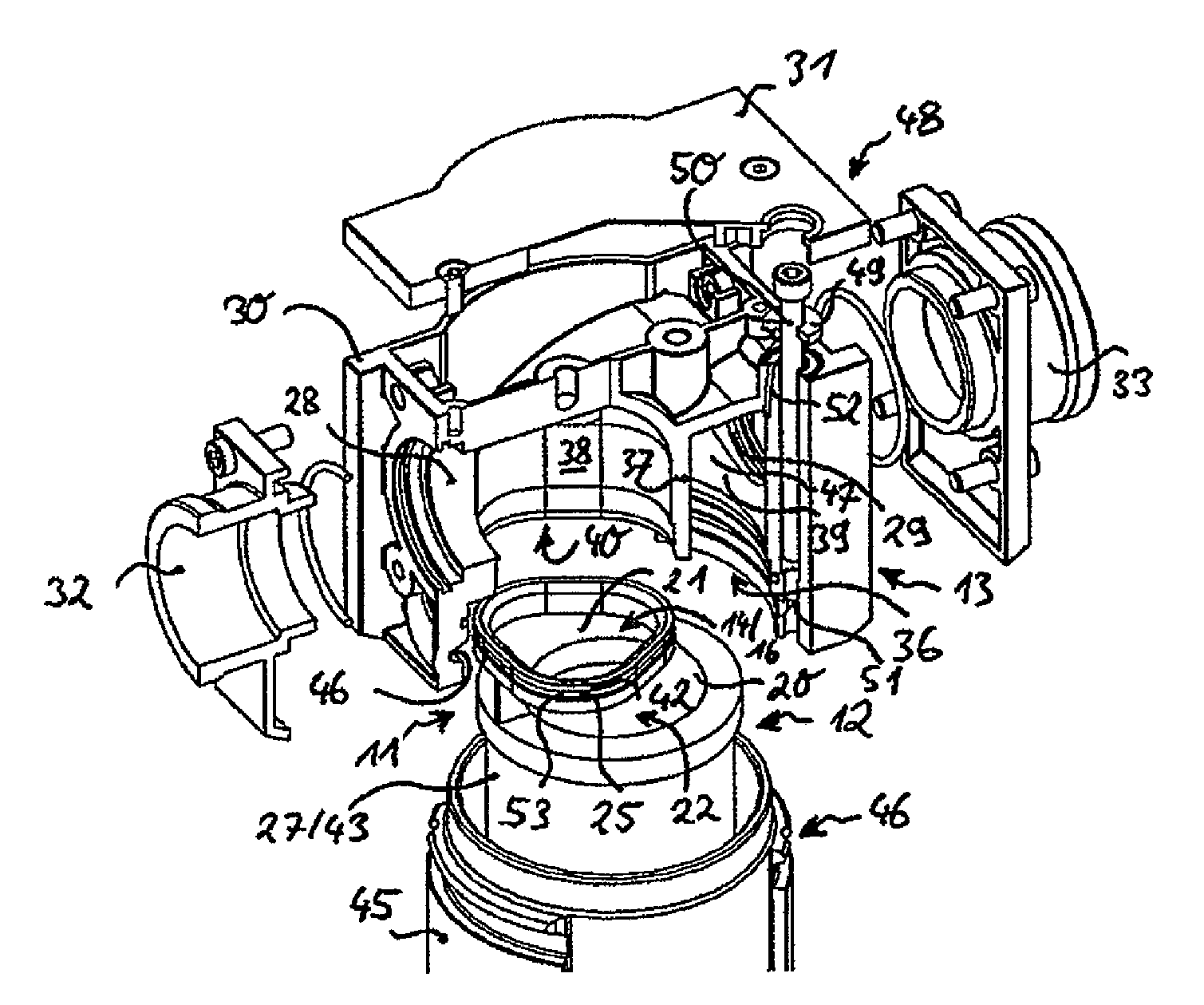

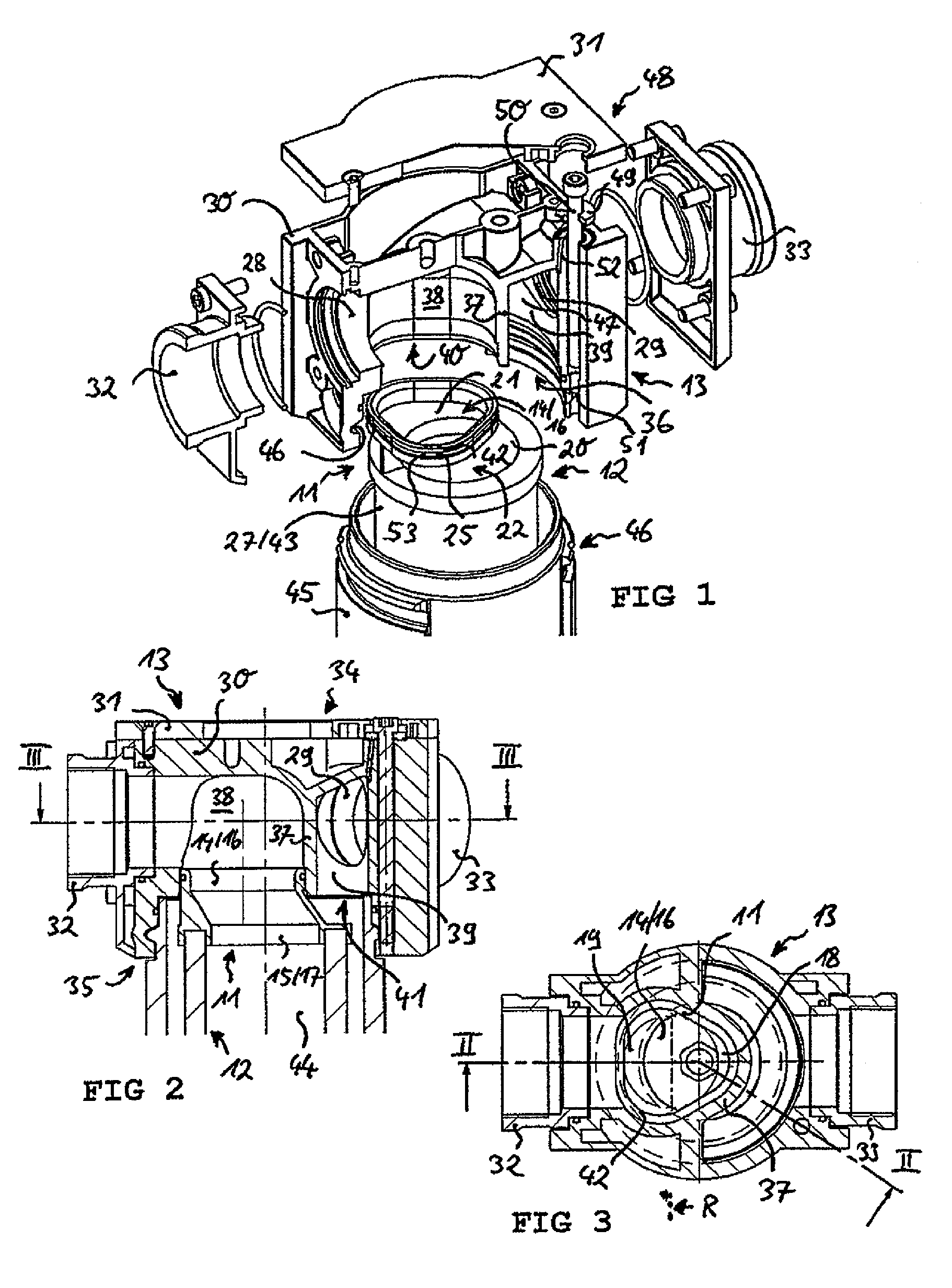

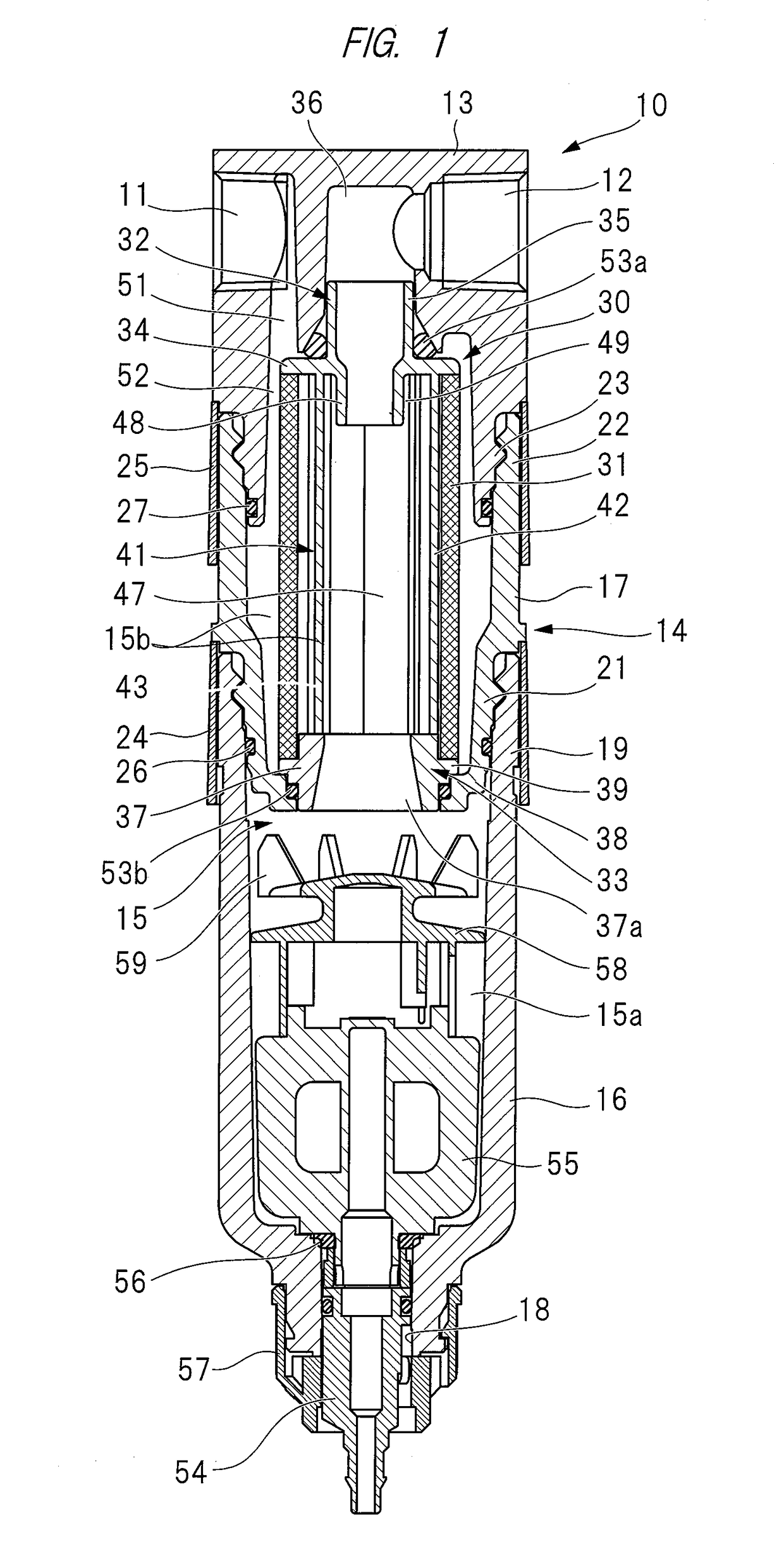

Adapter for a compressed air filter and use of the same

ActiveUS20100058723A1Simple and reliable connectionFavorable flow conductionAuxillary pretreatmentDispersed particle filtrationEngineeringFilter element

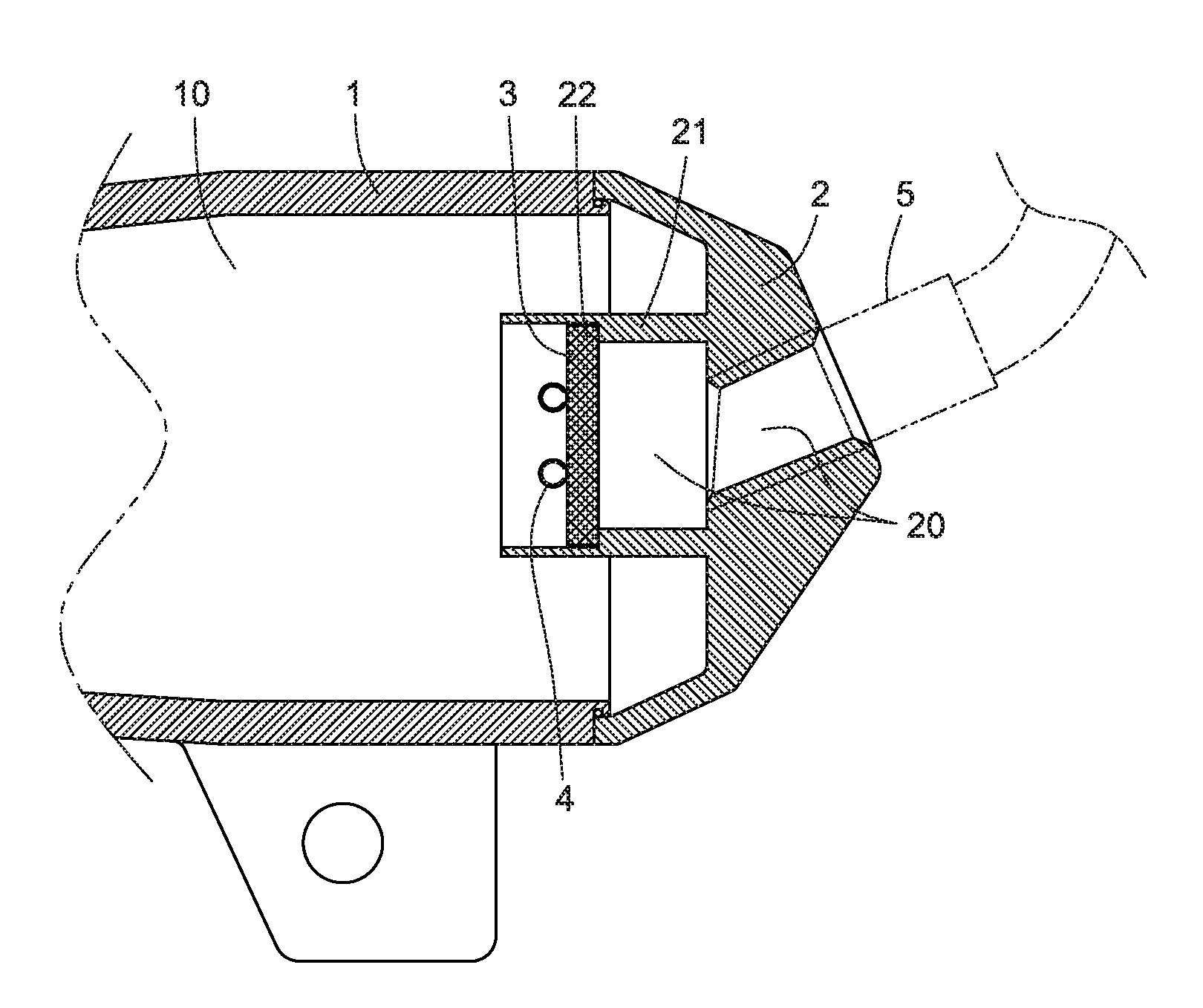

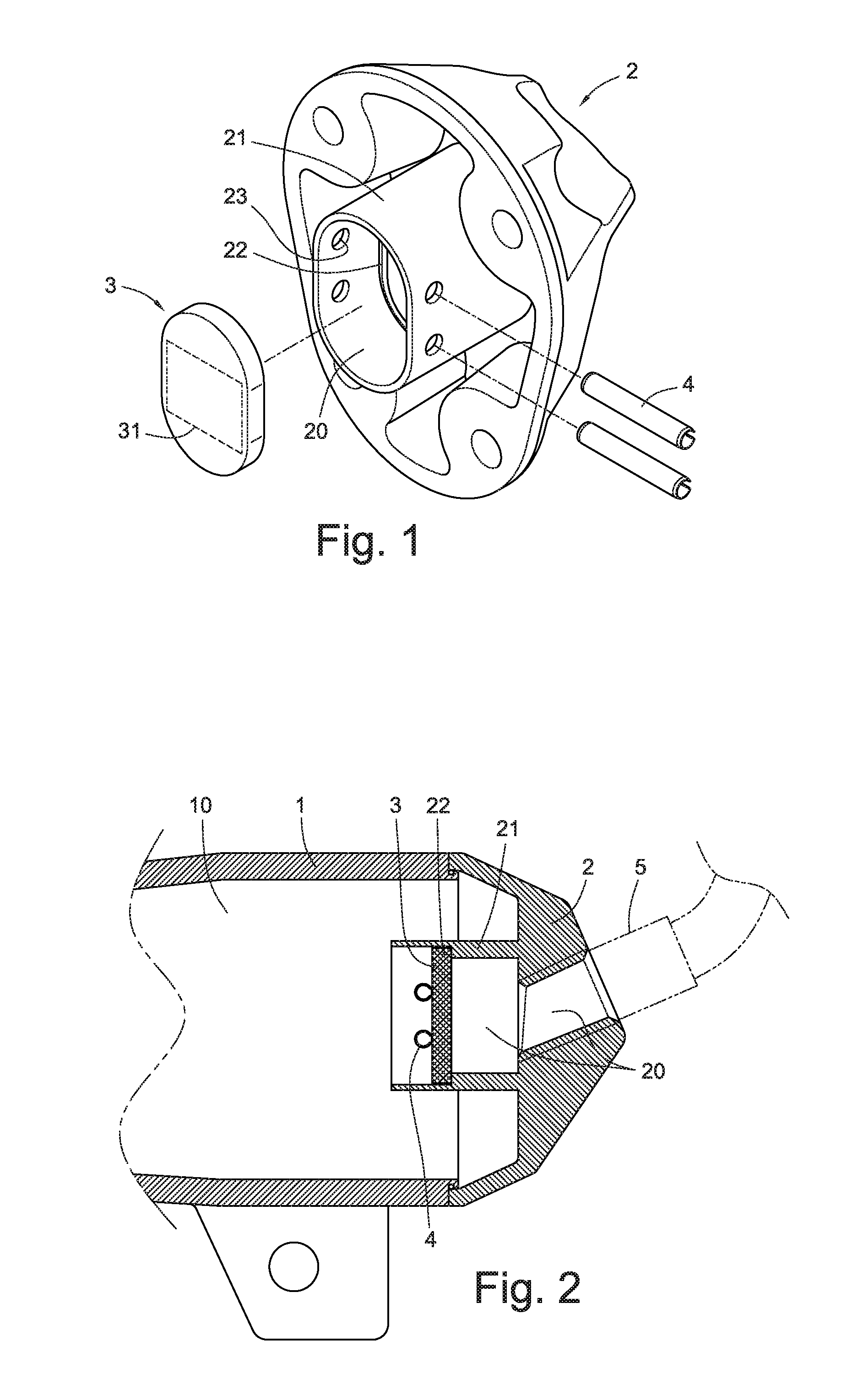

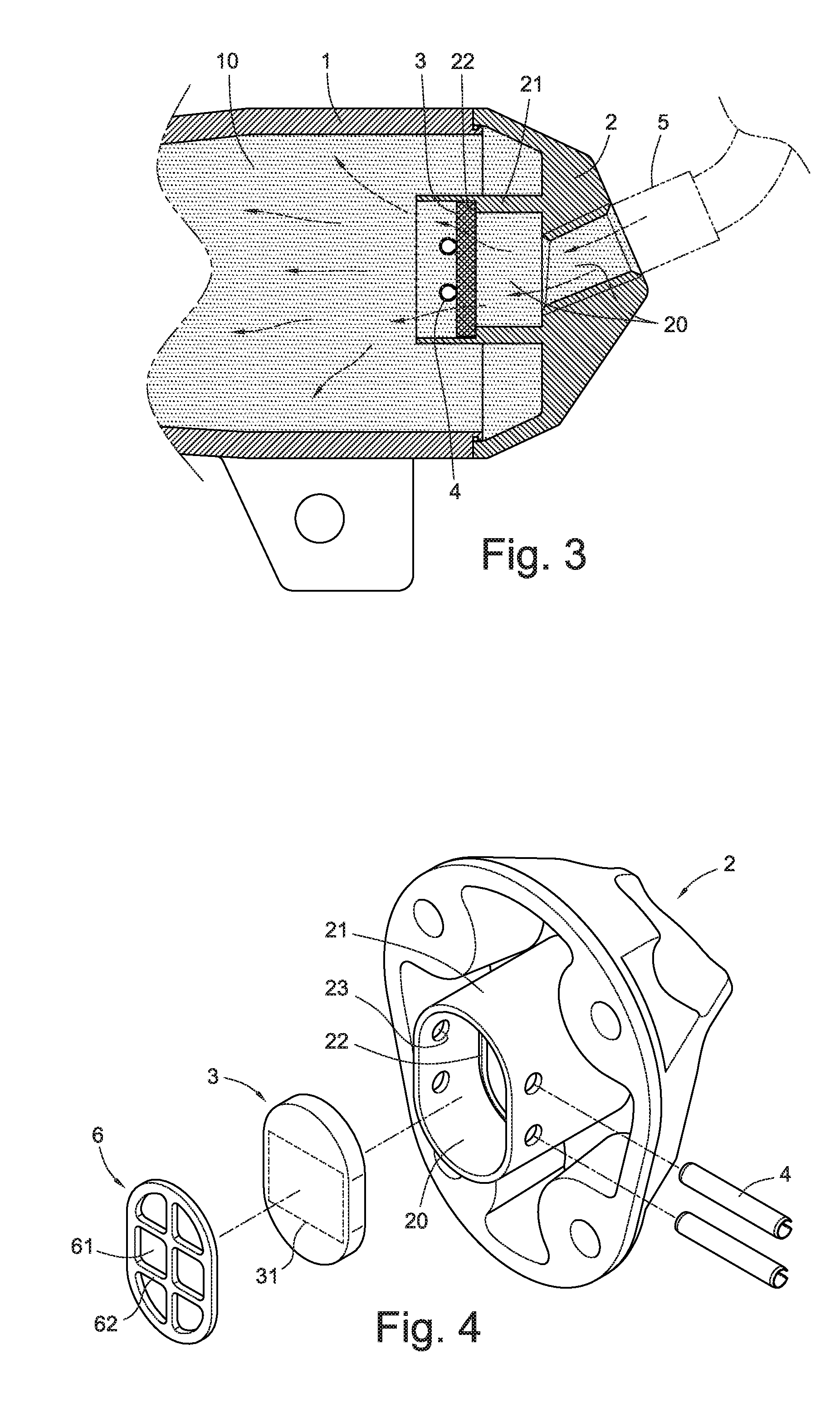

A compressed air filter adapter is provided for connecting a filter element (12) to a filter connection housing (13). The adapter (11) has a flow duct (21) enclosed by a wall (20) for compressed air, the flow duct (21) at a first end being delimited by a first opening (14), having an inner contour (142) defined by a first edge (141) and an outer contour (143), and at a second end by a second opening (15), having an inner contour (152) defined by a second edge (151) and an outer contour (153). The first opening (14) is provided for connection to a filter connection housing (13) and forms an opening cross-section (16), defined by the inner contour (142) of the first opening (14). The second opening (15) defines an opening on the filter side and forms a second opening cross-section (17), defined by the inner contour (152) of the second opening (15). The inner contour (142) of the first opening (14) and the inner contour of the second opening (15) are offset from each other, such that the surface center of gravity of the first opening cross-section (16) is displaced in relation to the normal extending from the surface center of gravity of the second opening cross-section (17) in an offset direction (R). The outer contour (143) of the first opening (14) has a basic shape that deviates from the circular shape, such that the outer contour (143) is derived from a transformation of a circle (165) centrically aligned in relation to the normal extending from the surface center of gravity of the second opening (15), the circle in the direction of the offset direction (R) being displaced by a length R1 and defining a displaced circle (166), and on the side of the circle (166) pointing in the offset direction (R) having constrictions (18) or expansions (19) by removing or adding surface sections, and on the side pointing opposite from the offset direction (R) having corresponding expansions (19) or constrictions (18) by adding or removing substantially equally large surface sections.

