Multifunctional compressed air filter

A compressed air and filter technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of easy leakage, large space occupation, troublesome production and assembly, etc., and achieve high integration and small space occupation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

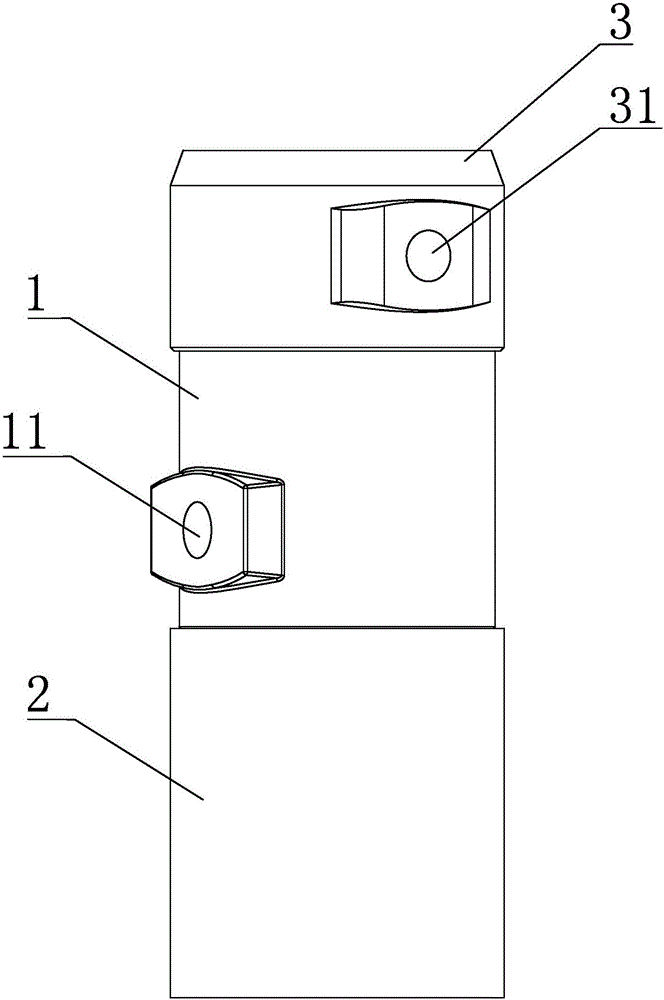

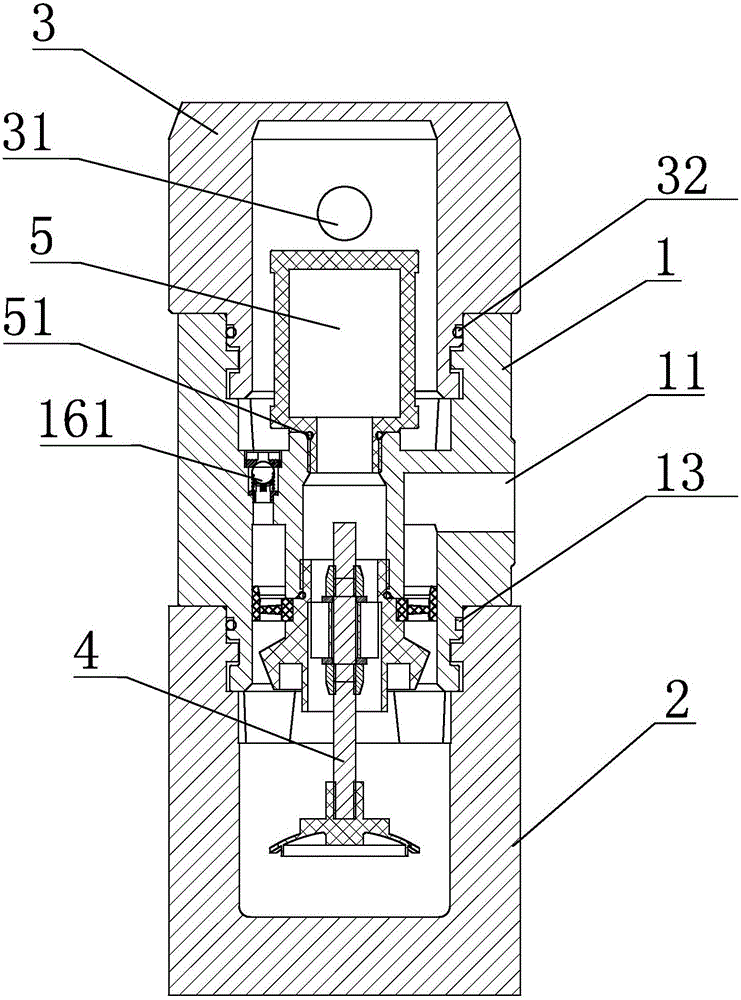

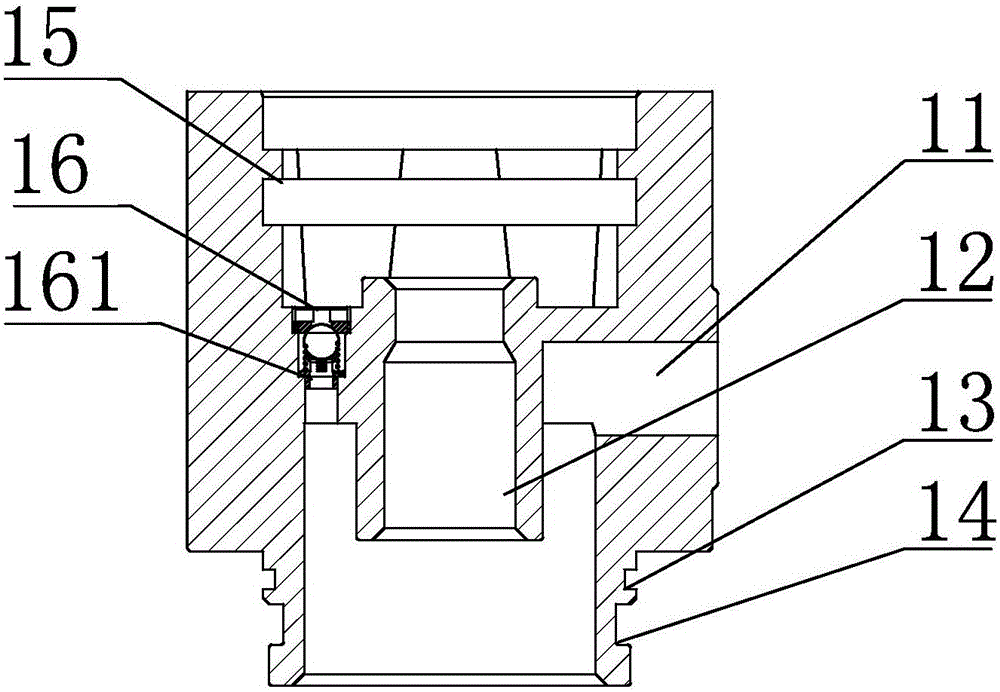

[0024] see Figure 1-Figure 5 , figure 1 It is the overall schematic diagram of the compressed air filter of the embodiment of the present invention, figure 2 It is a schematic diagram of the internal structure of the compressed air filter of the embodiment of the present invention, image 3 It is a structural schematic diagram of the pipe head 1 of the embodiment of the present invention, Figure 4 It is a structural schematic diagram of the tube body 2 of the embodiment of the present invention, Figure 5 It is a structural schematic diagram of the cap 3 of the embodiment of the present invention. A multifunctional compressed air filter of the present invention comprises a pipe head 1 provided with a filter air inlet 11, a pipe body 2 provided with a filter sewage outlet 21 and a pipe cover provided with a filter air outlet 31 3. An air channel 12 is also provided in the pipe head 1, the gas-water separation device 4 is installed at the lower end of the air channel 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com