Automatic regulating device for water injection flow

An automatic adjustment and flow rate technology, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problems of inaccurate oil injection volume, increased driving pressure, low crude oil temperature, etc., and reduce manual adjustment Not in time, improve the transmission efficiency, the effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

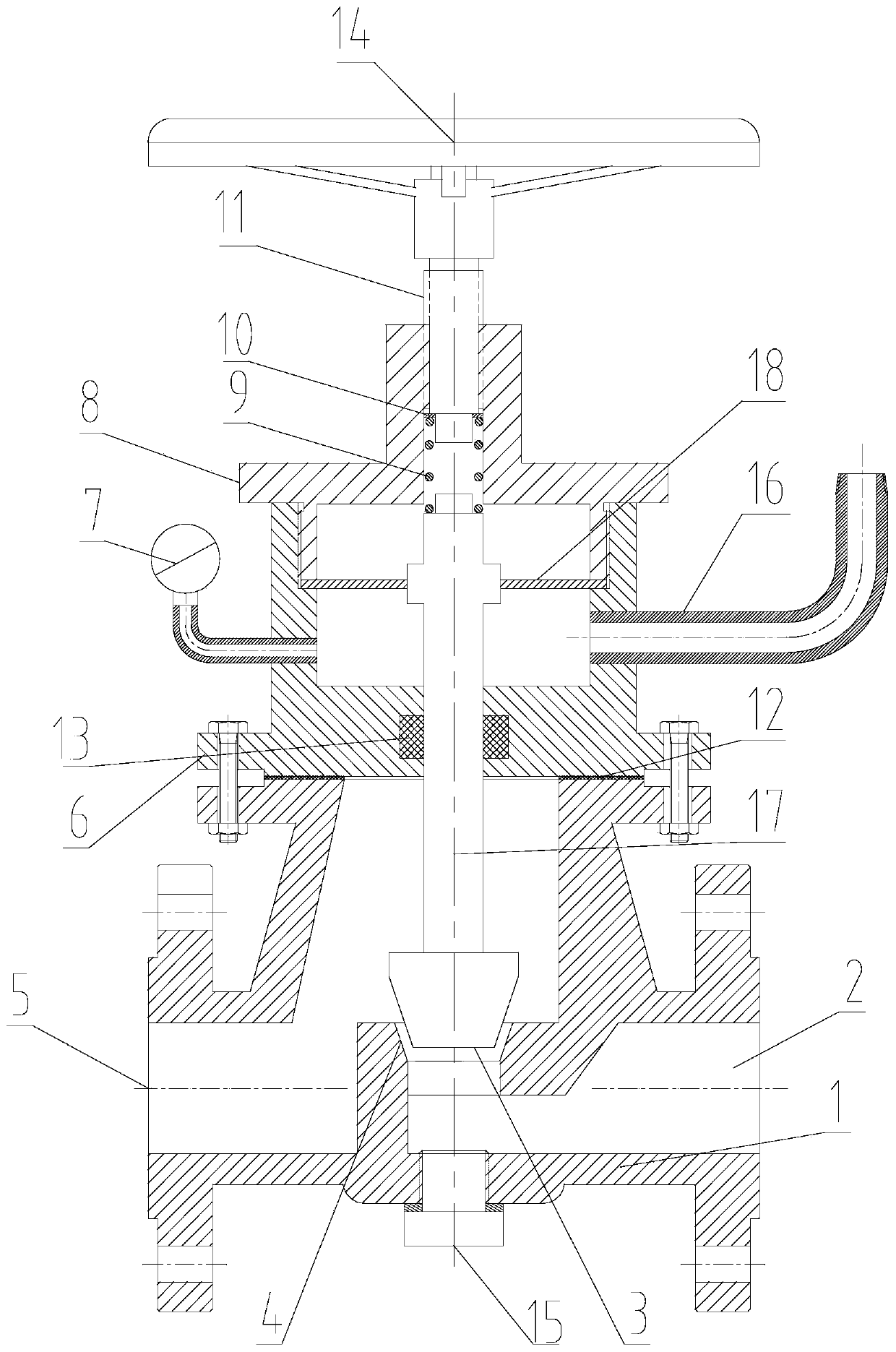

[0014] The present invention will be further explained below in conjunction with the drawings:

[0015] by figure 1 As shown, an automatic adjustment device for water injection flow includes a lower valve body 1. The lower valve body 1 is divided into an inlet cavity 5 and an outlet cavity 2. A tapered hole 4 is connected between the inlet cavity 5 and the outlet cavity 2. The tapered hole 4 is a structure with a large upper hole and a small lower hole. The conical surface between the tapered hole 4 and the valve core 3 is matched and the conical surface between the tapered hole 4 and the valve core 3 is matched. When the valve core 3 is pressed against the tapered hole The conical surface of 4 produces a sealing effect. Under a certain pressure, the size of the gap between the conical annular surface of the valve core 3 and the conical annular surface of the tapered hole 4 determines the liquid flow through the annular space;

[0016] The upper flange of the lower valve body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com