Owner:KAESER KOMPRESSOREN SE

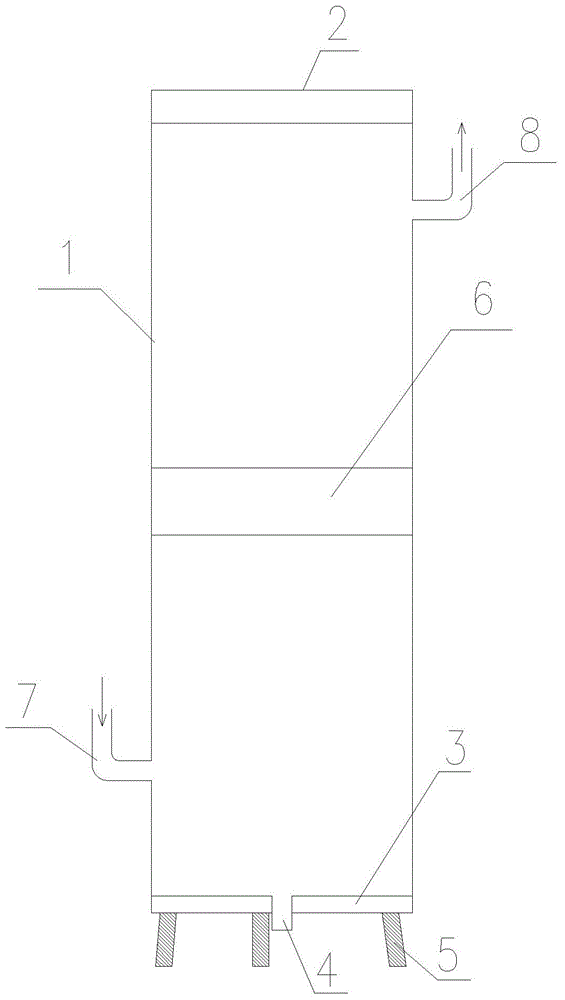

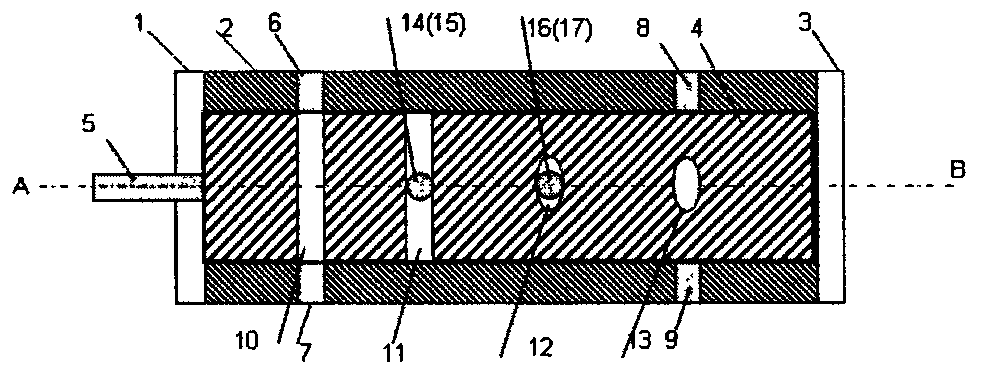

Cartridge compressed-air filter

The invention aims to provide a cartridge compressed-air filter and adopts the technical scheme that the cartridge compressed-air filter comprises a cartridge body, an upper cover, a lower cover, a filter screen, an air inlet pipe and an air outlet pipe, wherein the upper cover is arranged at an upper opening of the cartridge body; the lower cover is arranged at a lower opening of the cartridge body; a blow-down valve is arranged in the center of the lower cover; three support legs are arranged at the bottom of the lower cover; the filter screen is placed in the middle inside the cartridge body and comprises bagged activated carbon, wire screen filter cotton and an iron screen frame; the air inlet pipe and the air outlet pipe are arranged on the outer side of the side wall of the cartridge body; the air inlet pipe is located at the lower part of the cartridge body and below the filter screen; and the air outlet pipe is located at the upper part of the cartridge body and above the filter screen. The cartridge compressed-air filter can be used for effectively removing vapor, dust and rust sediments in compressed air so as to greatly reduce equipment failures caused by compressed air quality, and is suitable for various equipment utilizing compressed air. Besides, the cartridge compressed-air filter is simple in structure, low in cost and convenient to mount.

