Continuous drier suitable for low-melting point chip and use method thereof

A drying machine and low melting point technology, which is applied in the direction of drying machine, drying solid material, drying gas arrangement, etc., can solve the problems of regular damage of molecular chain, easy adhesion of polymer particles, difficulty of discharging and granulating, etc., and achieve drying The effect of cycle shortening, energy consumption reduction, and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

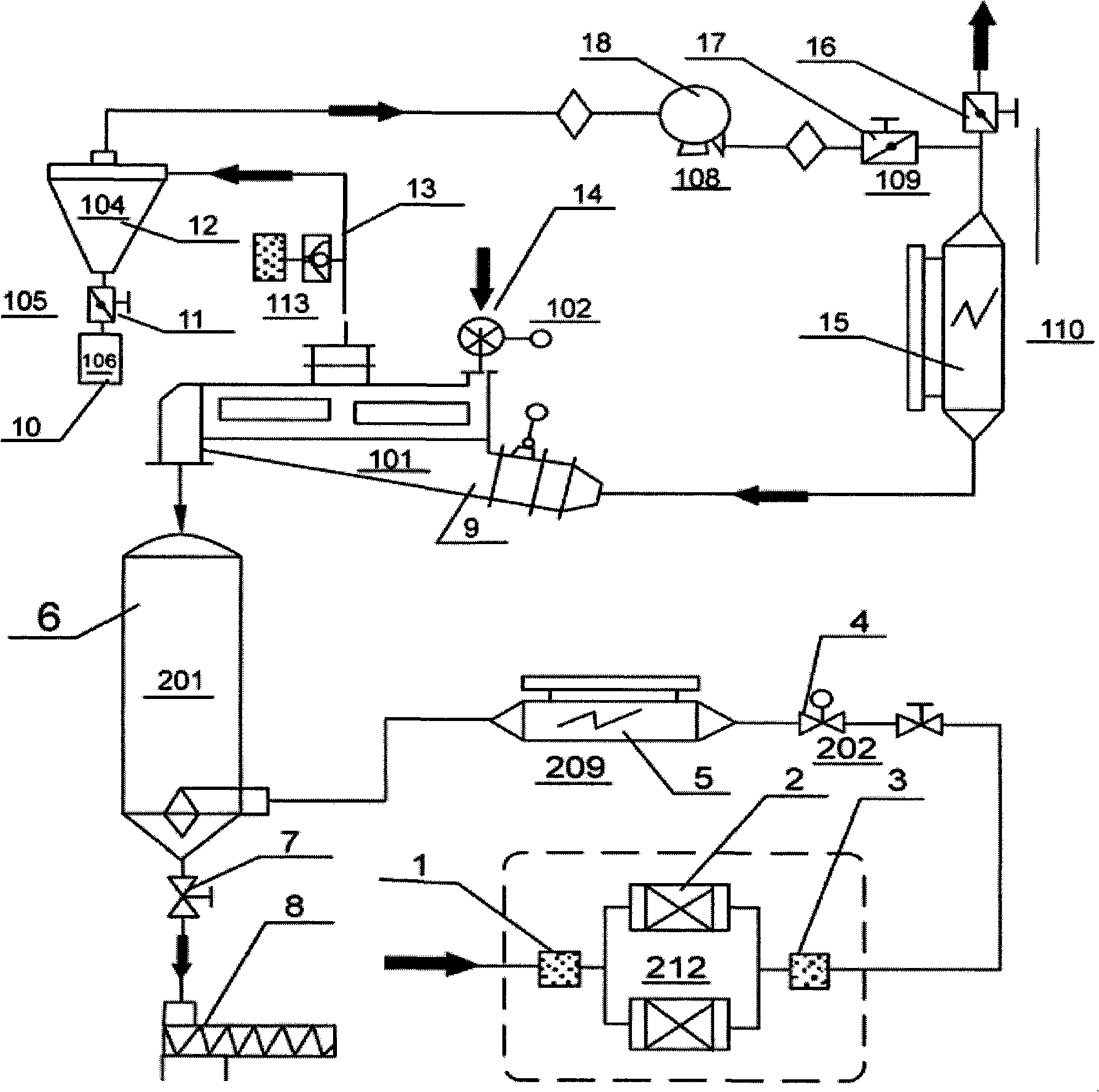

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0027] Such as figure 1 Shown: Except for the screw extruder, the shown devices are all supporting devices of the system of the present invention. After the outside air is filtered, it is dehumidified by the molecular sieve drying device. After the regeneration fan boosts the pressure, it is heated to the required temperature by the drying heater, and then enters from the bottom of the drying tower to contact with the slices for drying. Part of the airflow passing through the slice material layer passes through After filtering, return to the dehumidifier for recycling; the other part enters the crystallization circulation system to supplement the air discharged from the crystallization system. The gas in the pre-crystallizer is drawn out by the crystallization fan, and most of the water vapor and dust are removed by the cyclone separator and dust filter, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com