Patents

Literature

389 results about "Viscosity coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The coefficient of viscosity (η) is the ratio of applied stress to the rate of straining (change of strain with time). It is measured in units of poise; one poise equals one dyne-second per square centimetre.

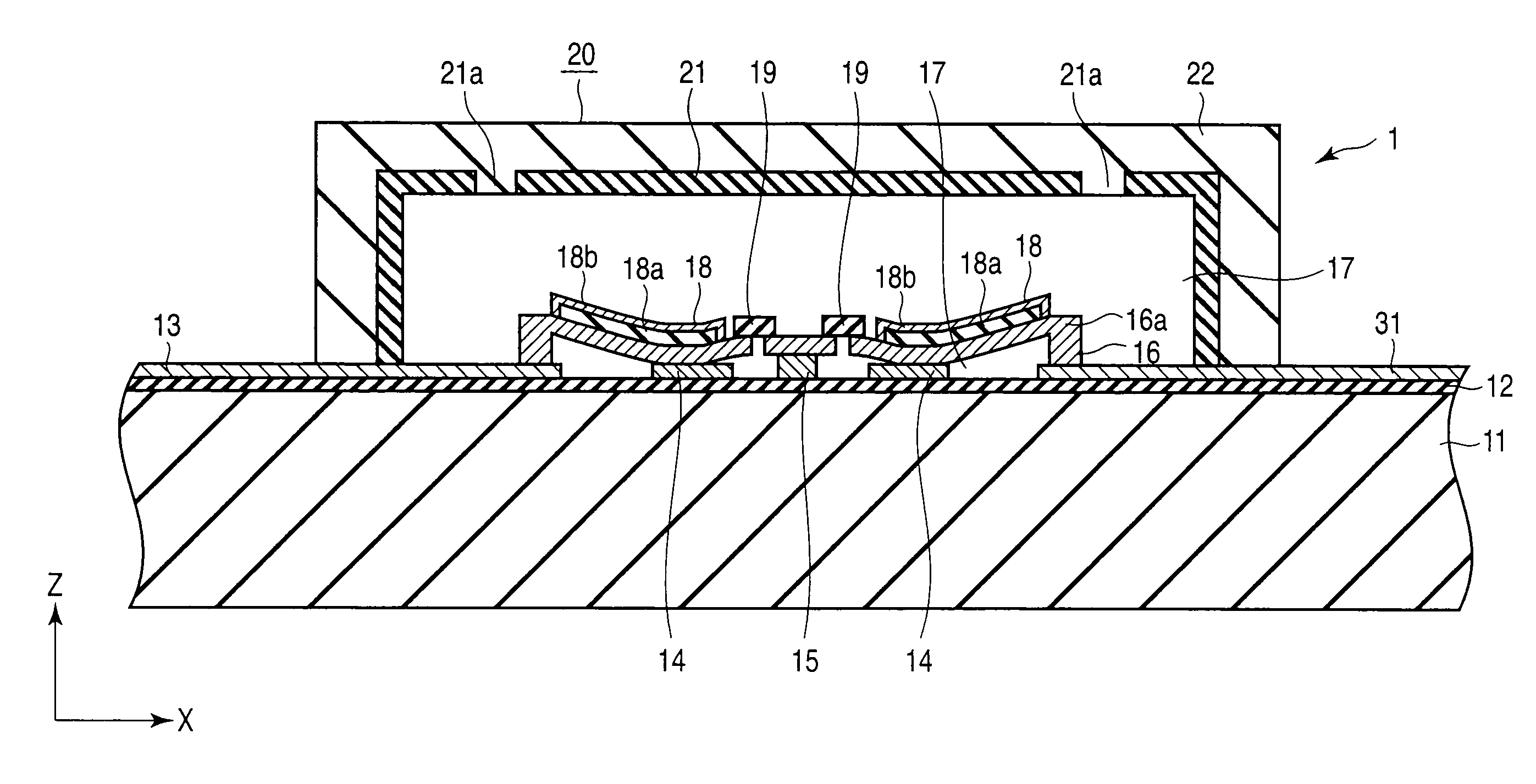

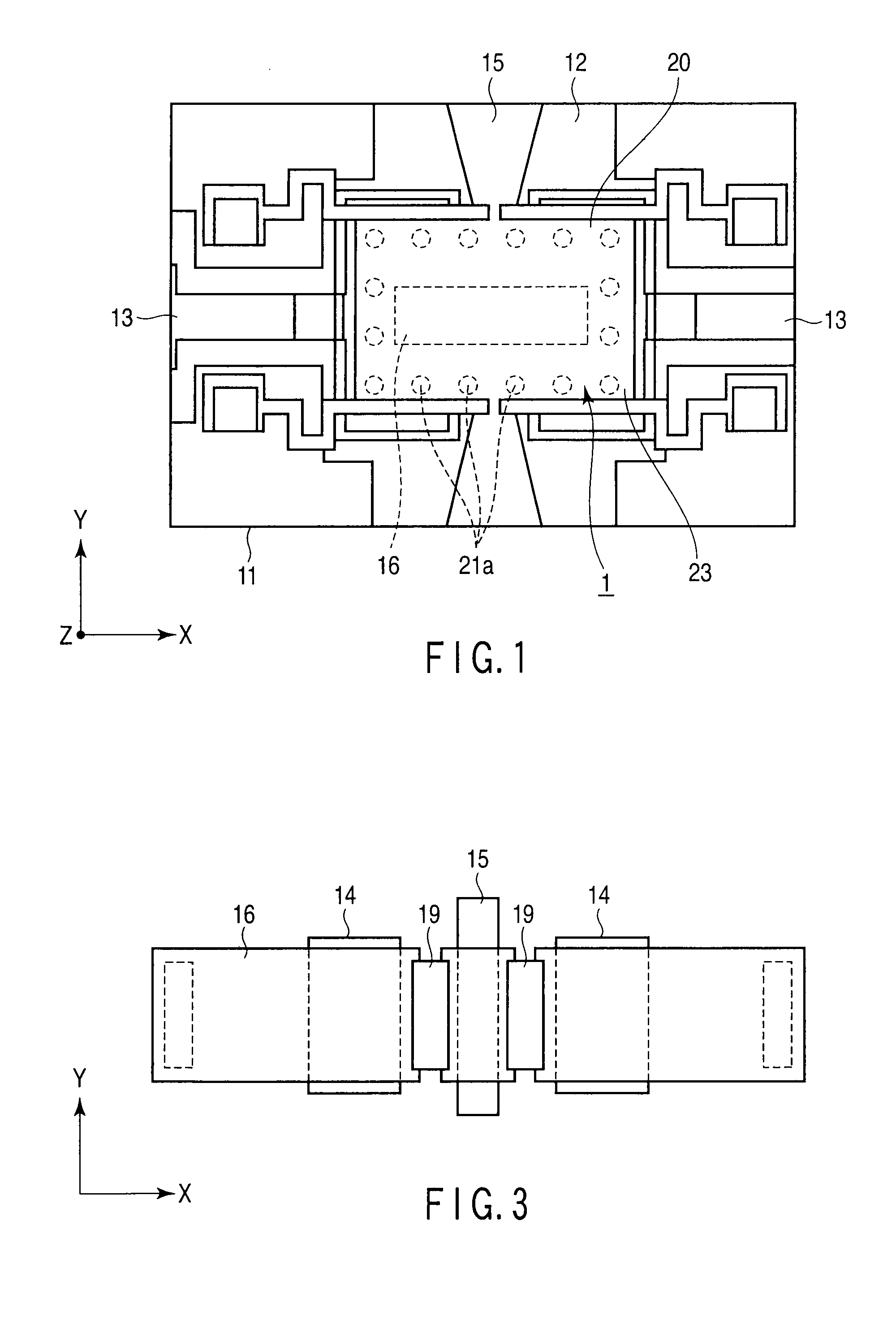