Owner:TIANJIN BOHUA ZHONGHE CHEM

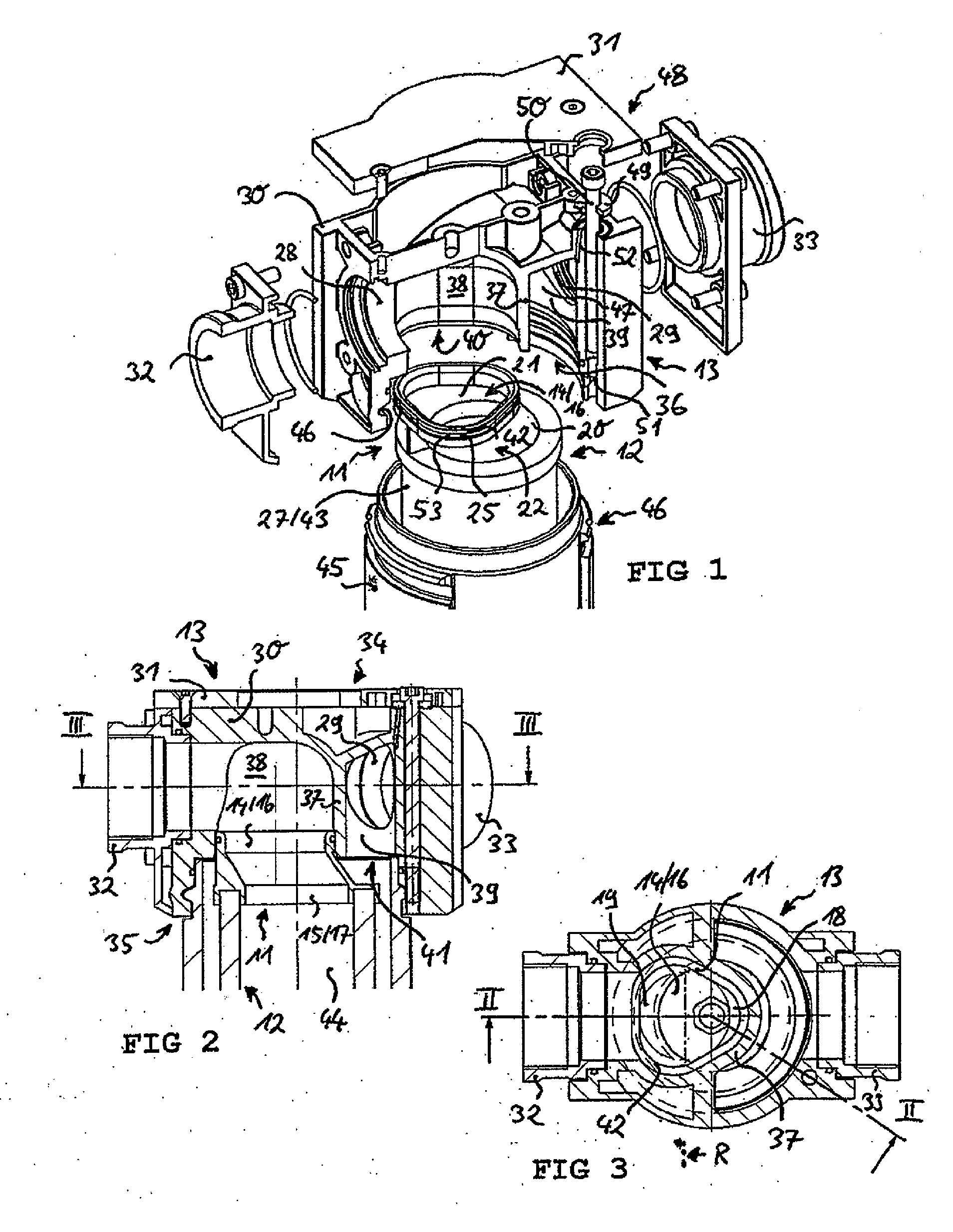

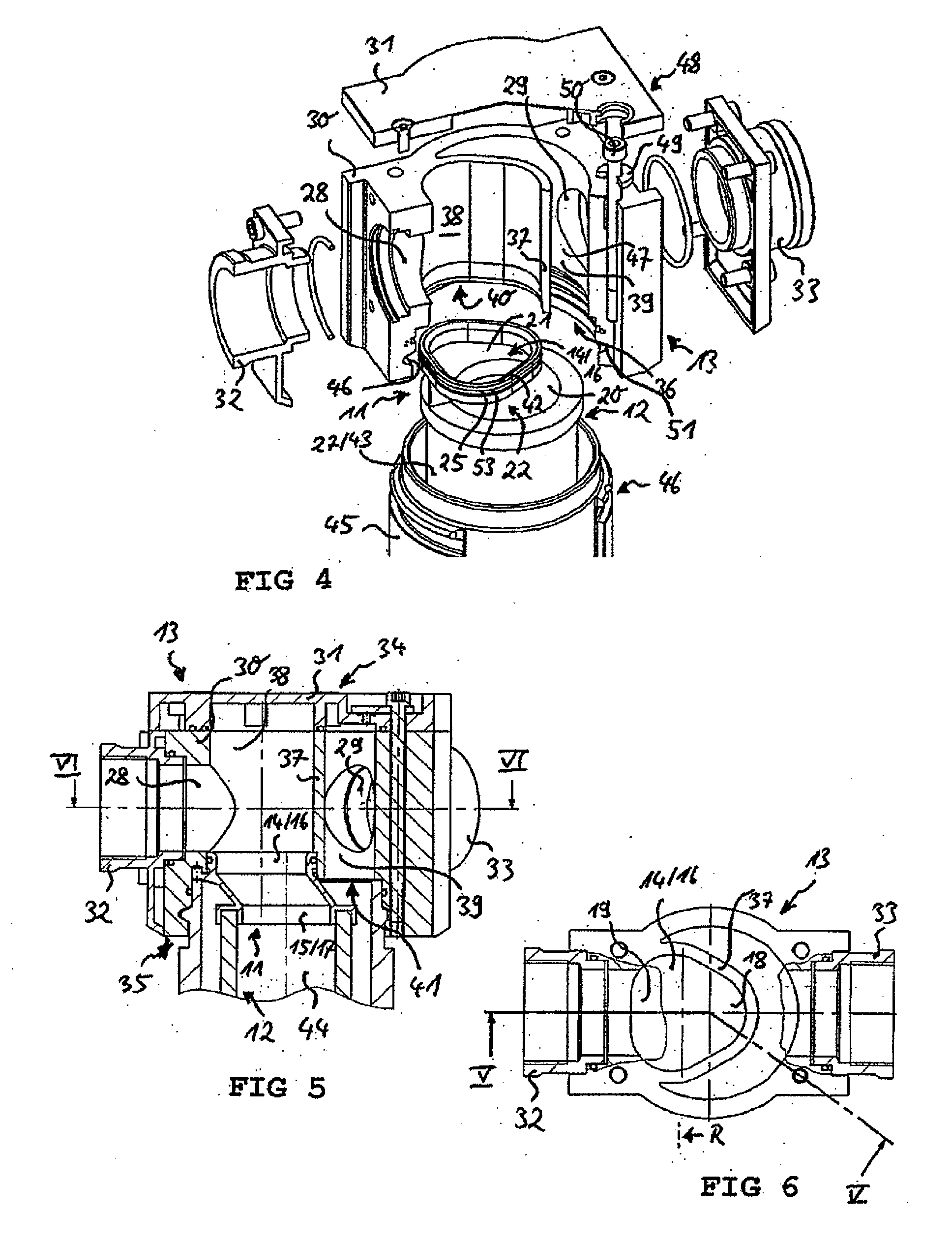

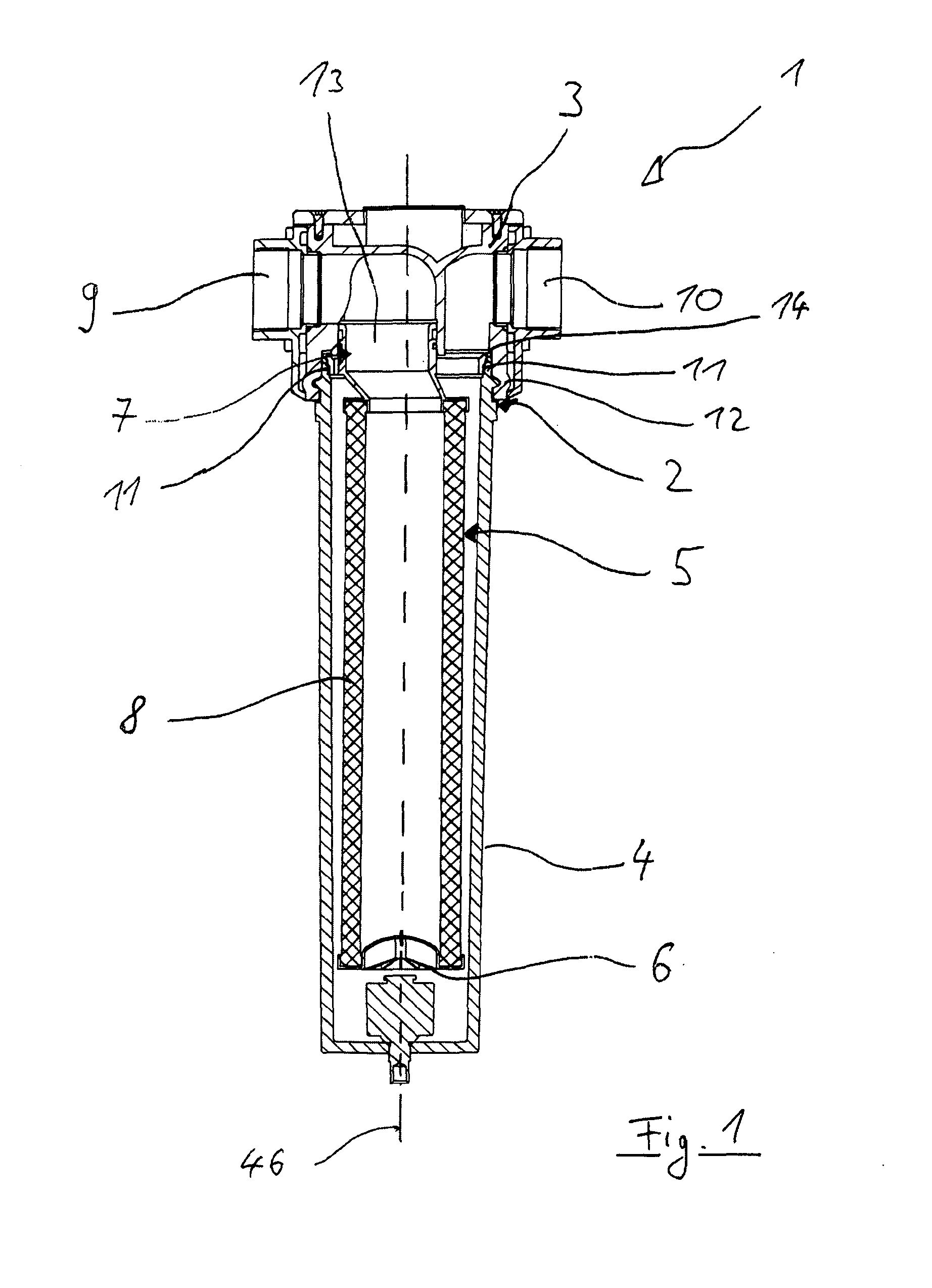

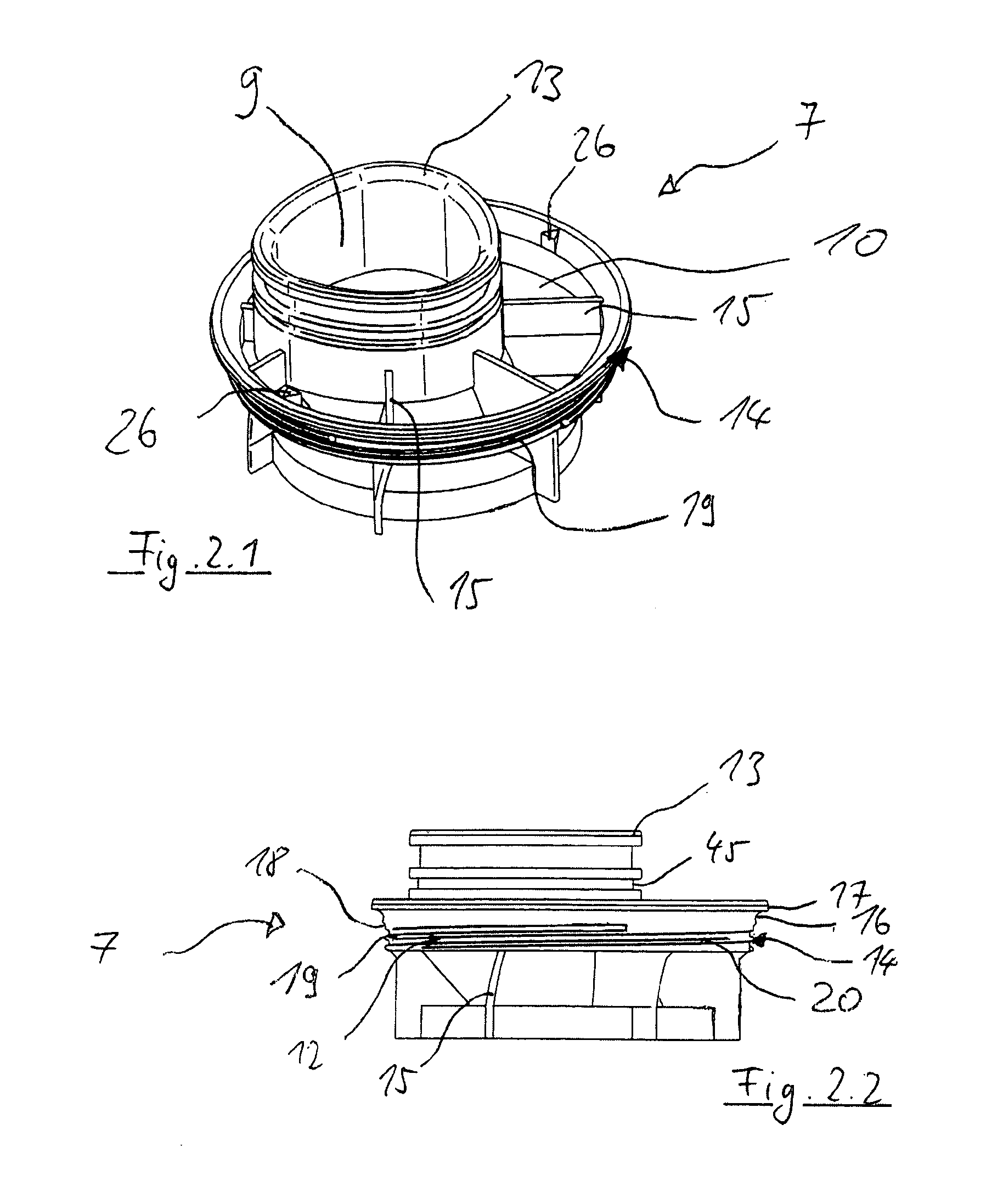

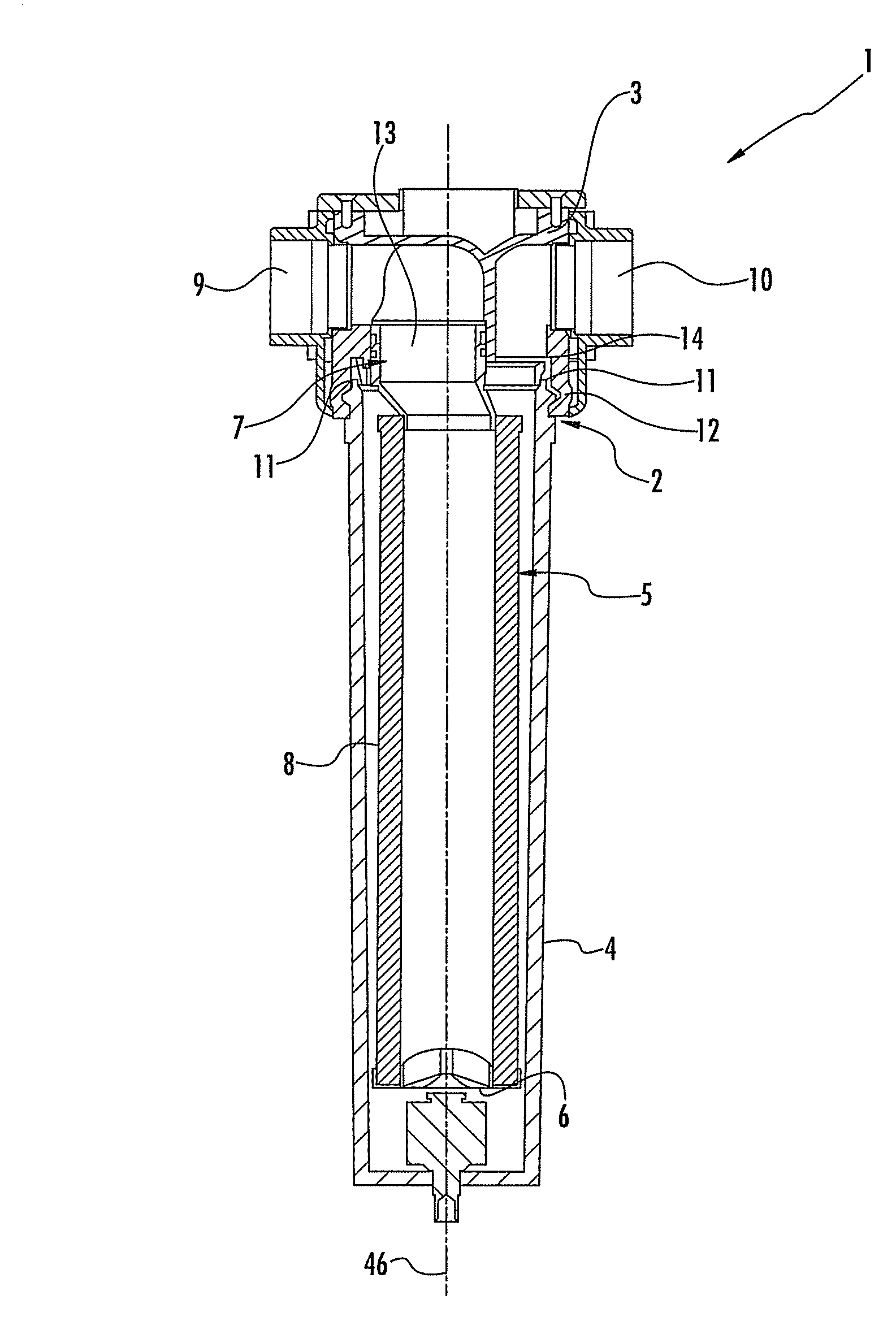

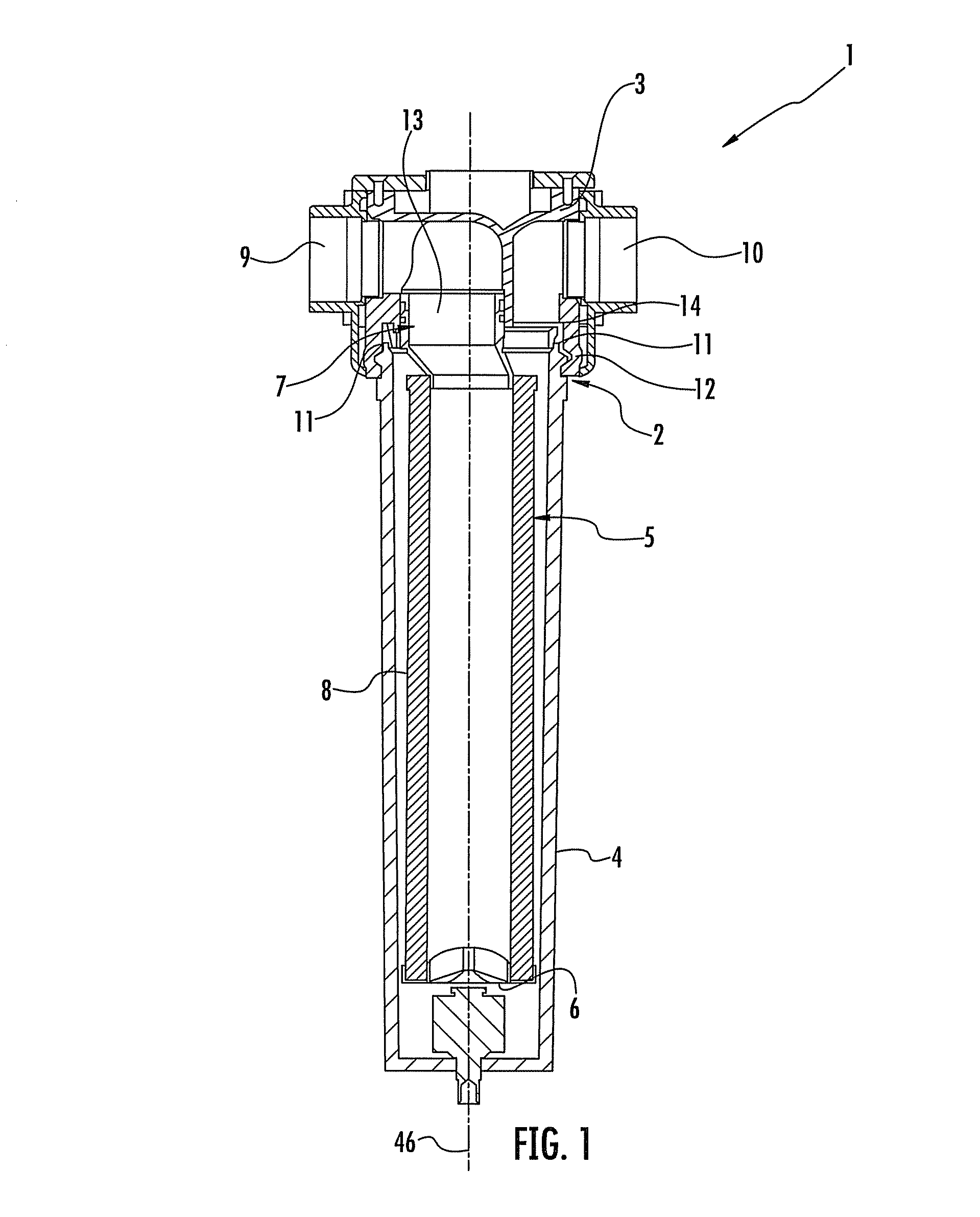

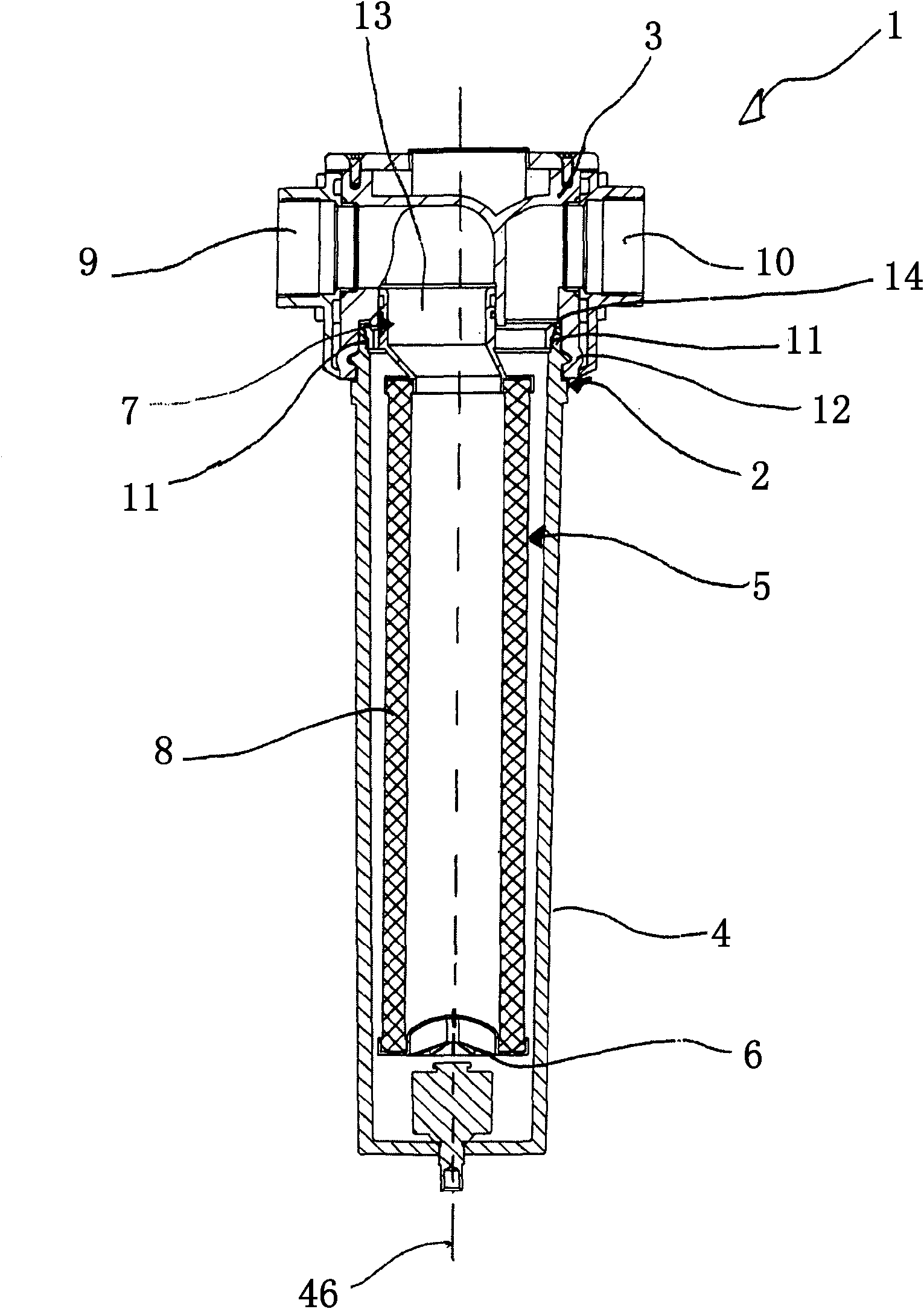

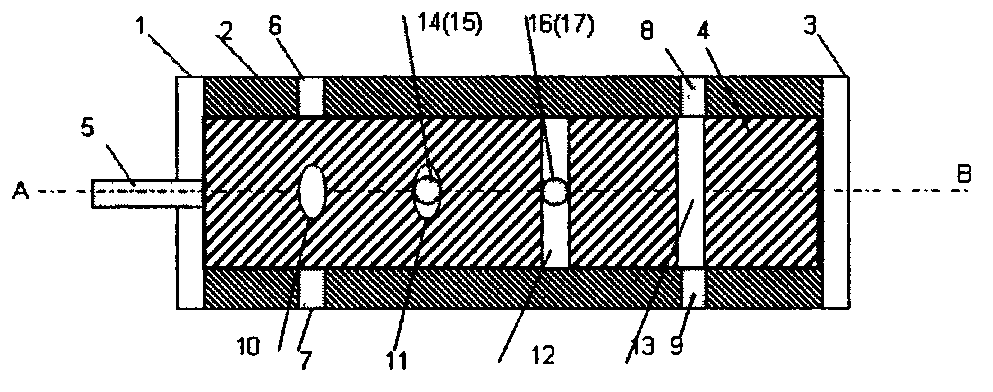

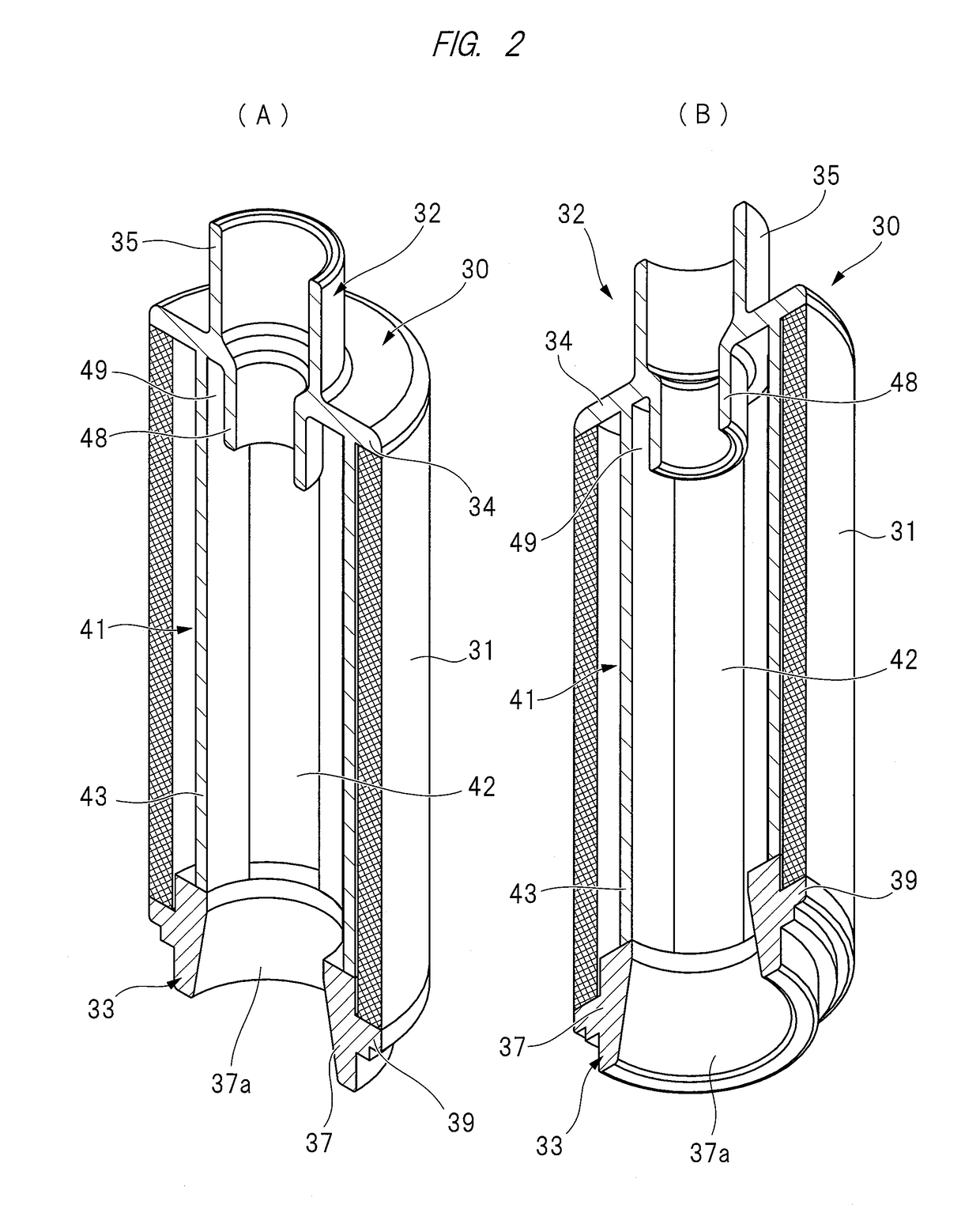

Filter element and compressed air filter for separating foreign matter from a compressed air stream

ActiveUS20110296999A1Easy to transformImprove sealingCombination devicesAuxillary pretreatmentForeign matterAir filter

A compressed air filter and a filter element which is for separating foreign bodies from a compressed air stream and which has an element lower portion, an element upper portion which has a neck portion which forms a first flow channel and a collar portion which is constructed so as to extend at least partially around the neck portion and which is connected to the neck portion so as to form a second flow channel, and a filter medium which is sealingly connected to the element lower portion and the element upper portion in order to form a gas flow path between the first flow channel and the second flow channel through the filter medium, the collar portion having an abutment face, which is provided at least partially at the outer periphery and which tapers in the direction of the element lower portion, in order to receive an associated sealing ring in such a manner that a force which acts substantially axially on the sealing ring from the direction of the element lower portion brings about radial expansion of the sealing ring along the abutment face.

Owner:KAESER KOMPRESSOREN SE

Filter element and compressed air filter for separating foreign matter from a compressed air stream

ActiveUS8333818B2Easy to transformImprove sealingCombination devicesAuxillary pretreatmentForeign matterAir filter

A compressed air filter and a filter element which is for separating foreign bodies from a compressed air stream and which has an element lower portion, an element upper portion which has a neck portion which forms a first flow channel and a collar portion which is constructed so as to extend at least partially around the neck portion and which is connected to the neck portion so as to form a second flow channel, and a filter medium which is sealingly connected to the element lower portion and the element upper portion in order to form a gas flow path between the first flow channel and the second flow channel through the filter medium, the collar portion having an abutment face, which is provided at least partially at the outer periphery and which tapers in the direction of the element lower portion, in order to receive an associated sealing ring in such a manner that a force which acts substantially axially on the sealing ring from the direction of the element lower portion brings about radial expansion of the sealing ring along the abutment face.

Owner:KAESER KOMPRESSOREN SE

Filter element and compressed air filter for separating foreign matter from a compressed air stream

The present invention provides a compressed air filter (1) and a filter element (5) for separating foreign matter from a compressed air stream, comprising an element base (6), an element top (7) with a neck section (13) that forms a first flow channel (9) and a collar section (14) that is designed at least in sections to surround the neck section (13) and that is connected to the neck section (13), thereby forming a second flow channel (10), and comprising a filter medium (8) that is connected to the element base (6) and to the element top (7) to form a gas stream path between the first flow channel (9) and the second flow channel (10) through the filter medium (8) in a sealing manner, wherein the collar section (14) comprises a support surface (16) that is provided on the outer periphery at least in sections and that narrows in the direction of the element base (6), said support surface accommodating an associated seal ring (22) such that a force acting on the seal ring (22) approximately axially from the direction of the element base (6) causes a radial expansion of the seal ring (22) along the support surface (16).

Owner:KAESER KOMPRESSOREN SE

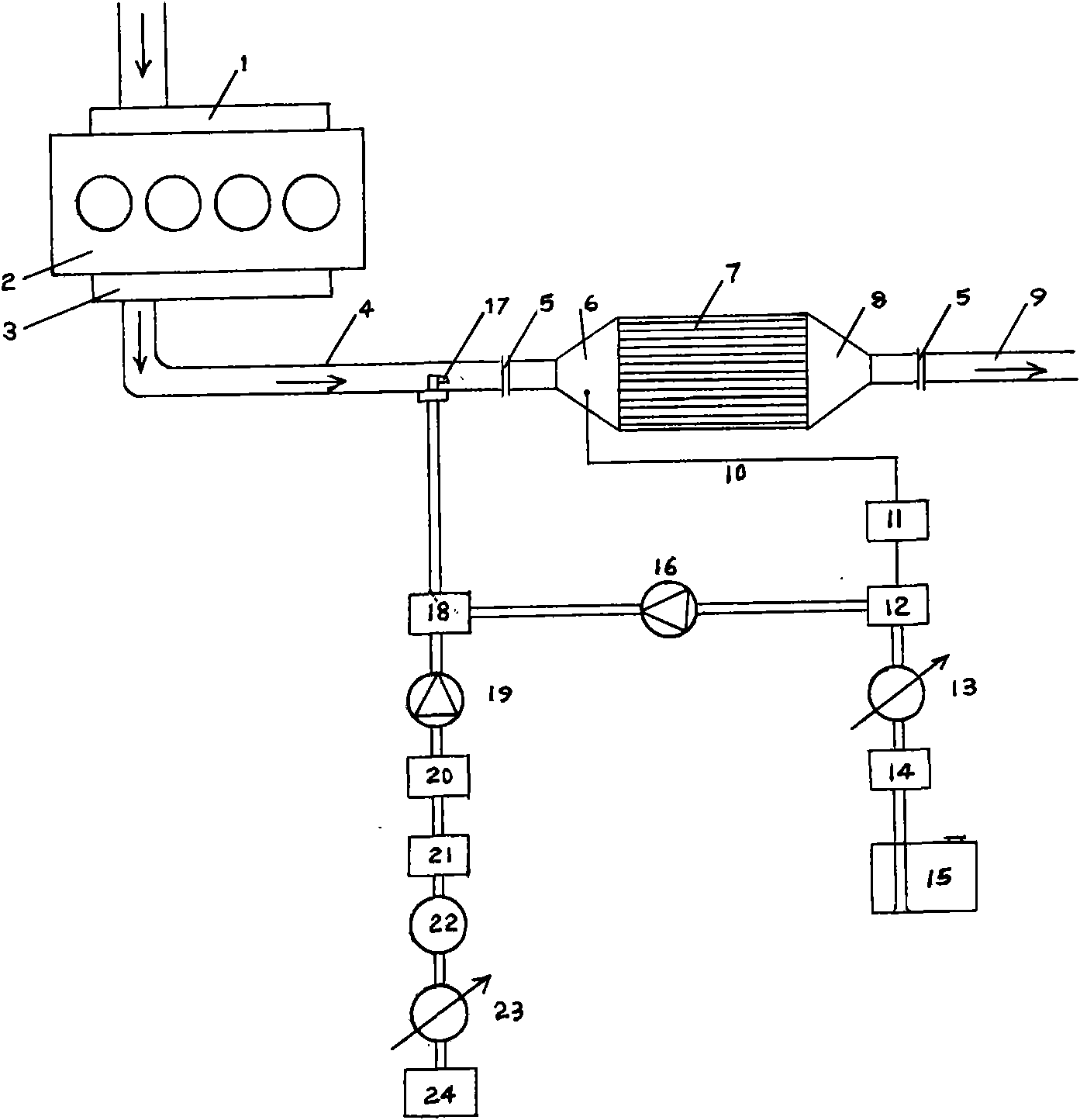

Vehicle-mounted SCR metering and ejecting system taking exhaust gas temperature as variable

ActiveCN101660443AImprove reliabilityRealize industrial applicationInternal combustion piston enginesExhaust apparatusEngineeringReducing agent

The invention relates to a vehicle-mounted SCR metering and ejecting system taking exhaust gas temperature as variable. The system is characterized in that a precision thermoelectric couple is connected with a temperature control unit through a wire and installed on an expansion pipe at the inlet end of an SCR rear processor, an electromagnetic metering diaphragm pump is connected on a pipeline, and a pressure reducing valve and a urea reducing agent filter are arranged between the electromagnetic metering diaphragm pump and a urea reducing agent tank; a one-way valve is arranged at the outputend of the electromagnetic metering diaphragm pump; and a urea reducing agent nozzle is arranged at the front end of the SCR rear processor, and a one-way valve, a compressed air filter, a pressure reducing valve, a pressure gauge and a valve are connected between a gas liquid mixing unit with two cavities and an air power source. By adopting the temperature measured by the thermoelectric couple,the temperature parameter is taken as the variable, and the electromagnetic metering diaphragm pump is started through an intelligent PID controller and a self-programming computer program, so that the urea reducing agent is completely atomized in the gas liquid mixing unit with the two cavities to achieve the purpose of eliminating NOX; and the cost of the system is equivalent to one fourth to one third of that of an imported system, the reliability is high, and the industrial application is realized.

