Patents

Literature

57results about How to "Achieve dispersion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

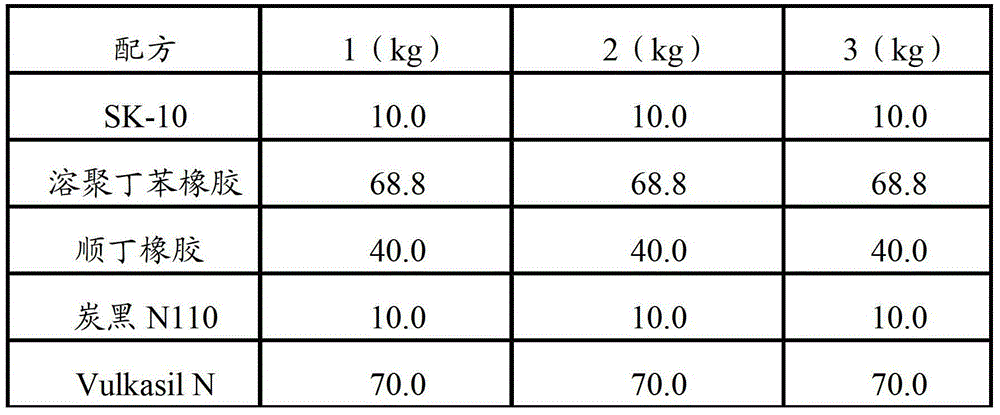

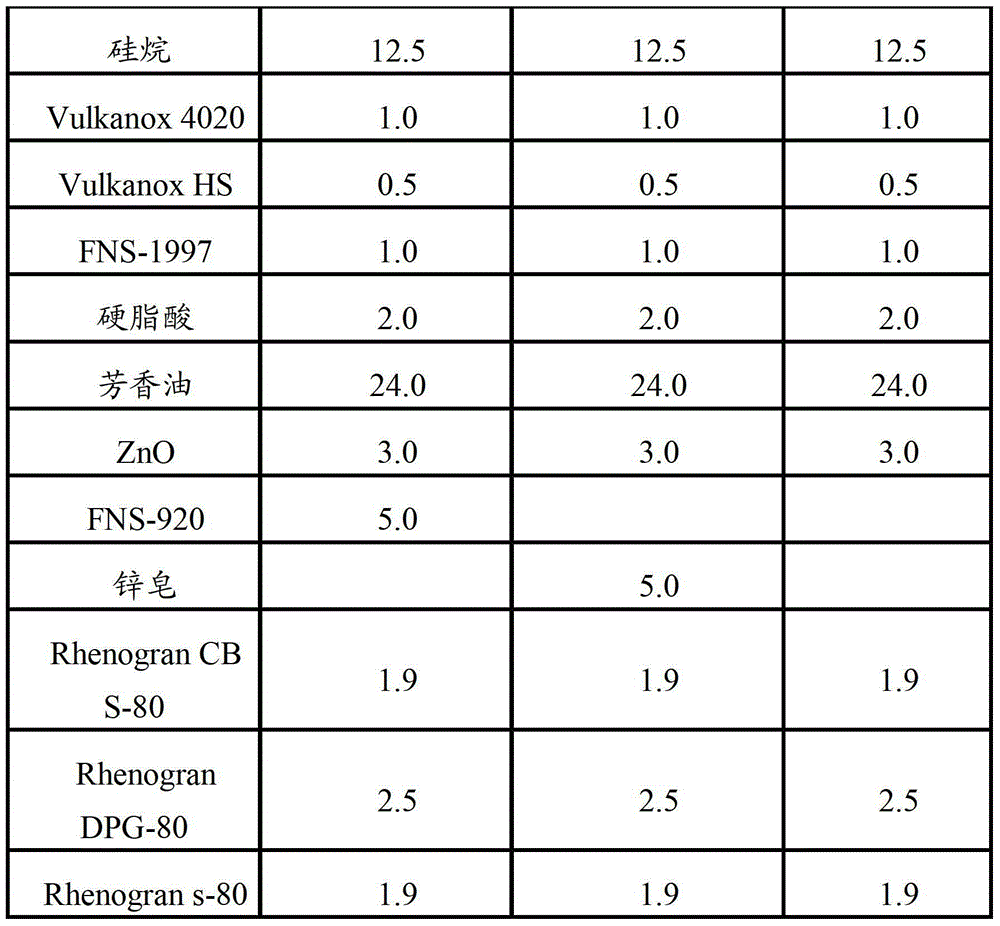

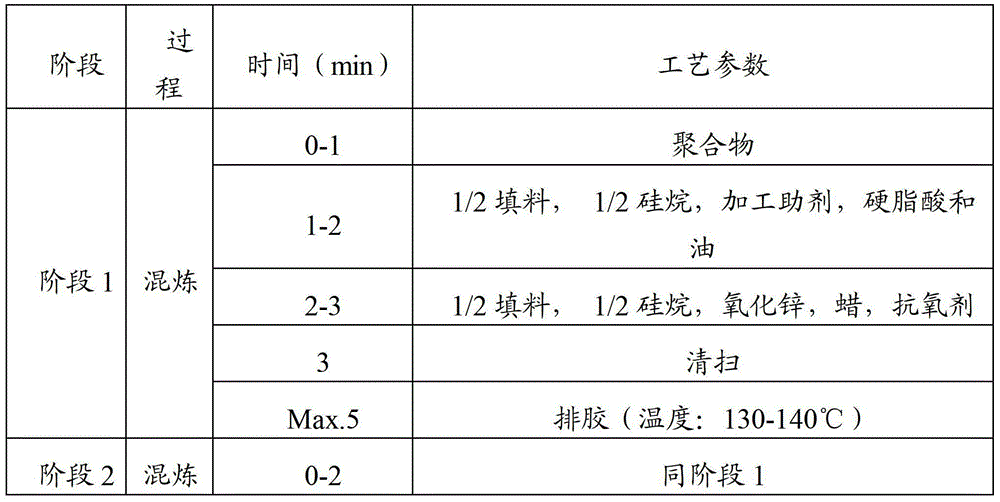

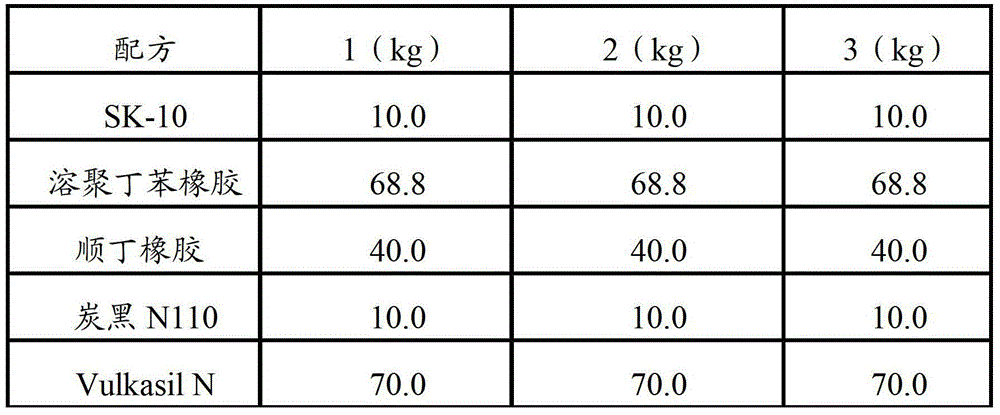

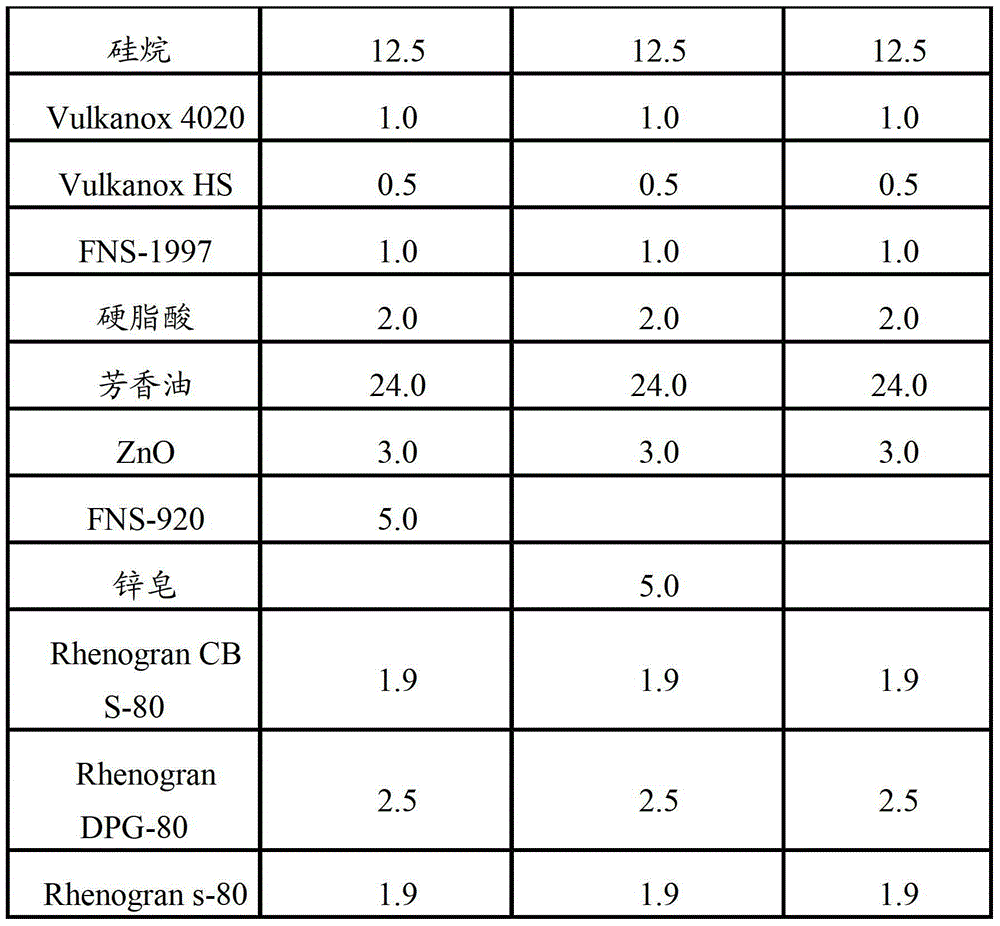

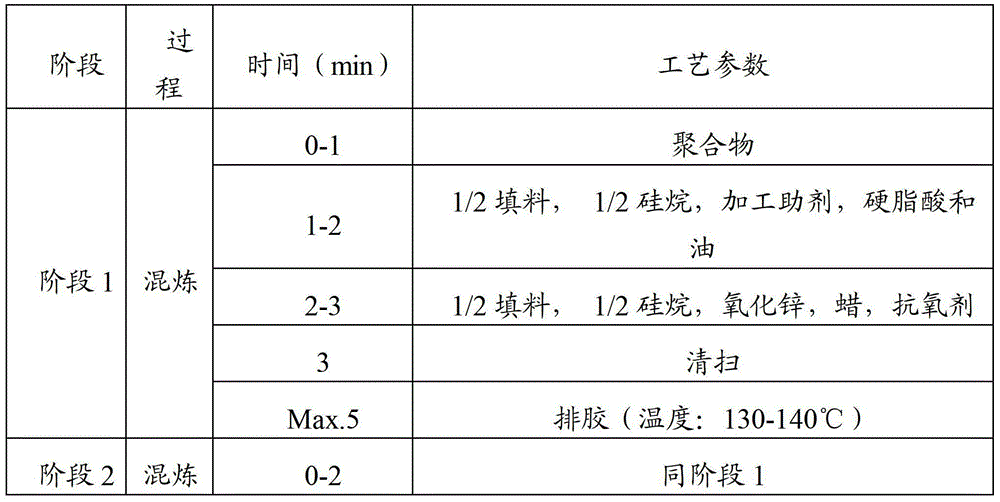

White carbon black dispersant and preparation method thereof

The invention discloses a white carbon black dispersant. The white carbon black dispersant comprises, by mass, 40 to 60% of C8-C22 fatty acid, 5 to 25% of protection wax, 10 to 28.8% of fatty acid ester, 6 to 10% of an inorganic filling material and 0.96 to 5% of an anti-oxidant. The invention also discloses a preparation of the white carbon black dispersant having a good white carbon black dispersion effect. The white carbon black dispersant is an environmentally-friendly high-dispersibility zinc-free white carbon black dispersant, can improve dispersibility of a filling material and rubber chemicals in rubber in rubber mixing, is suitable for improvement of dispersibility of rubber containing high-activity white carbon black, avoids re-condensation, improves wet-skid resistance of a tyre surface, and avoids the pollution produced heavy metal zinc on the environment.

Owner:青岛福凯橡塑新材料有限公司

Preparation method of flaky metal powder

ActiveCN103122465AThe process is reasonable and convenientPrepared products of good qualityElectrochemical responseElectrochemistry

The invention relates to a preparation method of flaky metal powder. The preparation method comprises the following steps in sequence: machining a metal to be prepared into flaky powder into a flake and using the flake as a soluble anode; in an anode chamber of an electrochemical reactor, taking sulfate of the metal and sulfuric acid water solution as an electrolyte, oxidizing the soluble anode into corresponding metal ions and enabling the metal ions to enter anolyte; and after solid-liquid separation and anolyte impurity removal, adding an alkyl glycoside surfactant to the anolyte and adjusting the pH value to 5.0-6.5, then injecting the electrolyte into a cathode chamber of the electrochemical reactor, carrying out electrochemical reduction reaction on the cathode and separating out the metal to be prepared through deposition, simultaneously starting an ultrasonic generating device to strip the metal to be prepared on the cathode and deposit the metal to be prepared in the electrolyte below the cathode and then obtaining the qualified flaky metal powder through solid-liquid separation, washing, vacuum drying, screening and packaging. The preparation method has the advantages of reasonable and convenient process, safe and reliable preparation course and good prepared product quality.

Owner:YANGZHOU SHUANGSHENG ZINC IND

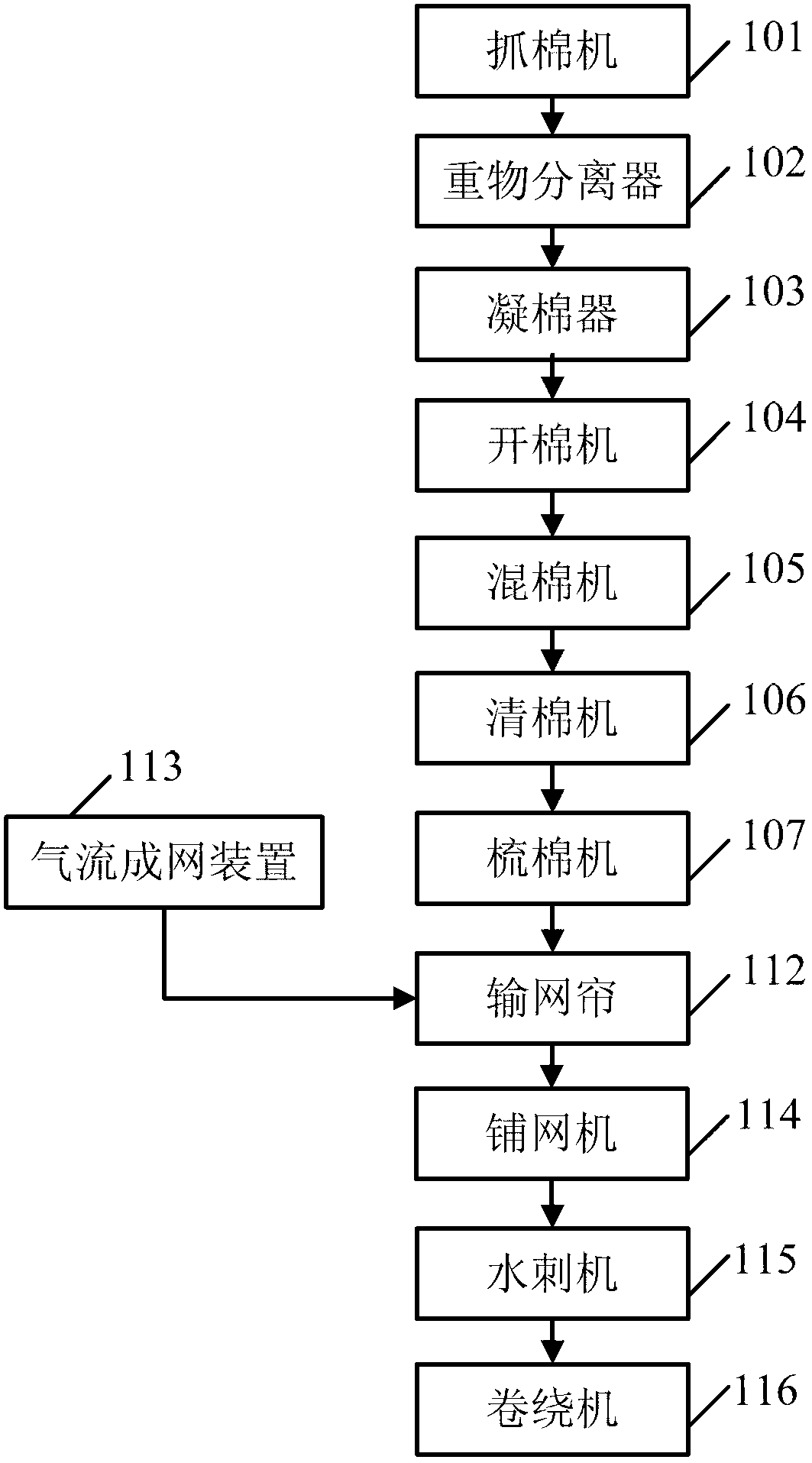

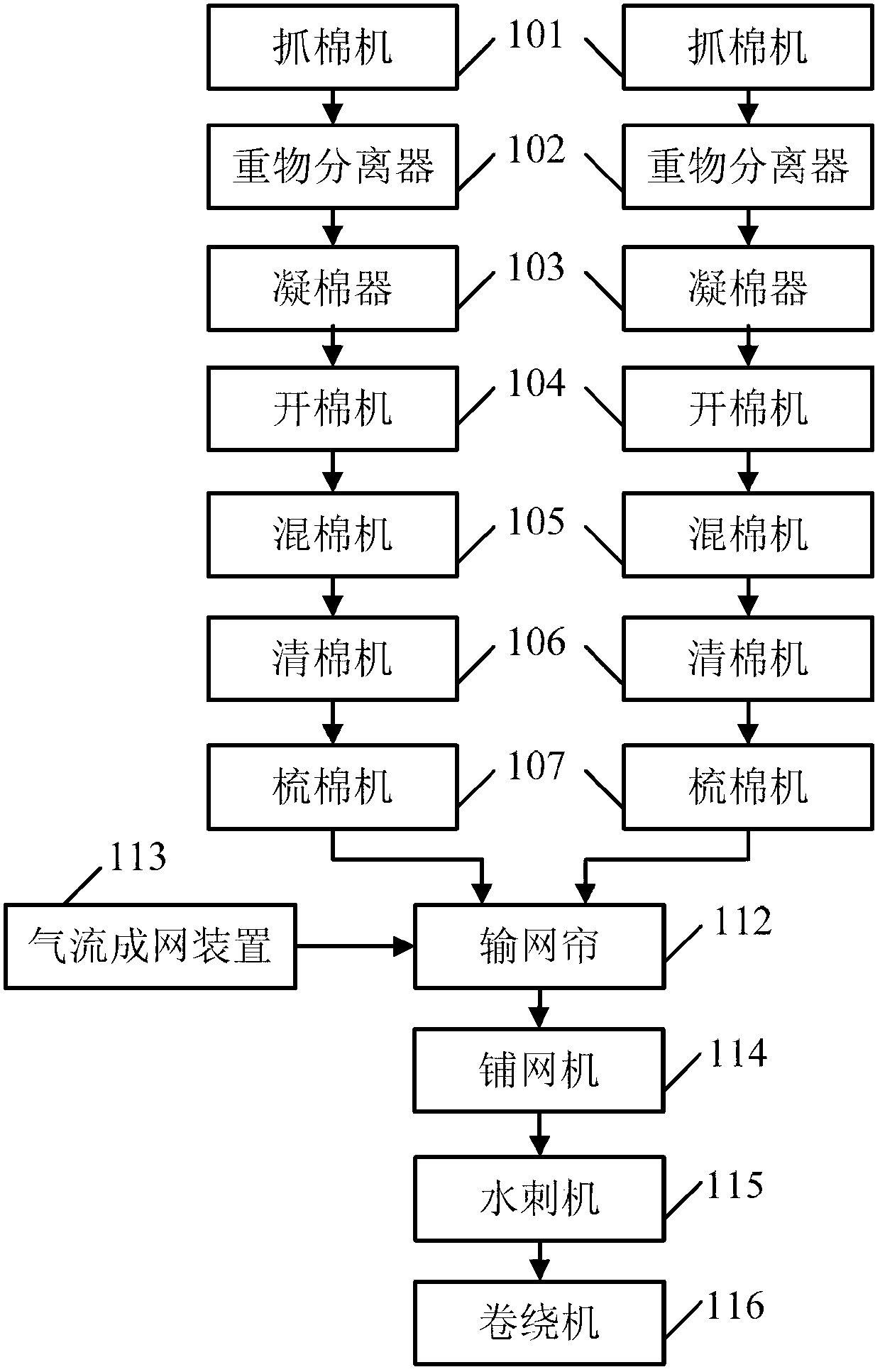

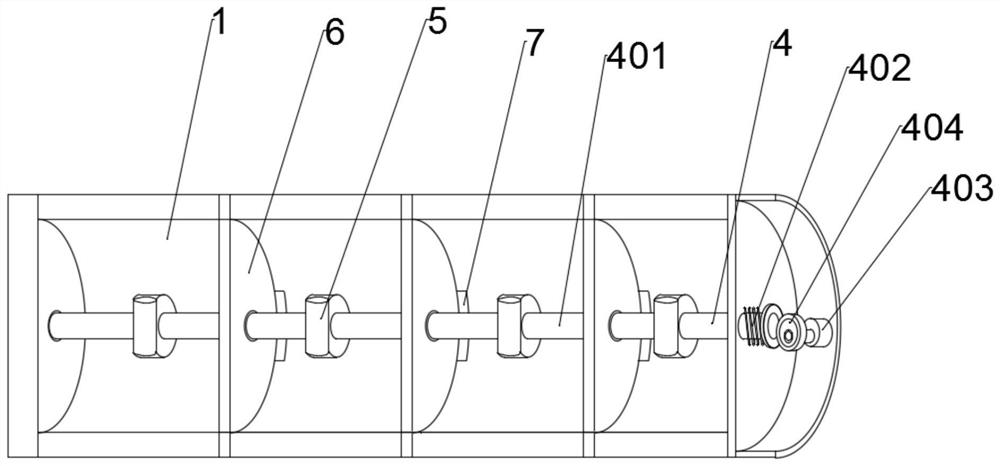

Spunlaced non-woven material, manufacturing method, manufacturing equipment and hygienic wet tissue

