Skid-mounted multifunctional anti-blowout pipe pressure test system

A multi-functional, blowout preventer technology, applied in the energy field, can solve the problems of low cost, increased volume of well control equipment, and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

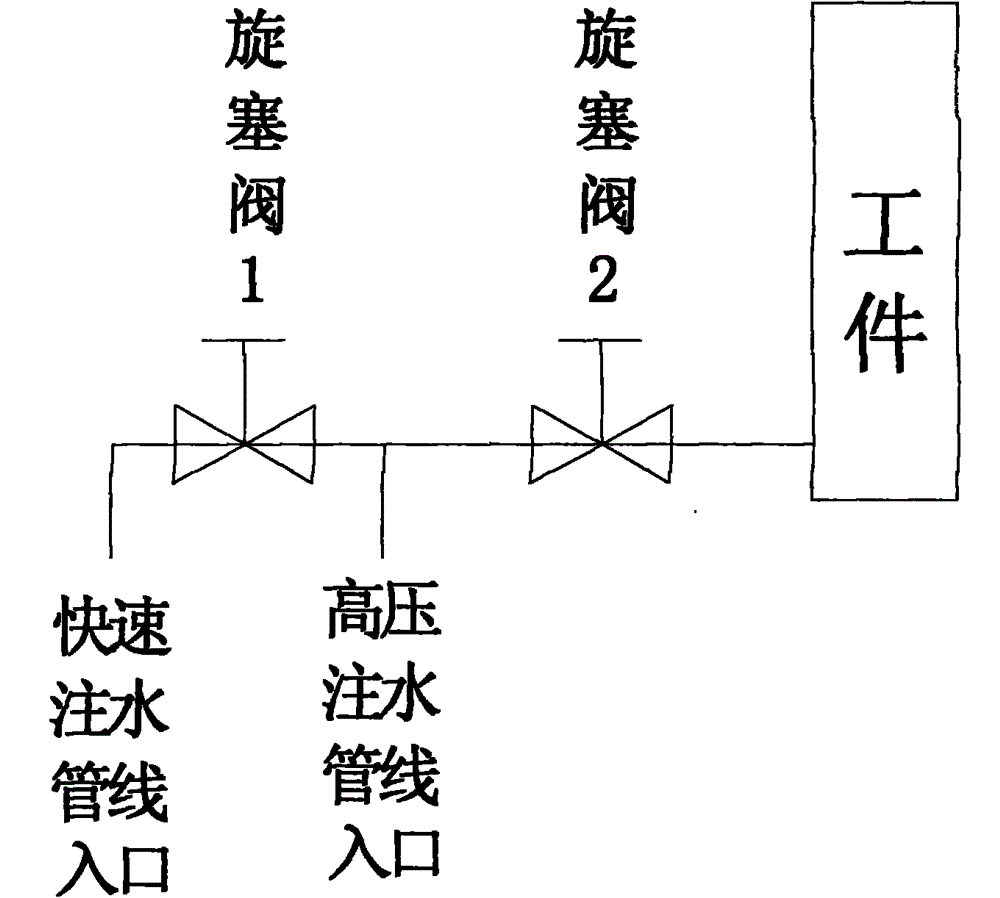

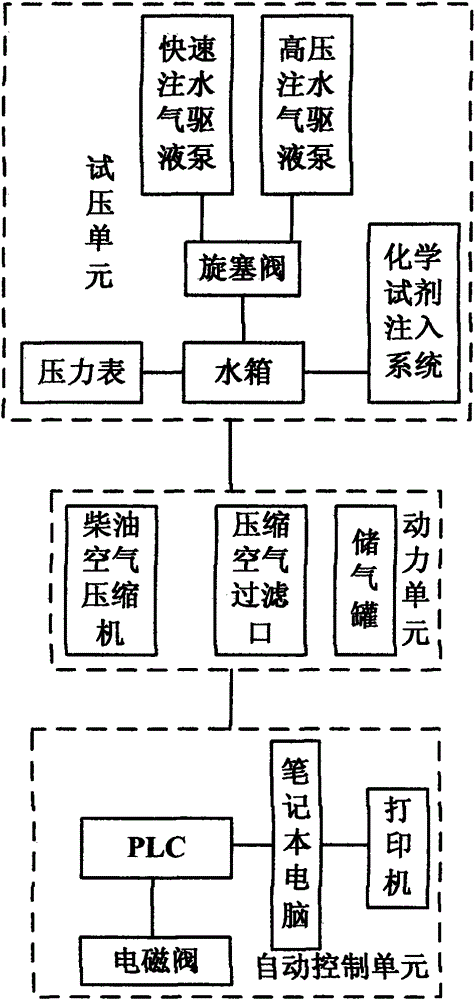

[0016] Aiming at the deficiencies of the existing technology, the present invention provides a skid-mounted multi-functional blowout preventer pressure test system, which is composed of a pressure test unit, a power unit and an automatic control unit. The power unit is mainly composed of a diesel air compressor, storage Air tank, compressed air filter and ball valve, the pressure test unit is mainly composed of fast water injection pump, high pressure water injection pump, water tank, high pressure water injection pipeline, fast water injection pipeline, cock valve, pressure gauge and chemical reagent injection system, and the The fast water injection pump and the high-pressure water injection pump are connected in parallel with two pumps. The automatic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com