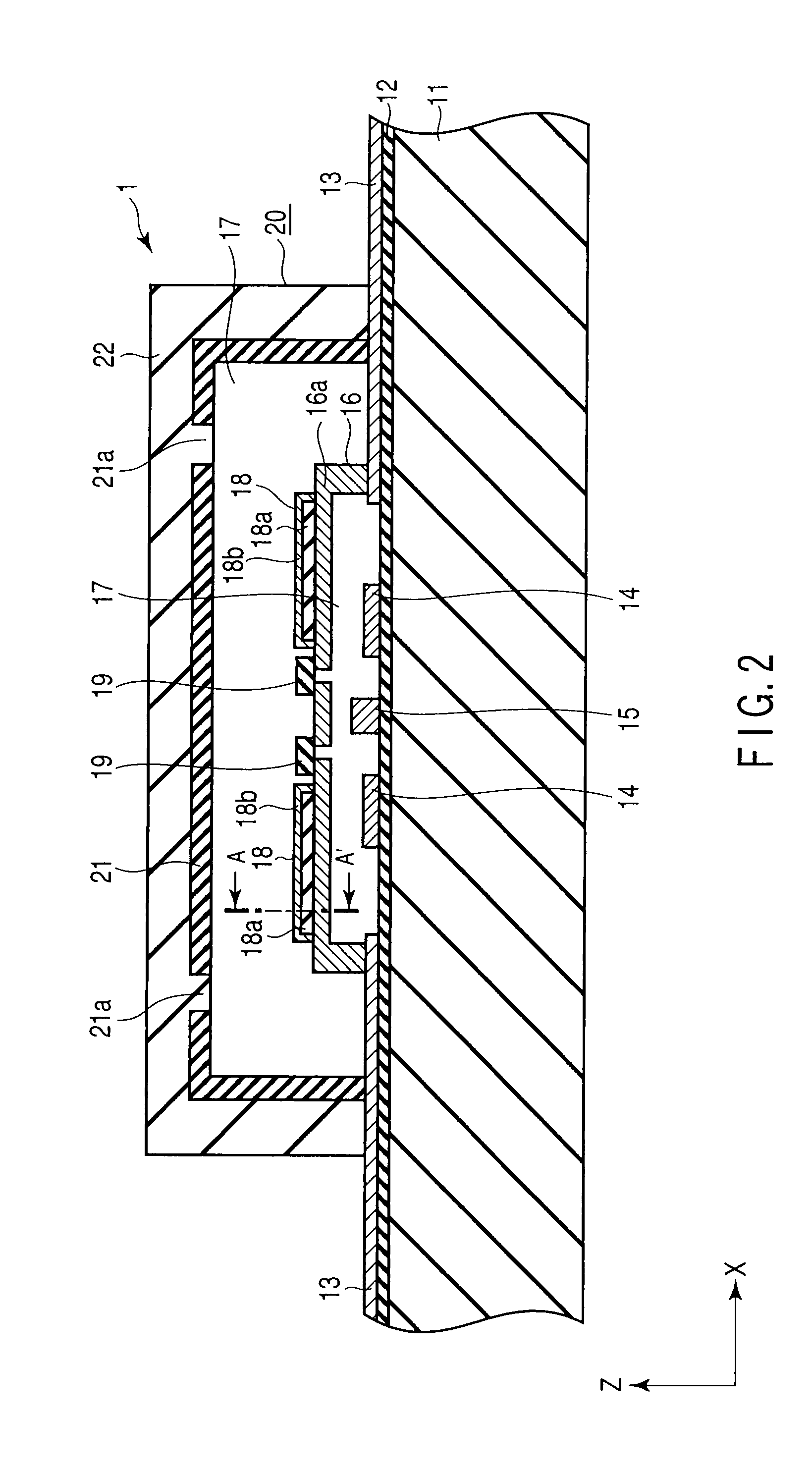

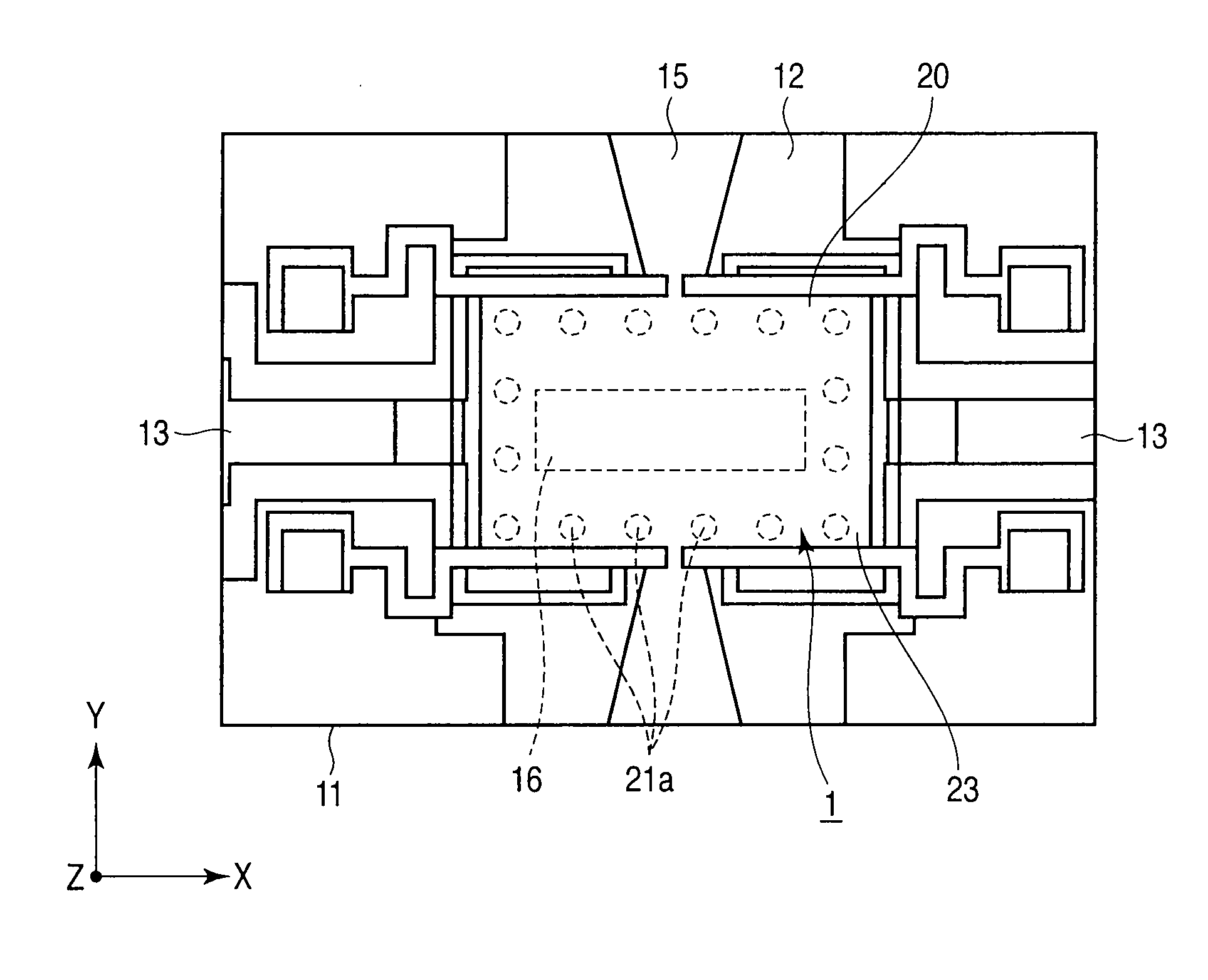