ActiveCN103215750AWill not polluteAchieve dispersion effectNon-woven fabricsFiber layerWinding machine

The invention discloses spunlaced non-woven material manufacturing equipment, comprising a bale plucker, a weight separator, a condenser, an opener, a cotton mixing machine, a scutcher, a carding machine, an air laying device, a web conveying curtain, a lapping machine, a spunlace machine and a winding machine. The spunlaced non-woven material manufacturing method comprises the steps of cotton plucking, weight separation, condensation, opening, mixing, cleaning, carding, air laying, jointing, lapping, spunlace, bleaching and winding. The spunlaced non-woven material manufactured by the manufacturing equipment and the manufacturing method comprises a pure cotton short fiber layer combined at one side of a pure cotton long fiber layer or between multiple pure cotton long fiber layers, and the short fiber layer is bonded on the long fiber layer. A hygienic wet tissue manufactured by the spunlaced non-woven material can realize good dispersion effect in water, can be directly thrown into a toilet after being used, has no stimulation to skin and causes no pollution to the environment.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

Formula and smelting key technique for high-strength and high-tenacity aluminum alloy

InactiveCN108300910AImprove thermal conductivityGood castabilityTransportation and packagingMixersThermal treatmentAluminium alloy

The invention discloses a formula and a smelting key technique for a high-strength and high-tenacity aluminum alloy. The high-strength and high-tenacity die-casting aluminum alloy has good casting performance, mechanical performance and thermal treatment performance, and also has high strength and tenacity, so that the mechanical performance of the aluminum alloy is good; recording of cicada chirping is placed in a metal fluid in the smelting key technique, so that characteristic sound vibration of cicada chirping can spread in the metal fluid; according to observation, sound vibration of cicada chirping can generate more scattering and dissipating in a spreading medium compared with sound vibration with more low-frequency components; and more ripples can be motivated on the surface of themetal fluid.

Owner:深圳市博锐专利新技术服务有限公司

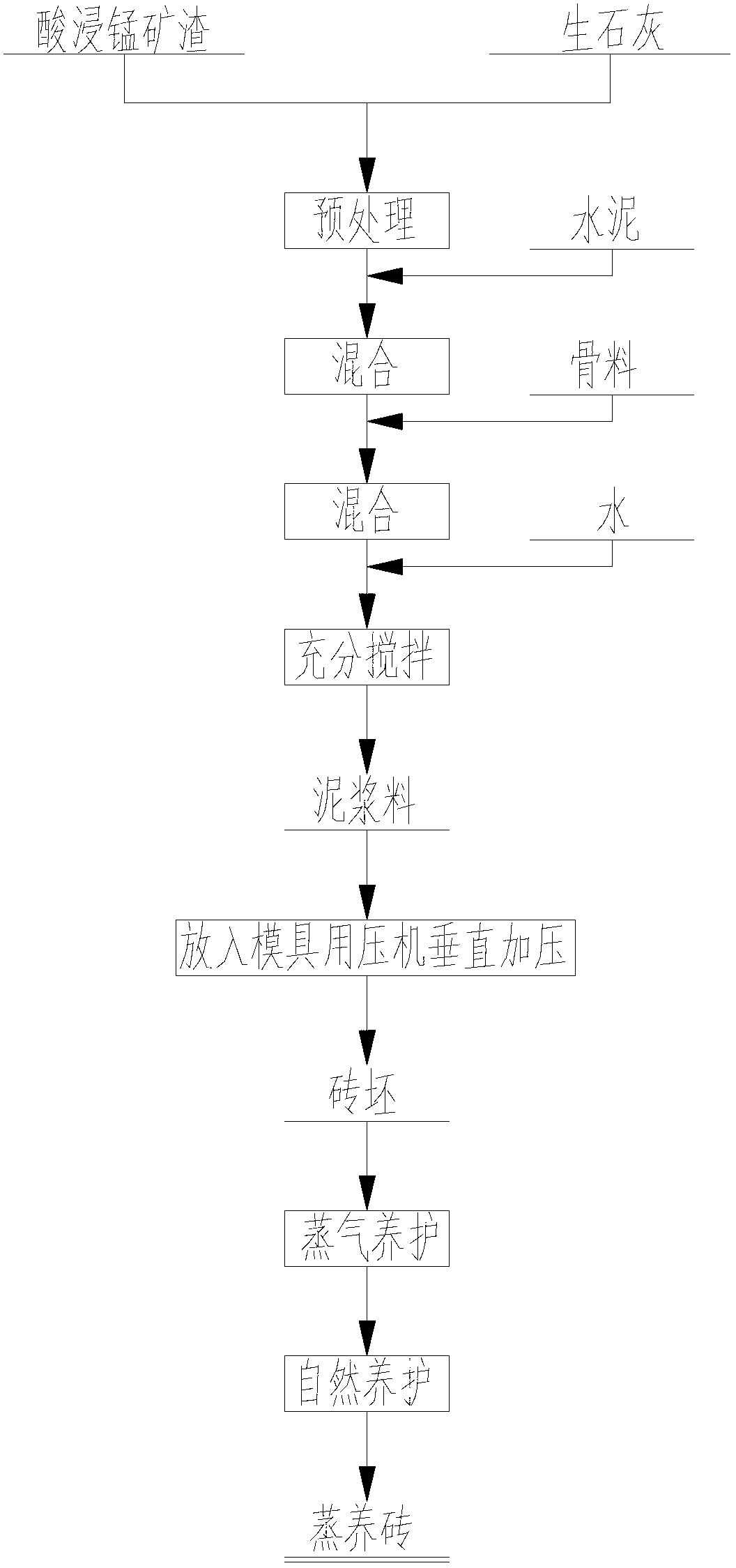

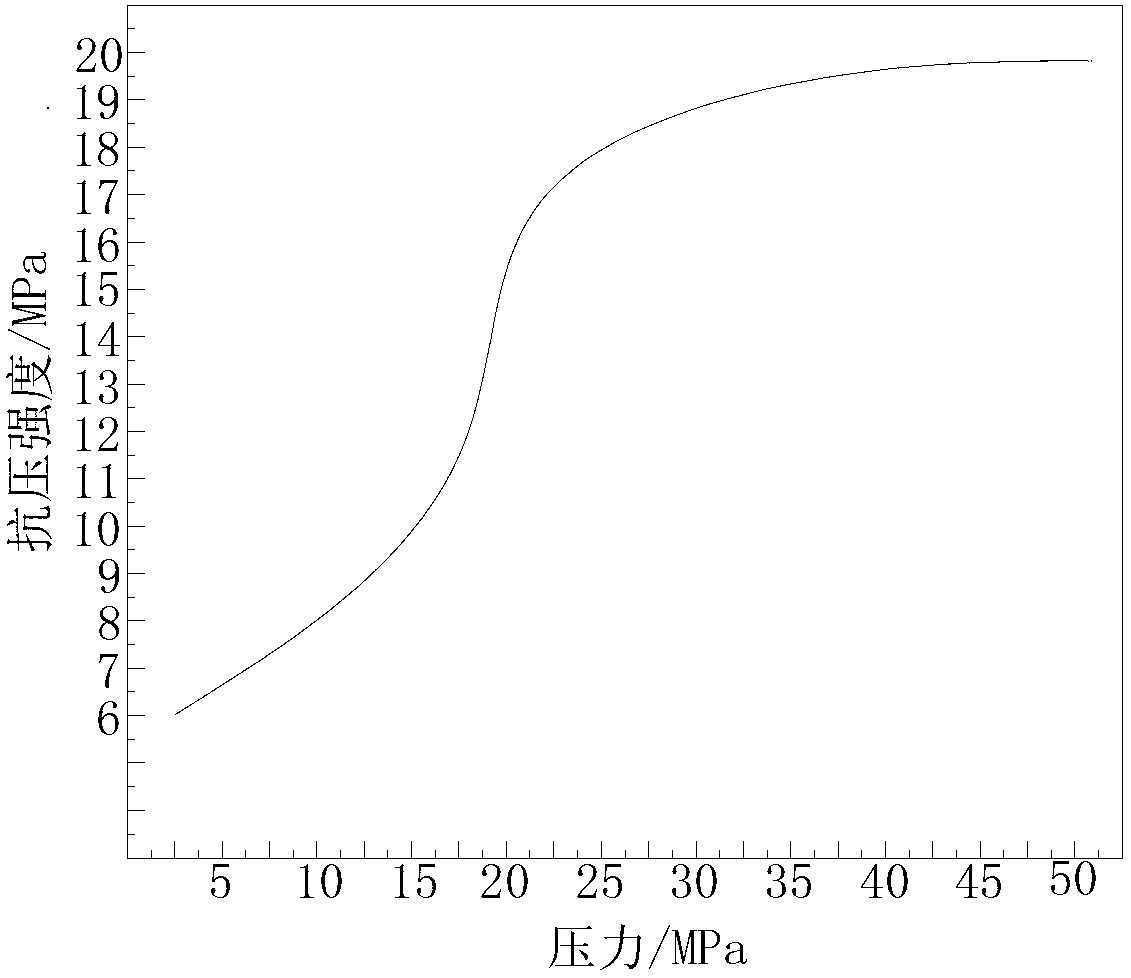

Method for preparing slag steam-cured brick

InactiveCN103193441AAvoid secondary pollutionEmission reductionSolid waste managementCeramic shaping apparatusWater bathsBrick

The invention discloses a method for preparing a slag steam-cured brick. The method comprises the following steps of adding quick lime to acid-leaching manganese slag according to a ratio, and carrying out pretreatment on the acid-leaching manganese slag; mixing the preprocessed acid-leaching manganese slag, cement and aggregate according to a certain ratio to obtain a mixture; adding water to the final mixture according to a certain water-solid ratio; agitating to obtain a slurry mixture; putting the slurry mixture into a home-made die to primarily mold; vertically pressurizing and molding the primarily molded brick by an electric oil press pressure head from top to bottom; obtaining a high-strength brick after pressurizing for a period of time; putting the high-strength brick into a constant-temperature water bath pan to carry out steam curing after a period of time; controlling the heating speed, and keeping the constant temperature for a period of time when certain temperature is achieved; taking out the steam-cured brick and putting in a room temperature environment; and naturally maintaining for 28 days by watering normal-temperature moisture measures to obtain the baking-free slag brick.

Owner:CENT SOUTH UNIV +1

Formula of high-strength high-toughness aluminum alloy and smelting key technology thereof

The invention provides a formula of a high-strength high-toughness aluminum alloy and a smelting key technology thereof. The high-strength high-toughness aluminum alloy has good casting properties, mechanical properties and heat treatment properties, and further has relatively high strength and toughness, so that mechanical properties of the aluminum alloy are good. In the smelting key technology,a cicada chirping record is placed into a metal liquid, so that characteristic sound vibration of cicada chirping can spread in the metal liquid, it is observed that compared with low-frequency soundvibration with multiple components, sound vibration of cicada chirping can better scatter and dissipate in a communication medium, and more ripples can be aroused on the surface of the metal liquid.

Owner:东莞市金羽丰知识产权服务有限公司

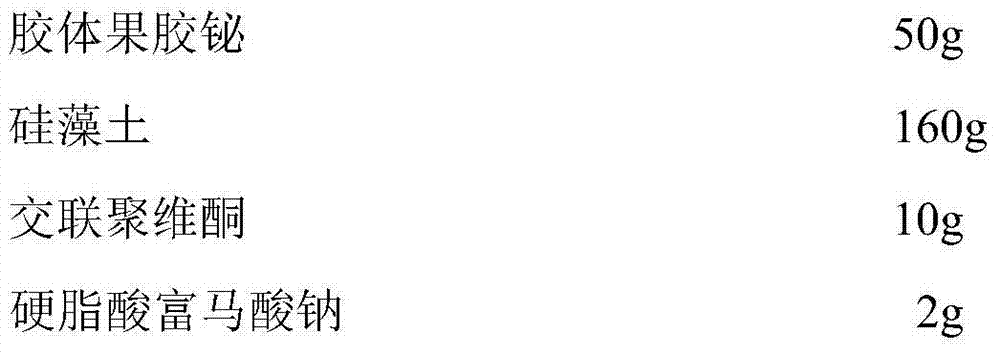

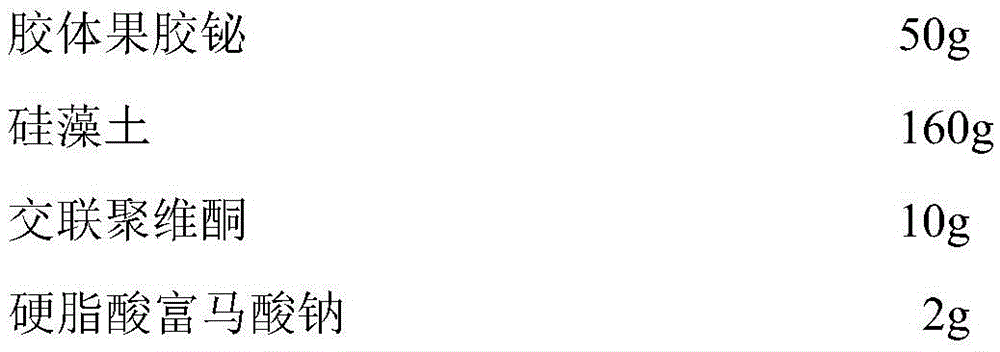

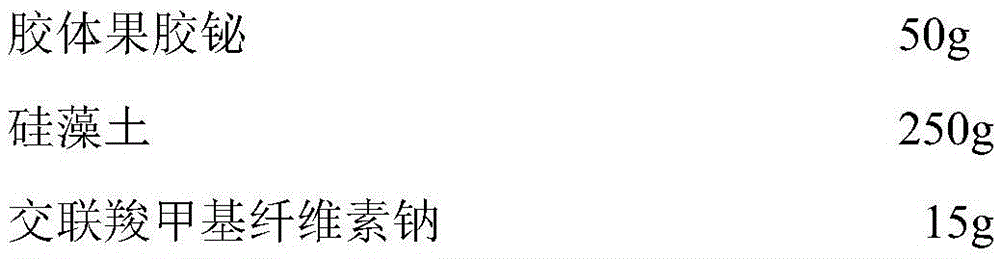

Colloidal bismuth pectin capsule and preparation process thereof

ActiveCN104116721AStrong adsorptionSimple preparation processAntibacterial agentsOrganic active ingredientsChemistryBall mill

The invention discloses a colloidal bismuth pectin capsule and a preparation process thereof. The capsule is formed by filling content into a capsule shell, and the content contains kieselguhr of adsorbing colloidal bismuth pectin. By adopting the preparation process, the colloidal bismuth pectin and the kieselguhr are added to a ball grinder so as to be crushed, and the colloidal bismuth pectin can be evenly adsorbed on the surface of the kieselguhr or into holes after the colloidal bismuth pectin and the kieselguhr are crushed, so that the medicine is prevented from easily agglomerating in water.

Owner:桂林华信制药有限公司

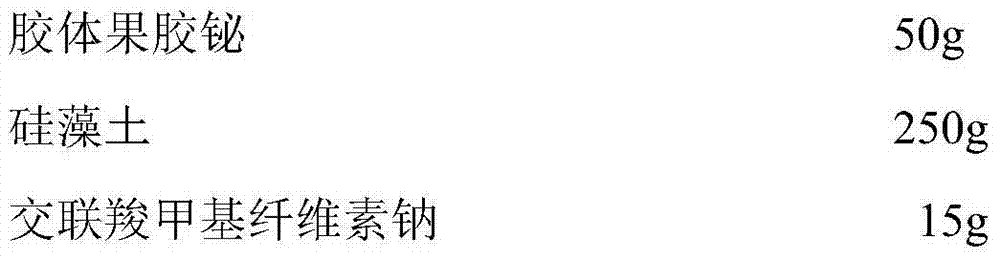

Yellow cadmium-wrapped pigment, ceramic ink and preparation method thereof

The invention discloses a yellow cadmium-wrapped pigment. The fineness of pigment powder is 0.5 to 3 [mu]m. The invention further provides a method of the yellow cadmium-wrapped pigment. The method comprises the following steps: putting cadmium sulfate, zirconium oxychloride, thiourea, urea, white carbon black, polycarboxylate and polyvinylpyrrolidone which serve as raw materials into water, mixing and stirring till the raw materials are dissolved, putting the solution into a reaction kettle, carrying out reaction under conditions of the temperature of 60 to 200 DEG C and rotating speed of 100 to 300 r / min for 5 to 24 hours, after the reaction is completed, carrying out natural cooling to obtain a pigment precursor, and carrying out washing, sintering and drying to obtain the yellow cadmium-wrapped pigment finished product. The mole ratio of the cadmium sulfate, the zirconium oxychloride, the thiourea, the urea, the white carbon black, the polycarboxylate and the polyvinylpyrrolidone is (6 to 15): (25 to 40): (5 to 35): (60 to 250): (10 to 50): (0.02 to 8.0): (0.01 to 4.0).