Owner:CHINA FIRST AUTOMOBILE +1

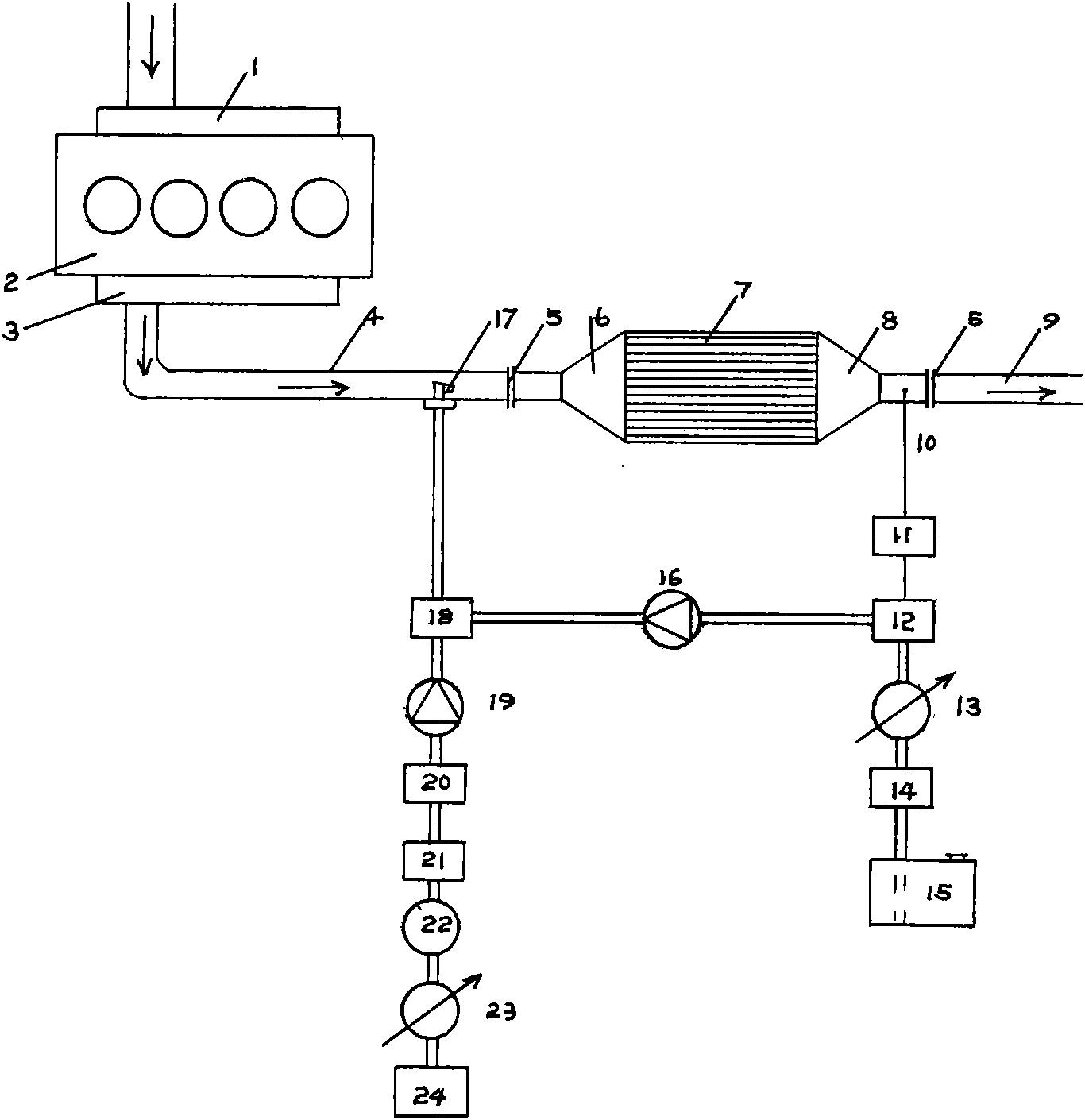

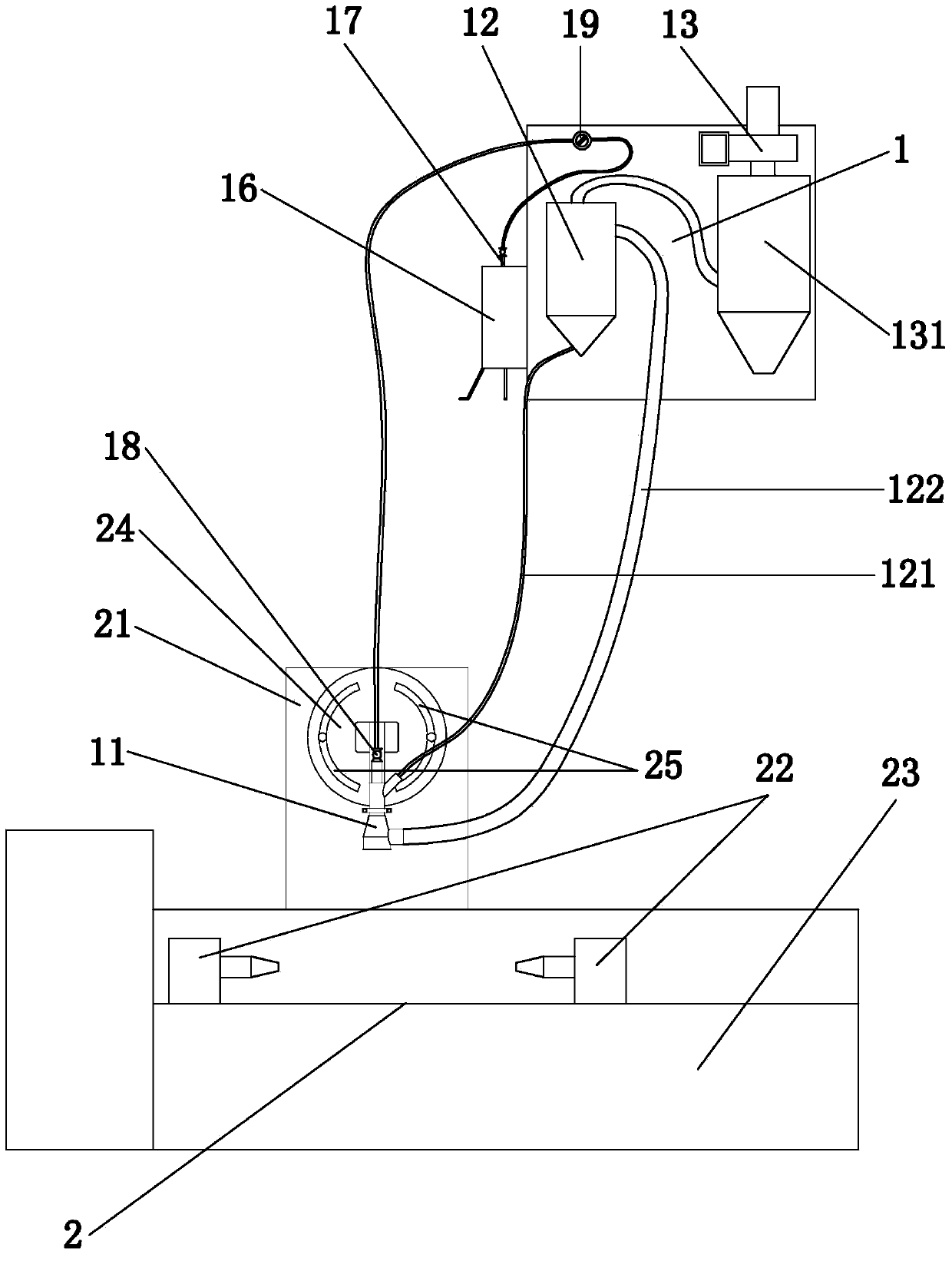

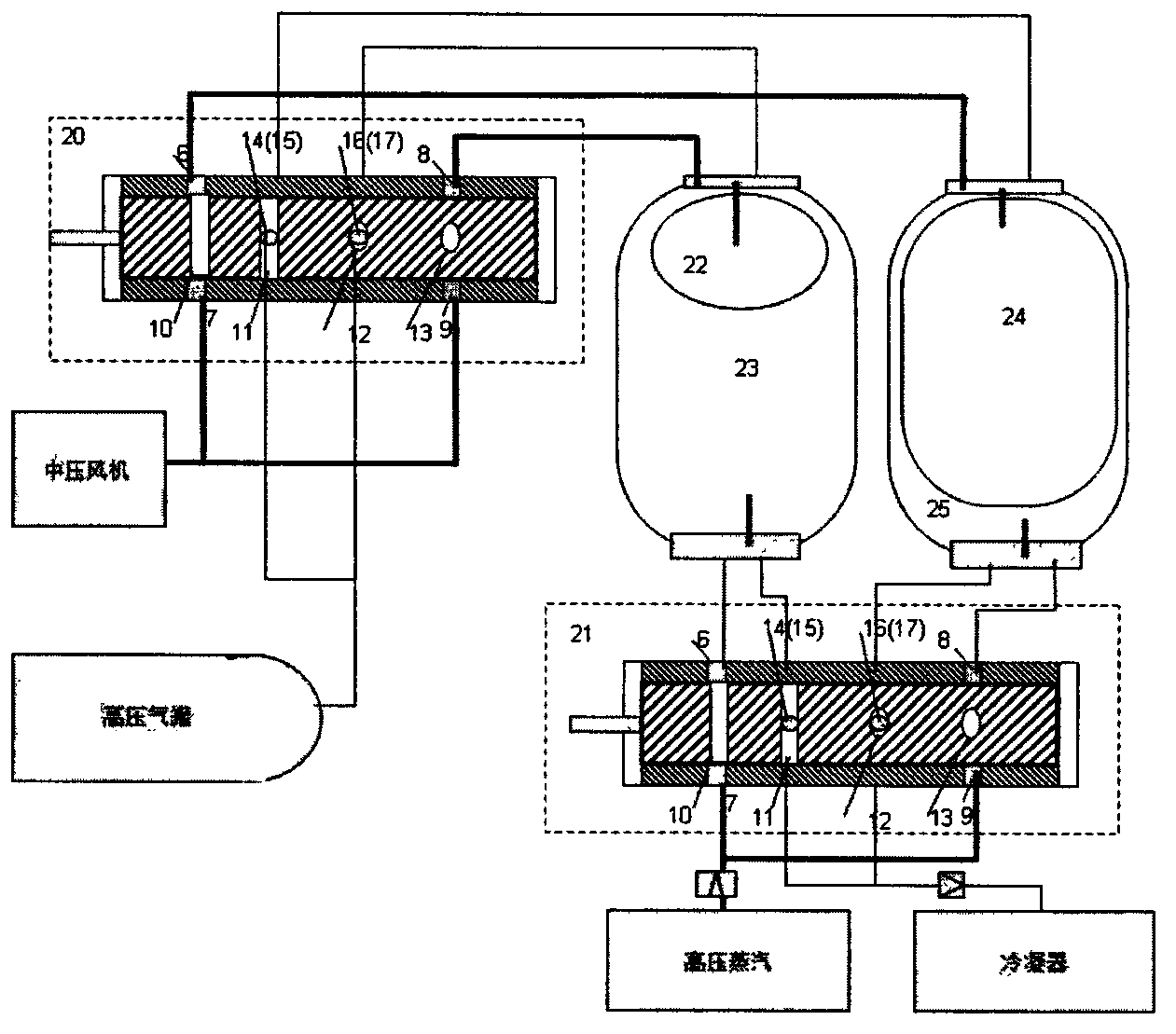

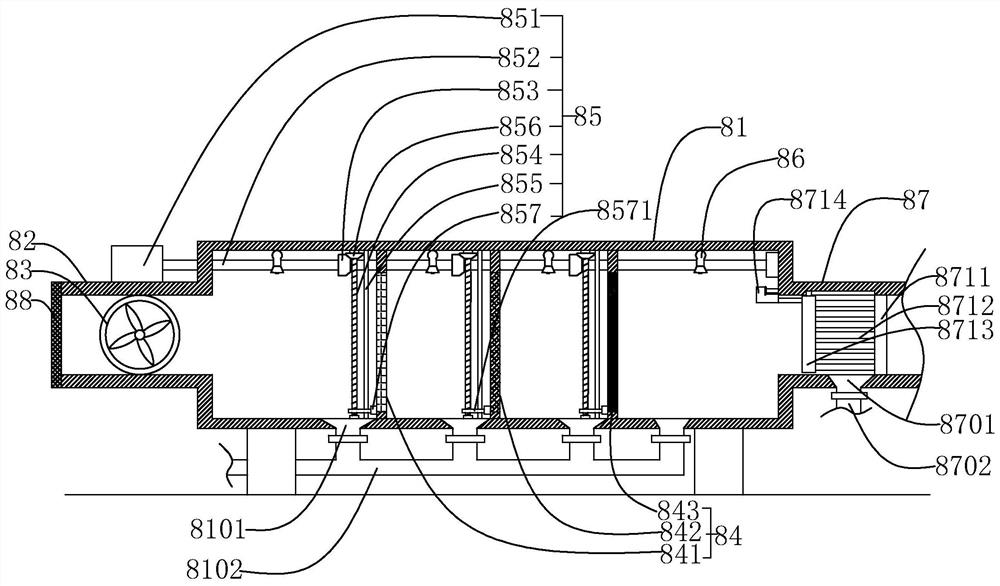

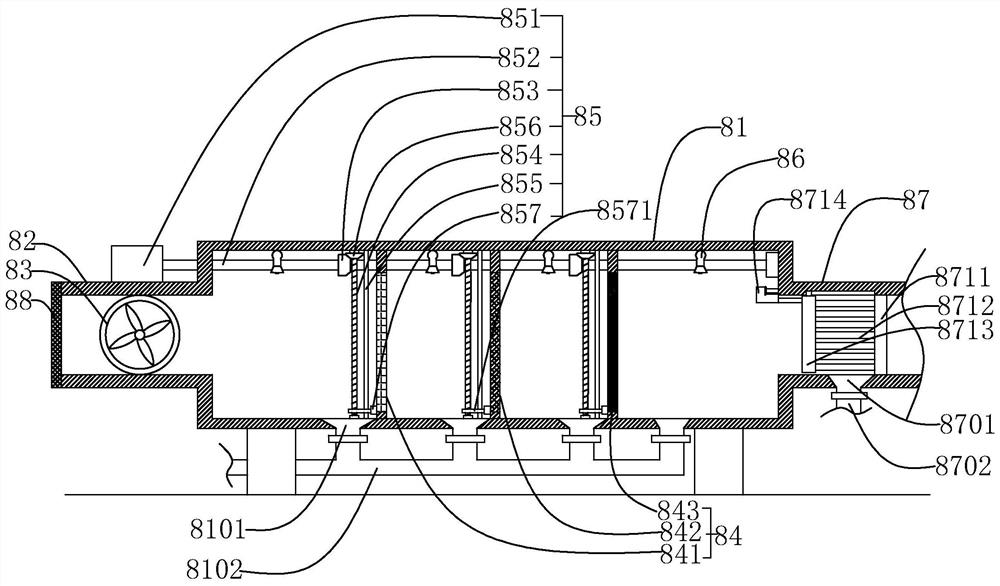

Continuous drier suitable for low-melting point chip and use method thereof

InactiveCN101270956ANo slice dwell time differenceNo blocking phenomenonDrying solid materials with heatDrying gas arrangementsMolecular sieveAir filter

The invention discloses a continuous dryer applicable for low melting point slices and the usage of the dryer. The dryer is characterized in that the dryer consists of a compressed air dryer, a molecular sieve drying device, a reducing valve, a dry heater, an inverse column stream mode drying tower, a gate valve, a screw extruder, a pulsed-bed crystallizer (pre-crystallizer), a dust trolley, a butterfly valve, a dust separator, an air filter, a rotary valve, a crystallization heater, a crystallization fan subsidiary pipeline systems. The usage of the continuous dryer has the characteristics that the drying capacity of the system is controlled between 50 to 1800KG / H; the water ratio of the wet slices is controlled equal to or less than 0.5 percent; the water ratio of the dry slices is controlled equal to or less than 0.002 percent (i.e., 20ppm); the duration of the feeding and discharging the slice materials (i.e., the drying duration) is controlled within 2 hours. The invention is especially applicable to low melting point PET slices.

Owner:张家港保税区万盛机械工业有限公司

Pre-dedusting automatic paint spraying robot

The invention belongs to the field of robots, and particularly relates to a pre-dedusting automatic paint spraying robot. The pre-dedusting automatic paint spraying robot comprises a spraying mechanical arm and further comprises an electric air pump, a compressed air filter, a first air delivery pipe, a second air delivery pipe and a jet head, wherein the spraying mechanical arm comprises a base, an arm rod and an arm front end, and a paint spraying opening is formed in the arm front end; the electric air pump comprises an air inlet and an air outlet, and the compressed air filter comprises an air inlet hole and an air outlet hole; one end of the first air delivery pipe is connected with the air outlet of the electric air pump, and the other end of the first air delivery pipe is connected with the air inlet hole of the compressed air filter; one end of the second air delivery pipe is connected with the air outlet hole of the compressed air filter, and the other end of the second air delivery pipe is connected with the jet head; and the compressed air filter, the first air delivery pipe and the second air delivery pipe are fixed in the arm rod, the electric air pump is mounted on the base, and the jet head is mounted on the arm front end. The pre-dedusting automatic paint spraying robot can use the air current of high-pressure filtered air to blow away dust on the surface of a workpiece before spraying paint on the workpiece and improves the paint spraying effect.

Owner:CHONGQING LEIBAO LASER INTELLIGENT ROBOT MFG

Multifunctional sand-blasting grinder

InactiveCN104191377AReduce lossReduce defectsAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention discloses a multifunctional sand-blasting grinder which comprises a sand-blasting machine and a machine stand, wherein the sand-blasting machine comprises a sand-blasting gun, a sand storage bucket, a fan and a compressed air filter; the machine stand comprises a bracket capable of making horizontal movement, a workpiece holder and a rack; the bracket is provided with a rotatable disc; the sand-blasting gun is fixedly connected onto the rotating disc and is provided with a sand-blasting hole in the center, and a ring-shaped sand return hole in the outer ring; the sand-blasting hole is communicated with the compressed air filter and the sand storage bucket by a compressed air pipe and a sand outlet pipe respectively; the sand return hole is connected with the fan by a sand return pipe; a grinding material is driven by compressed air to be sprayed outside for grinding a workpiece from the sand-blasting hole, and then is adsorbed and recovered at the sand return hole. The multifunctional sand-blasting grinder is simple and reasonable in structure, easy to operate, simple in implementation and low in cost.

Owner:HESHAN SEIKO PLATEMAKING CO LTD

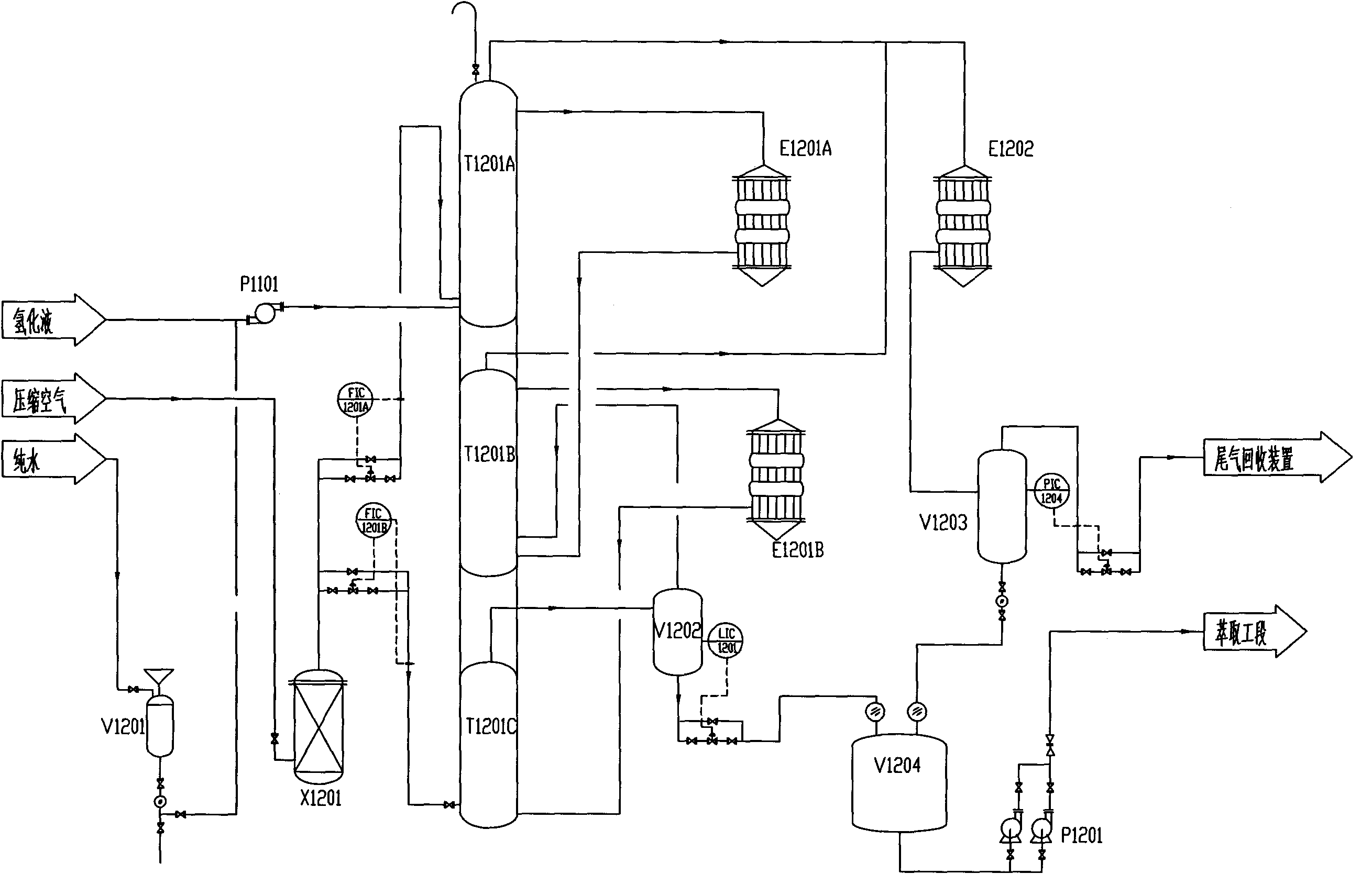

Oxidation system for producing hydrogen peroxide

ActiveCN101837956APeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPhosphoric acidEngineering

The invention discloses an oxidation system for producing hydrogen peroxide in the field of chemical equipment. In the oxidation system, the outlet of a phosphoric acid preparation tank and a hydride source are communicated with the inlet of a hydride pump; the outlet of the hydride pump is communicated with the bottom of an upper tower; the inlet of a compressed air filter is communicated with a compressed air source; the outlet of the compressed air filter is divided into two paths, one path is communicated with the bottom of the upper tower, and the other path is communicated with the bottom of a lower tower; the number of oxidizing solution coolers is two; an oxidizing solution outlet at the top of the upper tower is communicated with the bottom of a middle tower after passing through one oxidizing solution cooler; an oxidizing solution outlet at the top of the middle tower is communicated with the bottom of the lower tower after passing through the other oxidizing solution cooler; and the tail gas at the tops of the middle and upper towers can be condensed for recycling. When the system works, main reaction is performed in the upper and middle towers and complete oxidation reaction is performed in the lower tower, so that hydride can be more fully oxidized and the yield can be improved. The oxidation system is particularly used for producing the hydrogen peroxide.

Owner:YANGZHOU HUITONG CHEM ENG TECHN

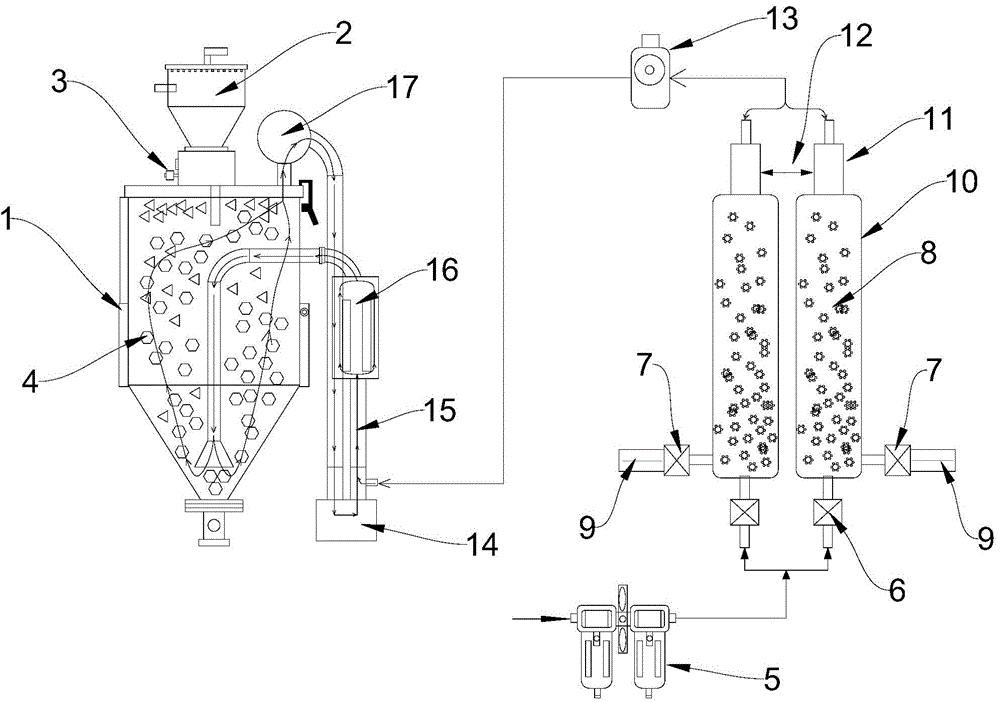

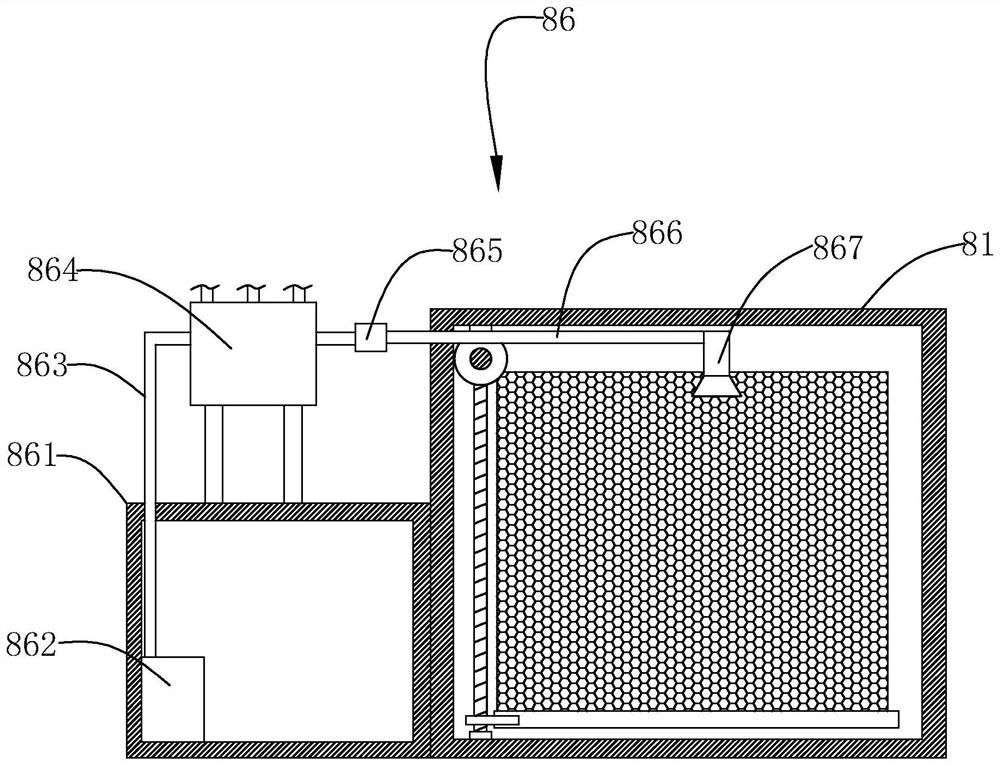

Nitrogen dehumidification dryer and dehumidification drying method of plastic material

InactiveCN104896883AEasy to meet drying requirementsNot affected by timeDrying gas arrangementsDrying machines with local agitationPlastic materialsNitrogen

The invention relates to a nitrogen dehumidification dryer and a dehumidification drying method of a plastic material, which can effectively shorten the drying time and improve the drying effect. The specific technical scheme is that a sealed material barrel is connected with a nitrogen delivery device; the device comprises a compressed air filter, a nitrogen evolver, a blower and a heating device which are arranged on a delivery pipeline in sequence; the compressed air filter is arranged at an inlet of the delivery pipeline; an output end of the compressed air filter is connected with the nitrogen evolver; an output end of the nitrogen evolver is connected with the blower; the blower is connected with the sealed material barrel; the part of the delivery pipeline between the blower and the sealed material barrel is provided with the heating device. The extremely dry nitrogen is adsorbed to molecules separated from the plastic material in the sealed material barrel to discharge the molecules; compared with a pure baking means, more time is saved, the drying effect is greatly improved, and the drying requirements of various plastic materials, particularly the transparent plastic material, are easily met.

