Patents

Literature

60 results about "Rubber chemicals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The main chemical constituents of rubber are elastomers, or “elastic polymers,” large chainlike molecules that can be stretched to great lengths and yet recover their original shape. The first common elastomer was polyisoprene, from which natural rubber is made.

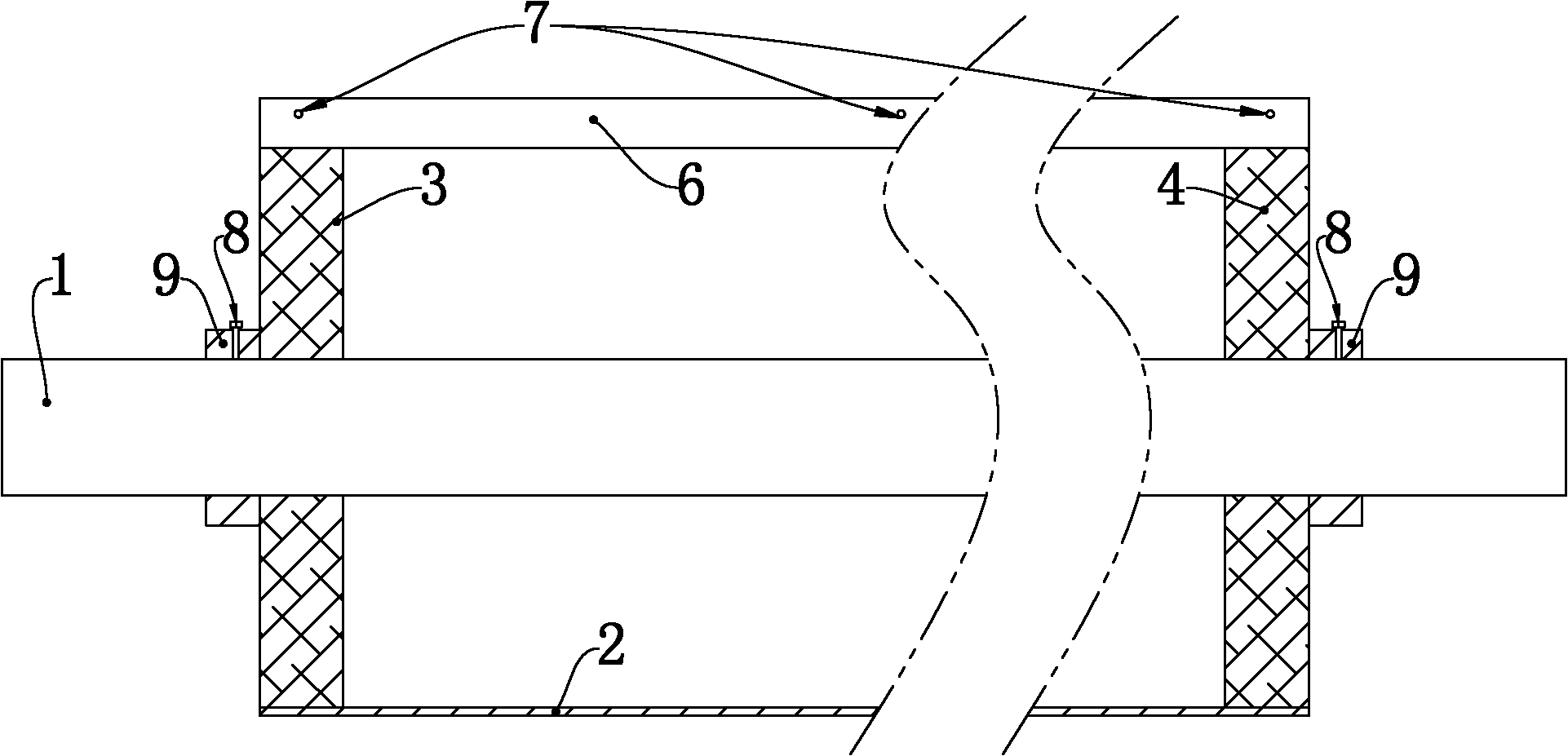

Sheet-like gasket and process for manufacturing same

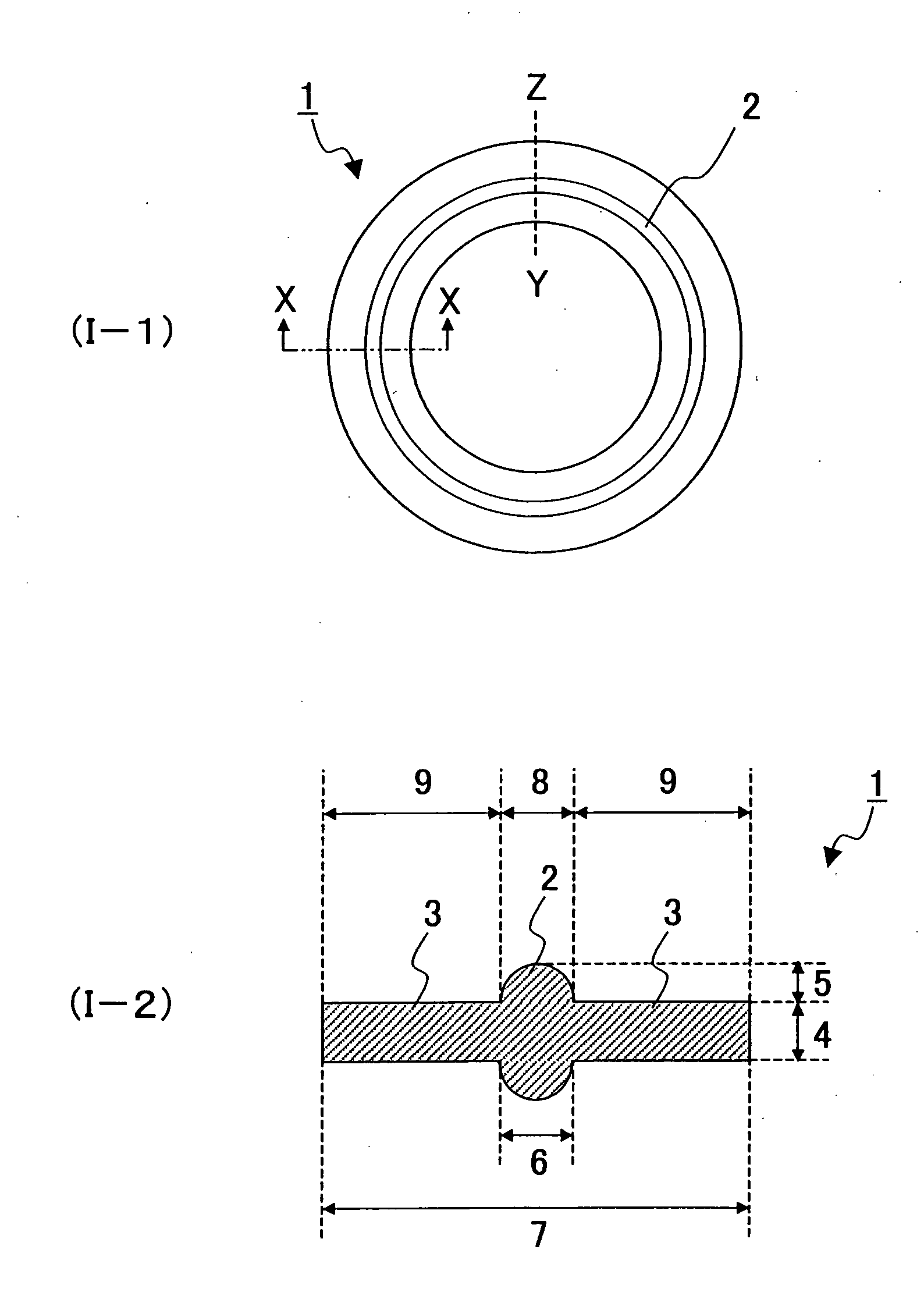

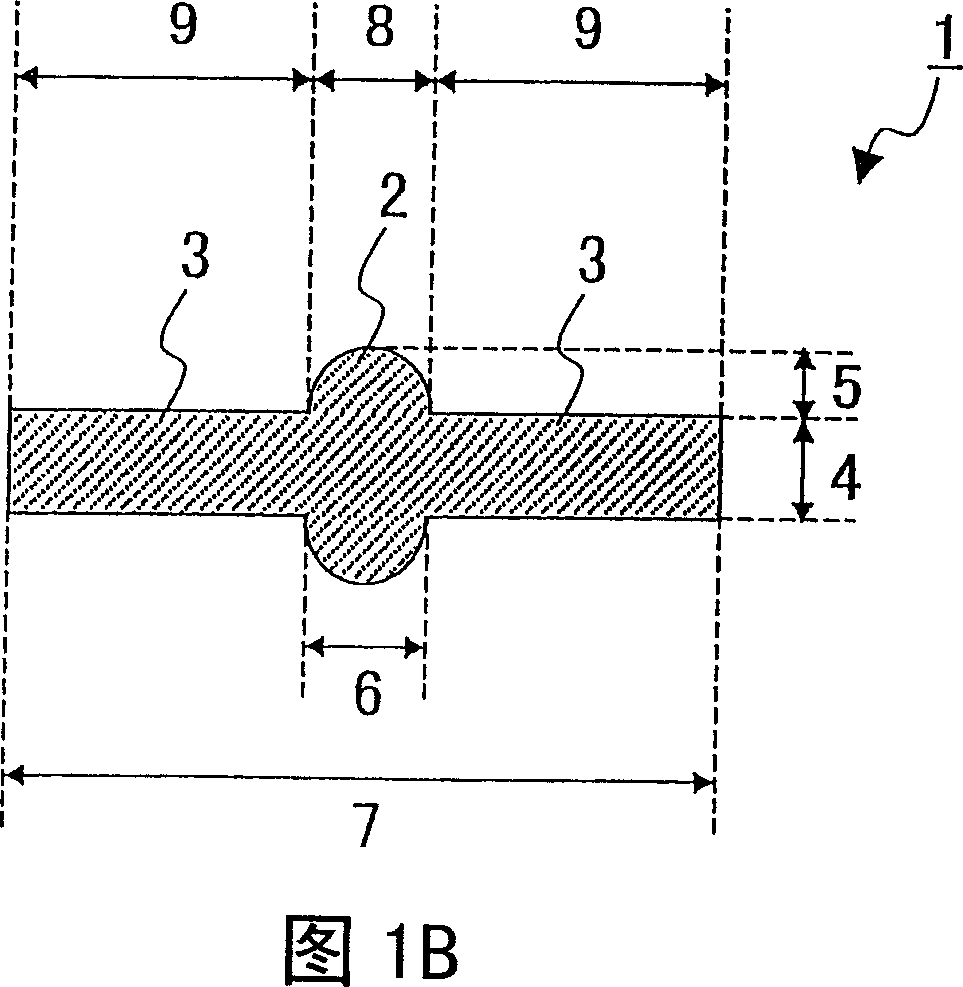

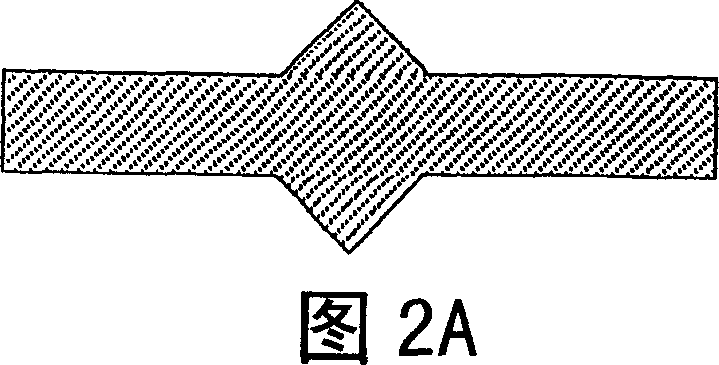

A sheet-like gasket having a dense structure and exhibiting excellent sealing performance with a small clamping force even on an irregular flange surface is provided. The sheet-like gasket is obtained by molding a composition comprising a substrate fiber, a rubber material, a filler, and a rubber chemical into a sheet, having a bead on both sides or one side, and having a flat part with a density of 1.0 g / cm3 or higher, the bead having a density lower than the density of the flat part.