Owner:FOSHAN HUAYI CERAMIC COLORS CO LTD

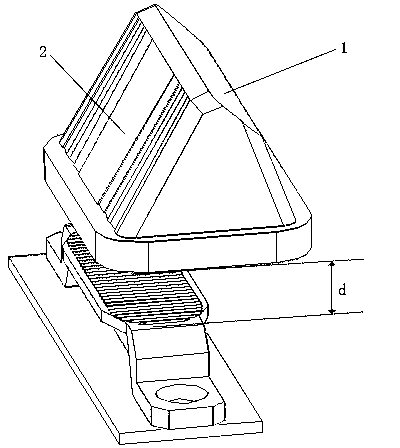

LED navaid lamp optical assembly used for generating rectangular spots

ActiveCN103267262ASimplify stand-alone structuresAchieve dispersion effectLighting applicationsPoint-like light sourcePrismExit surface

The invention discloses an LED navaid lamp optical assembly used for generating rectangular spots. The LED navaid lamp optical assembly used for generating the rectangular spots comprises a prism and a lens under the prism. A plurality of lens incident planes which are mutually independent are arranged on the bottom surface of the lens. A curved surface is arranged at the upper portion of the lens and the curved surface combines with the lens indecent planes at the bottom of the lens together to form a lens exit plane. Two adjacent prism exit planes are arranged on the prism, wherein a curved surface is arranged on one prism exit plane, after a black coating film is painted on the prism exit plane, a prism reflecting plane is formed. A prism indecent plane is arranged at the bottom of the prism. The prism indecent plane and the lens exit plane at the upper portion of the lens are mutually parallel. The LED navaid lamp optical assembly used for generating the rectangular spots has the advantages that the lens and the prism are respectively provided with the curved surfaces, and the lens exit plane and the prism reflecting plane are formed respectively, an independent structure of a light scattering piece is eliminated, space is saved, matching with a navaid lamp, the rectangular spots which meet requirements can be generated by only two LEDs under the driving of small current, luminous efficiency is improved, power is reduced, and energy is remarkably saved.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

A kind of colloidal bismuth pectin capsule and its preparation process

ActiveCN104116721BWell mixedSmall particle sizeAntibacterial agentsOrganic active ingredientsBismuth / pectinChemistry

The invention discloses a colloidal bismuth pectin capsule and a preparation process thereof. The capsule is formed by filling content into a capsule shell, and the content contains kieselguhr of adsorbing colloidal bismuth pectin. By adopting the preparation process, the colloidal bismuth pectin and the kieselguhr are added to a ball grinder so as to be crushed, and the colloidal bismuth pectin can be evenly adsorbed on the surface of the kieselguhr or into holes after the colloidal bismuth pectin and the kieselguhr are crushed, so that the medicine is prevented from easily agglomerating in water.

Owner:桂林华信制药有限公司

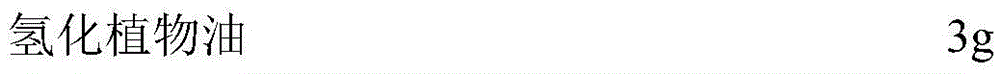

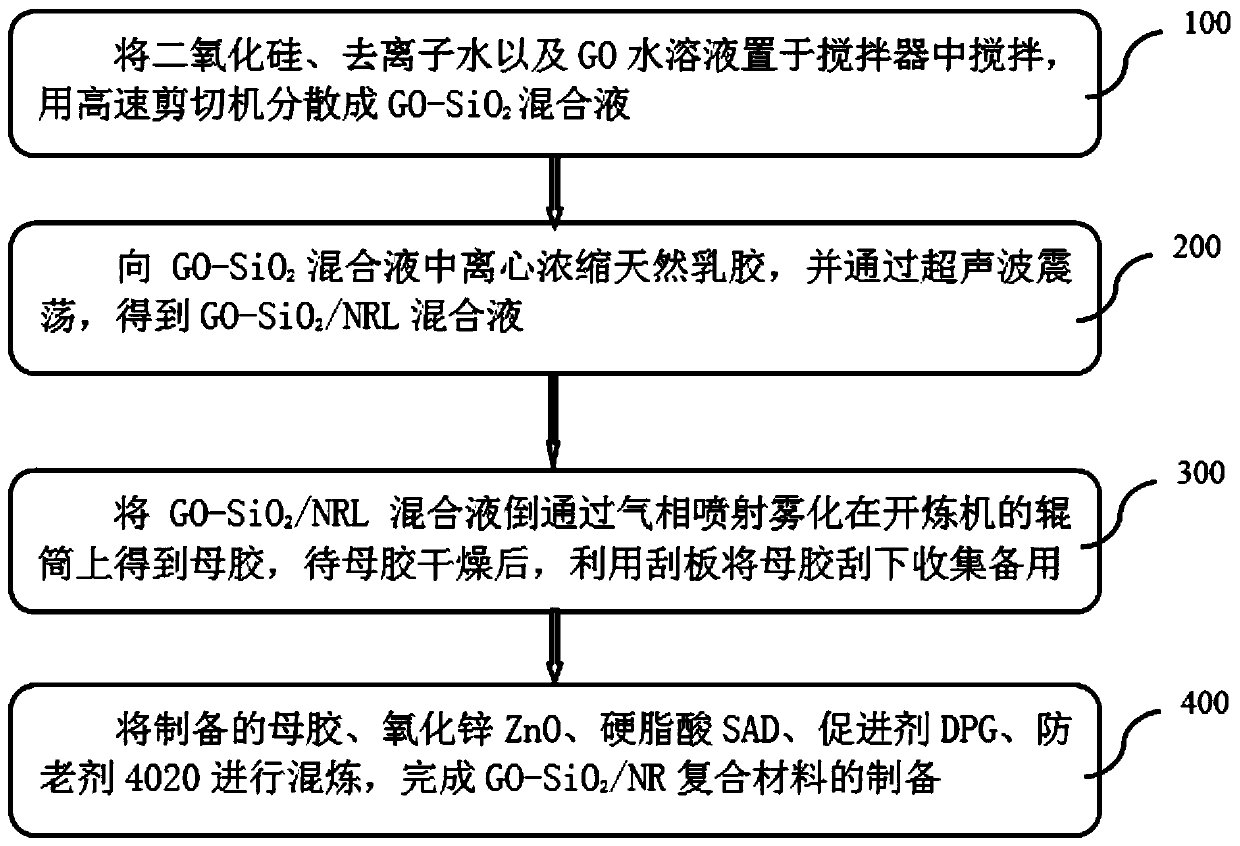

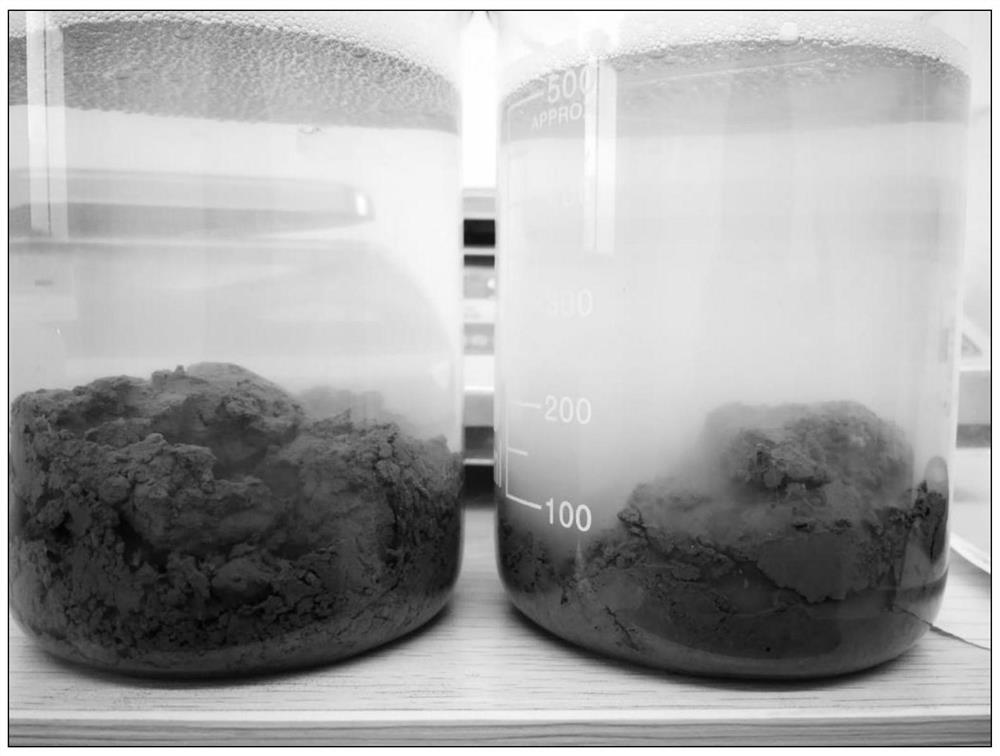

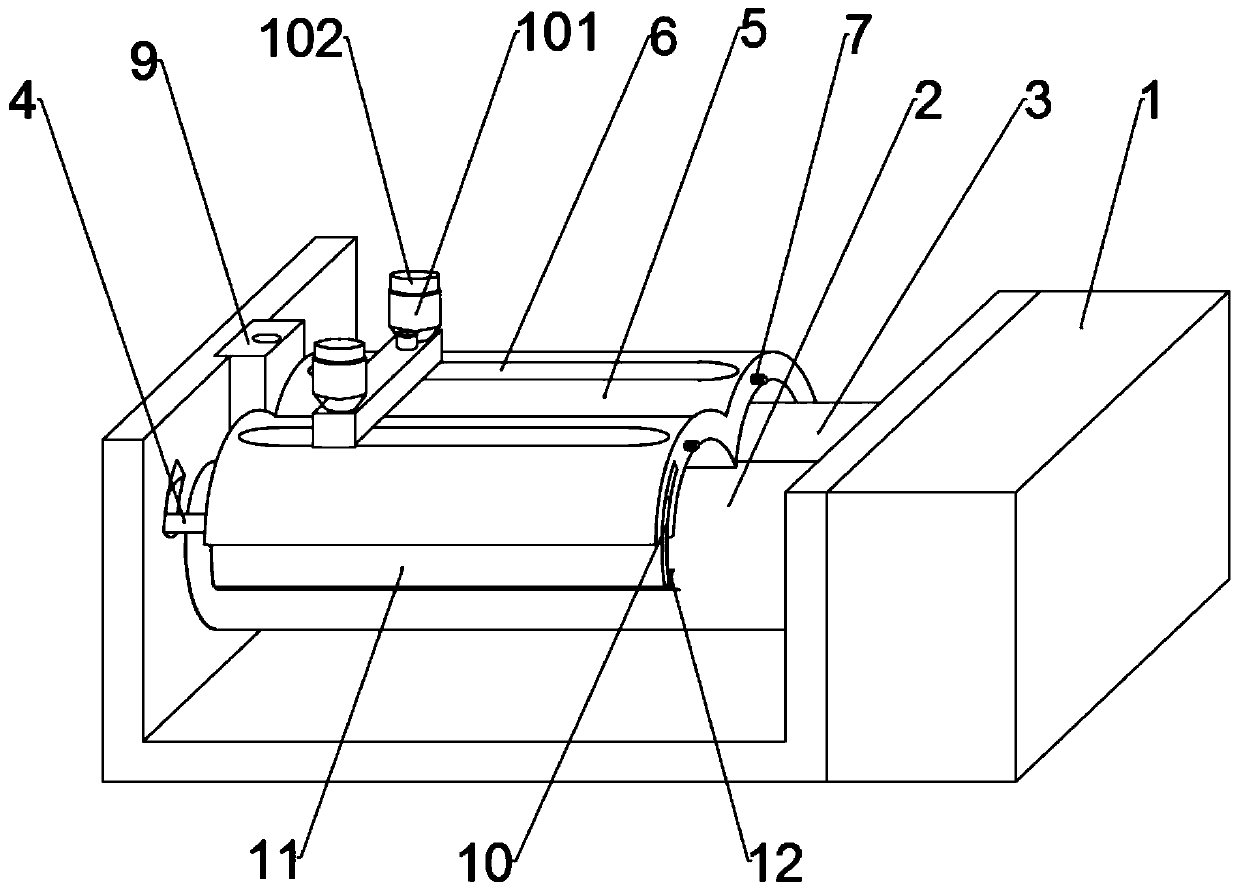

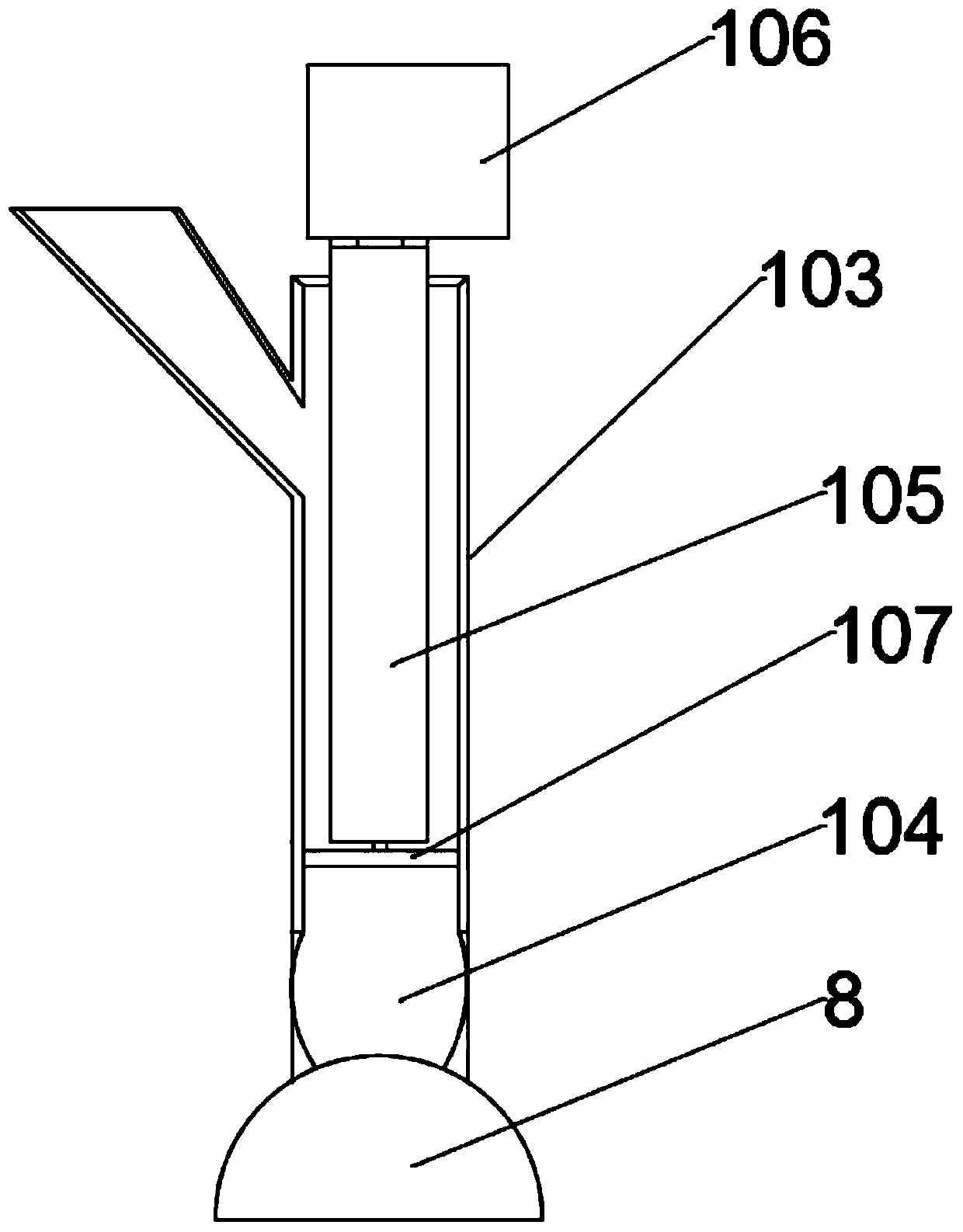

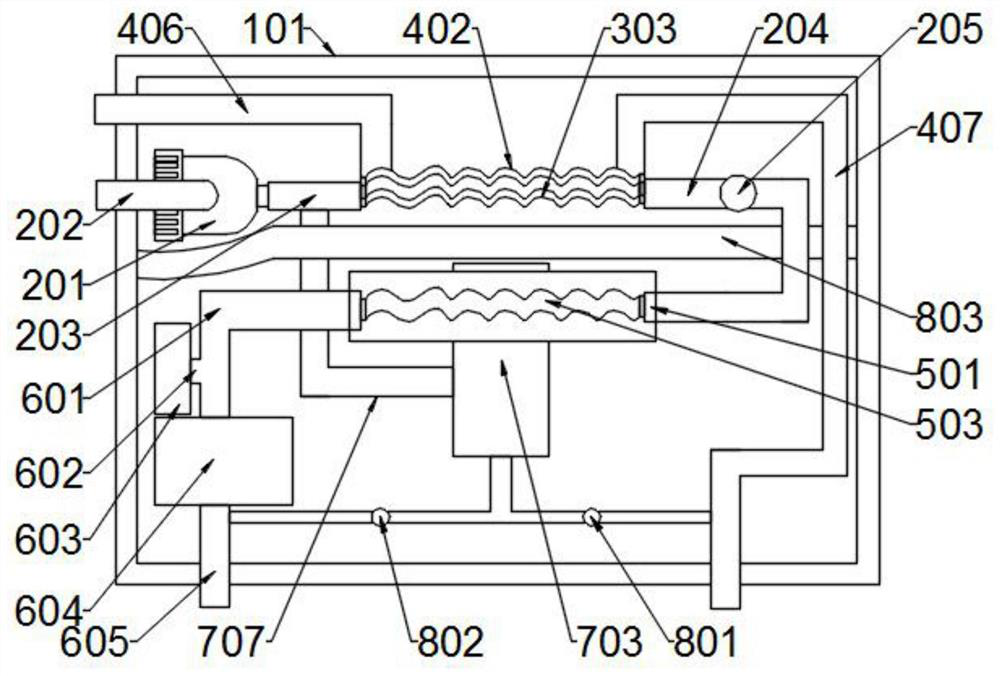

GO/NR composite preparation method and open mill for preparation thereof

ActiveCN109940776AAchieve dispersion effectThe process is simple and easy to controlPolymer scienceUltrasonic vibration

The invention discloses a GO / NR composite preparation method which comprises the following steps of S100, putting silicon dioxide, deionized water and a GO aqueous solution into a stirrer for stirring, and dispersing a mixture into a GO-SiO2 mixed liquid with a high-speed shearing machine; S200, adding 100 parts of centrifugal concentrated natural latex by mass in the GO-SiO2 mixed liquid, and performing ultrasonic vibration to obtain a GO-SiO2 / NRL mixed liquid; S300, pouring the GO-SiO2 / NRL mixed liquid into an open mill, obtaining a rubber master batch on a roller of the open mill, and scraping and collecting the rubber master batch with a scraper on the roller after the rubber master batch is dried for later use; and S400, mixing the prepared rubber master batch, zinc oxide (ZnO), stearic acid (SAD), an accelerant DPG and an anti-aging agent 4020 to finish preparation of a GO-SiO2 / NRL composite. By adopting the GO / NR composite preparation method, the phenomenon of uneven combinationof molecules in the rubber master batch caused by the accumulation of groups in the process of standing and jetting is avoided, and then liquid drops are instantaneously dehydrated and dried to obtain GO-SiO2 / NRL rubber master batch; and GO / NR composite preparation method is simple and controllable in process, scientific and reasonable in principle, low in energy consumption and production cost,strong in operability, more uniform in dispersion and friendly in use environment.

