Patents

Literature

31results about How to "Increase driving pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

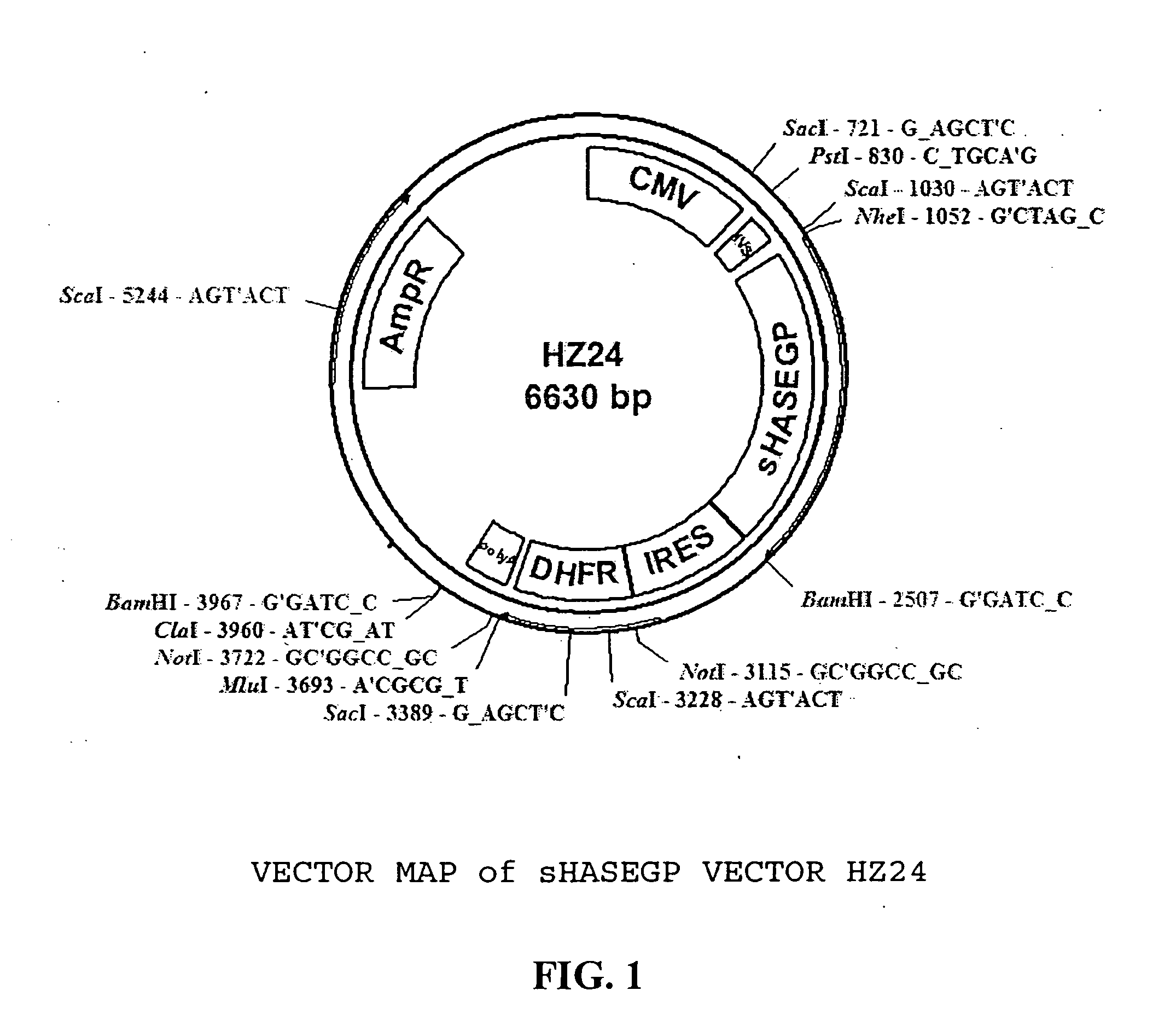

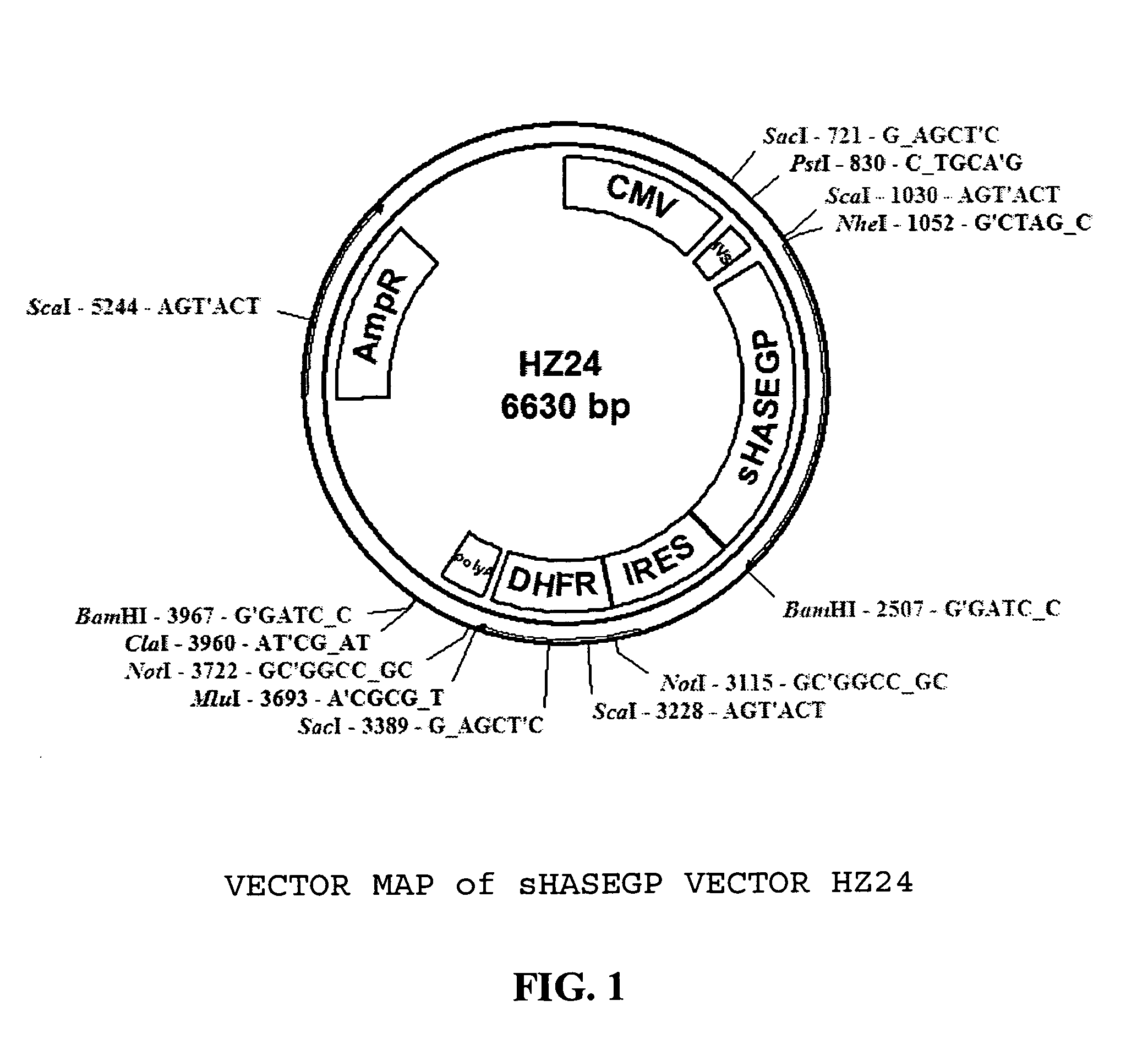

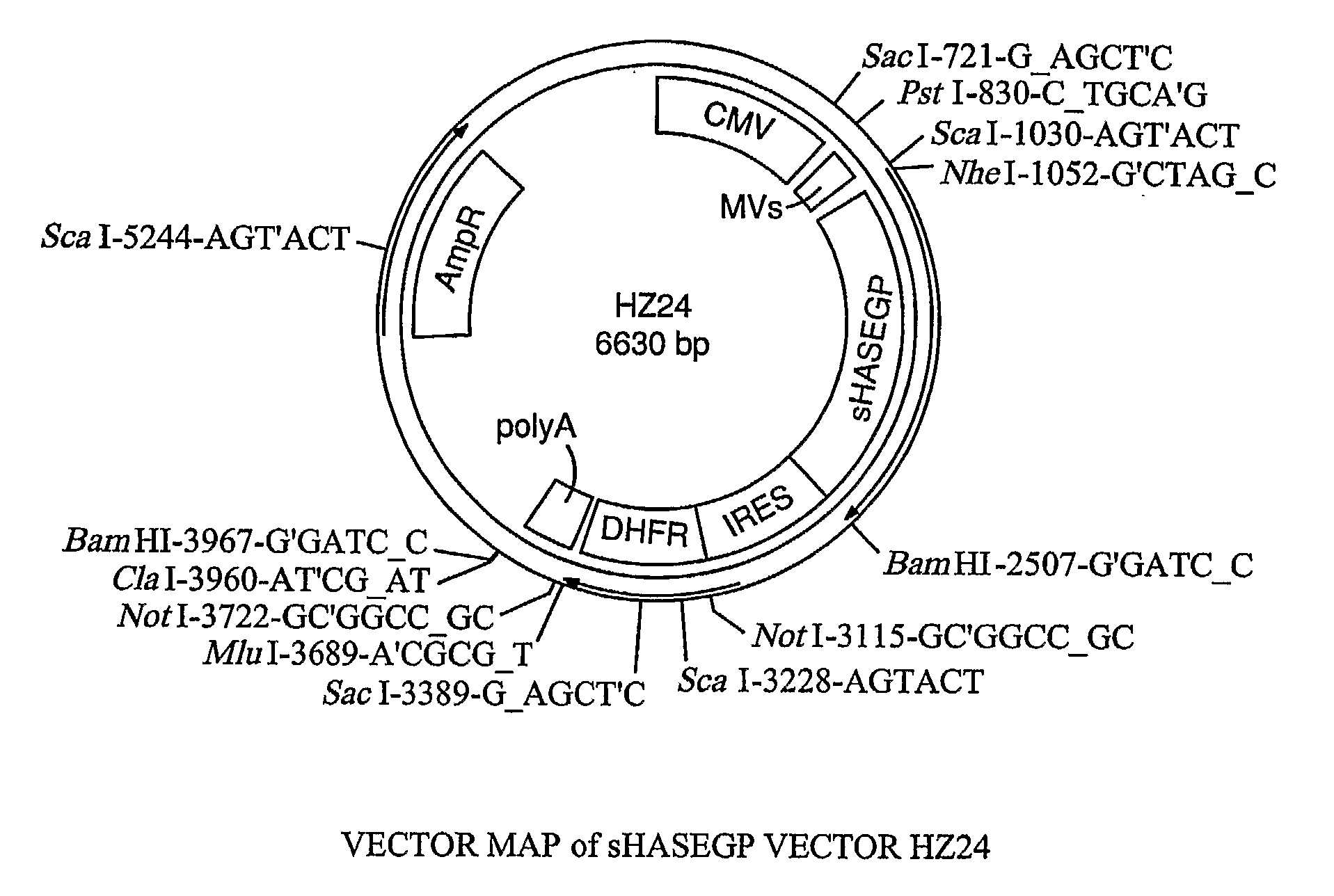

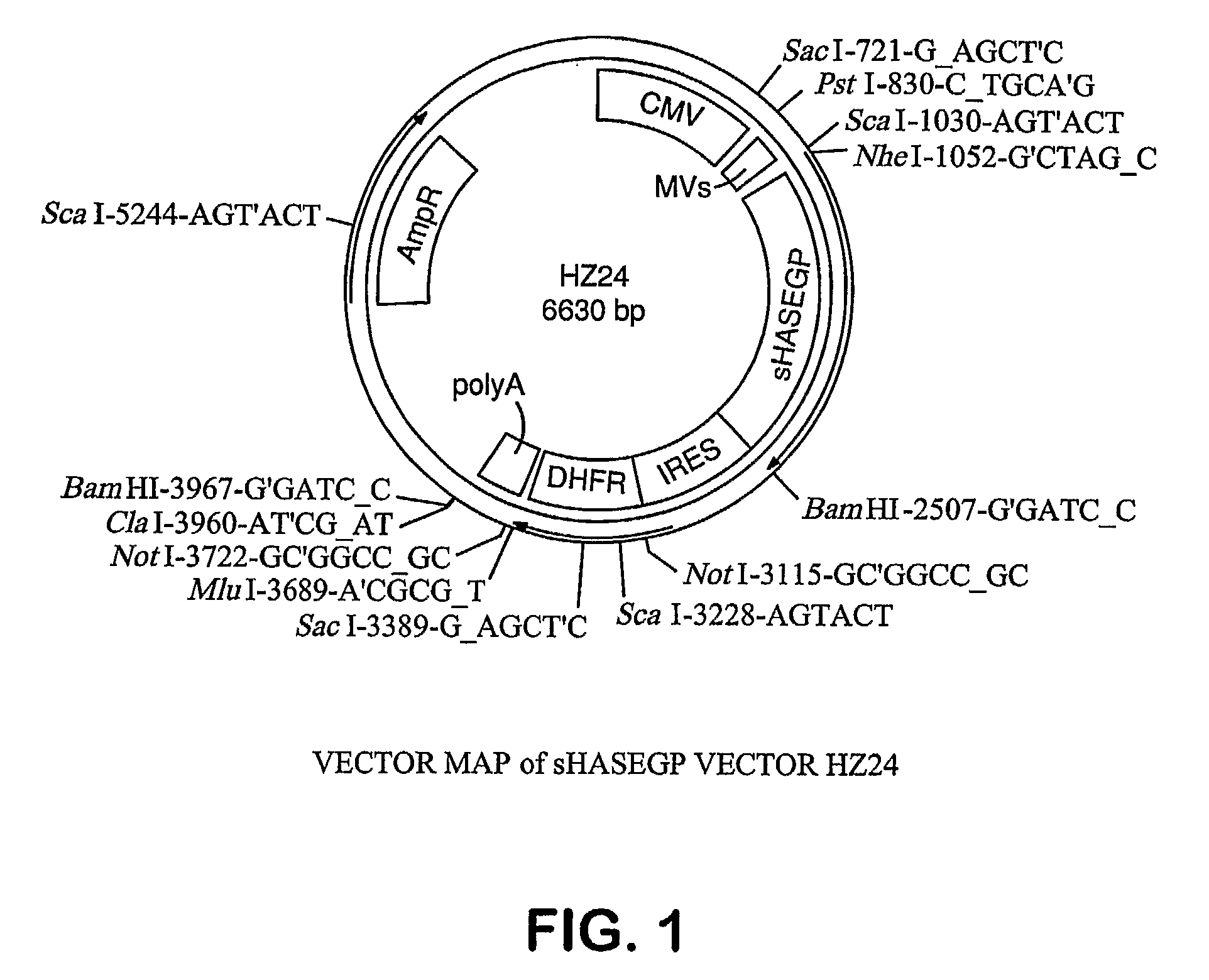

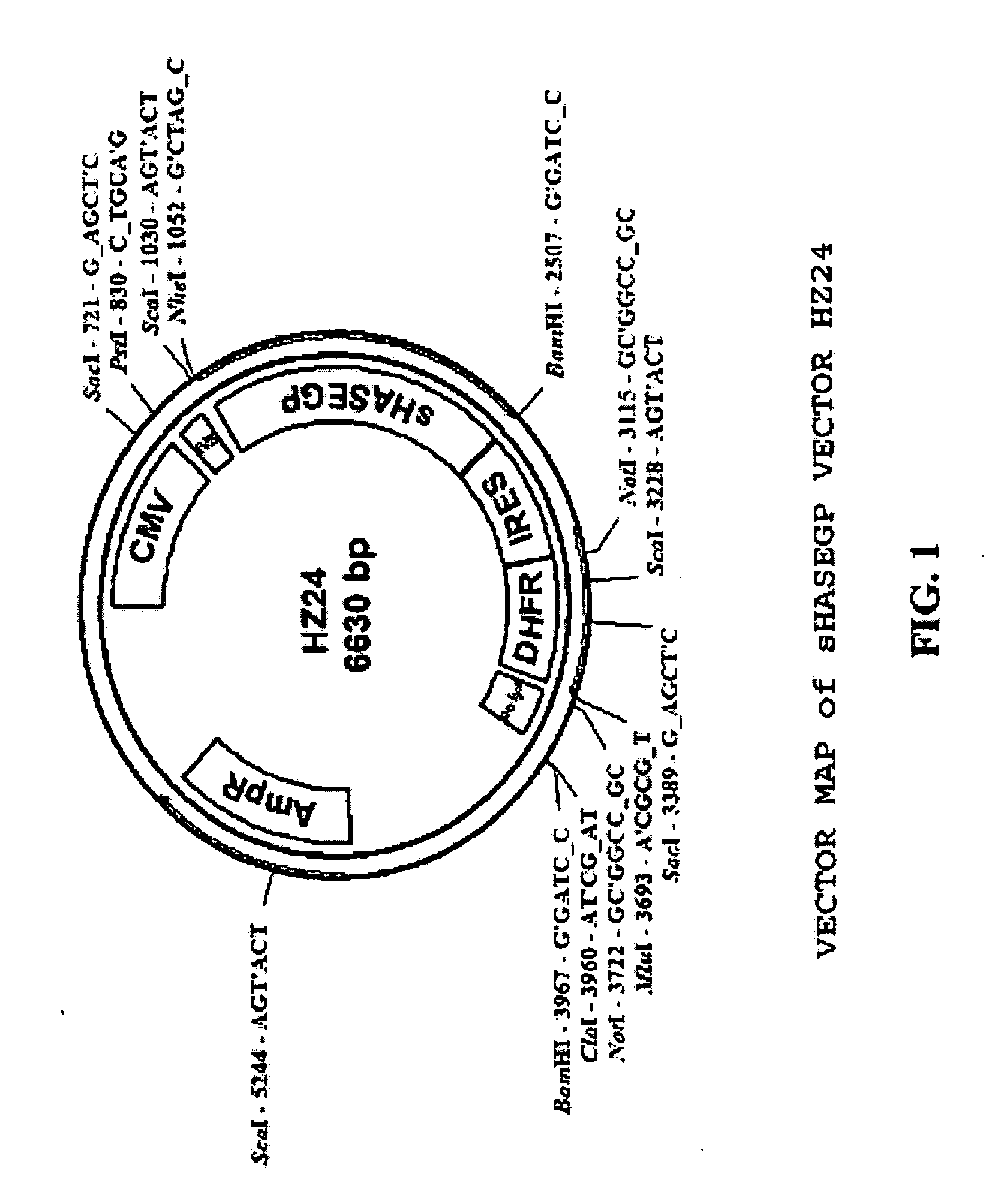

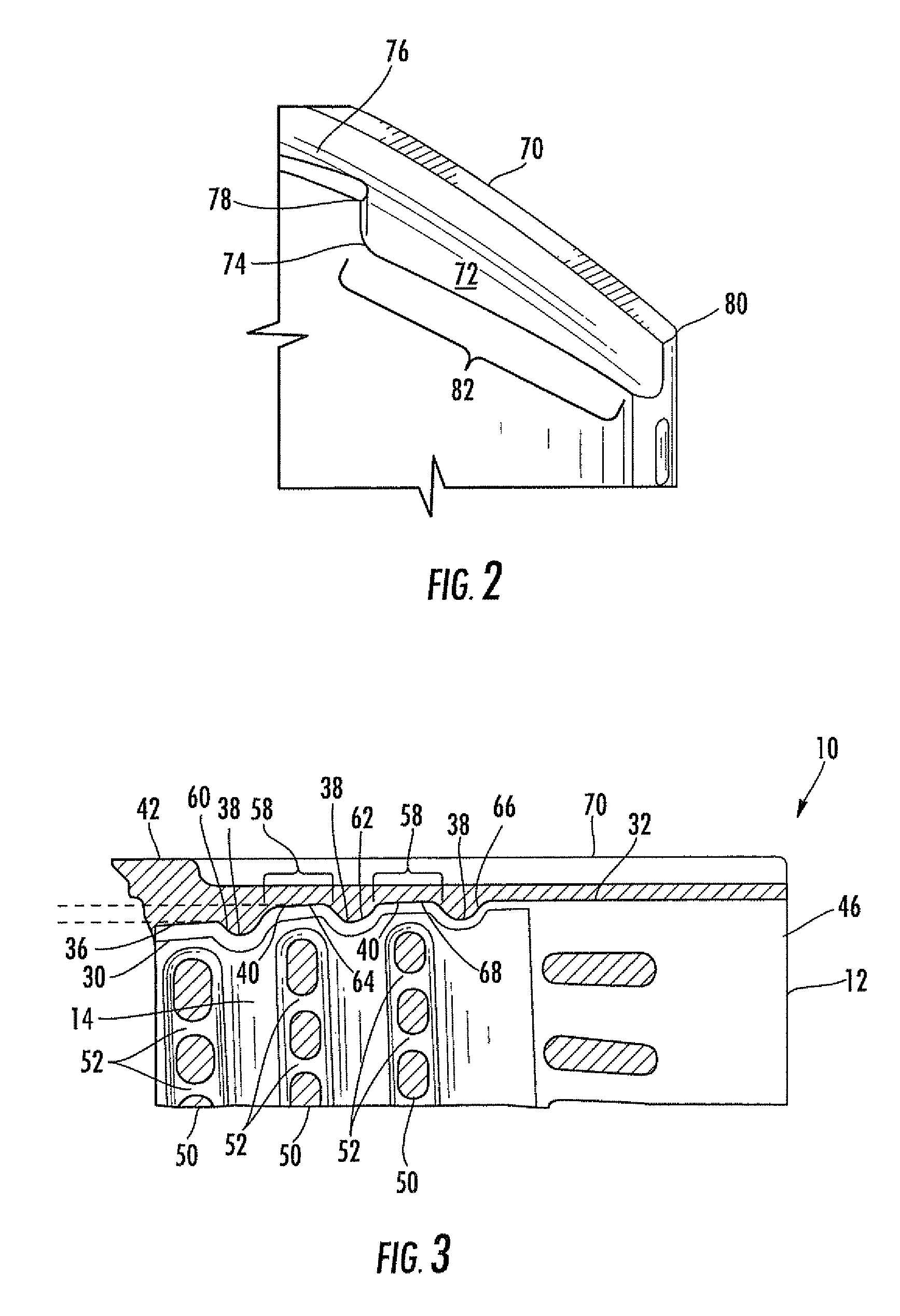

Soluble glycosaminoglycanases and methods of preparing and using soluble glycosaminogly ycanases

PendingUS20060104968A1Improve extentIncrease ratingsSenses disorderNervous disorderHyaluronidaseRecombinant glycoprotein

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated forms of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME

Soluble glycosaminoglycanases and methods of preparing and using soluble glycosaminoglycanases

ActiveUS20050260186A1Improve extentIncrease ratingsAntibacterial agentsSenses disorderHyaluronidasePathology diagnosis

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated forms of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME

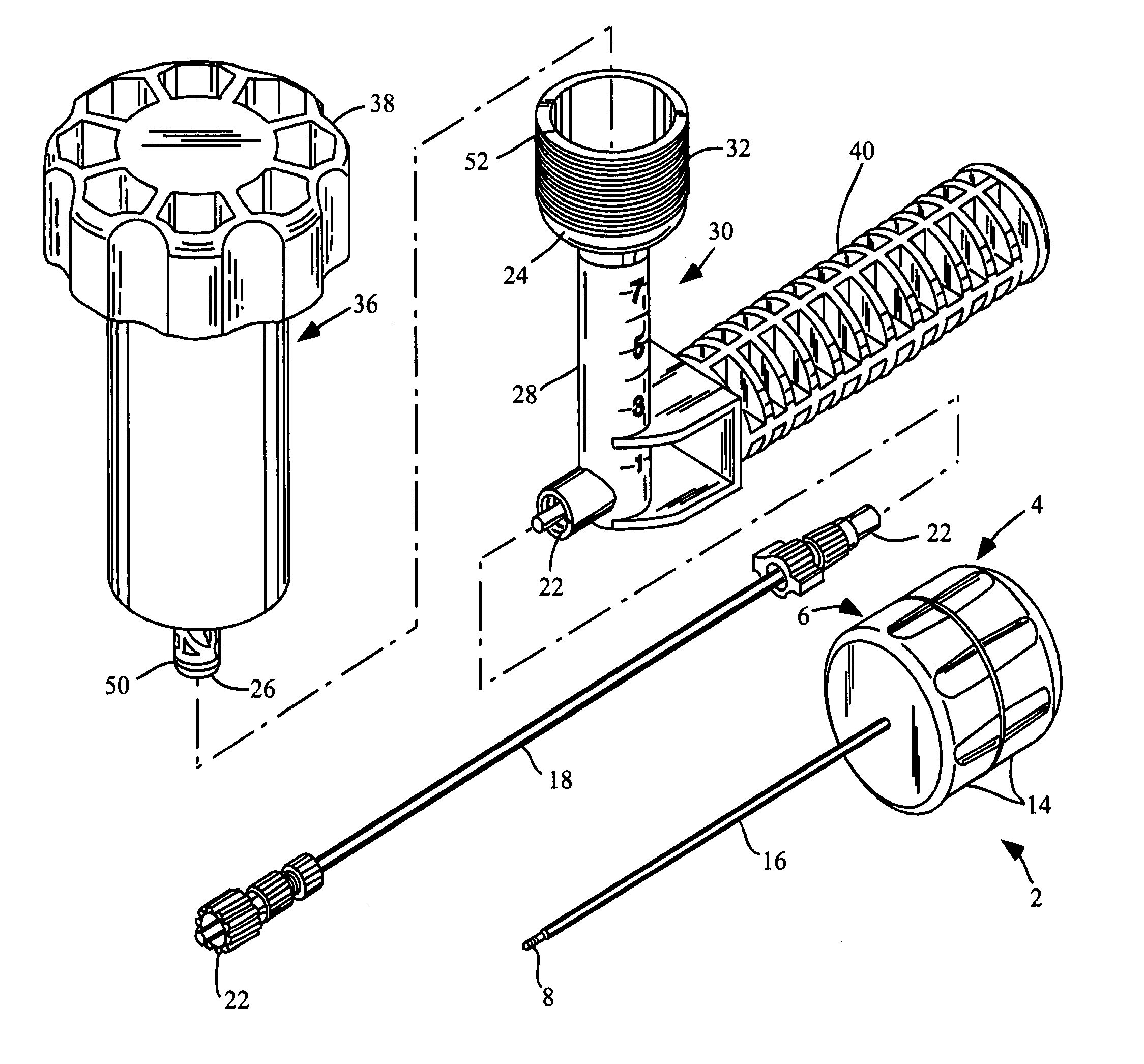

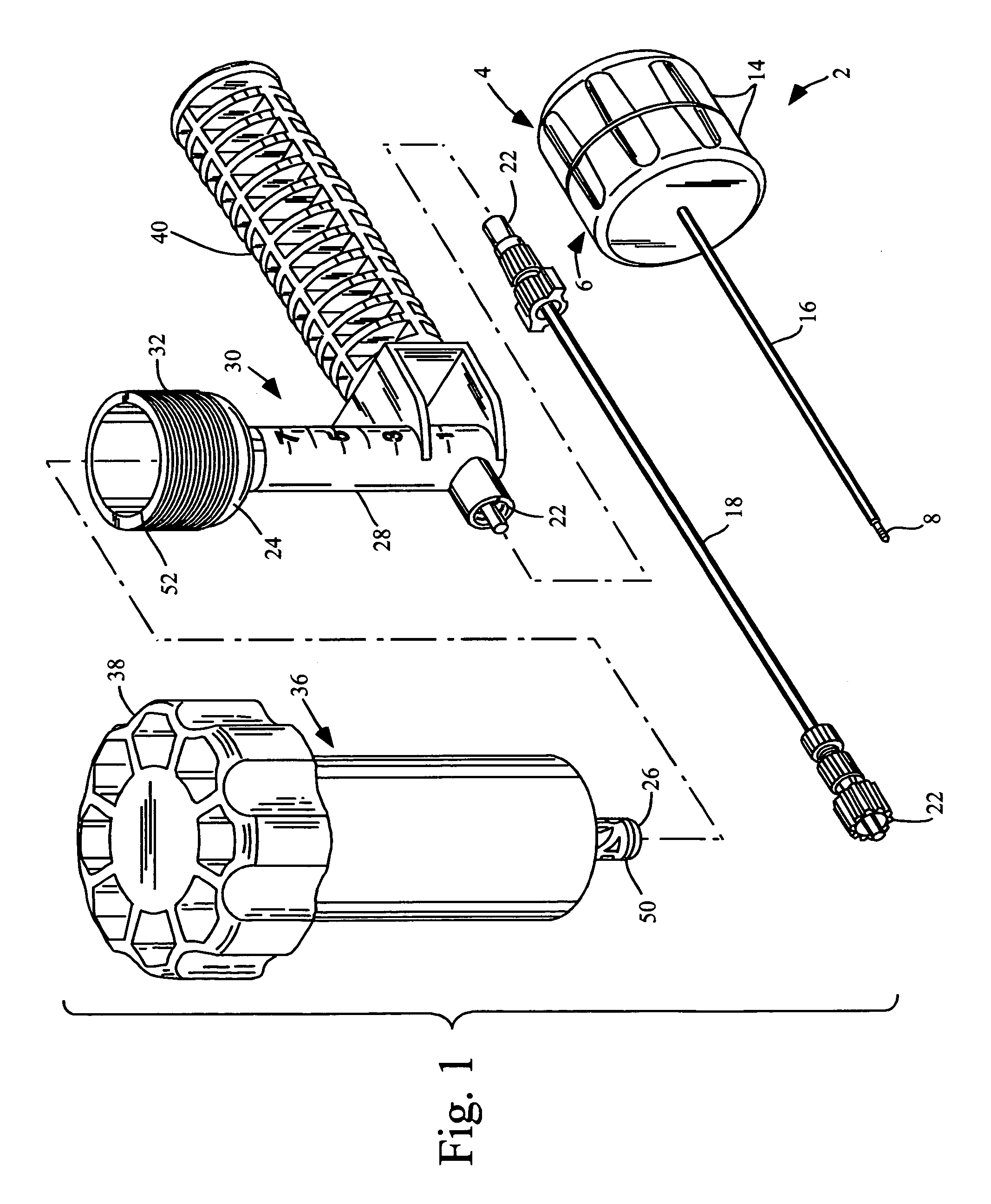

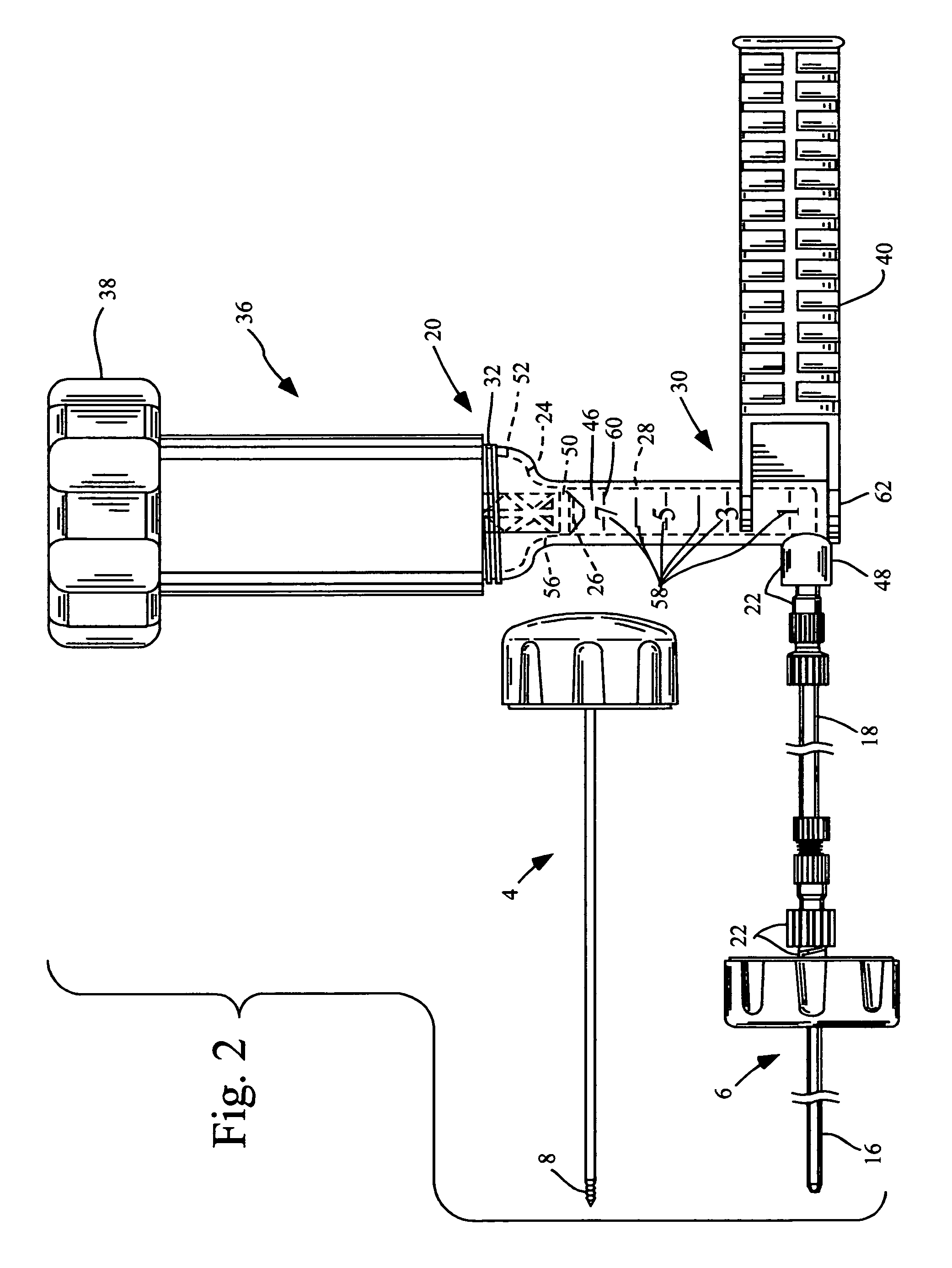

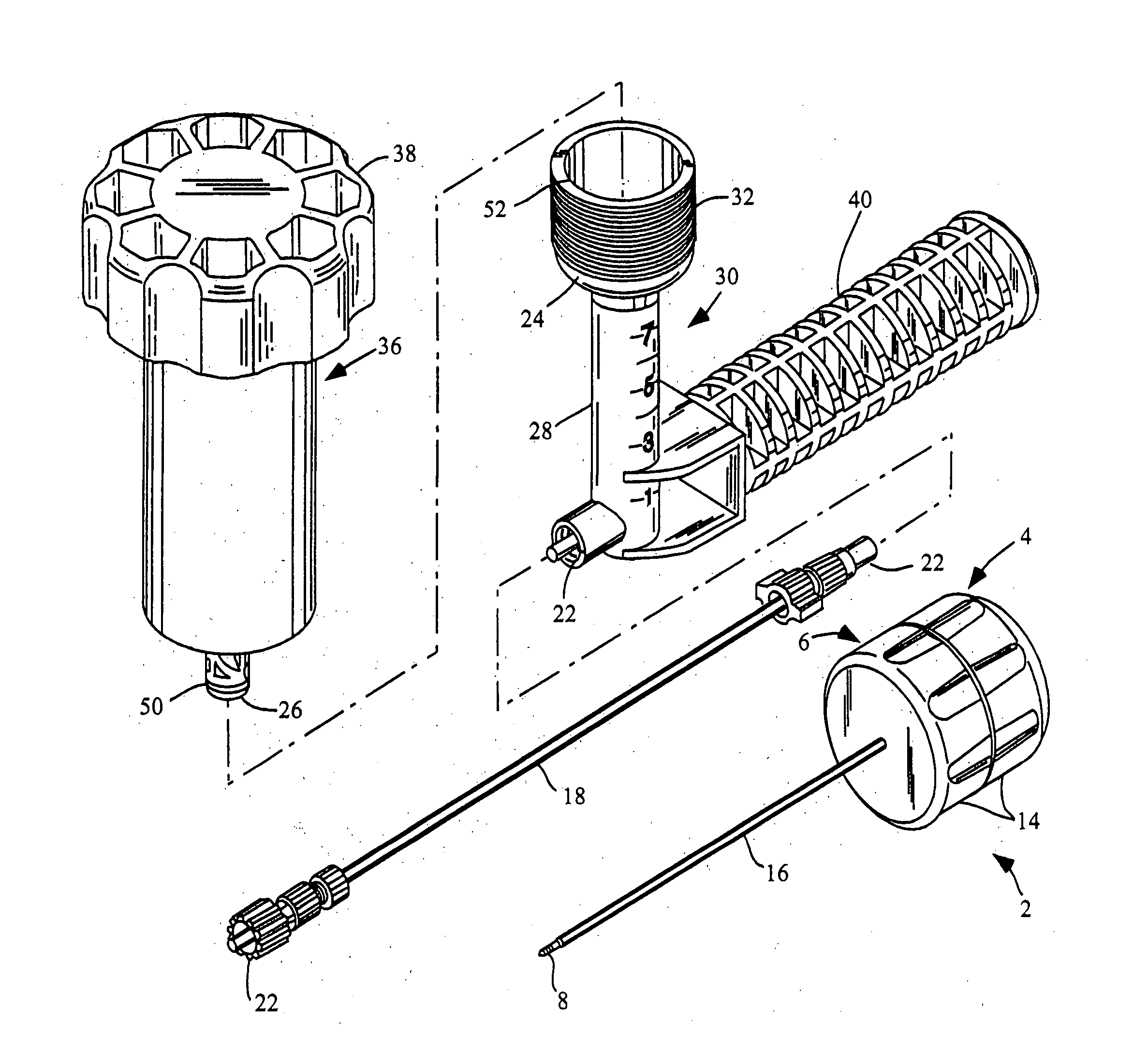

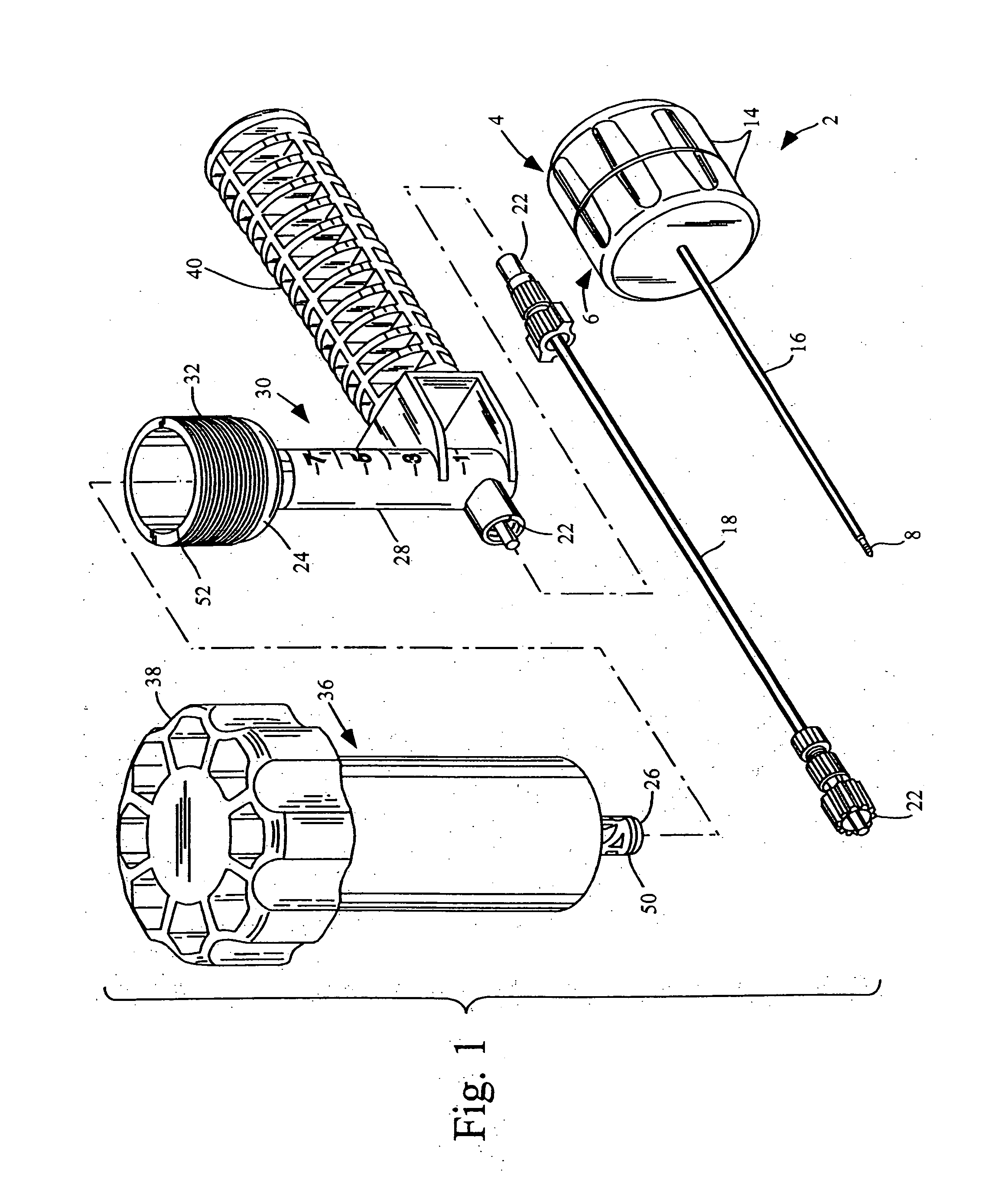

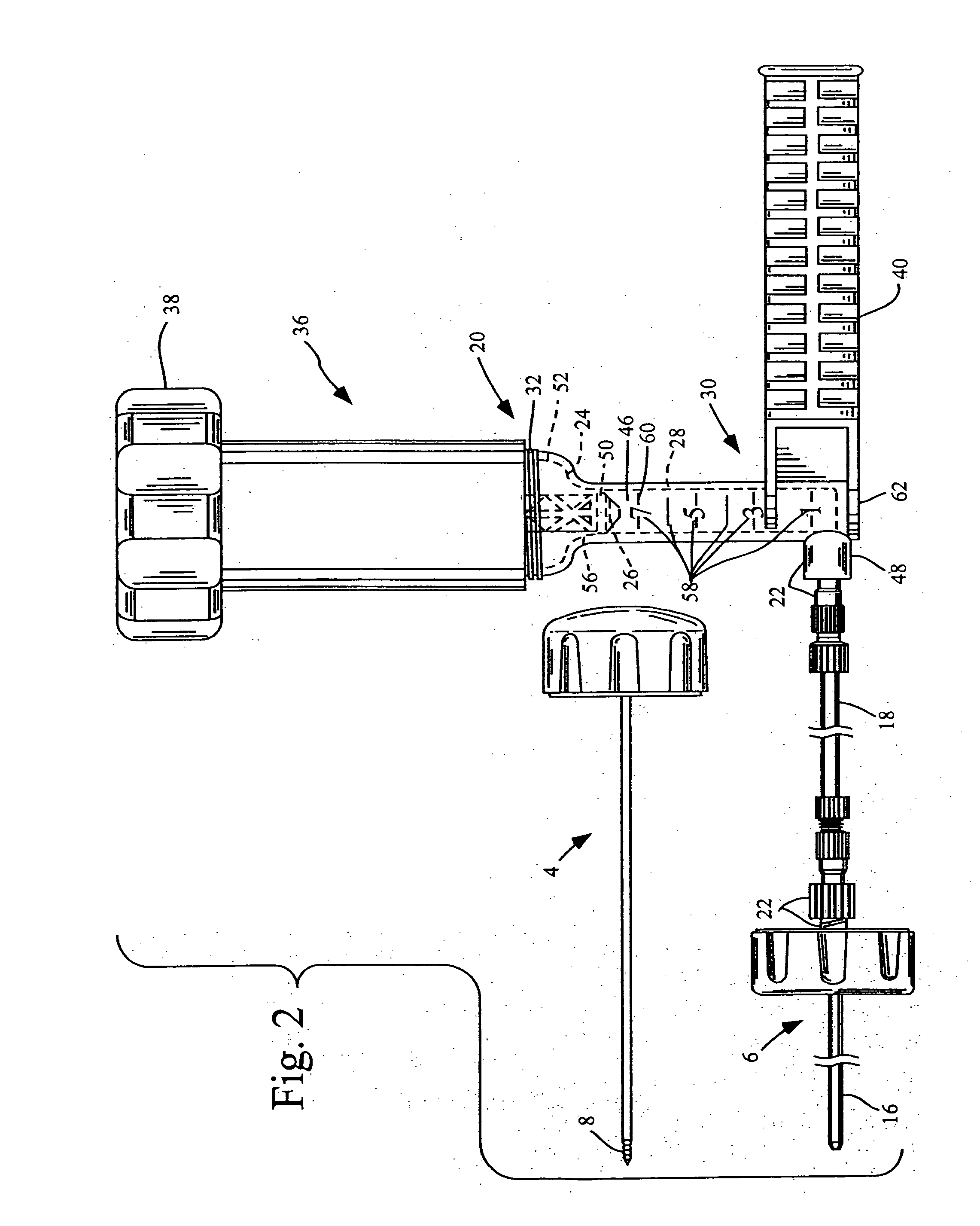

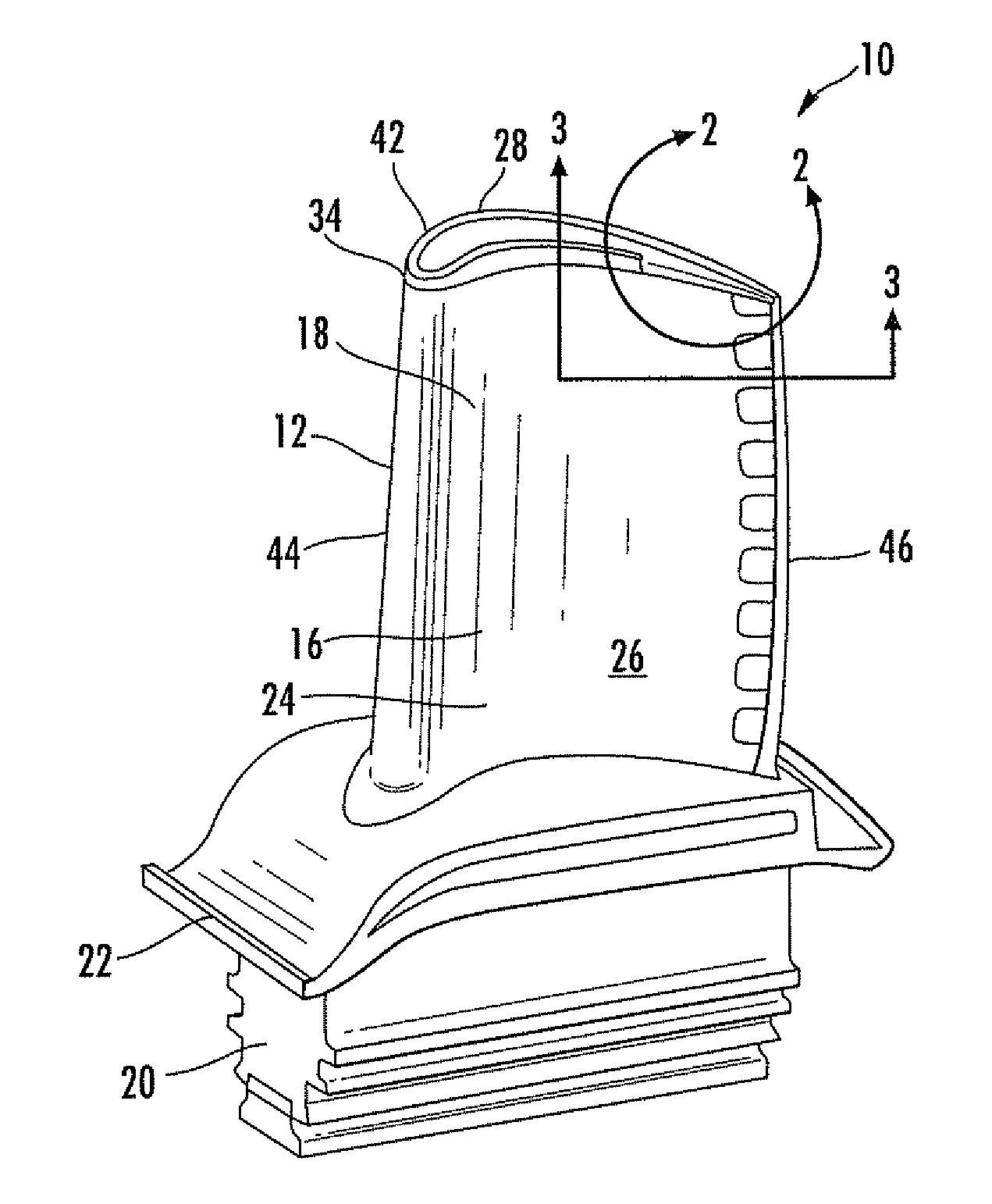

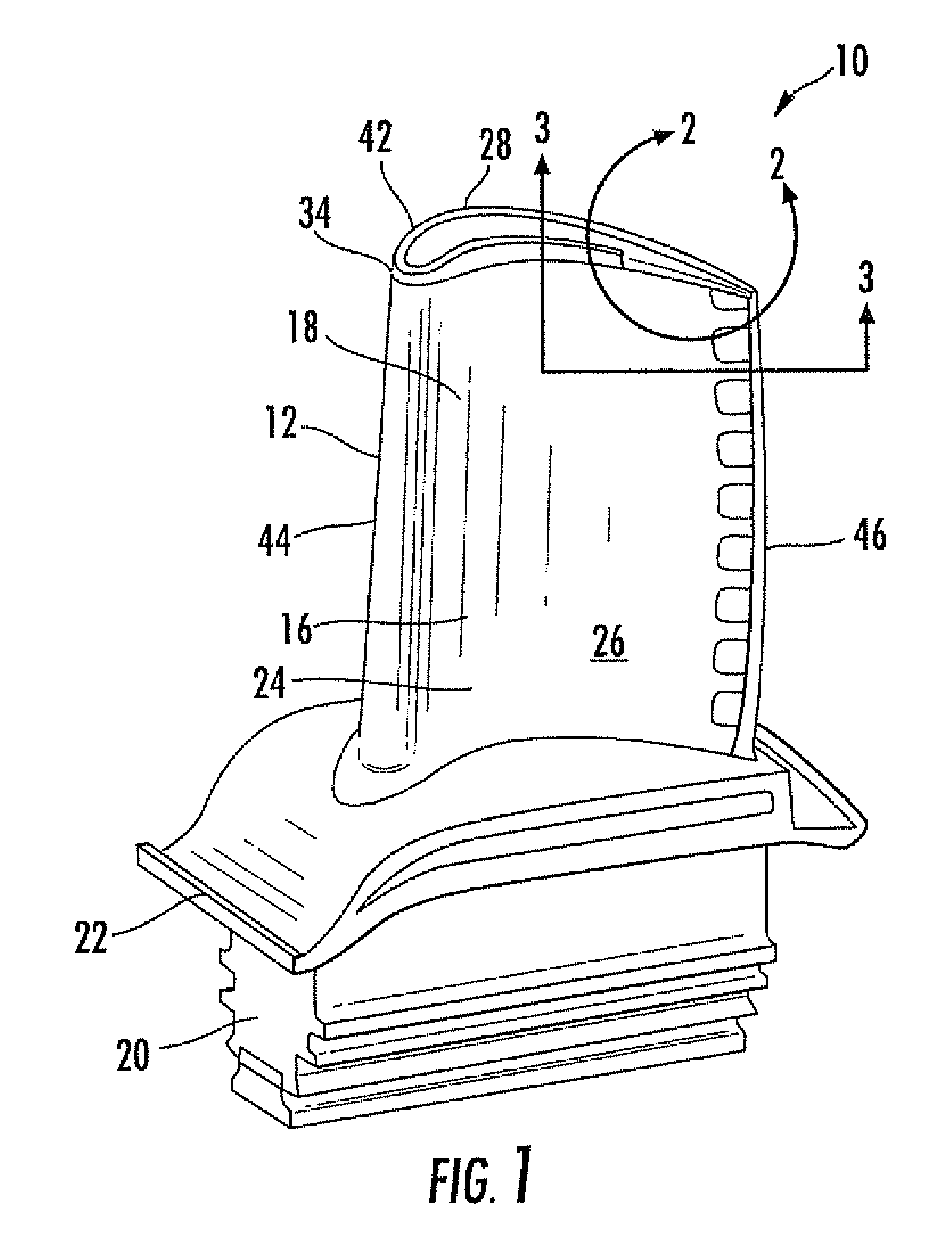

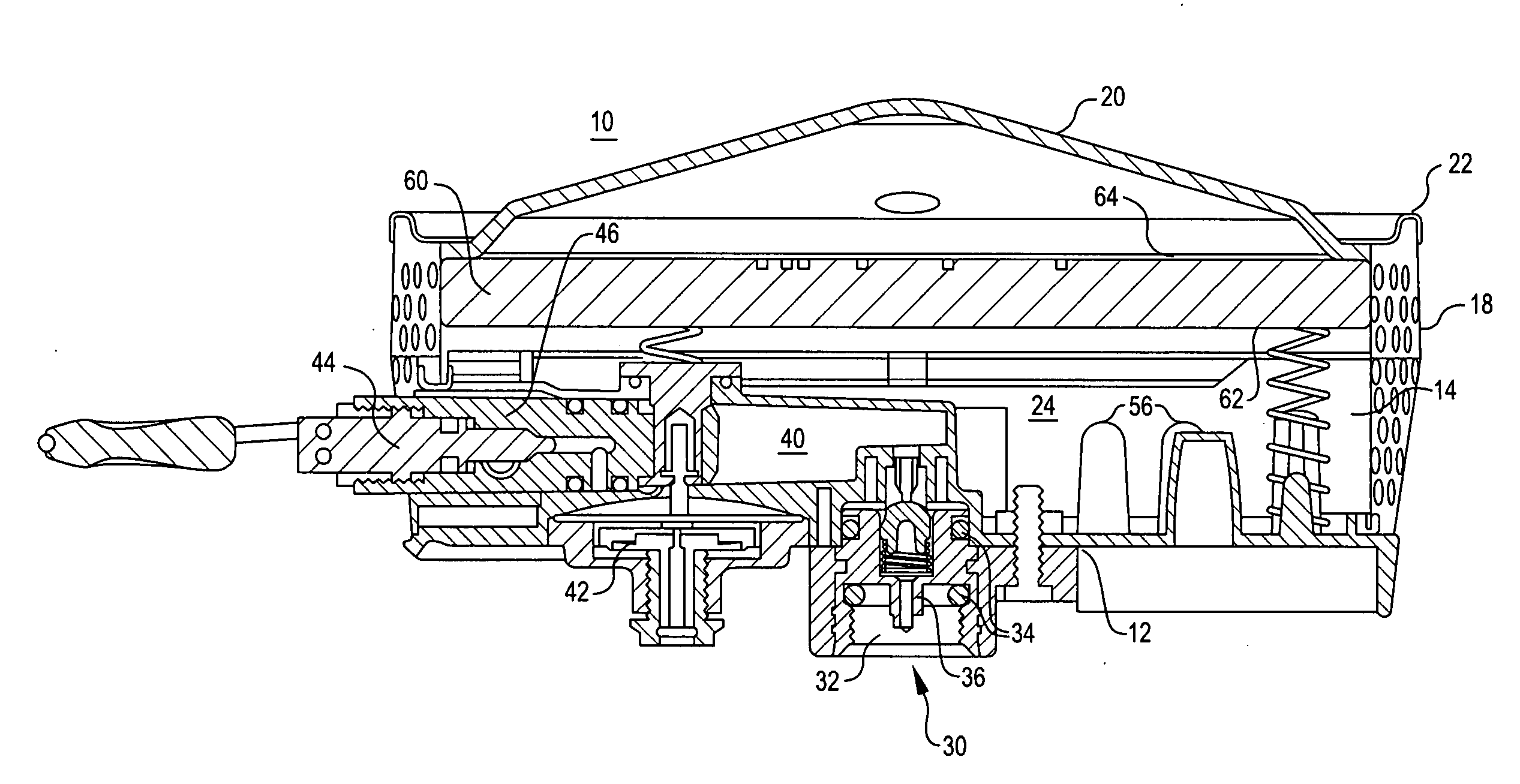

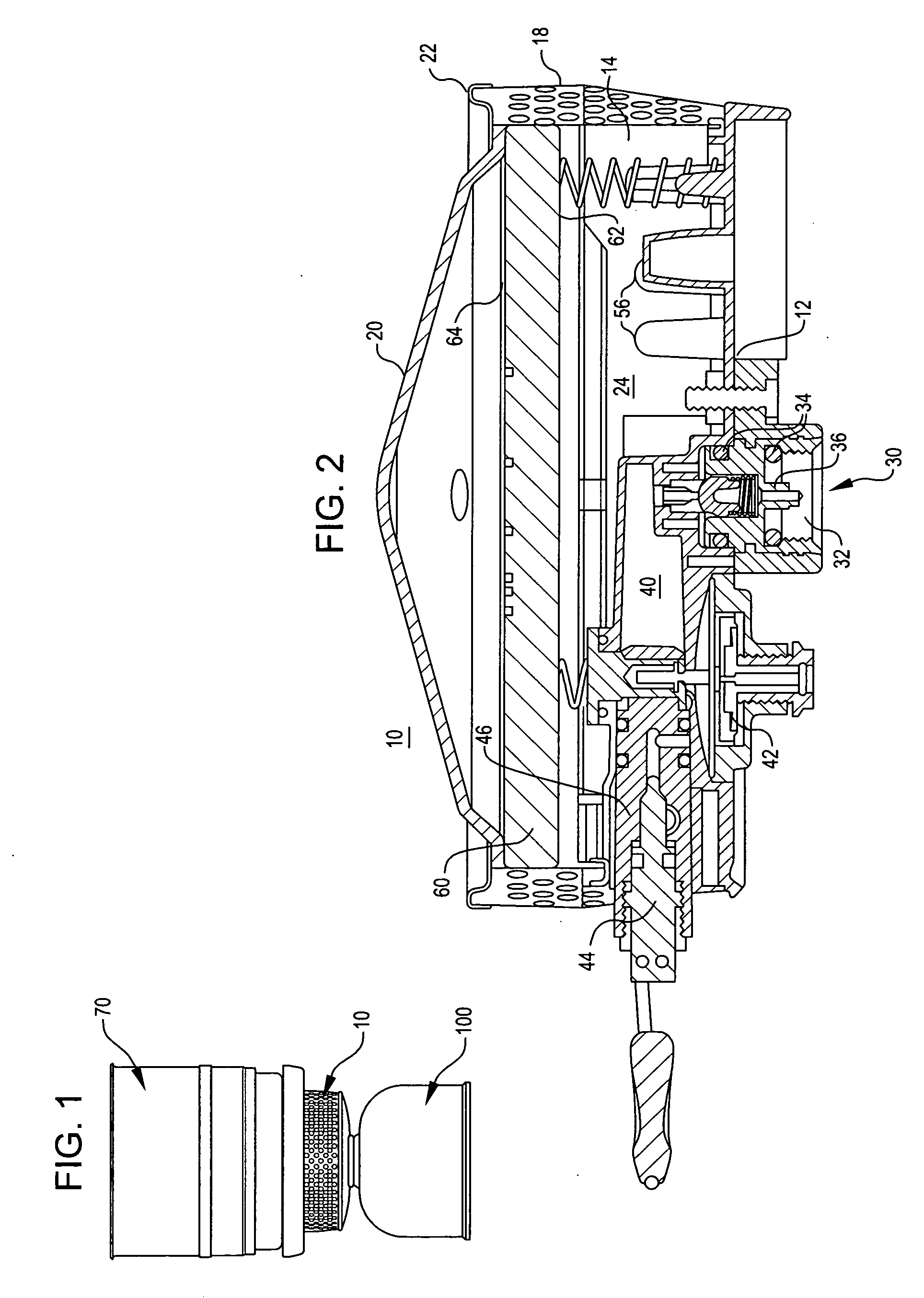

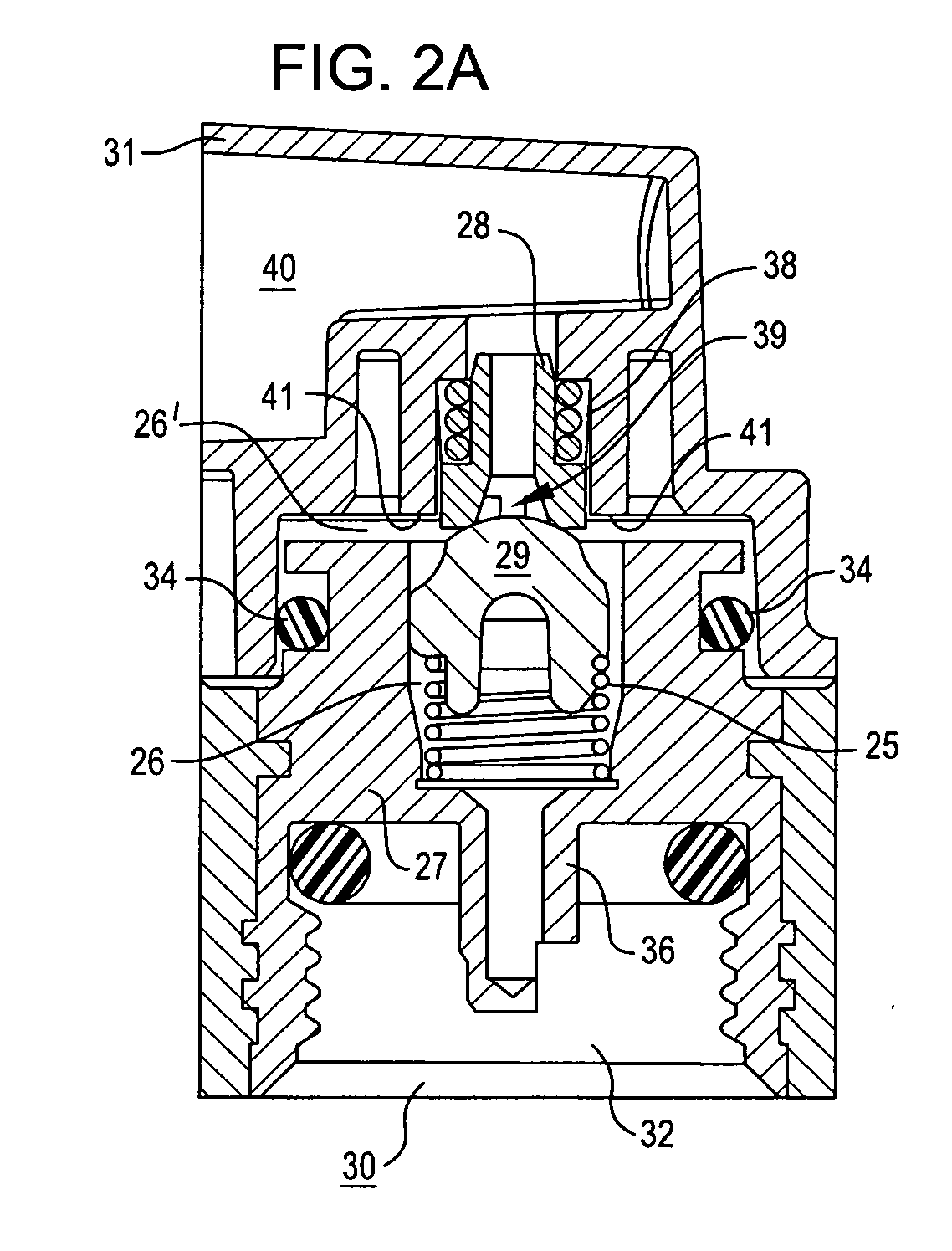

Methods for delivering tissue implant material with a high pressure applicator

InactiveUS7048743B2Increased margin of errorAvoid pollutionJoint implantsIntravenous devicesReady to useHigh pressure

This relates to an improved delivery system for accurately loading and controlling the delivery of flowable material to a patient. Particularly, the system may be used in the injection of hard tissue implant materials such as PMMA under pressures up to about 4000 psi. The system includes an applicator with a first column having an implant material introduction section adapted to provide for effective loading of the implant material and a second column housing a piston. The introduction section has a larger size than that of a vessel section or bore in which the requisite pressure seal between the piston and bore wall is formed. The first column may include an introduction section flared open to an included larger funnel-like opening or a separate funnel may be used that interfaces with the introduction section to facilitate the introduction of implant material. Handles on the first and second columns to be turned relative to each other to advance the columns toward each other may be provided for manual actuation of the applicator to drive implant material through a cannula and deliver implant material to a desired site.

Owner:NEUROTHERM

Soluble Glycosaminoglycanases and Methods of Preparing and Using Soluble Glycosaminoglycanases

InactiveUS20090123367A1Facilitated DiffusionEnhance convective transportBacterial antigen ingredientsPeptide/protein ingredientsHyaluronidaseNuclear chemistry

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated forms of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME +6

High pressure delivery system

This relates to an improved delivery system for accurately loading and controlling the delivery of flowable material to a patient. Particularly, the system may be used in the injection of hard tissue implant materials such as PMMA under pressures up to about 4000 psi. The system includes an applicator with a first column having an implant material introduction section adapted to provide for effective loading of the implant material and a second column housing a piston. The introduction section has a larger size than that of a vessel section or bore in which the requisite pressure seal between the piston and bore wall is formed. The first column may include an introduction section flared open to an included larger funnel-like opening or a separate funnel may be used that interfaces with the introduction section to facilitate the introduction of implant material. Handles on the first and second columns to be turned relative to each other to advance the columns toward each other may be provided for manual actuation of the applicator to drive implant material through a cannula and deliver implant material to a desired site.