Owner:NICHIAS CORP

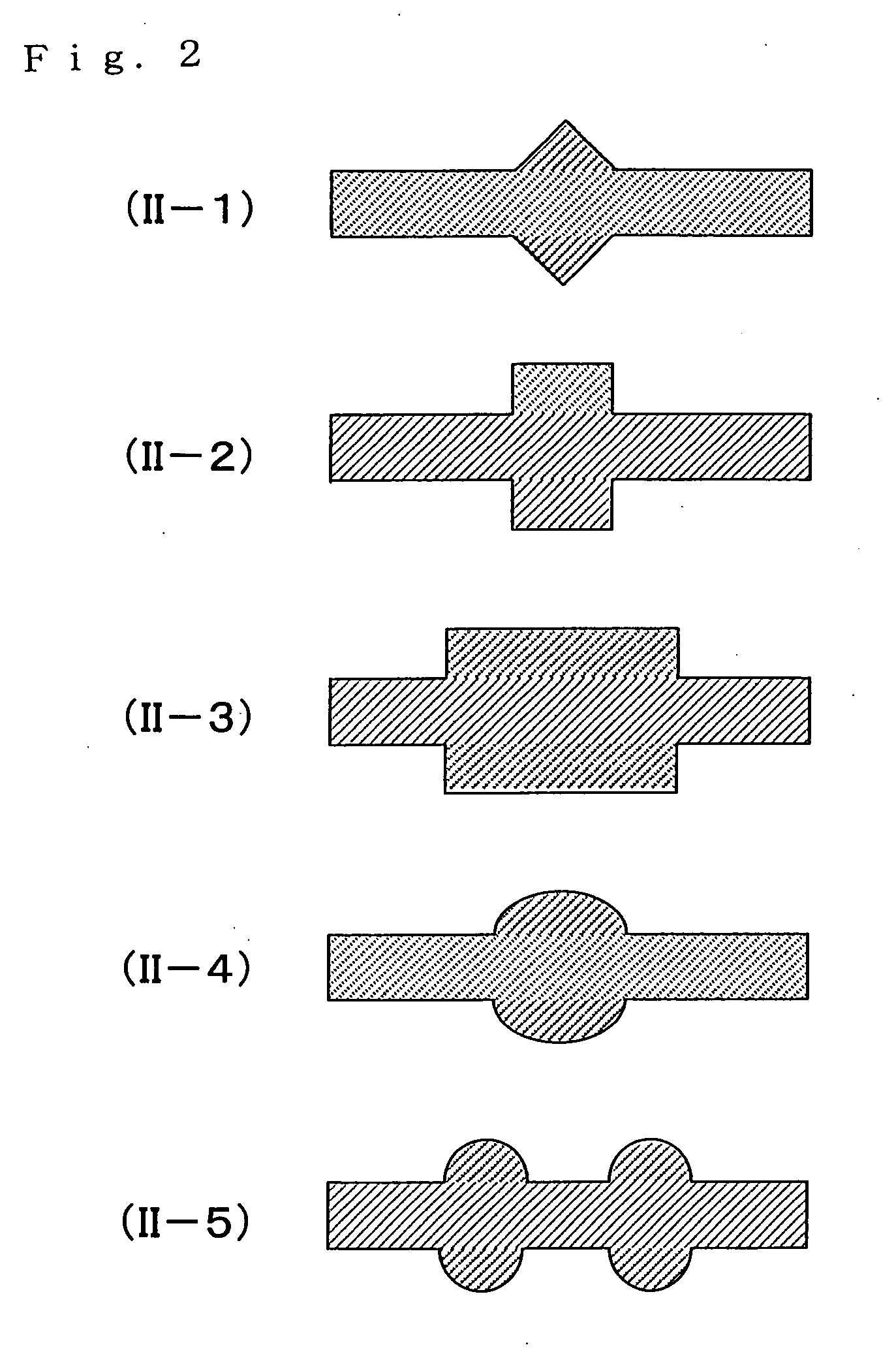

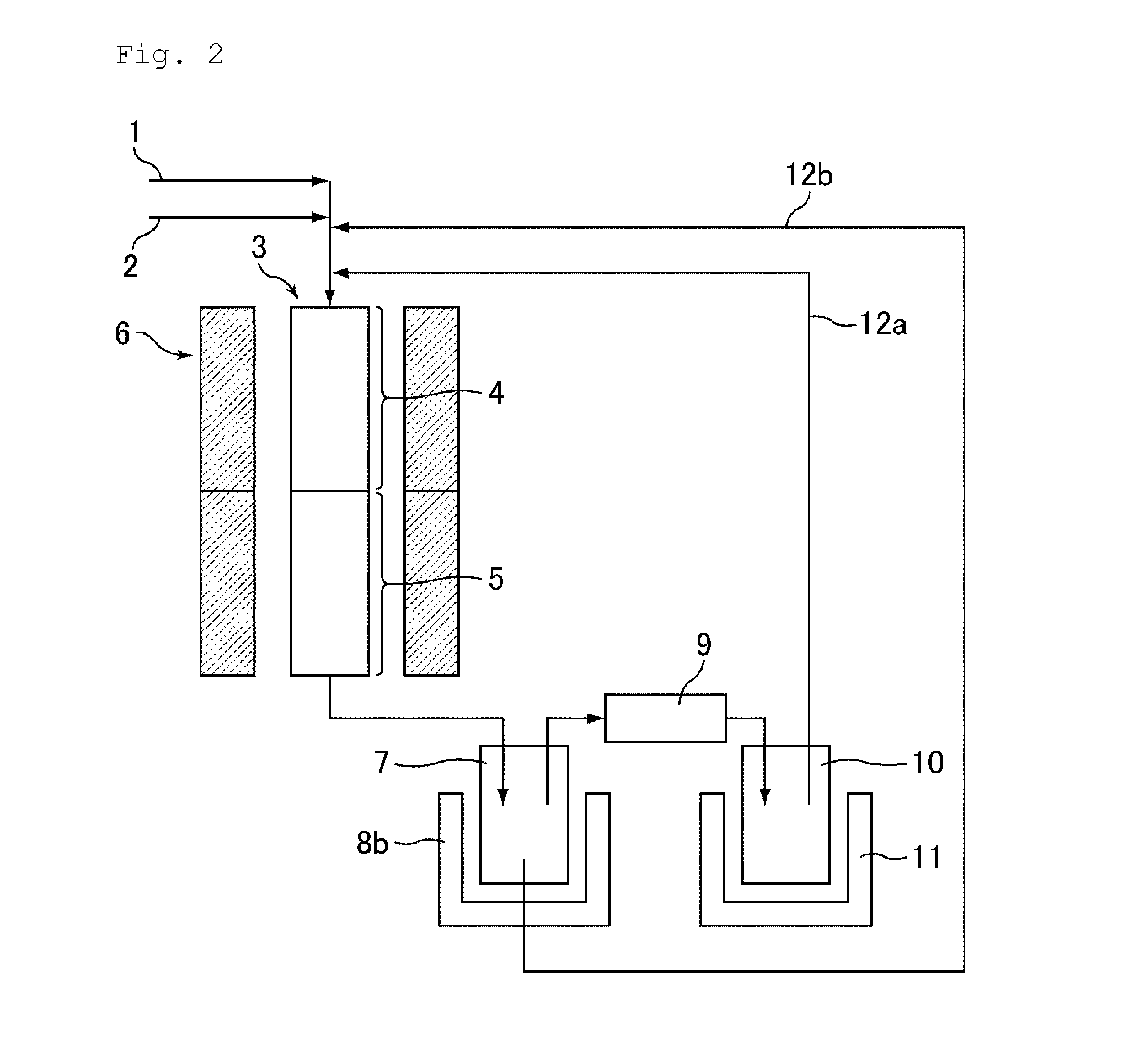

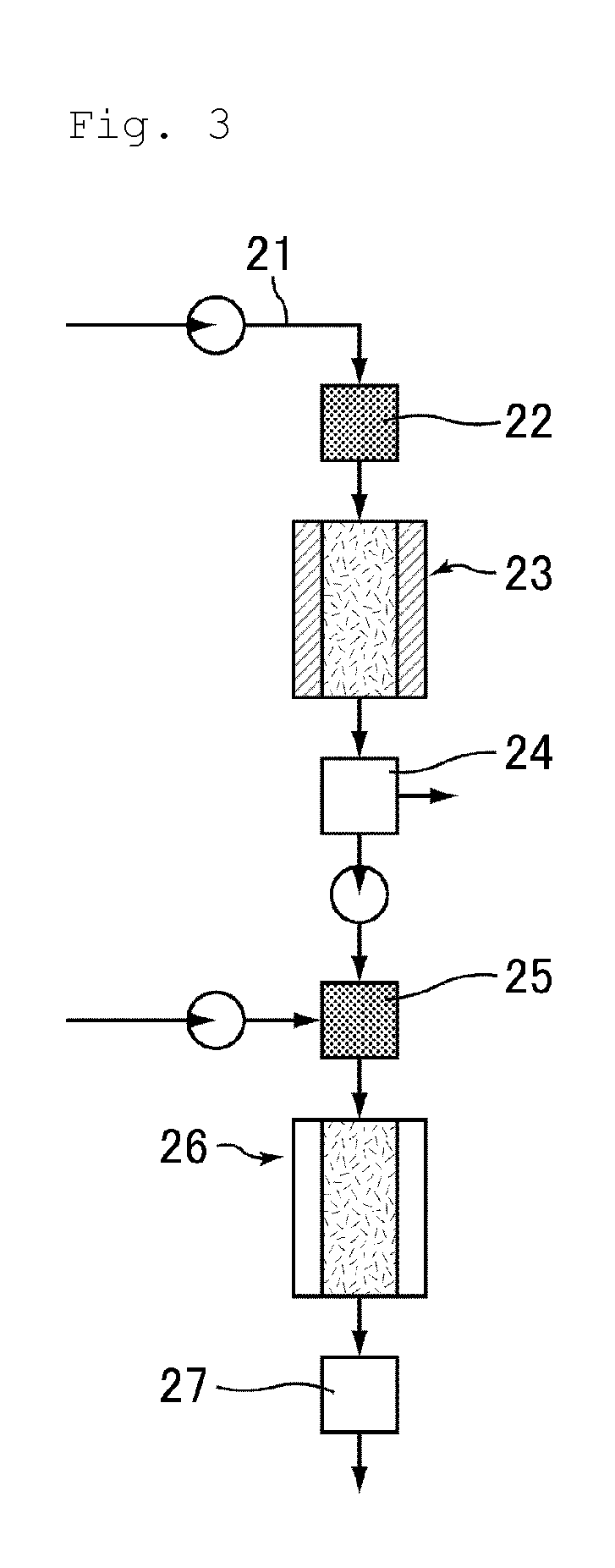

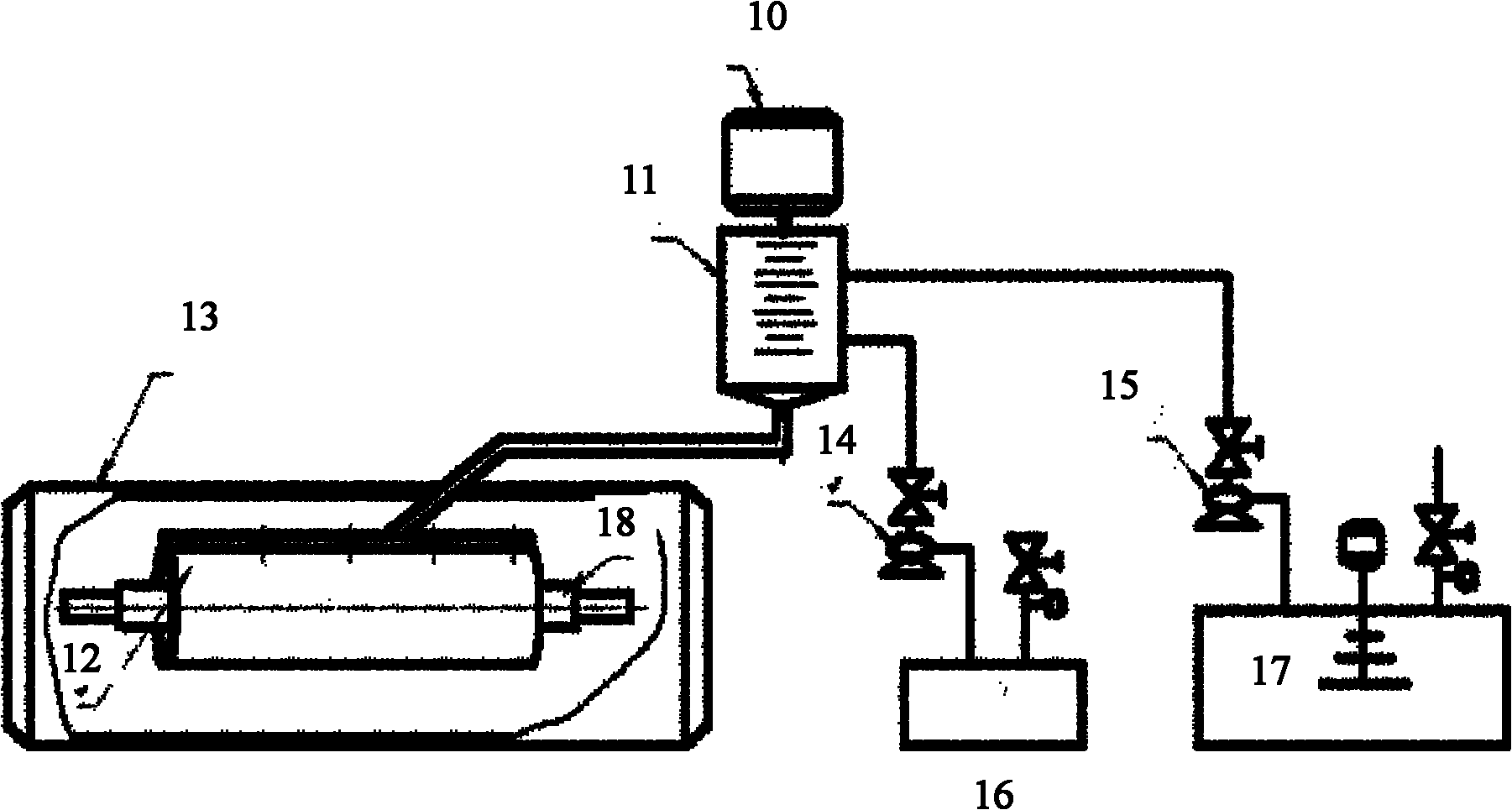

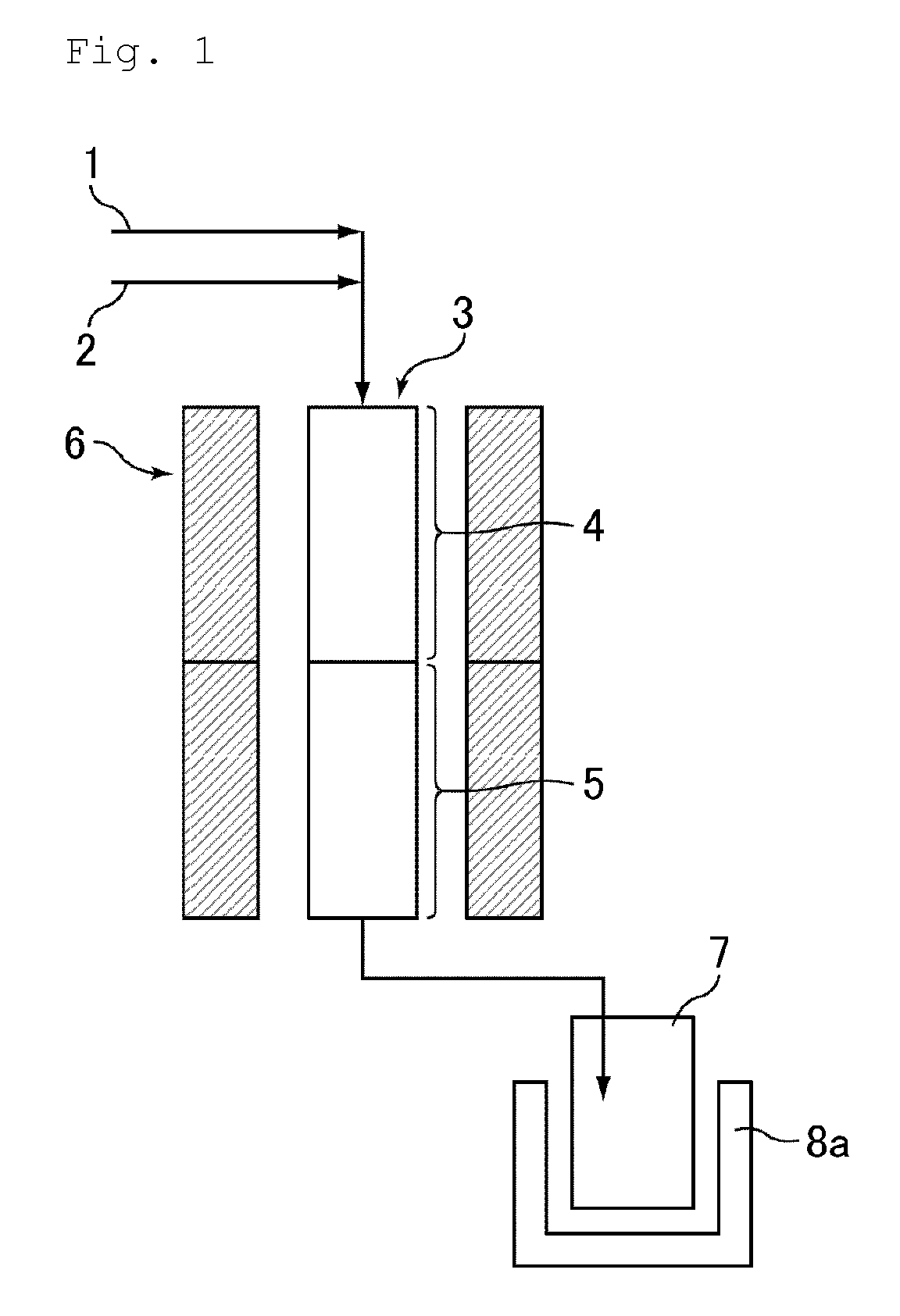

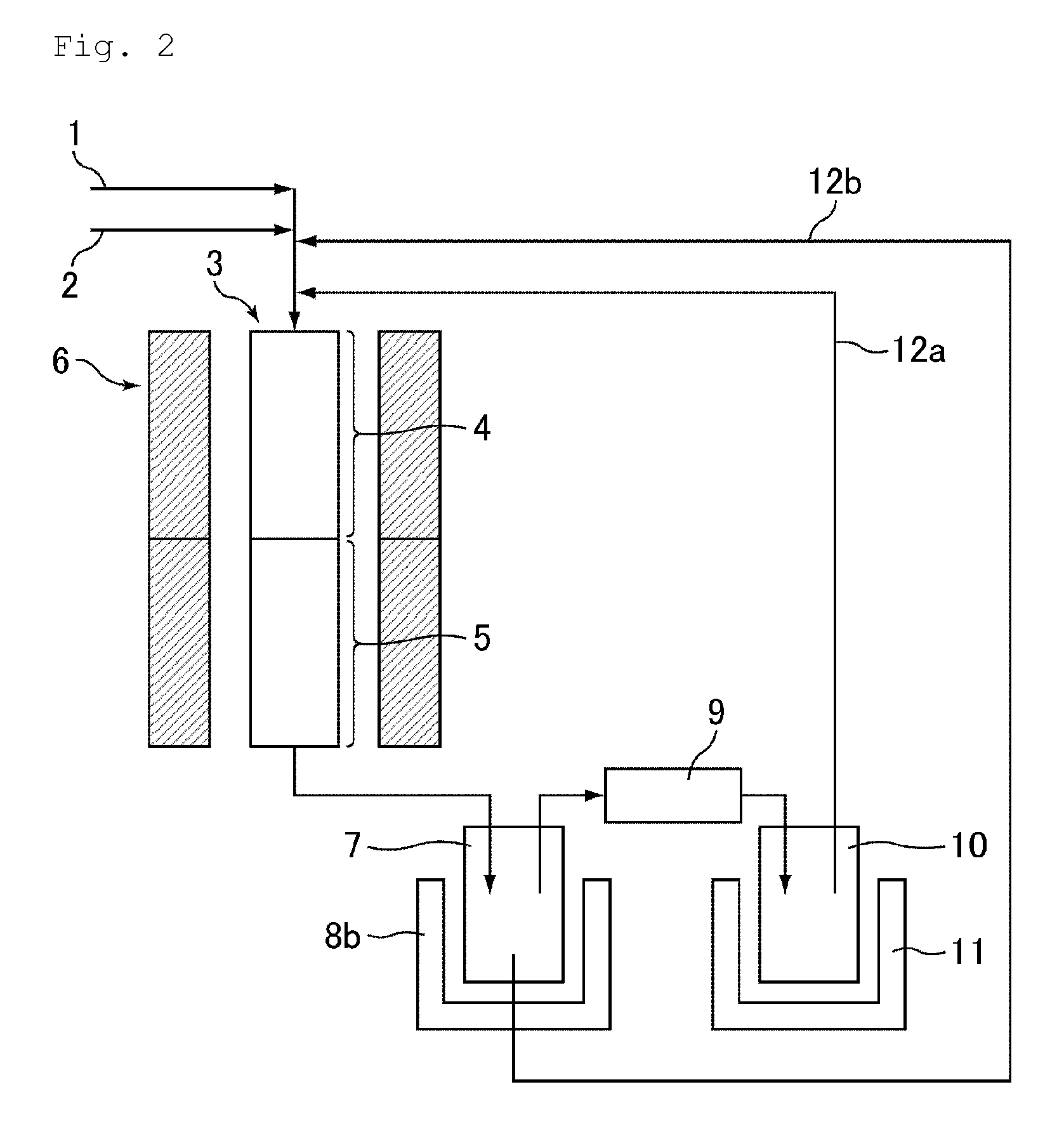

Synthesis system, rubber chemical substance for tires, synthetic rubber for tires, and pneumatic tire

ActiveUS20130090445A1Reduce the amount requiredEfficient synthesisMolecular sieve catalystsMolecular sieve catalystAlcoholAniline

The present invention provides a synthesis system that can synthesize aniline and / or styrene efficiently, a synthesis system that can synthesize butadiene (1,3-butadiene) efficiently, a rubber chemical for a tire which is synthesized from the aniline obtained by the synthesis system, a synthetic rubber for a tire which is synthesized from the styrene and / or butadiene obtained by the synthesis systems, and a pneumatic tire produced using the rubber chemical for a tire and / or the synthetic rubber for a tire. The present invention relates to a synthesis system for synthesizing aniline and / or styrene from an alcohol having two or more carbon atoms via an aromatic compound.