Owner:QINGDAO UNIV OF SCI & TECH

High-molecular water-soluble polymer residue soil dispersing agent

ActiveCN112029563ADissolve electrostatic adsorption binding forceReduce viscosityTunnelsLubricant compositionPolyethylene glycolPyrrolidinones

The invention discloses a high-molecular water-soluble polymer residue soil dispersing agent, which is composed of the following components in percentage by mass: 18%-24% of sodium polyacrylate, 4% ofpolyethylene glycol, 3% of fatty acid polyethylene glycol ester, 5-6% of fatty alcohol polyoxyethylene ether, 5-6% of N-methylpyrrolidone and 57-65% of water. The anionic dispersing agent composed ofsodium polyacrylate and an auxiliary agent thereof is designed according to the chemical principle of mud cake formation of residual soil, the electrostatic adsorption binding force of soil aggregation is decomposed, the viscosity of soil is reduced, the dispersion effect is achieved, the problem of 'mud cake formation' in a cutterhead of a shield tunneling machine is effectively prevented and solved, the use process is simple, the dispersing effect is good, the construction pressure of the shield tunneling machine is greatly relieved, and the construction efficiency and safety are improved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

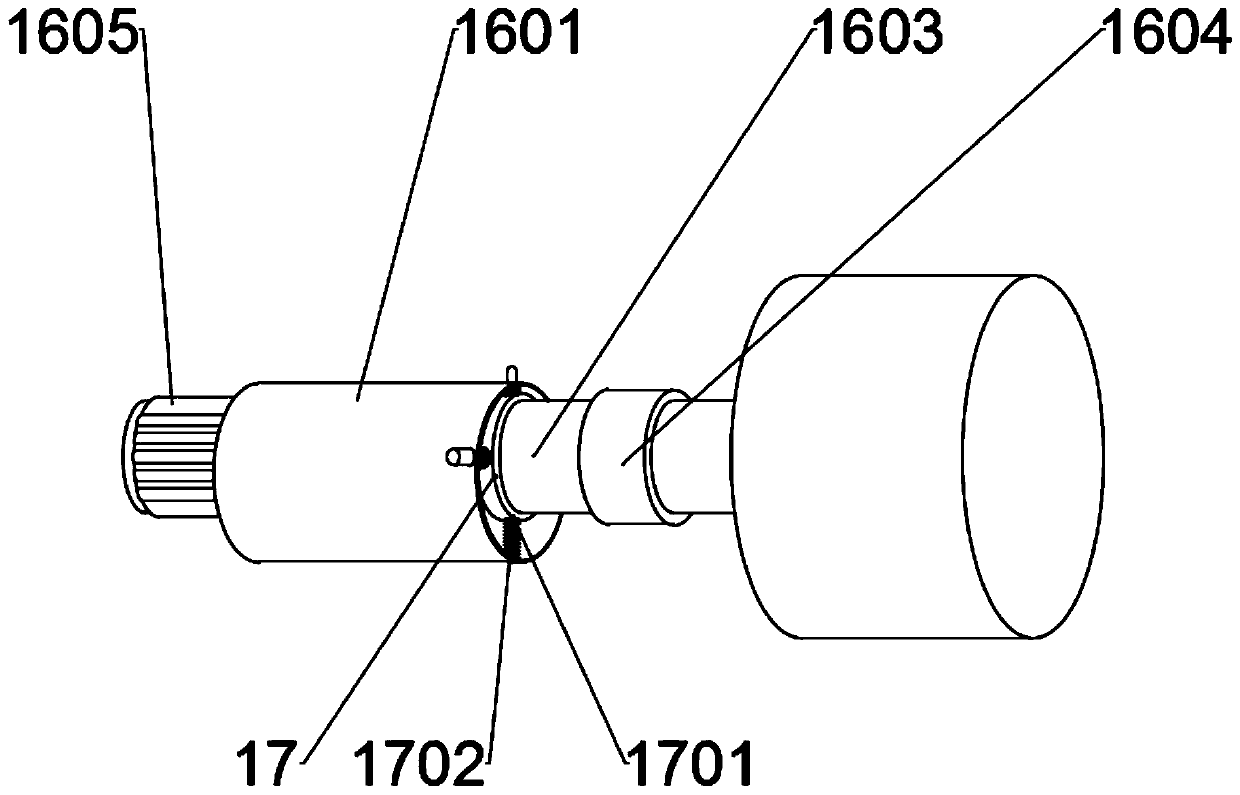

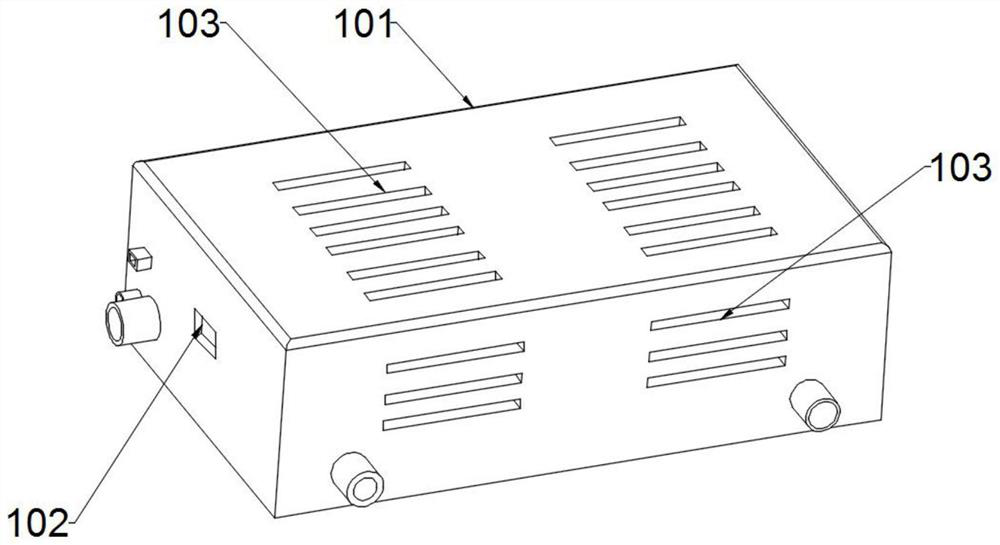

GR-SiO2/IIR material preparation method and glue spraying device

Owner:QINGDAO UNIV OF SCI & TECH

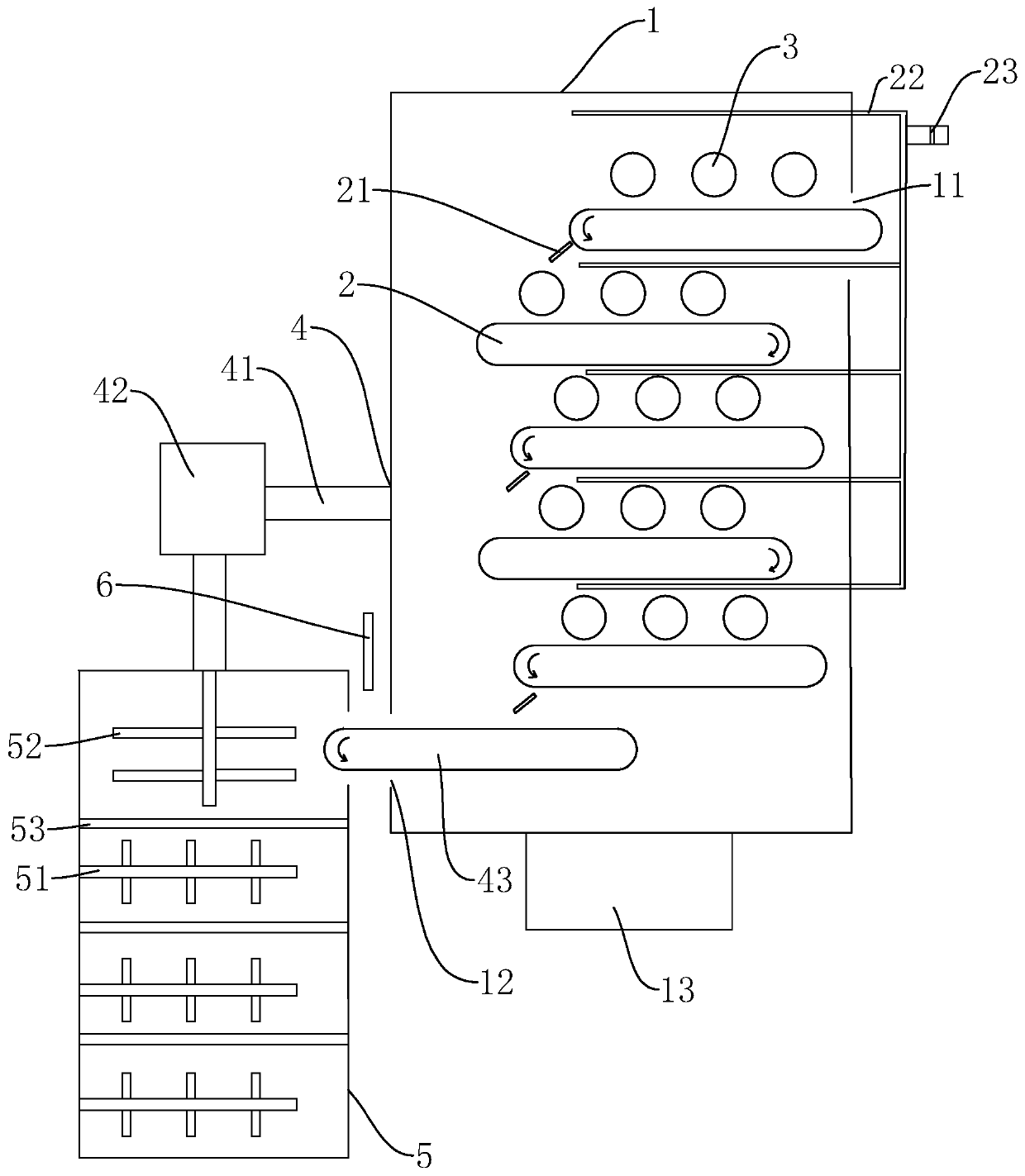

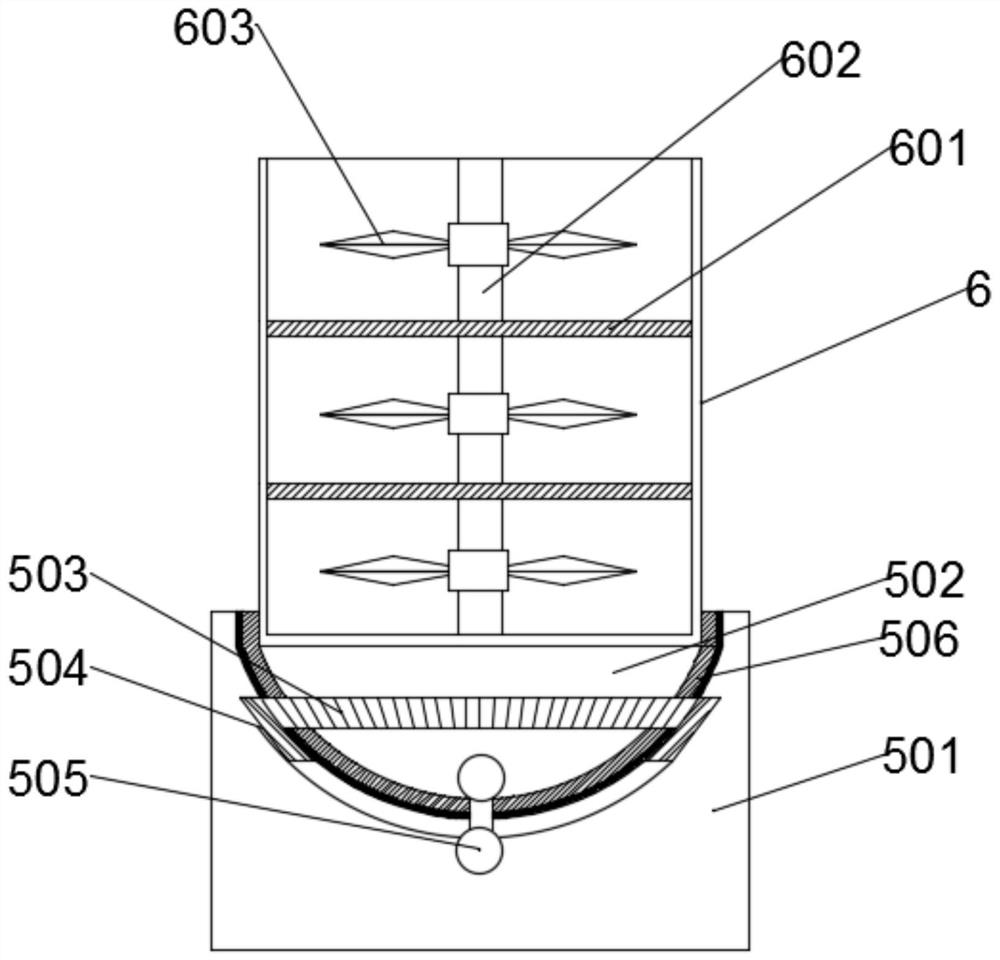

Drying device for algal protein feed preparation

InactiveCN111486690ADry fastFast dryingDrying solid materials without heatDrying gas arrangementsEnvironmental engineeringFodder

The invention discloses a drying device for algal protein feed preparation, relates to the technical field of feed preparation and aims to improve an existing drying device so as to improve the dryingquality of the existing drying device. According to key points of a technical scheme of the drying device, a plurality of conveying belts are arranged in the horizontal direction in a drying box, theconveying belts are distributed in the vertical direction, the conveying directions of every two adjacent conveying belts are opposite, the conveying belts which perform conveying clockwise deflect leftwards, and the conveying belts which perform conveying counterclockwise deflect rightwards; compression rollers are arranged above each conveying belt, the rotating linear velocity of the compression rollers is equal to the conveying velocity of the conveying belt, and scraping plates located below ends of the conveying belts are arranged in the drying box; and an air supply pipe used for supplying air from a feeding port to a discharging port is arranged in the drying box, and a heating pipe is arranged at one end, close to the feeding port, of the air supply pipe. The drying device achieves the effect of improving the drying quality.

Owner:NANJING YIXIAN BIOTECHNOLOGY CO LTD

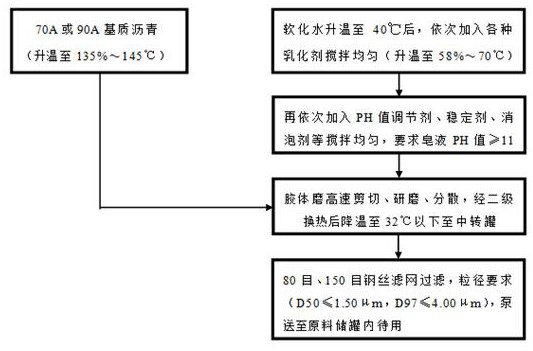

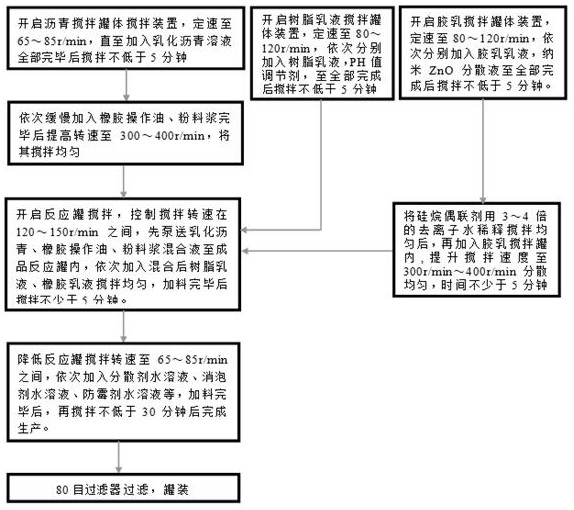

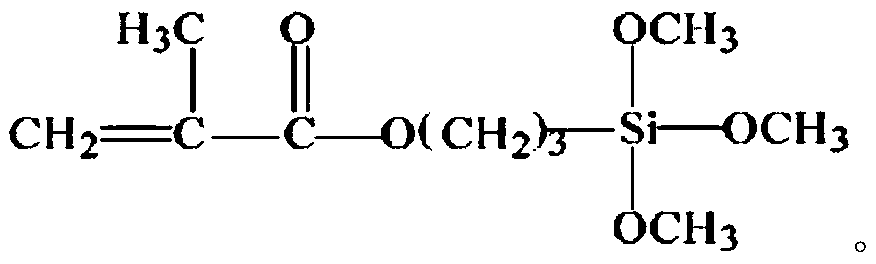

Preparation method and construction method of quick-setting polymer synthetic modified emulsified asphalt water shutoff agent

ActiveCN113604205AHigh salinity waterImprove mining efficiencyDrilling compositionSealing/packingBitumen emulsionProcess engineering

The invention provides a preparation method and construction method of a quick-setting polymer synthetic modified emulsified asphalt water shutoff agent and belongs to the technical field of materials. According to the preparation method and construction method of the quick-setting polymer synthetic modified emulsified asphalt water shutoff agent, stratum pores are quickly blocked under a high-temperature stratum condition, stratum pressure is kept, an oil layer is displaced from a high-temperature stratum to a range near a shaft of an oil well which is subjected to oil extraction in advance according to a certain method and direction, so that the oil extraction efficiency and the oil extraction quantity are greatly improved. the water shutoff agent can be used for oil well formation water shutoff under the environment of 60-120 DEG C and the stratum water mineralization degree of (20,000-25,000), and can effectively improve the oil production and the oil production efficiency, thereby playing an extremely important role in reducing the cost and increasing the yield of the oil well.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

White carbon black dispersant and preparation method thereof

The invention discloses a white carbon black dispersant. The white carbon black dispersant comprises, by mass, 40 to 60% of C8-C22 fatty acid, 5 to 25% of protection wax, 10 to 28.8% of fatty acid ester, 6 to 10% of an inorganic filling material and 0.96 to 5% of an anti-oxidant. The invention also discloses a preparation of the white carbon black dispersant having a good white carbon black dispersion effect. The white carbon black dispersant is an environmentally-friendly high-dispersibility zinc-free white carbon black dispersant, can improve dispersibility of a filling material and rubber chemicals in rubber in rubber mixing, is suitable for improvement of dispersibility of rubber containing high-activity white carbon black, avoids re-condensation, improves wet-skid resistance of a tyre surface, and avoids the pollution produced heavy metal zinc on the environment.