Owner:NEUROTHERM

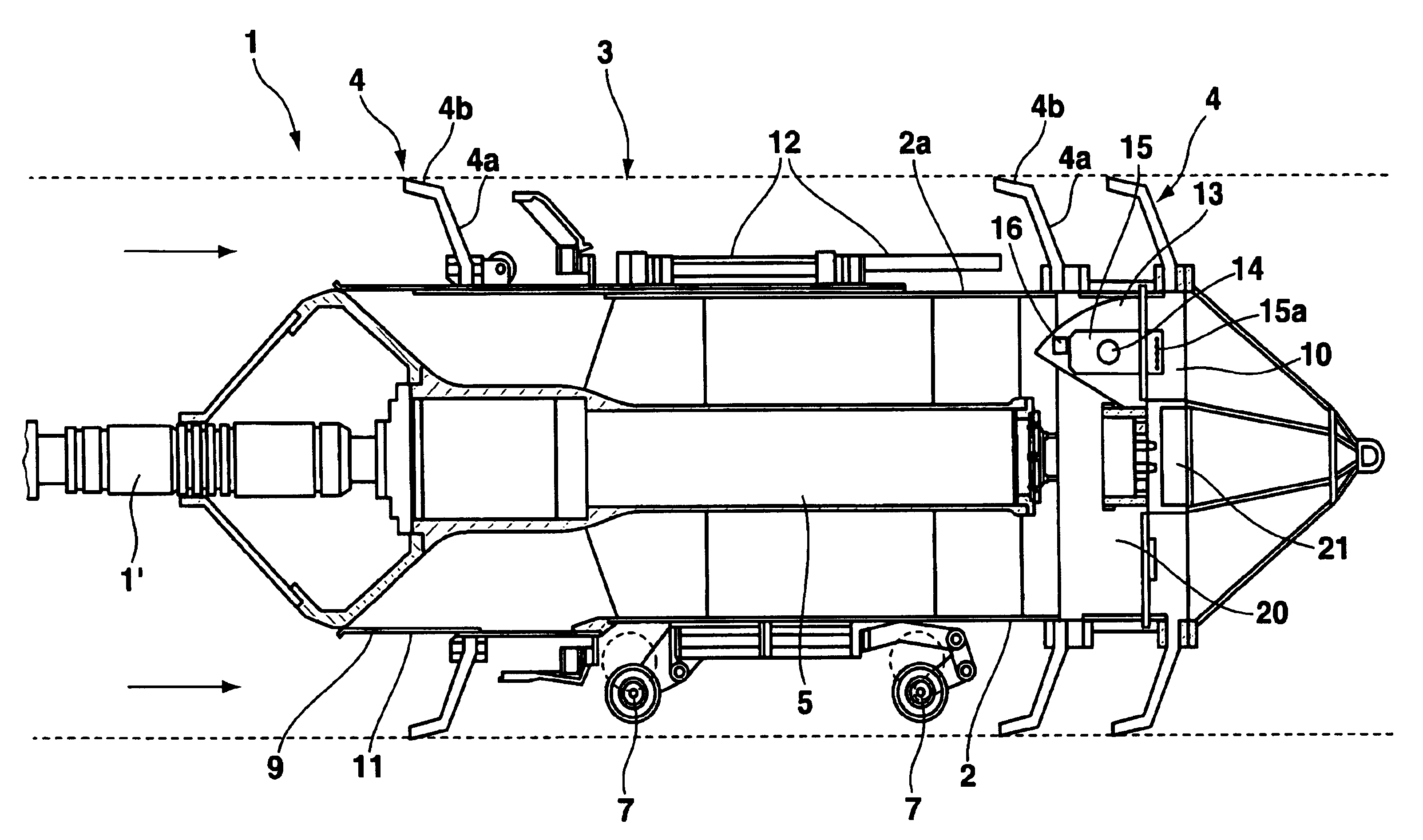

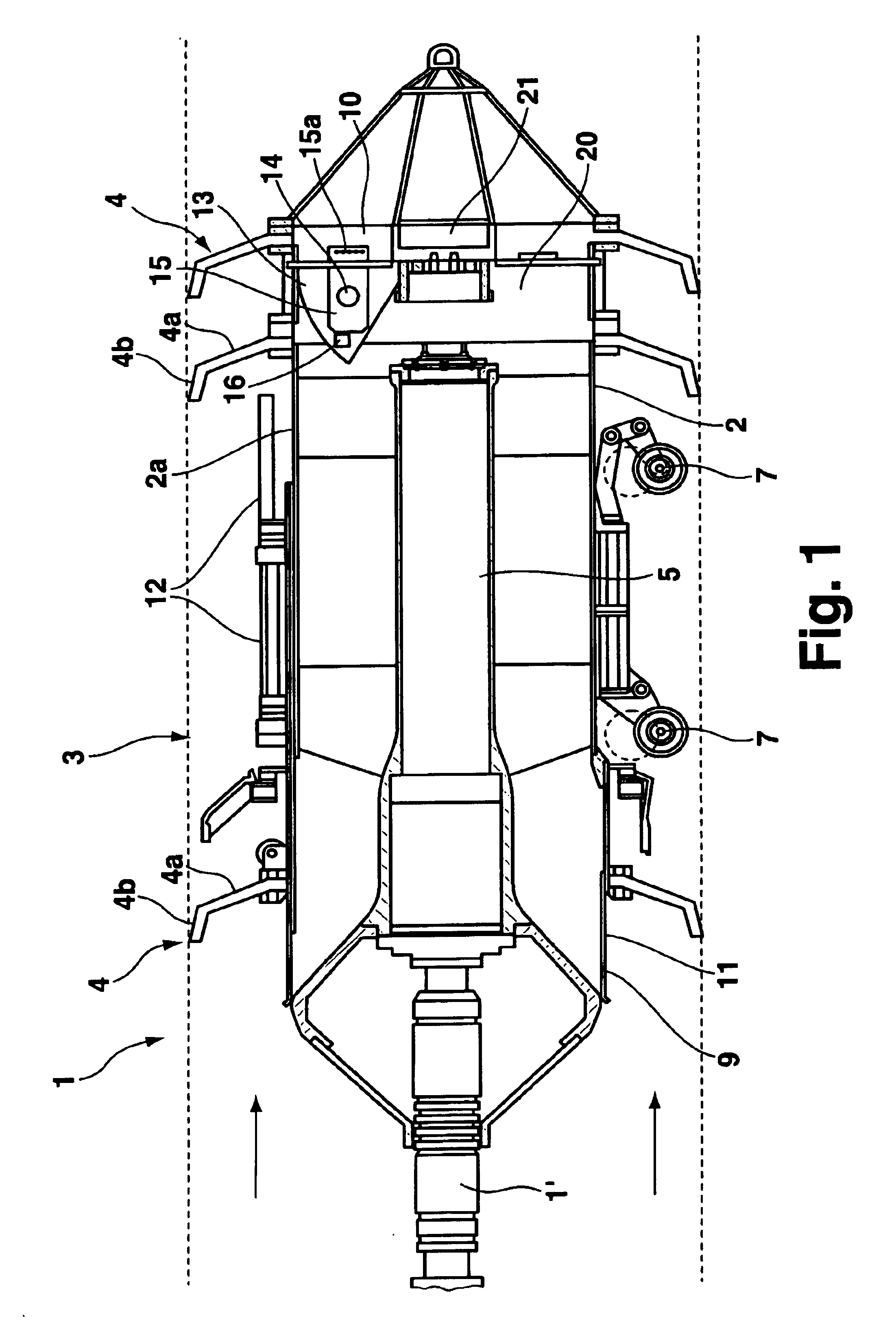

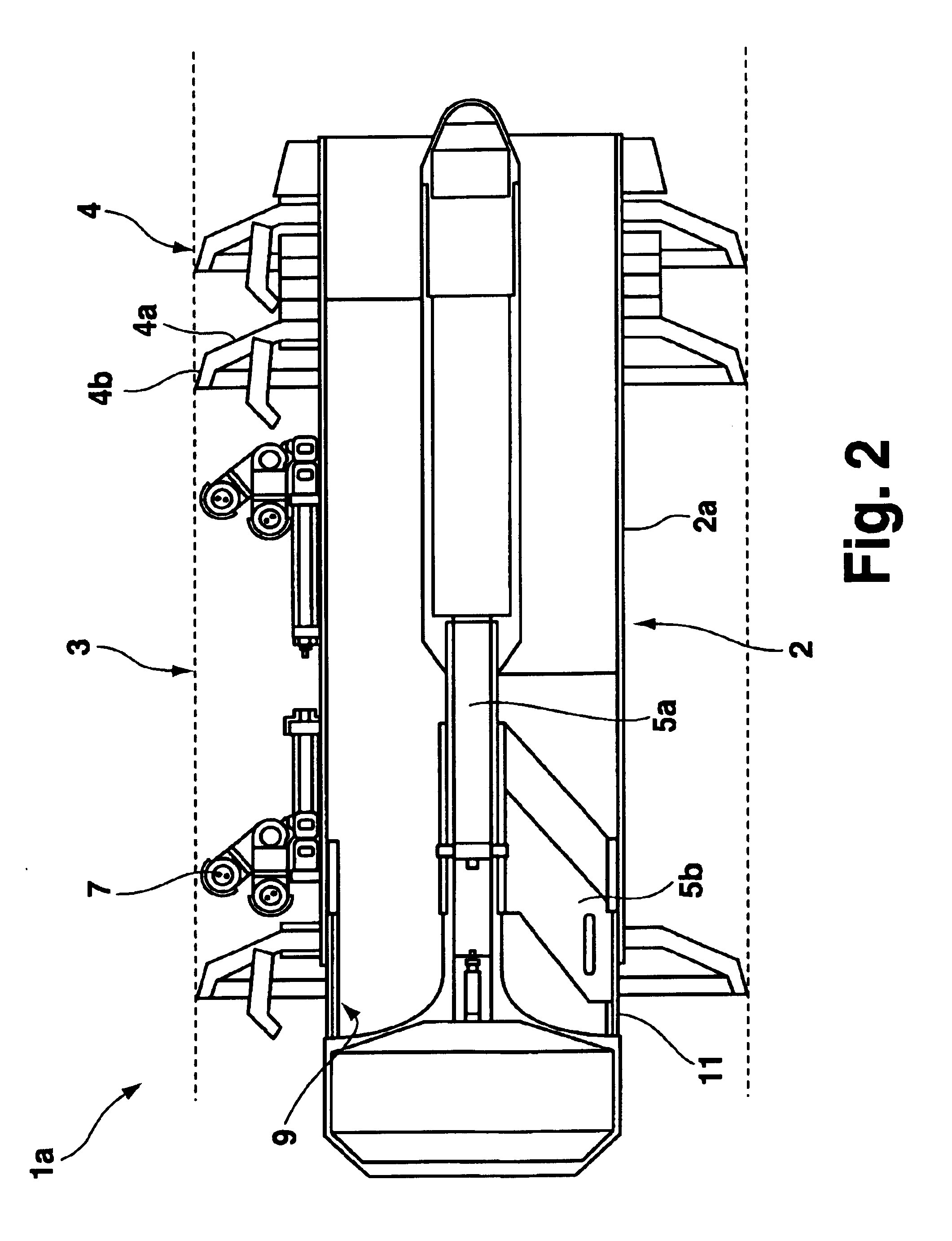

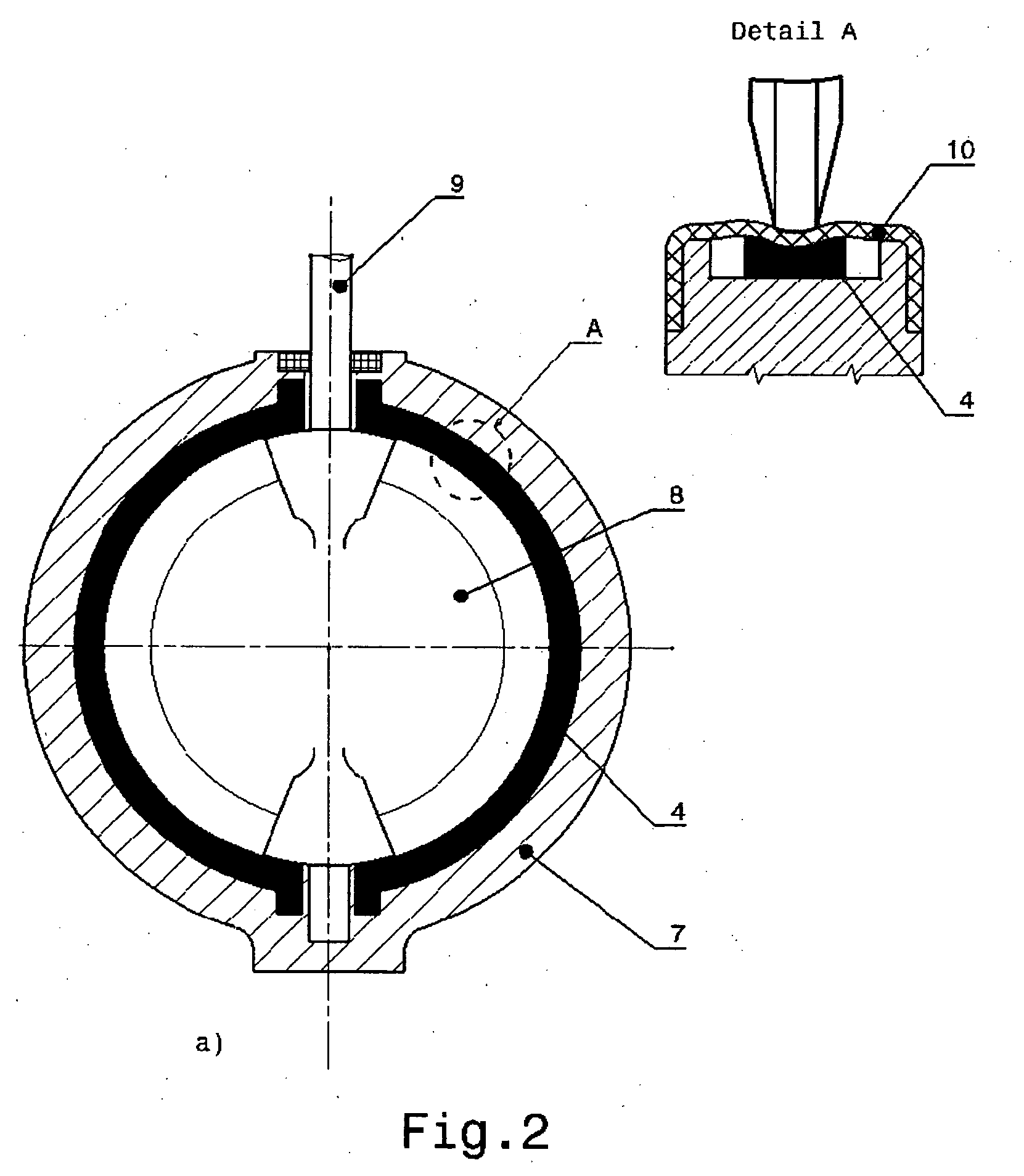

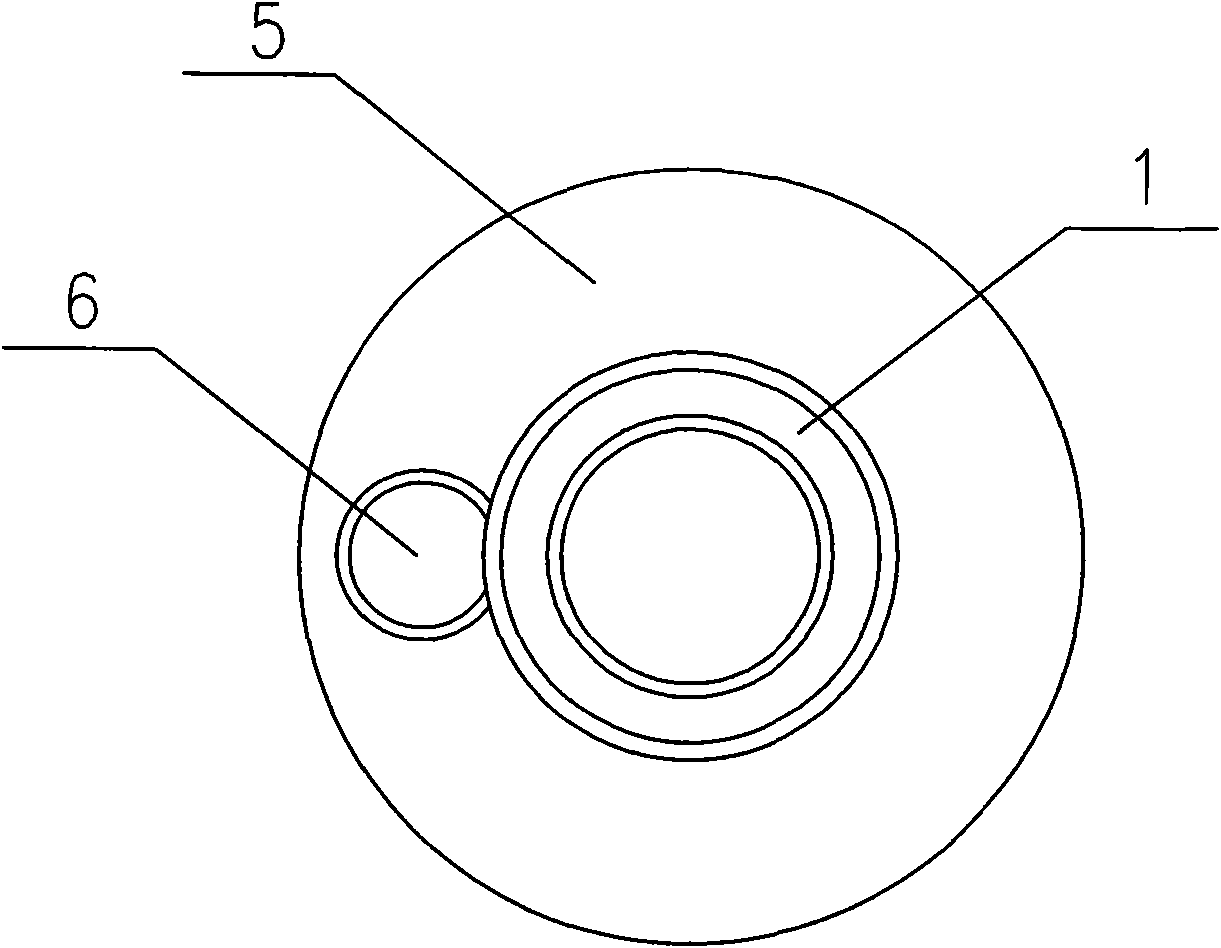

Pipe conduit vehicle

InactiveUS6944902B1Improved fluid dynamic for fluid flowingIncrease driving pressureHollow article cleaningCleaning using toolsEngineeringPressure difference

A pipe conduit vehicle having a substantially cylindrical housing and with at least one ring-shaped sealing element disposed between the outer side of the housing and the inner wall of the pipe conduit can be moved in the pipe conduit via the transport fluid flow. The pipe conduit vehicle thereby comprises at least one inlet opening and at least one outlet opening which form a bypass through the inner portion of the housing to reduce the pressure differential before and after the pipe conduit vehicle, wherein the at least one inlet opening is disposed on the outer surface of the cylindrical housing.

Owner:PII PIPETRONIX

Soluble glycosaminoglycanases and methods of preparing and using soluble glycosaminoglycanases

ActiveUS20100196423A1Reduce sensitivityGreater serum half-livesAntibacterial agentsSenses disorderHyaluronidaseNuclear chemistry

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated form of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME

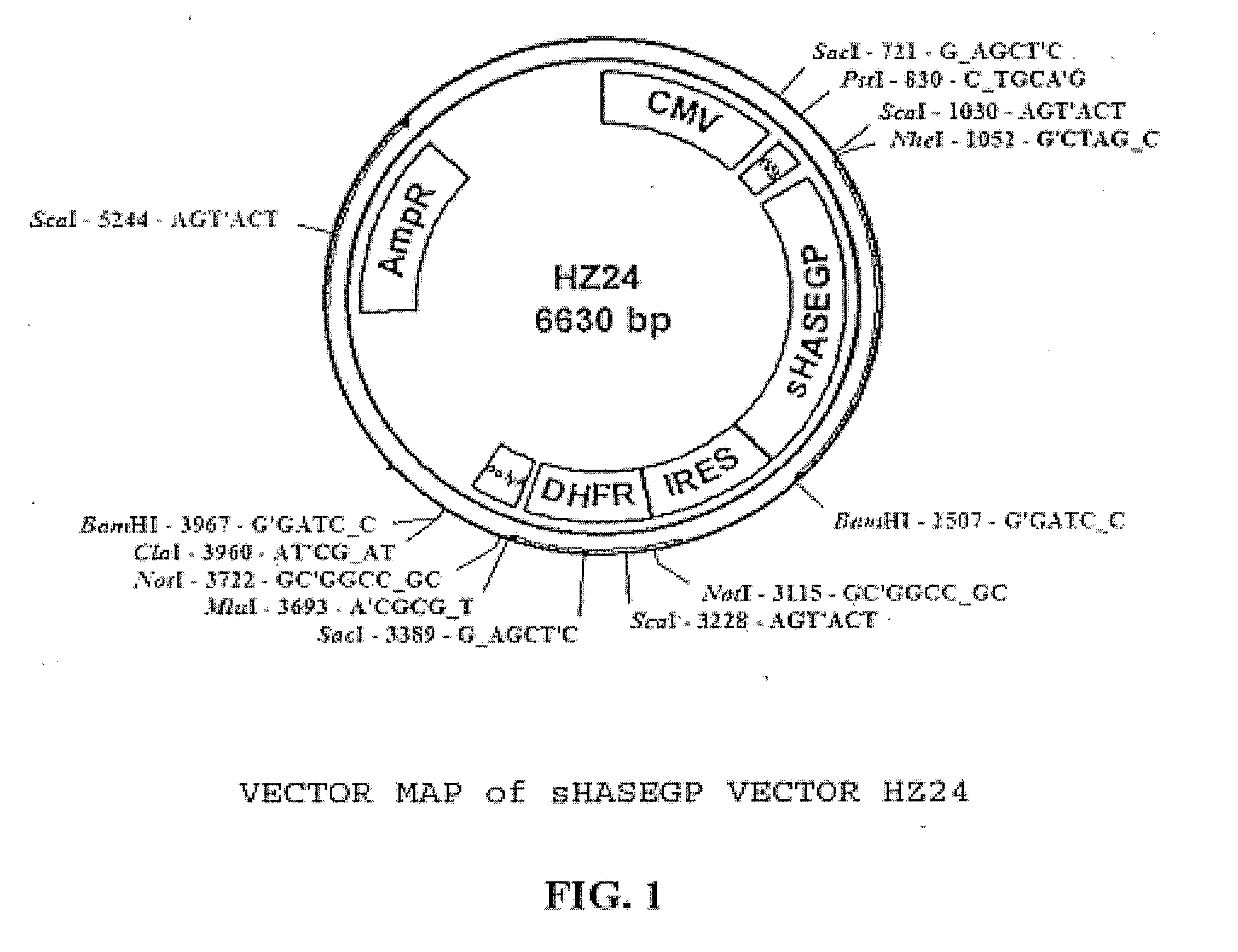

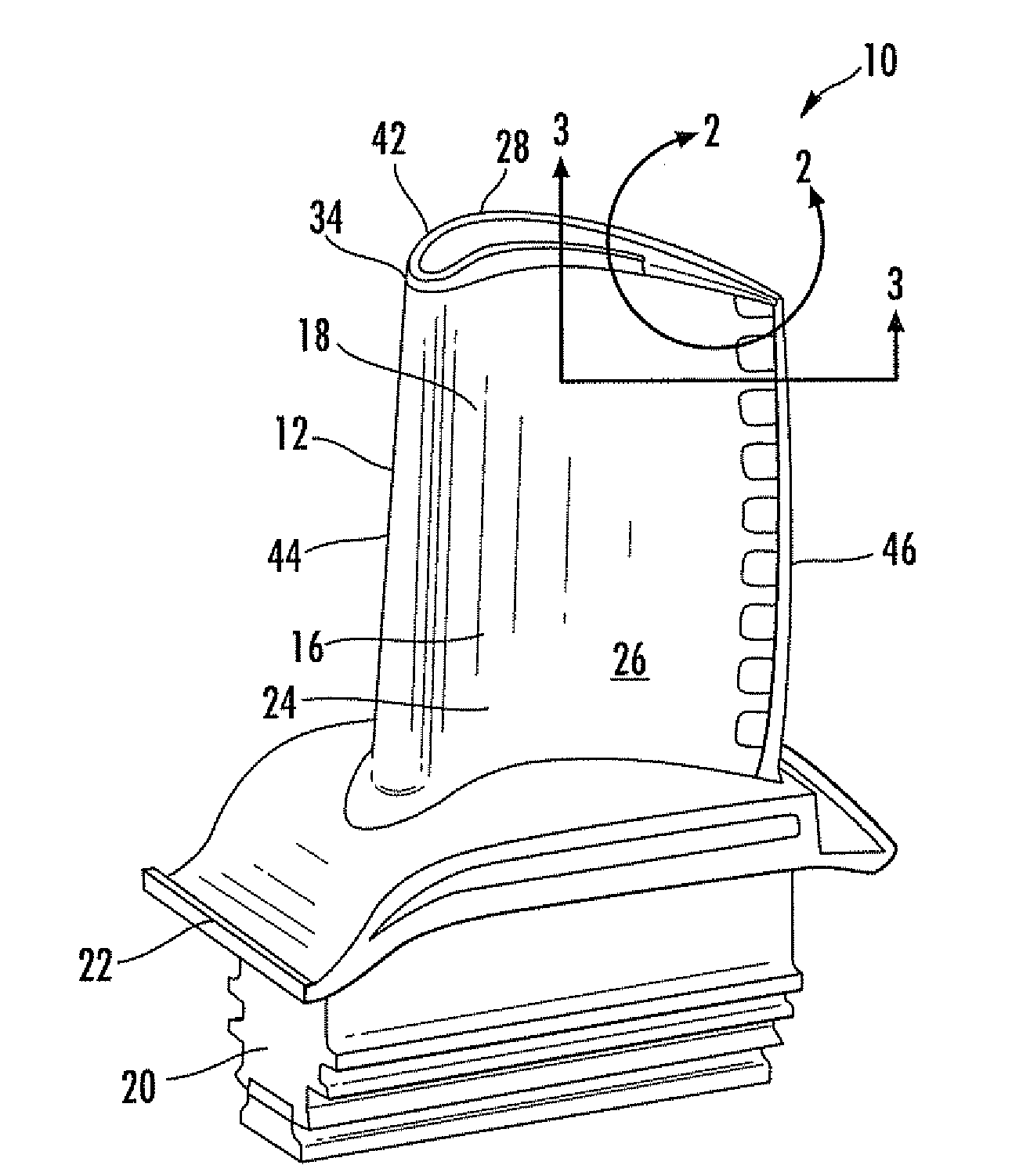

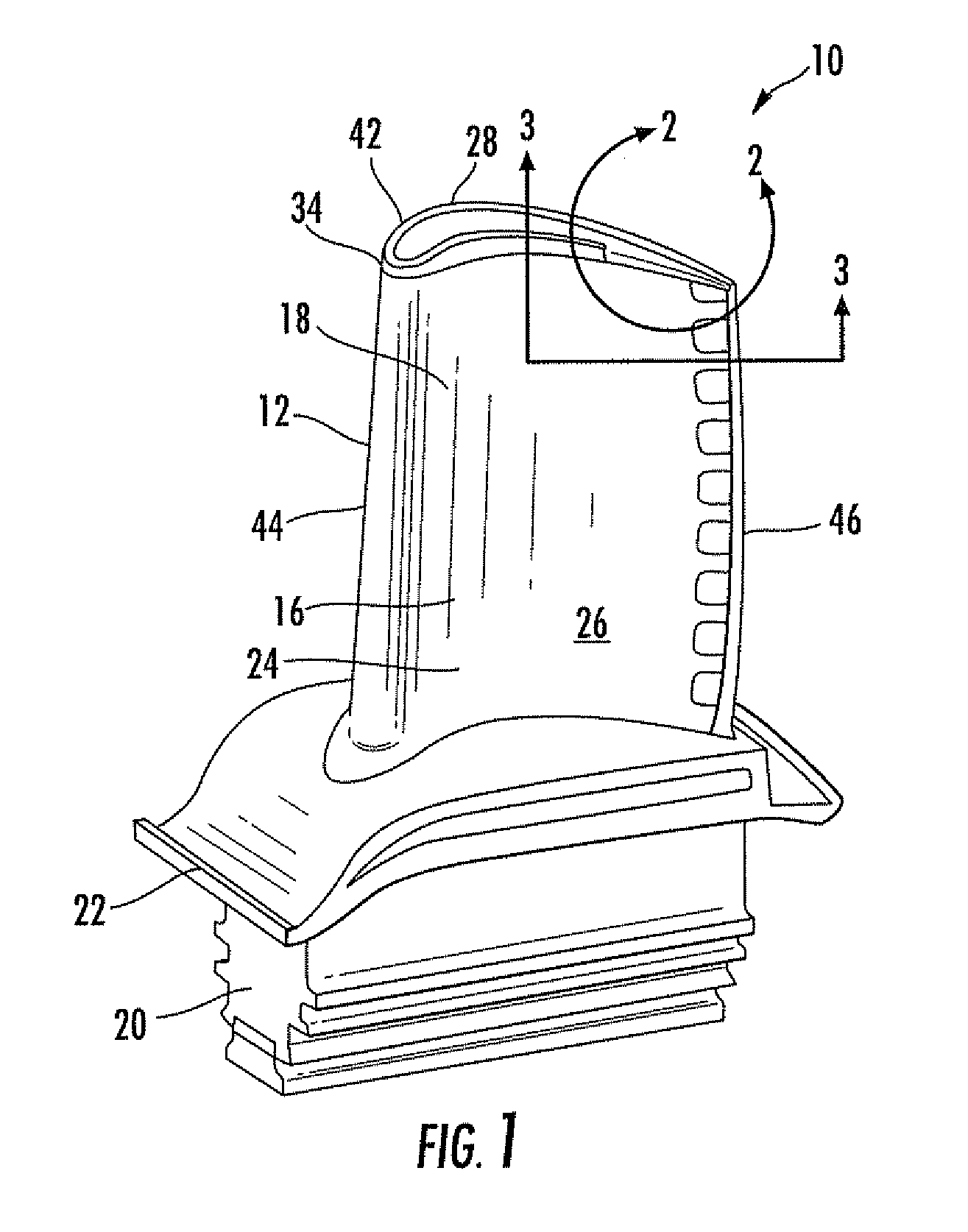

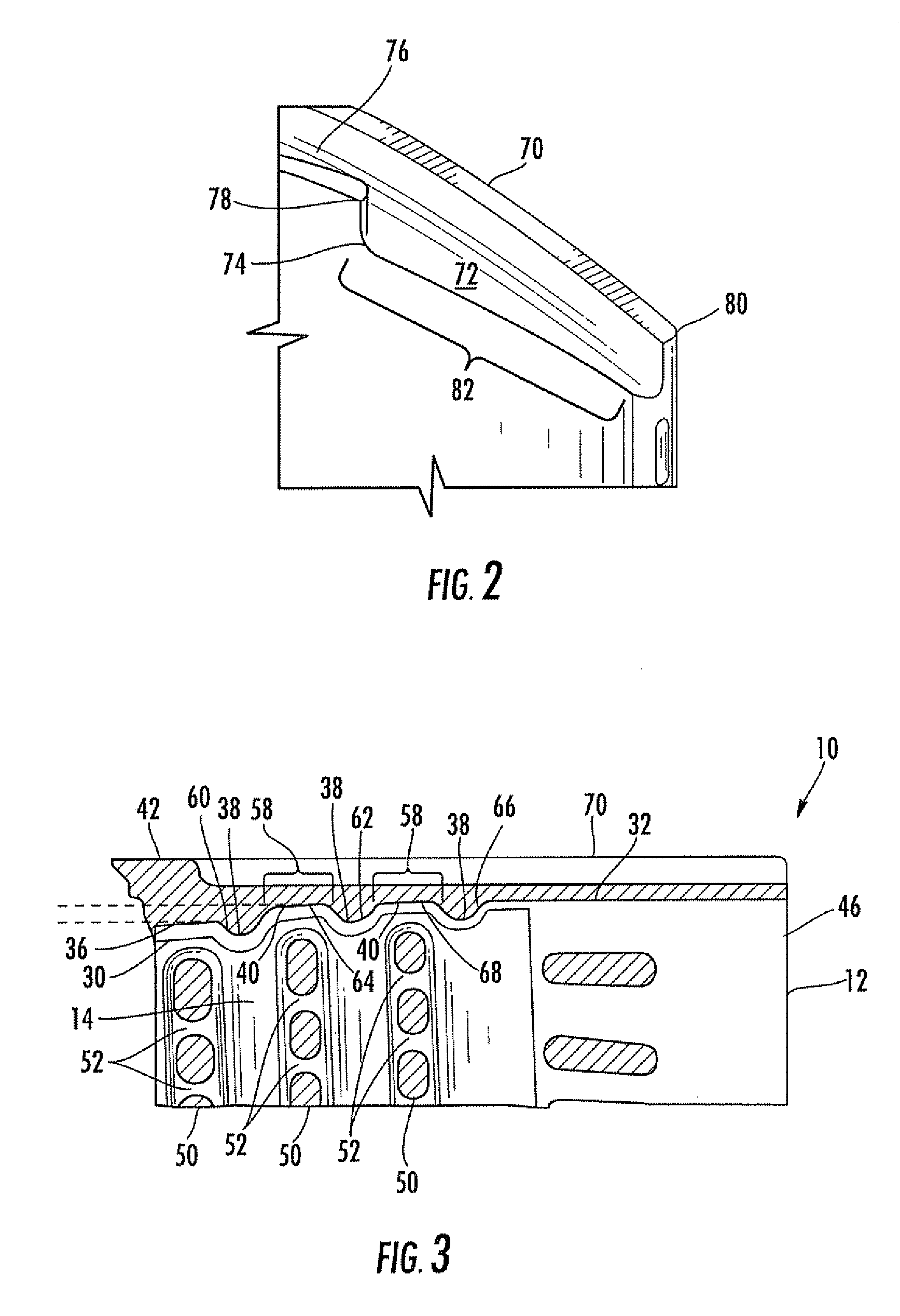

Turbine blade tip cooling system

ActiveUS7934906B2Improve cooling effectReduce thicknessEngine manufactureEngine fuctionsTurbine bladeCooling chamber

A turbine blade for a turbine engine having a cooling system in the turbine blade formed from at least one elongated tip cooling chamber forming a portion of the cooling system and at least partially defined by the tip wall proximate to the first end. An inner surface of the tip wall may include a plurality of curved bumper protrusions extending from the inner surface radially inward toward the root. The cooling system may include a plurality of ribs generally aligned with the trailing edge, and the curved bumper protrusions may be offset in a chordwise direction relative to the ribs. A throat section may extend between a first forwardmost curved bumper protrusion and a second immediately adjacent downstream curved bumper protrusion and may be offset radially outward from an inner tip surface, thereby creating a first recessed tip slot with a reduced tip wall thickness.

