Sulfur pre-dispersing mother rubber particle and preparation method thereof

A technology for pre-dispersing masterbatch and sulfur, applied in the field of rubber additives, can solve the problems of reduced deterioration speed and reduced powder loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The sulfur pre-dispersed masterbatch described in this example is composed of the following components in parts by mass: sulfur powder 80; EPDM 12; EVA 4; stearic acid 1; white oil 3.

[0027] The preparation steps of the sulfur pre-dispersed masterbatch particles described in the present embodiment are as follows:

[0028] ⑴Heat the plastic mixer to 90°C, adjust the roller distance to 0.5-1 mm, put EPDM and EVA into the plastic mixer according to the ratio and mix them evenly, then add stearic acid, after the mixing is even, take off the sheet, and cool down to room temperature for use .

[0029] ⑵ Mix the mixture obtained in ⑴ with sulfur powder and white oil according to the ratio on the open mill, and mix evenly, then tablet and granulate.

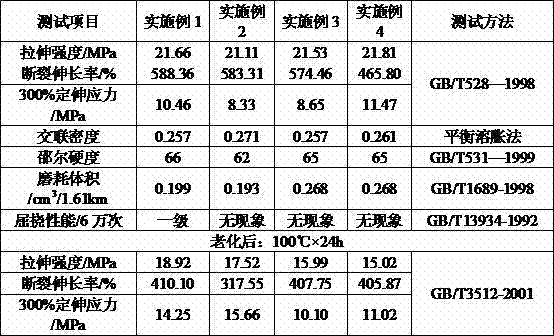

[0030] The sulfur pre-dispersed masterbatches prepared according to this embodiment are S-80A type sulfur pre-dispersed masterbatches. It is used in the tread rubber formulation for performance testing, and the test re...

Embodiment 2

[0032] The sulfur pre-dispersed masterbatch described in this example is composed of the following components in parts by mass: sulfur powder 80; EPDM 6; EVA 4; POE 6; stearic acid 1; white oil 3.

[0033] The preparation steps of the sulfur pre-dispersed masterbatch particles described in the present embodiment are as follows:

[0034] ⑴Heat the plastic mixer to 90°C, adjust the roller distance to 0.5-1 mm, put EPDM, POE and EVA into the plastic mixer according to the proportion and mix them evenly, then add stearic acid, after mixing evenly, release the sheet, and lower to room temperature stand-by.

[0035] ⑵ Mix the mixture obtained in ⑴ with sulfur powder and white oil according to the ratio on the open mill, and mix evenly, then tablet and granulate.

[0036] The sulfur pre-dispersed masterbatch prepared according to this embodiment is S-80B type sulfur pre-dispersed masterbatch. It is used in the tread rubber formulation for performance testing, and the test resul...

Embodiment 3

[0038] The sulfur pre-dispersed masterbatch described in this example is composed of the following components in parts by mass: sulfur powder 80; EVA 4; POE 12; stearic acid 1; white oil 3.

[0039] The preparation steps of the sulfur pre-dispersed masterbatch particles described in the present embodiment are as follows:

[0040] ⑴Heat the plastic mixer to 90°C, adjust the roller distance to 0.5-1 mm, put POE and EVA into the plastic mixer according to the ratio, mix evenly, add stearic acid, and mix evenly, then release the sheet, and lower it to room temperature for use .

[0041] ⑵ Mix the mixture obtained in ⑴ with sulfur powder and white oil according to the ratio on the open mill, and mix evenly, then tablet and granulate.

[0042] The sulfur pre-dispersed masterbatches prepared according to this embodiment are S-80C type sulfur pre-dispersed masterbatches. It is used in the tread rubber formulation for performance testing, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com