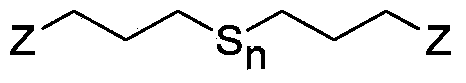

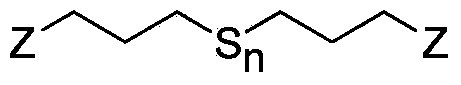

Sulfur-containing silane coupling agent and preparation method thereof

A technology of sulfur silane coupling agent and alkyl, which is applied in the field of sulfur-containing silane coupling agent compounds and their preparation, can solve the problems of reducing rubber porosity, increasing product porosity, increasing organic matter emissions, etc., to achieve the reduction of volatile organic compounds Emissions, avoiding premature scorch, and reducing the effect of organic matter emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 [x=2, y=5, m=1]

[0030] In this embodiment, Route 1 is adopted.

[0031] 1) Preparation of γ-chloropropylethoxypropyl polyether-based silane

[0032] In a 2L dry three-necked flask, under the protection of nitrogen, add 212g (1mol) γ-chloropropyltrichlorosilane, 46g (1mol) ethanol and 560g (2mol) polyethylene glycol monopropyl ether. The molecular formula can be expressed as CH 3 CH 2 CH 2 (OCH 2 CH 2 ) 5 After the OH is mixed evenly, drop it from the constant pressure dropping funnel, discharge the generated hydrogen chloride with nitrogen, and remove it through tail gas absorption treatment. After 30 minutes, the dropwise addition is completed, and the reaction is continued at 90-120°C. After 2 hours, no Then there is ethanol reflux, gas chromatography detects that γ-chloropropyltrichlorosilane and ethanol have completely reacted, stop heating, and after cooling down to below 60°C, reduce the pressure to -0.08Mpa, keep the reduced pressure for 15 minu...

Embodiment 2

[0037] Example 2 [x=2, y≈12, m=1]

[0038] This embodiment adopts route two.

[0039] 1) Preparation of γ-chloropropylethoxybis(polyethylene glycol monomethyl ether) silane

[0040] Add 240g (1mol) γ-chloropropyltriethoxysilane to a dry 2L three-necked flask, add 1100g (2mol) polyethylene glycol with an average molecular weight of 550 (mPEG-550, the average y value is about 12, Aldrich reagent) Alcohol monomethyl ether, under the protection of nitrogen, add 5g of sodium ethylate as a catalyst, start stirring, heat to 90-110°C, distill out the ethanol produced after transesterification, stop the reaction until the ethanol is no longer distilled out, and cool down to After 50°C, start to reduce the pressure to -0.8Mpa to remove the low boiling point. After reducing the pressure for 15 minutes, cool and filter to obtain γ-chloropropylethoxybis(polyethylene glycol monomethyl ether) silane.

[0041] 2) An aqueous solution of sodium polysulfide was prepared in the same manner as i...

Embodiment 3

[0042] Example 3 [x=2, y=5, m=2]

[0043] This embodiment adopts route three.

[0044] Add 530g (1.0mol) bis-[3-(triethoxysilyl)propyl]-tetrasulfide (Si-69) with an average sulfur chain length of 3.75 into a 2L dry three-necked flask, add 840g (2mol) molecular weight 420 polyethylene glycol monotridecyl ether (molecular formula can be expressed as: C 13 h 27 (OCH 2 CH 2 ) 5 OH), add 3g of sodium ethylate as a catalyst, heat to 90-110°C, continue to distill ethanol, react until no ethanol is distilled out, stop the reaction, add a little hydrogen chloride ethanol solution to neutralize to neutral, nitrogen protection to lower the temperature When the temperature is below 50°C, start to decompress and remove the low boiling point. After completion, cool and filter to obtain bis-[3-(diethoxy(polyethylene glycol monotridecyl ether) silicon)propyl]-tetrasulfide . The product is identified by proton nuclear magnetic resonance spectrum, and the result is 1 H-NMR (CDCl 3 , δ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com