Owner:青岛福凯橡塑新材料有限公司

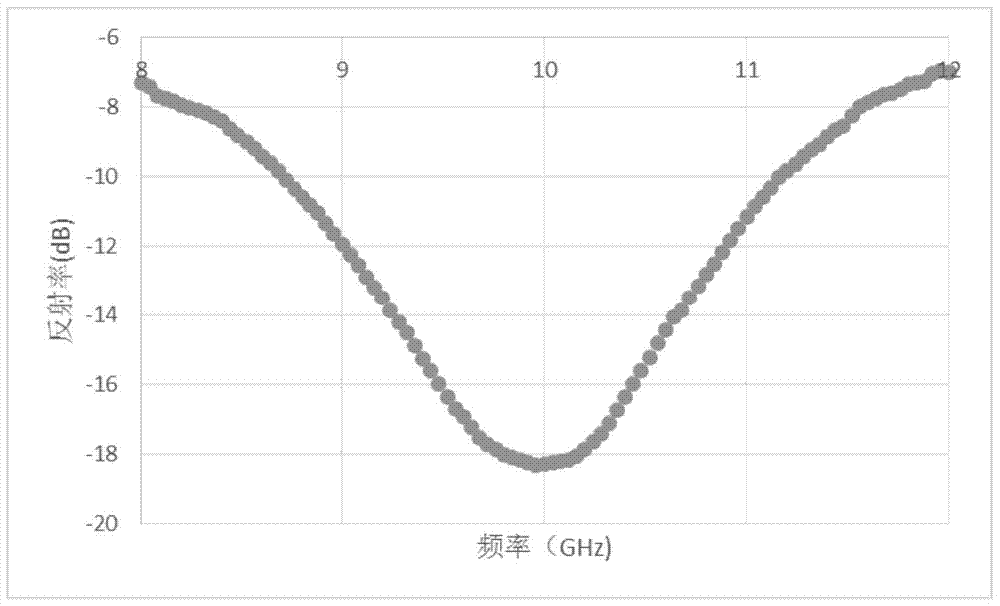

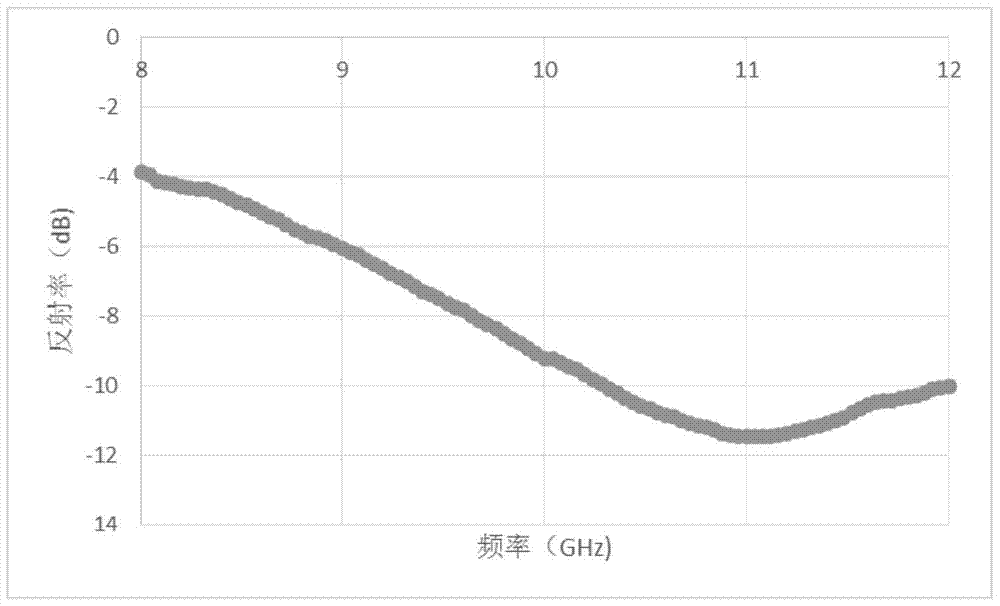

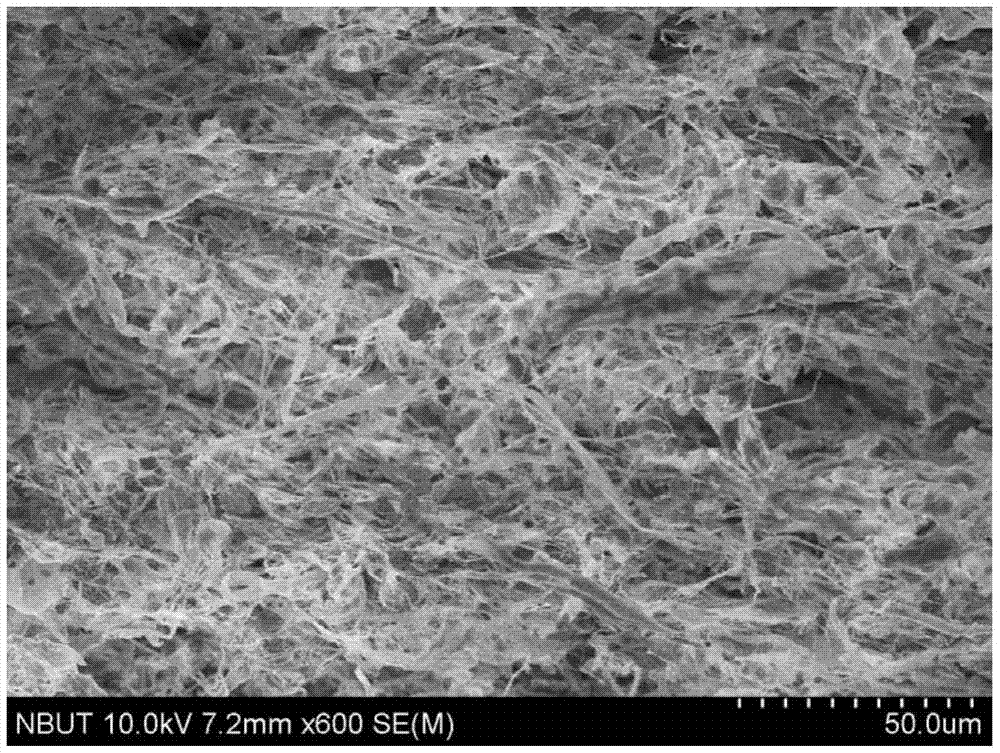

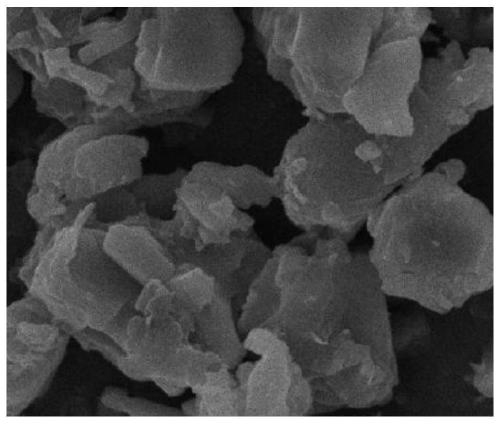

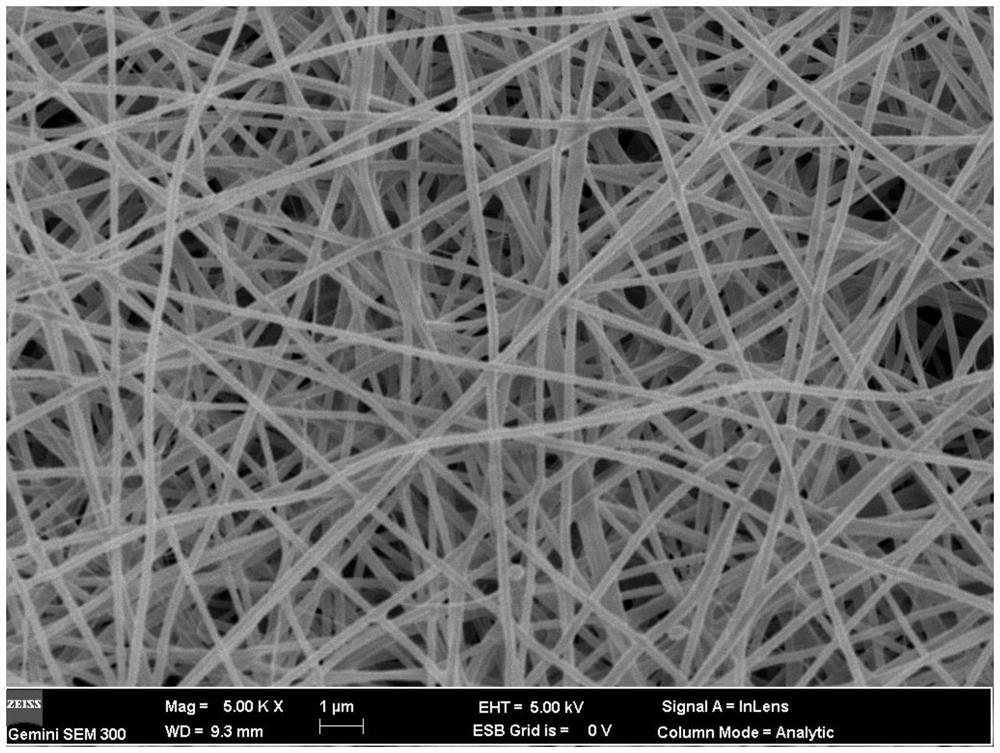

A kind of lightweight porous wave-absorbing film and preparation method thereof

ActiveCN104774346BWide selection of materialsEvenly dispersedOther chemical processesFiberMaterials science

The invention discloses a lightweight porous wave-absorbing film and a preparation method thereof. The light-weight porous wave-absorbing film includes fiber materials and wave-absorbing materials with a fibrillated structure. The fiber materials are in a three-dimensional cross-linked structure. The wave-absorbing material is dispersed in the three-dimensional cross-linked structure, and the mass proportion of the wave-absorbing material in the lightweight porous wave-absorbing film is 50-90%. The preparation method includes the steps of dispersing, homogenizing, filtering, baking and rolling. The invention adopts a wet papermaking process, and the wave-absorbing material is evenly distributed in the film-shaped wave-absorbing body. The preparation method has few steps and low cost, and the prepared wave-absorbing film has the surface density of the wave-absorbing body lower than 2kg / m2 and the porosity not lower than 30% under the premise of achieving the same wave-absorbing efficiency.

Owner:柔电(武汉)科技有限公司

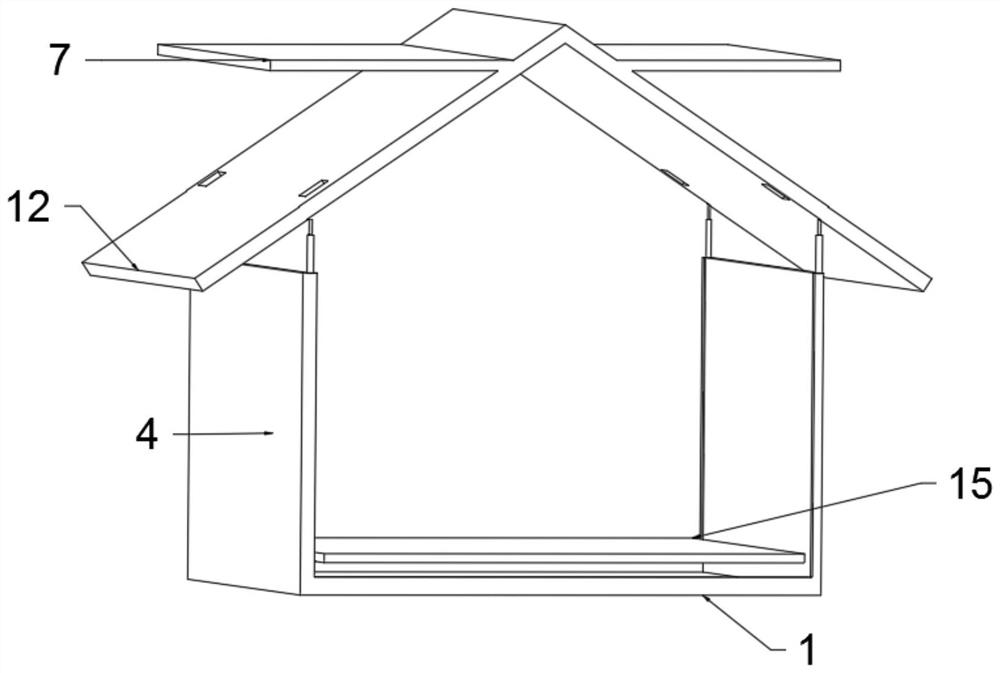

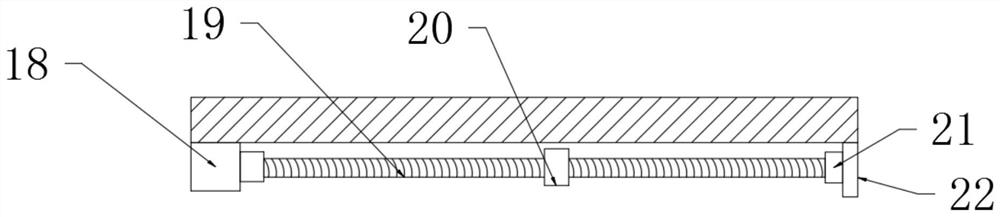

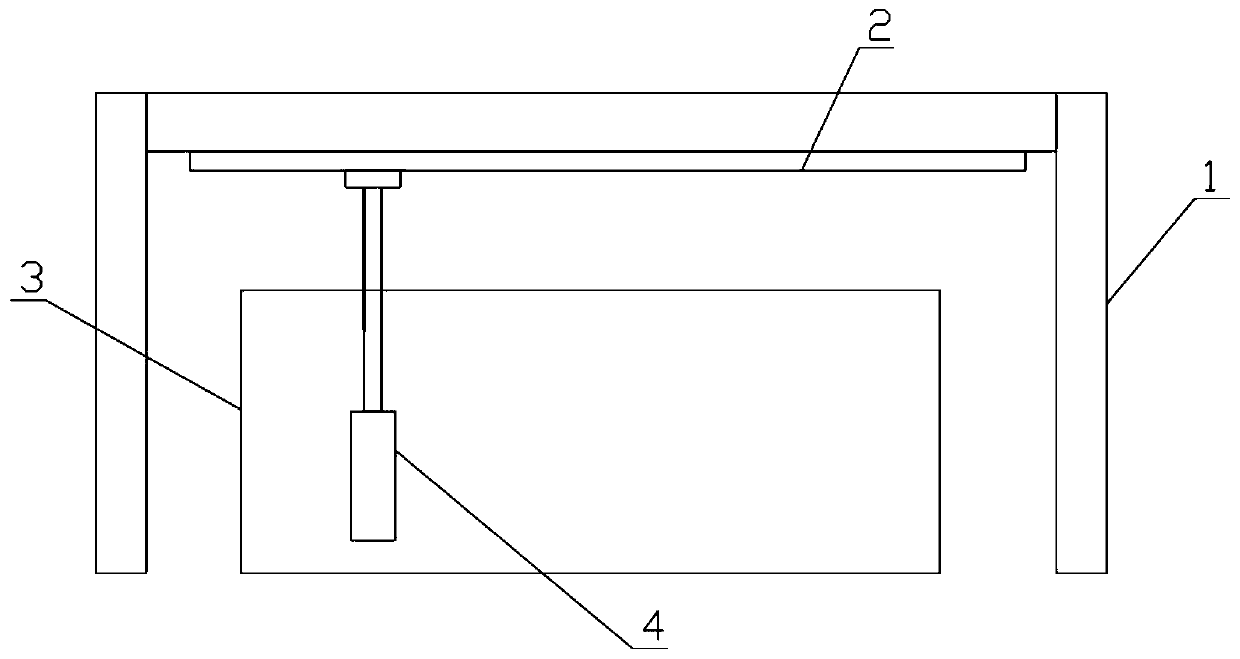

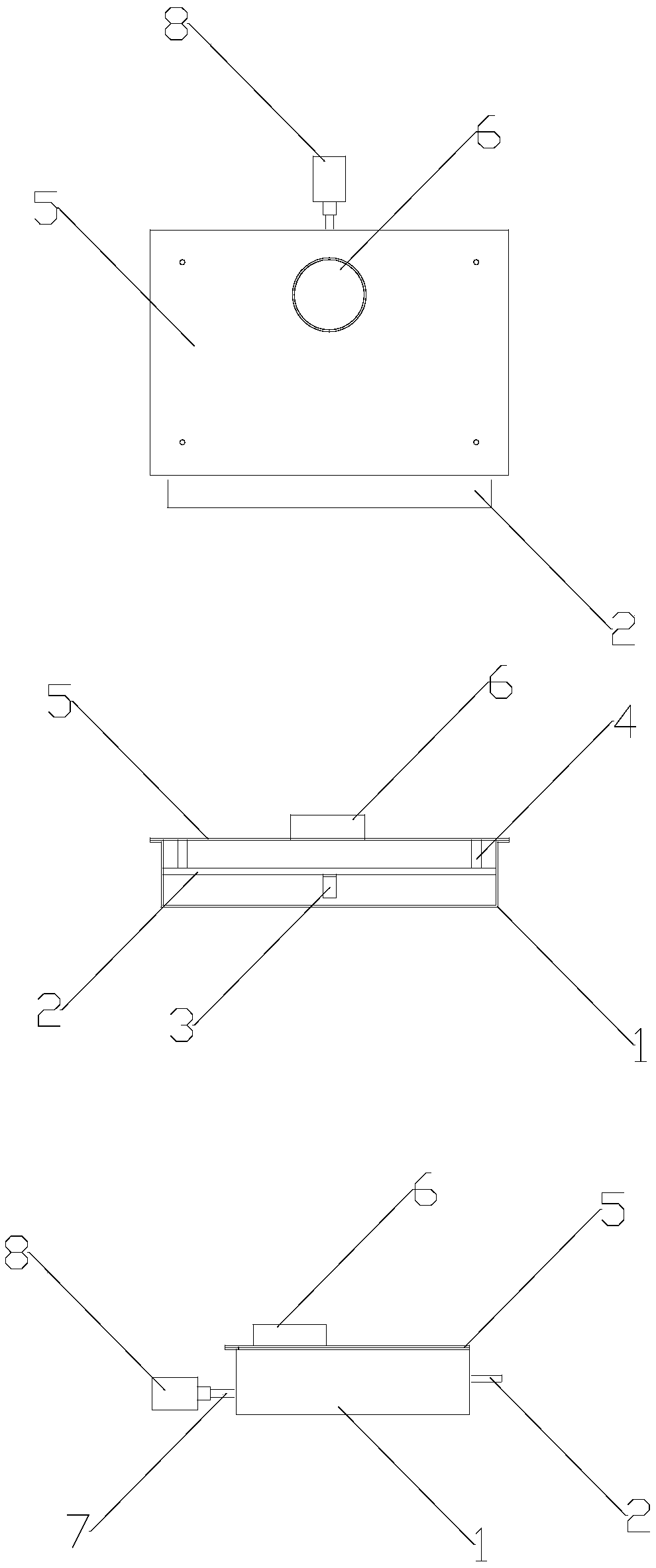

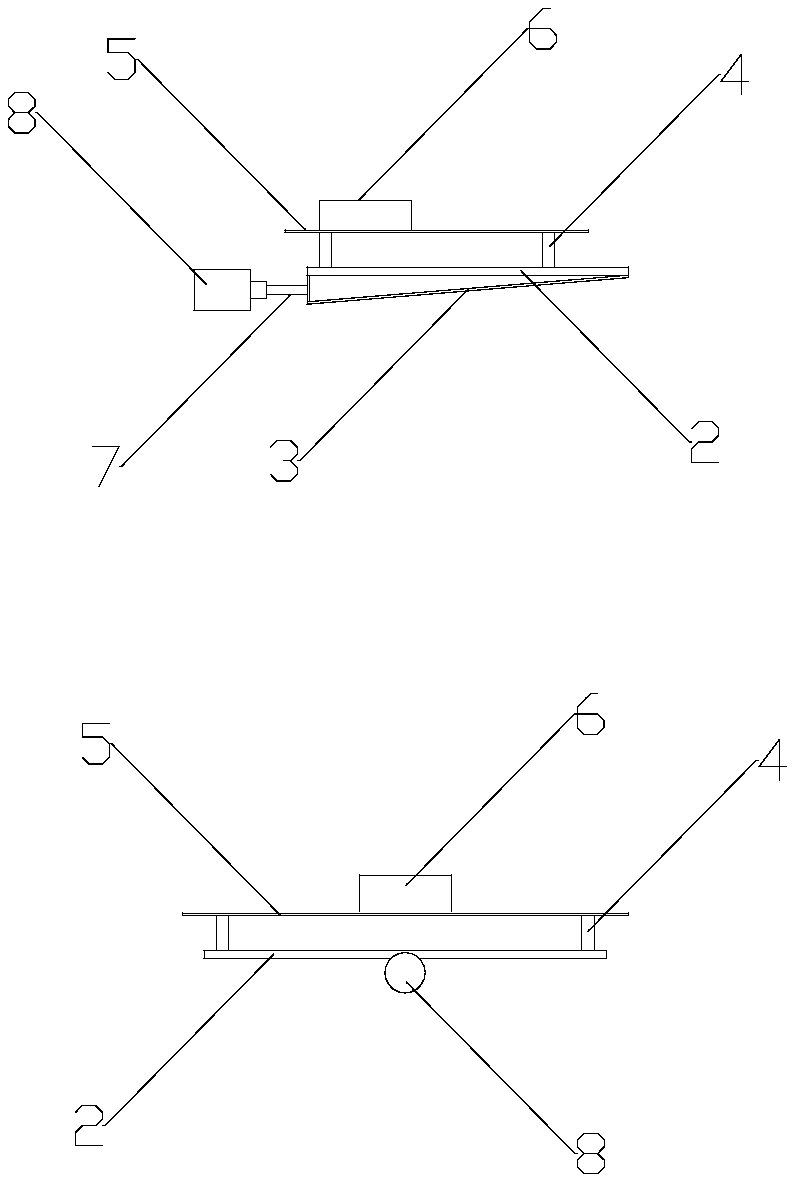

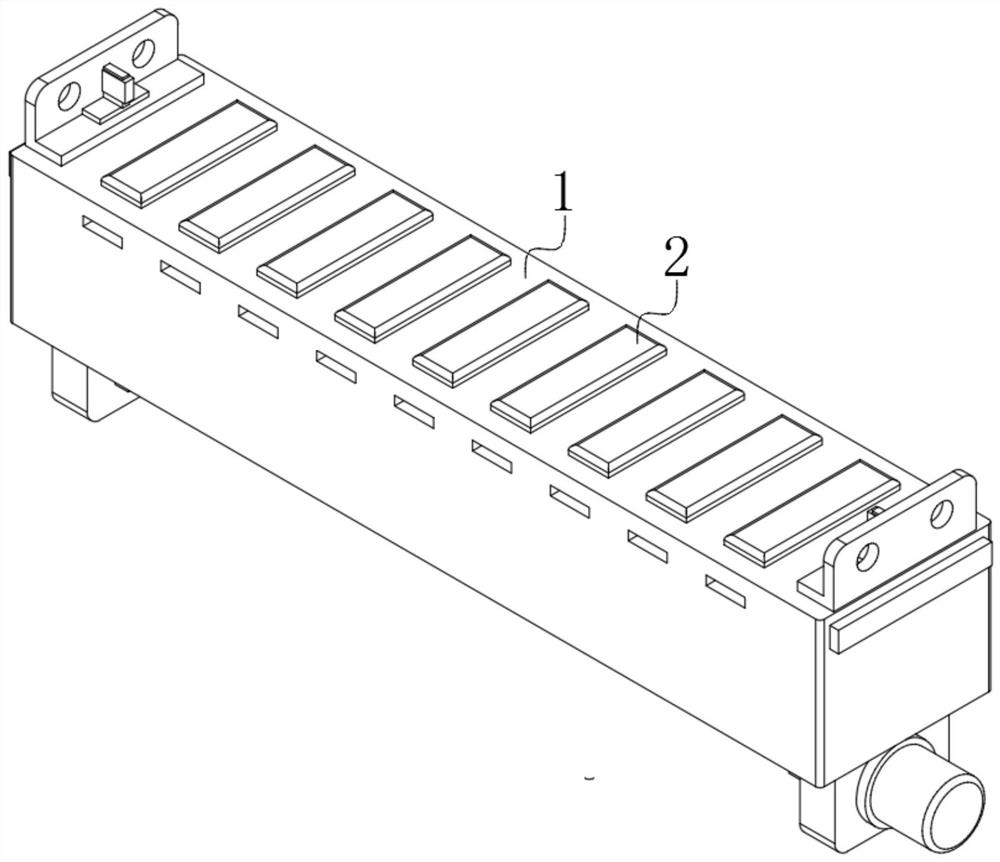

Pipeline placing device for building engineering

InactiveCN111703719AWon't hurtAchieve dispersion effectDischarging meansExternal fittingsBall screwGear wheel

The invention discloses a pipeline placing device for building engineering. The pipeline placing device comprises a base, a placing plate and a pipeline disassembling structure. The pipeline disassembling structure comprises a single pipeline disassembling mechanism and an overall disassembling mechanism. The single pipeline disassembling mechanism comprises an elevating mechanism, a third gear, asecond gear, a first gear, a clamping block, a fixing shaft, a sucker, a transverse motor, a transverse ball screw, a fixing sleeve, a tail device and a tail supporting base. The overall disassembling mechanism comprises a motor, a rotating shaft, a placing and releasing roller and a motor supporting base. According to the pipeline placing device, by arranging the single pipeline disassembling structure and the overall disassembling structure, different application occasions of multiple pipelines can be achieved, the situation that when the pipelines are taken out, the pipelines collapse andhurt personnel is avoided, when the overall disassembling structure acts, the pipelines topple over, thus the dispersing effect is achieved, and use is convenient.