Owner:彭林飞

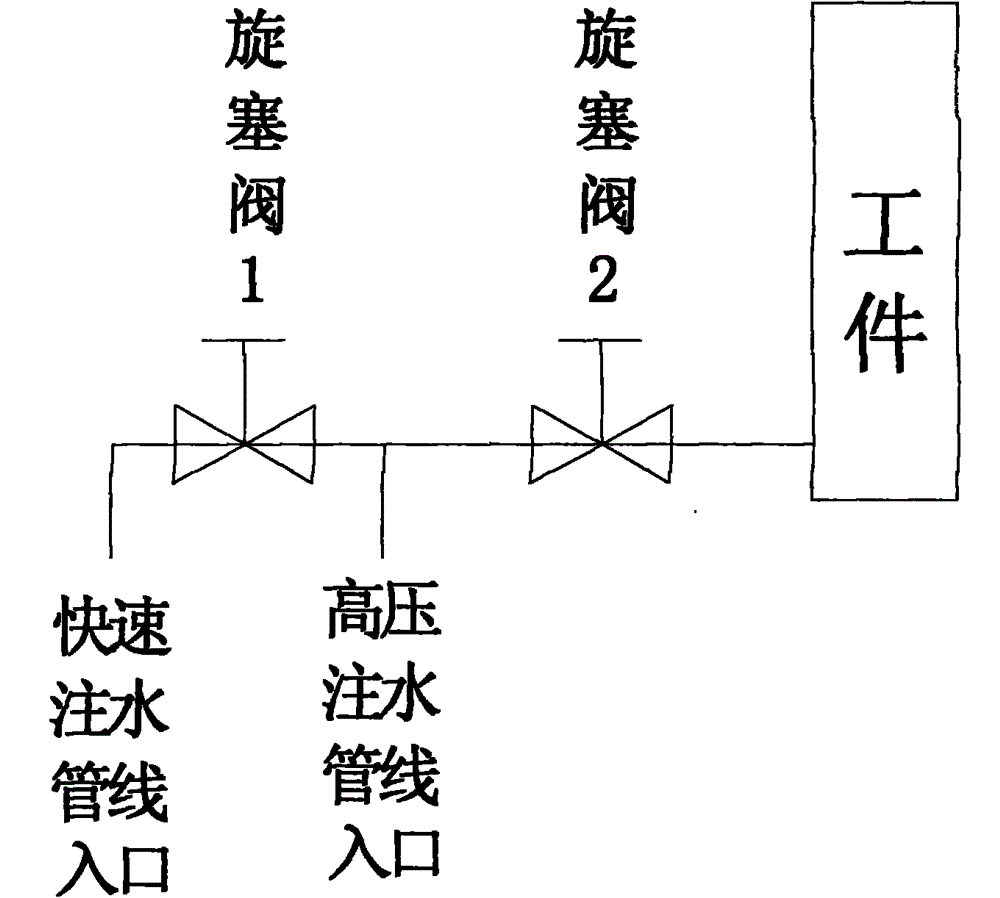

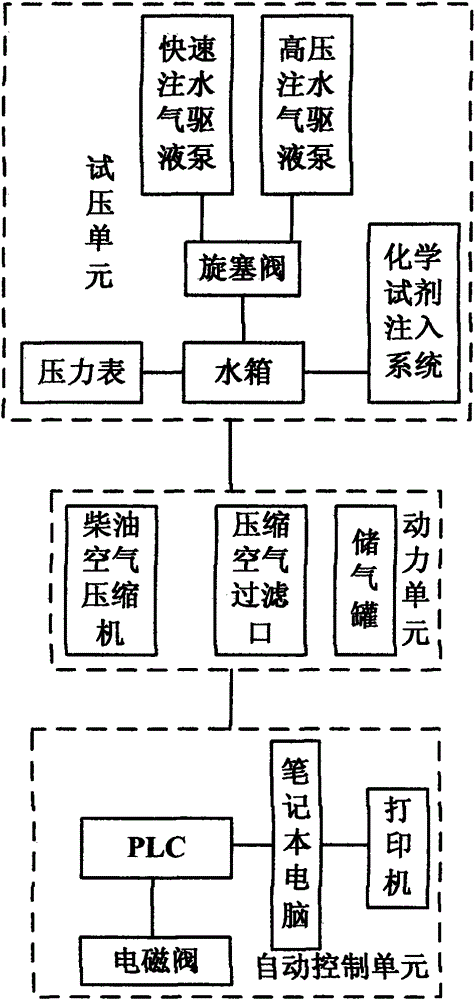

Skid-mounted multifunctional anti-blowout pipe pressure test system

InactiveCN104865129AEasy to transportFast emptyingMachine part testingMaterial strength using tensile/compressive forcesAutomatic controlHigh pressure water

The present invention provides a skid-mounted multifunctional anti-blowout pipe pressure test system, which comprises a pressure test unit, a power unit and an automatic control unit, wherein the power unit mainly comprises a diesel fuel air compressor, a gas storage tank, a compressed air filter and a ball valve, the pressure test unit mainly comprises a rapid water injection pump, a high-pressure water injection pump, a water box, a high-pressure water injection pipeline, a rapid water injection pipeline, a plug valve, a pressure gauge and a chemical reagent injection system, the rapid water injection pump and the high-pressure water injection pump adopt the dual pump connection in parallel, the automatic control unit mainly comprises various electromagnetic valves arranged on the pressure test unit, an anti-explosion box, PLC, a printer and a laptop, the power unit is connected with the pressure test unit, and the pressure test unit is connected with the automatic control unit. According to the present invention, the skid-mounted structure is adopted, the transportation is convenient, each skid body can be separately used under the special circumstance, the double pump connection in parallel is used to perform the grading pressure test, the low-pressure pump is used to rapidly empty the injected water, the high-pressure water injection pump is used to pressurize, and the pressure test work efficiency is improved.

Owner:CHONGQING HANHAI PETROLEUM TECH CO LTD

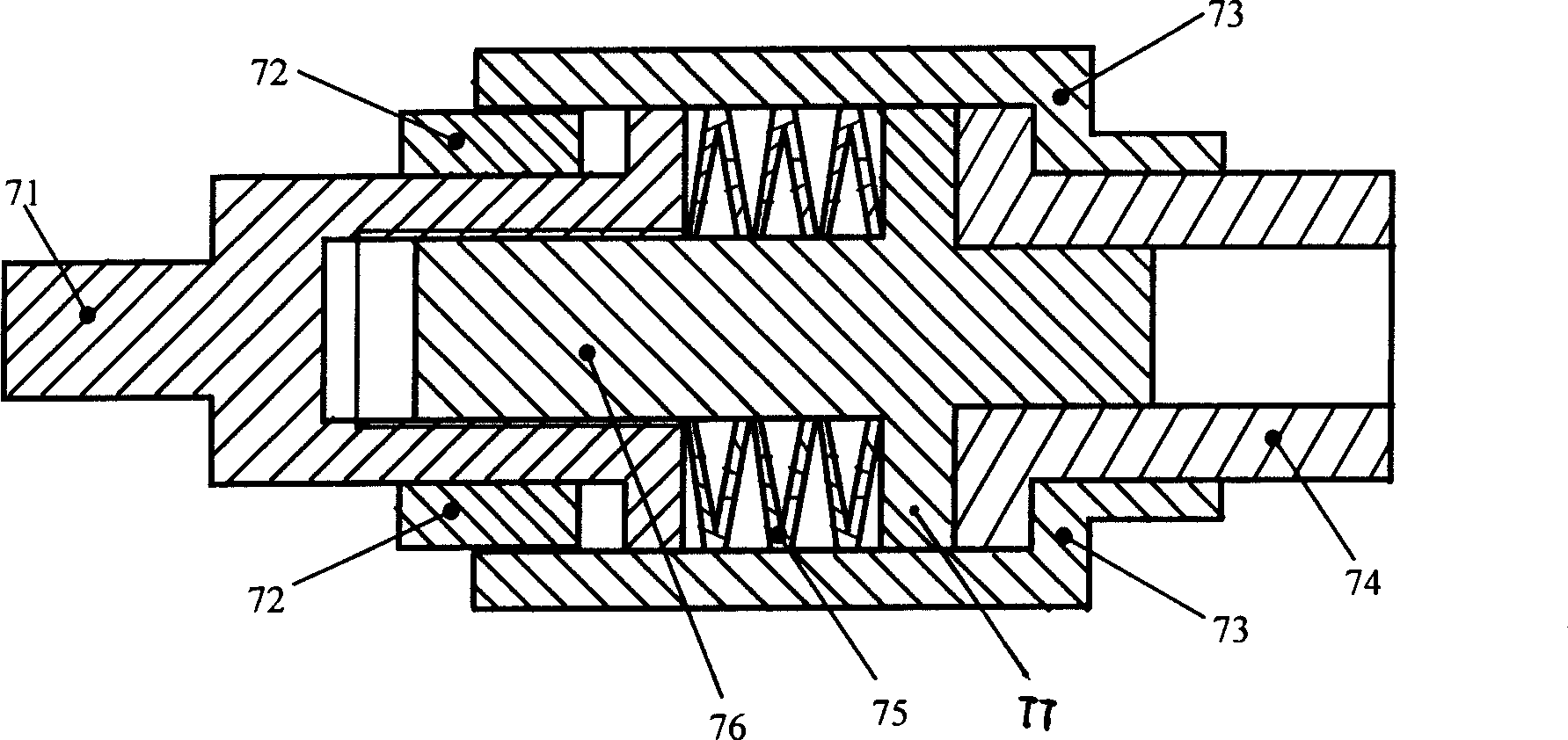

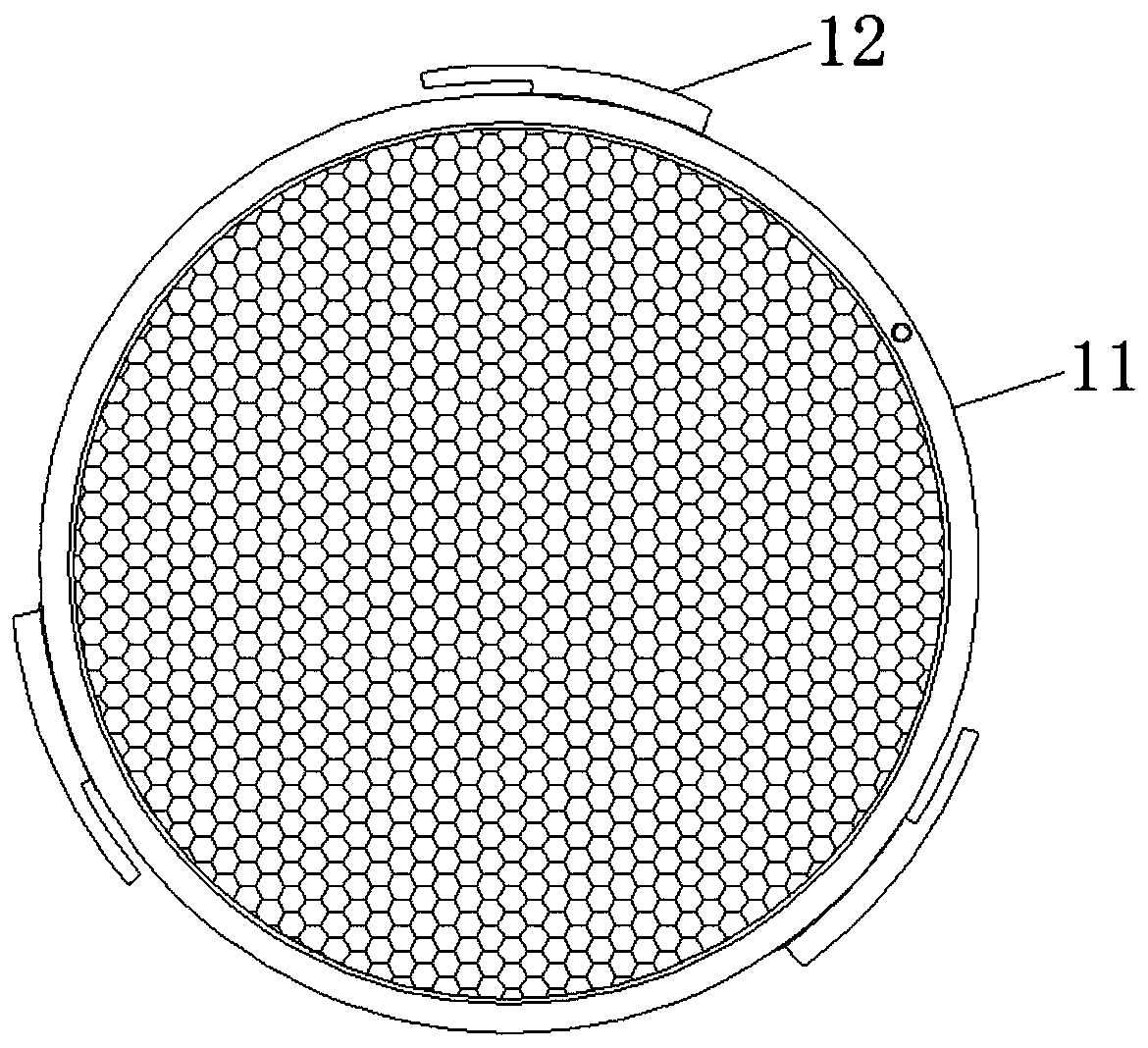

Compressed air Filter Assembly for Nail Gun

InactiveUS20090038277A1Low service durabilityAvoid distortionCombination devicesStapling toolsBiomedical engineeringCompressed air filters

An exemplary compressed air filter assembly for nail gun has an end cap at a handle of the nail gun, having an inlet aperture for guiding external compressed air therein, communicating with a main air chamber of the handle; an inlet pipe extending in the inlet aperture and the main air chamber, having a ring-shaped step formed at an inner peripheral surface of a sidewall thereof; and a filter disposed at the inlet pipe. At least one bar is provided at the sidewall of the inlet pipe, transversely disposed in the inlet aperture, and the filter being disposed between the at least one bar and the ring-shaped step. The compressed air filter assembly for nail gun utilize the at least one bar to support a center portion of the filter, which can improve the strength of the filter to resist the blasting of the compressed air.

Owner:ROBERT BOSCH TOOL +1

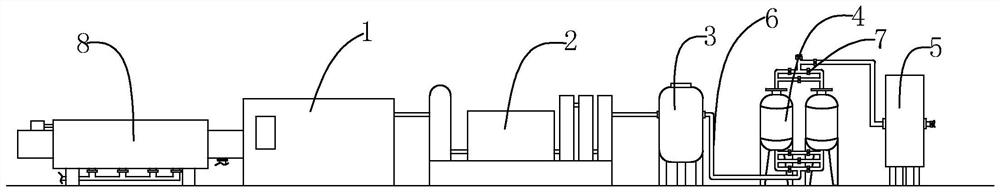

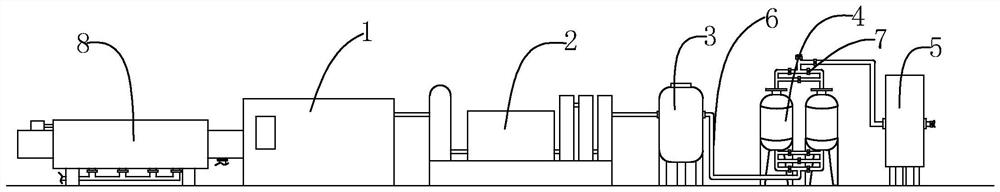

Compressed air comprehensive manufacturing, conveying and applying system

The invention relates to a compressed air comprehensive manufacturing, conveying and applying system and belongs to the technical field of compressed air application. The compressed air comprehensive manufacturing, conveying and applying system comprises a compressed air manufacturing sub-system, a compressed air filtering sub-system, a compressed air drying sub-system and a compressed air refrigeration sub-system. The compressed air manufacturing sub-system is used for compressing normal air into compressed air. The compressed air filtering sub-system is used for filtering the compressed air to obtain clean compressed air. The compressed air drying sub-system is used for removing excessive steam in the clean compressed air so that the humidity of the compressed air is constant. The compressed air refrigerating sub-system is used for cooling the compressed air to keep the temperature of the compressed air constant. The compressed air comprehensive manufacturing, conveying and applying system can provide clean compressed air with constant temperature, constant humidity and constant pressure.