Owner:SIEMENS ENERGY INC

Soluble glycosaminoglycanases and methods of preparing and using soluble glycosaminoglycanases

InactiveUS20150165059A1Reduce sensitivityGreater serum half-livesBiocideSenses disorderHyaluronidaseNuclear chemistry

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated forms of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME

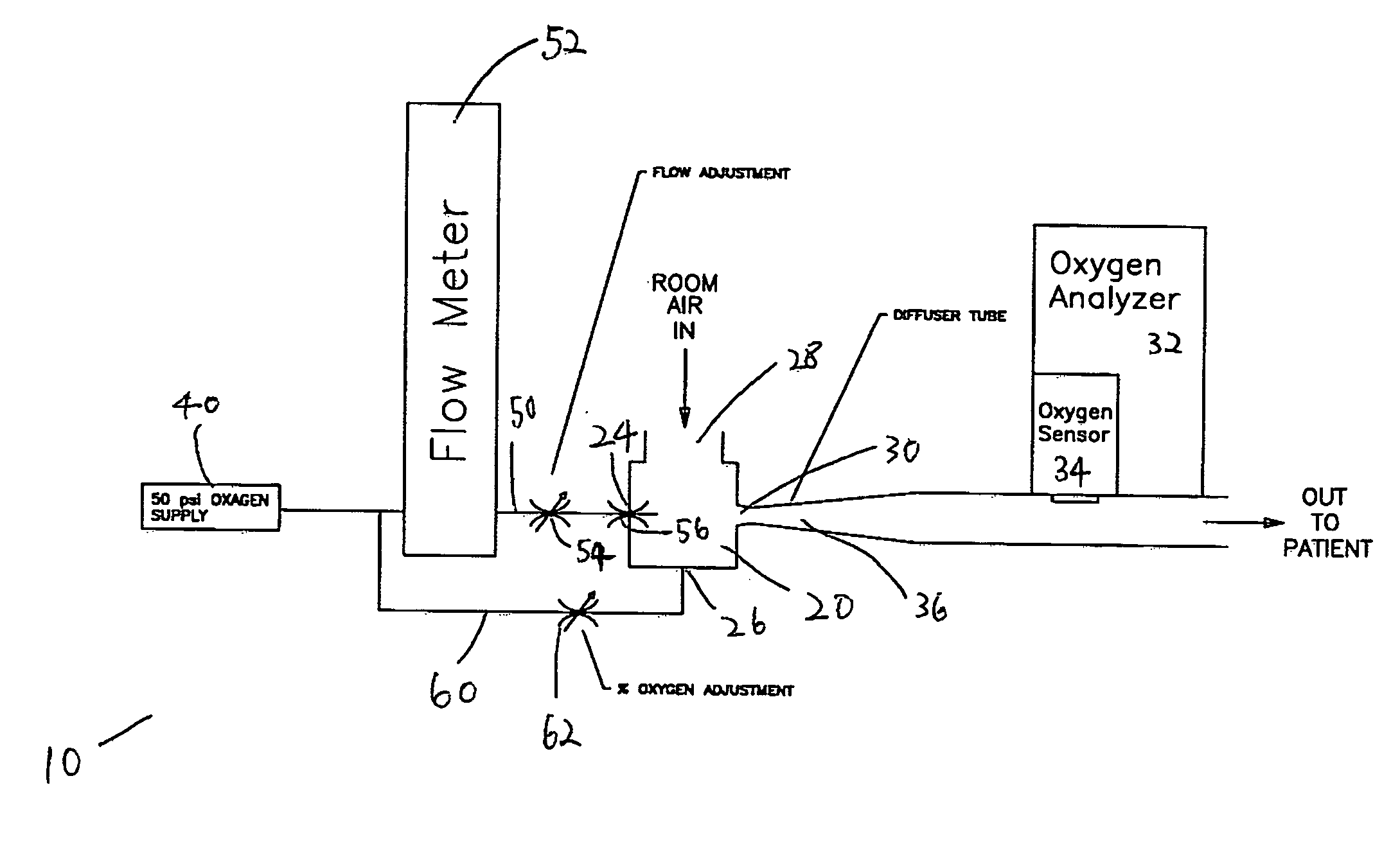

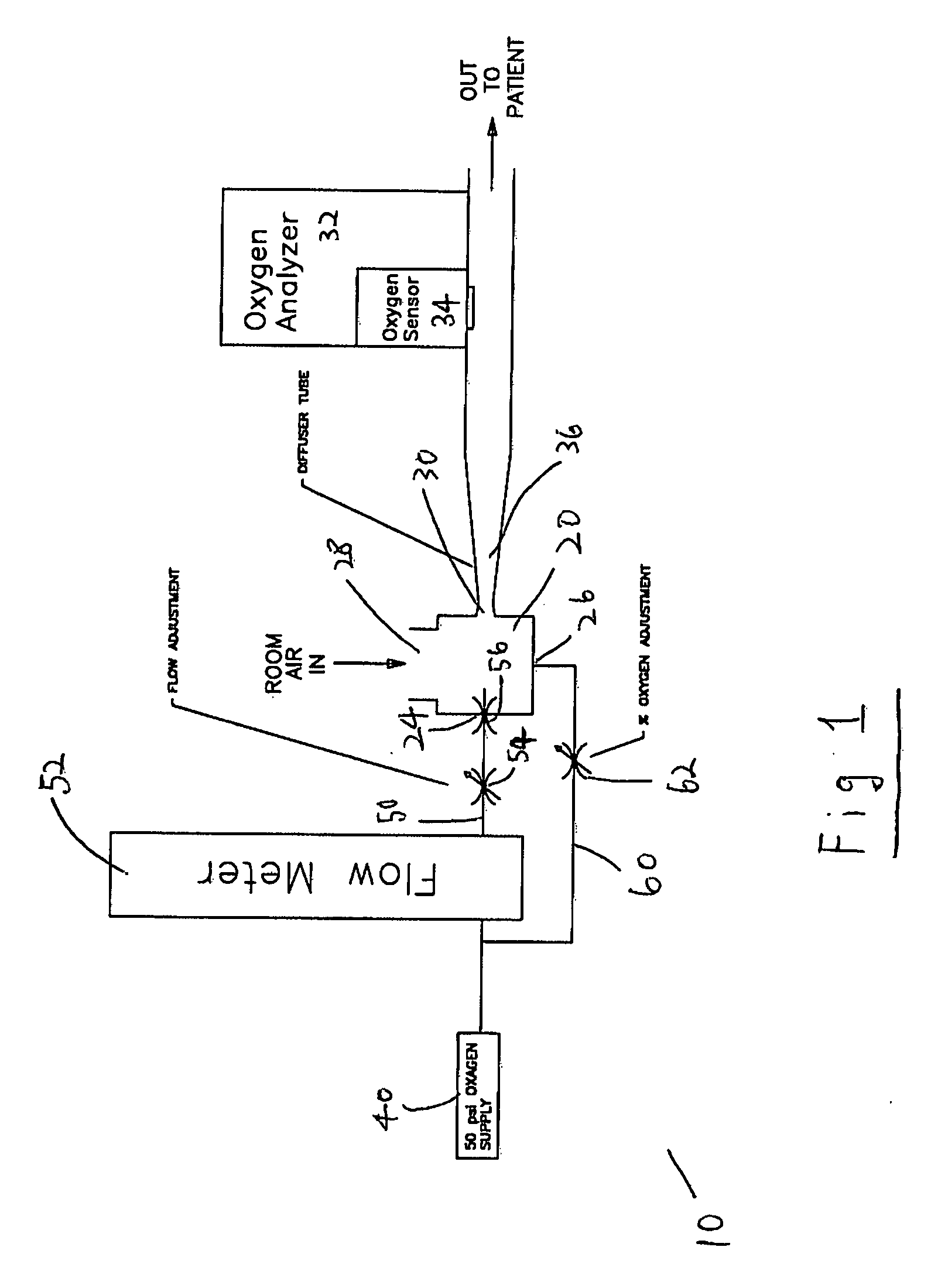

Venturi apparatus with incorporated flow metering device

InactiveUS20080190421A1Accurate measurementConserve costRespiratorsBreathing masksEngineeringProduct gas

A gas delivery apparatus for supplying an oxygen / air mix to a patient is discussed. Besides the conventional ability to adjust oxygen / air ratio independently via changes in the primary and / or secondary oxygen flow tube's flow rate adjustments, a flow meter is provided in the primary oxygen flow tube to give an accurate reading of the total flow of the oxygen / air mix exiting the venturi chamber of the apparatus.

Owner:MAXTEC

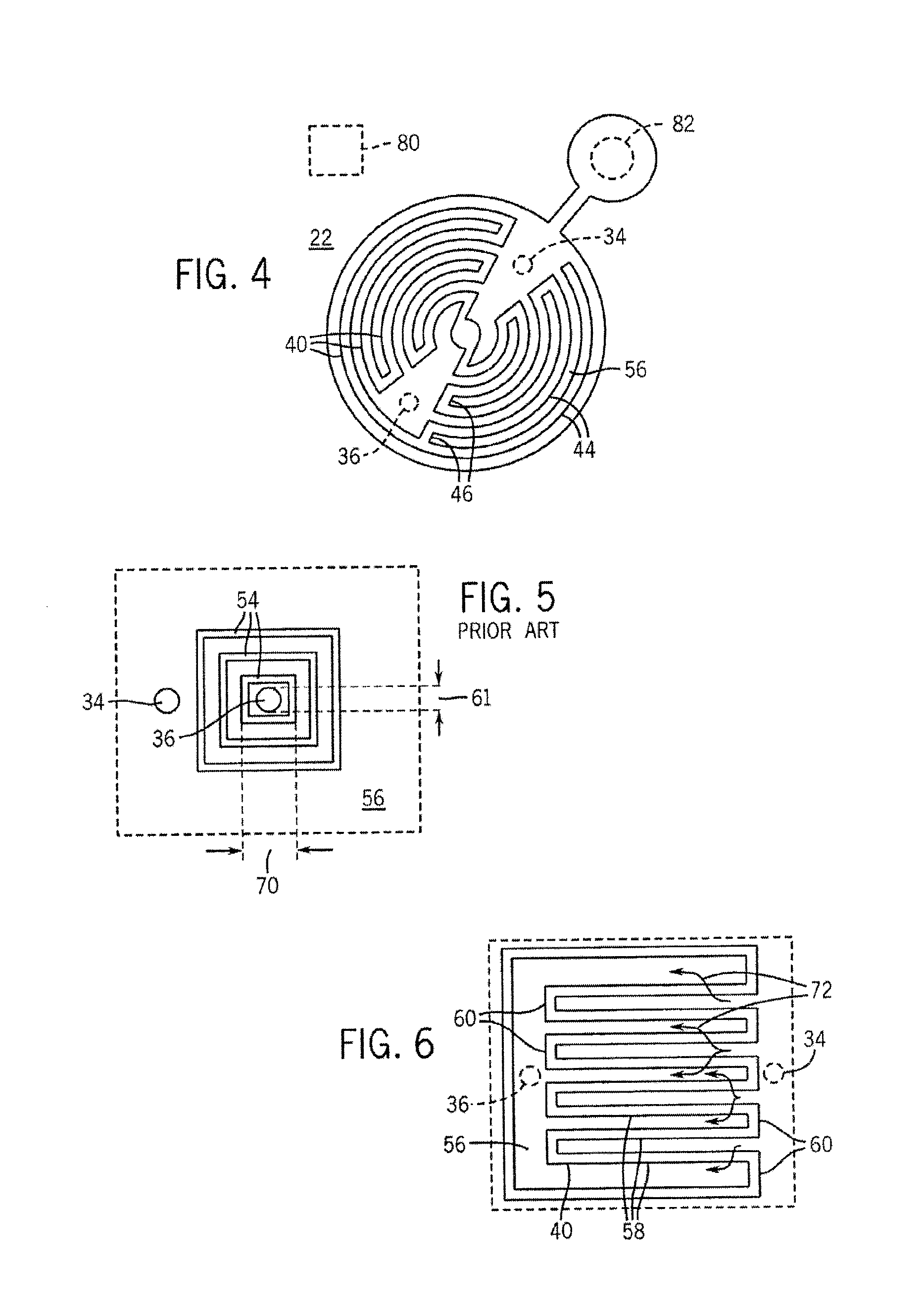

High efficiency radiant burner

InactiveUS20080213715A1Increasing burner efficiencyImprove efficiencyGaseous fuel burnerCombustion regulationInjectorProduct gas

A naturally aspirated, fully aerated radiant burner and optional heat exchanger arrangement where the radiant burner has a generally enclosed cavity defined, at least in part, by fuel gas impermeable surroundings and a lower surface of fuel gas permeable burner element, wherein cavity preferably has two opening exposed to an oxidizer source. Sealingly coupled to openings are mix tubes, each having respective first ends and second ends, wherein first ends occupy openings and second ends extend into and are exposed to cavity. Fuel gas injectors, which during use are in fluid communication with fuel gas, are positioned to introduce fuel gas into mix tubes and entrain only slightly more air than needed for stoichiometric combustion. Pre-combustion gasses migrate to upper surface where stable stoichiometric combustion occurs, resulting in low CO and NOx emissions, increased wind resistance and elevated combustion gas temperatures Connecting the heat exchanger directly to the burner further increases its wind resistance and prevents dilution of the combustion gases by wind or free convection.

Owner:CASCADE DESIGNS INC

Turbine Blade Tip Cooling System

ActiveUS20090123292A1Improve cooling effectReduce thicknessPropellersEngine manufactureTurbine bladeCooling chamber

A turbine blade for a turbine engine having a cooling system in the turbine blade formed from at least one elongated tip cooling chamber forming a portion of the cooling system and at least partially defined by the tip wall proximate to the first end. An inner surface of the tip wall may include a plurality of curved bumper protrusions extending from the inner surface radially inward toward the root. The cooling system may include a plurality of ribs generally aligned with the trailing edge, and the curved bumper protrusions may be offset in a chordwise direction relative to the ribs. A throat section may extend between a first forwardmost curved bumper protrusion and a second immediately adjacent downstream curved bumper protrusion and may be offset radially outward from an inner tip surface, thereby creating a first recessed tip slot with a reduced tip wall thickness.

Owner:SIEMENS ENERGY INC

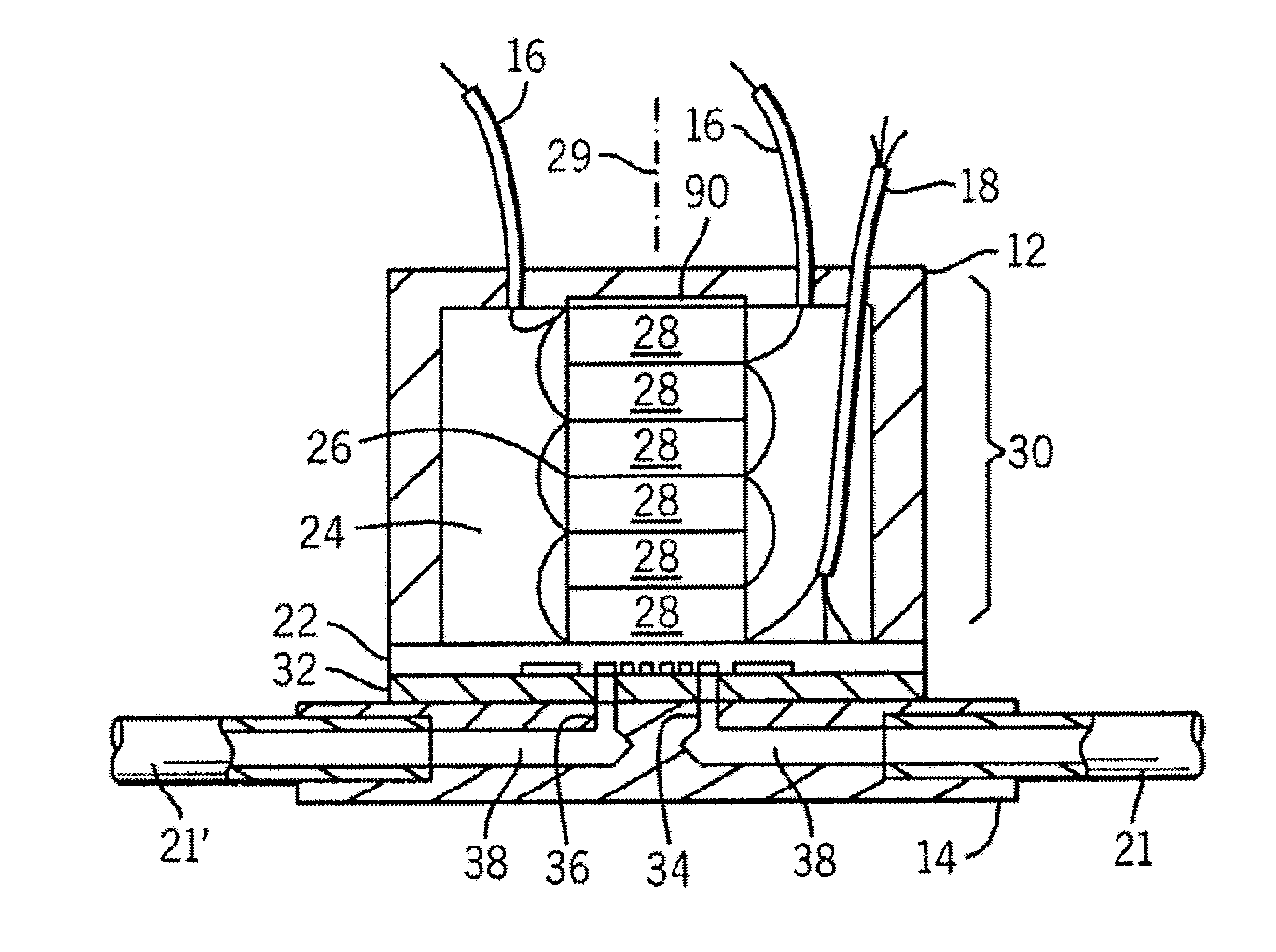

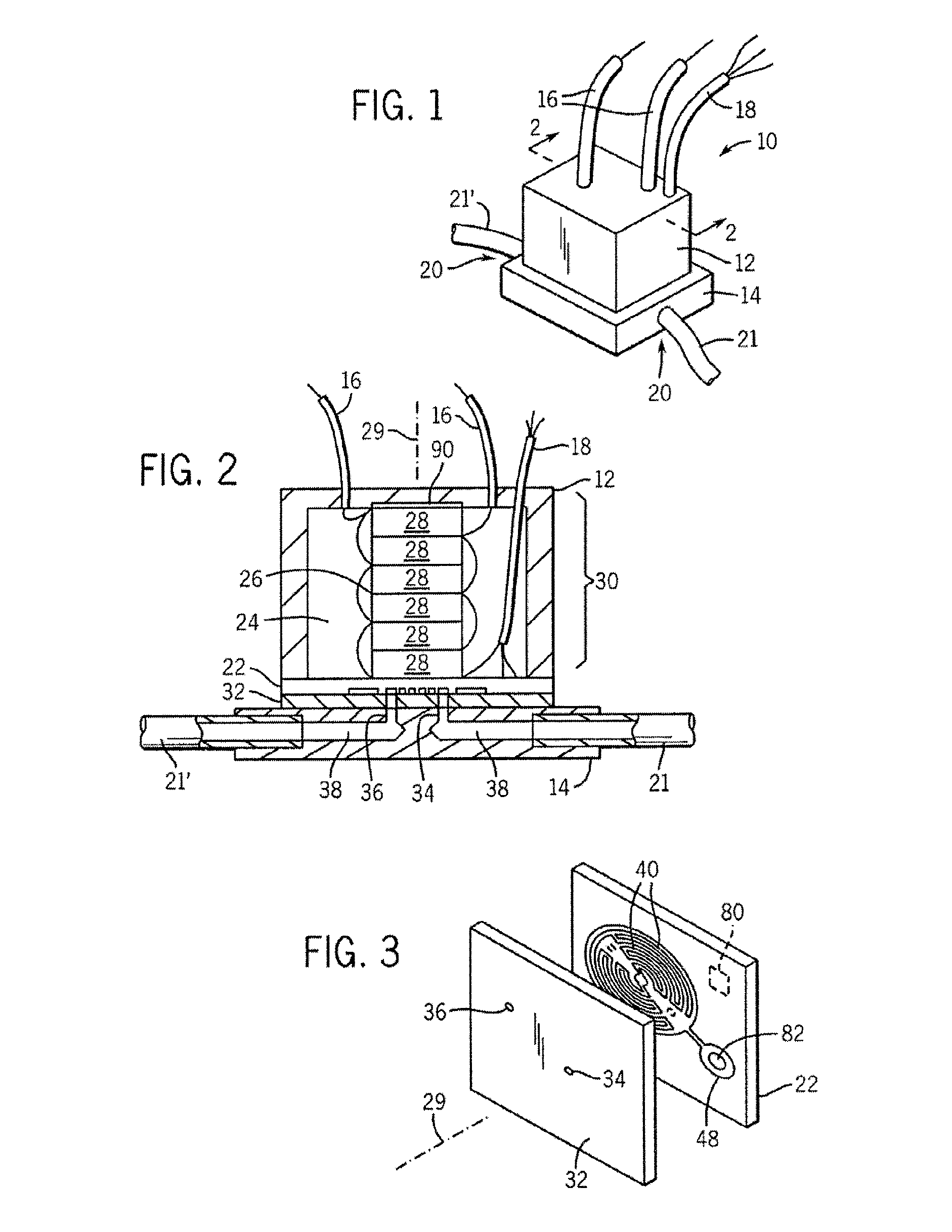

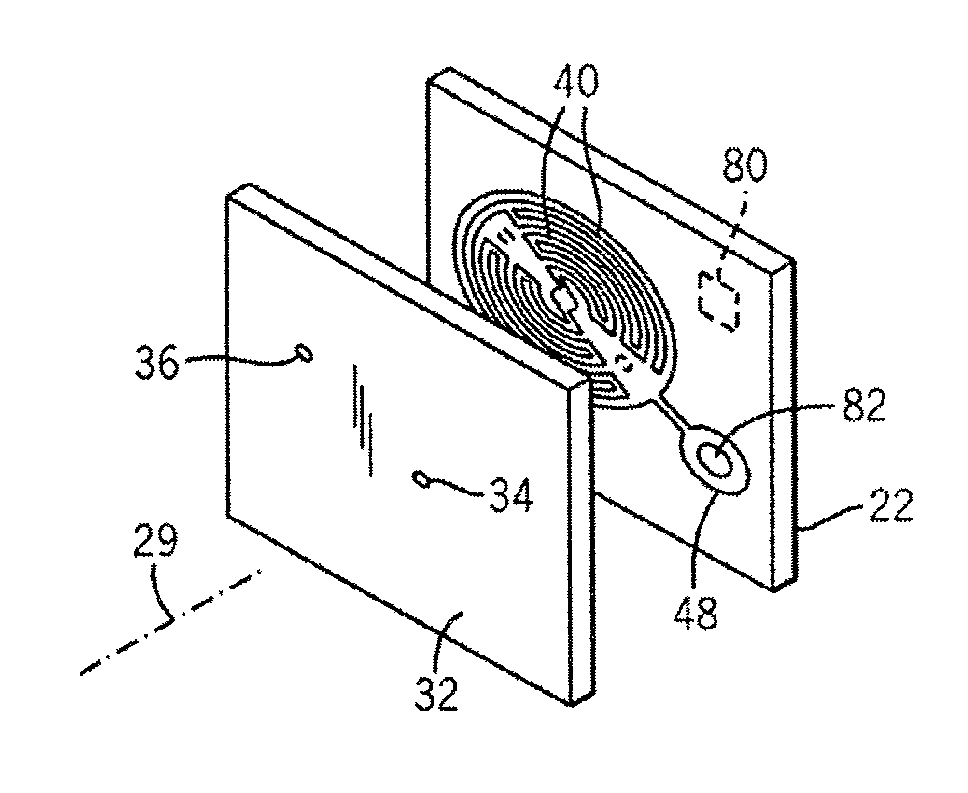

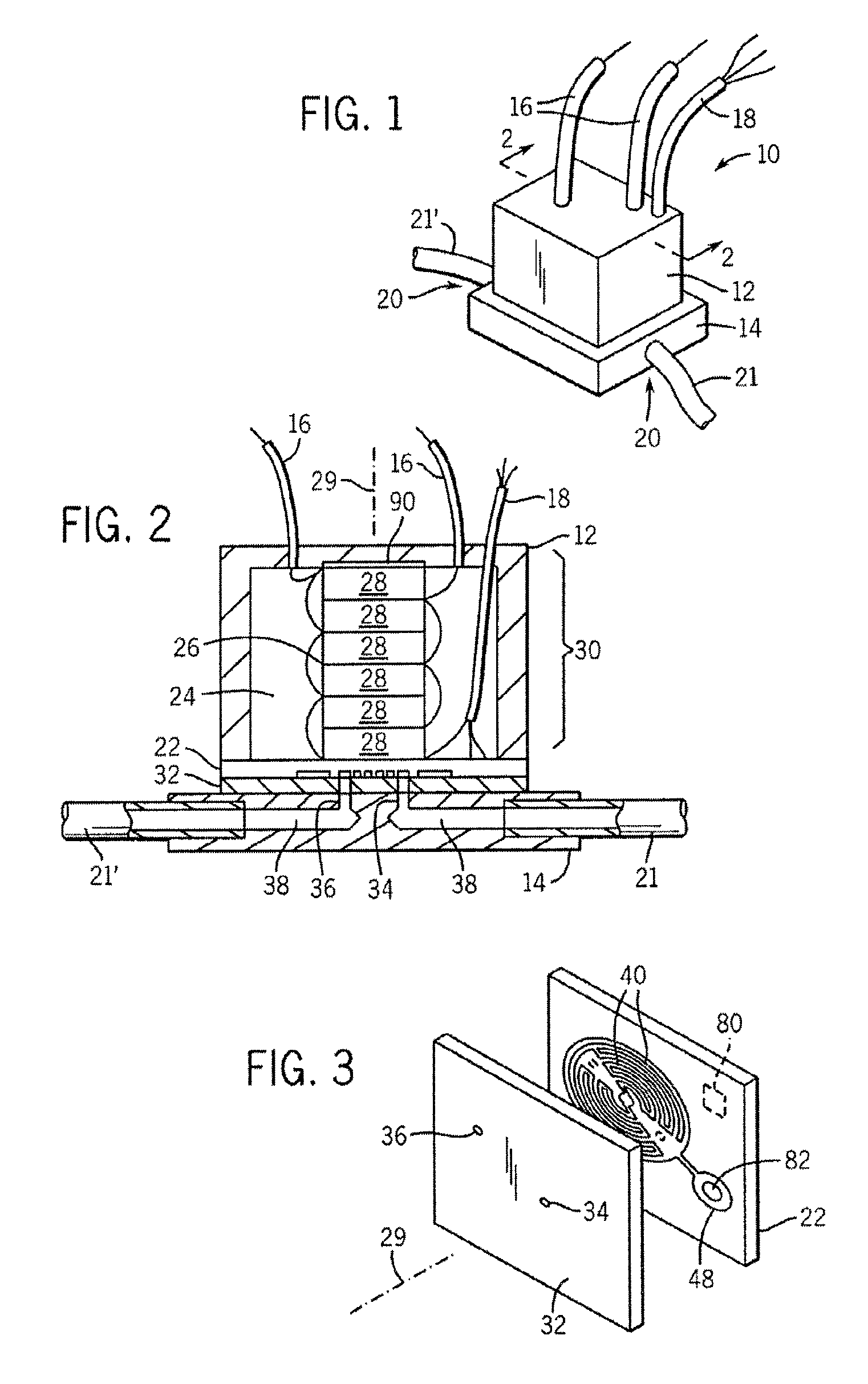

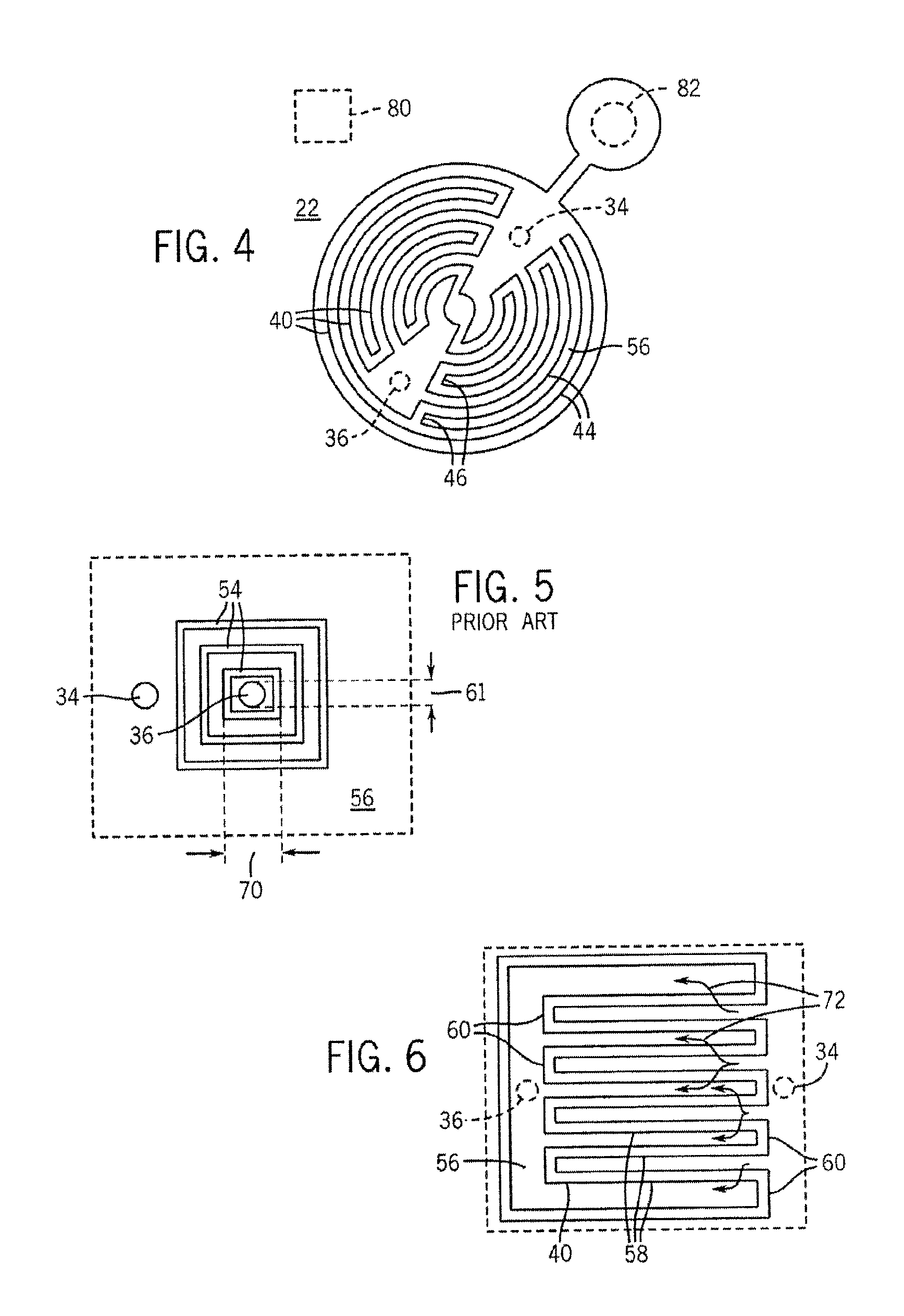

Low-power piezoelectric micro-machined valve

ActiveUS20080296523A1High actuation pressureLarge flow modulationOperating means/releasing devices for valvesCheck valvesElectricityEngineering

A piezoelectric microvalve employs a valve element formed of hermetically sealed and opposed plates flexed together by a cross axis piezoelectric element. Large flow modulation with small piezoelectric actuator displacement is obtained by perimeter augmentation of the valve seat which dramatically increases the change in valve flow area for small deflections.

Owner:WISCONSIN ALUMNI RES FOUND +1

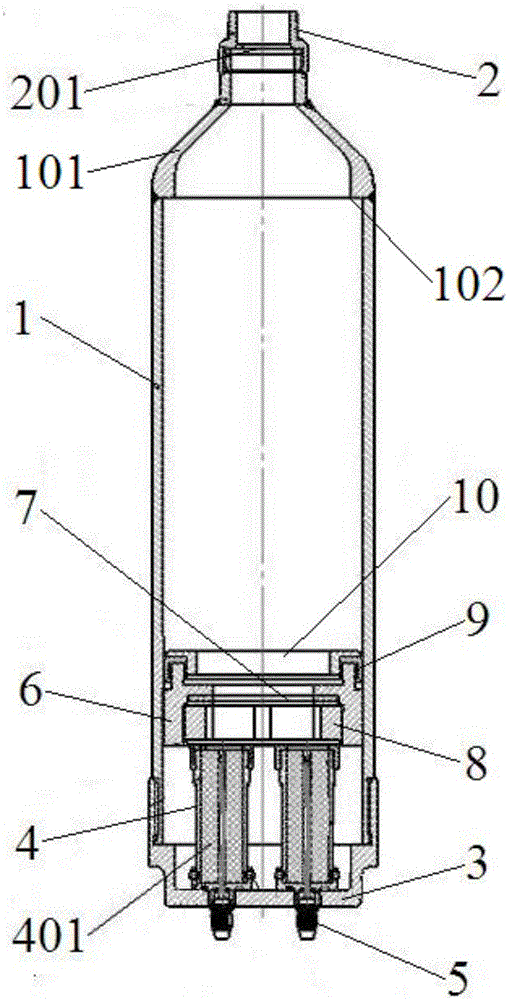

Stepped aerogenesis dry powder extinguishing device

The invention provides a stepped aerogenesis dry powder extinguishing device. The stepped aerogenesis dry powder extinguishing device comprises a tank body, a piston assembly and a stepped aerogenesis device; dry powder extinguishing agents are stored in the tank body; the tank body is provided with a first end and a second end; the first end of the tank body is provided with a pipeline connector for being connected with a flow collection pipeline, the pipeline connector is internally provided with a damp-proof diaphragm, and the second end of the tank body is provided with a lower end cover; the piston assembly is slidably arranged on the inner side of the tank body, and the middle of the piston assembly is provided with a pressure diaphragm; and the stepped aerogenesis device is arranged in a space which is formed between the lower end cover and the piston assembly. According to the stepped aerogenesis dry powder extinguishing device, the initial pressure of the extinguishing device is not too high during extinguishing, moreover, the pressure lasing time is long, and the extinguishing device is very suitable for an automatic extinguishing system with a long flow collection pipeline.

