Multifunctional sand-blasting grinder

A grinding machine and multi-functional technology, which is applied in the direction of abrasive jet machine tools, abrasives, used abrasives processing devices, etc., can solve the problems of difficult separation and recycling of abrasives, low product yield rate, and impact on workers' health, and achieve low cost, Improve the yield rate and eliminate the effect of instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

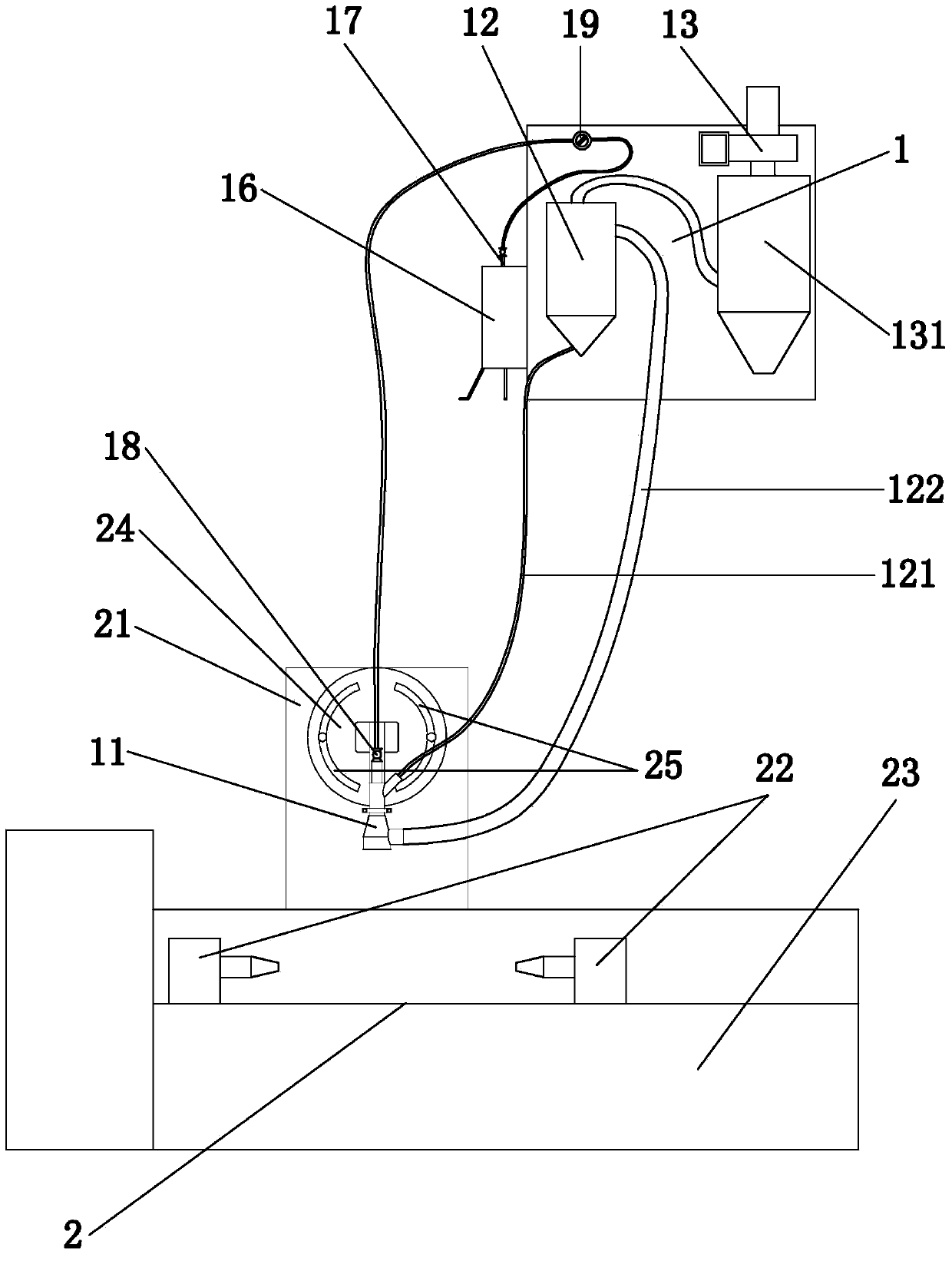