Owner:蔡方

A kind of thermal insulation coating for architectural glass and preparation method thereof

ActiveCN105482575BAchieve dispersion effectHas the effect of grinding aidPolyester coatingsArchitectural glassAlcohol

The invention proposes a method for preparing thermal insulation coatings for architectural glass, comprising: preparing ATO alcohol slurry: putting ATO powder into an alcoholic solvent, stirring evenly, adding a polymer cationic dispersant, stirring again evenly, adding Cationic surfactant, then use a pH regulator to adjust the pH to 9, and then use ultrasonic dispersion, high-speed disperser dispersion and ball mill dispersion to carry out staged dispersion after stirring evenly, and the weight percentage of ATO in the obtained alcohol slurry is 10-30% , the weight percentage of polymeric cationic dispersant is 2.5-6%, and the weight percentage of cationic surfactant is 0.5-3%; Add alcoholic resin and coating auxiliary agent to prepare ATO thermal insulation coating afterwards, final product is environment-friendly insulation Thermal coating has good dispersibility, high stability, uniform film formation, and better heat insulation effect.

Owner:TIANJIN BINTAI TECH DEV CO LTD

Electrolyte of colloidal battery

InactiveCN108808125AHigh affinityImprove cycle lifeLead-acid accumulatorsElectrolyte immobilisation/gelificationAluminium hydroxideColloid

The invention relates to the technical field of electrolytes, in particular to an electrolyte of a colloidal battery. The electrolyte of the colloidal battery is characterized by comprising the following components in parts by weight: 2-5 parts of fumed SiO2, 0.2-0.4 part of polyacrylamide, 2-4 parts of glycerin, 0.5-3 parts of H3PO4, 0.5-2.5 parts of anhydrous sodium sulfate, 34-38 parts of sulfuric acid, 0.5-0.8 part of EDTA, 0.1-0.5 part of aluminum hydroxide, 0.5-1 part of a propanetriol solution and the balance of water. In the electrolyte, the propanetriol solution is added, so that a moisturizing function is enhanced, and thus the cycle life of the colloidal battery under a high-temperature condition is prolonged; in addition, through the fumed SiO2 hydrosol, after addition of the sulfuric acid, the colloidal storage battery is stable in performance and good in thixotropic property, and electrochemical performance indexes of the storage battery are met.

Owner:东莞市德东科技有限公司

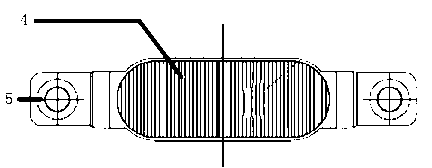

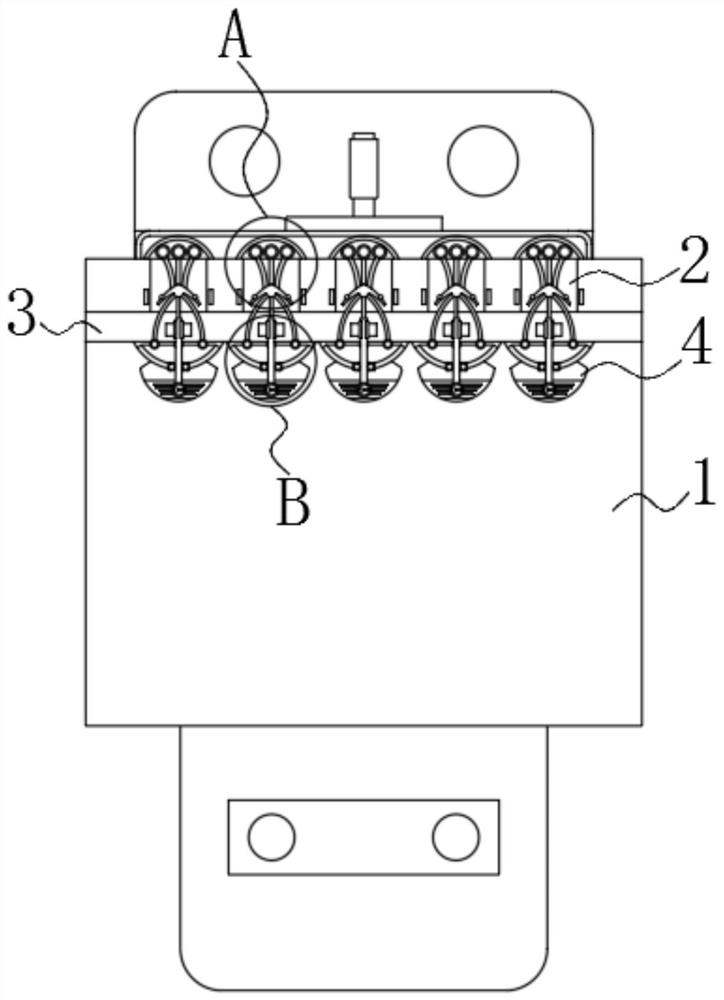

Ultrasonic micro-powder cleaning disperser and dispersion method thereof

PendingCN111112224AReduce pollutionReasonable designMechanical vibrations separationCleaning using liquidsEngineeringUltrasonic dispersion

The invention discloses an ultrasonic micro-powder cleaning disperser. The disperser comprises a cleaning groove and a plurality of ultrasonic dispersers mounted in the cleaning groove, wherein a moving gap is reserved between the ultrasonic dispersers and the inner wall of the cleaning groove, an opening for facilitating micro-powder placement is arranged at the top of the cleaning groove, a support frame convenient for installation of the ultrasonic dispersers is further arranged above the cleaning groove, a driving mechanism used for driving the ultrasonic dispersers to reciprocate in the cleaning groove is mounted on the support frame, and the ultrasonic dispersers comprise dispersion boxes and a plurality of ultrasonic transducers fixedly mounted in the dispersion boxes. The disperseris reasonable in design, the dispersion method of a chemical reagent is replaced by utilizing a mechanical physical method, the dispersion effect is several times of that of the common chemical reagent, the micro powder achieves the optimal dispersion effect, and meanwhile, the pollution to the micro powder is reduced to the greatest extent.

Owner:连云港秉文科技有限公司

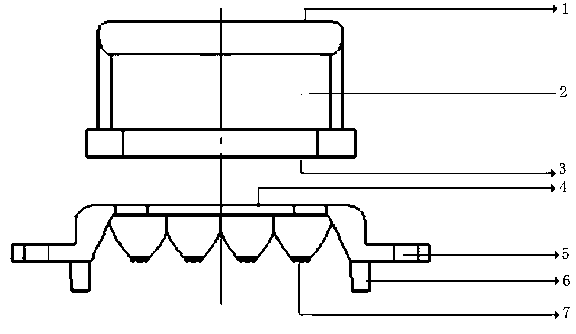

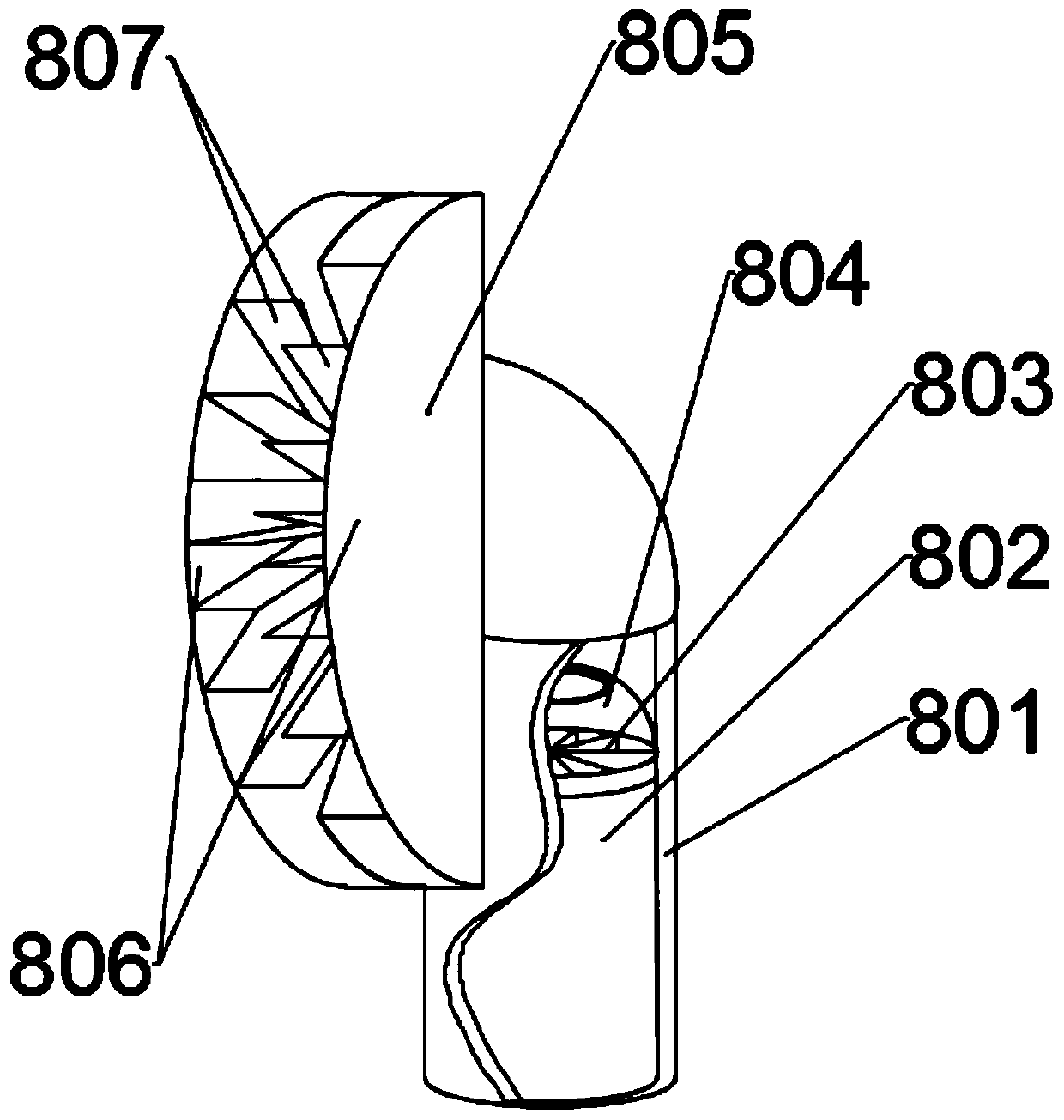

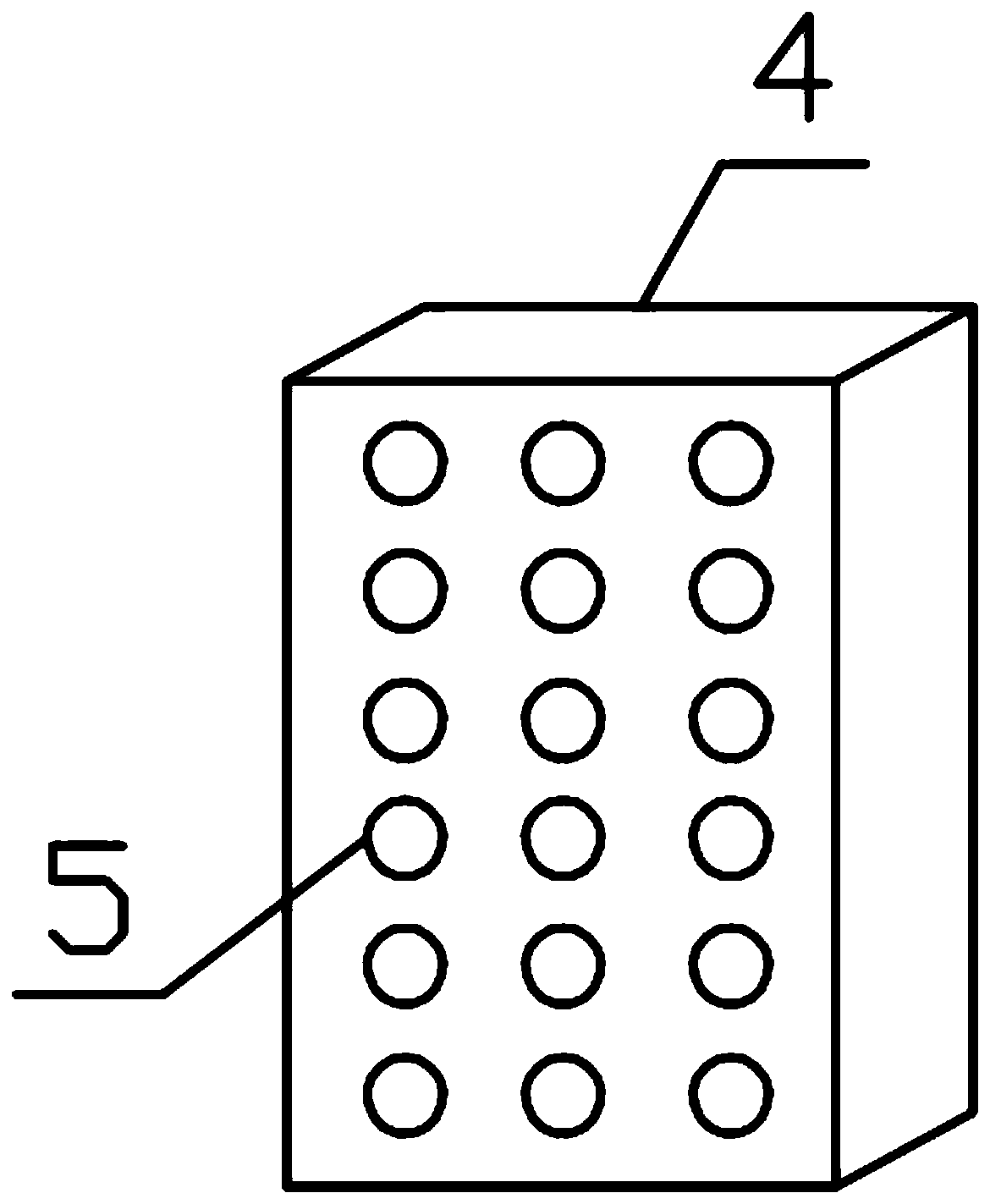

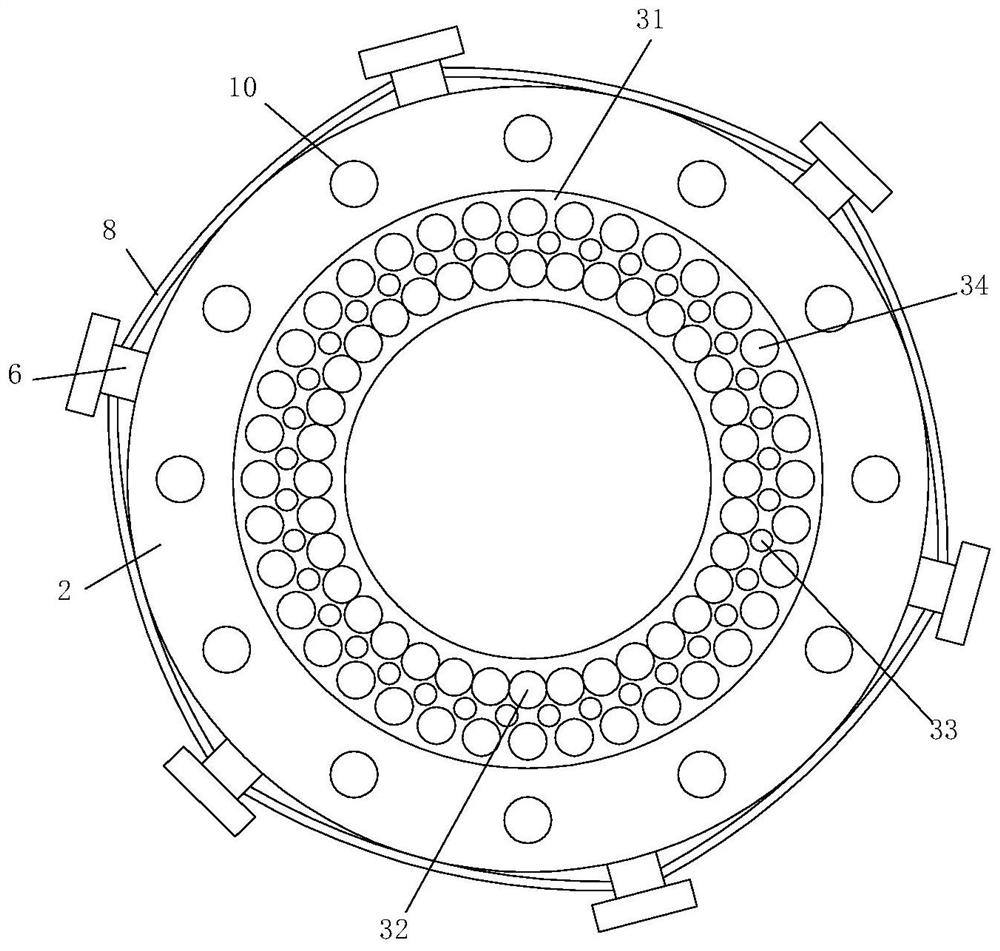

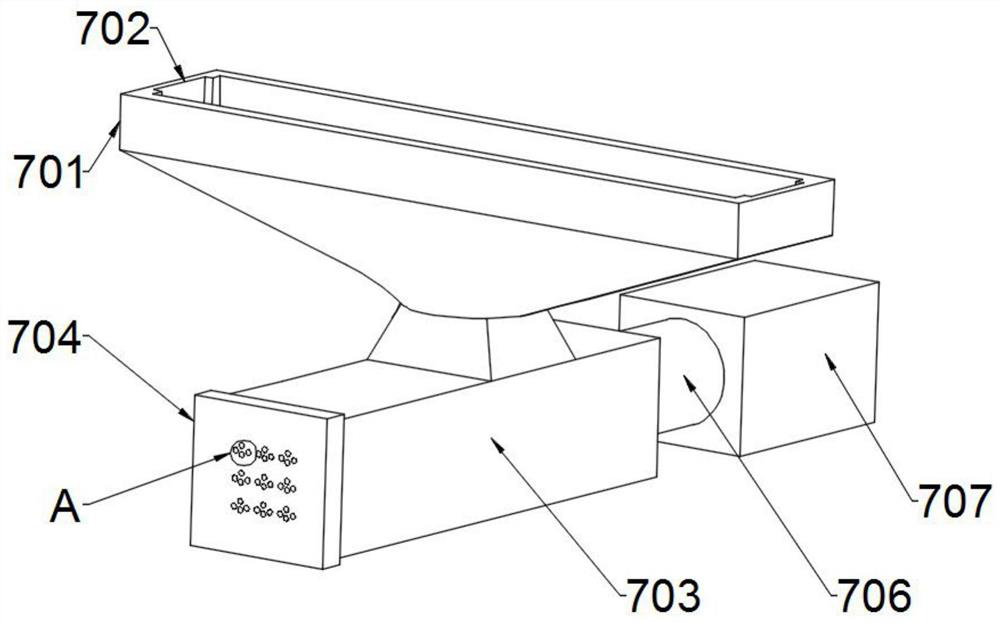

Ultrasonic material distribution structure

InactiveCN108927327ABreak bondAchieve dispersion effectSievingScreeningScreening proceduresUltrasonic sensor

The invention discloses an ultrasonic material distribution structure. The structure is composed of a shell, a material distribution plate, a transmission plate, connecting columns, a fixing plate, afeeding port, a transmission rod and an ultrasonic transducer, and an original feeding mode of screening equipment is replaced. According to the structure, through the high-frequency vibration of theultrasonic transducer, the material distribution plate is vibrated, the amplitude on the powder body at each position of the material distribution plate is different, so that the powder body is stressed unevenly, the binding force of agglomeration particles is destroyed, the agglomeration particles are out of balance, the powder is dispersed to the periphery, so that the effect of particle dispersion is achieved; and the material distribution plate is inclined downwards by a certain angle, the powder particles can fall out dispersedly under the amplitude motion force of the material distribution plate and the self-gravity, so that the powder is screened more sufficiently by subsequent screen meshes, and repetitive screening procedures are reduced.

