Cooling device for cutting process

A cooling device and cutting processing technology, applied in the direction of grinding/polishing safety devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem of high chip disposal costs, inability to transport low-temperature gas, pollute land, water sources and air, etc. problems, to achieve the effect of lowering the temperature, saving storage and handling costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

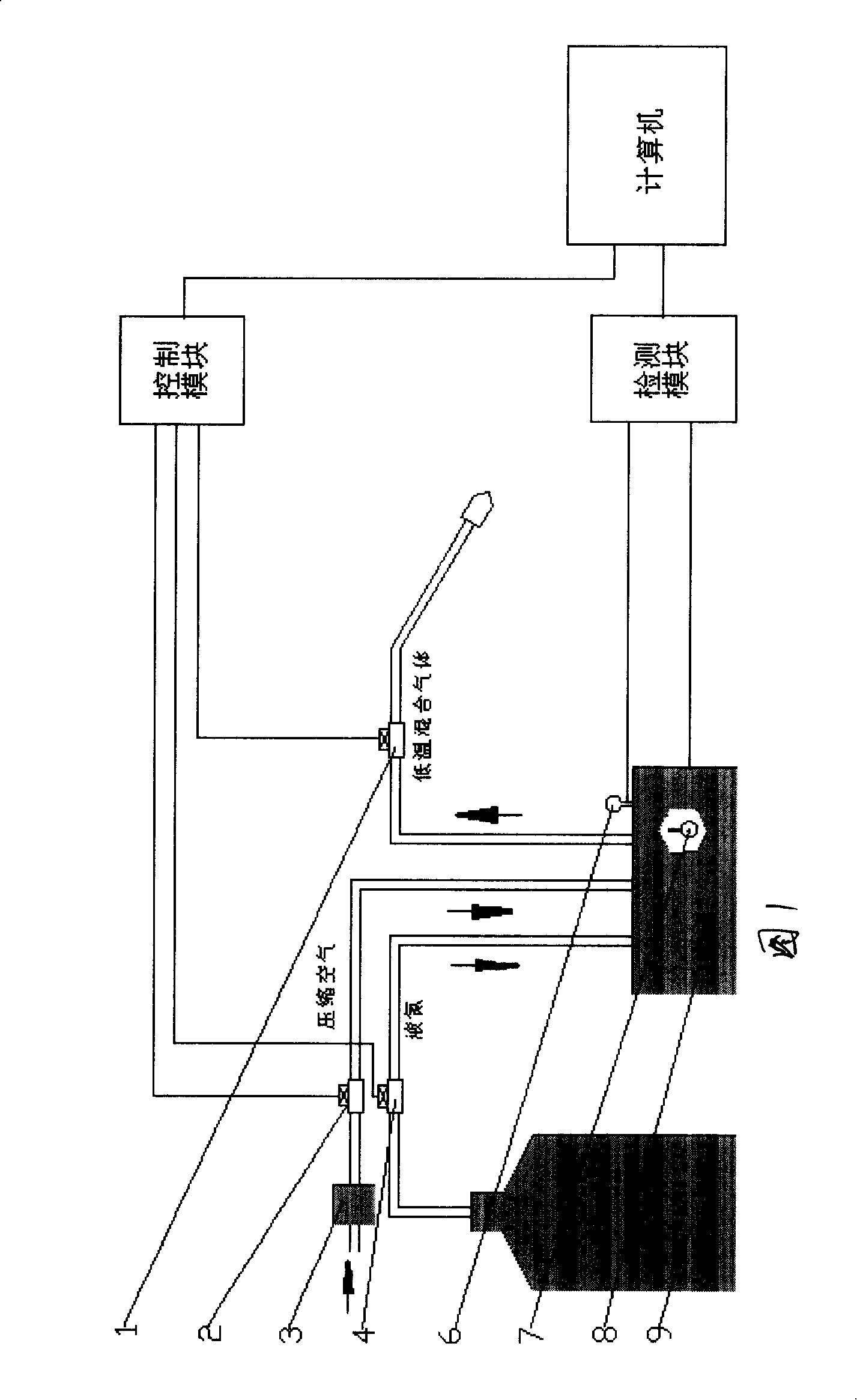

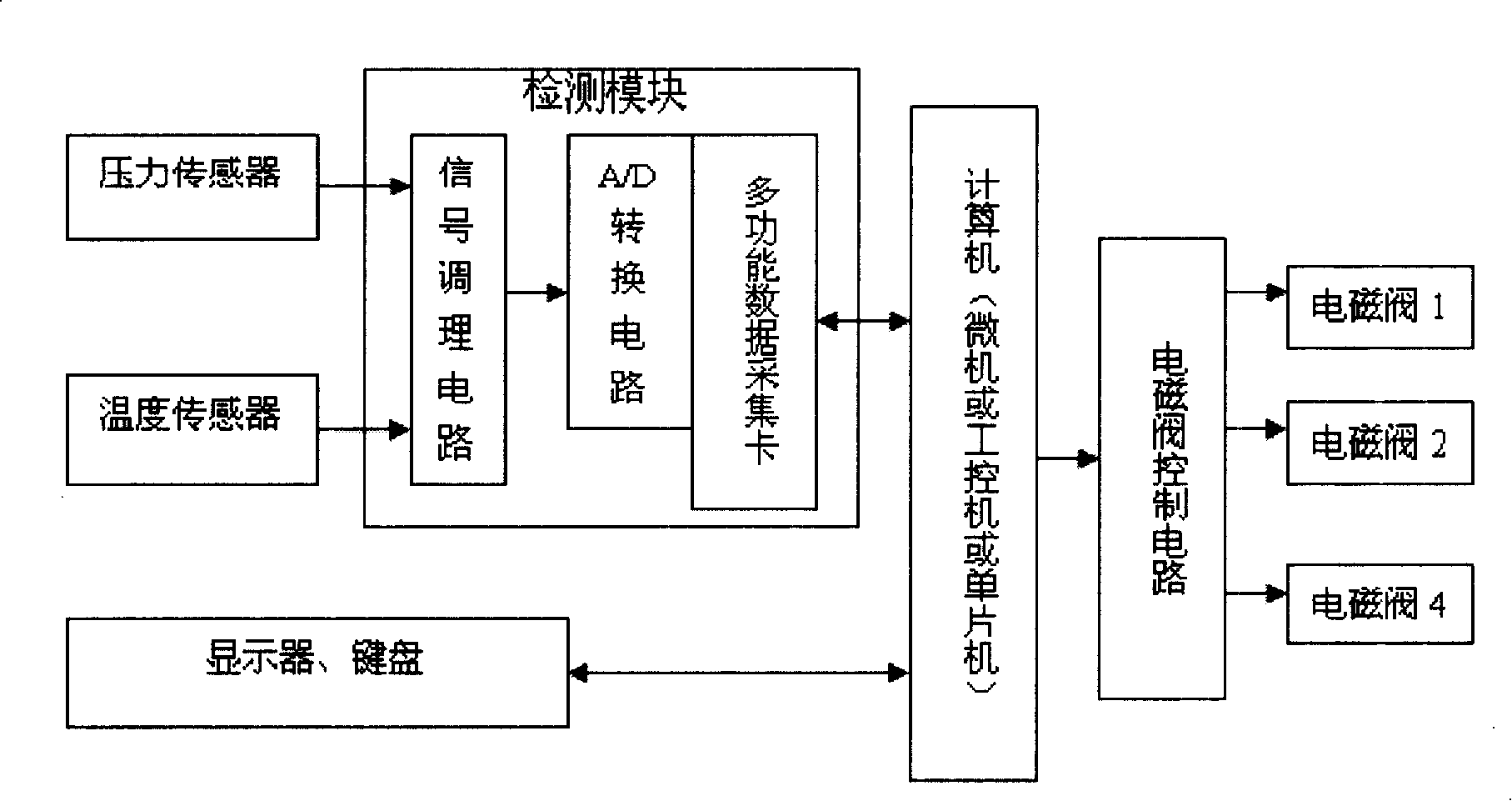