Owner:SUMITOMO RUBBER IND LTD

White carbon black dispersant and preparation method thereof

The invention discloses a white carbon black dispersant. The white carbon black dispersant comprises, by mass, 40 to 60% of C8-C22 fatty acid, 5 to 25% of protection wax, 10 to 28.8% of fatty acid ester, 6 to 10% of an inorganic filling material and 0.96 to 5% of an anti-oxidant. The invention also discloses a preparation of the white carbon black dispersant having a good white carbon black dispersion effect. The white carbon black dispersant is an environmentally-friendly high-dispersibility zinc-free white carbon black dispersant, can improve dispersibility of a filling material and rubber chemicals in rubber in rubber mixing, is suitable for improvement of dispersibility of rubber containing high-activity white carbon black, avoids re-condensation, improves wet-skid resistance of a tyre surface, and avoids the pollution produced heavy metal zinc on the environment.

Owner:青岛福凯橡塑新材料有限公司

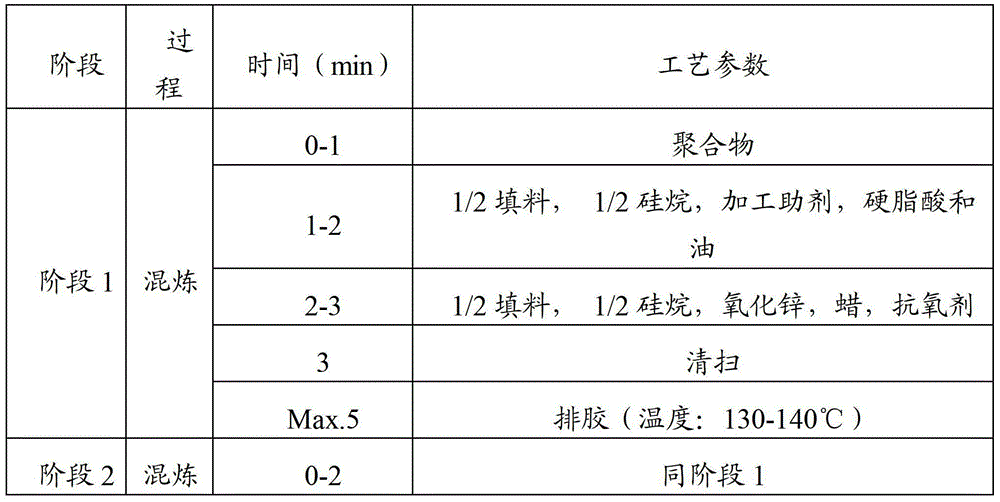

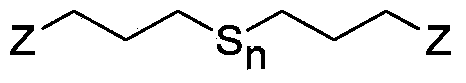

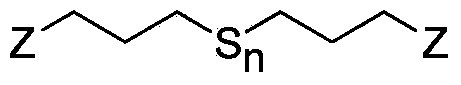

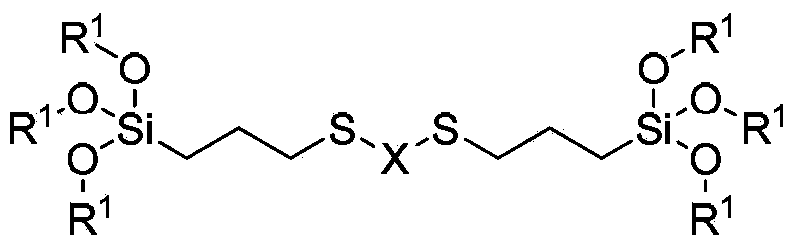

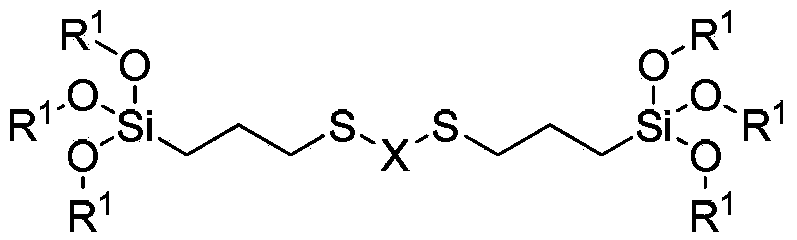

Sulfur-containing silane coupling agent and preparation method thereof

InactiveCN103351401AThe synthesis process is matureRaw materials are easy to getGroup 4/14 element organic compoundsHydrogenMethyl group

The invention discloses a sulfur-containing silane coupling agent and a preparation method thereof. The structural general formula of the sulfur-containing silane coupling agent is as follows (see the specification), wherein n=2-10, Z is perssad (R1O) m (G) 3-mSi, m is 1 or 2, R1 is methyl or ethyl, G is (R2) (O (CR' R'') x) yO, x=2-10, y=1-20, R2 is alkyl, R' is hydrogen, alkyl or phenyl, and R'' is hydrogen or alkyl. The preparation method is simple and reliable, and the prepared sulfur-containing silane coupling agent can be widely used in rubber chemicals to effectively improve the rubber performance.

Owner:WUHAN UNIV

Sheet-like gasket and process for manufacturing same

A sheet-like gasket having a dense structure and exhibiting excellent sealing performance with a small clamping force even on an irregular flange surface is provided. The sheet-like gasket is obtained by molding a composition comprising a substrate fiber, a rubber material, a filler, and a rubber chemical into a sheet, having a bead on both sides or one side, and having a flat part with a density of 1.0 g / cm<3 >or higher, the bead having a density lower than the density of the flat part.

Owner:NICHIAS CORP

Non-asbestos gasket sheet

A non-asbestos gasket sheet including a composition which includes a base fiber containing an organic fiber as a major fiber component, rubber, a filler, and a rubber chemical, the amount of the organic fiber in the composition is 15 to 30 wt %, and the filler including graphite. The non-asbestos gasket sheet exhibits tensile strength equivalent to or greater than that of an asbestos joint sheet, and can be used under high temperature conditions.

