Nitrogen dehumidification dryer and dehumidification drying method of plastic material

A drying machine, nitrogen technology, applied in the direction of local stirring dryers, static material dryers, dryers, etc., can solve the problems of desiccant pollution, long time, insufficient dryness of plastic materials, etc., to save time and dry The effect of effect enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

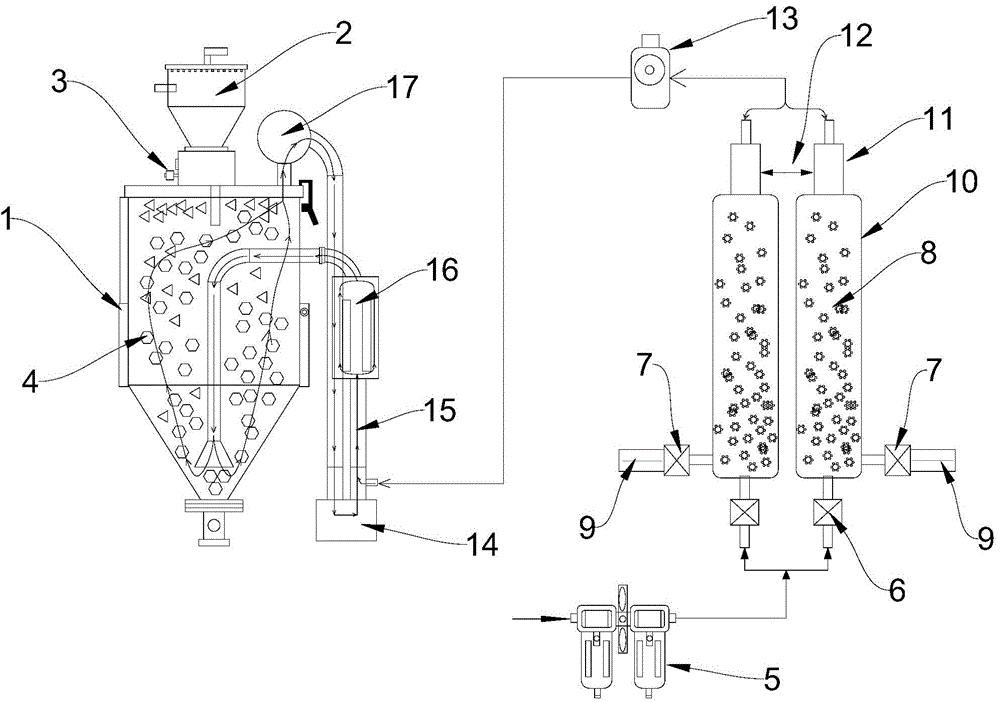

[0027] Such as figure 1 A nitrogen dehumidification dryer shown includes a sealed material barrel 1, which is provided with an automatic material feeding device 2, a moisture discharge port 3, and also includes a nitrogen delivery device. The nitrogen delivery device includes sequentially arranged compression Air filter 5, intake solenoid valve 6, exhaust solenoid valve 7, nitrogen evolution device (including carbon molecular sieve 8 and carbon molecular sieve cylinder 10), muffler 9, check valve 11, nitrogen return device 12, pressure reducing valve 13 . The output end of the compressed air filter 5 is connected to the intake solenoid valve 6, the output end of the intake solenoid valve 6 is connected to the carbon molecular sieve cylinder 10, and the two carbon molecular sieve cylinders 10 are connected to each other with a nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com