Owner:BEIJING HENGQI NEW ENERGY SCI & TECH CO LTD

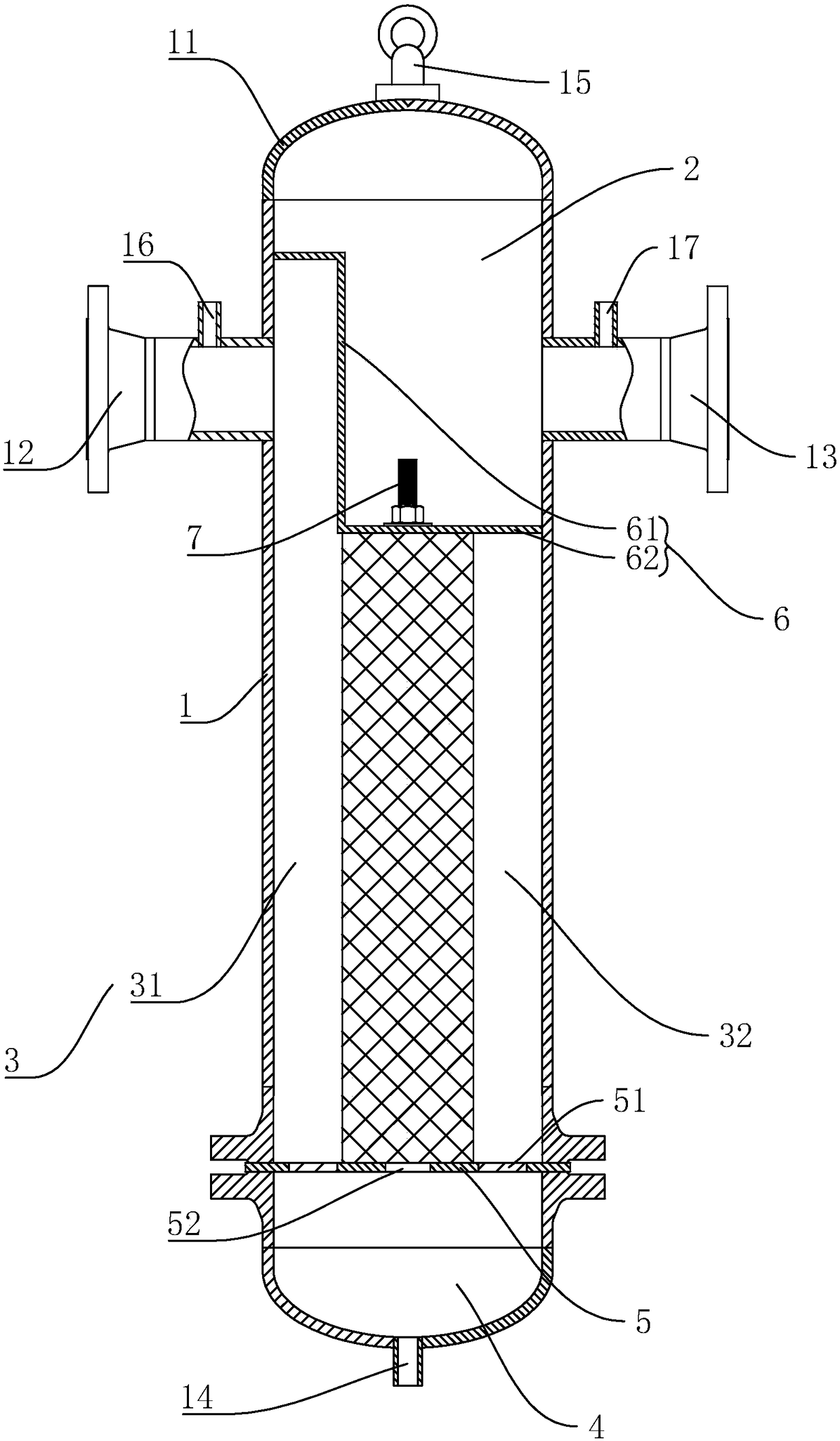

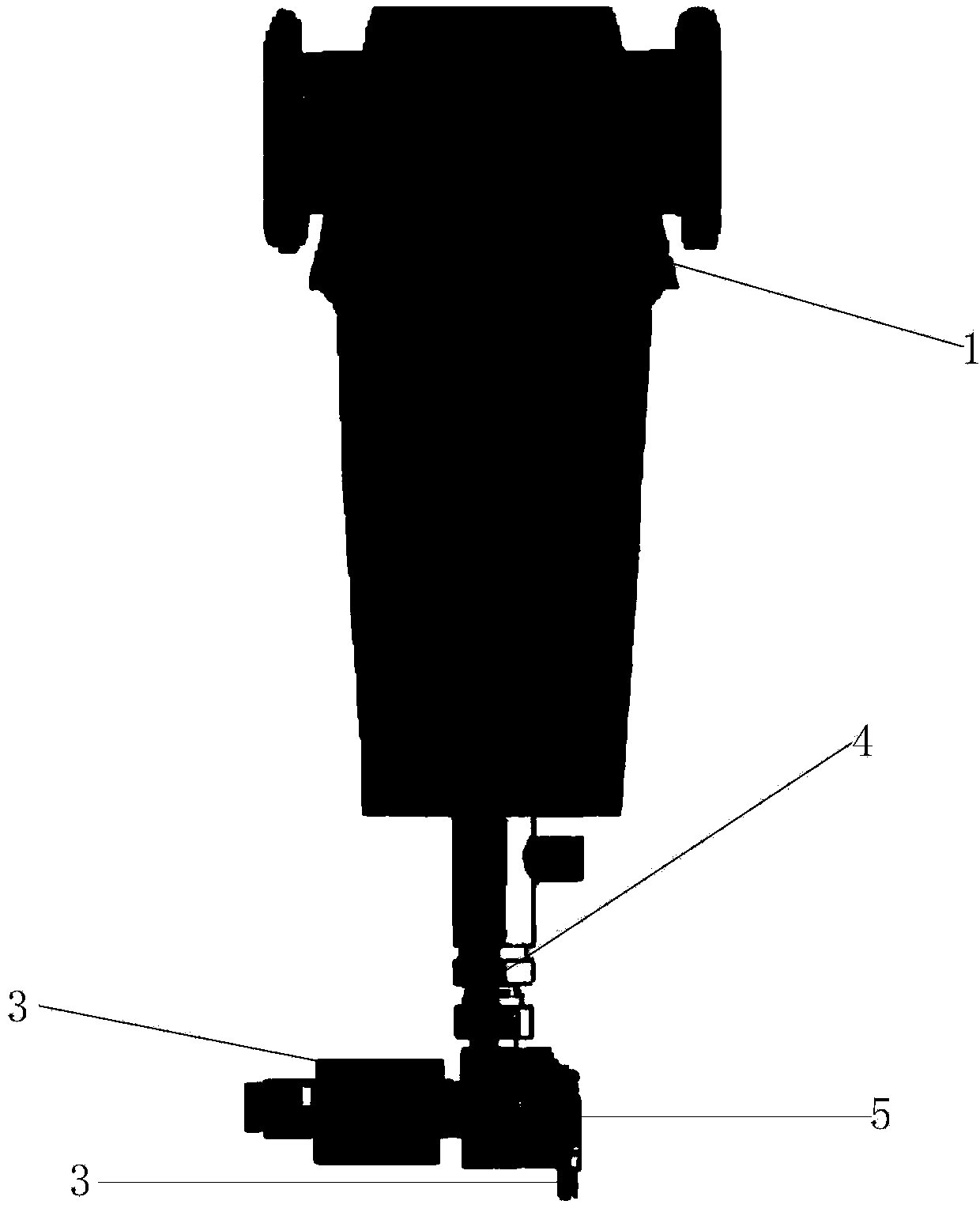

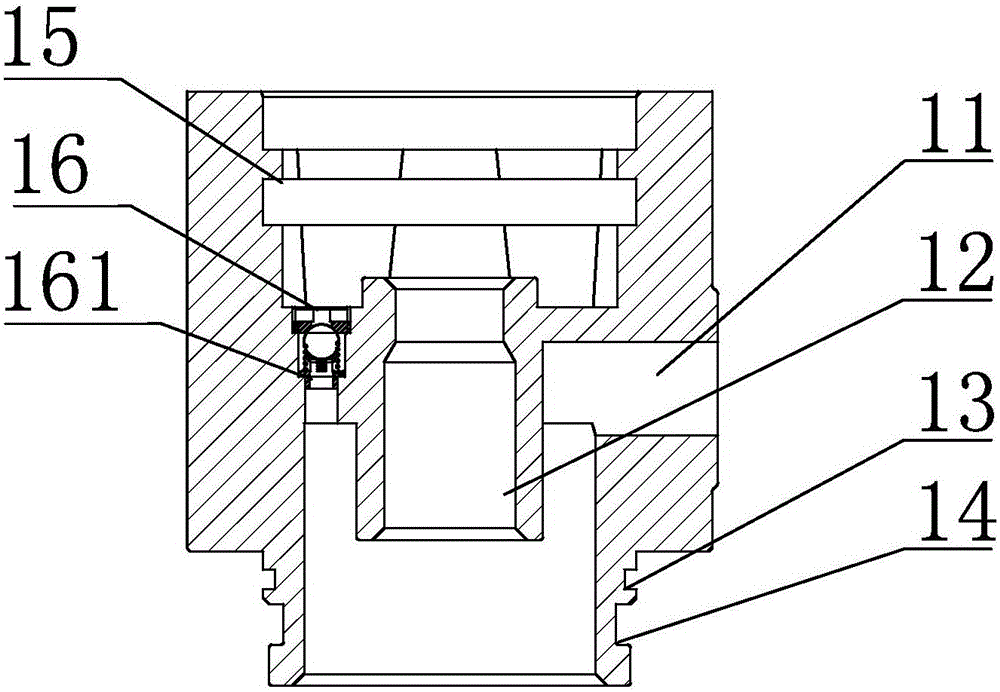

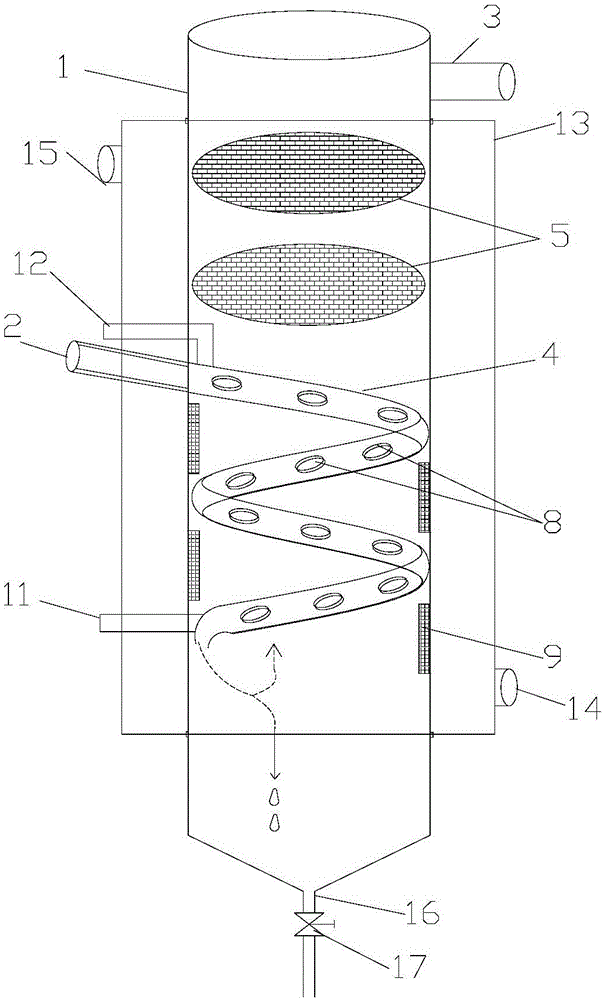

Compressed air filter

InactiveCN108144374AImprove filtering effectImprove filtration efficiencyDispersed particle filtrationGaseous fuelsProduct gasSewage

The invention discloses a compressed air filter, and aims to provide a compressed air filter which has the advantages that contact area of gas and a filter element can be increased, and overall filtering effects and filtering efficiency are improved. The technical scheme mainly includes that a venting zone, a filtering zone and a sewage collection zone are sequentially arranged in a cylinder fromtop to bottom, an inlet pipe and an outlet pipe are connected onto the cylinder, the filtering zone is separated from the sewage collection zone by a base, the venting zone is isolated from the filtering zone by a mounting plate, the filter element is fixed between the base and the mounting plate and divides the filtering zone into a left zone and a right zone, through holes are formed in two sides of the filter element on the base, the left zone is communicated with the right zone through the sewage collection zone by the two through holes, air can be filtered from two side faces of the filter element, so that the contact area of the air and the filter element can be increased, the use ratio of the surface of the filter element is increased, the filtering effects and the overall filteringefficiency of the filter element are improved, and the overall production efficiency of natural gas is improved.

Owner:江苏优耐特过滤装备有限公司

Adapter for a compressed air filter and use of the same

ActiveUS8337582B2Simple and reliable connectionFavorable flow conductionAuxillary pretreatmentDispersed particle filtrationEngineeringFilter element

A compressed air filter adapter for connecting a filter element (12) to a filter connection housing (13) includes a flow duct (21) enclosed by a wall (20) for compressed air, the flow duct (21) at a first end being delimited by a first opening (14), having an inner contour (142) defined by a first edge (141) and an outer contour (143), and at a second end by a second opening (15), having an inner contour (152) defined by a second edge (151) and an outer contour (153). The first opening (14) is provided for connection to a filter connection housing (13) and forms an opening cross-section (16), defined by the inner contour (142) of the first opening (14). The second opening (15) defines an opening on the filter side and forms a second opening cross-section (17), defined by the inner contour (152) of the second opening (15).

Owner:KAESER KOMPRESSOREN SE

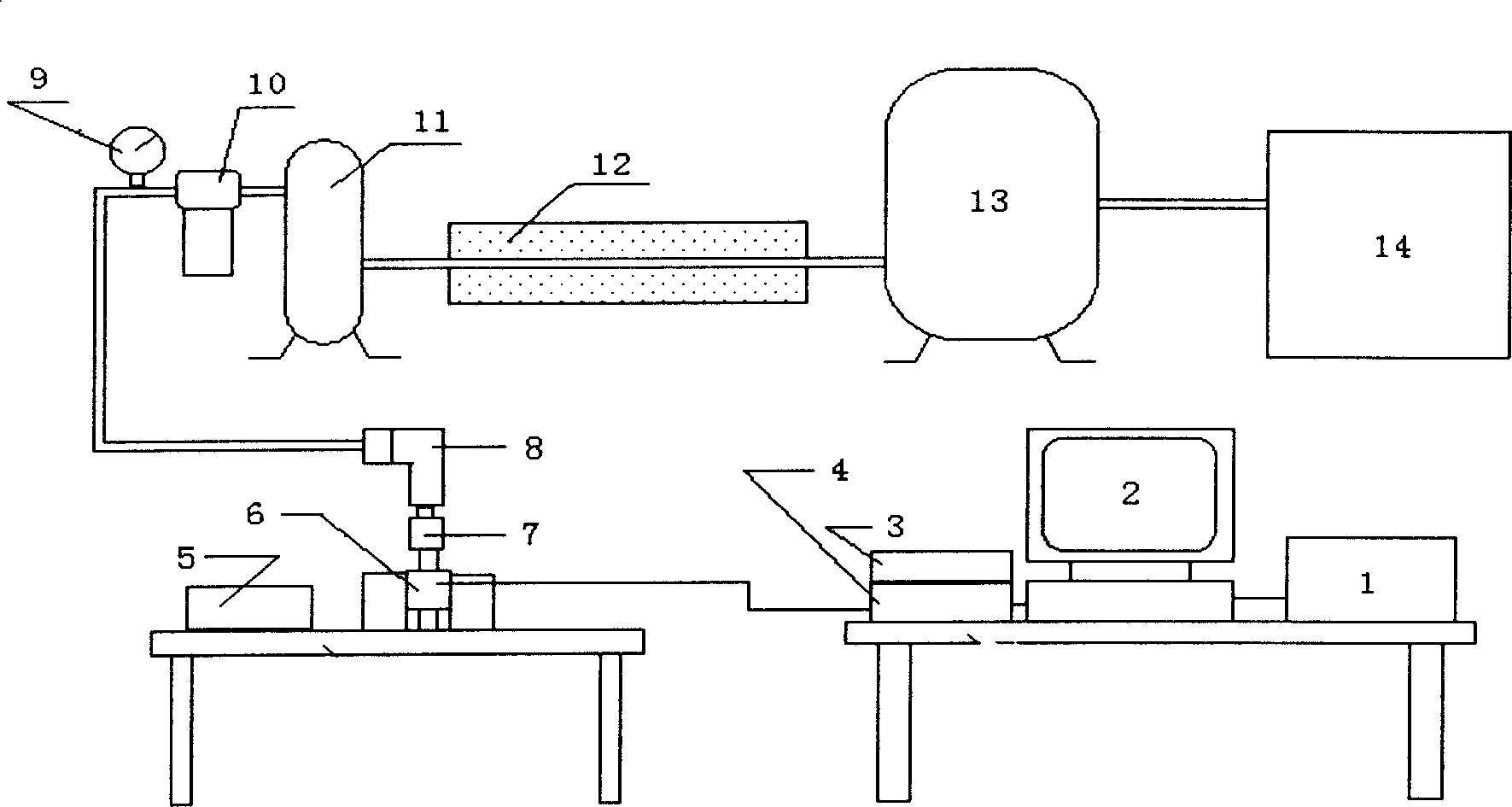

Pneumatic/electric torque spanner dynamic calibrating installation

InactiveCN1709647ARealize dynamic verificationRealize dynamic measurement of torqueSpannersWrenchesData acquisitionTester device

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

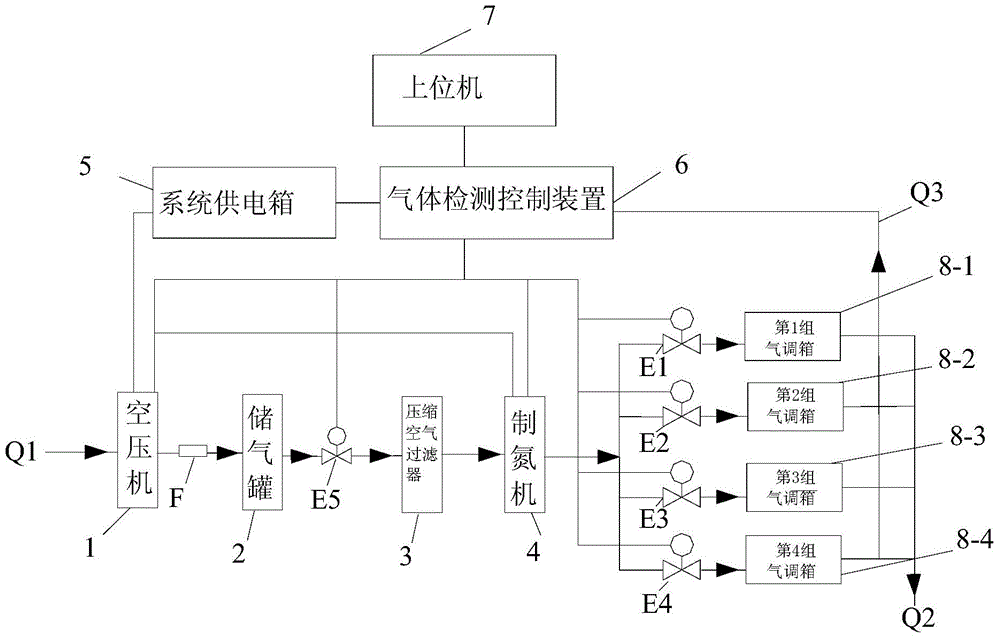

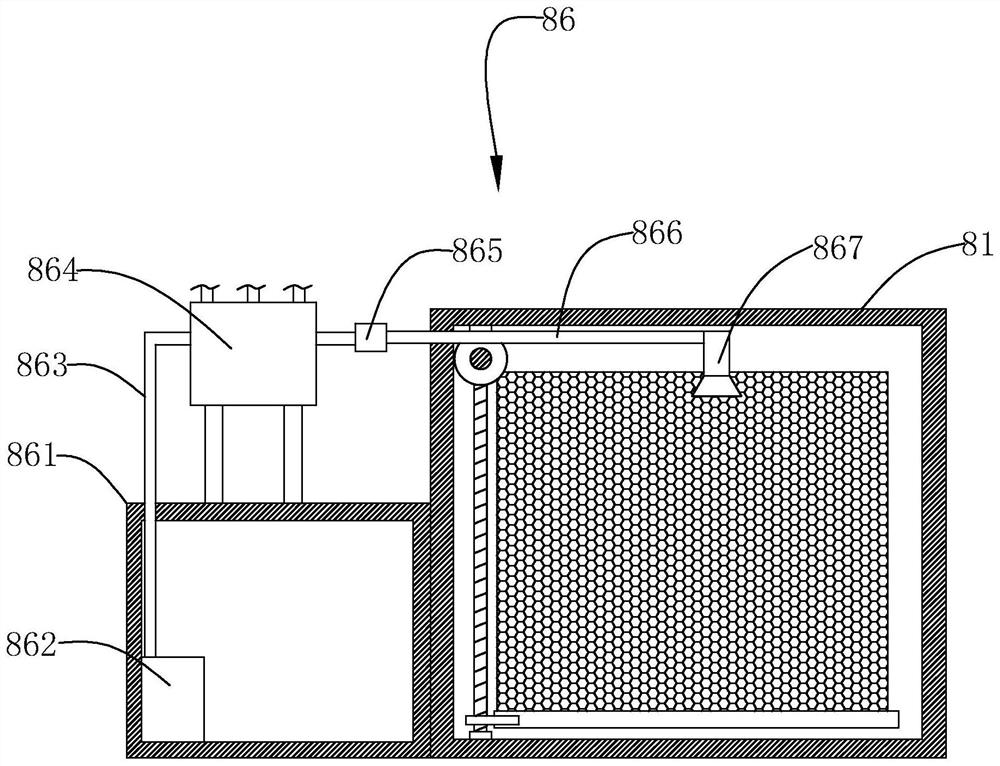

Control device of fruit and vegetable air-conditioning fresh-keeping box

InactiveCN104407585ATo achieve the purpose of long-term preservationIntelligentProgramme total factory controlNitrogenAir conditioning

The invention discloses a control device of a fruit and vegetable air-conditioning fresh-keeping box; the control device structurally comprises a system power supply box, an air detection control device, an upper computer, an air compressor, an air storage tank, a compressed air filter and a nitrogen making machine, wherein the air compressor, the air storage tank, the compressed air filter and the nitrogen making machine are sequentially connected in series; the output end of the nitrogen making machine is connected to the air inlet end of the air-conditioning box through an electromagnetic valve; the air outlet end of the air-conditioning box is connected to an air collecting end of the air detection control device; a one-way valve is connected between the air compressor and the air storage tank; the electromagnetic valve is connected between the air storage tank and the compressed air filter; the output end of the system power supply box is respectively connected to the air detection control device, the air compressor and a power supply switch of the nitrogen making machine; and the output end of the air detection control device is respectively connected to the air compressor, the control input end of the nitrogen making machine and the wiring terminal of the electromagnetic valve. The control device of the fruit and vegetable air-conditioning fresh-keeping box disclosed by the invention has the benefits that: the space of the air-conditioning box is sufficiently utilized; the air-conditioning environment in the whole storage space is unnecessary to damage while fetching vegetables; the air-conditioning box is safe and convenient to use and can be repeatedly used; and thus, the control device disclosed by the invention has the advantages of being simple in structure, small in occupation space and low in power consumption.

Owner:TIANJIN CNRO SCI TECH

Trace air-oil lubrication system of horizontal decanter screw centrifuge

InactiveCN109323114ARigorous structureReasonable layoutBearing componentsSafety/regulatory devicesAir filterFuel tank