Owner:NICHIAS CORP

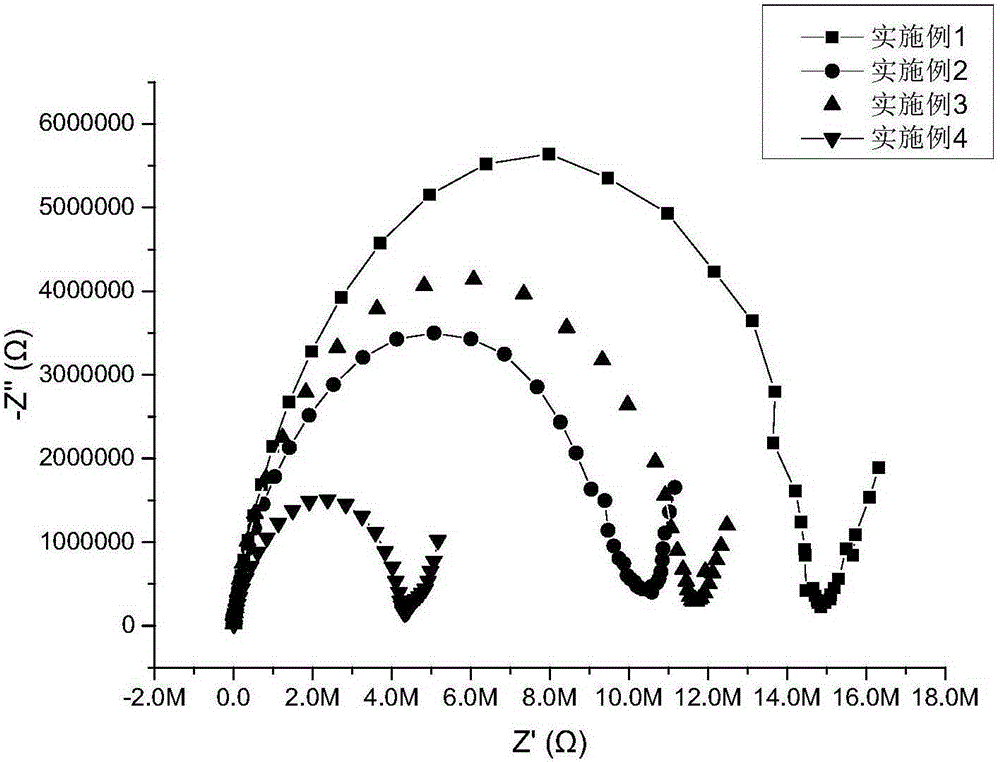

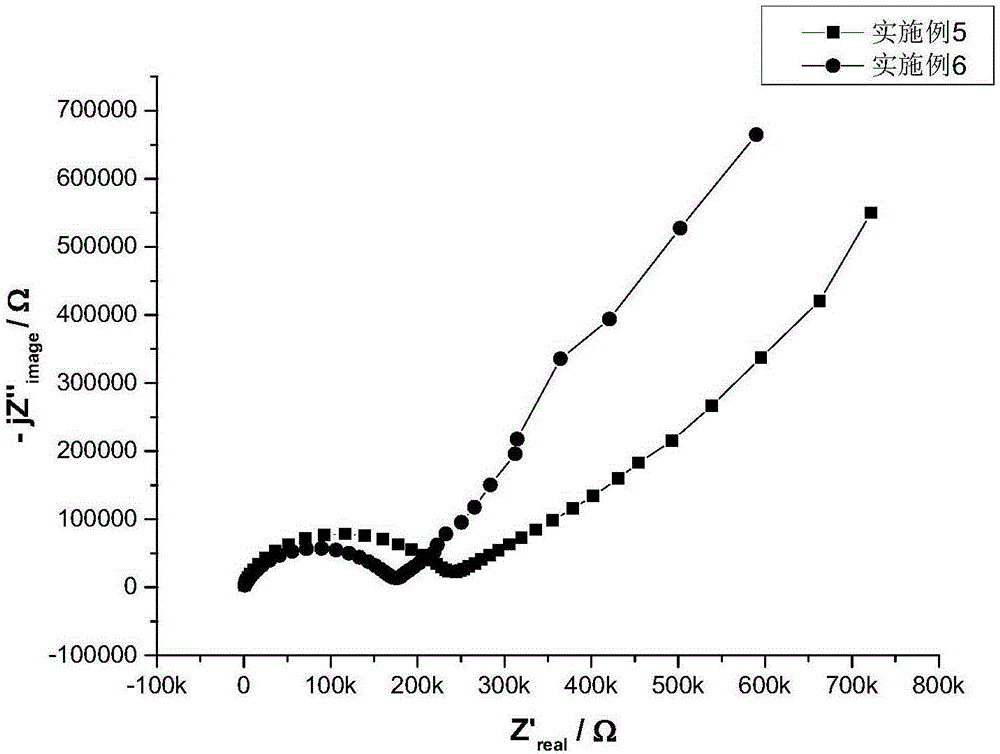

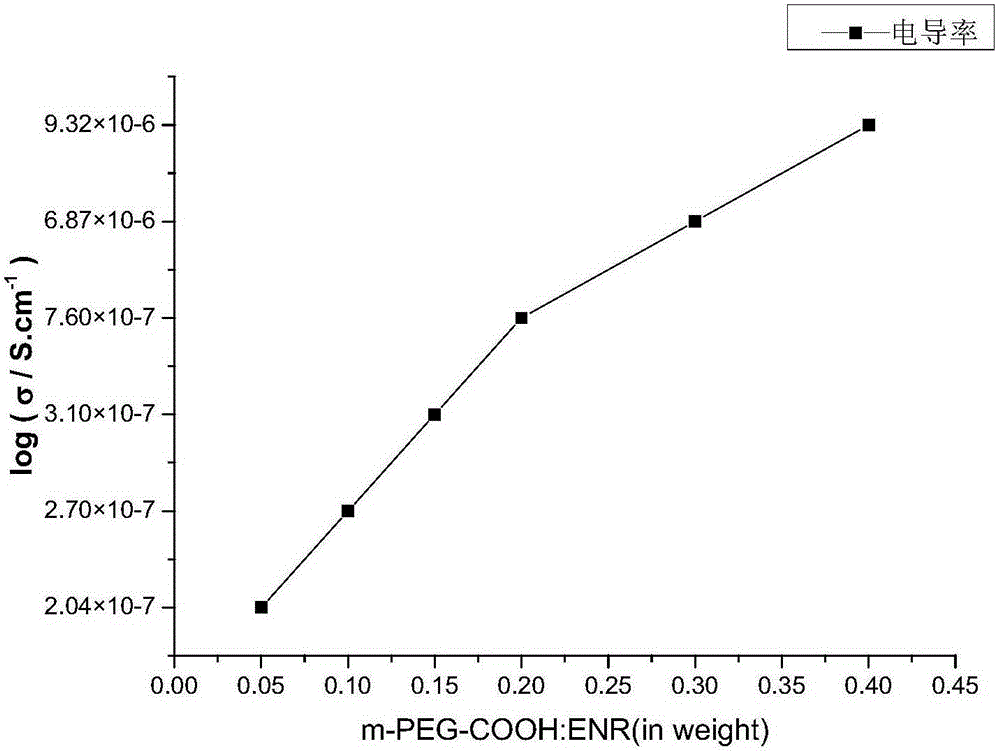

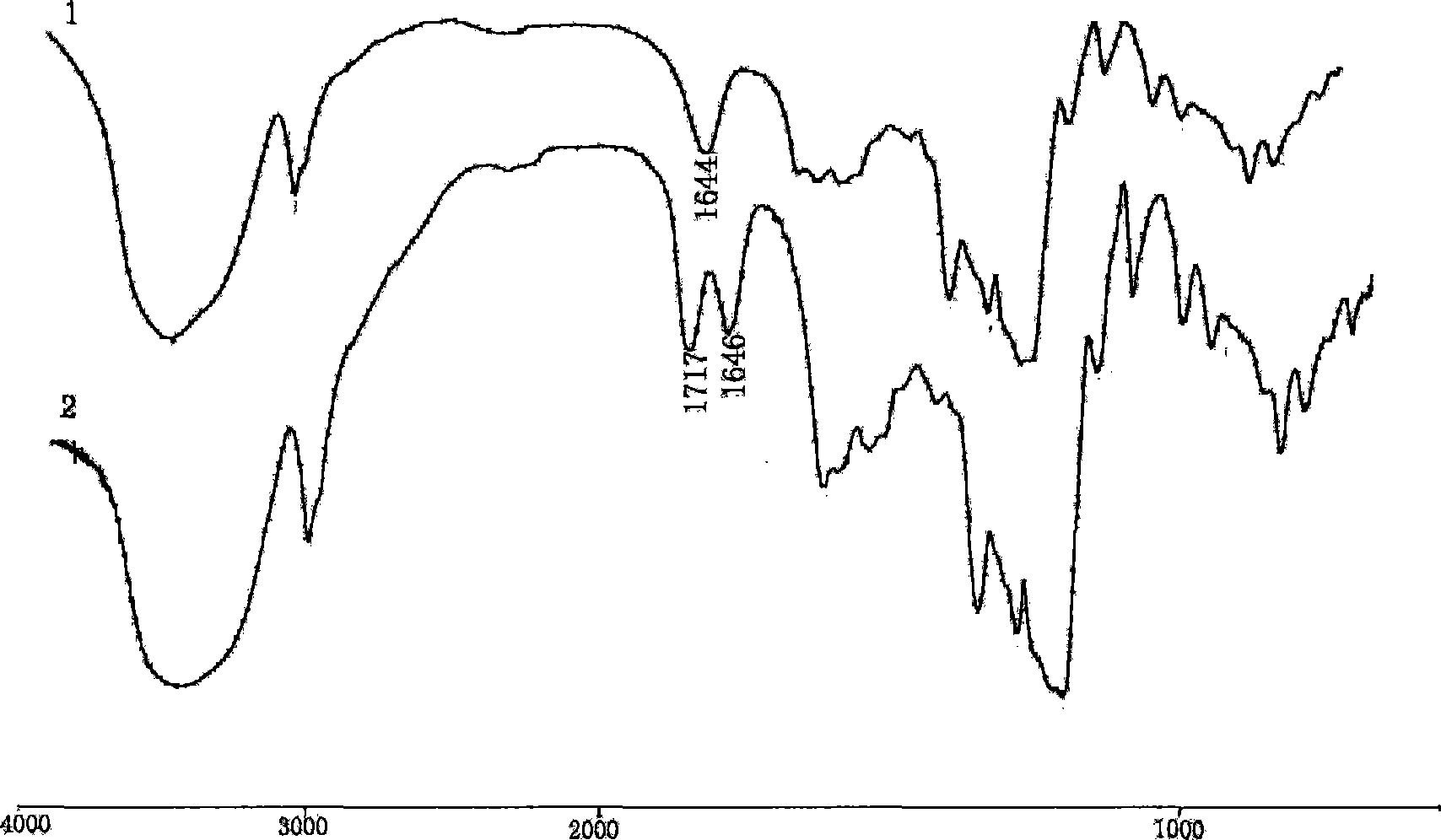

Grafting type comb polymer solid electrolyte material and preparation method thereof

InactiveCN105206872AImprove athletic abilityImprove electrochemical stabilitySolid electrolytesSecondary cellsVulcanizationPolymer science

The invention relates to a grafting type comb polymer solid electrolyte material and a preparation method thereof. The raw material comprises epoxidized natural rubber, methoxy polyethylene glycol carboxylic acid and lithium perchlorate, a flexible segment is introduced in the epoxidized natural rubber through a grafting reaction, the graft methoxy polyethylene glycol carboxylic acid provides the high segment motion ability and the ability of interaction with lithium salt, and ether oxygen atoms on the graft act with lithium perchlorate to dissociate the lithium perchlorate into lithium ions and form a coordinated complex. Compared with the prior art, no other plasticizer or active agent or vulcanization accelerator or rubber chemical is introduced, no small molecule product residue exists in the prepared material, and the electrochemical stability and ionic conductivity of the electrolyte can be improved.

Owner:SHANGHAI JIAO TONG UNIV

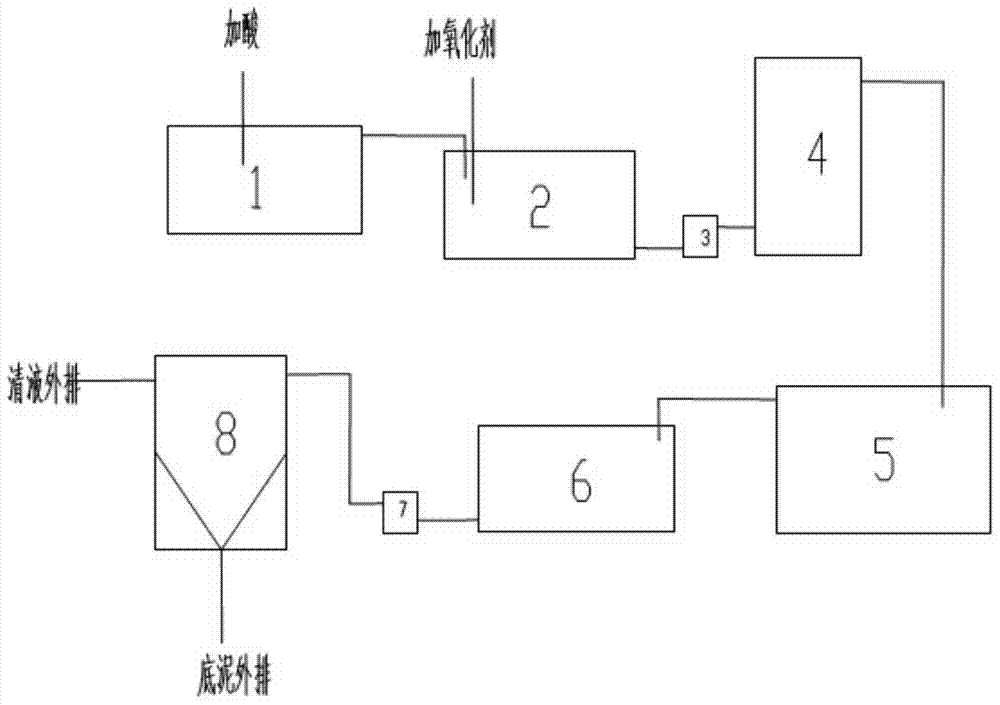

Method for treating rubber chemical wastewater by microwave enhanced microelectrolysis combined oxidation

ActiveCN104291506AReduce speculationLow costWater contaminantsMultistage water/sewage treatmentFlocculationTreatment effect

The invention provides a method for treating rubber chemical wastewater by microwave enhanced microelectrolysis combined oxidation. The method is characterized by comprising the following steps: pre-oxidizing wastewater, and carrying out microelectrolysis treatment; carrying out microwave radiation after organic matters in rubber chemical wastewater are subjected to ring-opening and chain.-scission; enhancing the treatment effect of microelectrolysis and oxidation by utilizing the electromagnetic effect of microwave, and quickly heating the wastewater by means of the heat effect of microwave. According to the method, the oxidation speed can be accelerated by means of temperature rising, so that separation of organic matters can be favored, a subsequent flocculation reaction is accelerated, and the total amount of sludge of wastewater can be reduced; and multiple processes are gradually combined for rubber chemical wastewater treatment, so that discharge of the wastewater with standard level at relatively low cost can be realized.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

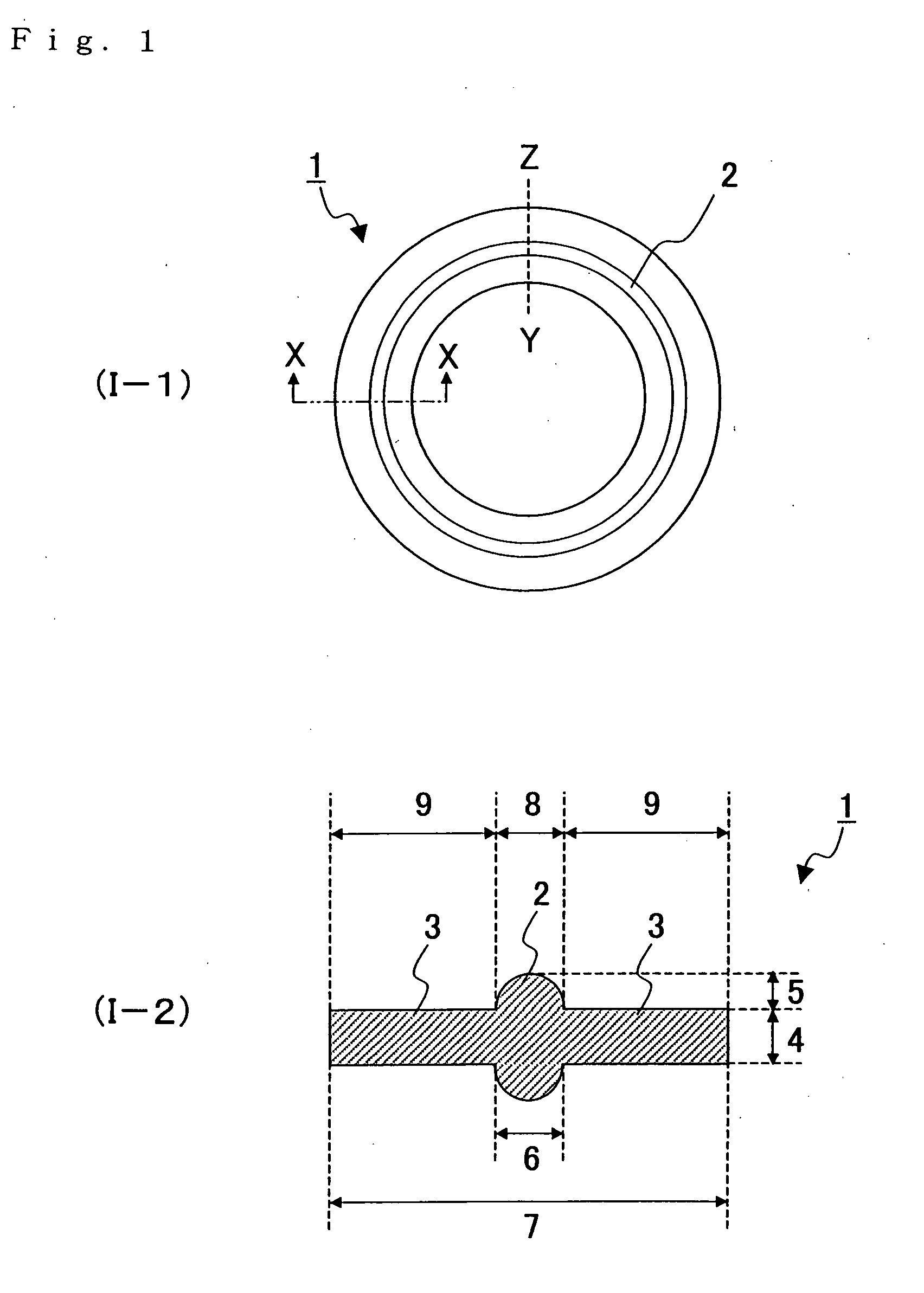

Method for manufacturing sheet-like gasket

InactiveCN101033386AReduce compounding amountLow tensile strengthEngine sealsOther chemical processesAsbestos sheetFiber

A non-asbestos sheet-like gasket usable at a high temperature, exhibiting only a small decrease in tensile strength and stress relaxation under high temperature conditions is provided. The method for manufacturing the sheet-like gasket comprises a step of obtaining a sheet-forming composition comprising a base fiber other than asbestos, a latex of hydrogenated acrylonitrile-butadiene, a filler, and rubber chemicals and a step of obtaining the sheet-like gasket by molding the composition and vulcanizing the rubber.

Owner:NICHIAS CORP

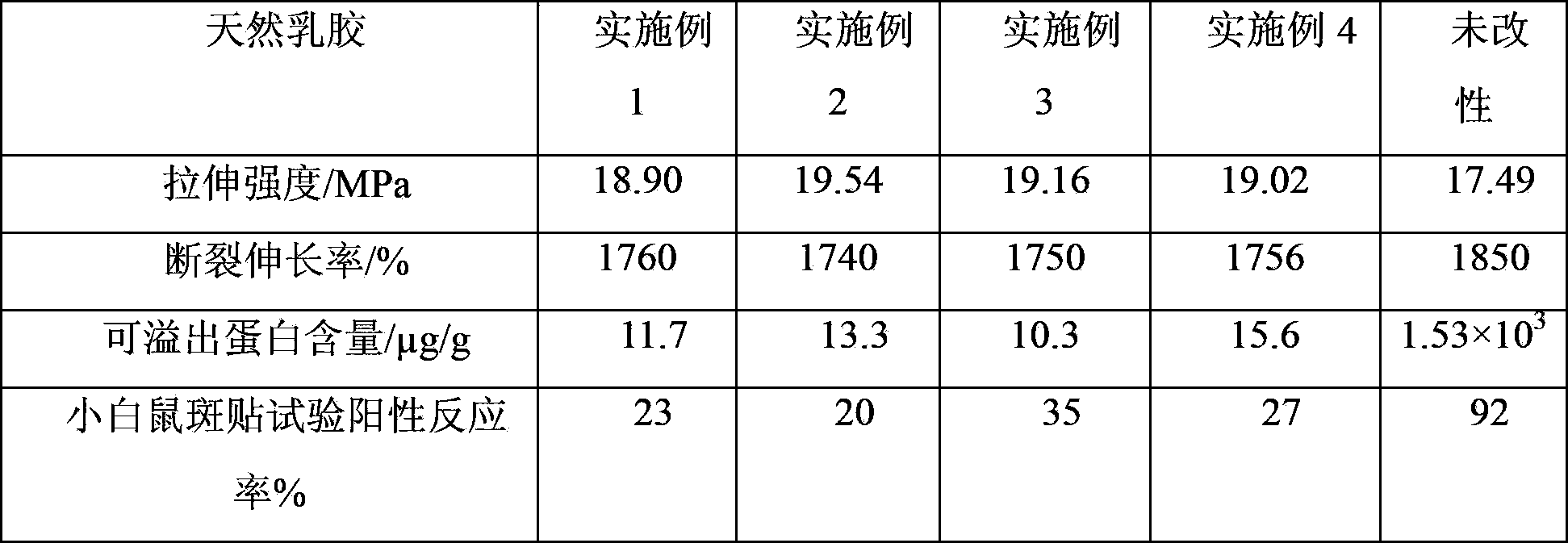

Modified nature latex, preparation method and use thereof

The invention belongs to the technical field of rubber chemical modification, and relates to a preparation method and a use of a modified nature latex. The modified nature latex is prepared from the following components by weight: 100 parts of nature latex, and 10-30 parts of sericin grafted aqueous polyurethane emulsion. According to the present invention, the modified rubber has advantages of surface functionalization, good biocompatibility and the like; the mechanical property and the allergy of the nature latex gloves are improved; and the traditional method that the protein removing method is adopted to solve the allergy of the latex product is changed, the allergy problem is solved without reduction of the protein content, and the physical and mechanical properties of the latex product are ensured.