Owner:XIAN XINZHU FIRE & RESCUE EQUIP

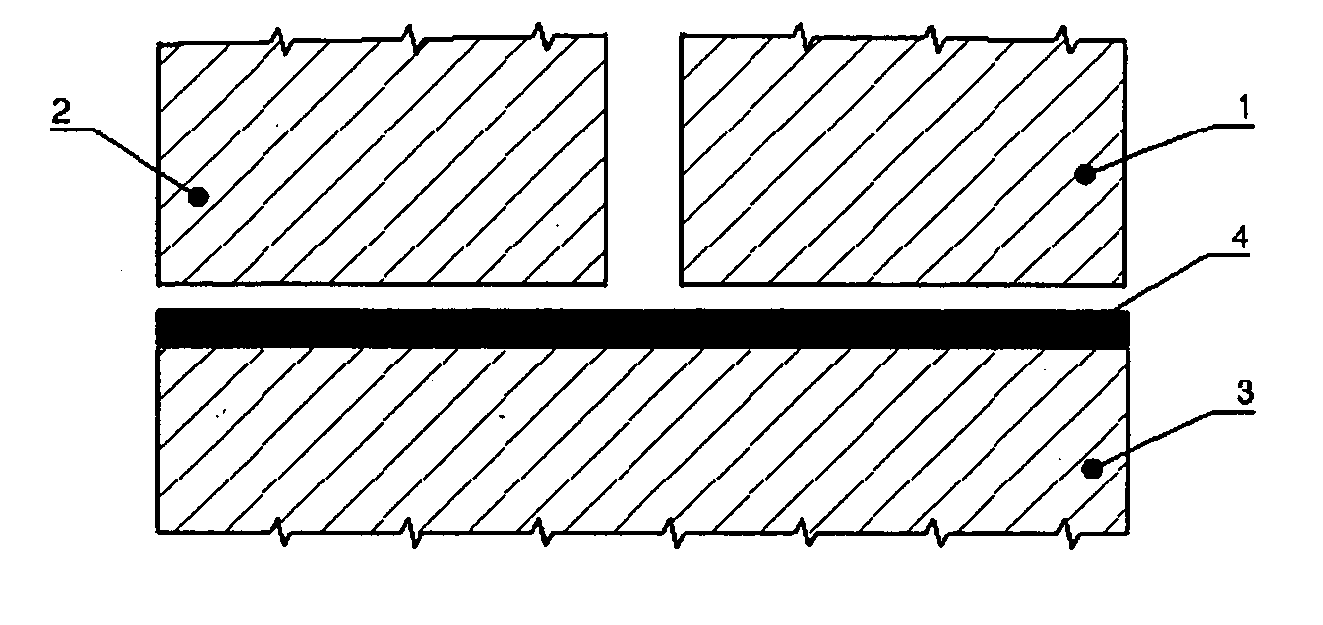

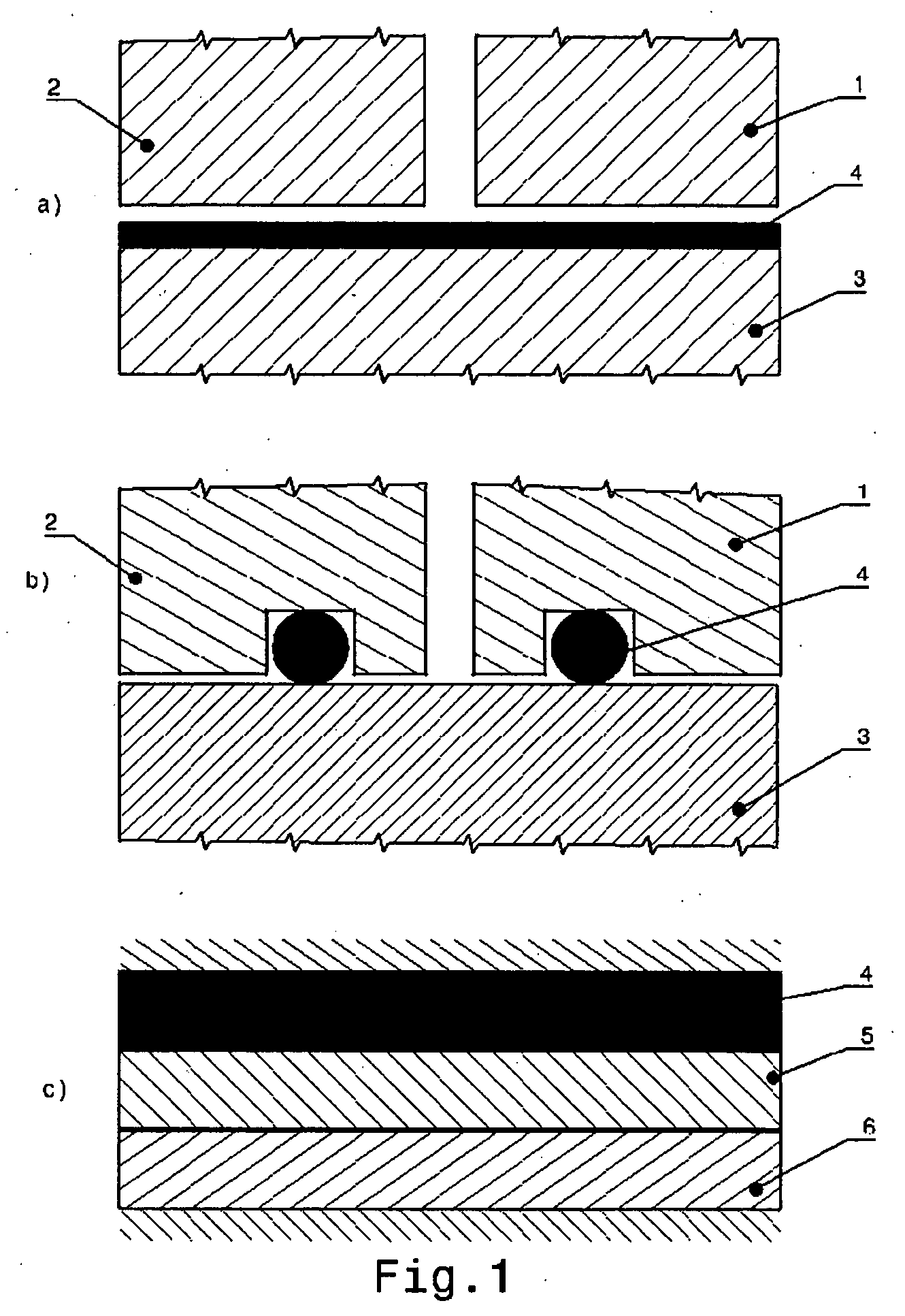

Method of sealing machine components

InactiveUS20050211937A1Avoid Insufficient SealingMinimize energy consumptionOperating means/releasing devices for valvesLift valveMechanical engineeringElectroactive materials

This application relates to a method of sealing machine components using electroactive materials that can be energized through a separate electric circuit or electric field in order to eliminate most friction and deformation losses during a sealing process.

Owner:POPADIUC PETER OVIDIU

Low-power piezoelectric micro-machined valve

ActiveUS7789371B2Increase driving pressureHigh trafficOperating means/releasing devices for valvesCheck valvesElectricityPiezoelectric actuators

A piezoelectric microvalve employs a valve element formed of hermetically sealed and opposed plates flexed together by a cross axis piezoelectric element. Large flow modulation with small piezoelectric actuator displacement is obtained by perimeter augmentation of the valve seat which dramatically increases the change in valve flow area for small deflections.