Owner:广东仁开科技有限公司

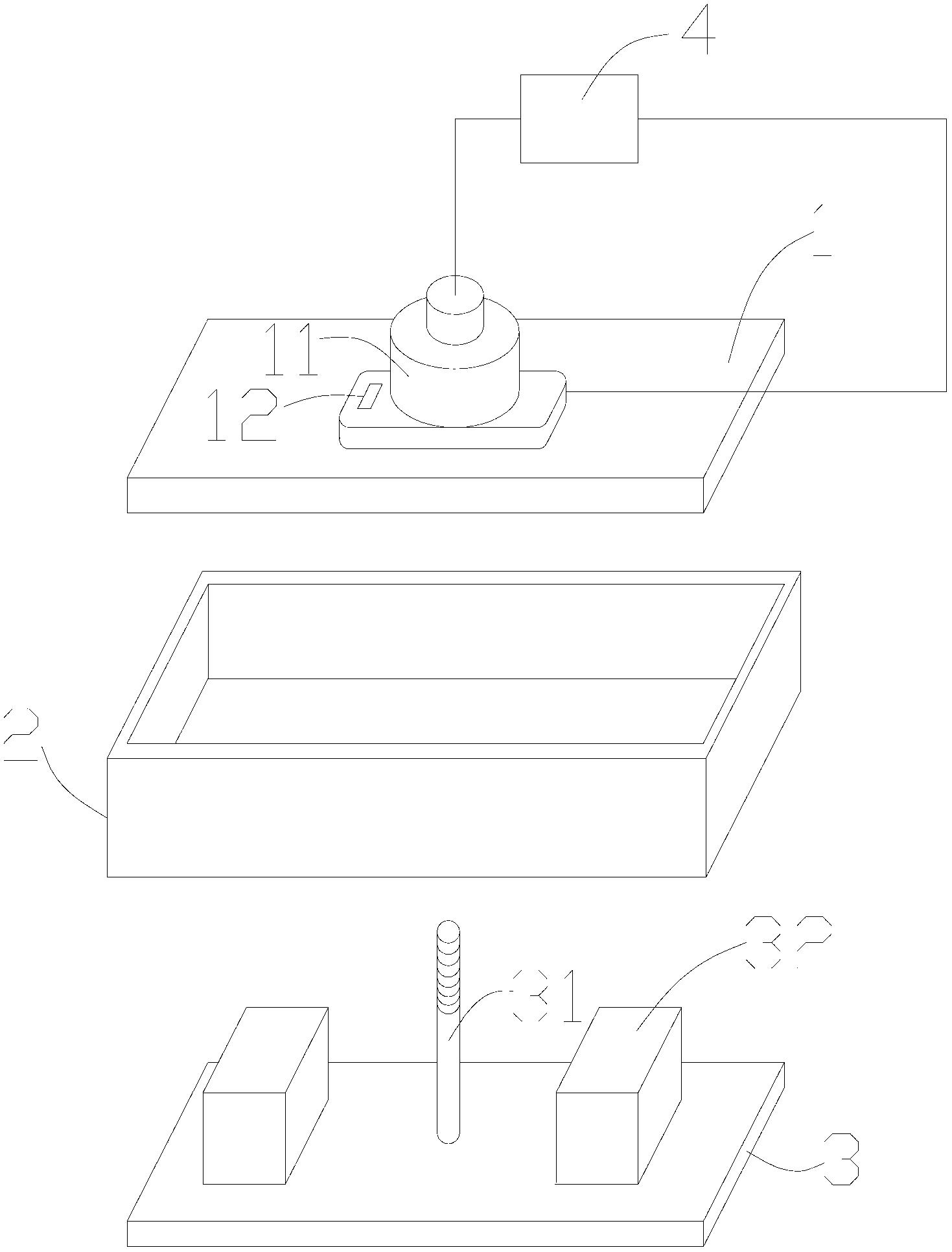

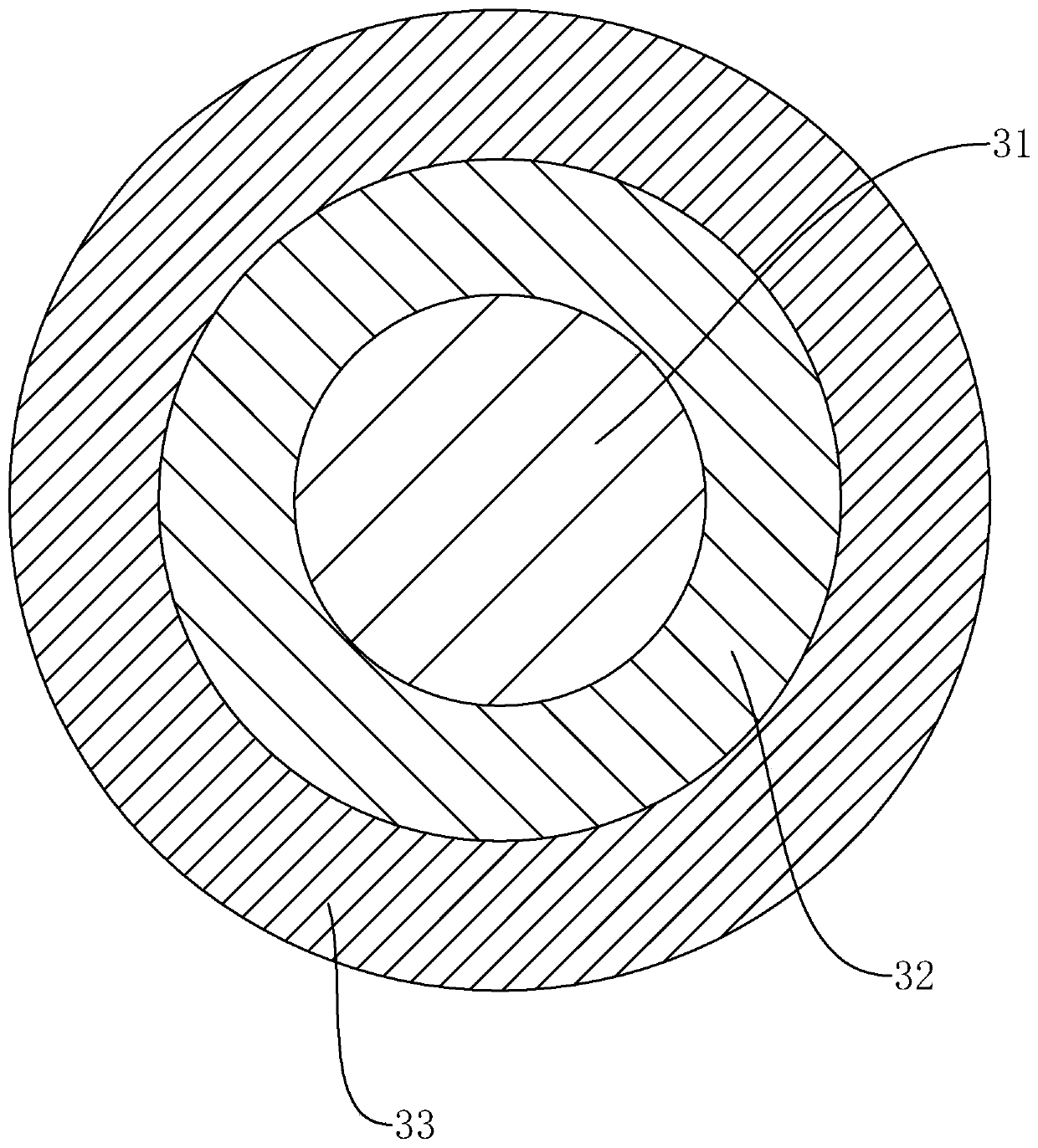

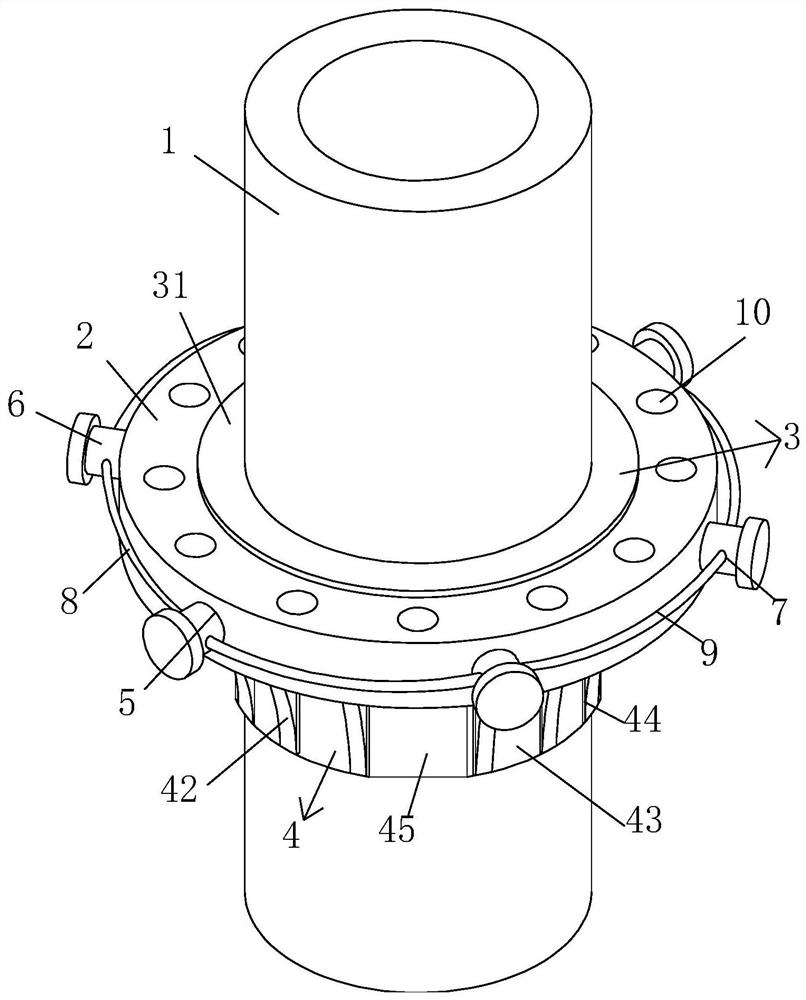

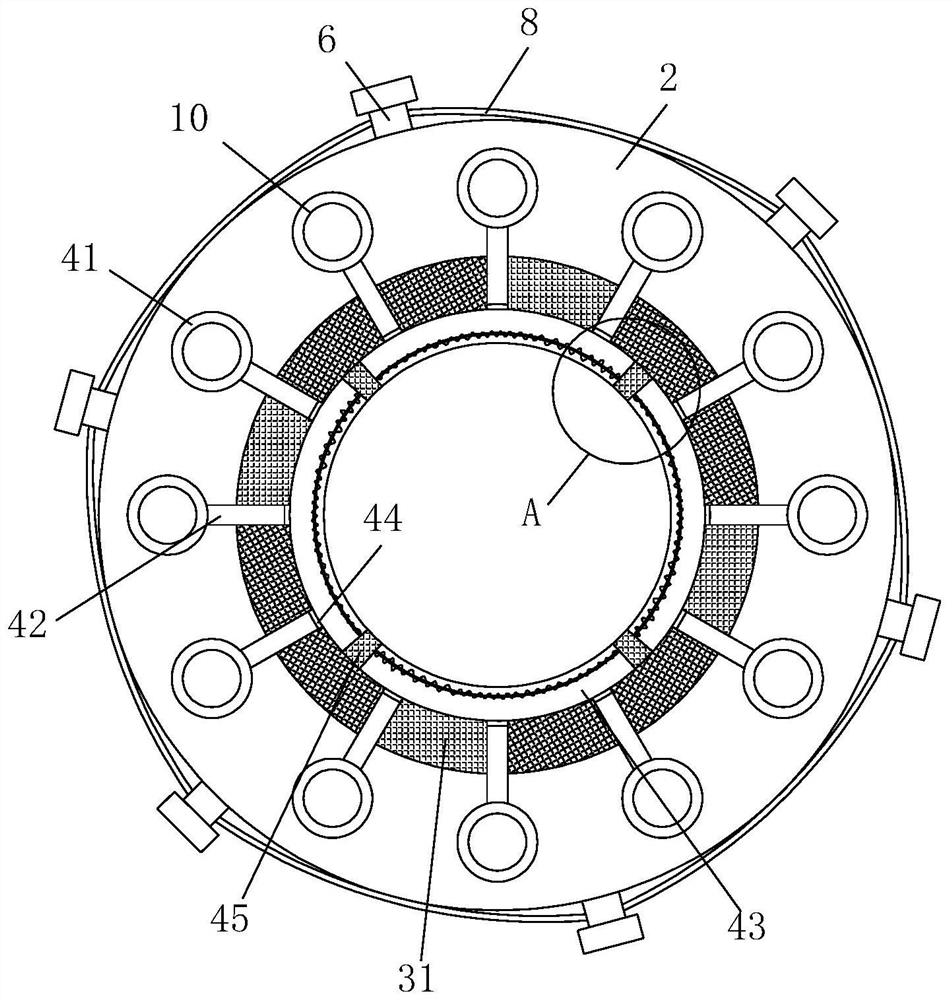

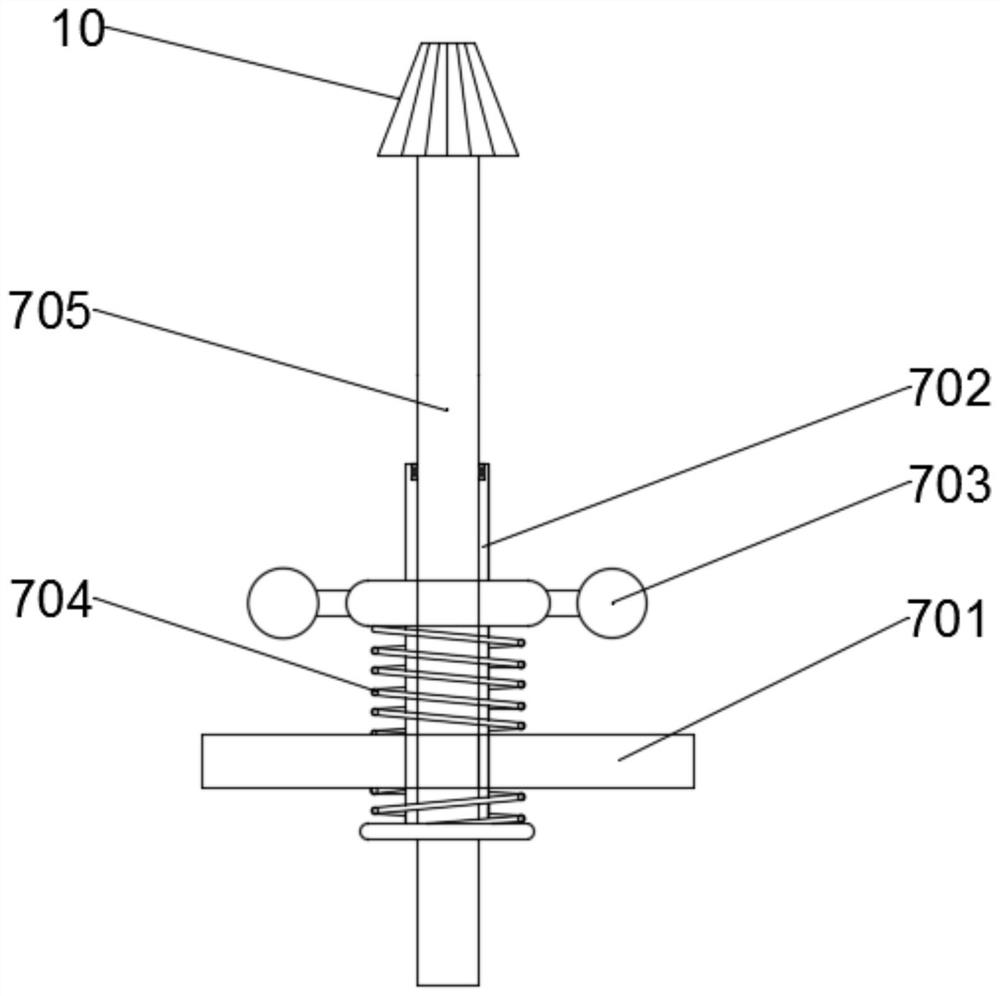

Modularized high-efficiency disc buckle frame support and construction method thereof

PendingCN114541716AAchieve dispersion effectStable supportScaffold connectionsSound proofingConstruction engineeringShock resistance

The invention provides a modular high-efficiency disc buckle frame support and a construction method thereof, and the modular high-efficiency disc buckle frame support comprises supporting pipes used for forming a scaffold, a support base used for connecting the supporting pipes, an external force circumferential transmission mechanism used for transmitting external pressure, and an inclined expansion supporting mechanism used for enhancing the supporting effect, the supporting pipe is sleeved with the supporting base, and the external force circumferential transmission mechanism is arranged in the supporting base. According to the modular high-efficiency disc buckle frame bracket and the construction method thereof, a bracket structure which is more efficient, convenient to mount and better in supporting strength is designed according to the problems that an existing modular disc buckle frame is invariable in mounting, prone to being damaged and the like, and therefore the problems that a common disc buckle frame bracket is poor in shock resistance, high in practicability and the like are effectively solved. The problems that in the prior art, bearing force is not uniform in guiding during bearing, damage is prone to happening, the supporting pipe needs to be replaced together when damaged, the height is not easy to adjust during installation, and replacement and installation efficiency is low are solved.