Owner:HEFEI GENIUS NEW MATERIALS

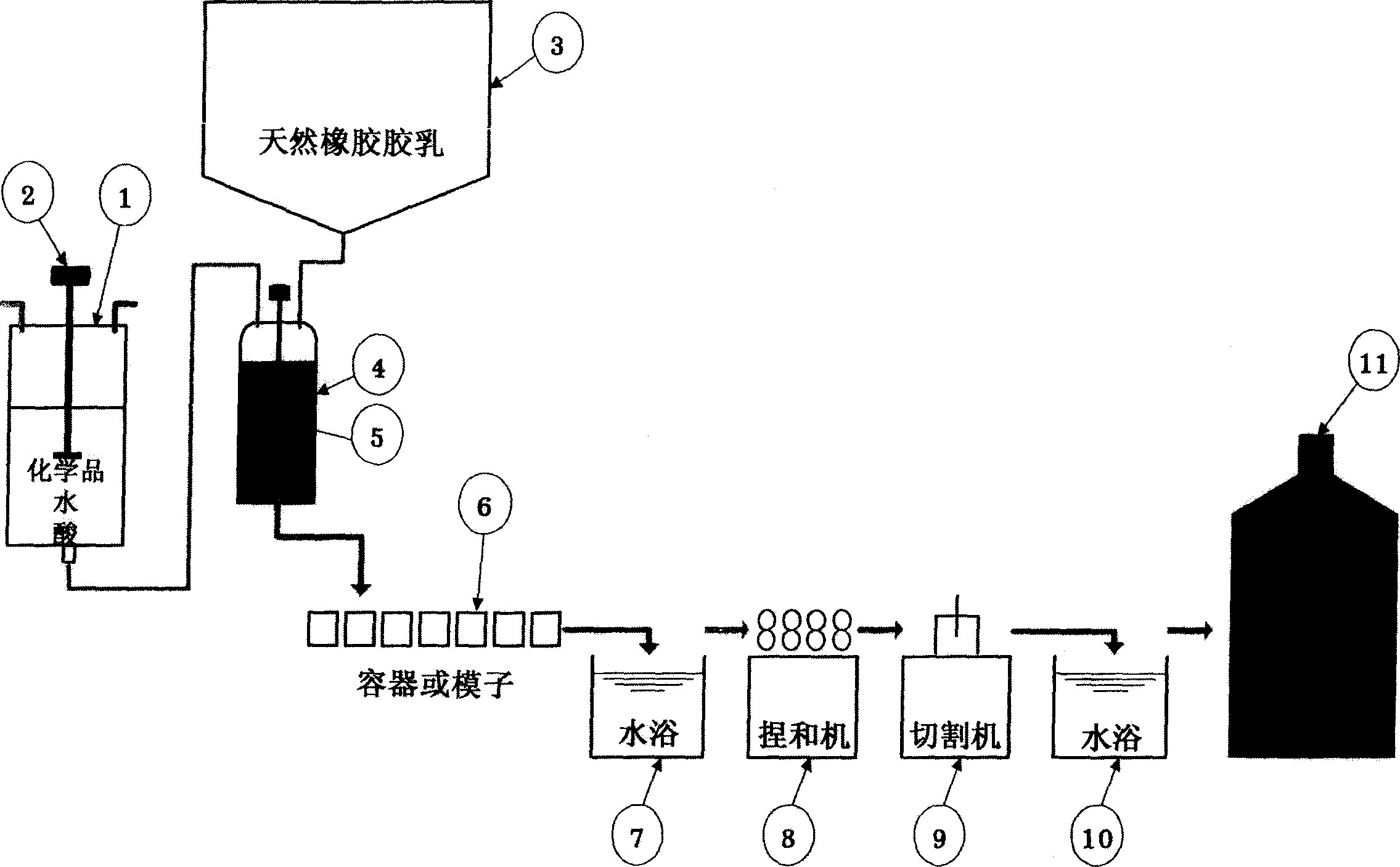

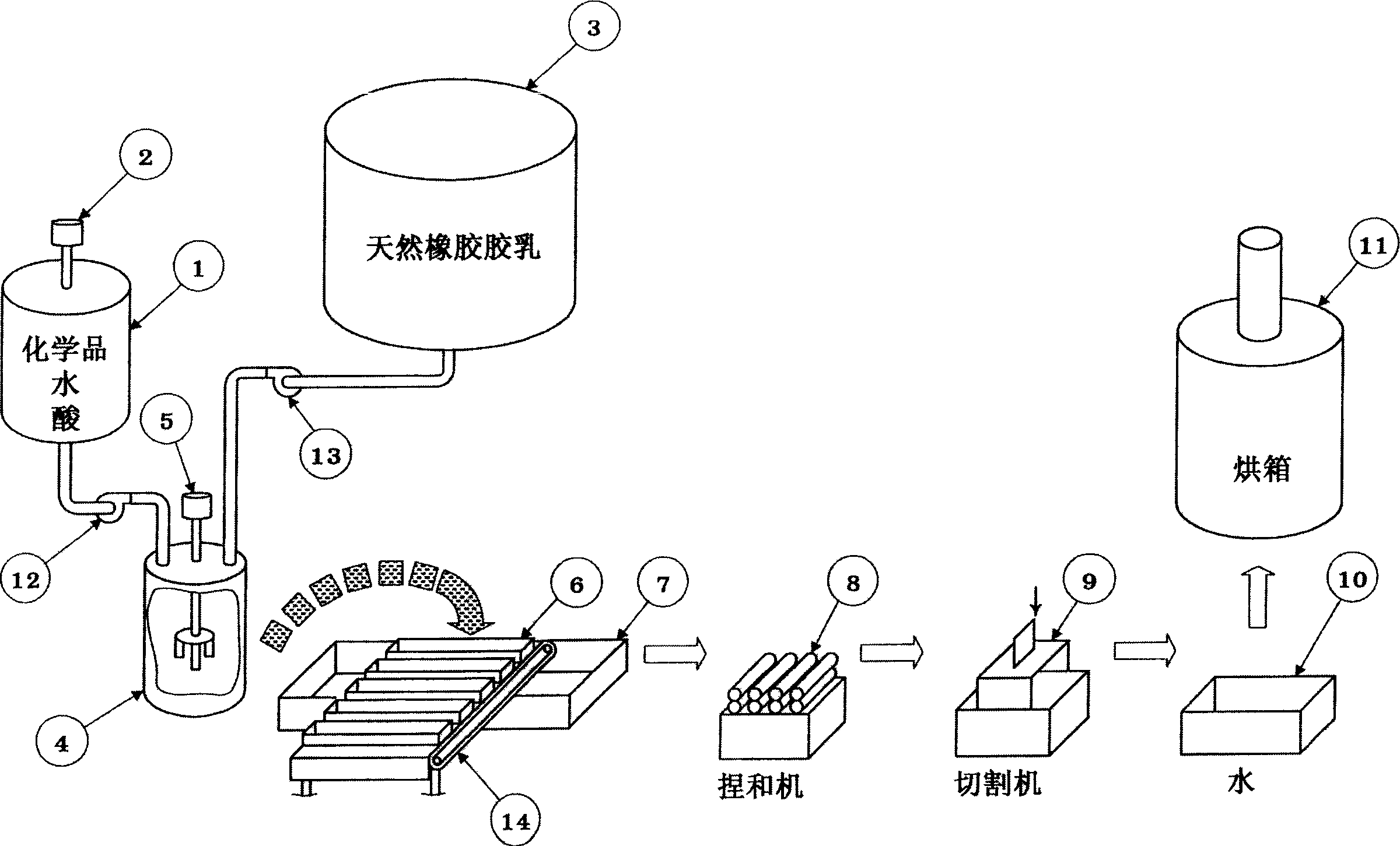

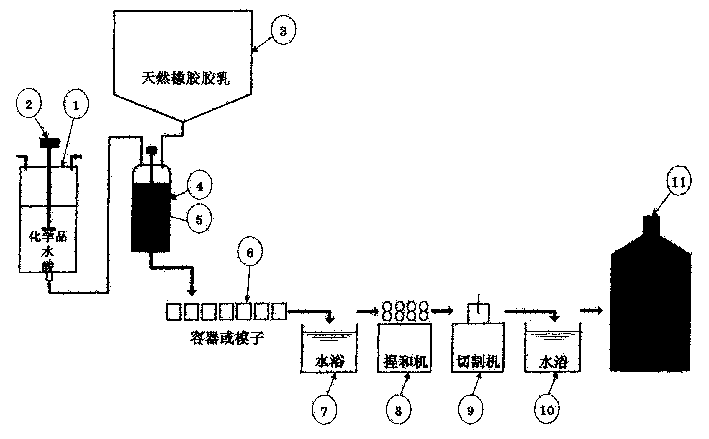

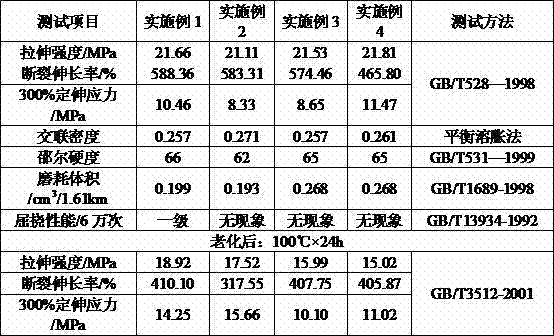

Wet natural rubber compound and producing process thereof

The invention relates to a method for preparing rubber compound, which is widely used for directly mixing chemicals in the rubber products, such as silicon dioxide, carbon black, calcium carbonate, sulfur, ect., with natural rubber latex (natural latex or concentrated latex). The method contains mixing chemicals with dilute acid before mixing with natural rubber latex. The inventive rubber-chemicals master batch is suitable for producing rubber products because chemicals is fully dispersed in the whole master batch.

Owner:多元化学工程有限公司

Sulfur pre-dispersing mother rubber particle and preparation method thereof

The invention discloses sulfur pre-dispersing mother rubber particle and a preparation method thereof and relates to a rubber chemical. The sulfur pre-dispersing mother rubber particle is composed of the following components by mass: 80 parts of sulfur powder, 16 parts of base materials, 1 part of stearic acid and 3 parts of white oil, wherein the used base materials are composed of ethylene-propylene-diene monomer (EPDM), ethylene-vinyl acetate copolymer (EVA) and polyolefin elastomer (POE), the type of the used EPDM is 4045, the content of vinyl acetate in the EVA is 30%, and the type of the POE is 8108. The sulfur pre-dispersing mother rubber particle is pre-dispersing mother rubber particle obtained by evenly dispersing sulfur powder into a carrier and performing pelleting. The sulfur pre-dispersing mother rubber particle is particularly suitable for being applied to a formula of tread rubber, and can solve the problems of dust, mixing rate and the like in mixing of the tread rubber.

Owner:CHAOYANG TIANMING IND TRADE

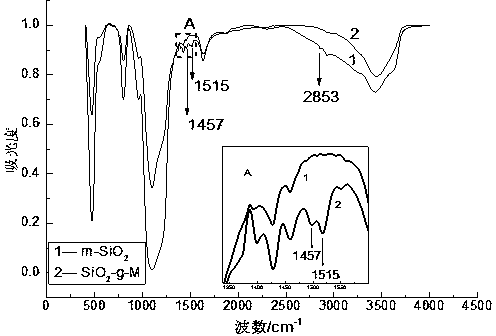

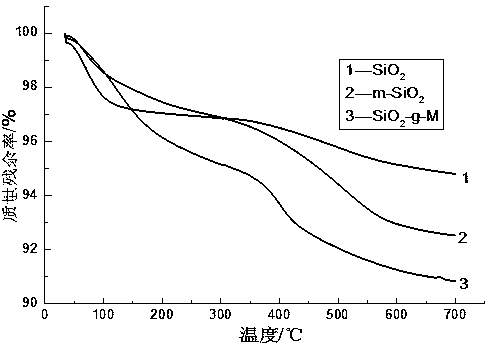

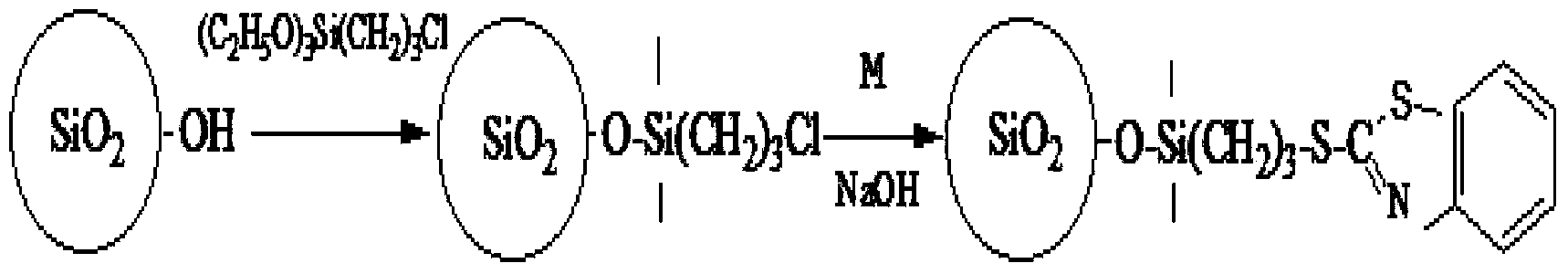

Loaded-type rubber vulcanization accelerant as well as preparation method and application thereof

ActiveCN103360628AGood dispersionImprove the efficiency of promoting vulcanizationPolymer scienceOrganic solvent

The invention relates to a loaded-type rubber vulcanization accelerant as well as a preparation method and an application thereof. The loaded-type rubber vulcanization accelerant is prepared by firstly, blending a silane coupling agent and an organic solvent into a 0.5-30% by mass solution, mixing with an inorganic carrier and forming into a mixture with a solid content of 2-80%, stirring for 6-30 hours at 40-100 DEG C, subsequently adding a rubber vulcanization accelerant with a mole number which is 1.0-1.8 times of that of the coupling agent into a product of the reaction, reacting for 10-20 hours under the protection of nitrogen at 50-80 DEG C, and finally filtering and drying the reaction product. The loaded-type rubber vulcanization accelerant is capable of remarkably improving the vulcanization acceleration efficiency of rubber and reducing environment pollution caused by an ordinary accelerant, has the functions of a reinforcing agent, an interfacial modifier and the like, is an efficient, multifunctional, environment-friendly and novel rubber chemical, and has a wide application prospect in the rubber industry.

Owner:SOUTH CHINA UNIV OF TECH

Non-asbestos gasket sheet

InactiveUS20060166580A1Other chemical processesSynthetic resin layered productsAsbestos sheetGraphite

A non-asbestos gasket sheet including a composition which includes a base fiber containing an organic fiber as a major fiber component, rubber, a filler, and a rubber chemical, the amount of the organic fiber in the composition is 15 to 30 wt %, and the filler including graphite. The non-asbestos gasket sheet exhibits tensile strength equivalent to or greater than that of an asbestos joint sheet, and can be used under high temperature conditions.

Owner:NICHIAS CORP

Gasket sheet and method for manufacturing same

InactiveUS20070010613A1Improve sealingFlat surfaceNon-fibrous pulp additionEngine sealsAsbestosRubber chemicals

A non-asbestos gasket sheet comprising 30% or more of the organic fiber obtained by forming a sheet from a slurry containing an organic fiber, a rubber, fillers, and rubber chemicals, followed by drying and rolling. The obtained gasket sheet possesses excellent sealing properties and tensile strength.

Owner:NICHIAS CORP

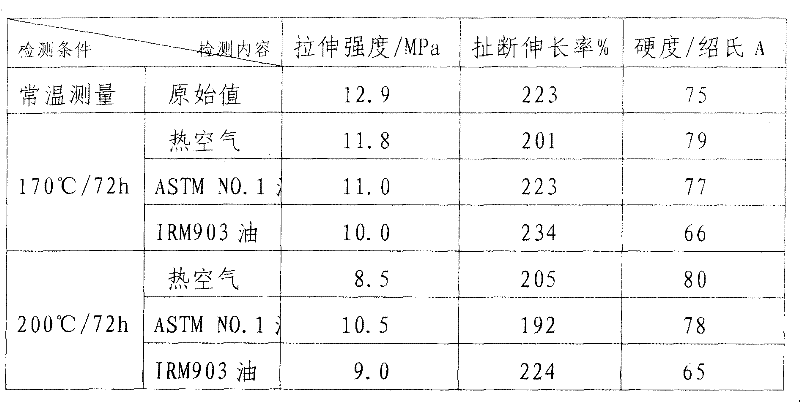

Horizontal production process of polyurethane rubber roller

The invention belongs to the technical field of rubber chemical industry, and in particular relates to a horizontal production process of a polyurethane rubber roller. The invention aims to provide a horizontal production process of a large polyurethane rubber roller for improving the integral physical properties of the rubber roller. The horizontal production process of the large polyurethane rubber roller comprises the processing steps of: dissolving and mixing raw materials, synthesizing prepolymer, pretreating a rubber roller pouring mold, pouring and forming, vulcanizing and grinding, wherein in the pretreating step of the rubber roller pouring mold, the rubber roller pouring mold is horizontally placed and heated to 80-85 DEG C; and the temperature in the pouring and forming step is kept at 80-85 DEG C for pouring and forming. The method provided by the invention improves the pouring mode, and the product has few defects, good appearance quality and excellent integral properties.

Owner:SICHUAN GUOXIN MACHINERY MFG CO LTD

Gasket sheet and method for manufacturing same

InactiveCN1724606AStable manufacturingImprove sealingNon-fibrous pulp additionEngine sealsAsbestos sheetFiber

The non-asbestos sheet gasket is obtained by making a slurry containing an organic fiber, a rubber, a filler, and rubber chemicals into a sheet, drying the sheet, and rolling the dried sheet. The organic fiber is contained in an amount of at least 30% based on the sheet gasket. The invention provide an NA (non asbestos) sheet gasket having excellent sealability and tensile strength equivalent to that of an asbestos sheet gasket.