Owner:CSSC NANJING LUZHOU MACHINE

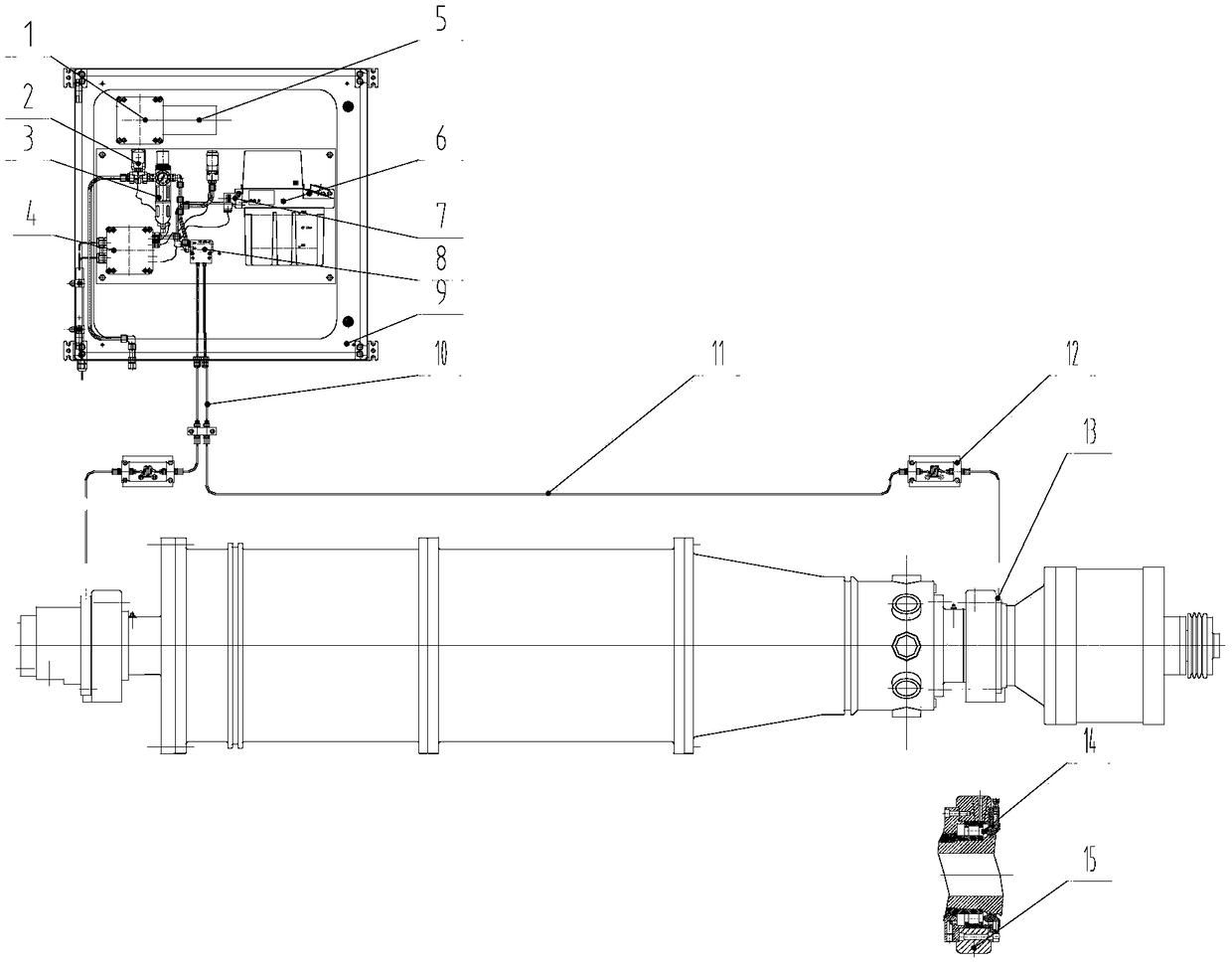

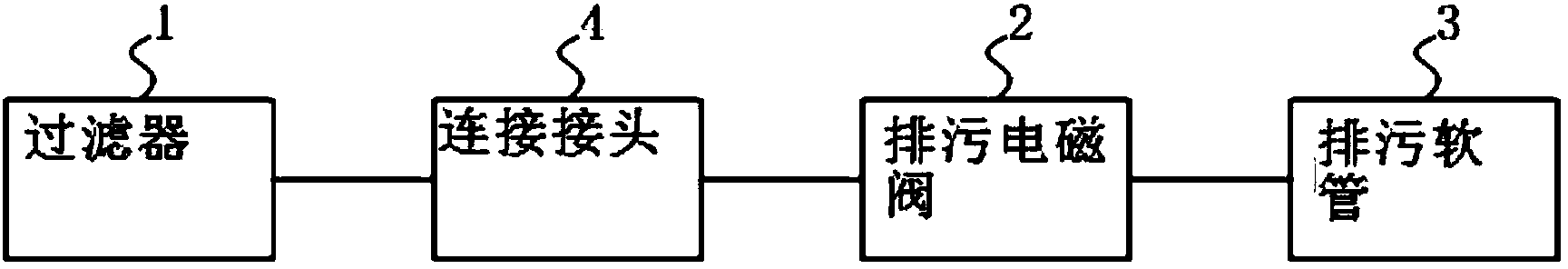

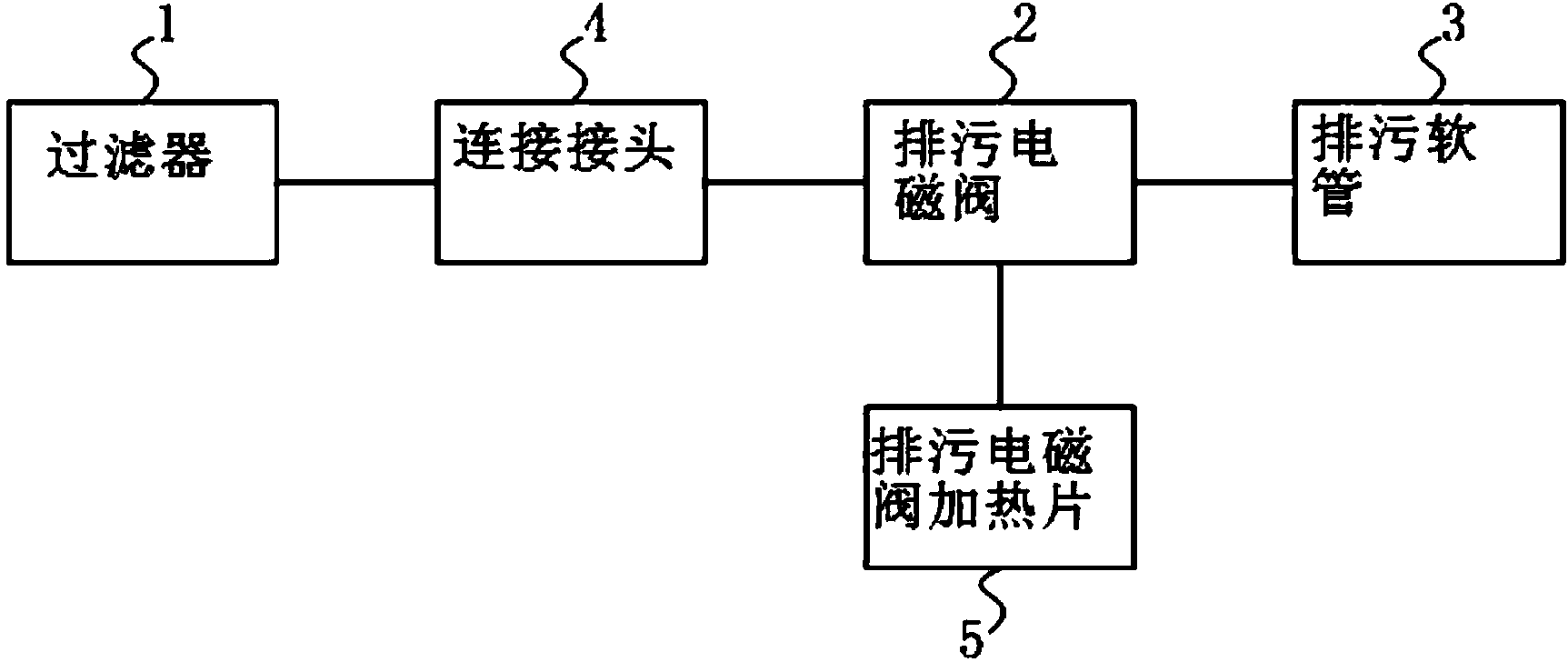

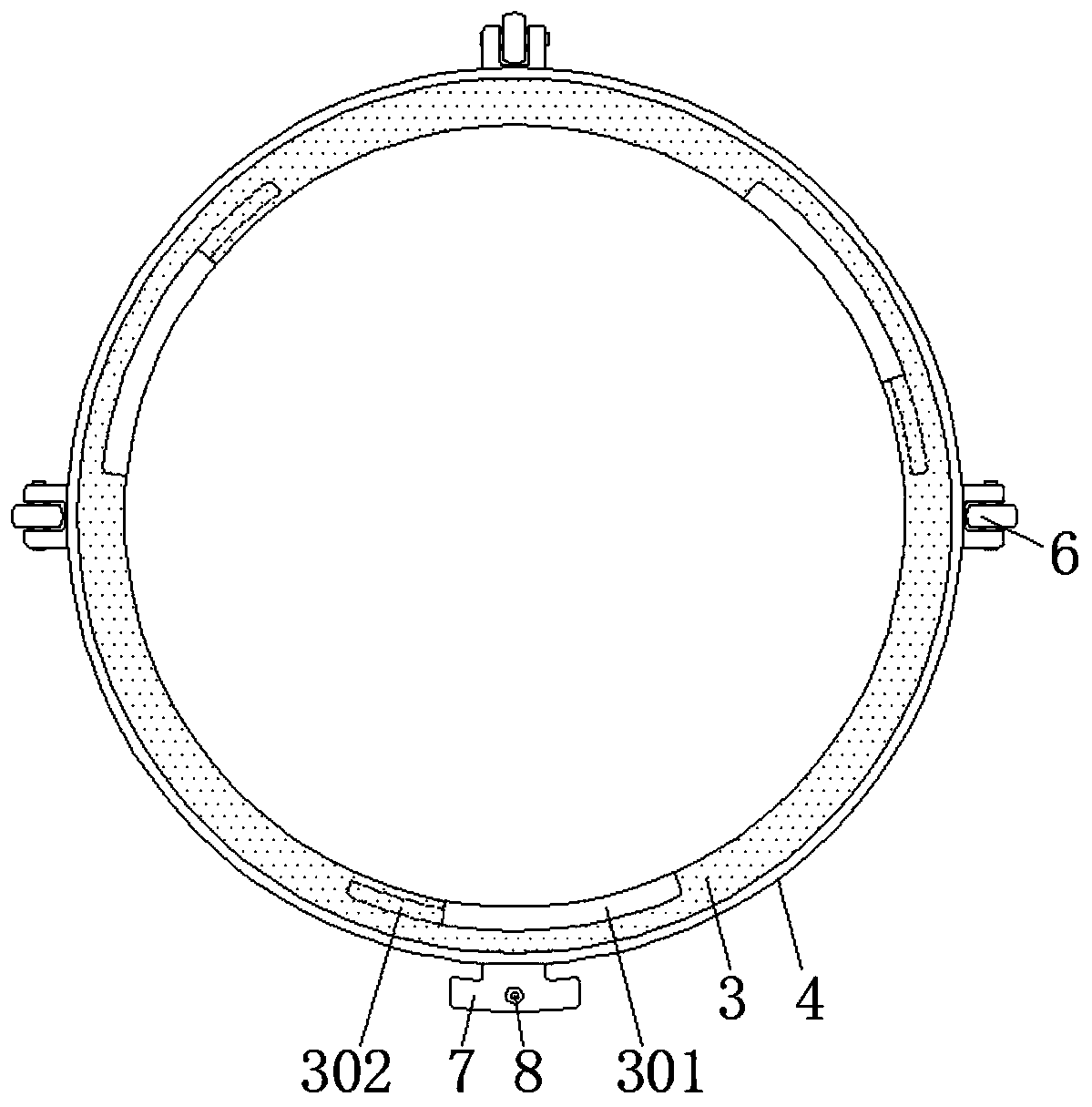

Compressed air filter system for haulage motor and application method thereof

InactiveCN103446811ACompressed air quality is cleanReduce potential hidden dangersHuman health protectionDispersed particle filtrationGas compressorAir filter

The invention provided with a compressed air filter system for a haulage motor and an application method thereof. The system comprises a filter for removing lubricating oil in compressed air, solid dust and condensate water, a sewage discharging electromagnetic valve for discharging sump oil, sewage and the solid dust as well as a sewage discharging flexible pipe connected with the sewage discharging electromagnetic valve, wherein the sewage discharging flexible pipe is used for discharging sump oil, the sewage and solids out of the haulage motor, and the filter is connected with the sewage discharging electromagnetic valve through a connecting joint. According to the technical scheme, the compressed air generated at the outlet of an air compressor is discharged with sump oil removal, sewage removal and solid particle removal, the oil content of the compressed air after filtering is reduced to be below 0.1mg / m<3>, the condensate water and the solid particles are effectively filtered, the quality of the compressed air of the haulage motor is clean, the compressed air filter system is beneficial for the stable operation of a braking system, the potential hidden danger during running of the haulage motor is effectively reduced, fault of the braking system is effectively reduced, and the running safety of the haulage motor is increased.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Compressed air filtering device with inner wall cleaning function

InactiveCN110652803AWith inner wall cleaning functionQuick scrape jobDispersed particle filtrationActivated carbon filtrationPulley

The invention discloses a compressed air filtering device with an inner wall cleaning function. The device comprises an abutting pipeline, cleaning cotton and an activated carbon filter layer, a firstsliding groove is formed in the inner surface of the abutting pipeline, a mounting block is mounted at the inner side of the butting pipeline; cleaning cotton is fixedly connected to the outer surface of the mounting block, the left end of the mounting block is fixedly connected with a balancing weight, the outer side of the mounting block is rotationally connected with a pulley, the pulley is connected with the first sliding groove, the lower end of the mounting block is fixedly connected with a fixing block, the fixing block is connected with the first sliding groove, and the outer side ofthe fixing block is fixedly connected with a traction rope. The compressed air filtering device with the inner wall cleaning function can be circumferentially rotated through holding a movable handleby a user, the wound traction rope drives the cleaning cotton fixed to the outer side of the mounting block to be attached to the inner side of the abutting pipeline for cleaning work, and the movableblock is pulled to conveniently and rapidly scrape away cleaned accumulated dusts.

Owner:浙江汉至蓝特种装备有限公司

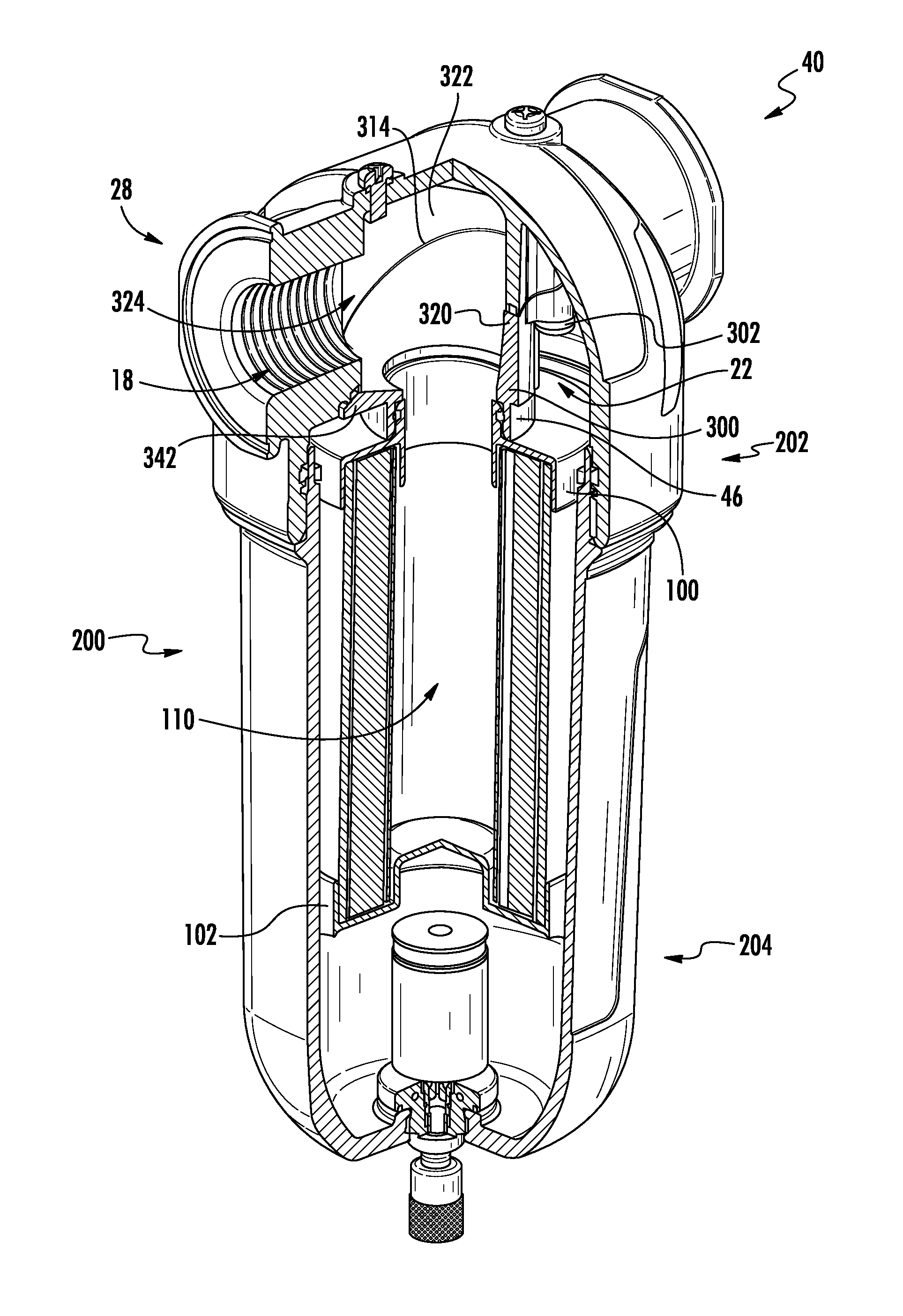

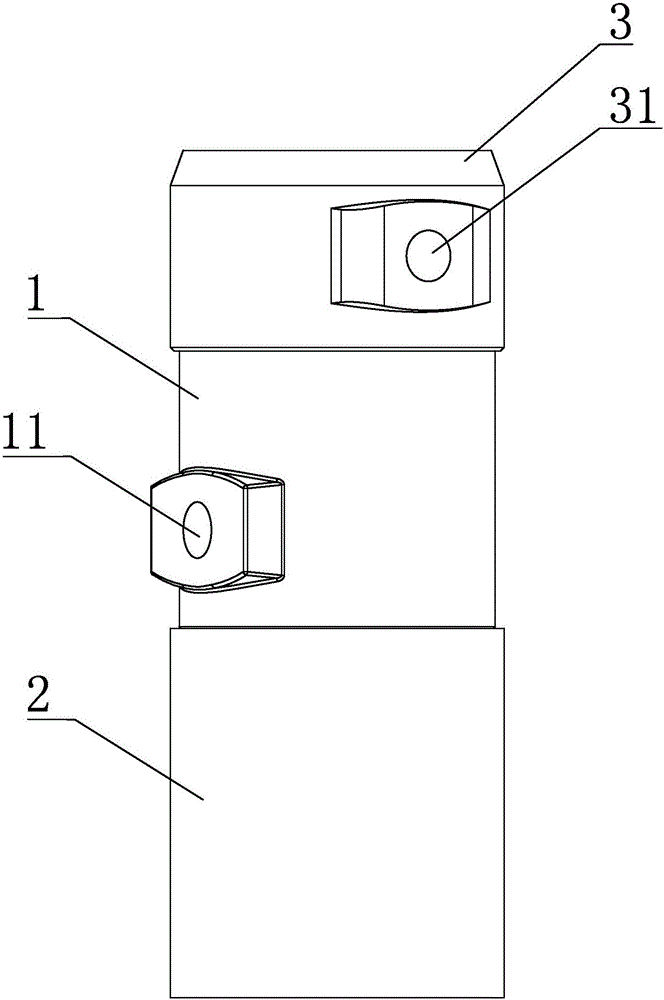

Filter element adaptor for compressed air filter

ActiveUS20150251120A1Reduce component countShorten the counting processDispersed particle filtrationMembrane filtersAdaptor/connectorInlet channel

A filter head adaptor for a compressed air filter. The filter head adaptor capable of modifying a filter head to accommodate a variety of different style filter elements. The filter head adaptor including a main body connector, a filter element connector, and a second inlet channel in fluid communication between the main body connector and the filter element connector, the main body connector is adapted for coupling to the adaptor connector of the main body, whereby the main body connector is adapted for coupling to a filter head. The invention includes contemplates requiring a reduced inventory of filter heads and filter bodies for a plurality of filter elements, as the appropriate filter head adaptor may be selected which presents a particular filter element connector which matches that of the filter element intended to be used.

Owner:INGERSOLL RAND IND U S INC

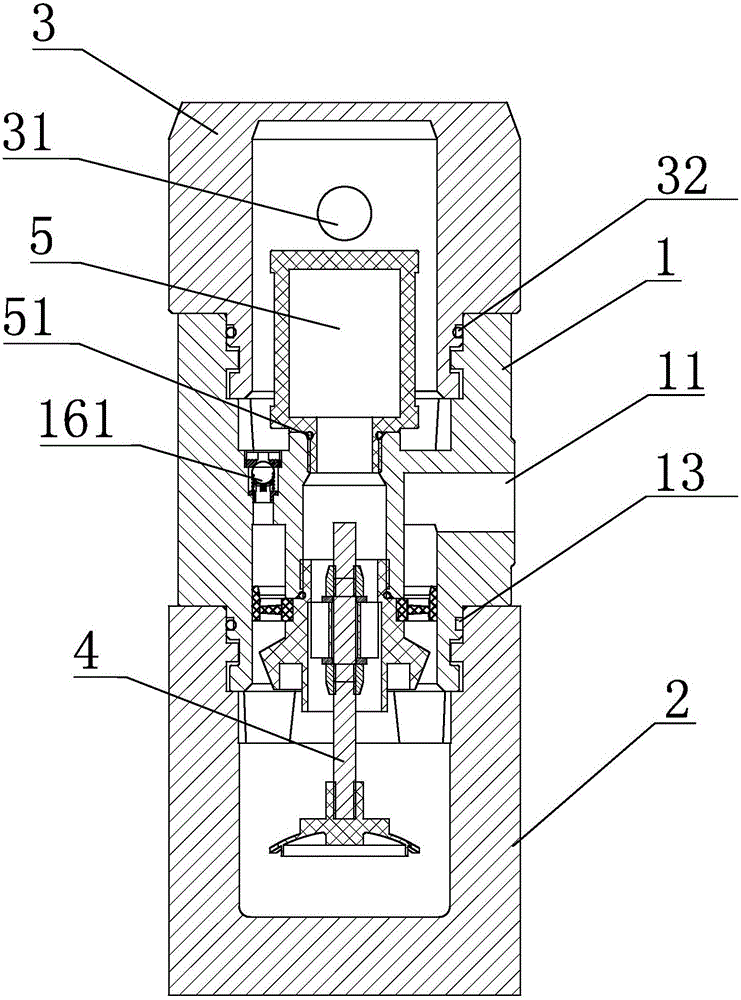

Multifunctional compressed air filter

ActiveCN105935532AHigh degree of integrationSmall footprintCombination devicesAir filterCentrifugation

The invention discloses a multifunctional compressed air filter, which includes a pipe head, a pipe body and a pipe cap. The pipe head is internally provided with an air channel, both ends of the air channel are respectively provided with a gas-water separation device and a filter core, one pipe head end equipped with the gas-water separation device is close fit with the pipe body, one pipe head end equipped with the filter core is in close fit with the pipe cap, compressed air enters the filter through a filter air inlet, firstly passes through the gas-water separation device and goes upward into the filter core through the air channel, then passes through the filter core from the inside out and is discharged through a filter air outlet. Through scientific integration of the gas-water separation device and the high efficiency filter, a lot of moisture in the compressed air can be removed by centrifugation, gravity, inertia, collision and other mechanisms, and solid particles, water droplets and oil mist and other aerosol impurities in the compressed air can also be separated by physical barrier technology of the filter, thus realizing dewatering, deoiling and dedusting. The multifunctional compressed air filter has the advantages of small space occupation, few components, high degree of integration, simple structure and low cost, etc.

Owner:ZHUHAI HECA PURIFICATION TECH

Mold local cooling system based on low-temperature high-pressure gas

The invention discloses a mold local cooling system based on low-temperature high-pressure gas. The system comprises an air source capable of providing compressed air, a filter connected with the airsource through a first air pie, a pressurizing pump connected with the filter through a second gas pipe, an exchange refrigeration assembly connected with the pressurizing pump through a third air pipe and capable of refrigerating the pressurized compressed air, a mold internally provided with a cooling air flow way, and a controller. One end of the cooling air flow way is connected with the exchange refrigeration assembly through a fourth air pipe, mold cooling is carried out, and an electromagnetic valve is arranged on the fourth air pipe, and the controller is connected with the pressurizing pump, the exchange refrigeration assembly and the electromagnetic valve for control. Through the above manner, according to the mold local cooling system based on the low-temperature high-pressure gas, the low-temperature high-pressure gas is used for serving as mold cooling media, the gas can reach the mold interior where a common cooling medium cannot arrive, local cooling is rapidly achieved,the injection molding period is shortened, and the pollution is reduced.

Owner:苏州斯泰姆克工业智能科技有限公司

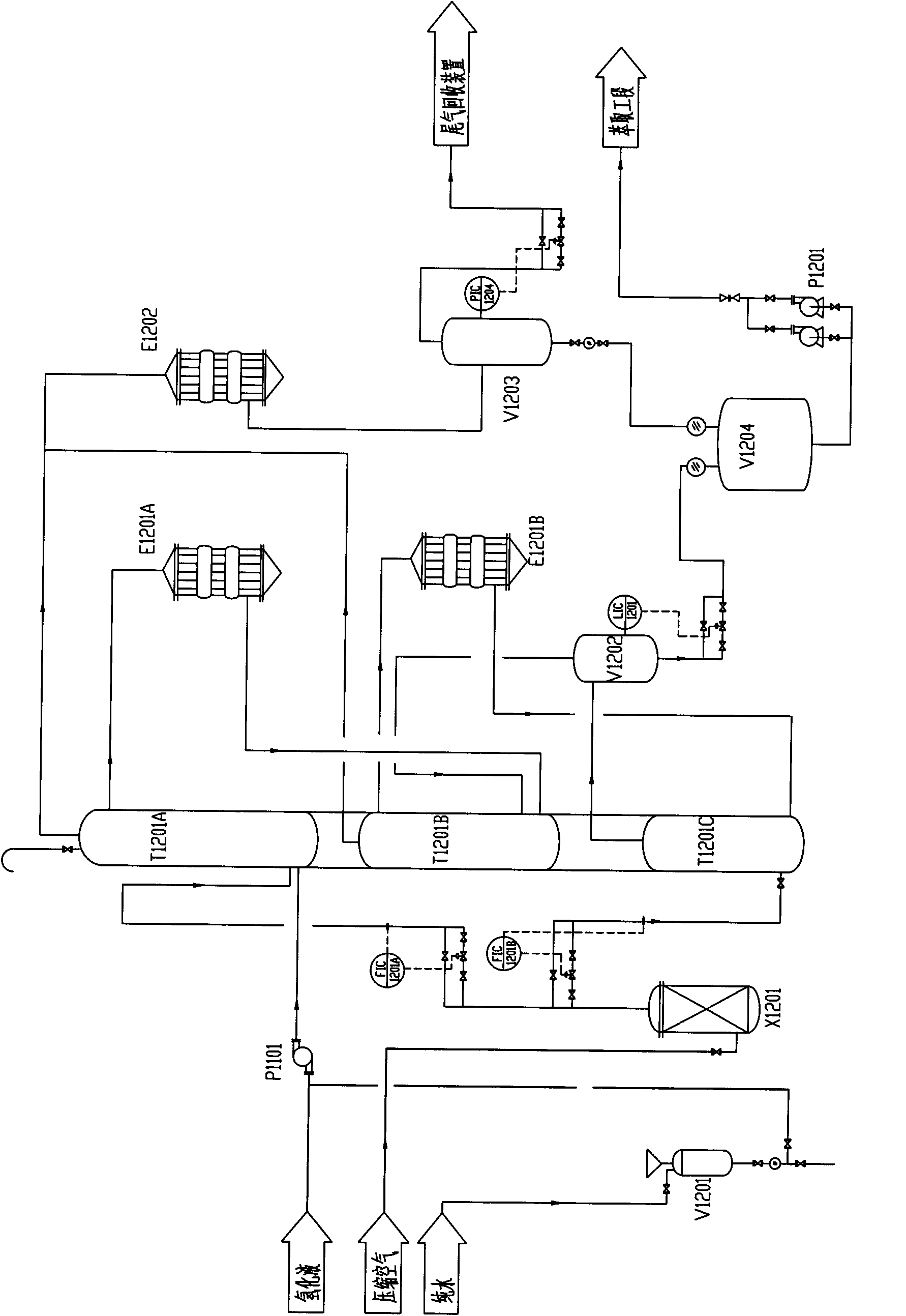

Pressure swing adsorption nitrogen generation system and nitrogen generation method thereof

ActiveCN112897480AReduce chemical impuritiesReduce the frequency of filter replacementNitrogen purification/separationAir filterAir compressor

The invention relates to the technical field of gas preparation, in particular to a pressure swing adsorption nitrogen generation system and a nitrogen generation method thereof. The pressure swing adsorption nitrogen generation system comprises an air compressor, a compressed air filtering assembly, a buffer gas storage tank, an adsorption tower set, a nitrogen tank, a connecting pipeline and a valve set. The system is characterized in that the air compressor, the compressed air filtering assembly, the buffer gas storage tank, the adsorption tower set and the nitrogen tank sequentially communicate with one another through the connecting pipeline, the valve set is arranged on the connecting pipeline, and an inlet air filtering device is arranged at the input end of the air compressor and used for filtering inlet air of the air compressor. According to the pressure swing adsorption nitrogen generation system and nitrogen generation method thereof, primary filtering and impurity removal can be conducted on inlet air of the air compressor during nitrogen preparation, the frequency of replacing a filter element of filter equipment in the later period is reduced, the production cost is reduced, the impurity removal pressure of the filter equipment in the later period is reduced, and the filtering effect of the filter equipment in the later period is guaranteed.