Owner:WISCONSIN ALUMNI RES FOUND +1

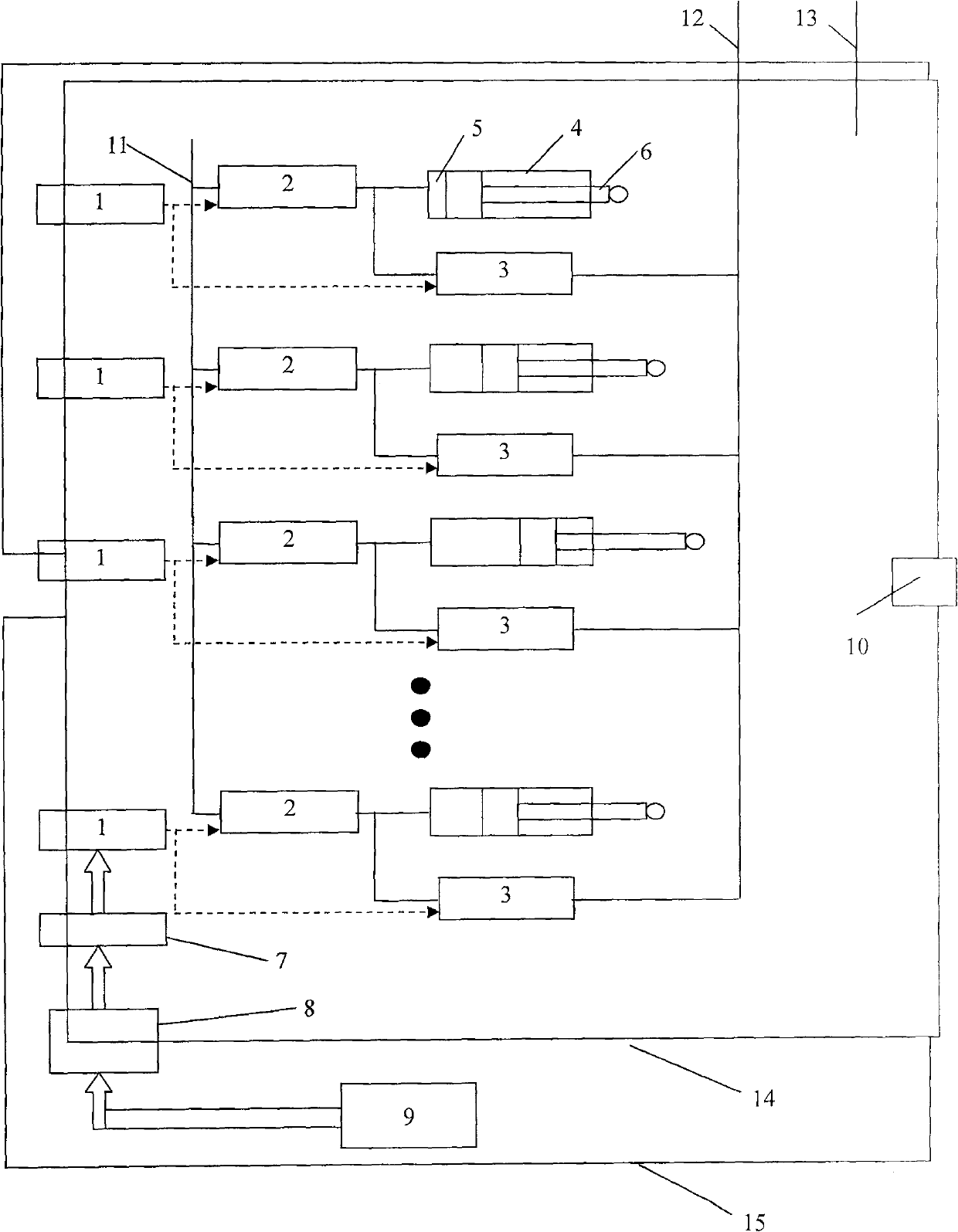

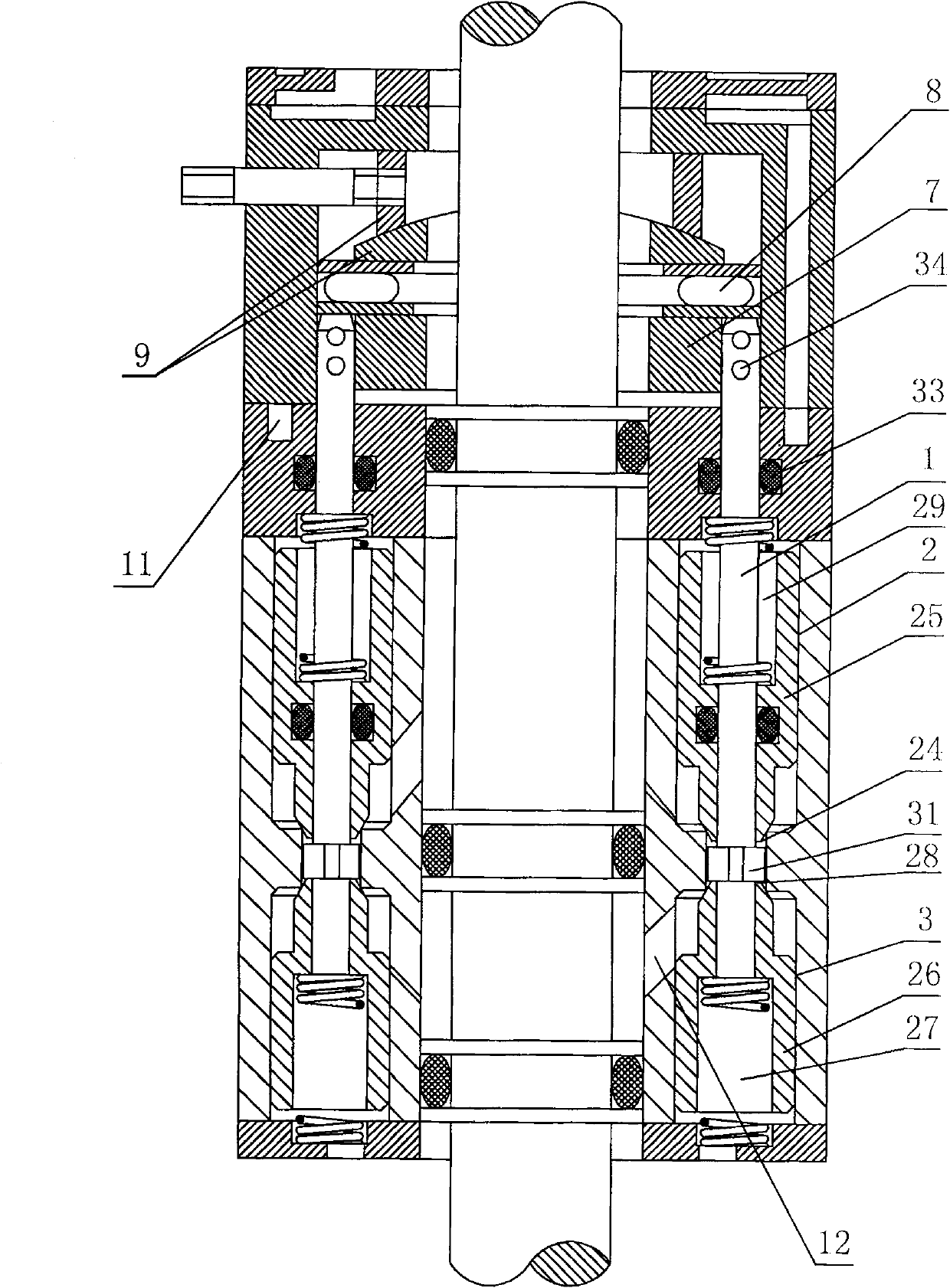

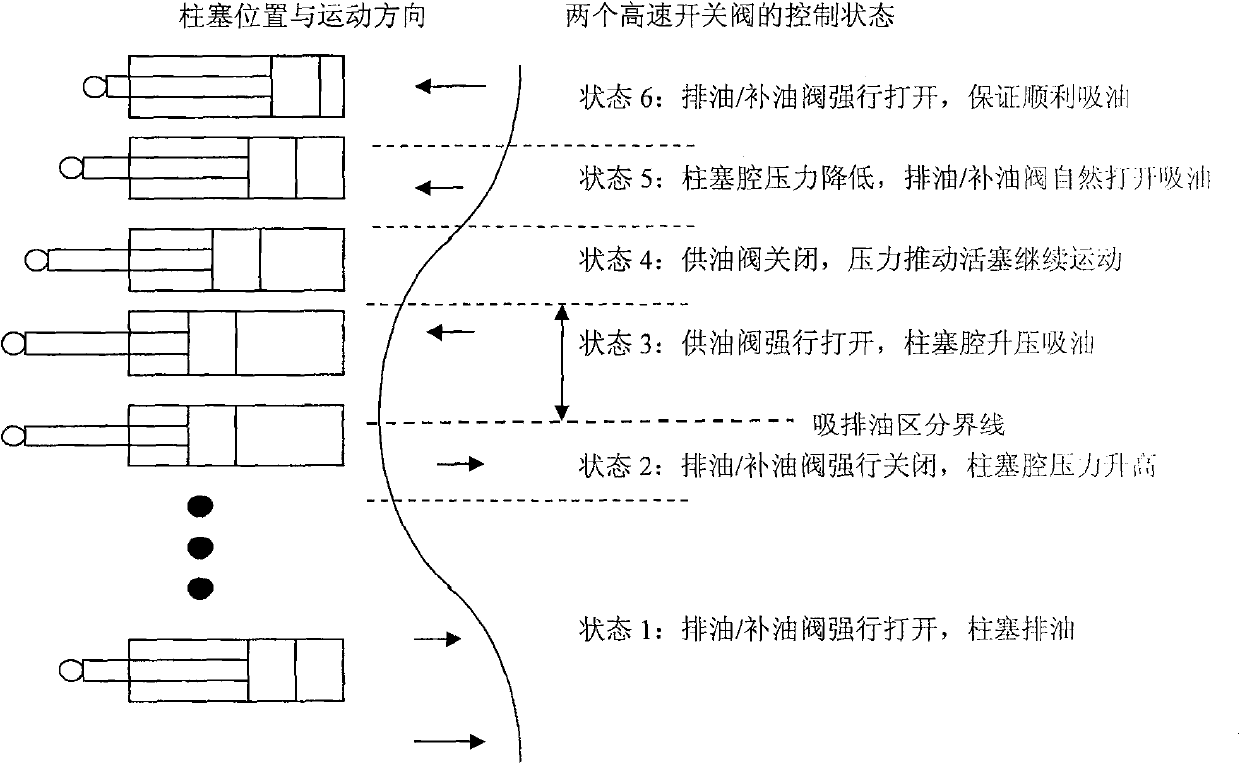

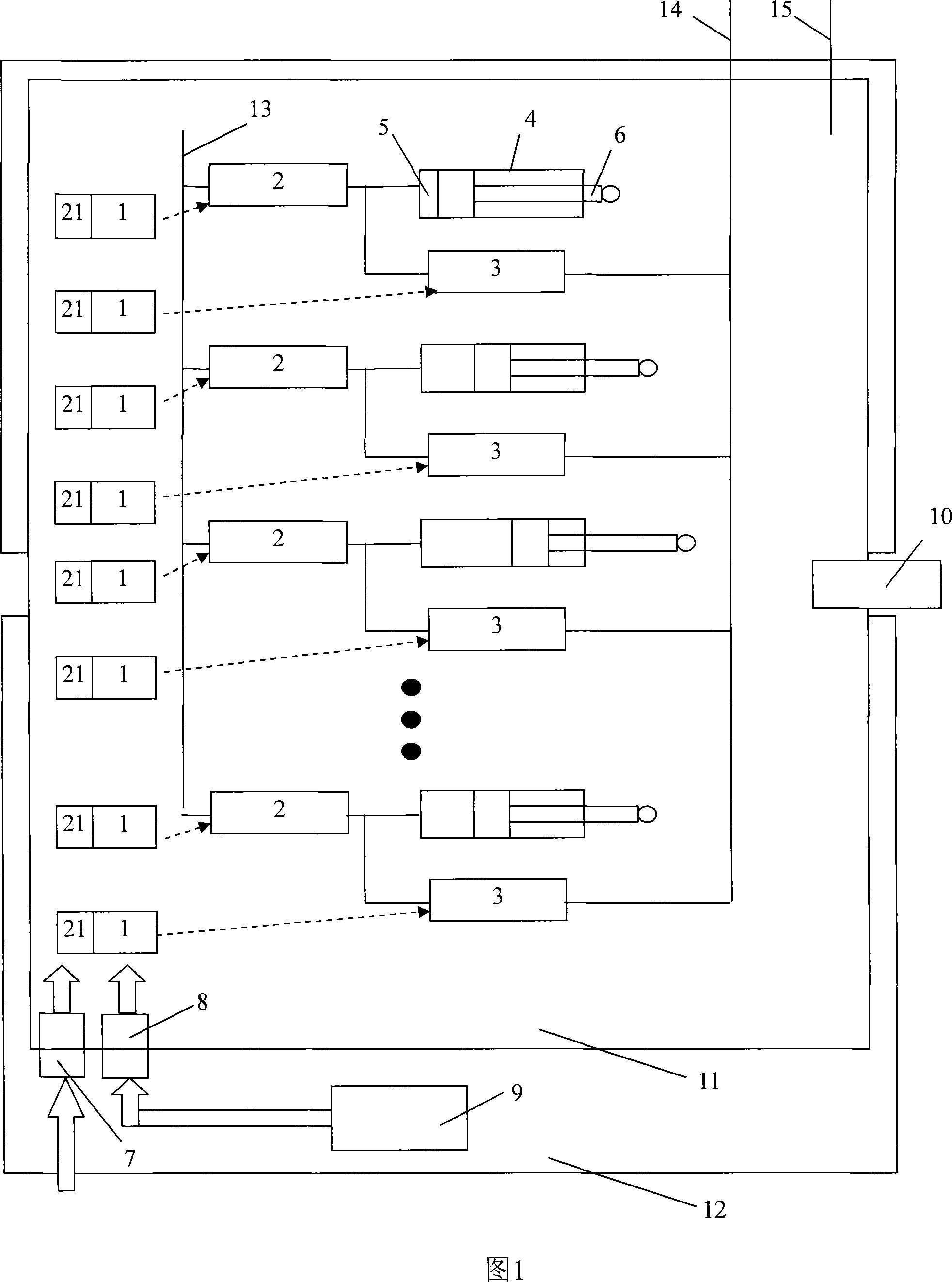

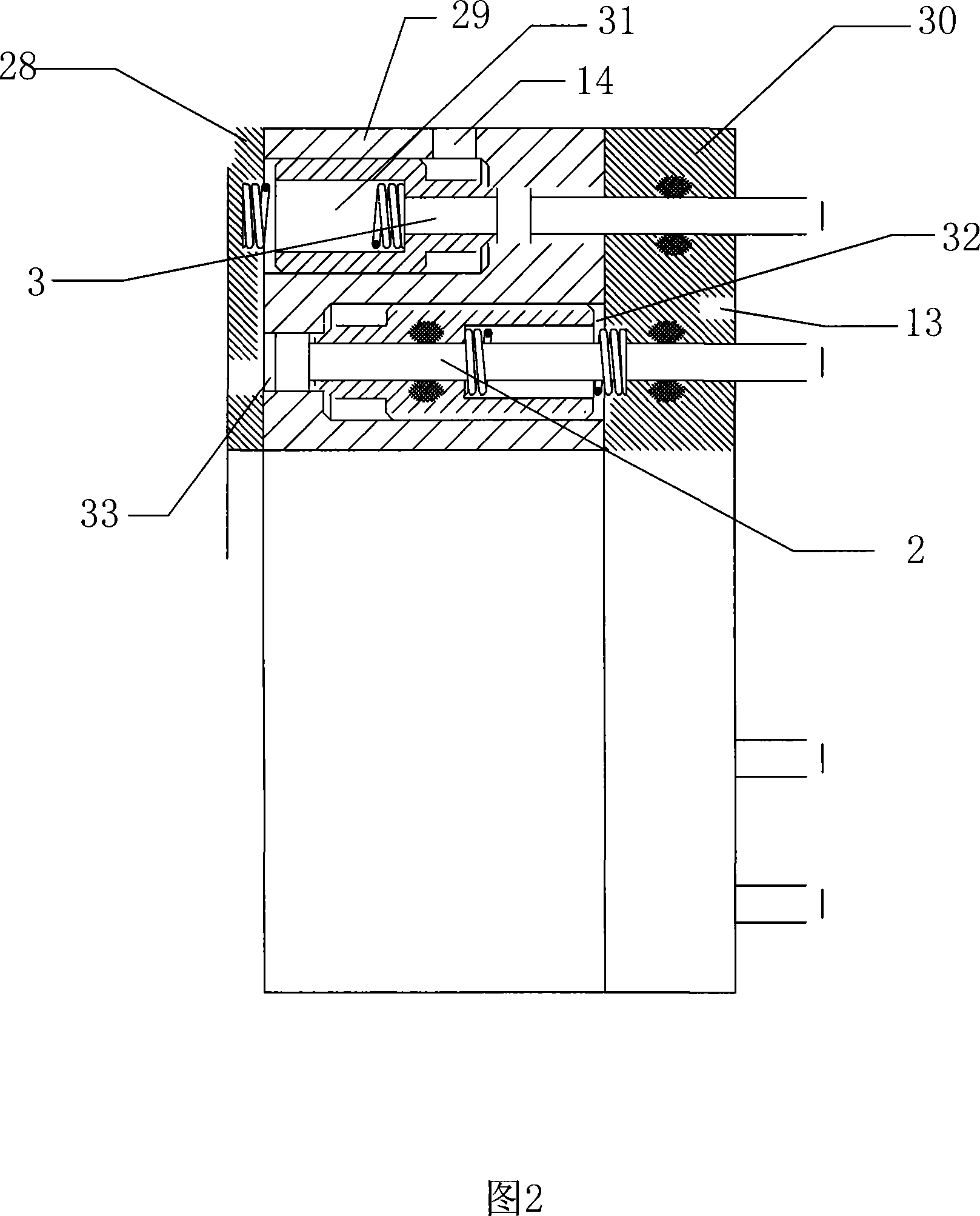

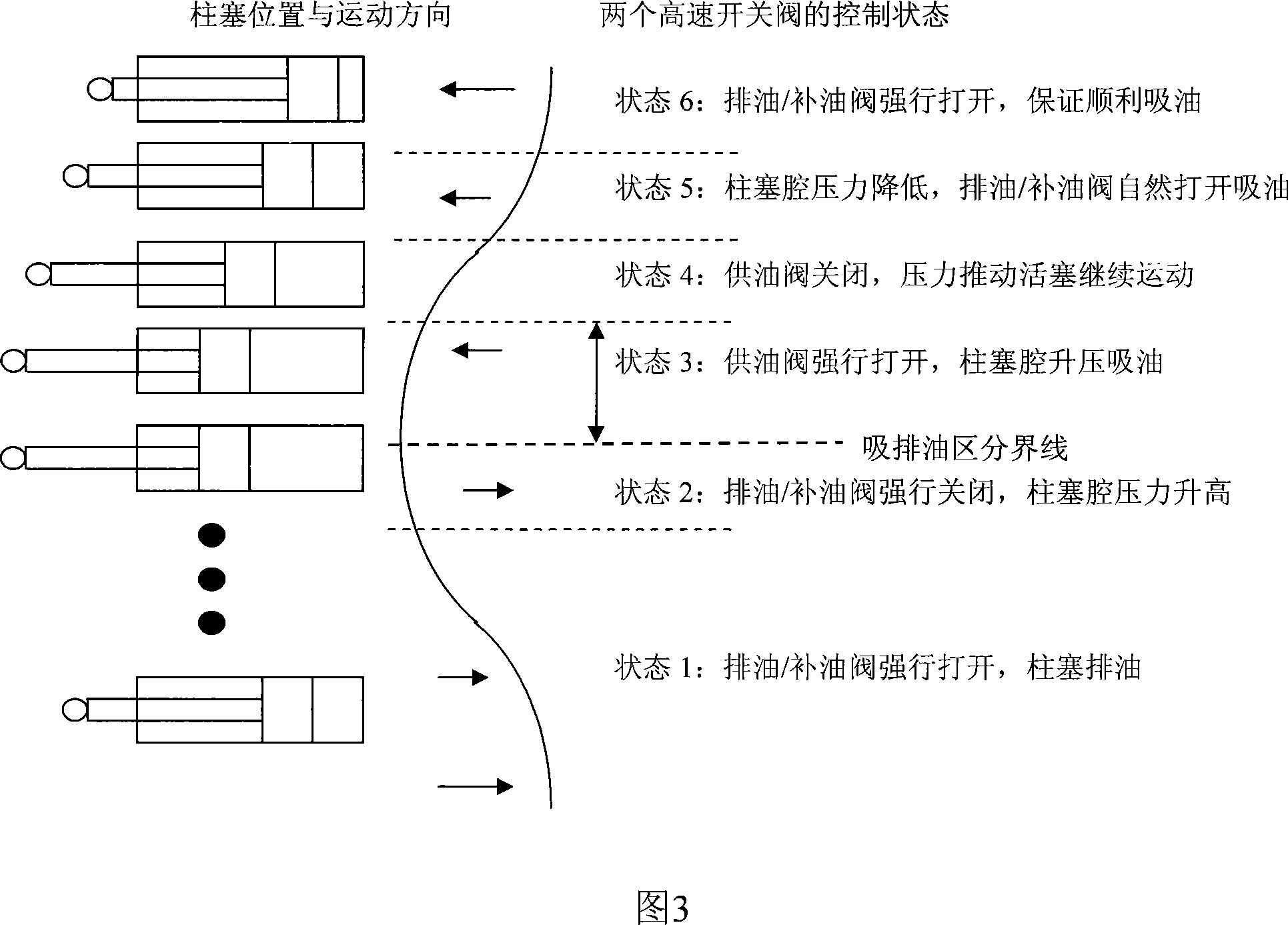

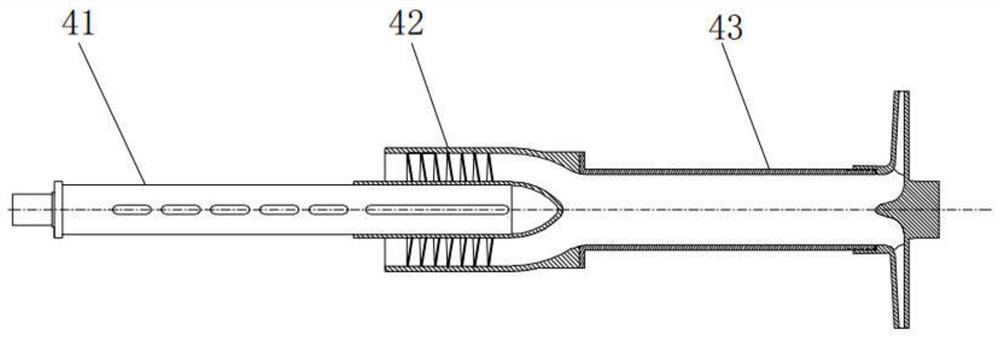

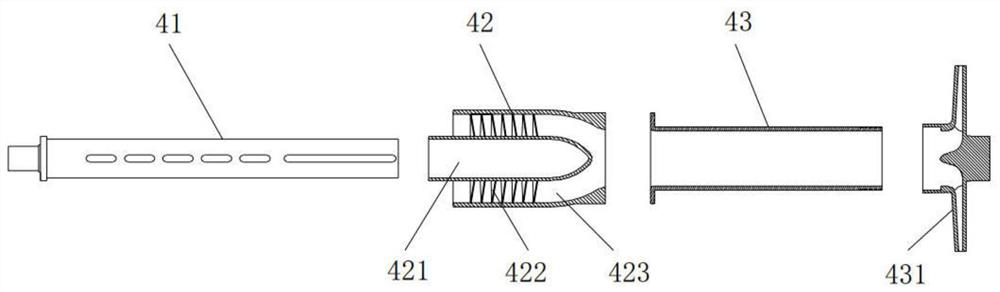

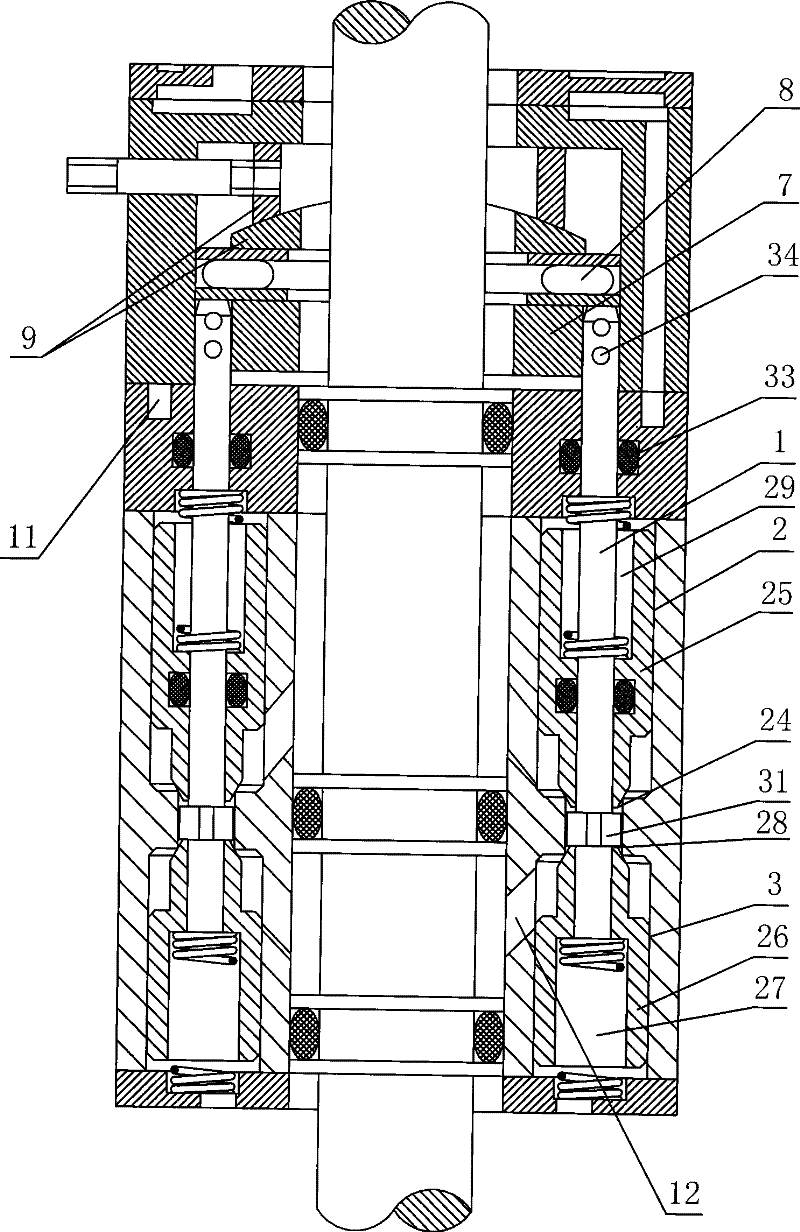

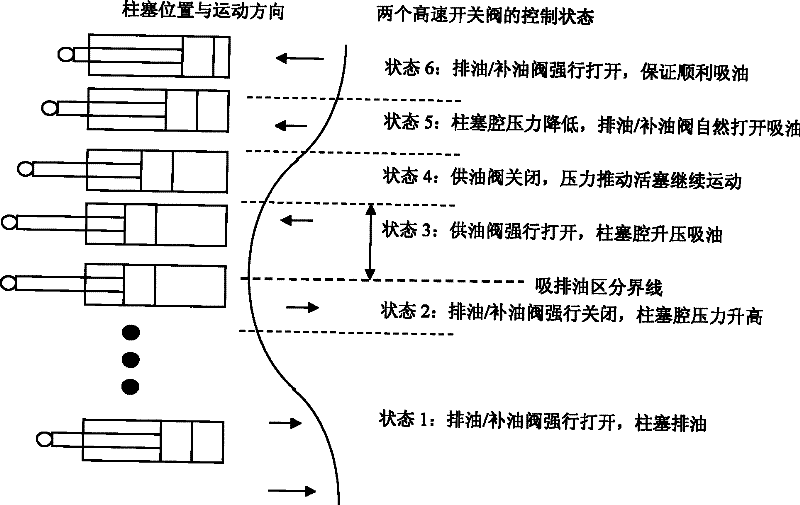

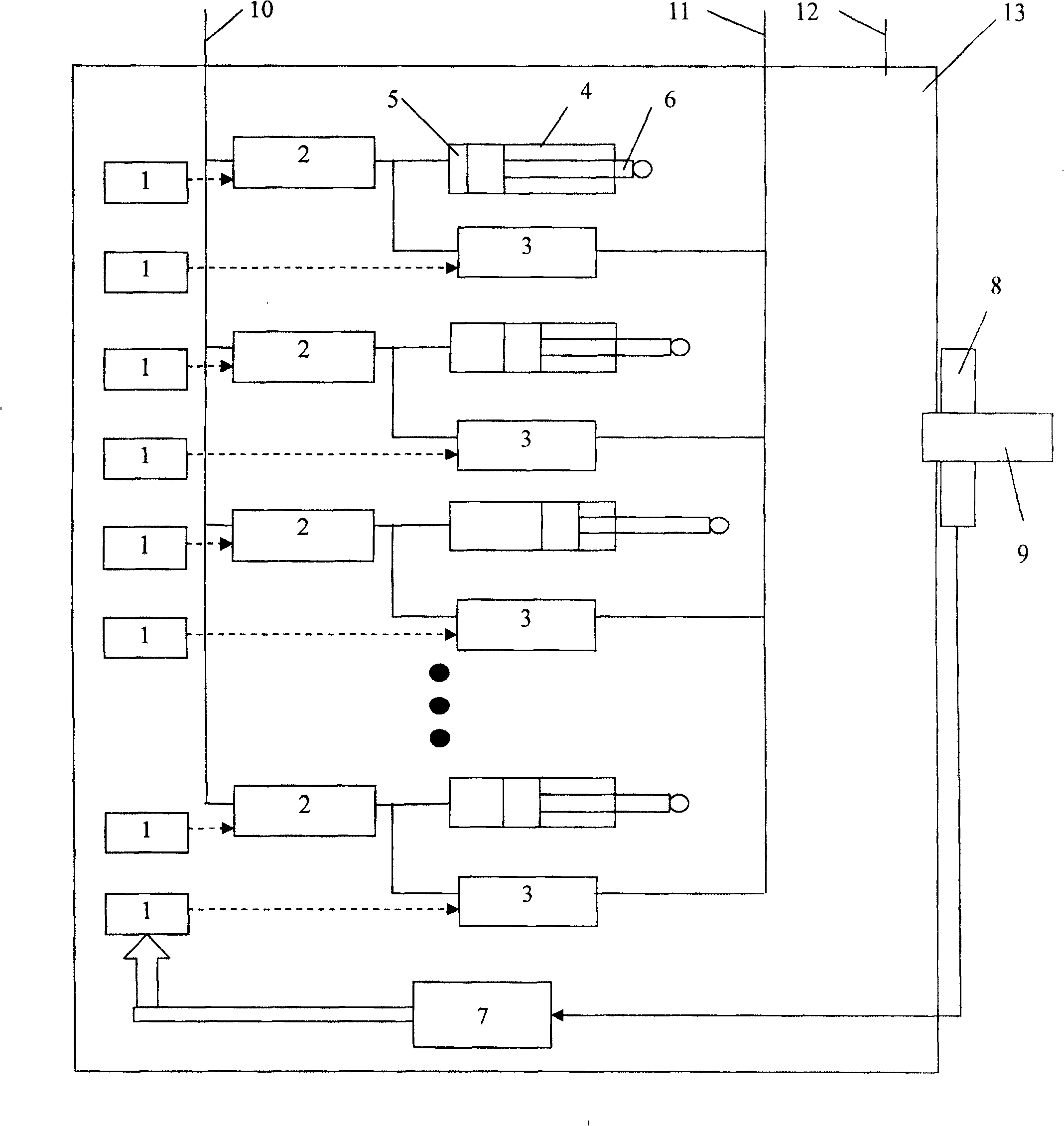

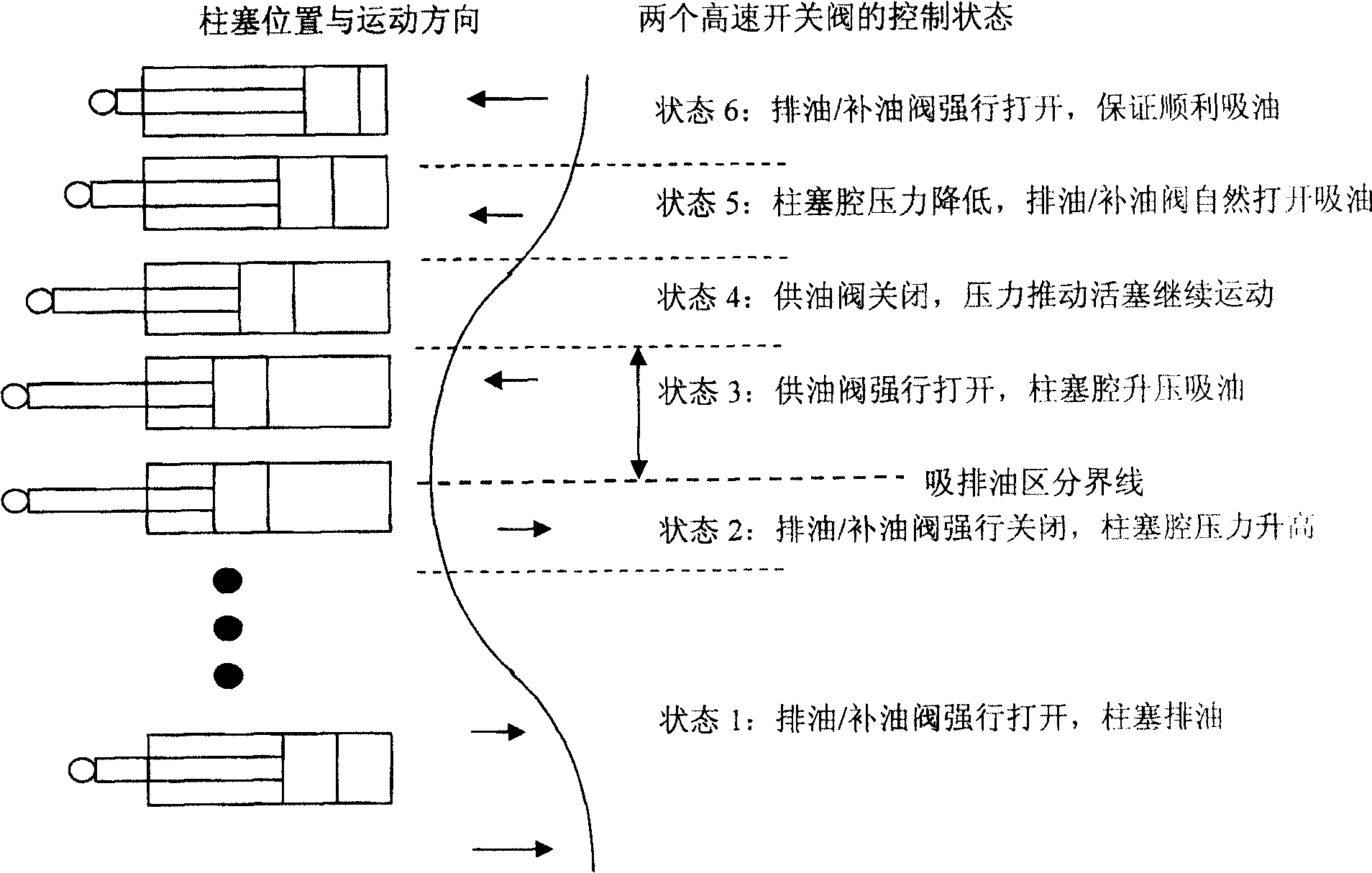

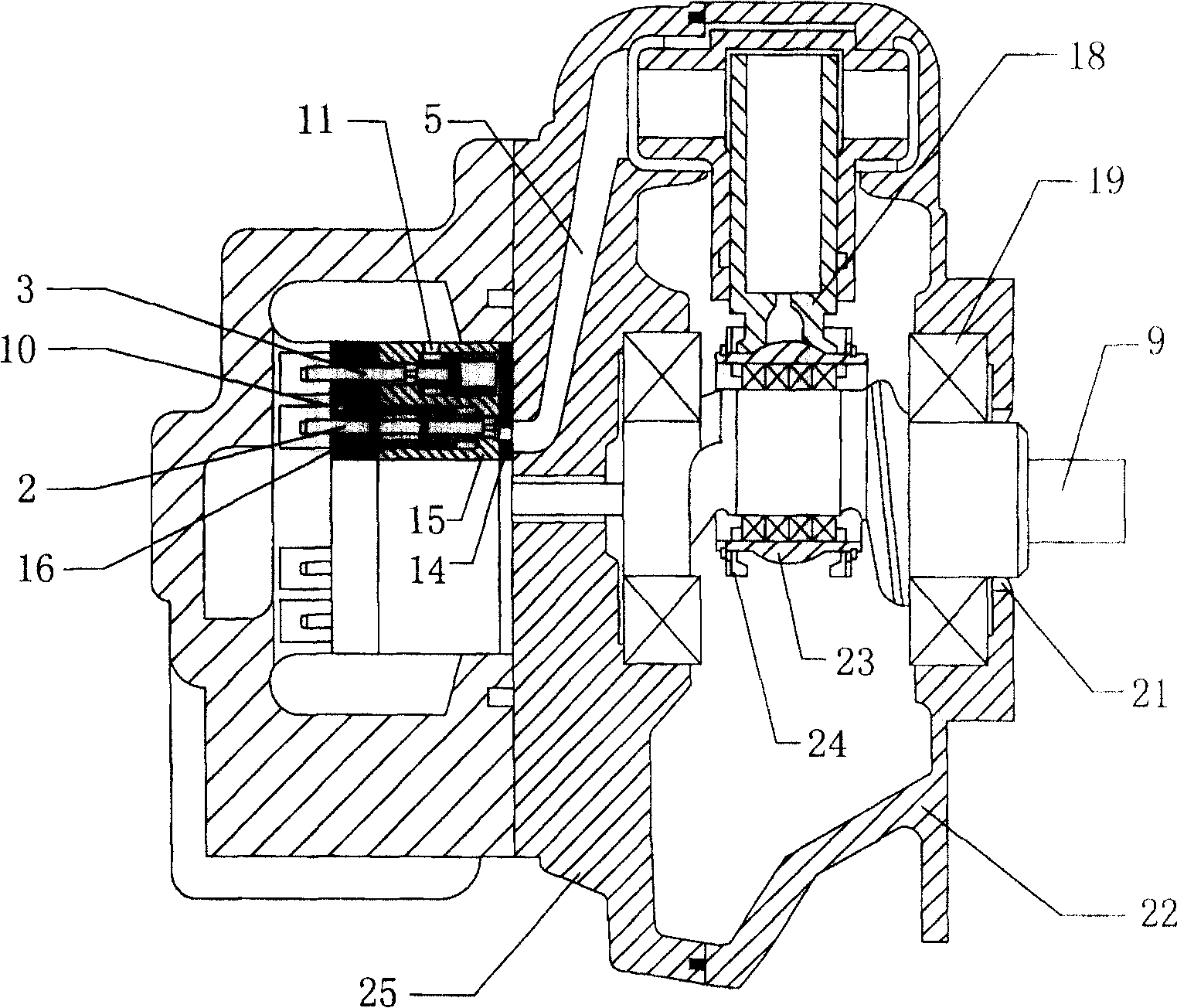

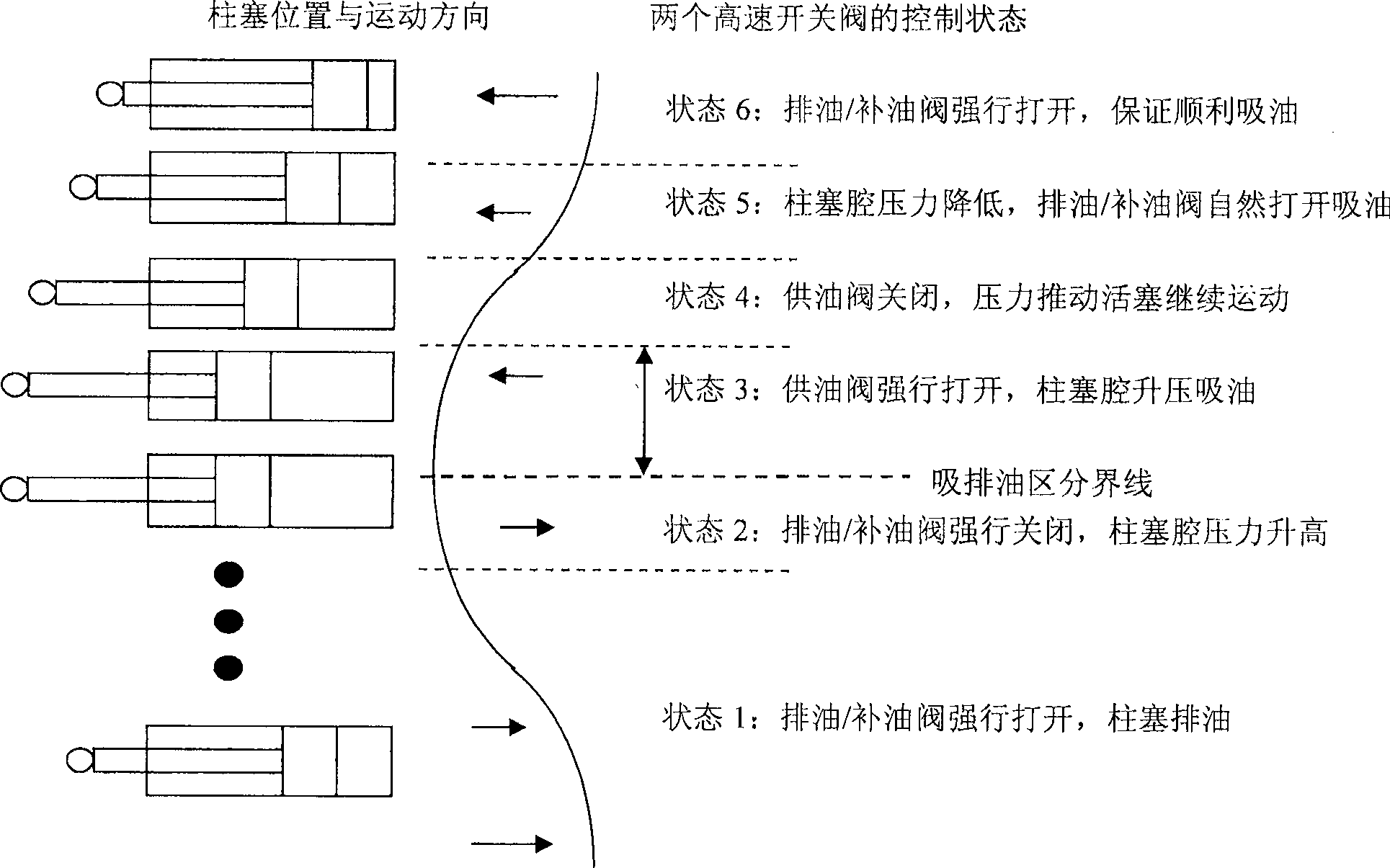

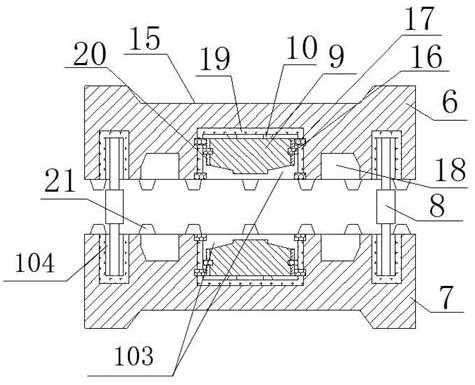

Plunger type quantitative hydraulic motor electro-hydraulic switch torque-changing oil dispensing subassembly

InactiveCN100588837CReduce energy consumptionIncrease driving pressurePump controlPiston pumpsHydraulic motorEngineering

The invention relates to an oil matching mechanism for a hydraulic motor, which aims at providing a plunger type quantitative hydraulic motor liquid switch torque-converting and oil-matching component. The oil-matching component comprises plungers, an oil-matching valve group and a liquid torque-converting driving mechanism, wherein, the oil matching valve group is composed of integrated valves ofidentical number of the plungers; each integrated valve is composed of a high-speed switch high pressure oil supplying valve and a corresponding high-speed switch oil discharging / complementing valve;each high speed switch oil discharging / complementing valve is provided with an oil return hole, and each high speed switch high pressure oil supplying valve is provided with a pressure oil hole; thetail part of a push and pull rod penetrates out of a spring cavity of the high speed switch high pressure oil supplying valve and is connected with the liquid torque-converting driving mechanism; theliquid torque-converting driving mechanism is used for driving the integrated valves to work. The hydraulic motor has the advantages that the torque-converting control of the switch can be realized; alarge quantity of energy consumption can be saved; the driving pressure of the hydraulic motor is greatly improved.

Owner:HANGZHOU YUKONG MECHANICAL & ELECTRICAL ENG +1

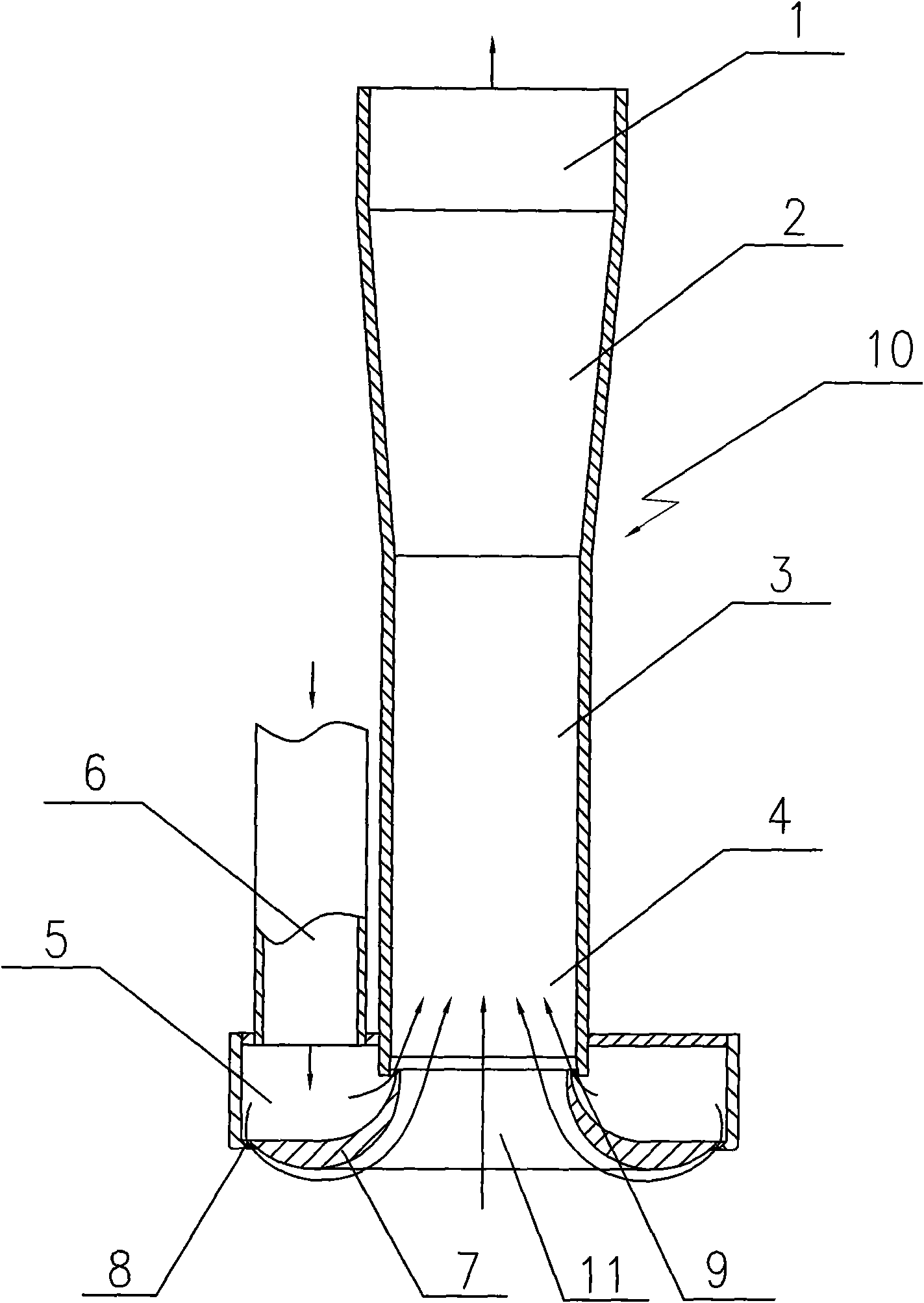

Ecological dredging jet pump

InactiveCN101571148BIncrease driving pressureImprove suction effectJet pumpsMachines/enginesRiver routingCoal dust

The invention discloses an ecological dredging jet pump, which comprises a jet water inlet pipe, a high-pressure distribution cavity and a silt outlet pipe which are connected in turn. Jet water is jetted into the outlet pipe through a primary jet spout and a secondary jet spout in the high-pressure distribution cavity, wherein the primary jet spout directly jets the jet water into the outlet pipe; and the secondary jet spout introduces the jet water into the outlet pipe through a streamline inlet. The ecological dredging jet pump utilizes the hydrodynamics Coanda effect to realize high speedflow, can avoid secondary pollution caused by using rotating components, and can be widely applied to ecological dredging and environment-friendly dredging of river courses, lakes and the like, and absorption of coal dust on the mine bottom of a coal mine.

Owner:中国船舶重工集团公司第七〇二研究所

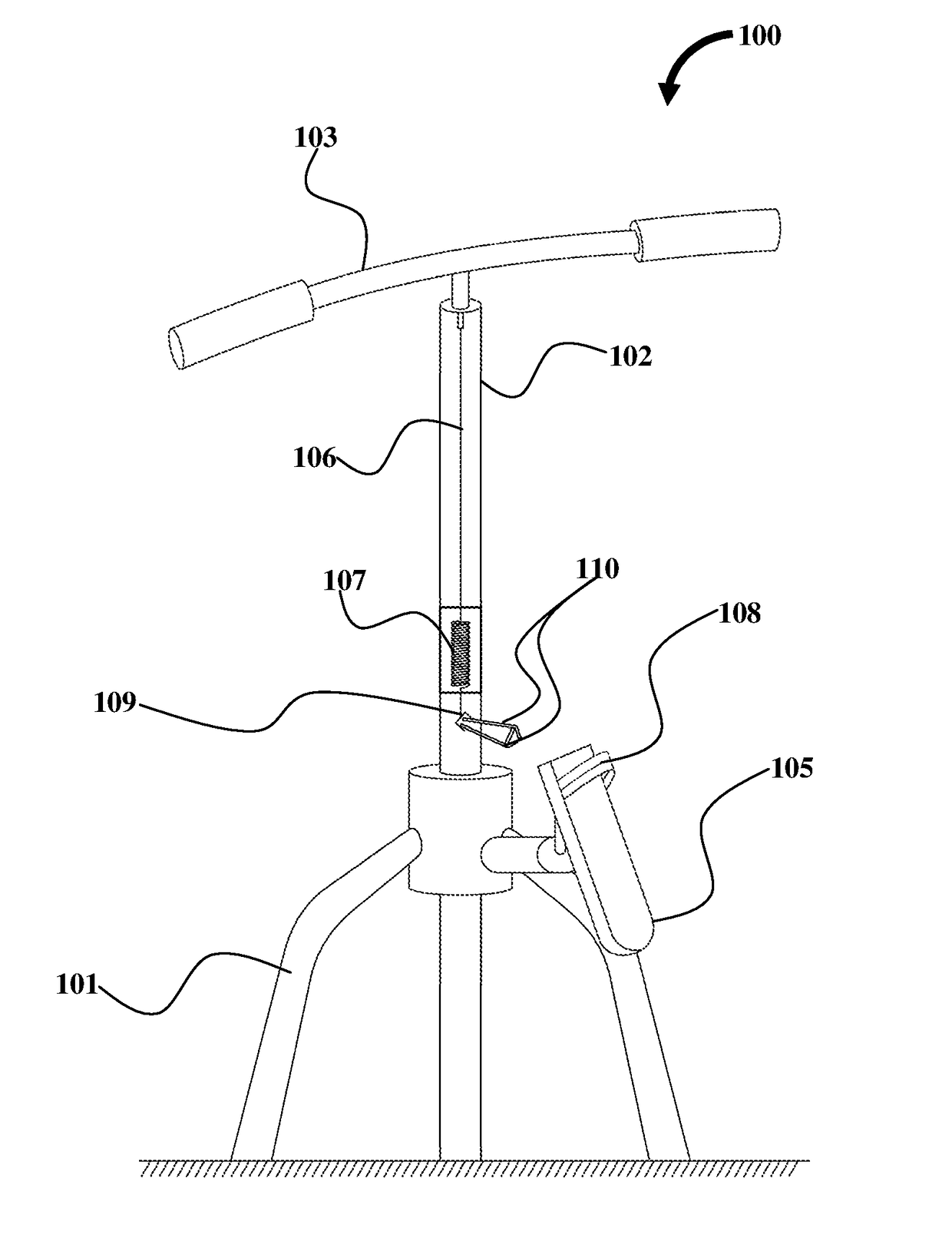

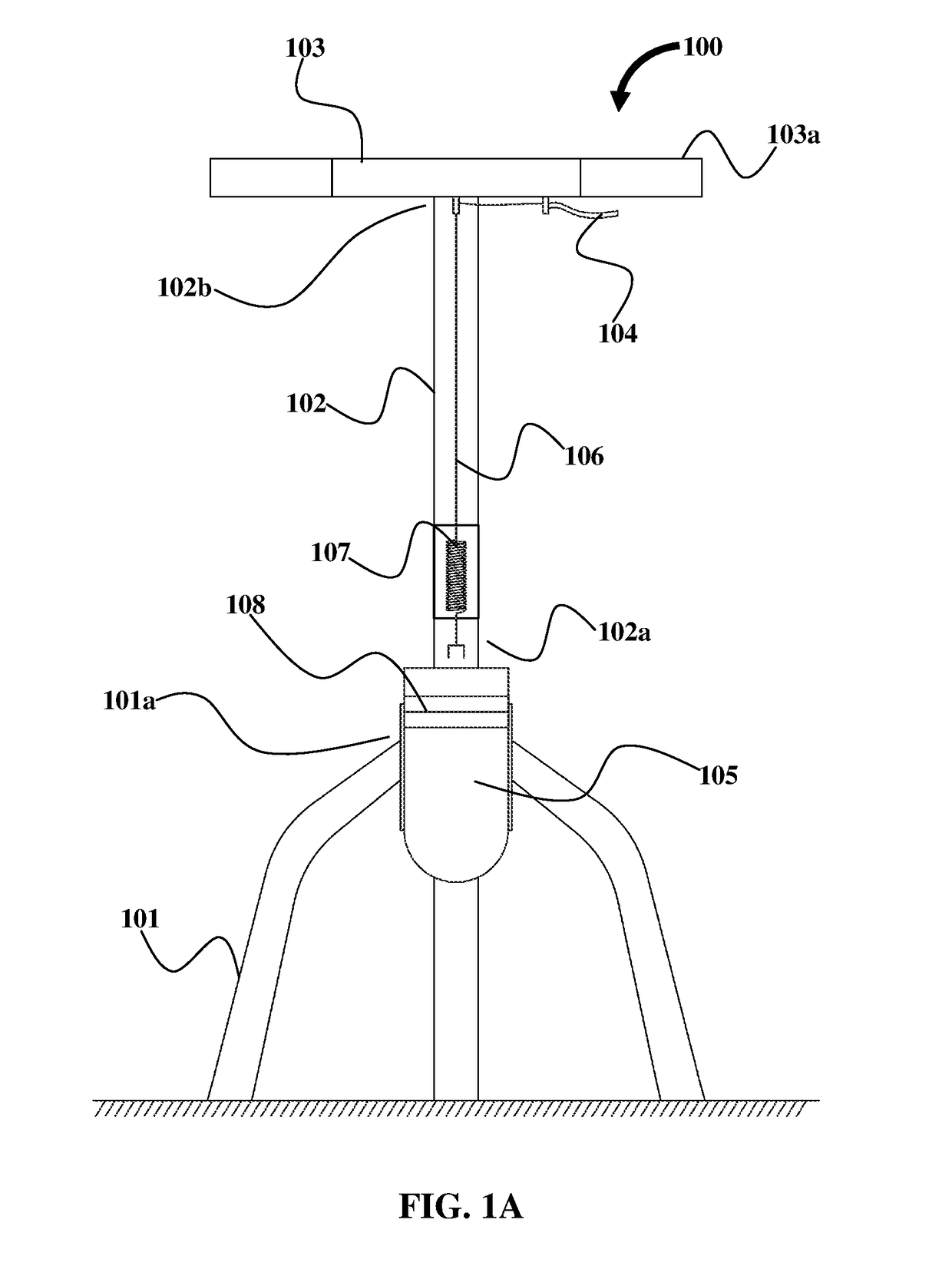

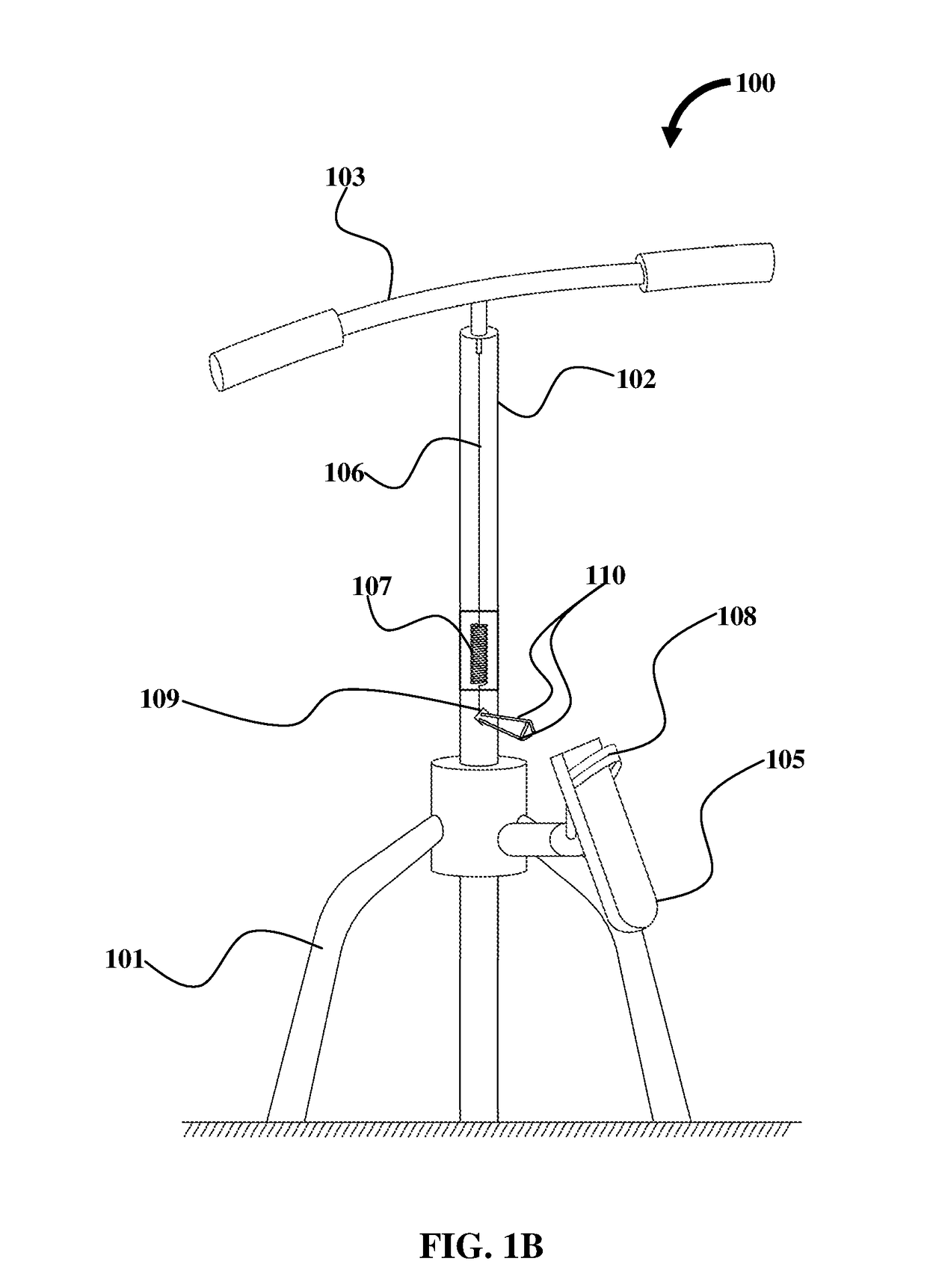

Adjustable nail clipper

InactiveUS20180199689A1Increases actuation pressureIncrease driving pressureManicure/pedicureNail clipperEngineering

An adjustable nail clipper supports a foot of a user to clip toe nails of the user. The adjustable nail clipper comprises a support leg assembly, a hollow shaft, a handle, a clipper head with cutting blades, and a foot rest. The hollow shaft extends from an upper end of the support leg assembly, and the handle is attached to the hollow shaft. The clipper head is attached proximal to a bottom end of the hollow shaft, and the cutting blades of the clipper head are actuated via a clipping lever attached to the hollow shaft. The foot rest is pivotally connected to the hollow shaft, and positioned frontally to the clipper head. The foot rest is configured to receive and support the foot of the user seated on a chair, and to allow the user to clip each toe nail after aligning each toe nail between the cutting blades.

