A multi-stage liquid co 2 Phase change composite fracturing stimulation system and method

A composite fracturing and CO2 technology, applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of difficult fracturing sand-carrying, short loading time, complicated construction, etc. Improve flow conductivity and enhance the effect of driving pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

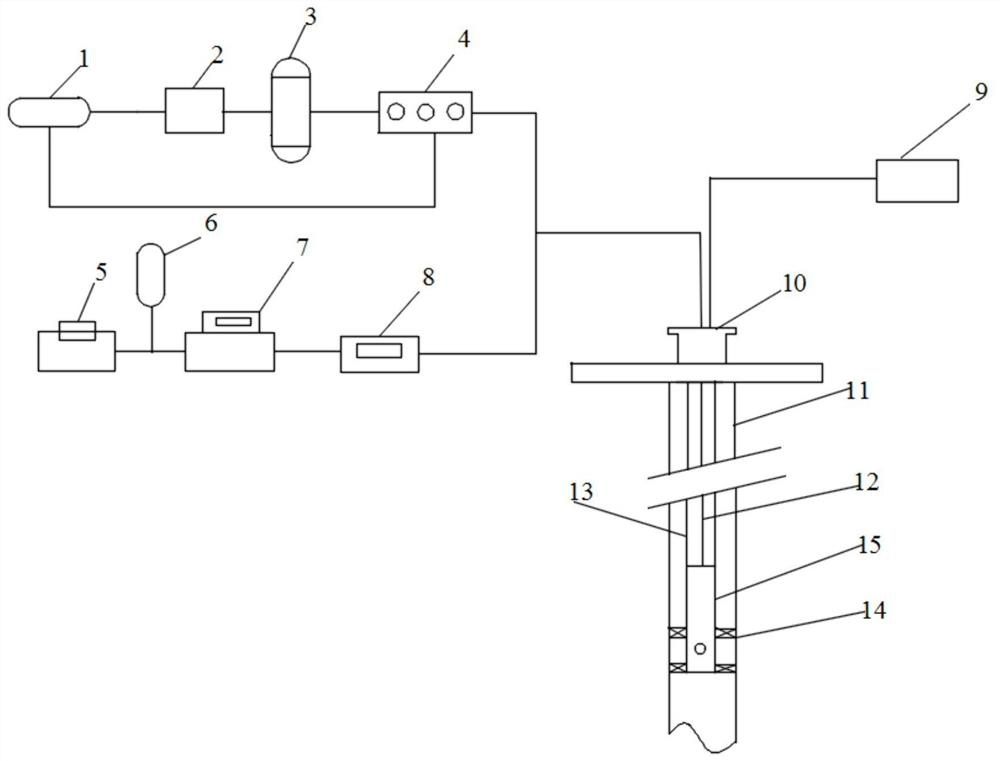

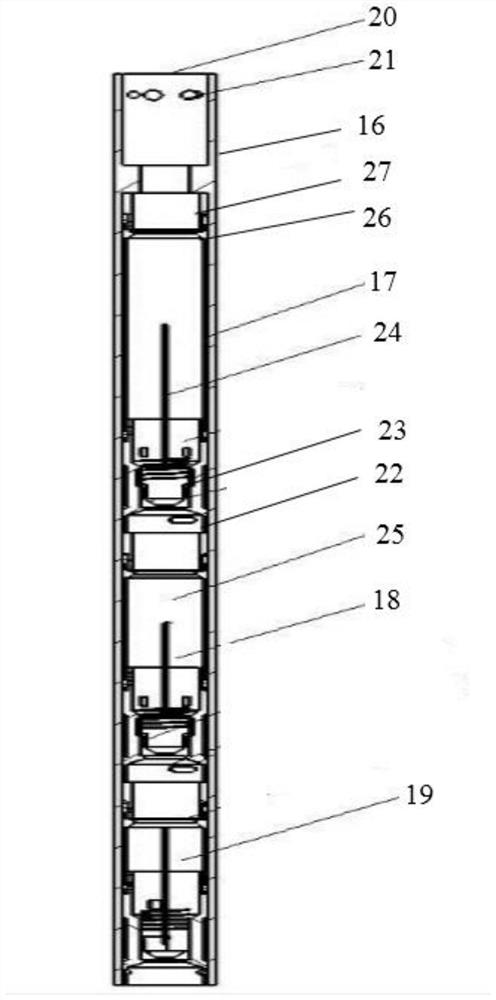

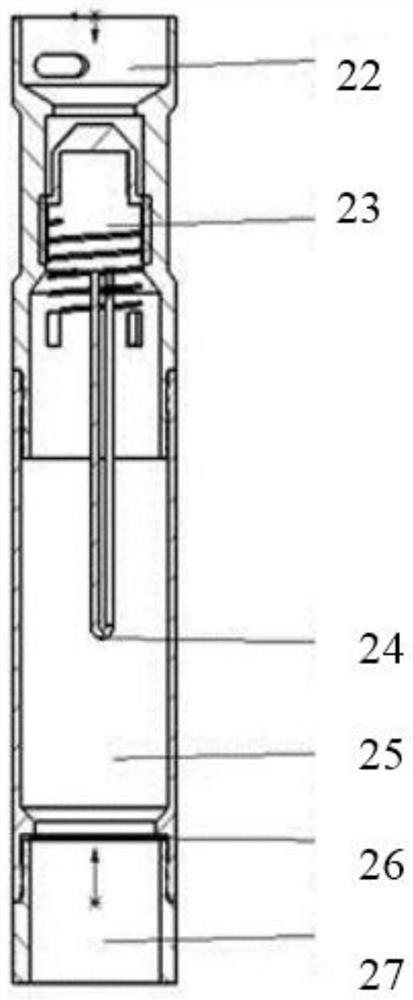

[0042] Such as Figure 1~4 As shown, a multistage liquid CO based 2 Composite fracturing stimulation system with phase change, including liquid CO 2 Injection unit, conventional fracturing fluid injection unit, underground blast fracturing unit and surface control unit; said liquid CO 2 The injection unit and the conventional fracturing fluid injection unit are connected to the underground blasting and fracturing unit through the fracturing string 13; the ground control unit includes a ground control device 9, and the ground control device 9 is connected to the underground blasting and fracturing unit through a cable 28. connect;

[0043] The liquid CO 2 Injection unit includes liquid CO 2 Tank 1, liquid CO 2 Pressurization equipment 2, gas-liquid separation equipment 3, high-pressure pumping equipment 4; the liquid CO 2 Tank 1, liquid CO 2 Pressure boosting equipment 2, gas-liquid separation equipment 3, and high-pressure pumping equipment 4 are connected in sequence t...

Embodiment 2

[0053] Based on multistage liquid CO as described in Example 1 2 Phase change composite fracturing stimulation system, the difference is that the multi-stage liquid CO 2 In the phase change blasting device 15, four liquid CO 2 Phase change generator. The liquid CO 2 The pipe lengths of the phase change generators are 800mm, 600mm, 400mm and 400mm respectively.

Embodiment 3

[0055] Based on multistage liquid CO as described in Example 1 2 Phase change composite fracturing stimulation system, the difference is that the multi-stage liquid CO 2 Phase change blasting device 15 is provided with 2 liquid CO 2 Phase change blasting device. The liquid CO 2 The tube lengths of the phase change blasting devices are 800mm and 600mm respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com