Owner:浙江瑞鸿机电设备有限公司

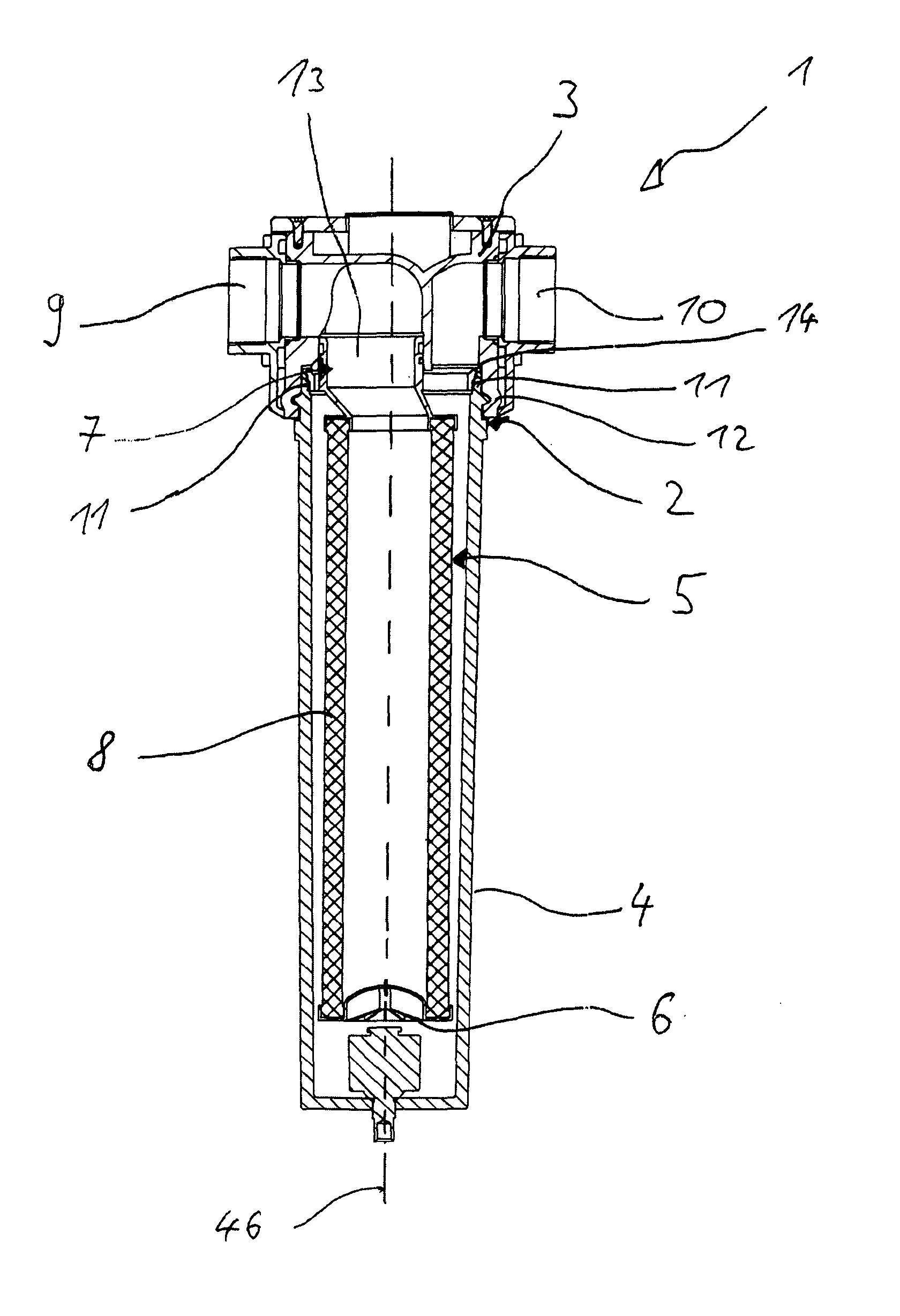

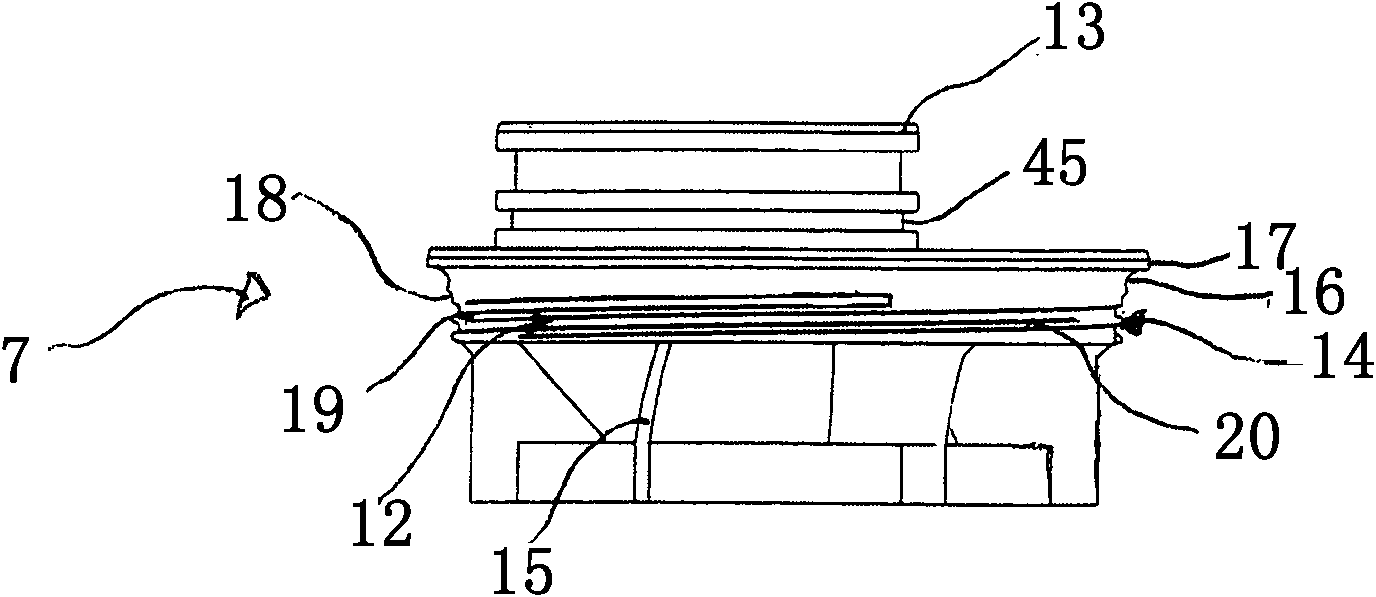

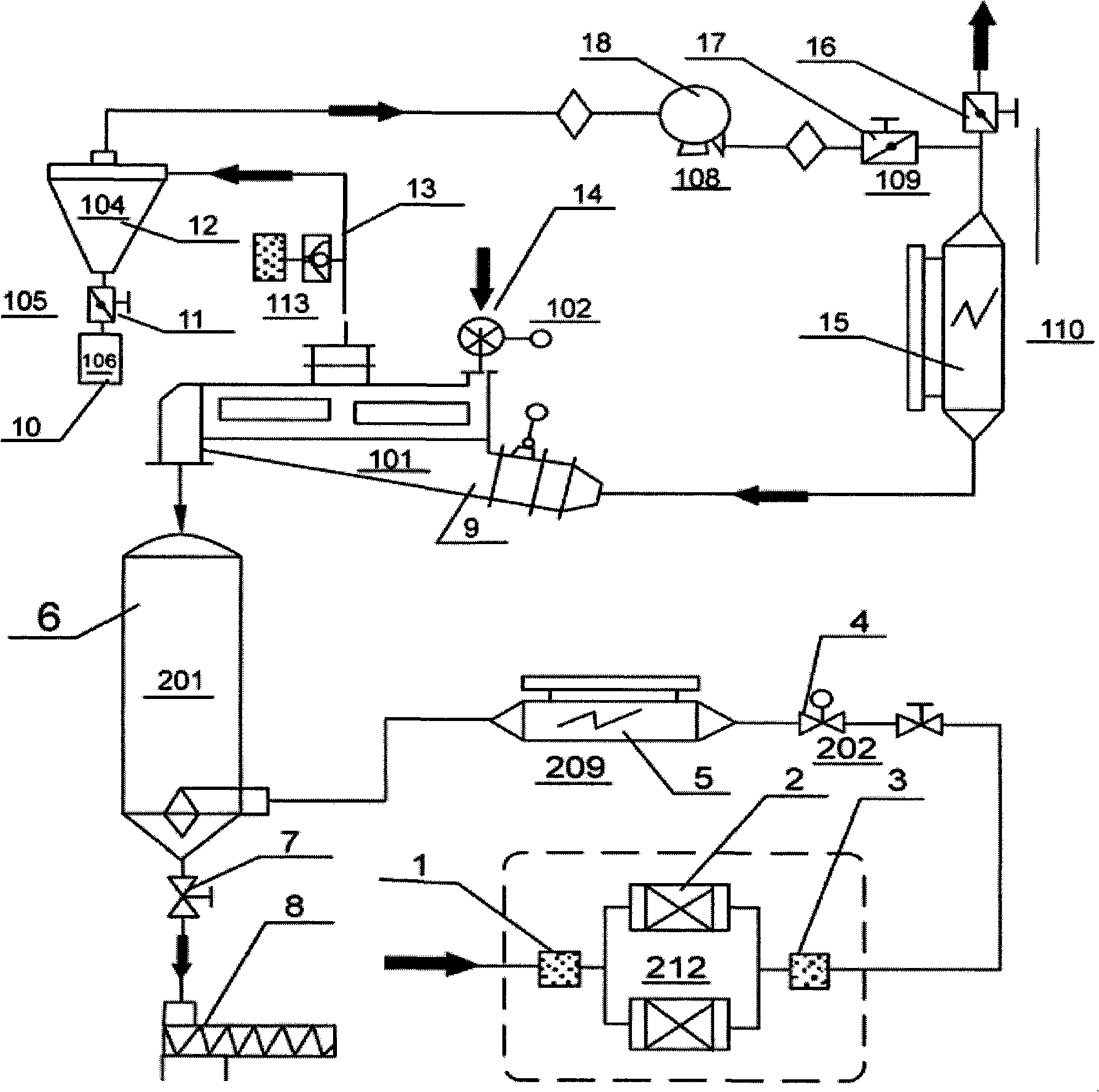

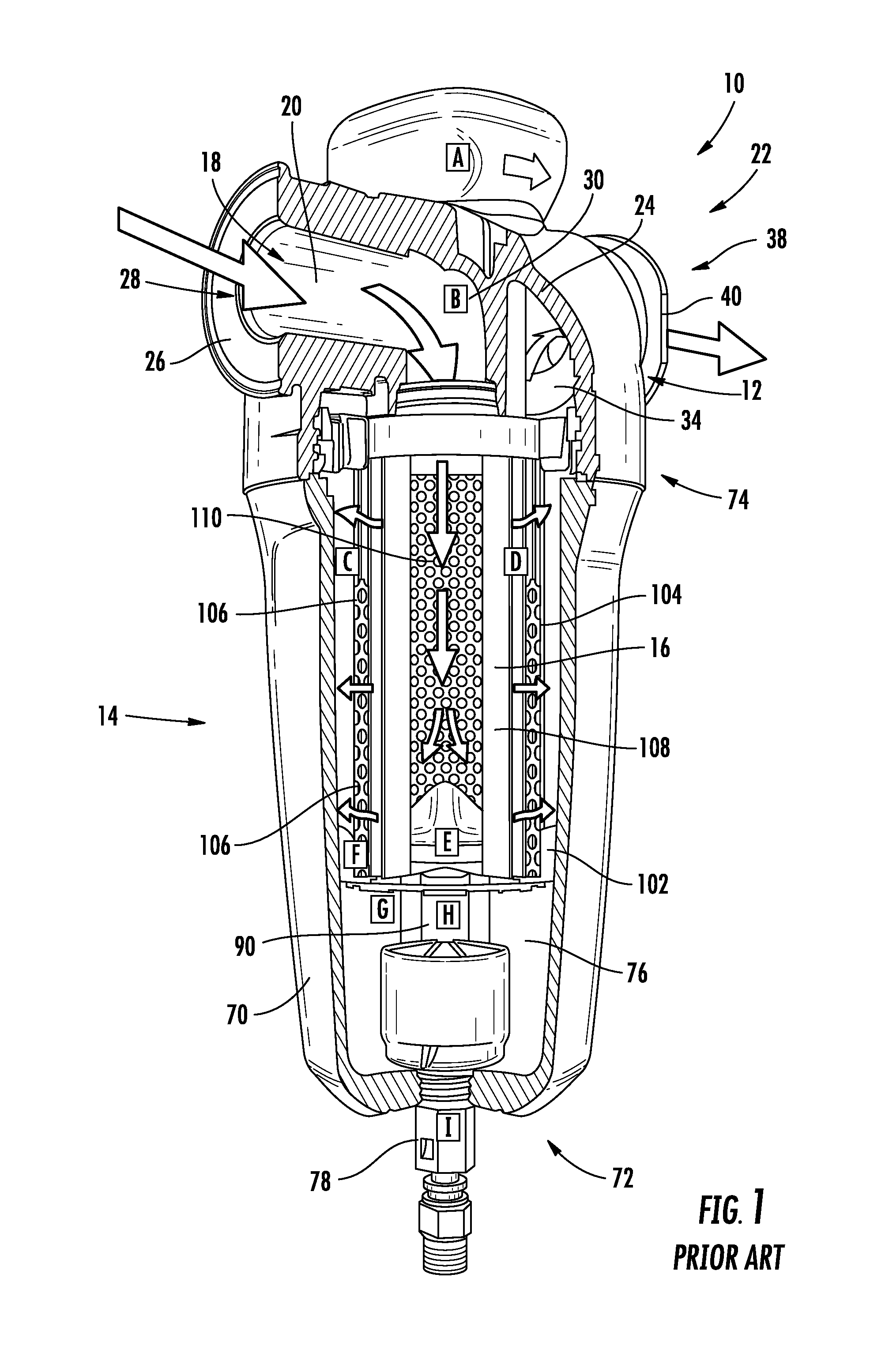

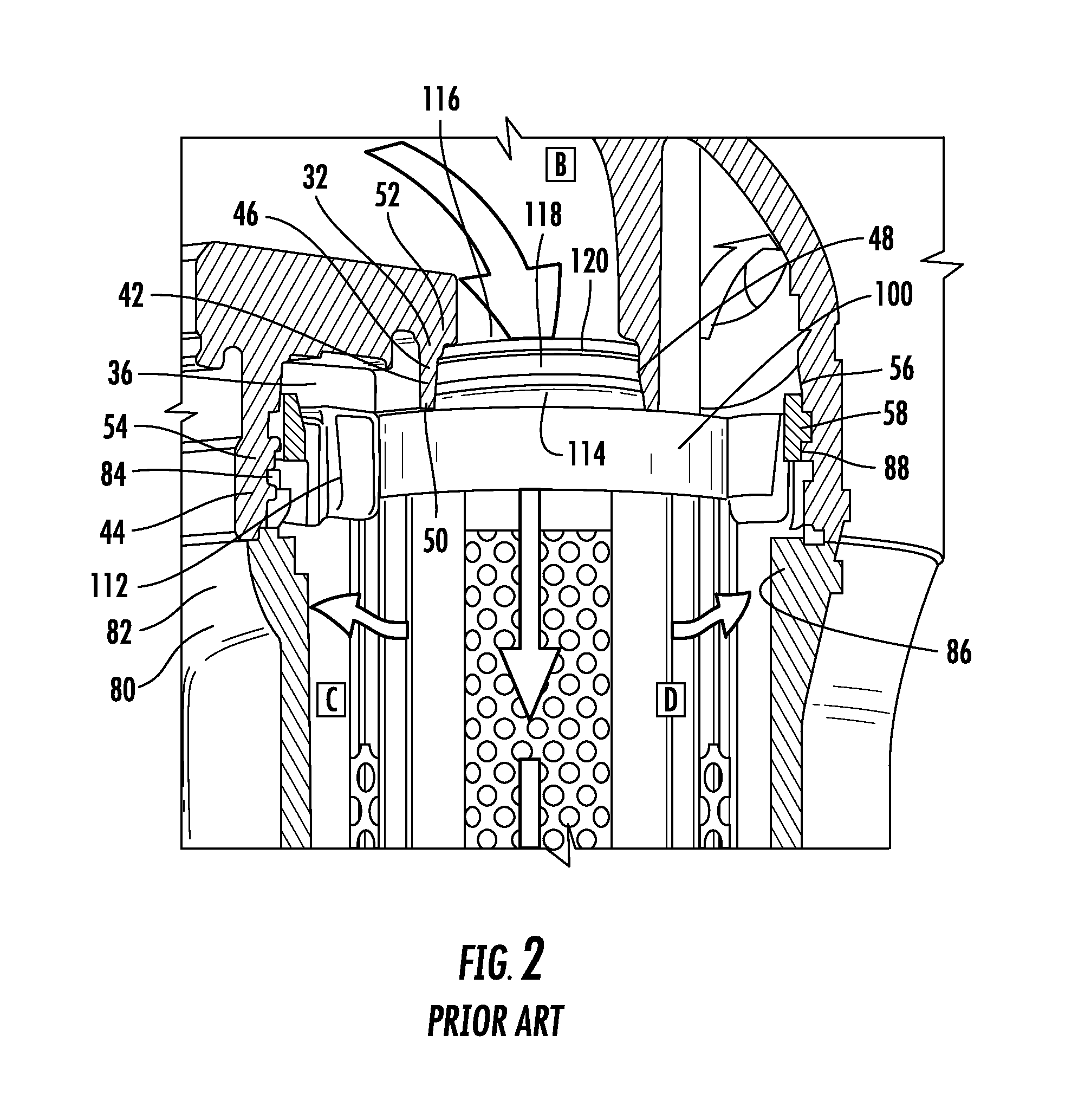

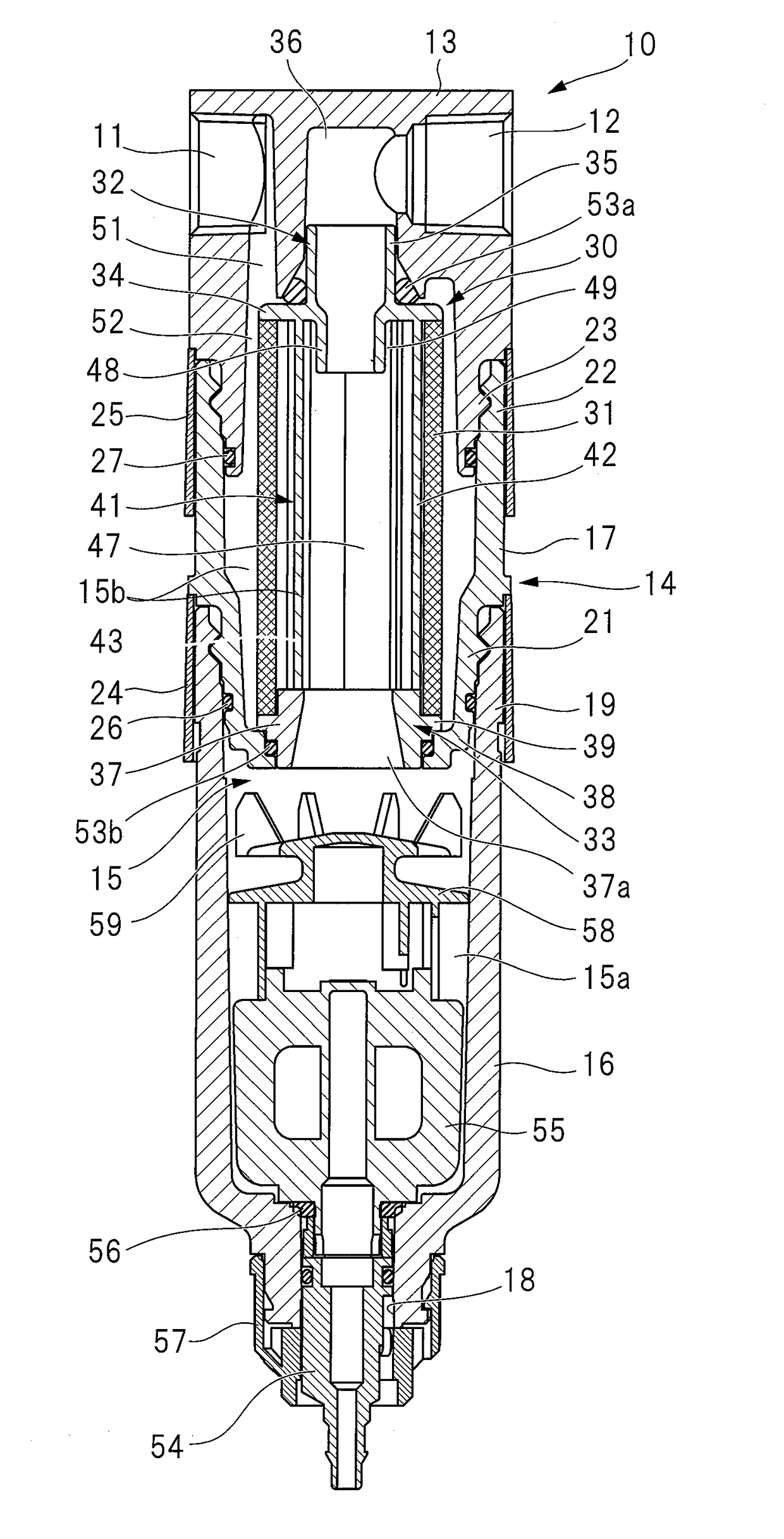

Element assembly and filter

ActiveUS20180126312A1Improve efficiencyPositive displacement pump componentsDispersed particle filtrationEngineeringFilter element

A filter (10) has a port block (13) provided with: an inflow port (11) to which compressed air is supplied; and an outflow port (12) from which purified compressed air flows out. A filter container (14) is attached to the port block (13), and an element assembly (30) is disposed inside the filter element (31). The element assembly (30) has: a filter element (31); and an air guide member (41) provided inside the filter element (31). The compressed air filtered through the filter element (31) is guided to an inner surface of the air guide member (41) through a slit (46).

Owner:KOGANEI

A kind of pressure swing adsorption nitrogen production system and nitrogen production method

ActiveCN112897480BReduce chemical impuritiesReduce the frequency of filter replacementNitrogen purification/separationProcess engineeringAir compressor

The invention relates to the technical field of gas preparation, in particular to a pressure swing adsorption nitrogen production system and a nitrogen production method thereof, including an air compressor, a compressed air filter assembly, a buffer gas storage tank, an adsorption tower group, a nitrogen tank, connecting pipelines and The valve group is characterized in that: the air compressor, the compressed air filter assembly, the buffer gas storage tank, the adsorption tower group, and the nitrogen tank are sequentially connected through the connecting pipeline, the valve group is arranged on the connecting pipeline, and the air compressor The input end of the machine is provided with an air intake filter device, which is used for the air intake filter of the air compressor, which provides a filter and impurity removal for the initial effect of the air intake of the air compressor during the preparation of nitrogen, reducing the need for later The frequency of replacing the filter element of the filter equipment reduces the production cost, reduces the impurity removal pressure of the later filter equipment, and ensures the filtration effect of the later filter equipment. The pressure swing adsorption nitrogen production system and its nitrogen production method.

Owner:浙江瑞鸿机电设备有限公司

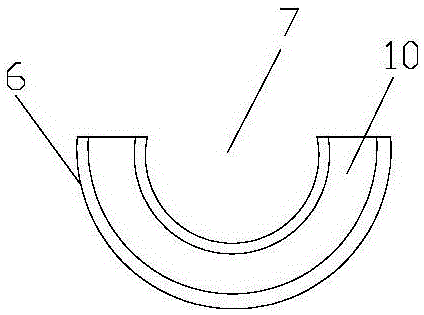

Compressed air filter

The invention discloses a compressed air filter, and belongs to the field of compressed air filtering devices. The compressed air filter comprises a cylinder body. A gas inlet pipe and a gas outlet pipe are arranged on the cylinder body. The gas inlet pipe inclines downwards and backwards to intersect with the wall of the cylinder body so that an included angle can be formed. A spiral diversion groove is formed in the cylinder body. The inlet end of the diversion groove is connected with the gas inlet pipe. The outlet end of the diversion groove is open. A plurality of filter screens are arranged in the cylinder body. The gas inlet pipe is connected with the diversion groove in a tangent mode so that the direction of compressed air entering the gas inlet pipe can be smoothly guided. By fine filtering out water in compressed air in the filter and discharging compressed air, the quality of an air source is prevented from being influenced by too much water in compressed air, pneumatic elements are prevented from being damaged by too much water, basically no electric energy is needed, mechanical loss is little, and no maintenance is needed.

Owner:HUNAN JIUDING TECH (GRP) YONGZHOU DINGLI FEED CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com