Loaded-type rubber vulcanization accelerant as well as preparation method and application thereof

A rubber vulcanization and accelerator technology, applied in the field of loaded rubber vulcanization accelerator and its preparation, can solve the problems of environmental pollution, promotion efficiency to be improved, single function, etc., achieve large specific surface area, increase apparent crosslinking density, Improve the effect of the reinforcing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

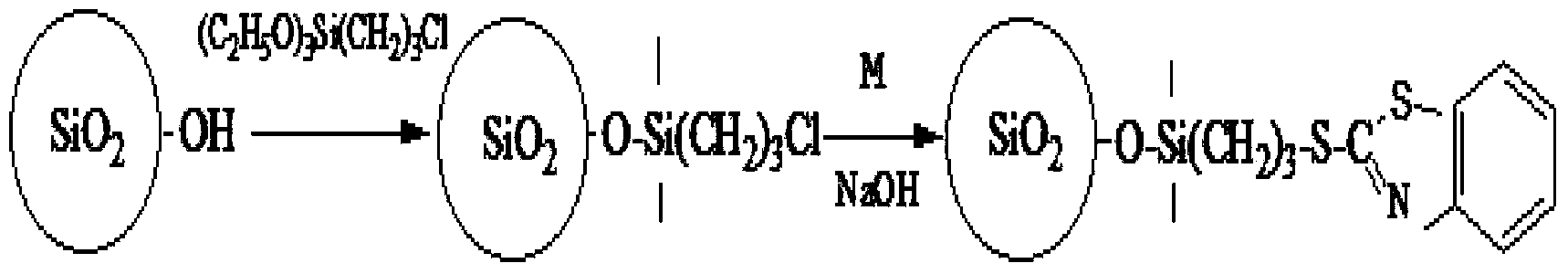

[0023] 20g of precipitated silica (SiO 2 ) was dispersed in 300ml of ethanol, 4g of γ-chloropropyltriethoxysilane was added, and reacted at 70°C for 10 hours to obtain coupling agent modified silica (m-SiO 2 ). Then add 2.8g vulcanization accelerator 2-mercaptobenzothiazole (M) and react at 80°C for 18 hours. The product is centrifuged and washed with ethanol, and dried in a vacuum oven to constant weight to obtain a supported vulcanization accelerator. SiO 2 -g-M.

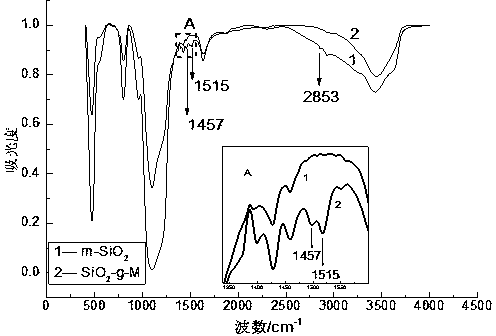

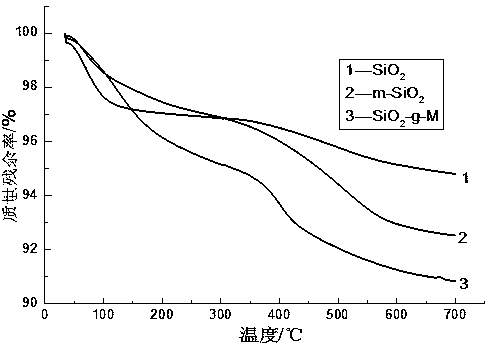

[0024] The infrared spectrum of the above-mentioned loaded vulcanization accelerator after solvent extraction (attached figure 1 ) shows that at 1457cm -1 and 1515cm -1 The absorption band is added at , which corresponds to the vibration absorption of the benzene ring in the accelerator M, indicating that the accelerator M is successfully grafted on the surface of silica through the bridging effect of the coupling agent, and the synthesized product is the target product. Thermogravimetric analysis (attached ...

Embodiment 2

[0034] Dissolve 15g of γ-chloropropyltrimethoxysilane in 80g of acetone, mix it with 150g of halloysite nanotubes (HNTs), stir and react at 50°C for 20 hours, and obtain coupling agent-modified halloysite nanotubes (m-HNTs) dispersion. Then 12 g of vulcanization accelerator M (2-mercaptobenzothiazole) was added, and the reaction was stirred at 50° C. for 20 hours. The product was filtered and dried to constant weight to obtain the supported vulcanization accelerator HNTs-g-M.

[0035] Infrared spectrum showed that the synthesized product was the target product. Thermogravimetric analysis showed that the mass fraction of accelerator M in HNTs-g-M was 3.78%. The basic formula of the styrene-butadiene rubber / halloysite composite material prepared with HNTs-g-M is shown in Table 4, and the vulcanization parameters of the corresponding compound are shown in Table 5. It can be seen from Table 5 that compared with the same amount of unloaded vulcanization accelerator M, HNTs-g-M c...

Embodiment 3

[0044] Dissolve 12g of γ-mercaptopropyltriethoxysilane in 300ml of toluene, then add 45g of fumed silica and stir to disperse into a mixed solution, react at 90°C for 8 hours, then add 12g of vulcanization accelerator N-cyclohexane Base-2-benzothiazole sulfenamide (accelerator CZ), stirred and reacted at 80°C for 8 hours under nitrogen protection. The product is filtered and dried to obtain the final product loaded accelerator SiO 2 -g -CZ.

[0045] Infrared spectroscopy and nuclear magnetic resonance showed that the synthesized product was the target product SiO 2 -g -CZ. Thermogravimetric analysis showed that the mass fraction of N-cyclohexyl-2-benzothiazole sulfenamide in the supported rubber vulcanization accelerator was 3.14%. Table 7 shows that compared with the same amount of unloaded vulcanization accelerator CZ, HNTs-g-CZ can significantly increase the vulcanization rate, shorten the normal vulcanization time Tc90 of the compound, and maintain a longer scorch time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com