Owner:NICHIAS CORP

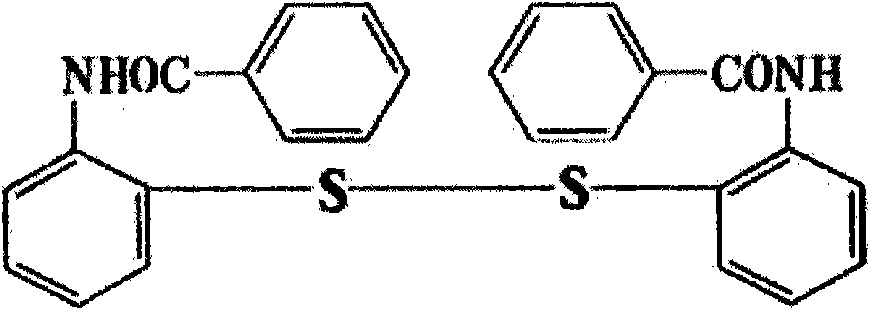

Diacylthioxo silane coupling agent and preparation method thereof

InactiveCN103396433AReasonable designLow equipment requirementsGroup 4/14 element organic compoundsPolymer scienceMethyl group

The invention discloses a diacylthioxo silane coupling agent and a preparation method thereof. A structural general formula of the silane coupling agent is shown in the specification, wherein in the formula, R1 is methyl or ethyl, and the X group is oxalyl group, phthaloyl / m-benezene diformyl / terephthaloyl, malonyl, succinyl, adipoyl, fumaryl, isodivaleryl, 2-methyladipyl, octanedioyl, decanedioyl and other dicapryloyl. The diacylthioxo silane coupling agent is accessible in raw materials and low in equipment requirements, can be produced in most plants or laboratories, can be widely used in rubber chemicals and effectively improves rubber properties.

Owner:WUHAN UNIV

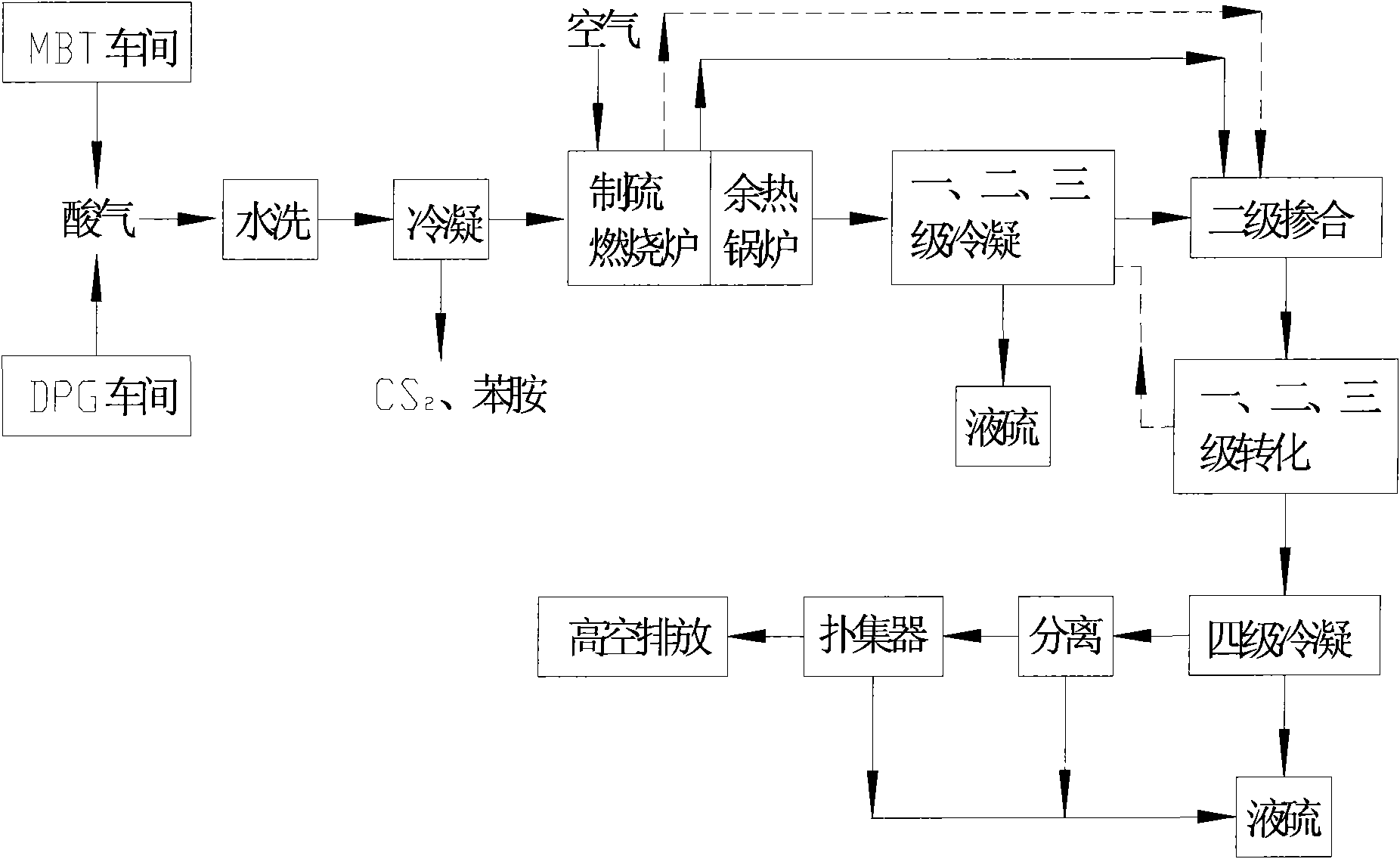

Method for recovering sulfur from byproduct of acid gas generated in production of rubber chemicals

ActiveCN101565172AGuaranteed uptimeRealize automatic air distributionSulfur preparation/purificationHigh energyRubber chemicals

The invention discloses a method for reclaiming sulfur from a byproduct of acid gas generated in the production of rubber chemicals. The method overcomes the defects that the conventional Claus furnace has low hydrogen sulfide transformation reclaiming ratio, high energy consumption and the like, and adopts a novel process to generate the sulfur by mixing hydrogen sulfide and air according to a volume ratio of 1:2 in a sulfur production combustion furnace, and adopting a straight flow partial combustion process to perform high temperature hot reactions, namely a first-stage high temperature hot reaction, a second-stage high temperature hot reaction, a third-stage catalytic conversion and a fourth-stage condensation cooling. The method has the advantages of advanced and mature process route, safety and reliability, high automation degree, convenient operation and low energy consumption.

Owner:SHANDONG SUNSINE CHEM

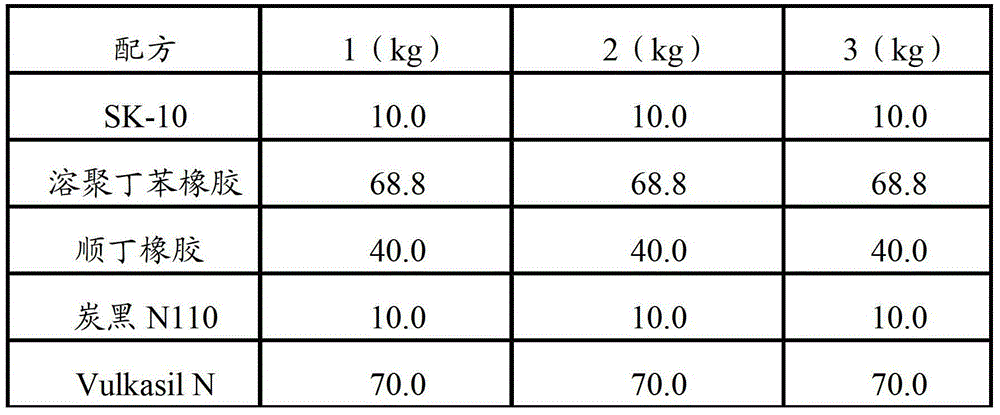

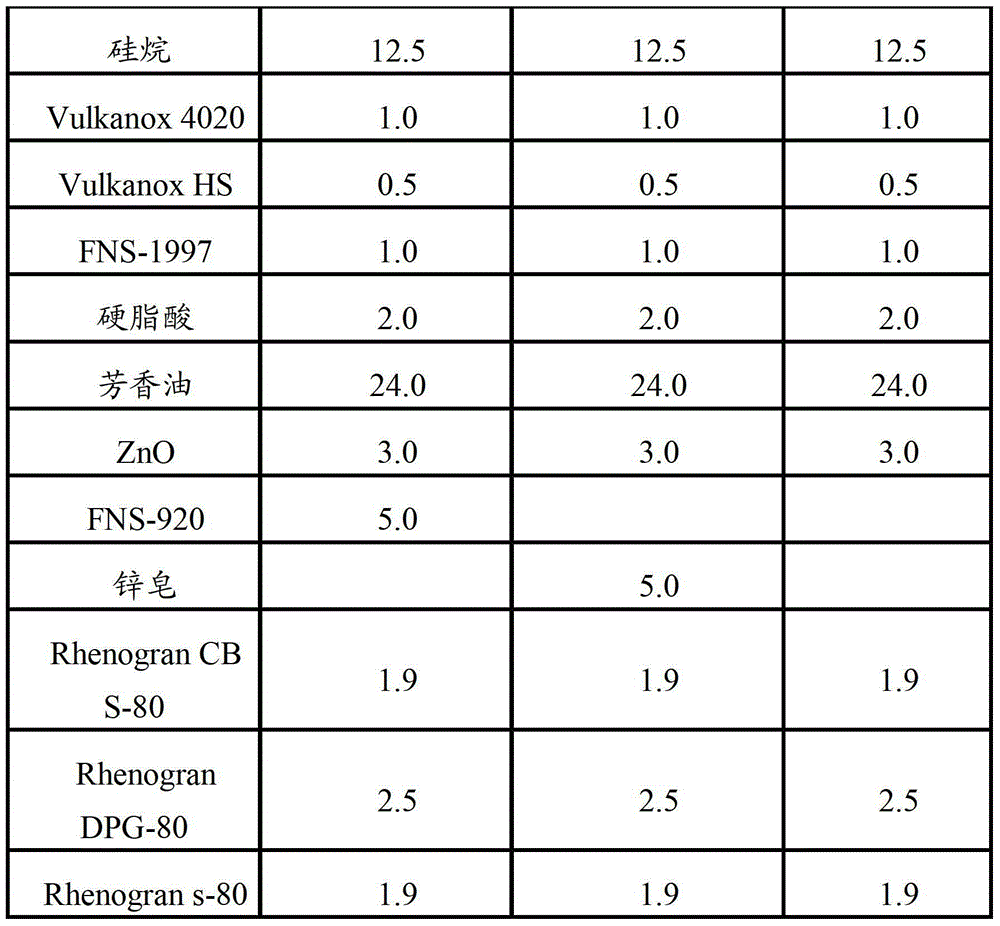

Predispersions, process for their preparation, compositions therefor, process for the preparation of such compositions

The present invention relates to predispersions of rubber chemicals and to a process for the preparation thereof. The present invention also relates to a novel polymeric composition for dispersing a rubber chemical and to a process for the preparation of said composition.

Owner:维平·夏尔马

Multifunctional rubber chemicals and method for producing the same

A multi-functional rubber ingredient and a preparation method thereof relate to the chemical engineering accessory ingredient and the preparation method thereof. Starch derivate is prepared by adding a strong alkaline solution component A with 15 percent of concentration, a halogenating epihydrin component B and a carbon bisulfide component C to the mixed solution of starch and sodium chloride, and then the multi-functional rubber ingredient is obtained by adding a strengthening agent, a coupling agent and a plasticizer. Firstly the starch xanthate is prepared, and then 100 parts of prepared starch xanthate are used as base stock, then the multi-functional rubber ingredient is obtained by adding 20 to 25 parts of strengthening agent, 0.1 to 1 part of coupling agent and 3 to 10 parts of plasticizer. Using the method to prepare the multi-functional strengthening agent has the simple technique and high grafting ratio, so the multi-functional strengthening agent has good effect when being used as a tyre rubber ingredient and processing an accelerating agent.

Owner:DALIAN TIANBAO CHEM IND

Sericin graft-modified natural latex, preparation method and applications thereof

InactiveCN103626940AReduce contentReduce the possibility of inducing an allergic reactionNitrogen atmosphereWater soluble

The invention belongs to the technical field of rubber chemical modification, and discloses a sericin graft-modified natural latex, a preparation method and applications thereof. The natural latex comprises following ingredients, by weight, 50 to 100 parts of natural latex, 25.3 to 69.6 parts of a sericin water solution, 0.2 to 1.0 part of a first initiator, and 0.2 to 1.0 part of a second initiator. The preparation method comprises following step: in nitrogen atmosphere, 50 to 100 parts of natural latex and 25.3 to 69.6 parts of the sericin water solution are stirred with a uniform speed; 0.2 to 1 part of the first initiator is added dropwise; and 0.2 to 1.0 of the second initiator is added dropwise at a uniform speed; and an obtained mixture is subjected to polymerization, and is allowed to stand so as to obtain the sericin graft-modified natural latex. The preparation method is based on surface energy difference of sericin and natural latex, and sericin is gathered at the surface of natural latex so as to isolate allergic proteins. At the same time, hydrogen-bond interaction between amino acids in sericin and allergic water soluble proteins in natural laxe is induced, and the allergic water soluble proteins are denatured, so that occurrence possibility of induced allergic reaction is reduced greatly without influencing rubber physical and mechanical properties.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Synthetic method for novel rubber sulfur-containing silane coupling agent--bis-[gamma-(trimethoxy)silylpropyl]tetrasulfide

InactiveCN104961760AHigh sulfur contentReduce manufacturing costGroup 4/14 element organic compoundsSolventColor changes

The invention relates to a synthetic method for a novel rubber chemical--bis-[gamma-(trimethoxy)silylpropyl]tetrasulfide. The method comprises the following steps: with methanol as an esterification agent, esterifying gamma-chloropropyltrichlorosilane into gamma-choropropyltrimethoxysilane; with methanol as a solvent, preparing a sodium hydroxide methanol solution with a mass concentration of 20 to 25% and reacting the sodium hydroxide methanol solution with a certain amount of sulfur powder at 50 to 60 DEG C; and pouring the prepared sodium sulfide solution into a synthetic kettle, adding a catalyst--cetyltrimethylammonium bromide prepared in advance, then adding gamma-choropropyltrimethoxysilane and judging reaction process according to color changes of a reaction solution and production of the by-product NaCl. According to the invention, methanol is used as a starting raw material, sulfur content of the novel rubber sulfur-containing silane coupling agent is increased, and production cost is substantially reduced; methanol is used both as an esterification reagent participating in reaction and as a solvent and can be easily separated from the prepared rubber sulfur-containing silane coupling agent by using a distillation method due to the low boiling point, and the purity of the prepared rubber sulfur-containing silane coupling agent is more than 99%.

