Ultrasonic material distribution structure

A technology of ultrasonic wave and material distribution plate, which is applied in the direction of solid separation, filter screen, grid, etc., and can solve the problems of large influence, no separation or passage, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the inventive content, characteristics and effects of the present invention, the following examples are hereby described.

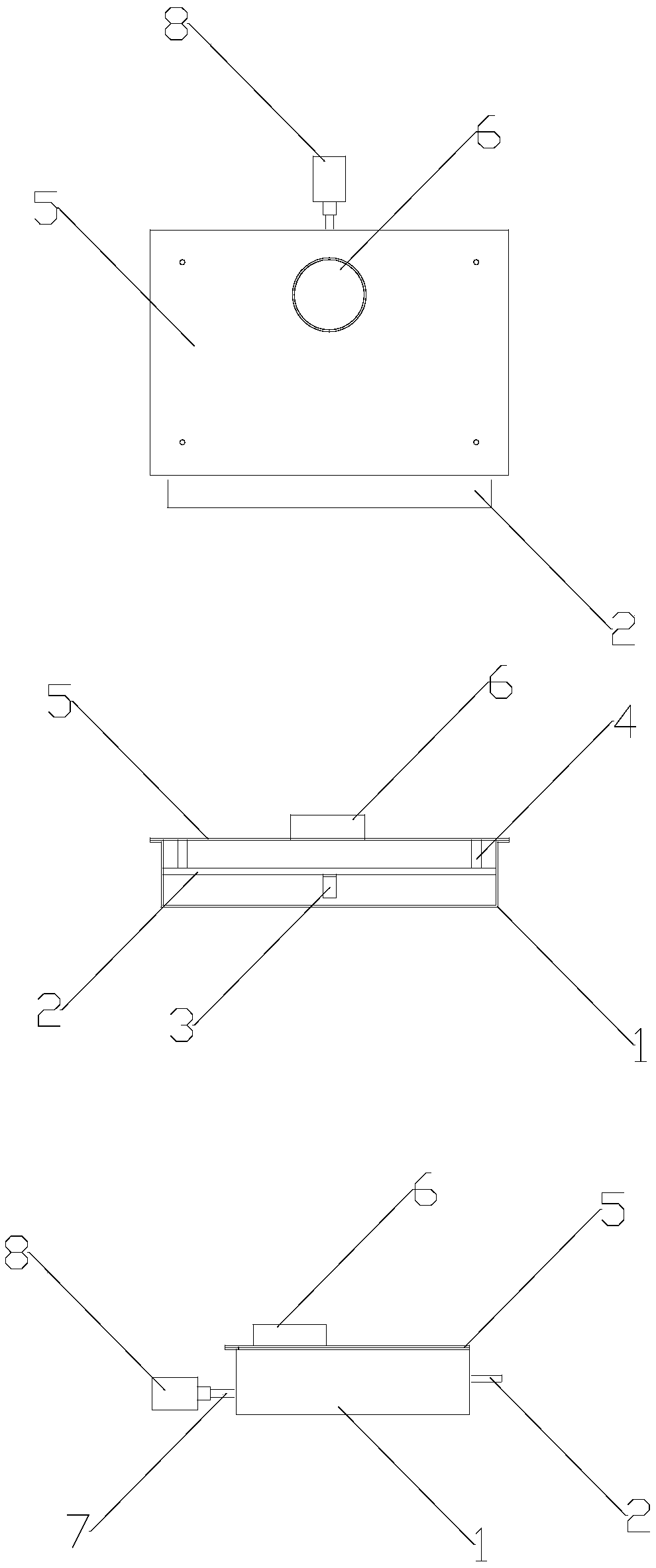

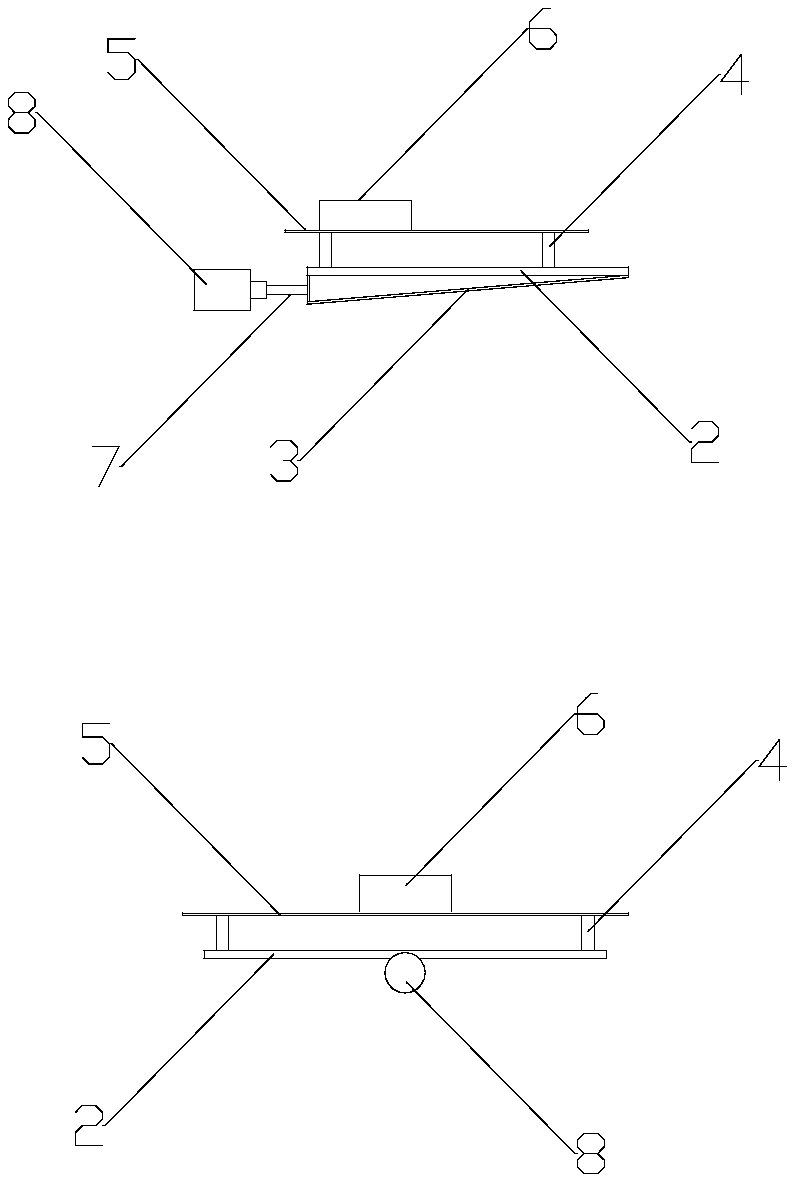

[0015] see Figure 1-2 , the technical scheme adopted in the present invention is as follows: an ultrasonic material distribution structure, which consists of a casing 1, a material distribution plate 2, a transmission plate 3, a connecting column 4, a fixed plate 5, a feeding port 6, a transmission rod 7, an ultrasonic transducer 8, the casing 1 is in the shape of a cuboid, its upper surface and one side are set as openings, the fixing plate 5 is arranged on the upper surface of the casing 1, the fixing plate 5 and the periphery of the casing 1 are fixedly connected by welding, and the feeding port 6 is cylindrical. The cavity is arranged on the upper surface of the fixing plate 5 and penetrates through the fixing plate 5. The distribution plate 2 is arranged in the middle of the inner cavity of the casing 1 and exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com