Owner:宁波博尔雅电子材料科技有限公司

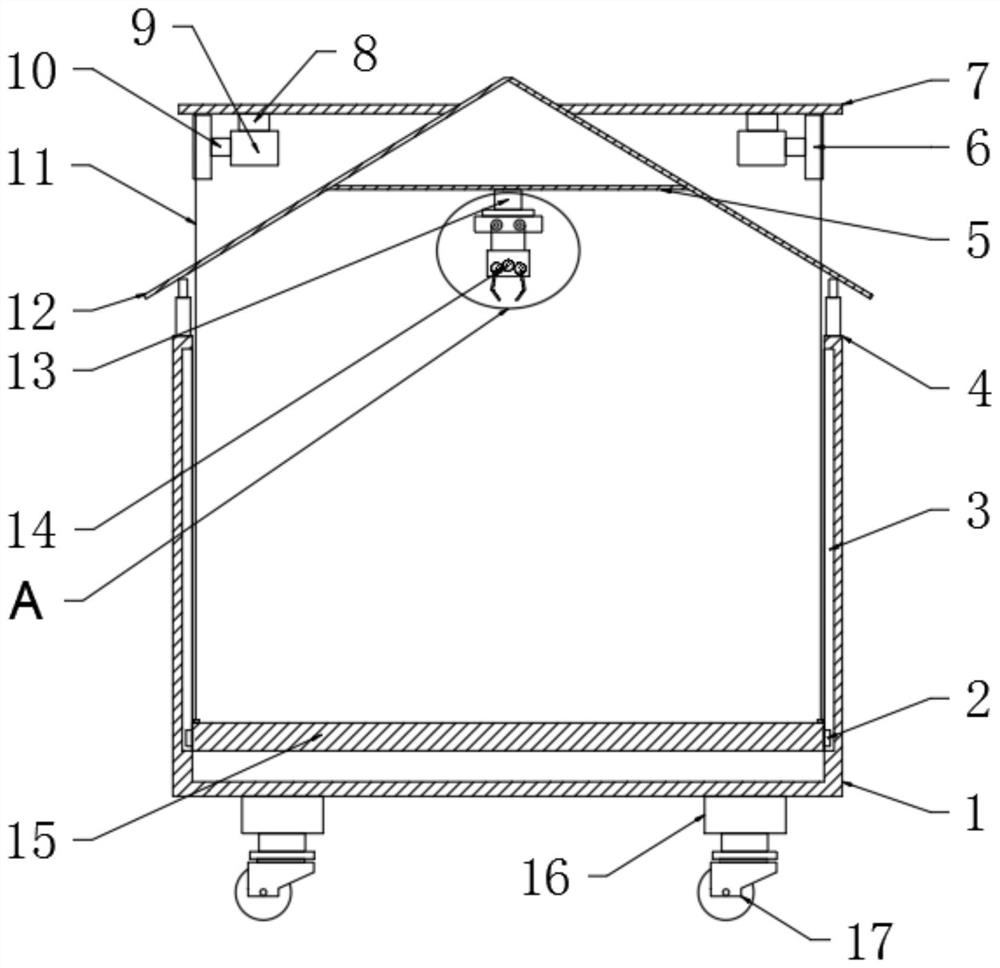

Intelligent grabbing equipment for port loading and unloading containers

InactiveCN113682939ANo shakingEffective coverageLoad-engaging elementsHydraulic cylinderLogistics management

Owner:丁岳勇

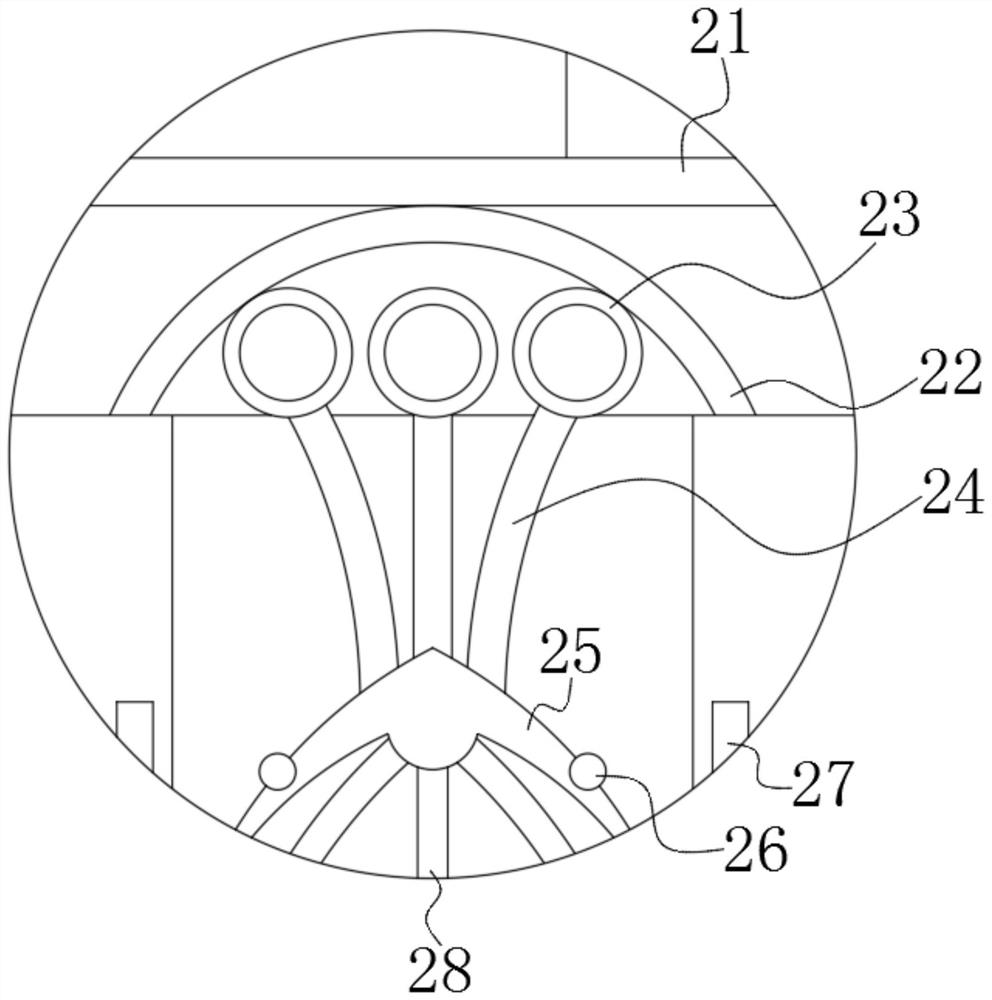

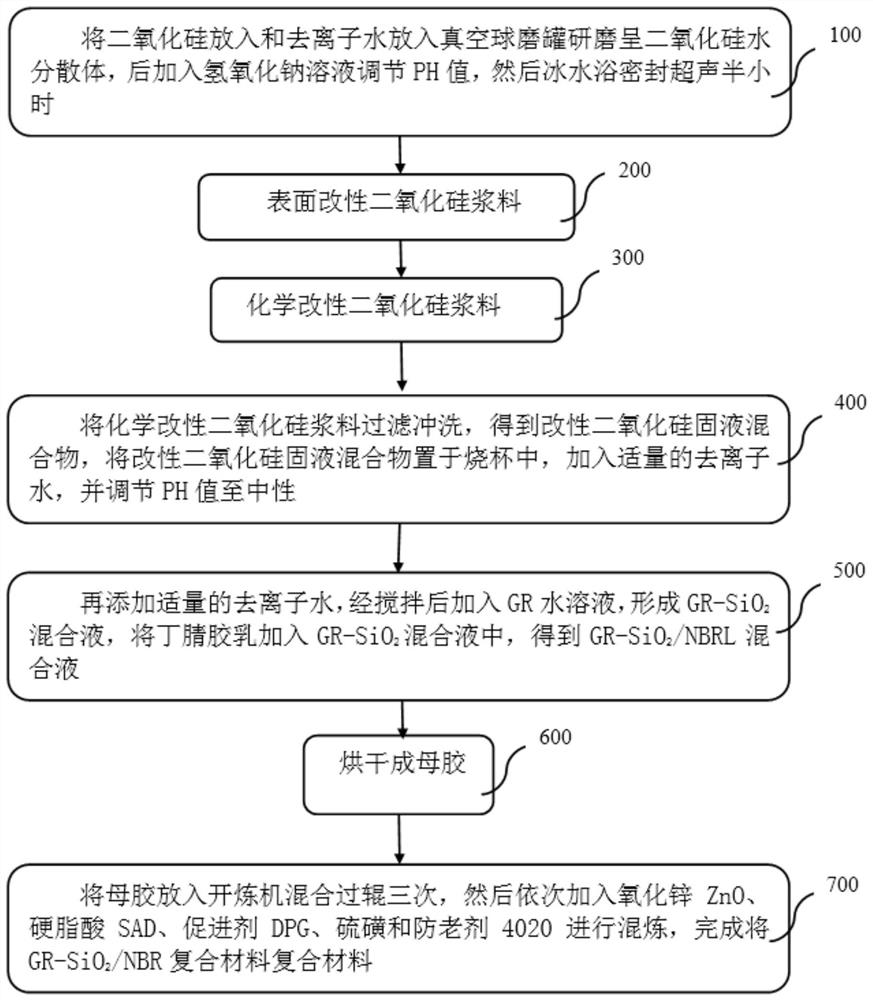

A gr-sio2/nbr material preparation method and ball mill assembly

The invention discloses a GR‑SiO 2 / NBR material preparation method, put silicon dioxide into and deionized water to grind into silicon dioxide water dispersion, adjust the pH value with sodium hydroxide solution, seal the ultrasonic in ice water bath; use deionized water to configure cetyl-three The methyl bromide aqueous solution is mixed with the silica aqueous dispersion, and forms a surface modified silica slurry under high-speed shearing; to the surface modified silica slurry, add toluene solution, toluene sulfur and poly Ethylene glycol is actually mixed, and a small amount of methanol solution is added after heating to reflux to form a chemically modified silica slurry; the silica slurry is filtered and rinsed and placed in a beaker; then an appropriate amount of deionized water is added to stir and GR aqueous solution is added. and add concentrated nitrile latex to GR‑SiO 2 In the mixed solution, GR‑SiO 2 / NBRL mixed solution, the mixed solution is heated and poured into the container tank, the mixed solution is sprayed onto the high-temperature roller, dried into masterbatch, put the masterbatch into the open mill and mixed through the roller for three times, physical and chemical modification , which is more structural.

Owner:QINGDAO UNIV OF SCI & TECH

A heat pump type solution humidity control air treatment device

ActiveCN111594935BClean useAchieve temperature control effectCondensate preventionLighting and heating apparatusWater vaporOxygen ions

Owner:纽爱新能源(广州)有限公司

A resource utilization method of landfill leachate

ActiveCN109988912BAchieve recyclingRealize secondary economic valueProcess efficiency improvementEnvironmental engineeringSpray dried

The invention relates to a recycling utilization method of landfill leachate. The method comprises the following steps that a landfill leachate concentrated solution with solid content of 30%-40% is evenly mixed with a sodium hydroxide solution and stirred to react under the water bath condition of 80-90 DEG C, and after the solution is cooled, modified landfill leachate is obtained; and the modified landfill leachate is evenly mixed with cement and modified dolomite in proportion, and after spray drying, a compound iron ore pellet binder is obtained. According to the recycling utilization method of the landfill leachate, the method is simple and available to operate. Recycling utilization of waste resources can be achieved, secondary economic value of the waste resources can also be realized, and great significance for sustainable development and utilization of energy can be brought.

Owner:鸿灌环境技术有限公司

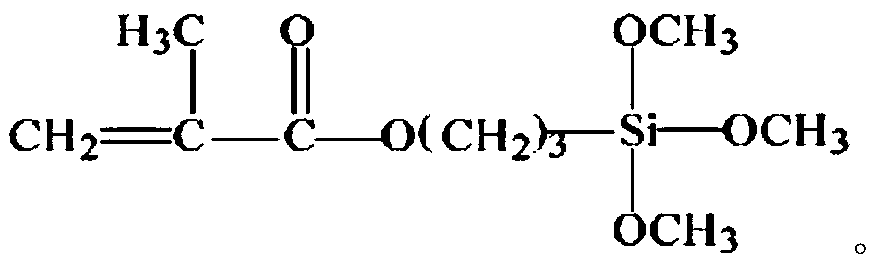

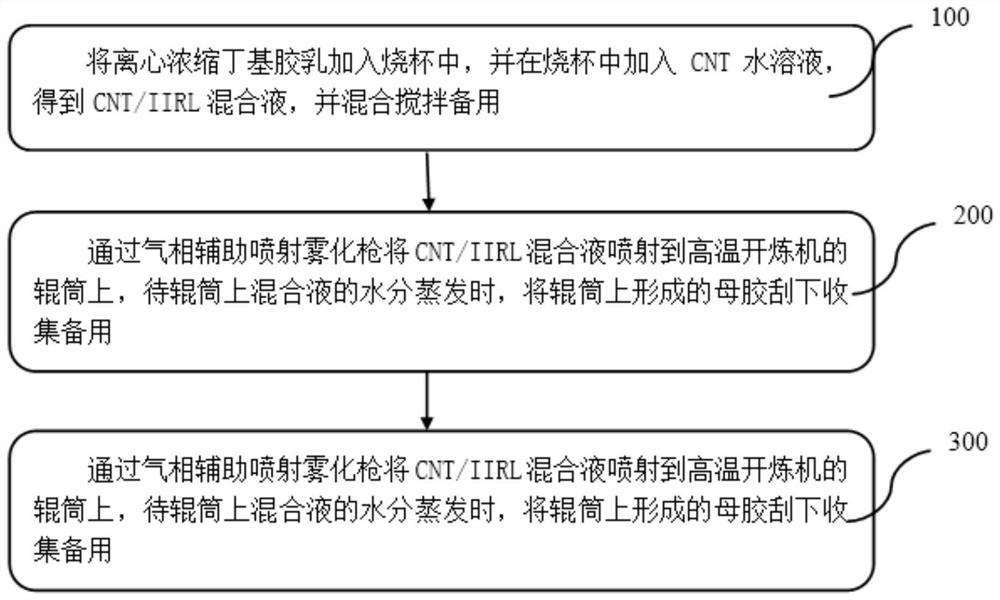

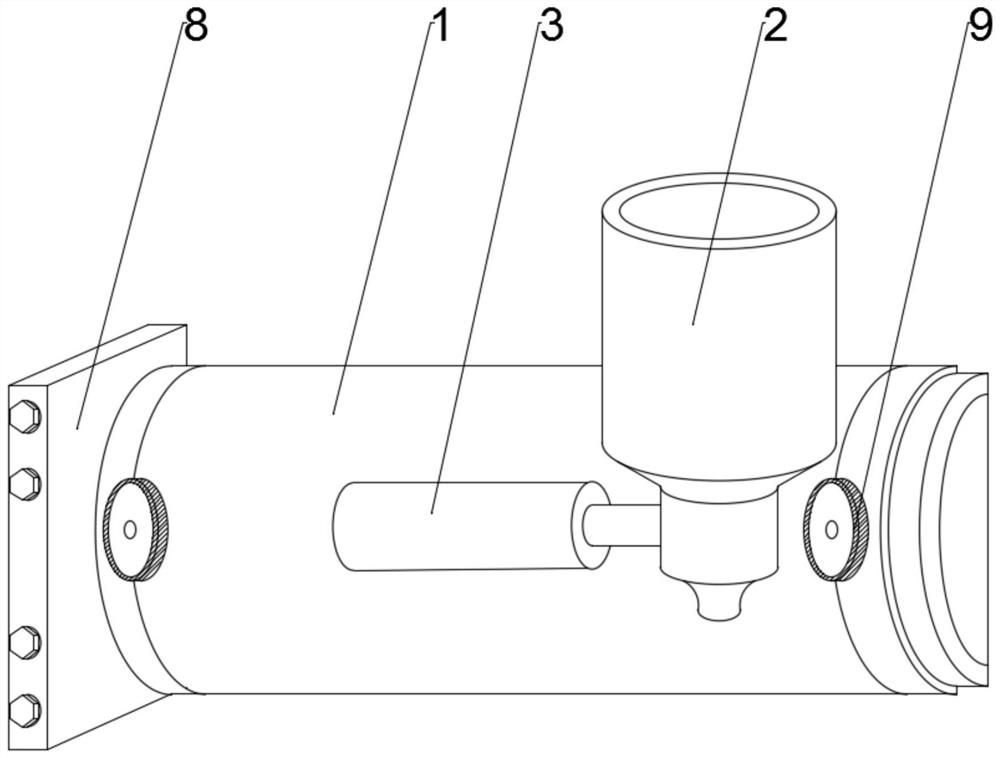

A kind of preparation method of cnt/iir composite material and jet atomization gun for preparation thereof

The invention discloses a method for preparing a CNT / IIR composite material, comprising the following steps: S100, obtaining a CNT / IIRL mixed liquid, and mixing and stirring it for standby; S200, spraying the CNT / IIRL mixed liquid to a high temperature through a gas-phase assisted spray atomizing gun On the roller of the open mill, when the water of the mixed solution on the roller evaporates, the masterbatch formed on the roller is scraped off and collected for later use; S300, add 111phr masterbatch, zinc oxide ZnO, hard Fatty acid SAD, sulfur, super-accelerator TMTD, DM accelerator, RD anti-aging agent, anti-aging agent 4020 for mixing, plasticizing and banburying of the masterbatch, and completing the preparation of GO / IIR composite materials, and atomization devices, including Assembling the frame, as well as the batching bottle, air pump and deflector set on the assembly frame, the inside of the assembly frame is provided with a micro-motion component, the micro-motion component is provided with an atomizing nozzle, and the deflector is connected to the assembly frame There is an air curtain groove at the center, the process is simple and controllable, and the principle is scientific and reasonable, which ensures uniform atomization and avoids secondary dripping due to the adhesion of water vapor.

Owner:QINGDAO UNIV OF SCI & TECH

Ultraviolet degradation method for preparing high-quality graphene material

The invention discloses an ultraviolet degradation method for preparing a high-quality graphene material, which comprises the following steps: (Step 1) graphene oxide is added into deionized water, adispersant is added, and after uniform agitation, ultrasonic reaction is carried out for 1 to 2 hours, so that graphene oxide dispersion liquid is obtained; (Step 2) the graphene oxide dispersion liquid is added into an agitating kettle, an initiator is added, and uniform agitation is carried out, so that a graphene oxide mixed liquor is obtained; (Step 3) the graphene oxide mixed liquor is addedinto an illuminating reaction kettle, a photocatalytic block is added, sealed illuminated circulated aeration reaction is carried out for 5 to 7 hours, and filtration is carried out, so that a mixed graphene precipitate is obtained; (Step 4) the mixed graphene precipitate and a photocatalytic block are added into absolute ethyl alcohol to ultrasonically react for 2 to 4 hours, the photocatalytic block is removed, and after filtration, drying is carried out, so that the graphene material is obtained. The ultraviolet degradation method solves the problems of pollution and unsafety existing in sgraphene material oxidation-reduction method in the prior art; by adopting the ultraviolet degradation method, an environment-friendly method can be adopted to prepare the graphene material, which issafe and environmentally friendly, and moreover, the photocatalytic material is recyclable, so the cost is reduced.

Owner:张静娟

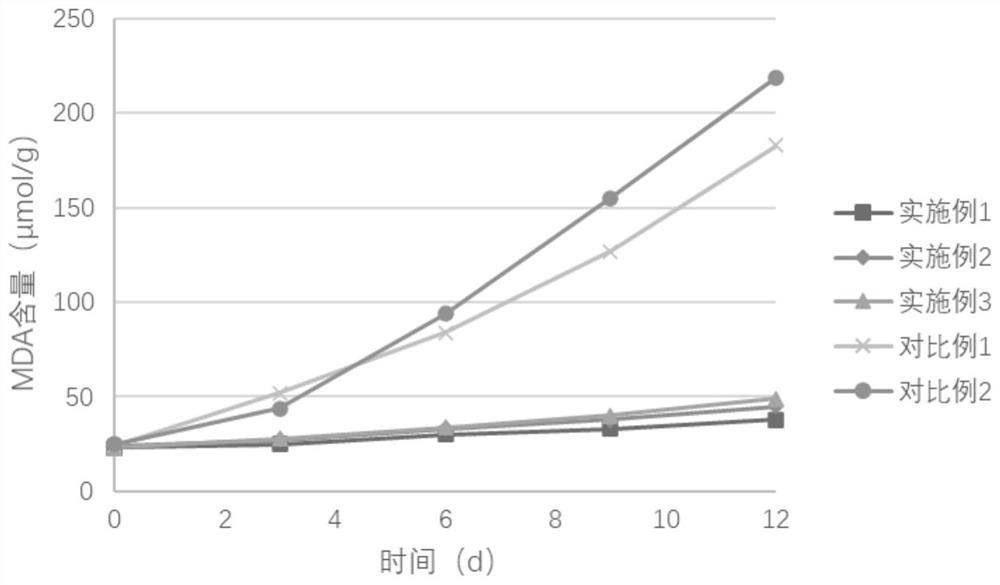

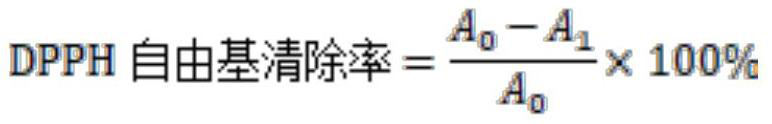

Antioxidant food preservative film and preparation method thereof

ActiveCN113089314ALarge adsorption capacityImprove stabilityFibre typesFilament/thread formingBiotechnologyPolyvinyl alcohol

The invention belongs to the technical field of food preservation, and discloses an antioxidant food preservative film and a preparation method thereof. The preparation method comprises the steps that lecithin type omega-3 unsaturated fatty acid is added into ethyl alcohol and fully stirred to be dissolved, illite powder is added for being continues stirred to form paste, the pH value is adjusted to be 7.0, standing and filtering are carried out, sediment is washed with water three times, vacuum drying is carried out, and organic illite powder is obtained; and an epigallocatechin gallate solution is added for being fully adsorbed, filtering, precipitating are drying are carried out, the epigallocatechin gallate solution is added into a mixed solution of sodium lignin sulfonate, polyoxyethylene and polyvinyl alcohol, electrostatic spinning is carried out to form a nanofiber membrane, fumigating and cross-linking are carried out on glutaraldehyde and hydrochloric acid, washing with water is carried out to be neutral, and drying is carried out to obtain the antioxidant food preservative film. The antioxidant food preservative film has the effects of storing biological antioxidants and slowly releasing antioxidant substances, and has better antioxidant effect and lasting preservation performance when being applied to food preservation.

Owner:广州大鱼创福科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com