Owner:HEZE UNIV

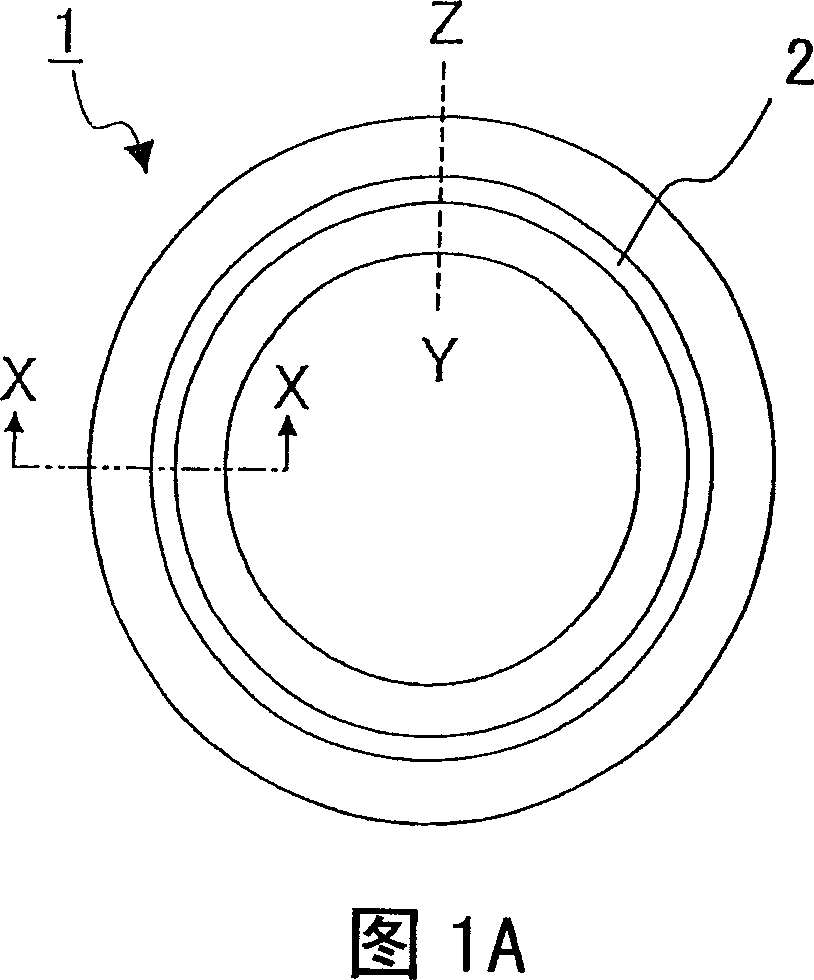

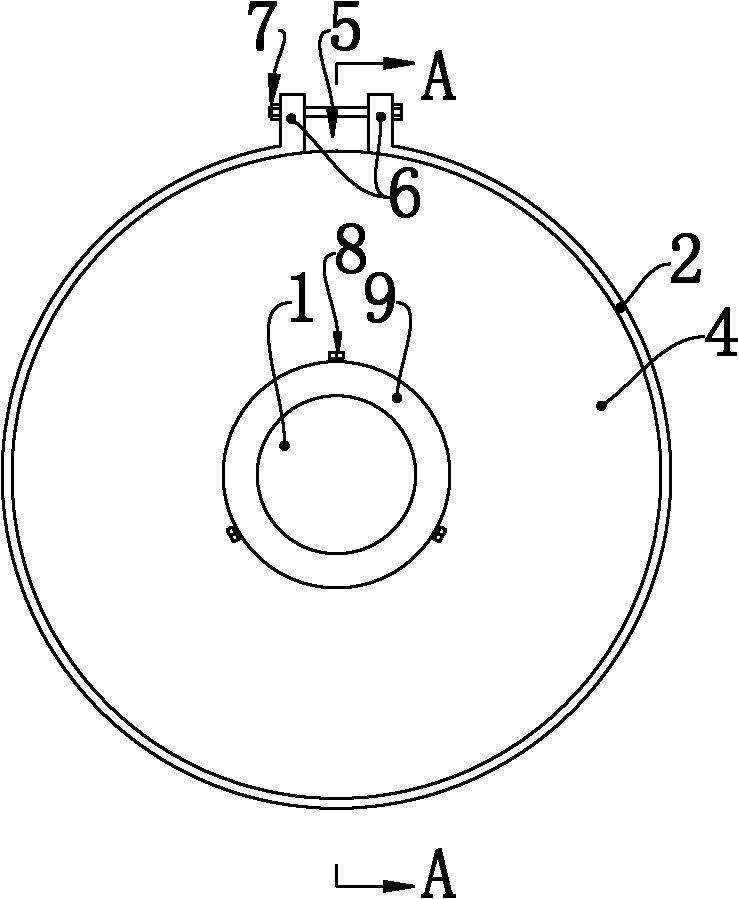

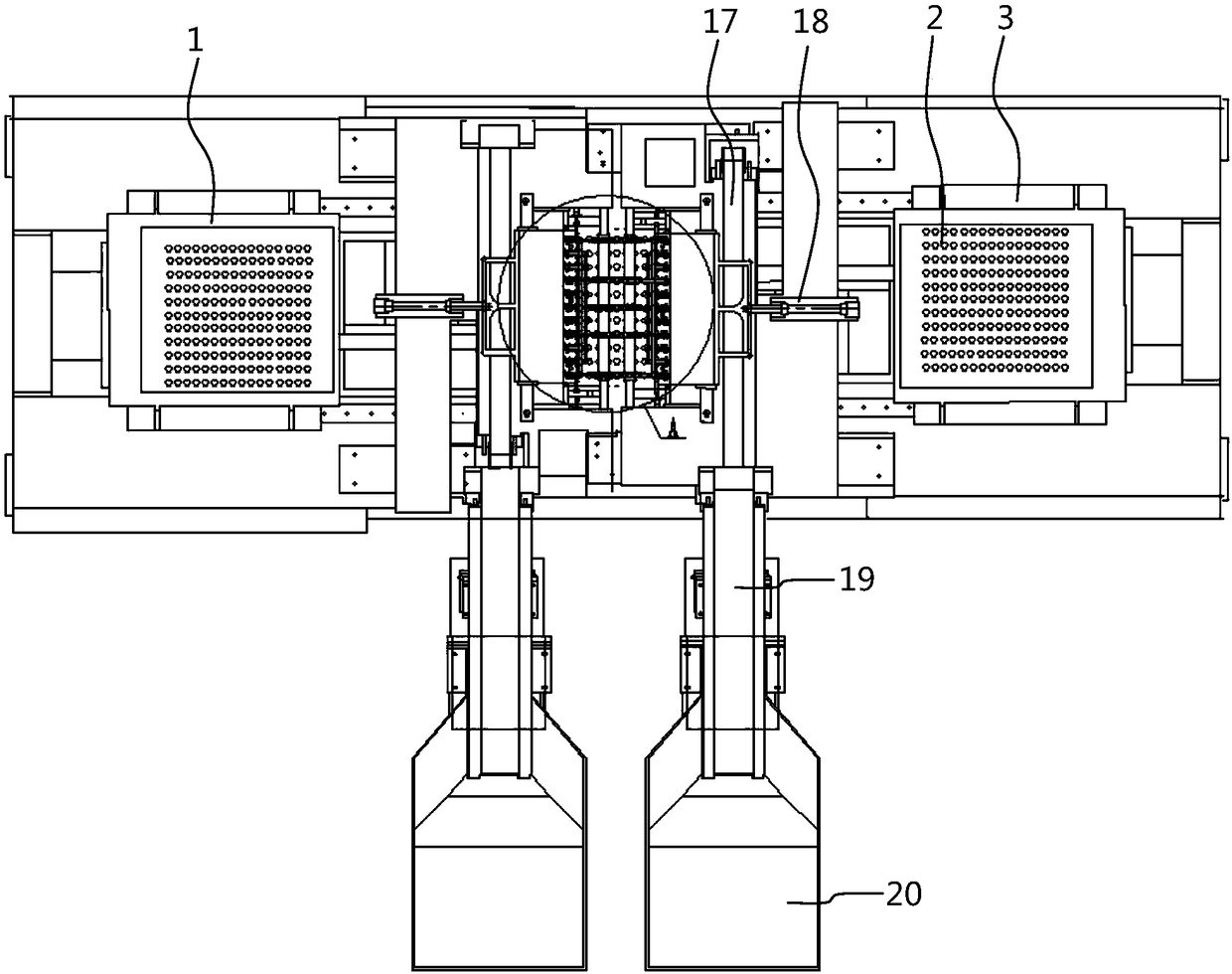

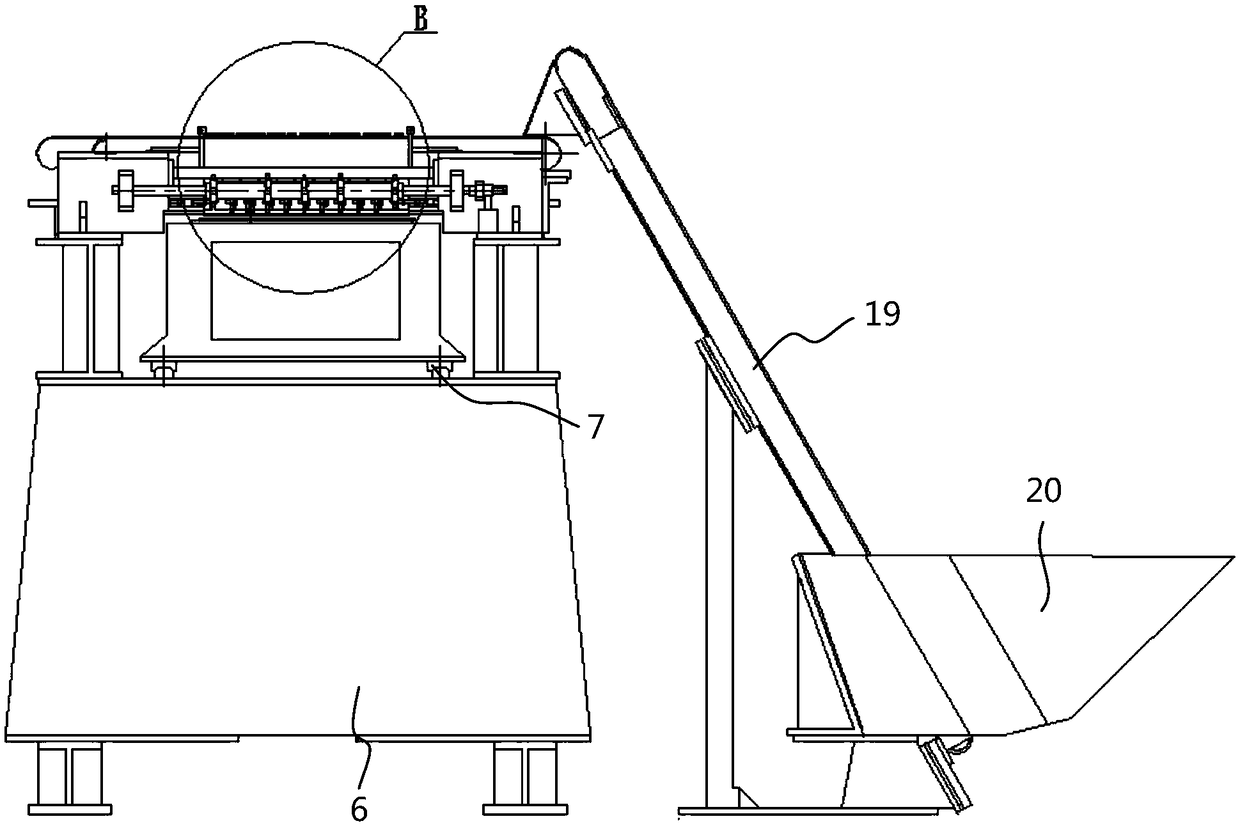

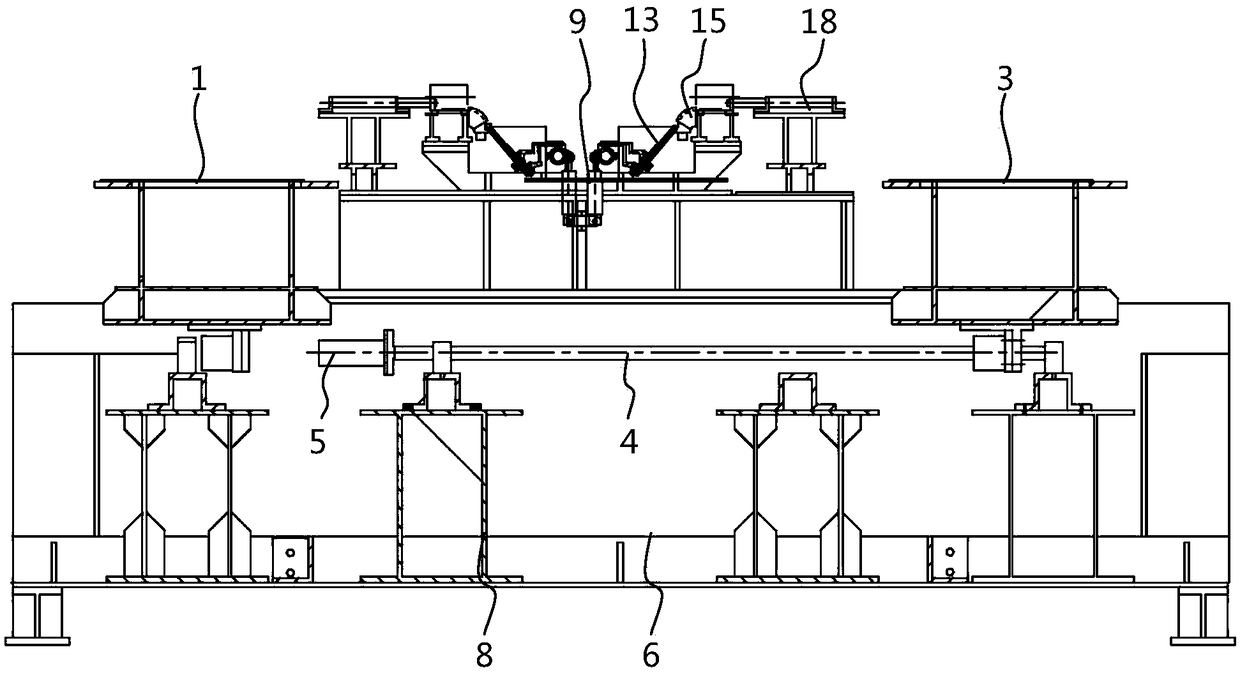

Device and method of automatic material distribution of vulcanization forming blank of framework O-shaped seal ring

The invention discloses a device and a method of automatic material distribution of a vulcanization forming blank of a framework O-shaped seal ring, and belongs to the technical field of rubber chemical engineering machinery equipment. The device comprises a base, a conveying mechanism, a first material distribution mechanism, a second material distribution mechanism and a PLC controller, whereinthe PLC controller is electrically connected with the first material distribution mechanism, the second material distribution mechanism and the conveying mechanism, and two guide rails and a pluralityof fixing bases are arranged on the base in parallel; the conveying mechanism is used for driving a movable material plate to carry out comprehensive material distribution, and the first material distribution mechanism is used for transporting the O-shaped sealing ring blank or an annular steel sheet to a belt conveyor from a hopper; and the distance between a blanking and material falling pointof a material distributing hopper of the first material distribution mechanism and a blanking and material falling point of the material distribution hopper of the second material distribution mechanism is an integer N times of the hole distance of the movable material plate, wherein N is large than or equal to 1 and less than or equal to 8. According to the device and the method, the material which is distributed rapidly in rows and multihole manner is realized, so that the distribution efficiency and automation are improved, the condition of the automatic combination of a material distribution process and a vulcanization feeding process is provided.