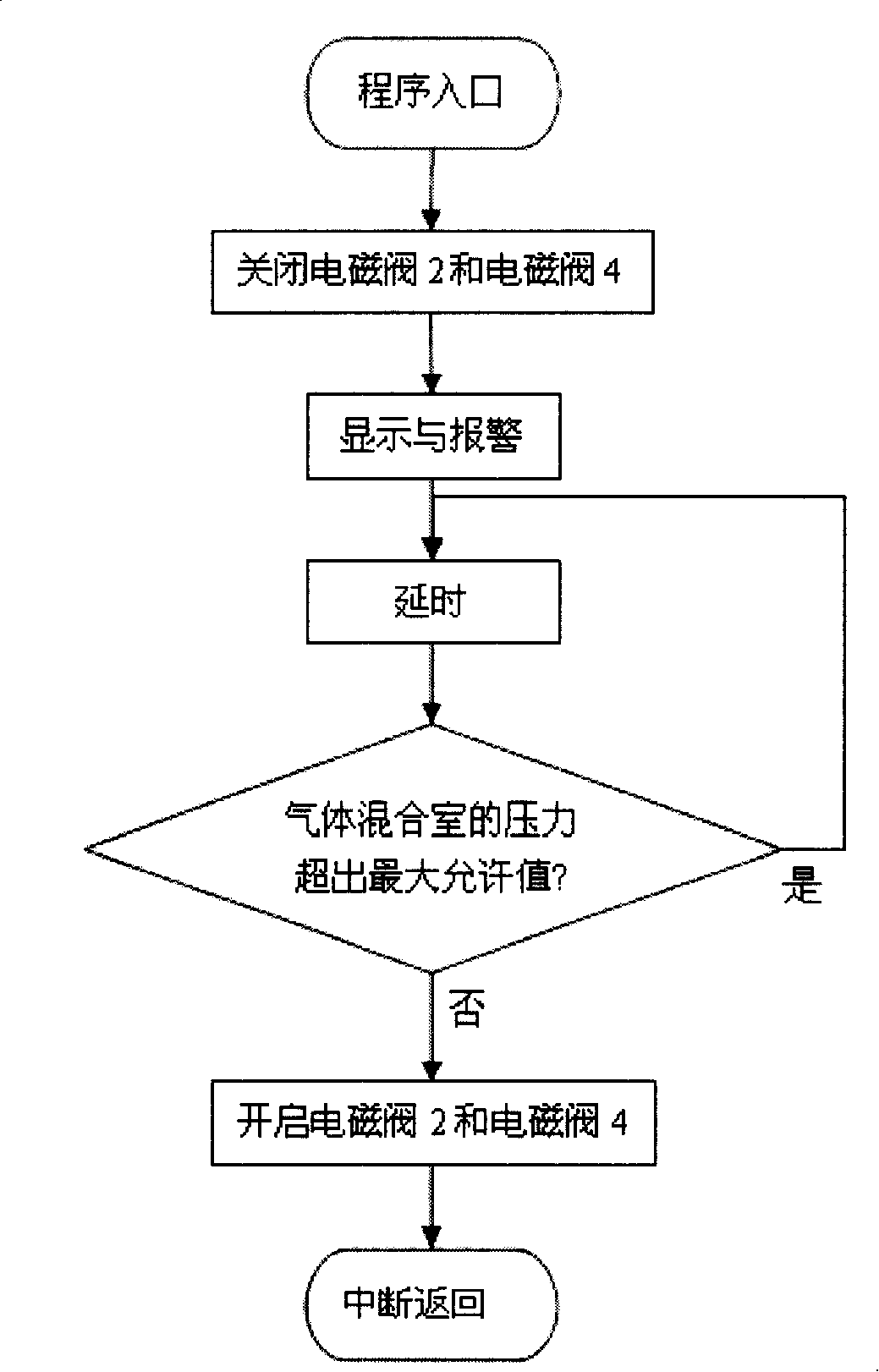

[0014] The cutting cooling device of the present invention includes a cryogenic liquid storage tank 9, a gas mixing chamber 8, a compressed air filter 3, a pipe joint, a liquid nitrogen delivery pipe, solenoid valves 1, 2, 4, a pressure sensor 6, and a temperature sensor 7. Control module, detection module, computer (industrial personal computer, microcomputer or single-chip microcomputer), display, keyboard, signal line, low-temperature liquid storage tank 9 is connected to gas mixing chamber 8 through gas delivery pipe and electromagnetic valve 4, and compressed air passes through gas delivery pipe Connect the gas mixing chamber 8 through the filter 3 and the electromagnetic valve 2, and the low-temperature gas and the normal temperature gas are mixed in the mixing chamber, and the output of the gas mixing chamber 8 passes through the gas delivery pipe and the electromagnetic valve 1; the temperature sensor 7 and the The pressure sensor 6 is connected with the detection modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com