A kind of production method and equipment of plastic environmental protection glue

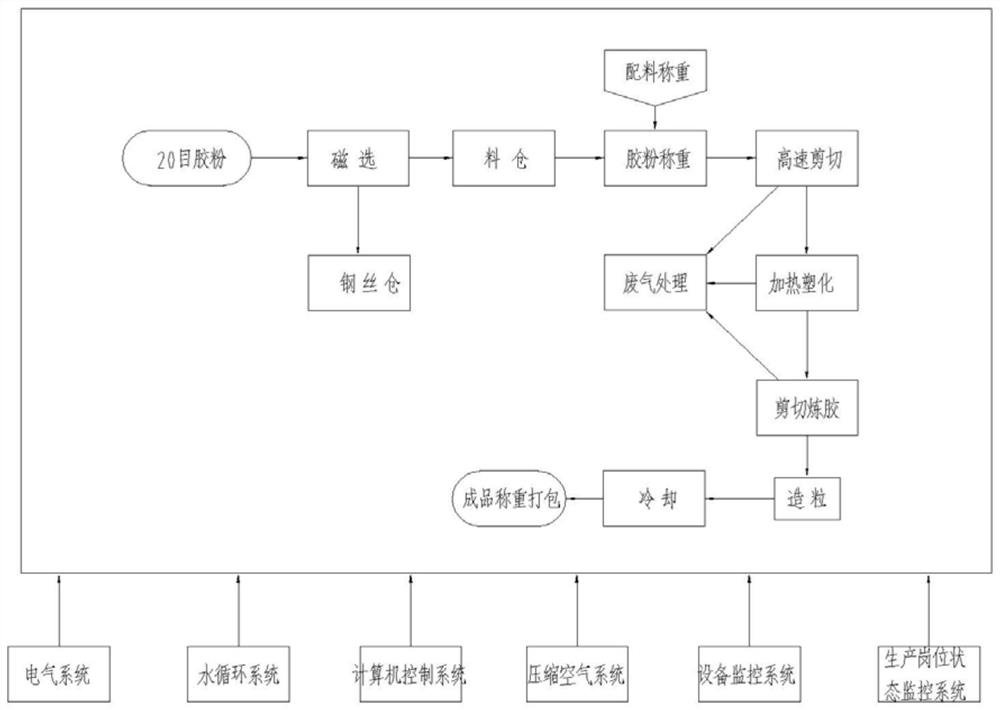

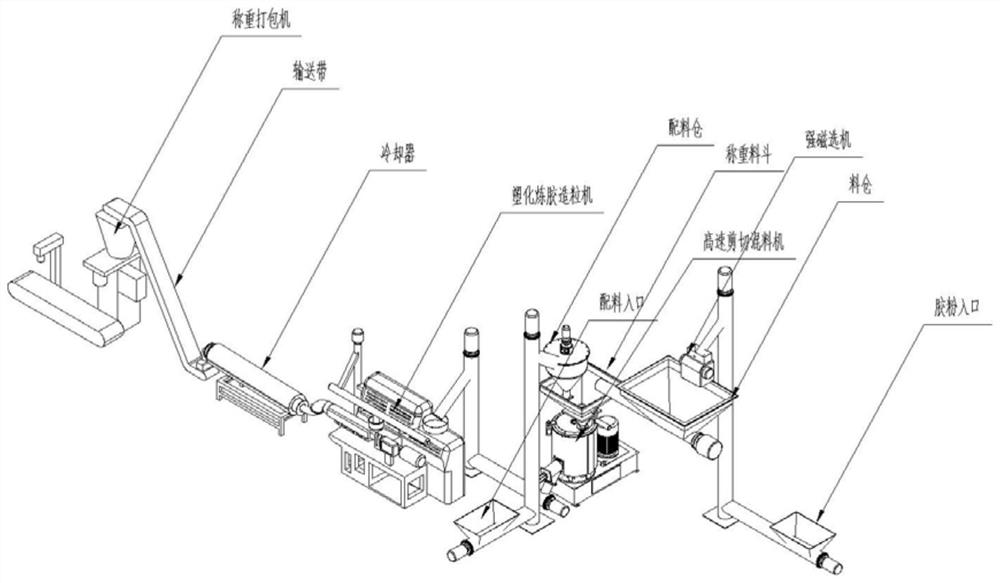

A production method and technology of production equipment, applied in the field of waste rubber utilization, can solve the problems of unstable product quality, high requirements, low precision, etc., and achieve the effects of saving labor and space, superior product performance, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

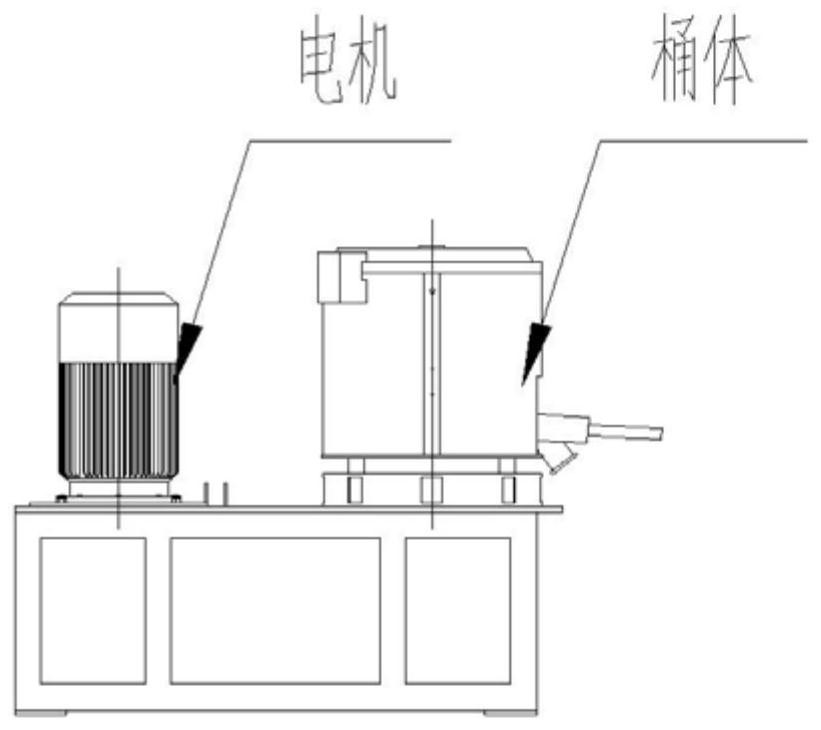

Method used

Image

Examples

experiment example

[0068] Experimental example The physical property detection result of the finished reclaimed rubber of the present invention

[0069] According to the plastic environment-friendly rubber production method and equipment of the present invention, 10 batches of finished reclaimed rubber are produced, and their physical properties are tested according to the test method of "Reclaimed Rubber" (GB13460-2008). The test results are shown in Table 1.

[0070] Table 1 The physical property test results of the finished reclaimed rubber of the present invention

[0071]

[0072] As can be seen from Table 1, the ash content of the finished reclaimed rubber of the present invention is 3 ; Mooney viscosity 6.5Mpa; elongation at break > 300%, meeting the index requirements of "Recycled Rubber" (GB13460-2008).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com