Owner:宣城市安工大工业技术研究院有限公司

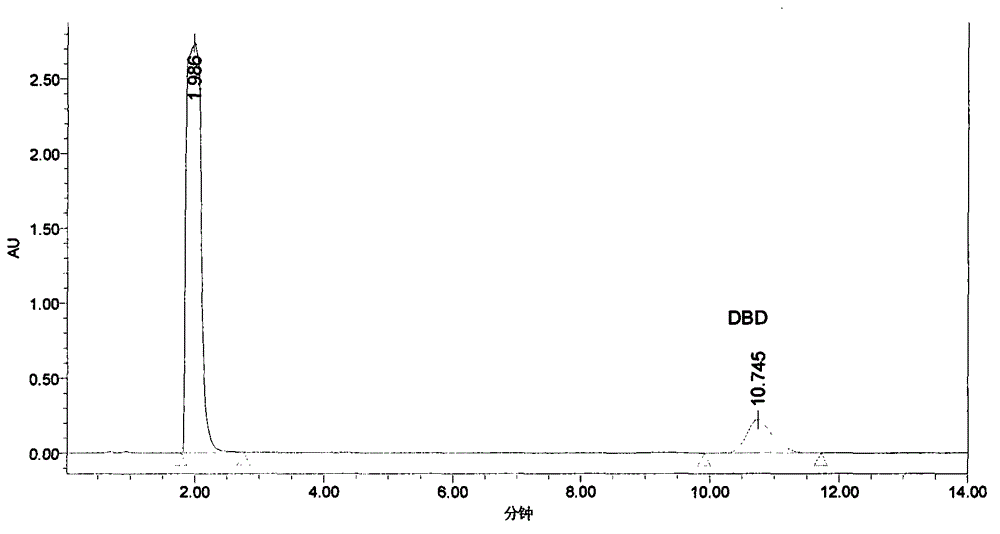

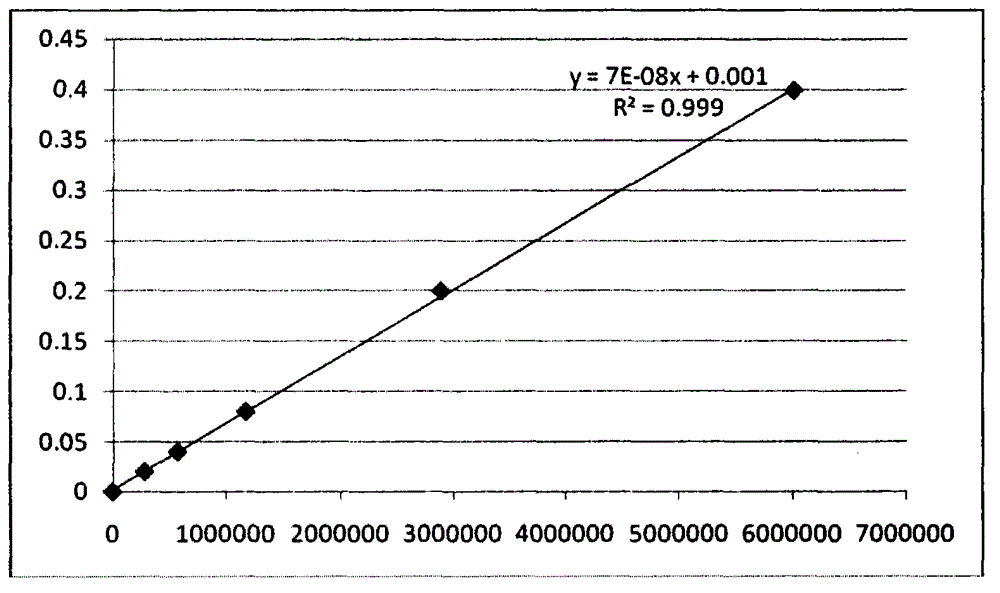

Measuring method for content of DBD (2, 2'-diphenyle formamidodiphenyl disulphide) in rubber chemical peptizer

ActiveCN104458967AFlexible selection of typesEasy to handleComponent separationQuantitative determinationPre treatment

The invention provides a measuring method for content of 2, 2'-diphenyle formamidodiphenyl disulphide (DBD) in a rubber chemical peptizer. The measuring method comprises the following steps: adding a solvent to dissolve a sample, testing filtrate by use of an efficient liquid-phase chromatographic instrument after filing by use of a filter film, and quantitatively measuring the content of the DBD in the sample by comparing with a DBD standard solution. The measuring method disclosed by the invention is flexible in chromatographic column and detector type selection, simple and easy in pre-treatment process, short in analysis time, and high in precision and accuracy, and adopts normal and easily available reagents.

Owner:BEIJING RED AVENUE INNOVA

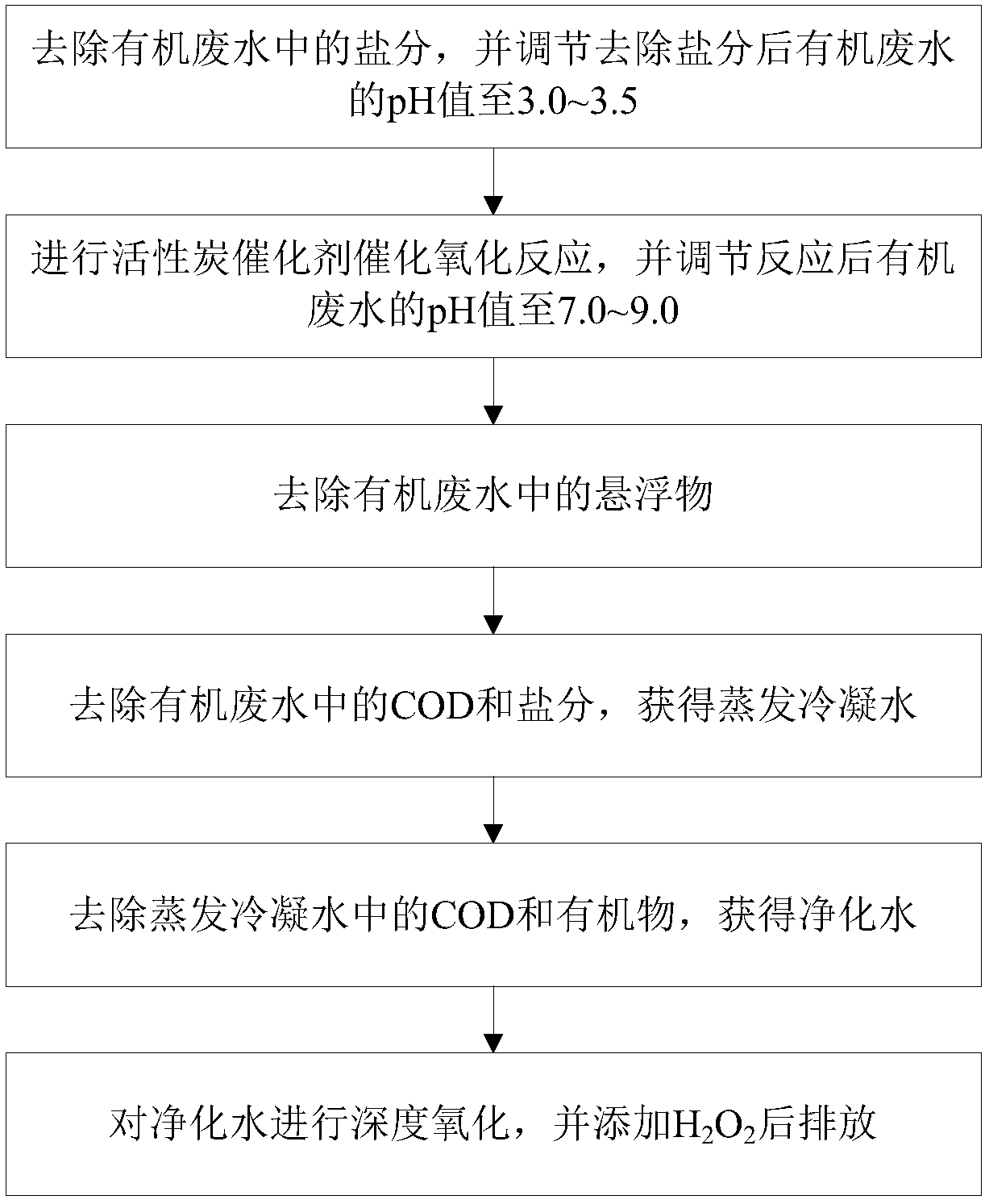

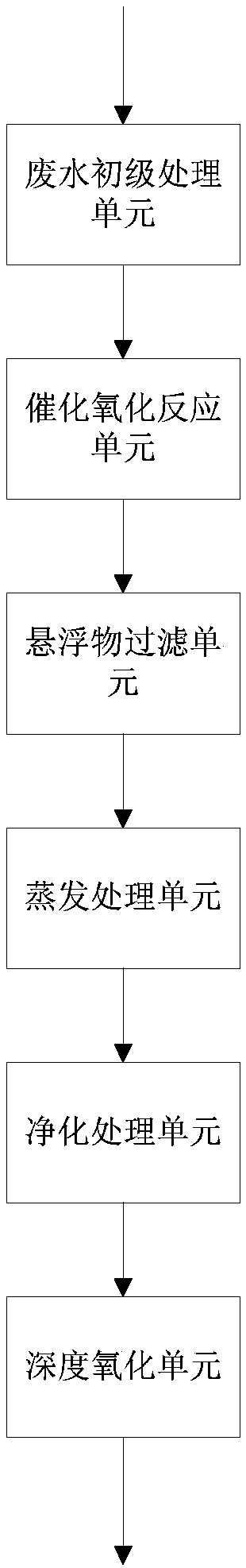

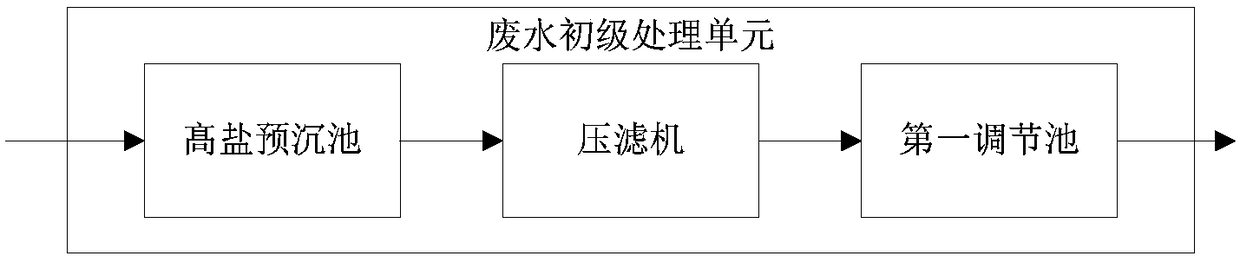

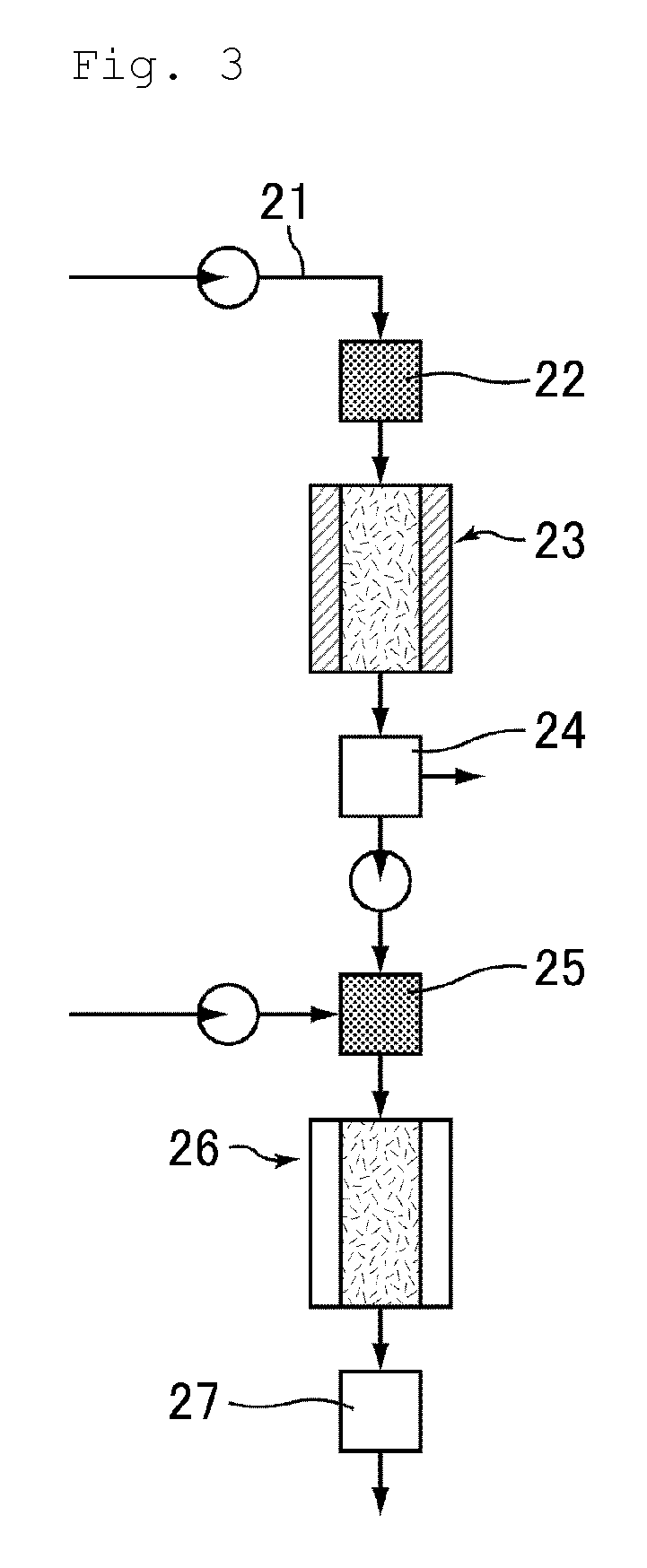

Processing process and processing system of high-concentration organic wastewater with rubber chemicals

PendingCN108218146ALow costSmall footprintWater contaminantsTreatment involving filtrationActivated carbonHigh concentration

The invention discloses a processing process and a processing system of high-concentration organic wastewater with rubber chemicals. The processing process comprises steps of removing salt in the wastewater and regulating pH; performing activated carbon catalyst catalysis oxidation reaction on the wastewater and regulating pH; removing suspended matters in the wastewater; removing COD and salinityin the wastewater; removing COD and organic matters in the wastewater; and deeply oxidizing the wastewater and adding H2O2 and then discharging. The processing process can treat high-concentration organic wastewater with rubber chemicals and discharge the wastewater reaching the standard. The processing system has the advantages of being low in cost, occupying a small area, simple operation conditions, and being suitable for large-scale treatment.

Owner:苏州依斯倍环保装备科技有限公司

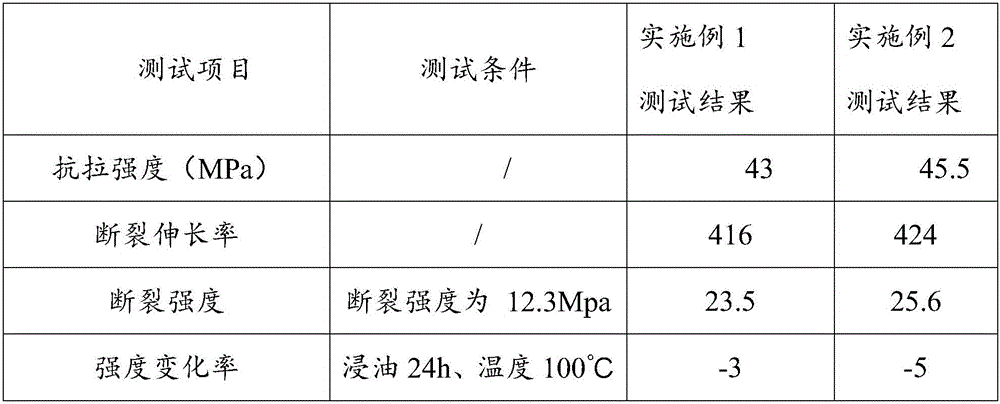

Production method of wear-resisting, oil-resisting insulating sheath material for high-voltage lines

InactiveCN106366487AImprove anti-aging propertiesImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chlorideHigh pressure

The invention relates to the technical field of cable sheaths, and discloses a production method of a wear-resisting, oil-resisting insulating sheath material for high-voltage lines. The method comprises the following steps: (1) preparing filler; (2) adding a base material and auxiliary materials, comprising polyvinyl chloride resin, polybutylene terephthalate and polyethylene wax; (3) adding rubber chemicals; (4) extruding through an extruder, and then cooling and pelleting. According to the method, by reasonably controlling all components in the technology in terms of ratio and processing, the cable material prepared can be high in tensile strength and good in stability, and have excellent water resistance. According to the method, through reasonable blending, compared with a common sheath, the tensile strength and the elongation at break of a sheath is obviously improved, and meanwhile, the oil resistance and the wear-resisting property are greatly improved.

Owner:DEQING BAISHENG PLASTIC CO LTD

Synthesis system, rubber chemical substance for tires, synthetic rubber for tires, and pneumatic tire

ActiveUS9115047B2Reduce the amount requiredEfficient synthesisMolecular sieve catalystsOrganic compound preparationAlcoholAniline

The present invention provides a synthesis system that can synthesize aniline and / or styrene efficiently, a synthesis system that can synthesize butadiene (1,3-butadiene) efficiently, a rubber chemical for a tire which is synthesized from the aniline obtained by the synthesis system, a synthetic rubber for a tire which is synthesized from the styrene and / or butadiene obtained by the synthesis systems, and a pneumatic tire produced using the rubber chemical for a tire and / or the synthetic rubber for a tire. The present invention relates to a synthesis system for synthesizing aniline and / or styrene from an alcohol having two or more carbon atoms via an aromatic compound.

Owner:SUMITOMO RUBBER IND LTD

Predispersions, process for their preparation, compositions therefor, process for the preparation of such compositions

The present invention relates to predispersions of rubber chemicals and to a process for the preparation thereof. The present invention also relates to a novel polymeric composition for dispersing a rubber chemical and to a process for the preparation of said composition.

Owner:SHARMA VIPIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com