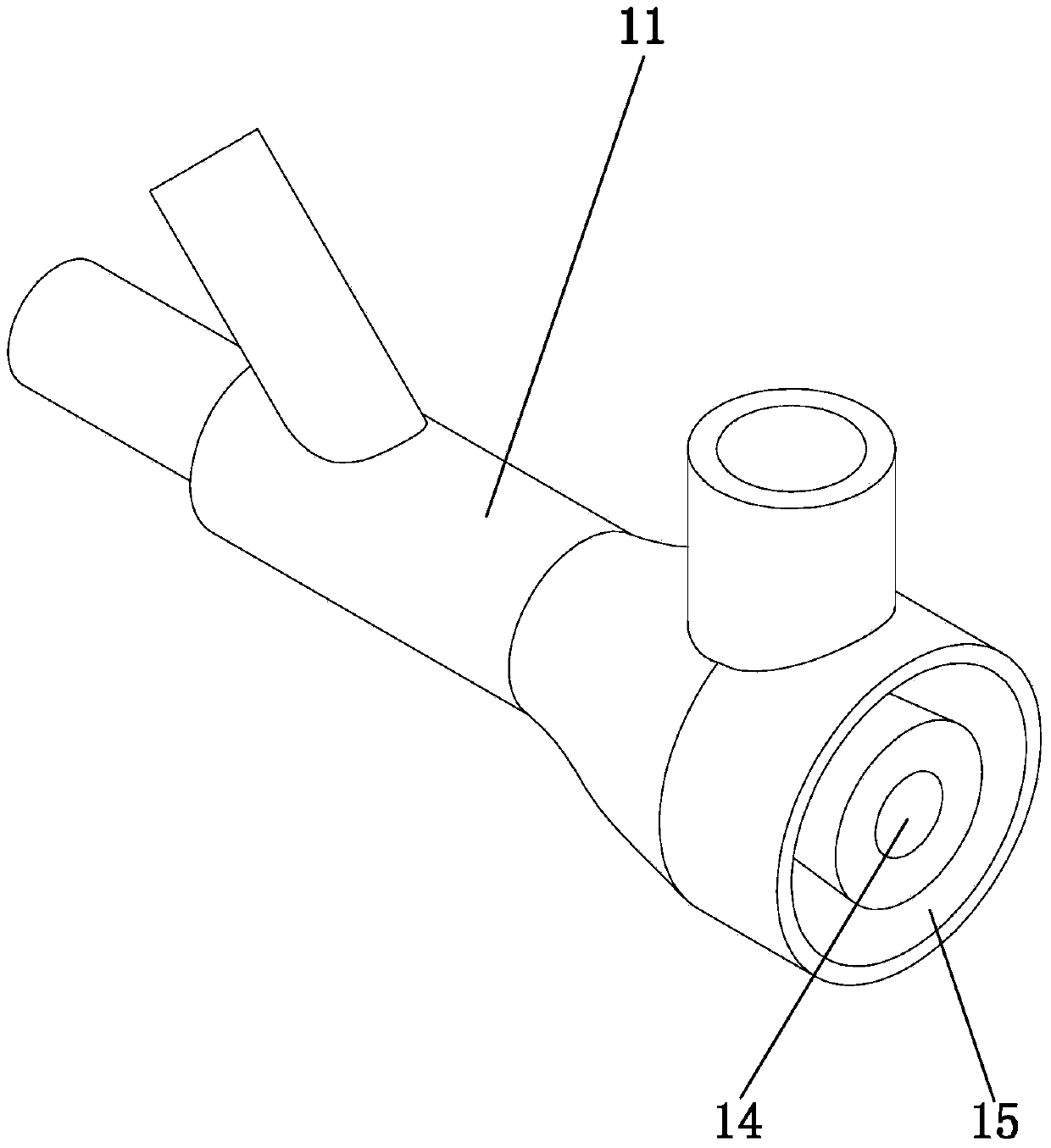

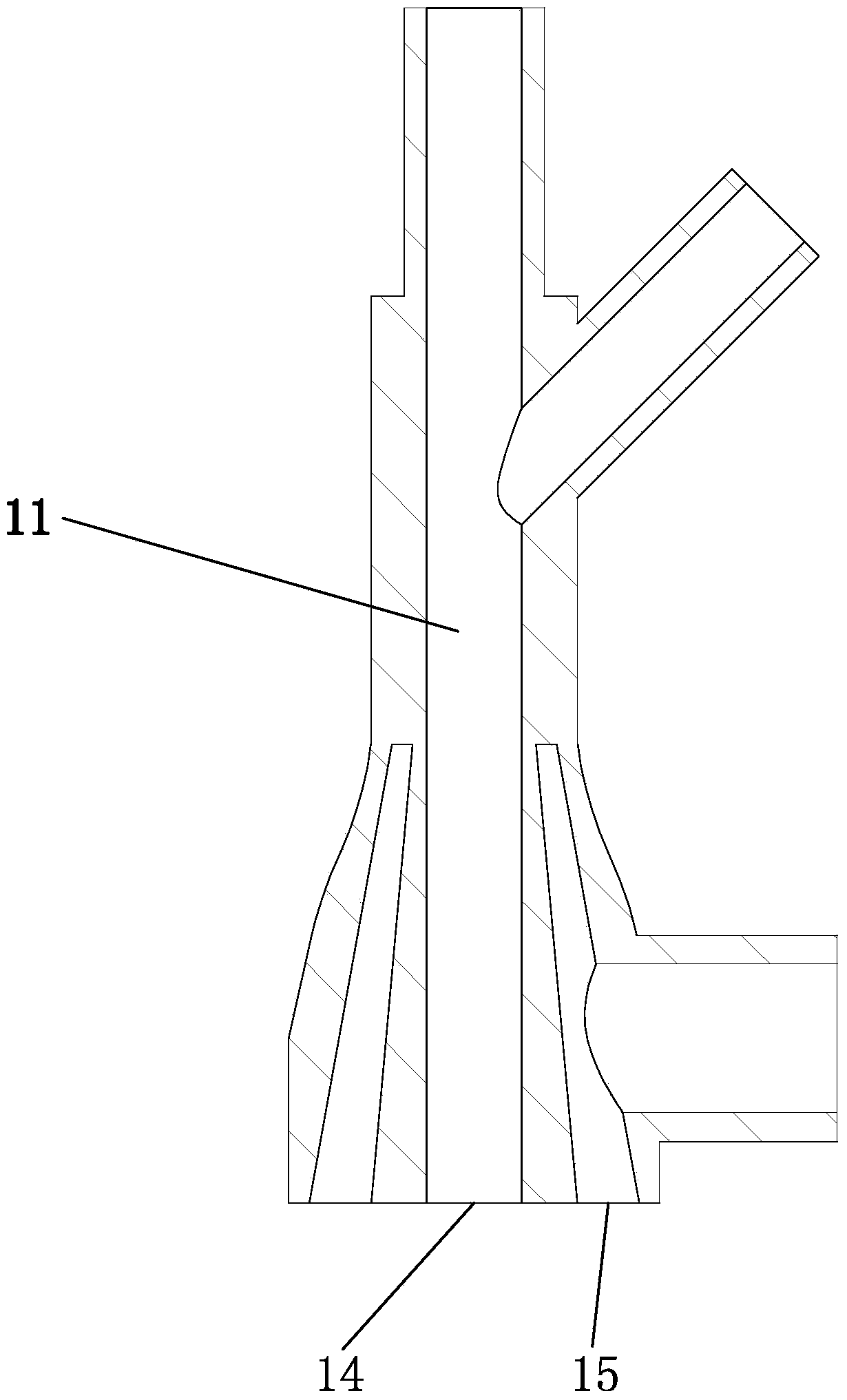

[0017] refer to Figure 1~Figure 4 , a multifunctional sandblasting machine of the present invention, comprising a sandblasting machine 1 and a machine platform 2, said sandblasting machine 1 comprising a sandblasting gun 11, a sand storage barrel 12, a blower fan 13 and a compressed air filter 16, the Said machine platform 2 comprises laterally movable support 21, workpiece fixture 22 and frame 23, and is characterized in that: said support 21 is equipped with rotatable rotating disc 24, and said rotating disc 24 is fixedly connected with sandblasting gun 11. The sandblasting gun 11 is provided with a sandblasting port 14 located in the center and a sand return port 15 located in the outer ring, wherein the sandblasting port 14 is filtered with compressed air through the compressed air pipe 17 and the sand outlet pipe 121 respectively. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com