Owner:CARTON PATRICK

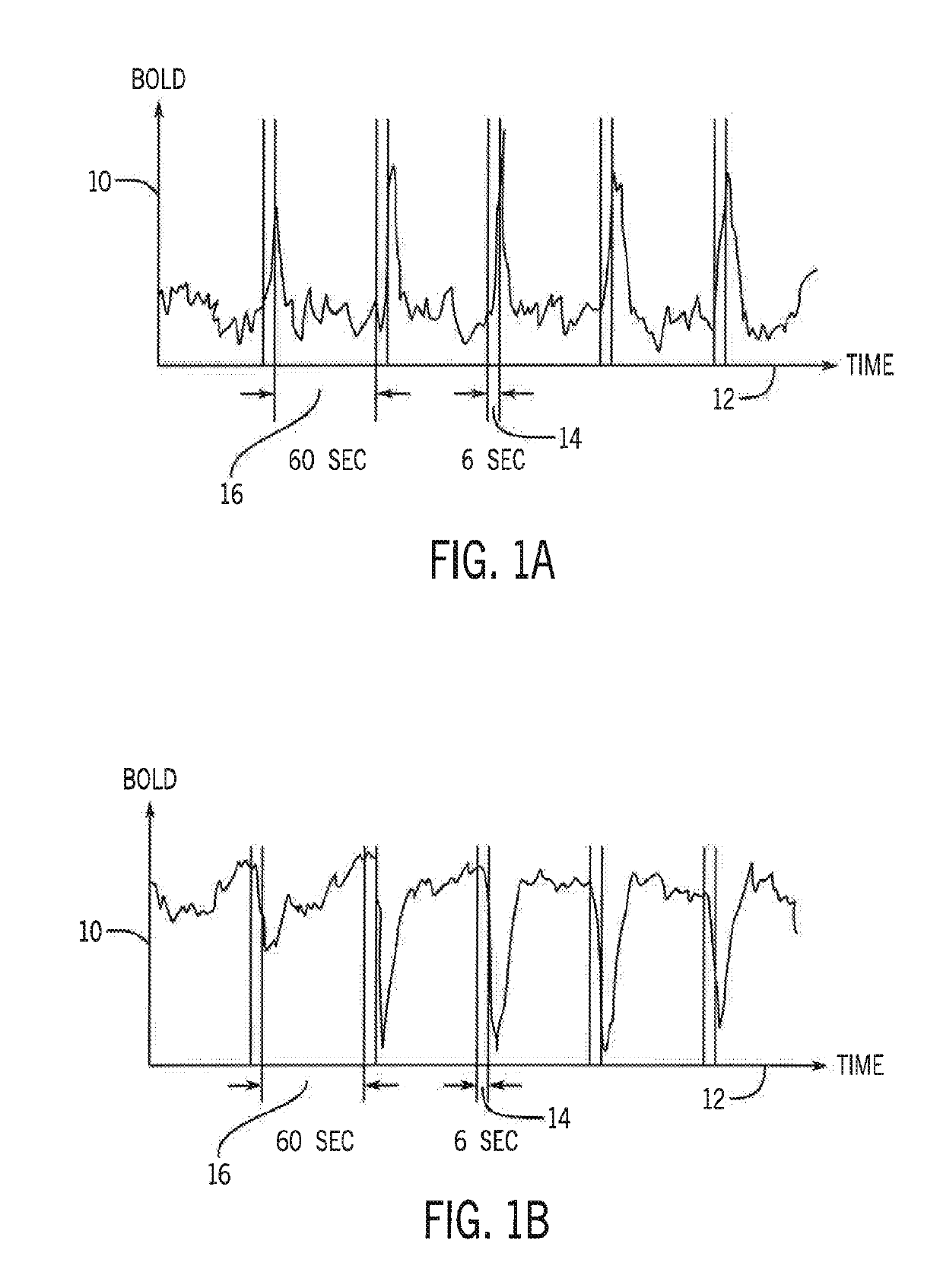

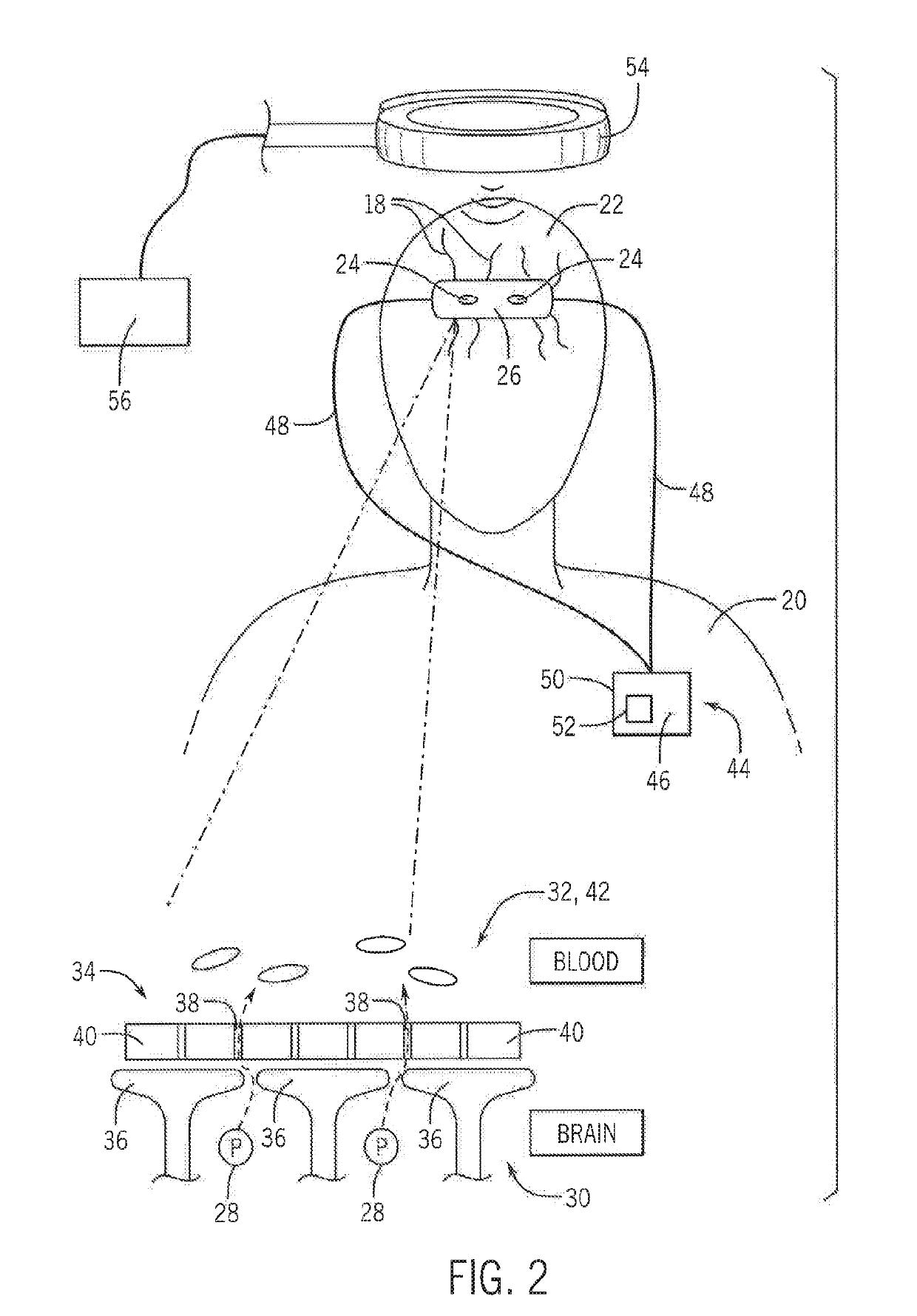

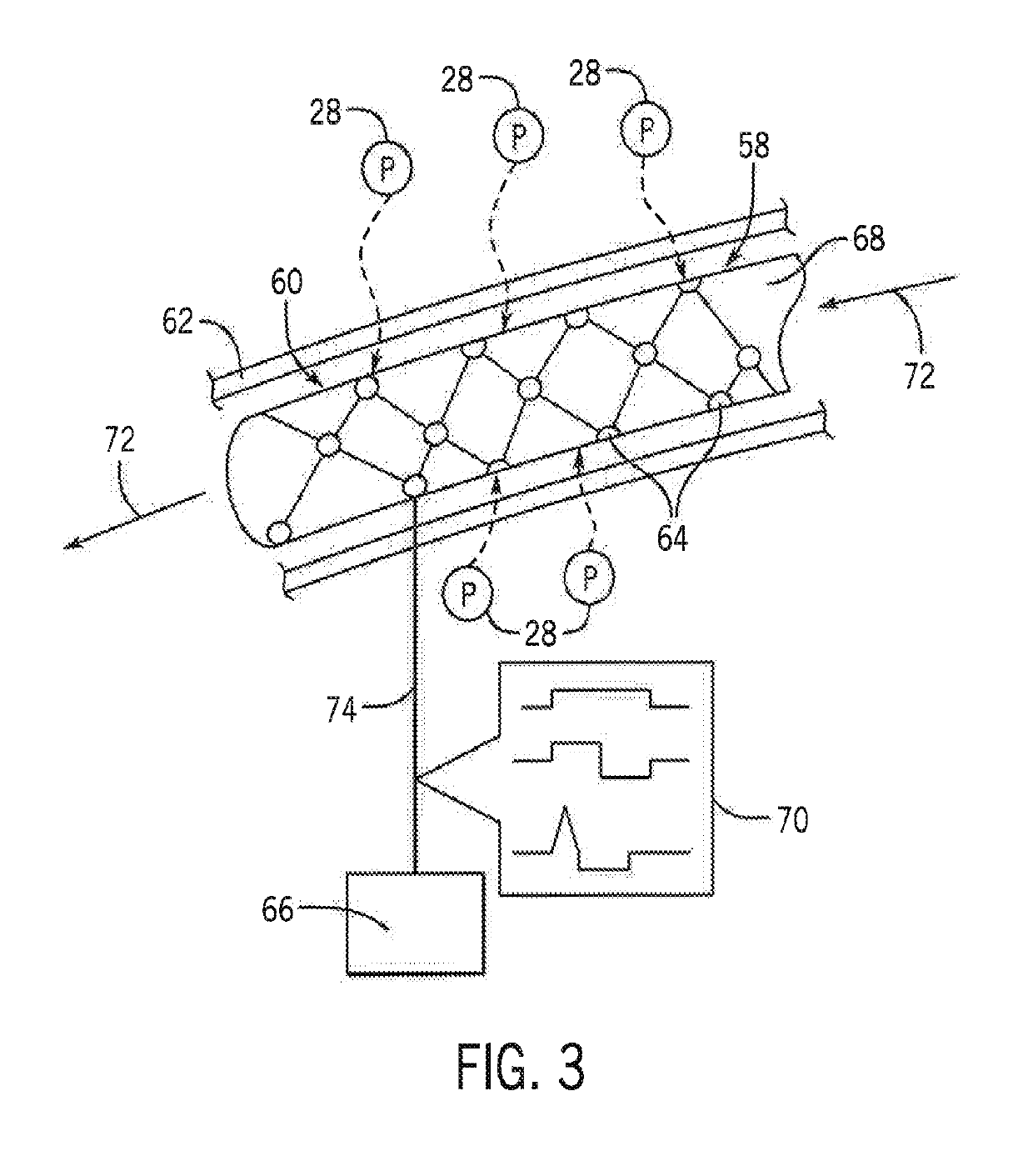

Neuromodulation to Modulate Glymphatic Clearance

ActiveUS20190201684A1Reduce resistanceIncreasing glymphatic flowSpinal electrodesHead electrodesDiseaseMammal

The present invention provides materials and methods for using electrical stimulation to treat a mammal having a proteinopathy (e.g., neurodegenerative diseases) or at risk of developing a proteinopathy are provided. For example, the present invention provides materials and methods for modulating glymphatic clearance (e.g., enhancing glymphatic clearance) of pathogenic proteins.

Owner:WISCONSIN ALUMNI RES FOUND +1

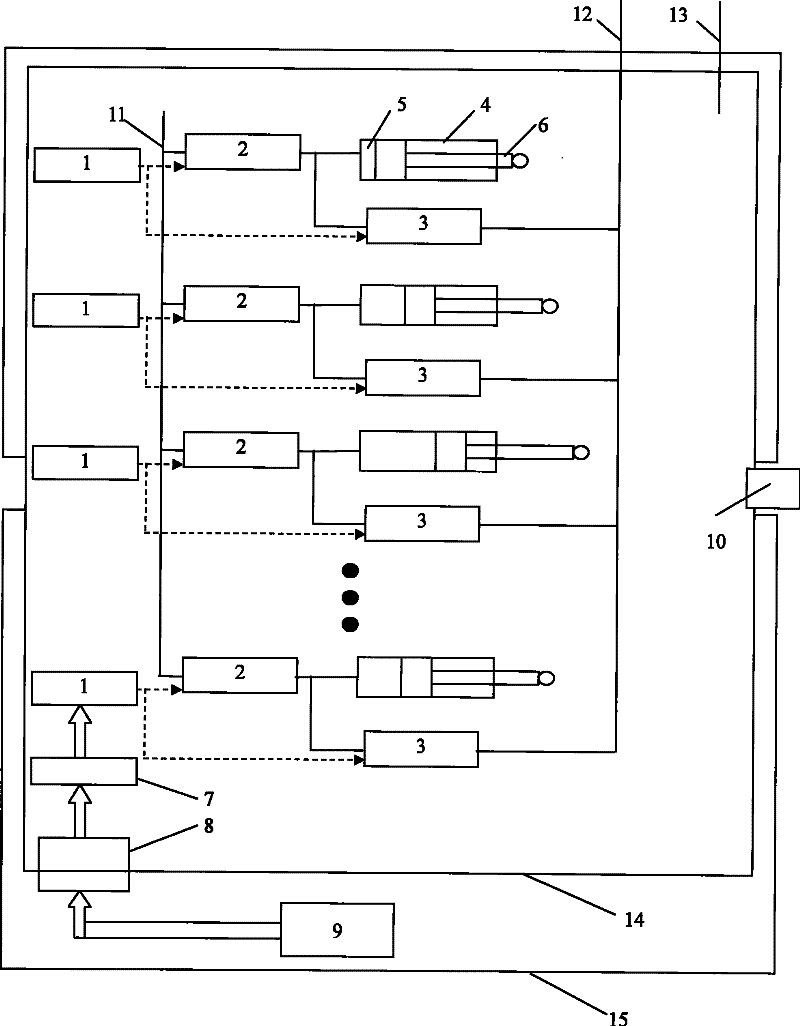

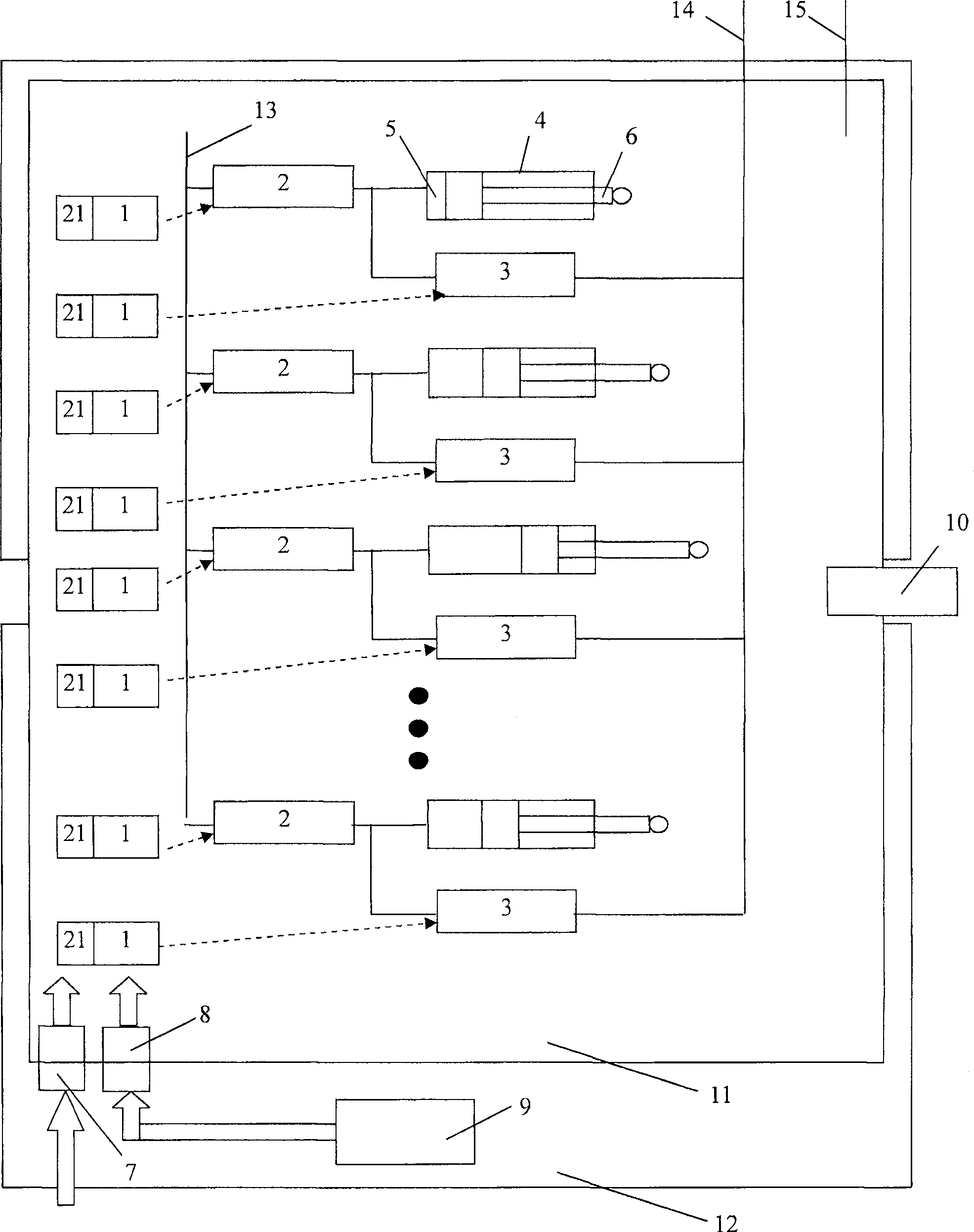

Constant plunger hydraulic motor with rotary cylinder with electrohydraulic valve variable torque feeding oil

InactiveCN101074658AReduce energy consumptionIncrease driving pressurePump controlPiston pumpsHydraulic motorAudio power amplifier

The invention relates to hydraulic motor which includes the motor shell, the swashplate, the switch torque-change valve and oil controlling component, the electric-mechanism convertor, the driving amplifier, the electric brush, the induction ring and electron controller. The switch torque-change valve and oil controlling component includes the oil distributing valve groups which include the high-speed switch and high-pressure oil supplying valve and the high-speed switch oil drain / supplying valve; every valve is connected with the electric-mechanism convertor which is connected with the driving amplifier; the input of the high-speed switch and high-pressure oil supplying valve is connected with the pressure oil mouth; the output is connected with the plunger piston hollow which is also connected with the spring hollow of the high-speed switch oil drain / supplying valve and the other end is connected with the oil returning mouth. The invention can control by torque instead the switch and save much energy cost; the oil distributing component controlled by valve is installed on the top of the hydraulic motor piston cylinder to improve the driving pressure.

Owner:HANGZHOU YUKONG MECHANICAL & ELECTRICAL ENG +1

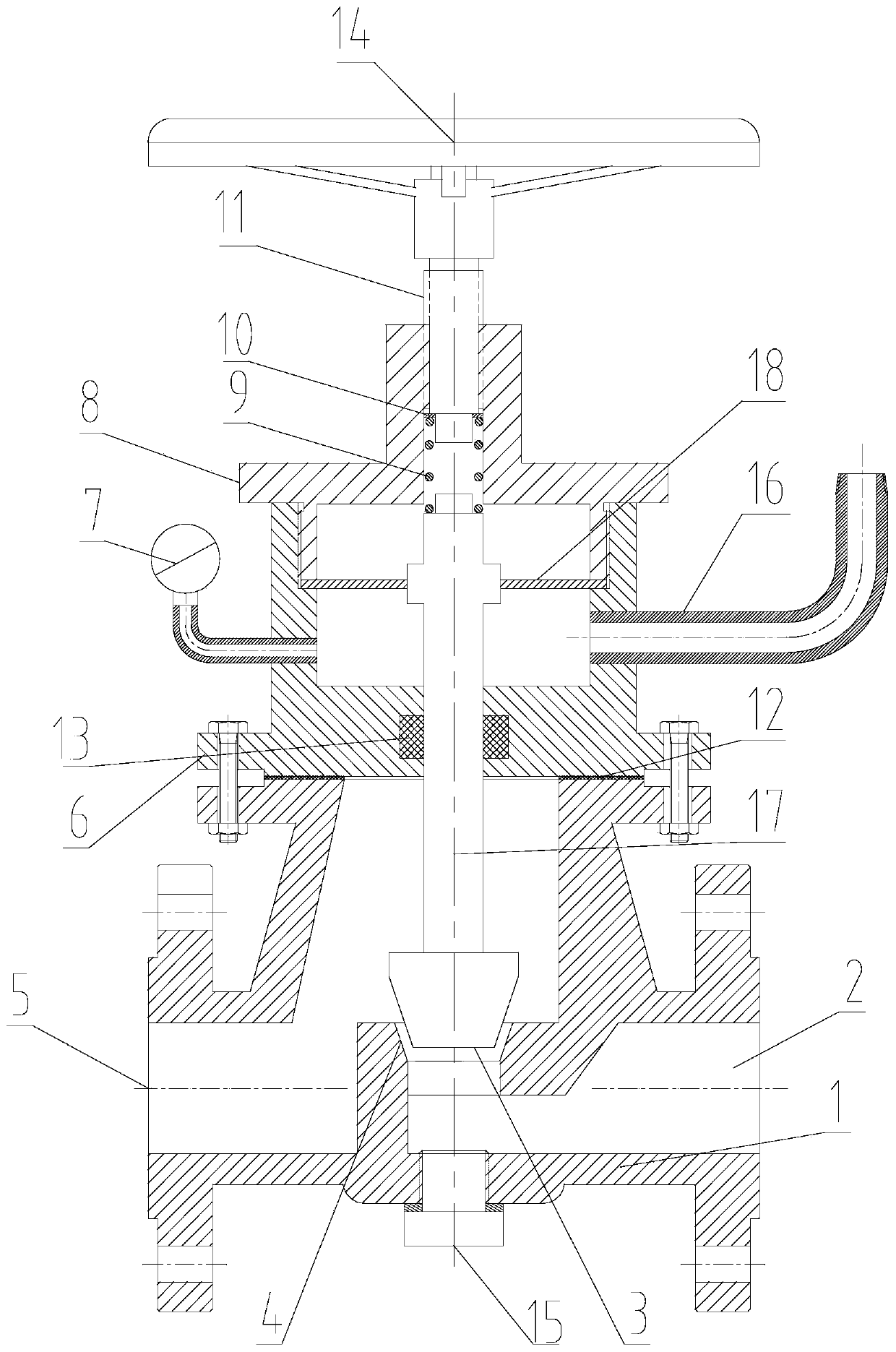

Automatic regulating device for water injection flow

InactiveCN111396607AReduce the temperatureHigh viscosityOperating means/releasing devices for valvesEqualizing valvesMechanical engineeringViscosity

The invention provides an automatic regulating device for water injection flow, and relates to the technical field of oil and gas gathering and transportation. A diaphragm is clamped between the bottom of an upper valve body connected to a valve cover and the upper valve body, the diaphragm is connected with a nut, the nut is in threaded connection with the upper thread of a valve rod, the lower part of the valve rod is fixedly connected with a valve core, and a back pressure connecting pipe is arranged in an inner cavity of the upper valve body at the lower part of the diaphragm and communicates with the inner cavity of the upper valve body at the lower part of the diaphragm. The automatic regulating device has the following beneficial effects that the device is designed by utilizing theprinciple that the temperature and the pressure of the crude oil fluid are in inverse ratio, the temperature of the crude oil is low, the viscosity is large, the driving pressure is increased, and theback pressure connecting pipe connected to a crude oil pipeline is adopted to drive the valve rod to rise and fall under the diaphragm to automatically adjust the water mixing flow; and moreover, theflow can be adjusted as required, manual operation is not needed, the water mixing flow is accurate, the energy consumption loss caused by the fact that manual adjustment is not timely and accurate is reduced, and the crude oil conveying efficiency is improved.

Owner:刘超

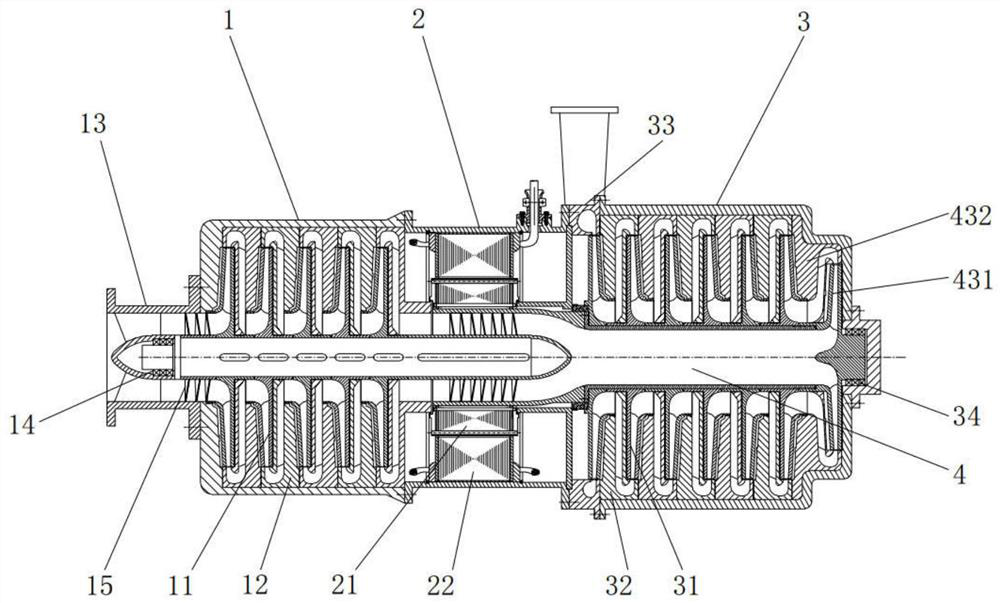

Multi-stage low-temperature centrifugal pump provided with built-in motor

ActiveCN112253492AImprove cooling effectImprove sealingPump componentsCooling/ventillation arrangementElectric machineryEngineering

The invention provides a multi-stage low-temperature centrifugal pump provided with a built-in motor. The multi-stage low-temperature centrifugal pump comprises a front shell, a motor shell and a backshell; a forward impeller and a forward guide vane are arranged in the front shell; the motor is arranged in the motor shell; a reverse impeller and a reverse guide vane are arranged in the back shell; the motor shell is located between the front shell and the back shell; an inlet horn pipe is arranged at the end of the front shell; an outlet volute is arranged between the back shell and the motor shell; the forward impeller, a motor rotor and the reverse impeller are connected in series through a rotating shaft assembly; the motor rotor is directly connected with the rotating shaft assemblyfrom the middle to drive the rotating shaft assembly to rotate so as to drive the forward impeller, the reverse impeller and an inducer to rotate. A low-temperature liquid enters a pump body from theinlet horn pipe, is pressurized by the forward impeller and the reverse impeller and is sprayed out of the outlet volute. According to the pump, the motor is arranged internally and is cooled throughthe low-temperature liquid, the overall sealing performance is good, the size is small, the weight is light, the structure is compact, and the pump is particularly applicable to conveying of low-temperature volatile liquids.

Owner:JIANGSU UNIV

Electro-hydraulic switch torque-changing oil-dispensing type rotating cylinder barrel type quantitative plunger piston hydraulic motor

InactiveCN101334013BReduce energy consumptionIncrease driving pressurePump controlPiston pumpsHydraulic motorPush and pull

Owner:HANGZHOU YUKONG MECHANICAL & ELECTRICAL ENG +1

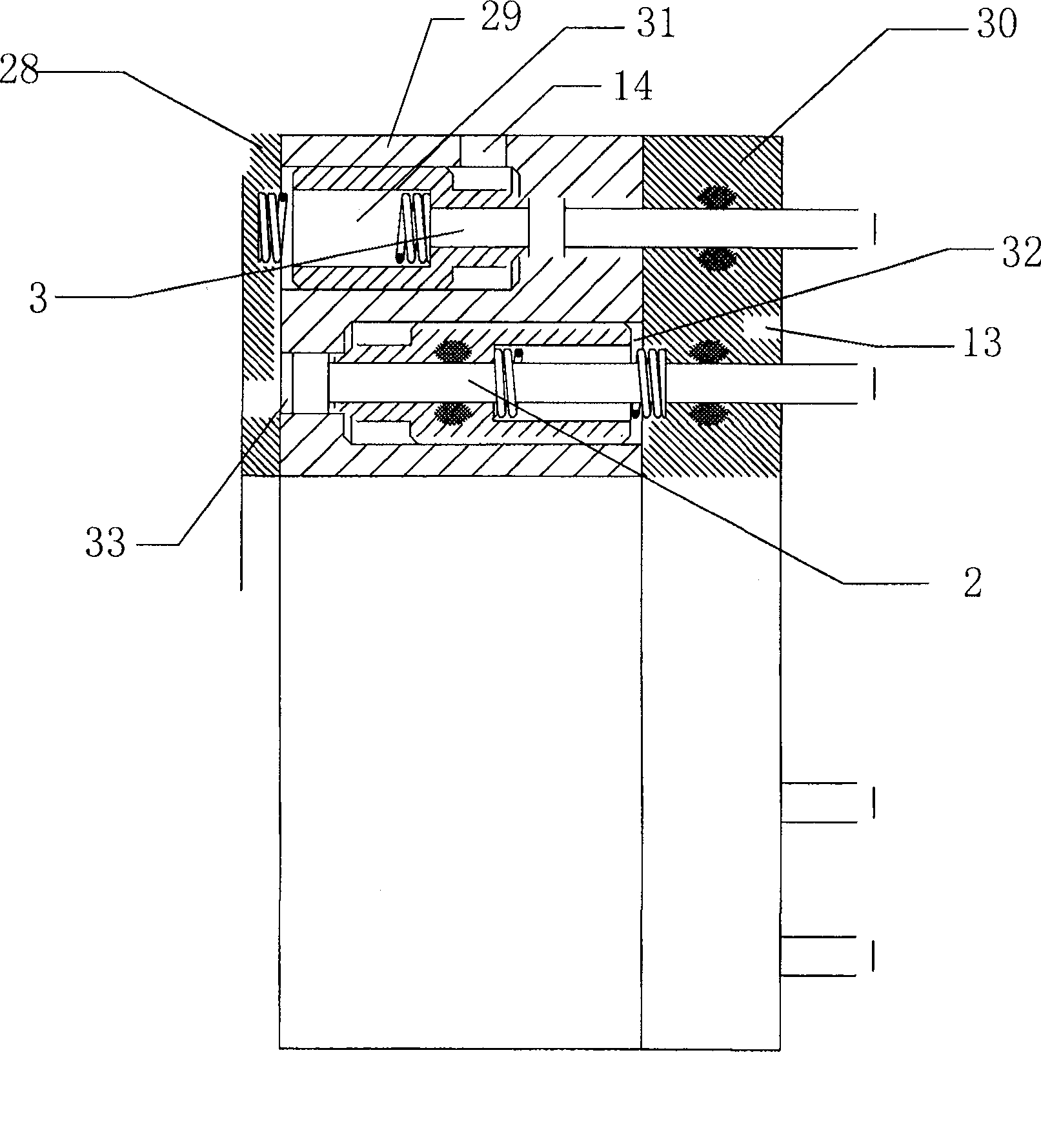

Polyphase multi-rhythm stepped plunger piston hydraulic motor

InactiveCN100458184CReduce energy consumptionIncrease driving pressureFluid-pressure actuator componentsElectronic controllerHigh pressure

The invention relates to a fluid power motor with polyphase and polystep plunger. It makeup with shell,sloping cam plate,oil distributing unit with switching change-torque value,electromechanical convertor,turn angle detection sensor and electronic controller. Switching change-torque value makeup with plunger piston and nil distributing value group which contains front end plate,valve plate, lower end plate,high speed-optical switching heavy pressure oil valve and high speed-optical switching oil vent / slippage valve. Entry end of high speed-optical switching heavy pressure oil valve connects to pressure oil port and export end connects to cavity of plunger piston. Spring end of high speed-optical switching oil vent / slippage valve connects to cavity of plunger piston. The motor take real-time adjusting on duty cycle and control the switching change-torque. The invention save large quantity of energy and improve driving pressure of fluid power motor by without relative slip between oil distributing unit and end surfave of cylinder body.

Owner:HANGZHOU YUKONG MECHANICAL & ELECTRICAL ENG +1

Constant plunger hydraulic motor with rotary cylinder with electrohydraulic valve variable torque feeding oil

InactiveCN100538066CReduce energy consumptionIncrease driving pressurePump controlPiston pumpsElectronic controllerInlet valve

The invention relates to a hydraulic motor and aims at providing an electro-hydraulic switch variable torque oil distribution type rotary cylinder type quantitative plunger hydraulic motor. The motor includes a motor housing, a swash plate, a switch variable torque valve-controlled oil distribution assembly, an electro-mechanical converter, a drive amplifier, a brush, an induction ring and an electronic controller; the switch variable torque valve-controlled oil distribution assembly includes an oil distribution valve The oil distribution valve group includes a high-speed switch high-pressure oil supply valve and a high-speed switch oil discharge / fill valve; each valve is connected to an electro-mechanical converter, and each electro-mechanical converter is connected to a drive amplifier; the high-speed switch high-voltage supply valve The inlet port of the oil valve is connected to the pressure oil port, and the outlet port is connected to the plunger chamber of the plunger; one end of the spring chamber of the high-speed switch oil discharge / fill valve is connected to the plunger chamber of the plunger, and the other end is connected to the oil return port . The invention realizes switch variable torque control and saves a lot of energy consumption; the valve-controlled oil distribution component is directly installed on the end face of the hydraulic motor plunger cylinder body, which greatly improves the driving pressure of the hydraulic motor.

Owner:HANGZHOU YUKONG MECHANICAL & ELECTRICAL ENG +1

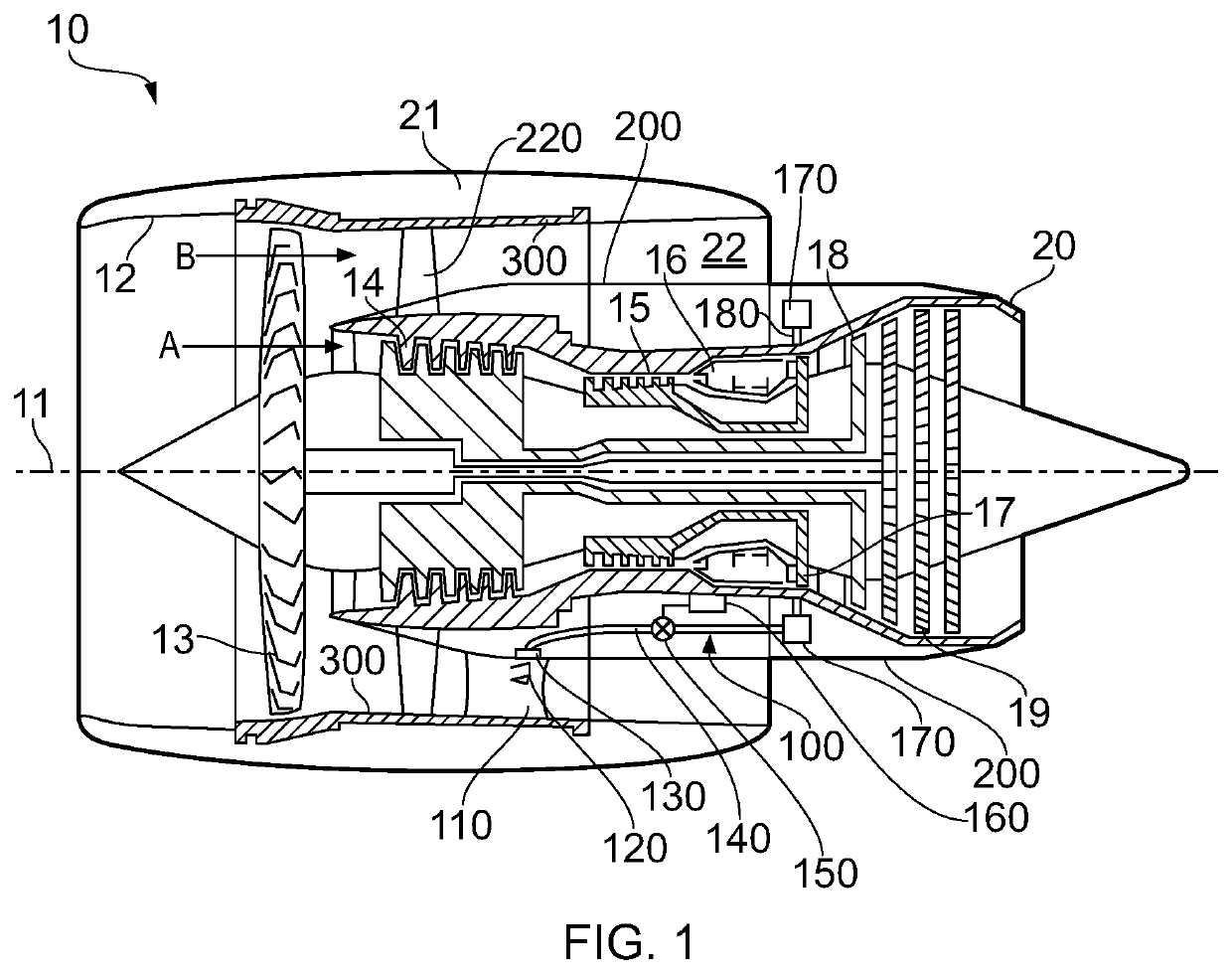

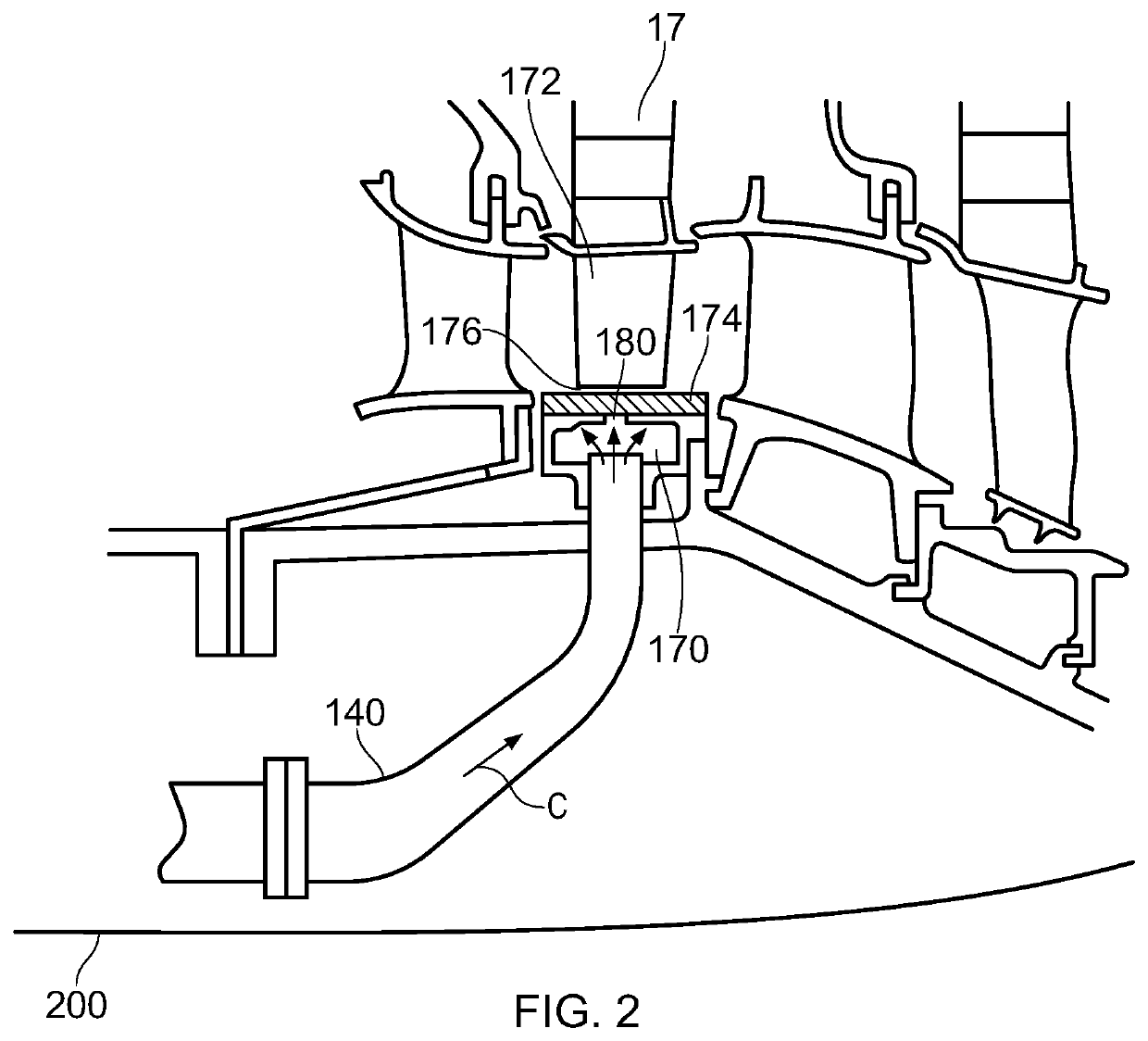

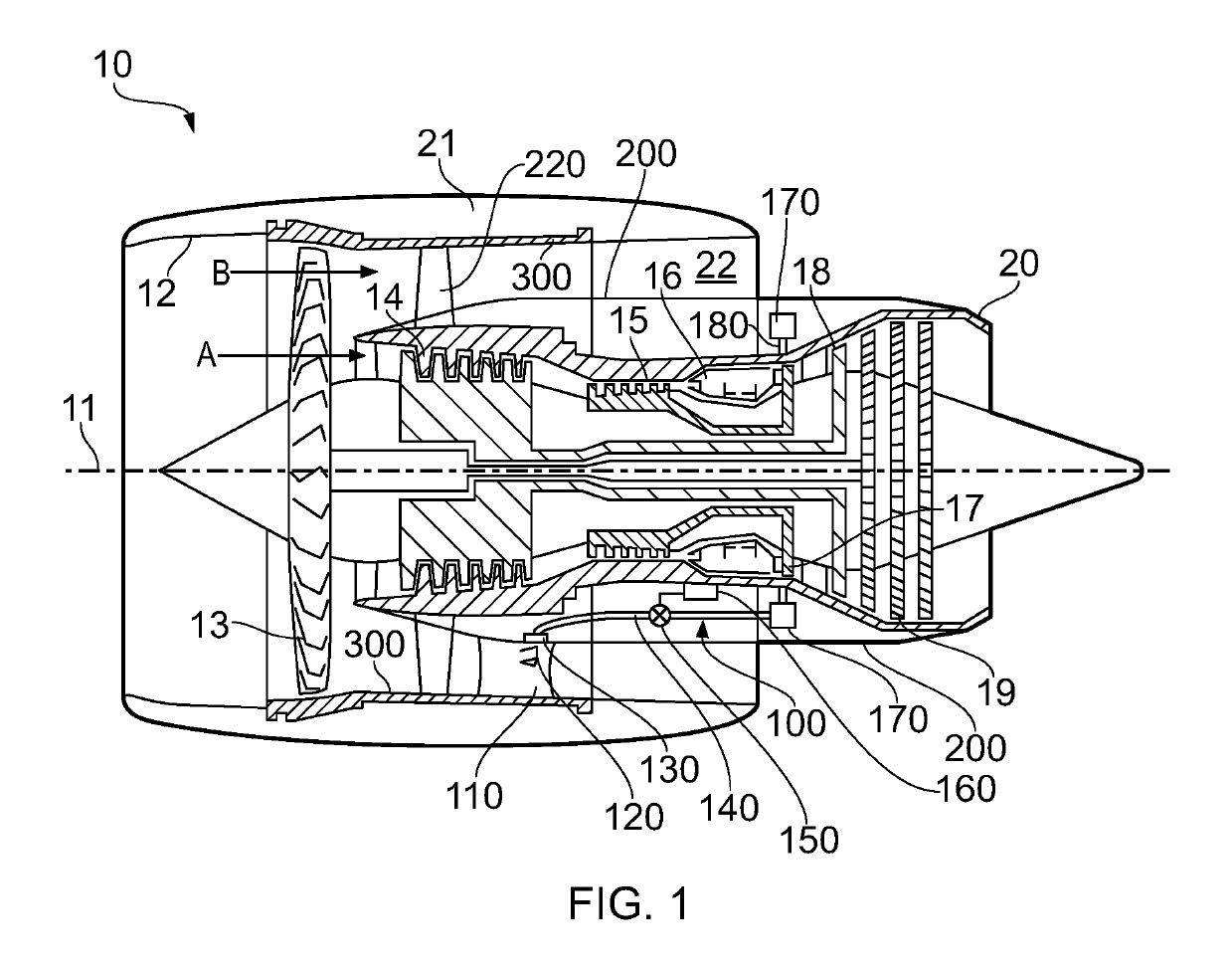

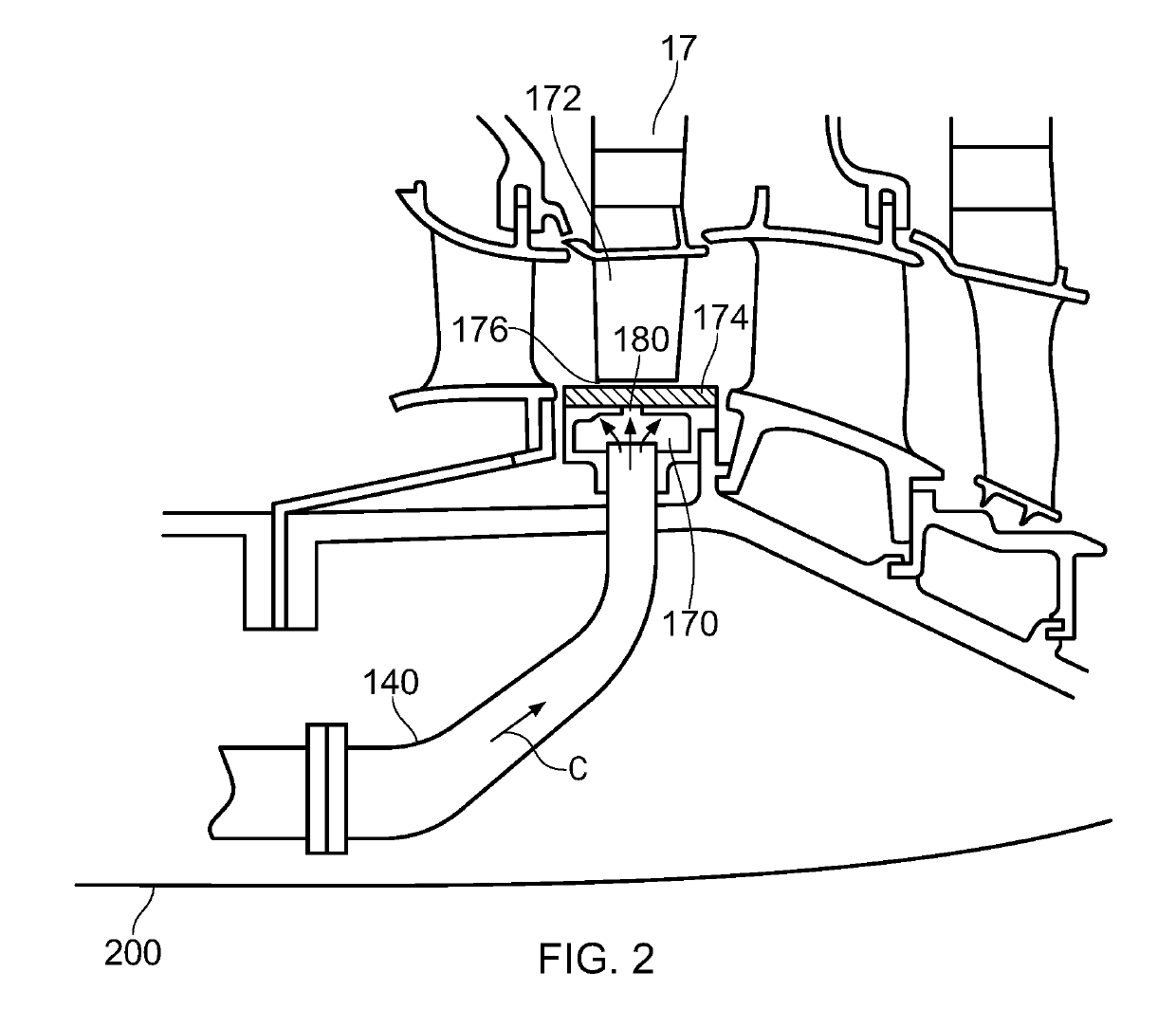

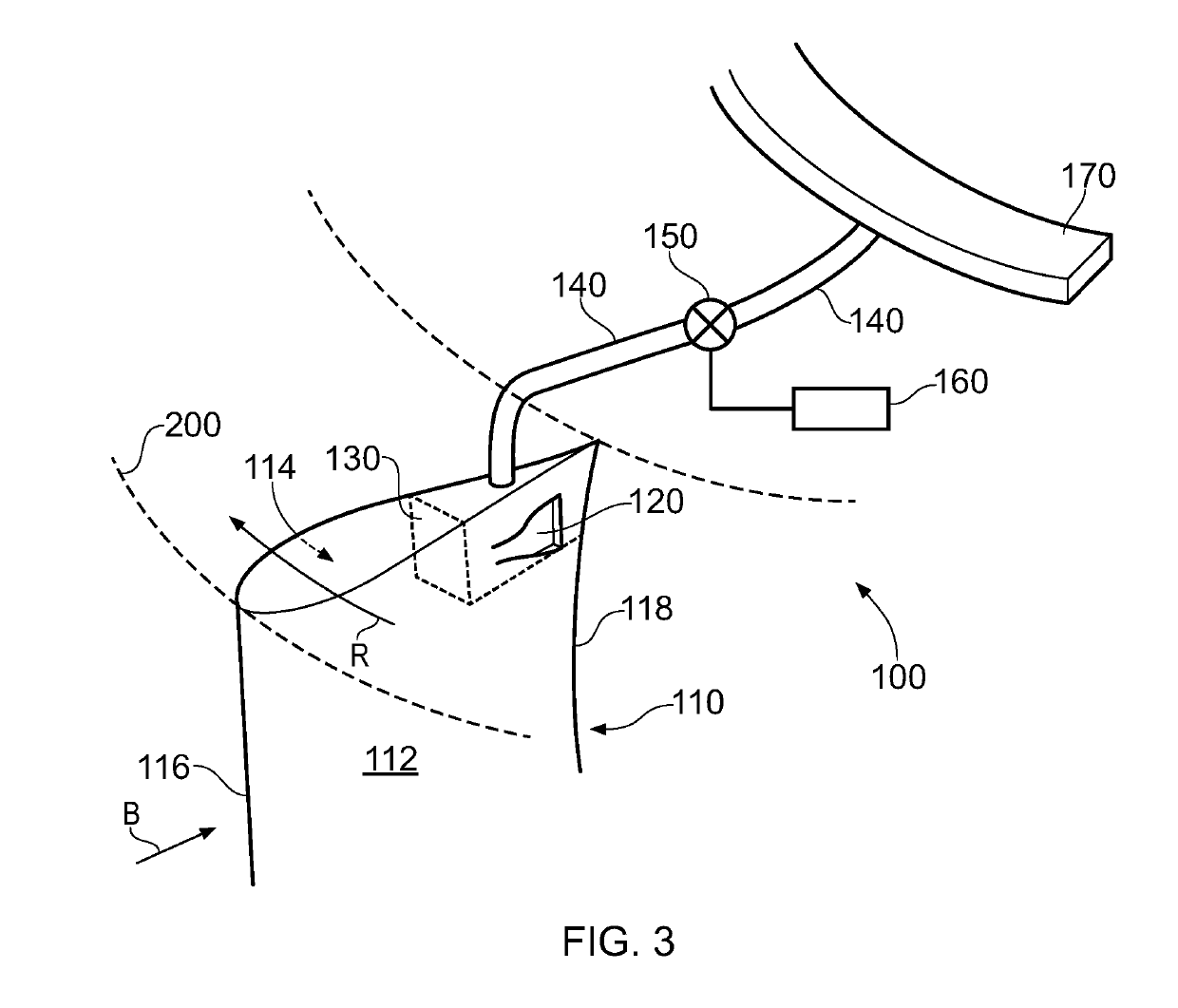

Gas turbine engine offtake

ActiveUS10900370B2Improve efficiencyIncrease driving pressureEngine manufactureEngine fuctionsTurbine bladeControl system

Owner:ROLLS ROYCE PLC

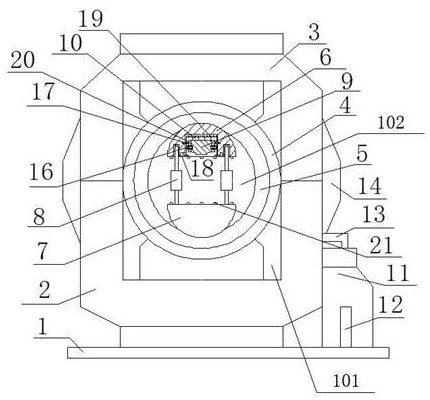

A high-efficiency two-sided top press

ActiveCN109821478BImprove stabilityImprove reliabilityUltra-high pressure processesControl systemEngineering

The invention relates to a high-efficiency two-sided top press, comprising a bearing base, a lower hinge beam, an upper hinge beam, a bearing chamber, a hydraulic bag, an upper pressure bearing block, a lower pressure bearing block, an auxiliary driving hydraulic column, an anvil, and a pressure sensor , Hydraulic station and control system, the lower end surface of the lower hinge beam is connected with the upper end surface of the bearing base, the upper end surface is connected with the upper hinge beam and distributed coaxially with each other, and the upper end surface of the lower hinge beam and the lower end surface of the upper hinge beam are both equipped with pressure grooves , the upper bearing block and the lower bearing block are embedded in the load-bearing chamber and are offset against the surface of the pressure-bearing chamber through the hydraulic bag. The front faces of the upper bearing block and the lower bearing block are both provided with molding cavities, and the top hammers are respectively embedded in the upper bearing block. , In the molding cavity of the lower bearing block. On the one hand, the present invention greatly simplifies the structure of the hydraulic drive system and improves the operating efficiency of the hydraulic drive system. On the other hand, the pressure output is uniform and stable, and the driving force can be effectively assisted to adjust.

Owner:焦作天宝桓祥机械科技有限公司

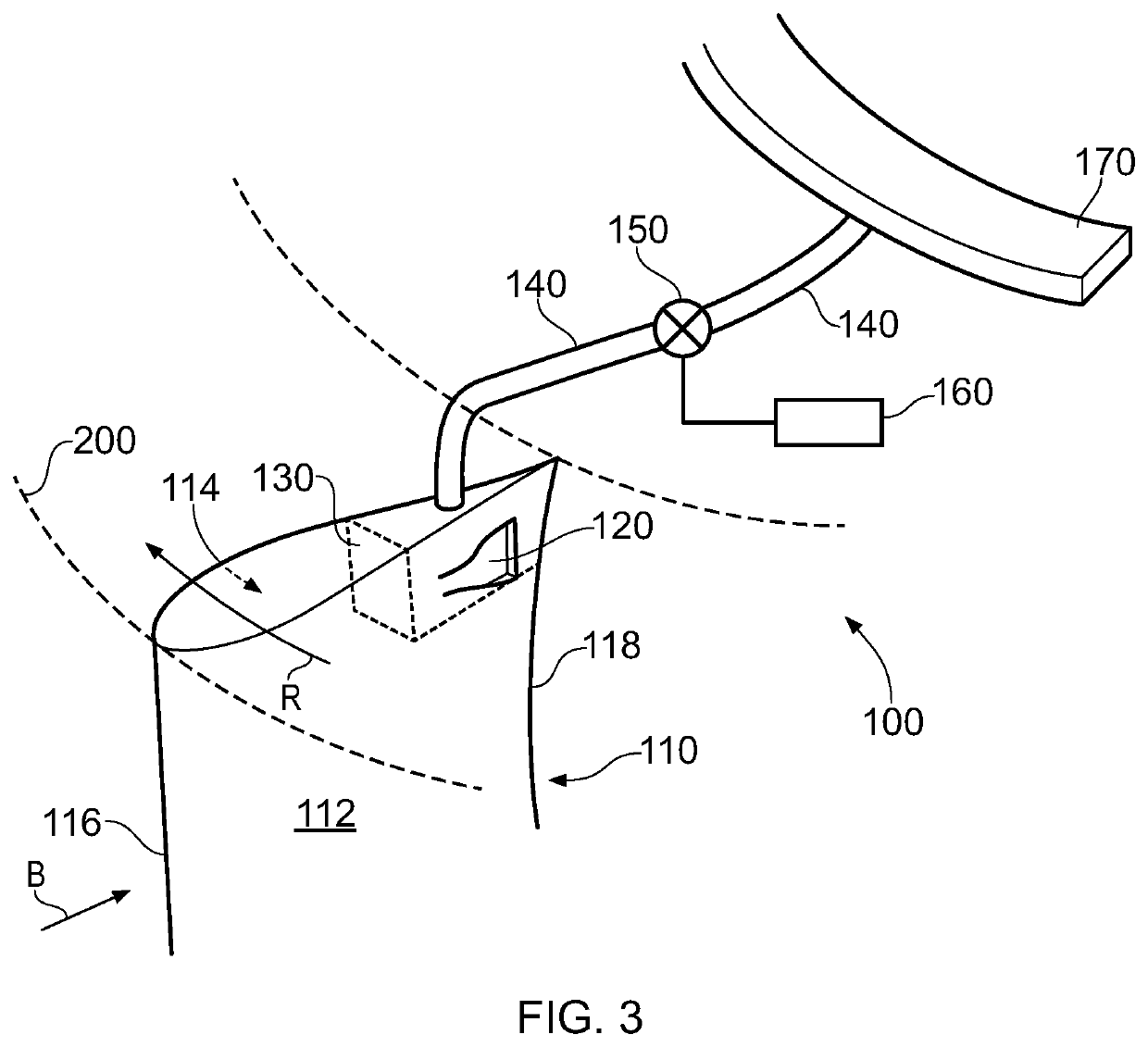

Gas turbine engine offtake

ActiveUS20190170008A1Improve efficiencyIncrease driving pressureEngine manufactureEngine fuctionsTurbine bladeGas turbines

A tip clearance control (TCC) system 100 is provided to control the gap 176 between the tips of turbine blades 172 of a gas turbine engine 10 and the casing 174 within which they rotate. The inlet 120 to the TCC system is provided in a bifurcation panel 110 that extends across a bypass duct 22 of the gas turbine engine 10. The inlet is provided on a first major surface 112 of the bifurcation panel 110 that is defined such that the direction (R) that points through the bifurcation panel from the first major surface 112 to a second major surface 114 corresponds to the fan rotation direction. This provides a particularly effective and / or efficient TCC system 100.

Owner:ROLLS ROYCE PLC

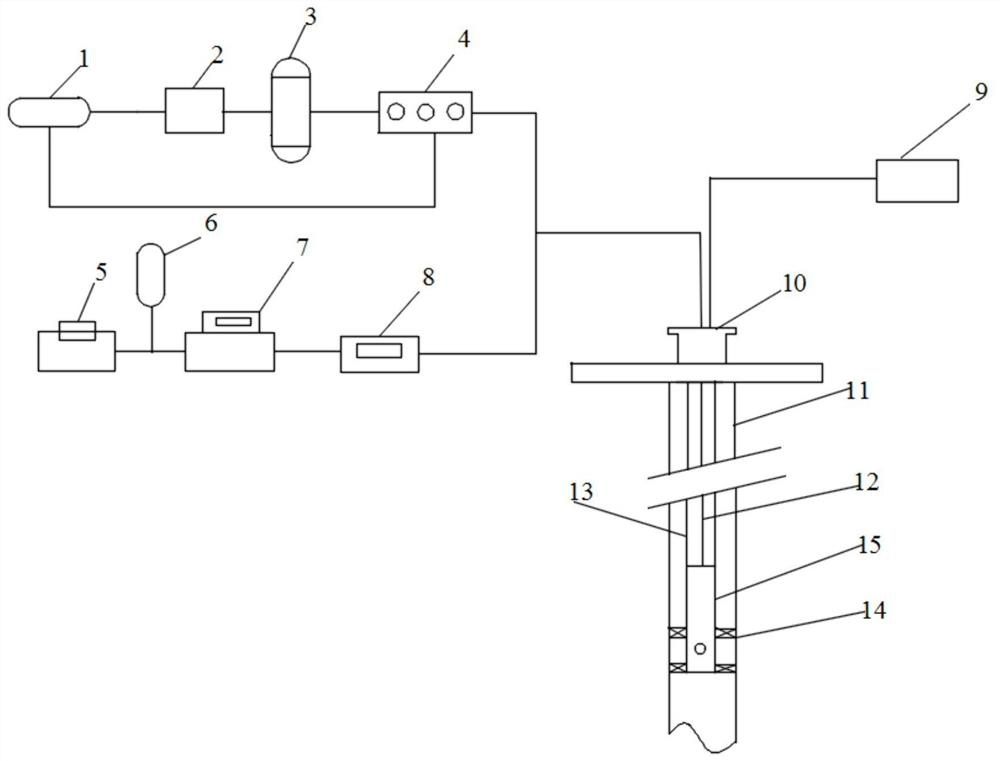

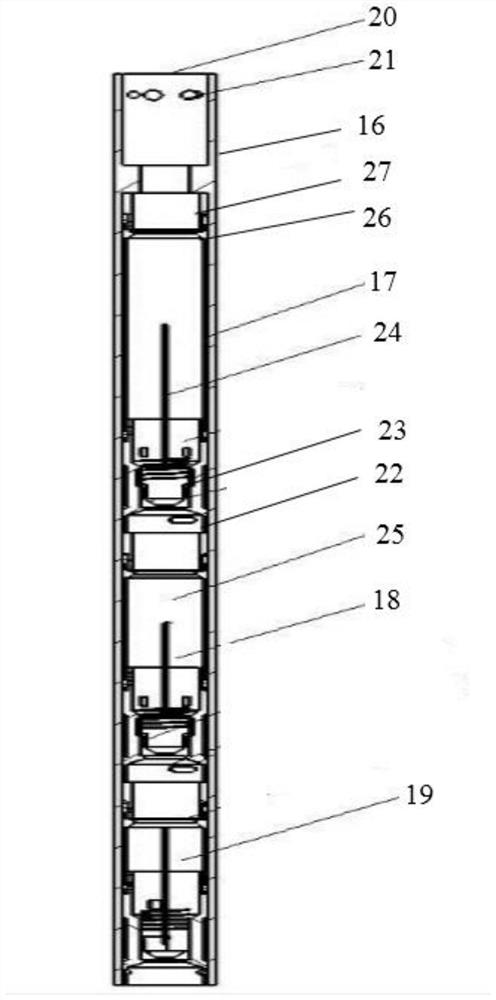

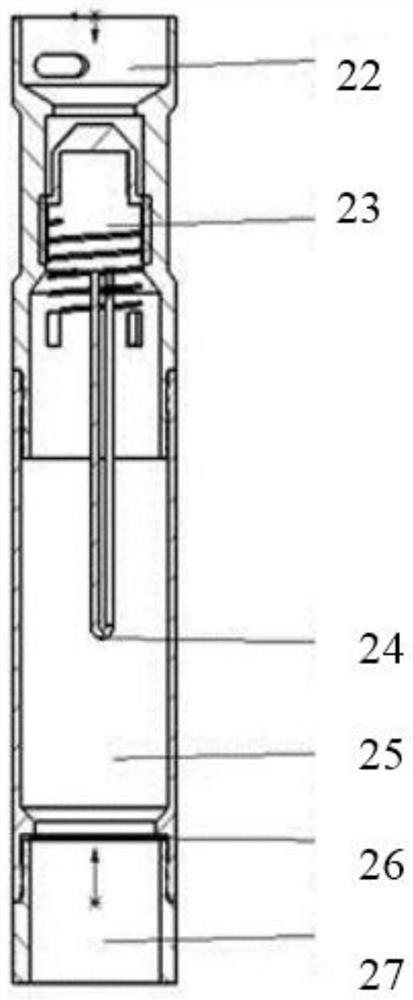

A multi-stage liquid co 2 Phase change composite fracturing stimulation system and method

The invention relates to a multi-stage liquid CO 2 Phase change composite fracturing reconstruction system and method, the composite fracturing stimulation system includes liquid CO 2 Injection unit, conventional fracturing fluid injection unit, underground blast fracturing unit and surface control unit; said liquid CO 2 The injection unit and the conventional fracturing fluid injection unit are connected to the underground blasting and fracturing unit through the fracturing string; the ground control unit is connected to the underground blasting and fracturing unit through cables; method of cracking. The composite fracturing reconstruction system provided by the present invention passes through multi-stage CO 2 Phase change and one-pass string achieve CO 2 Pre-amplification, make full use of CO 2 The safety of phase change blasting can effectively reduce the fracture pressure of rocks in low-permeability or deep tight oil and gas reservoirs; the driving pressure of underground crude oil can be increased by 2-5 MPa, and the flowback rate of fracturing fluid can reach more than 80% after 4 hours of fracturing. It can be extended for 6 to 18 months.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com