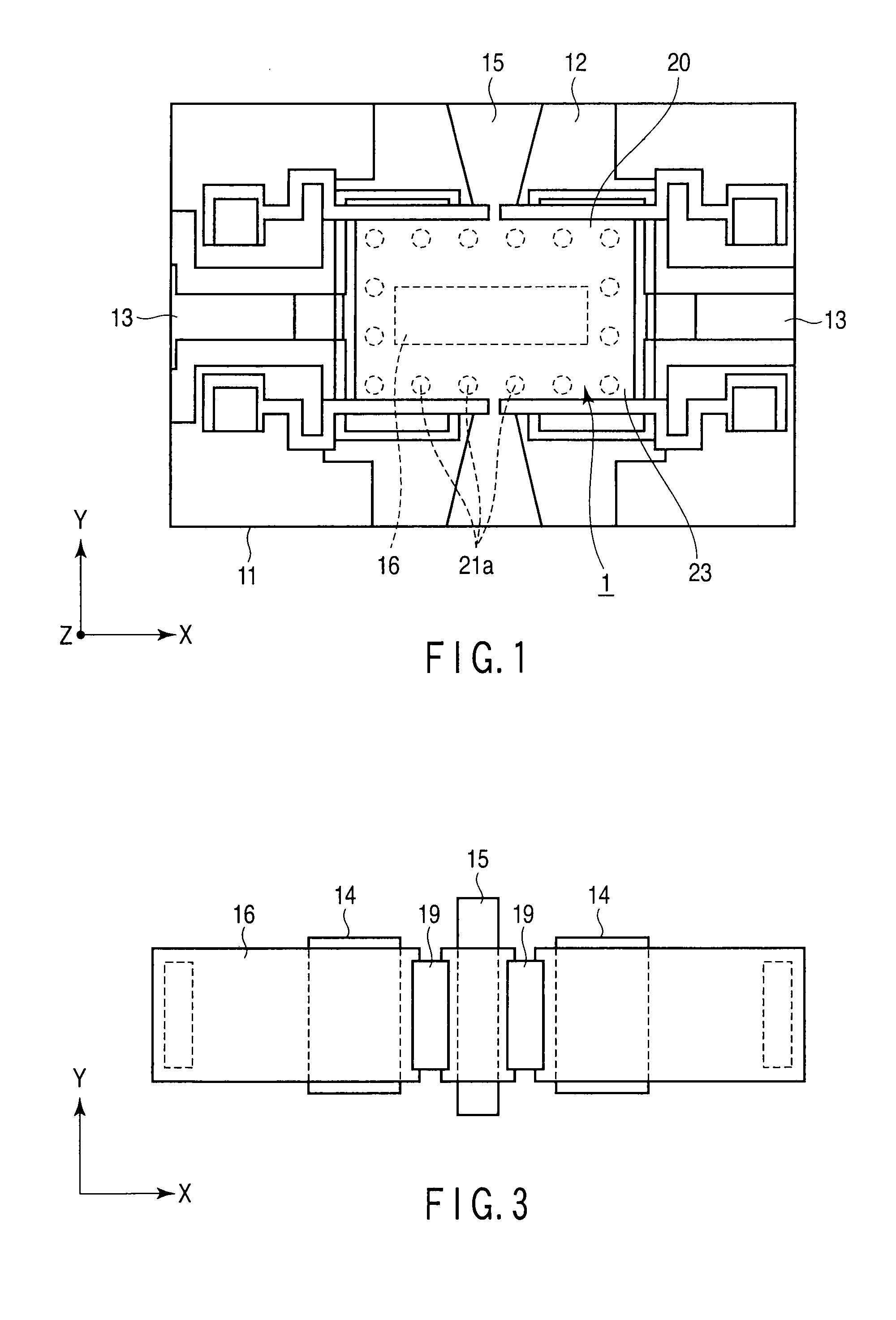

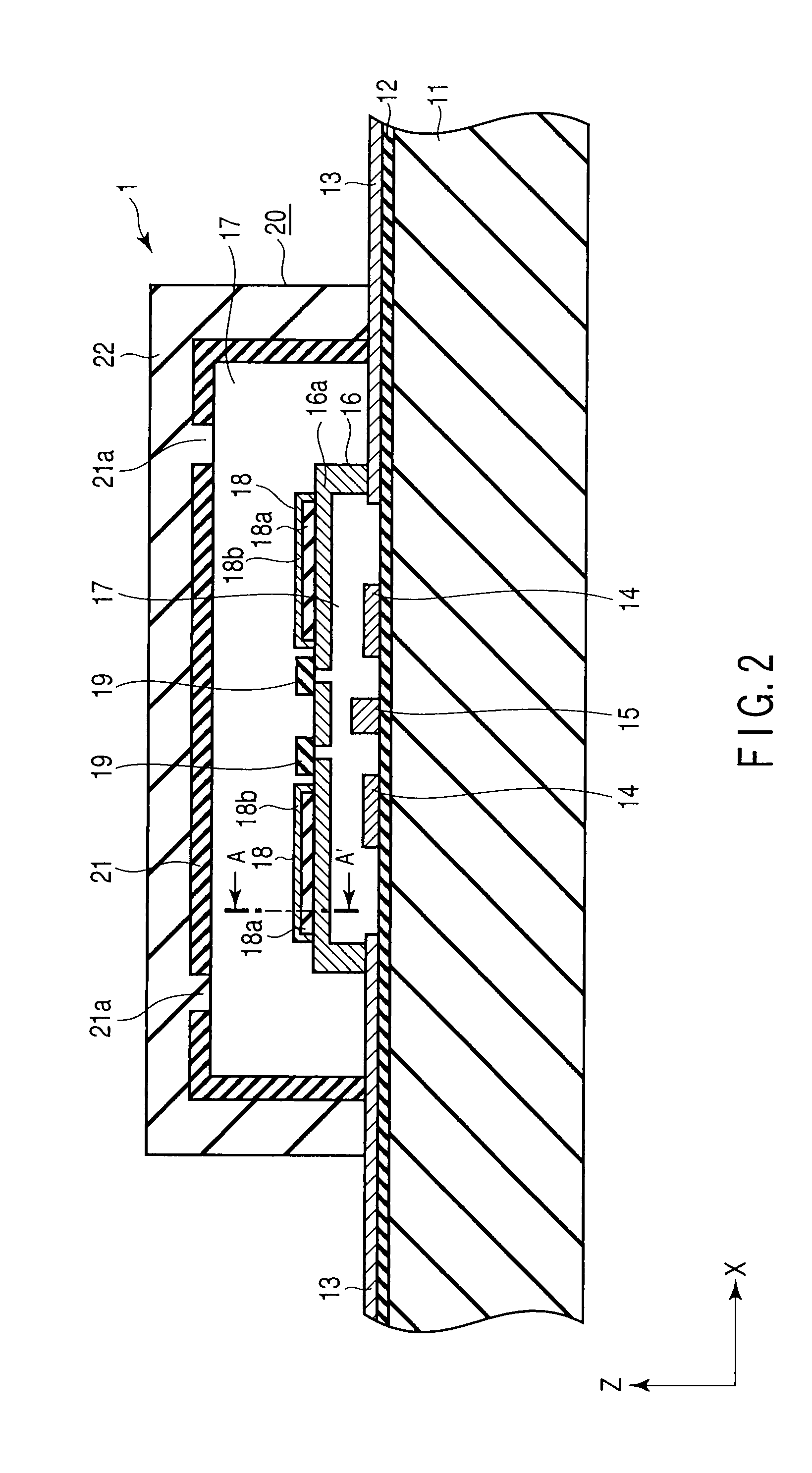

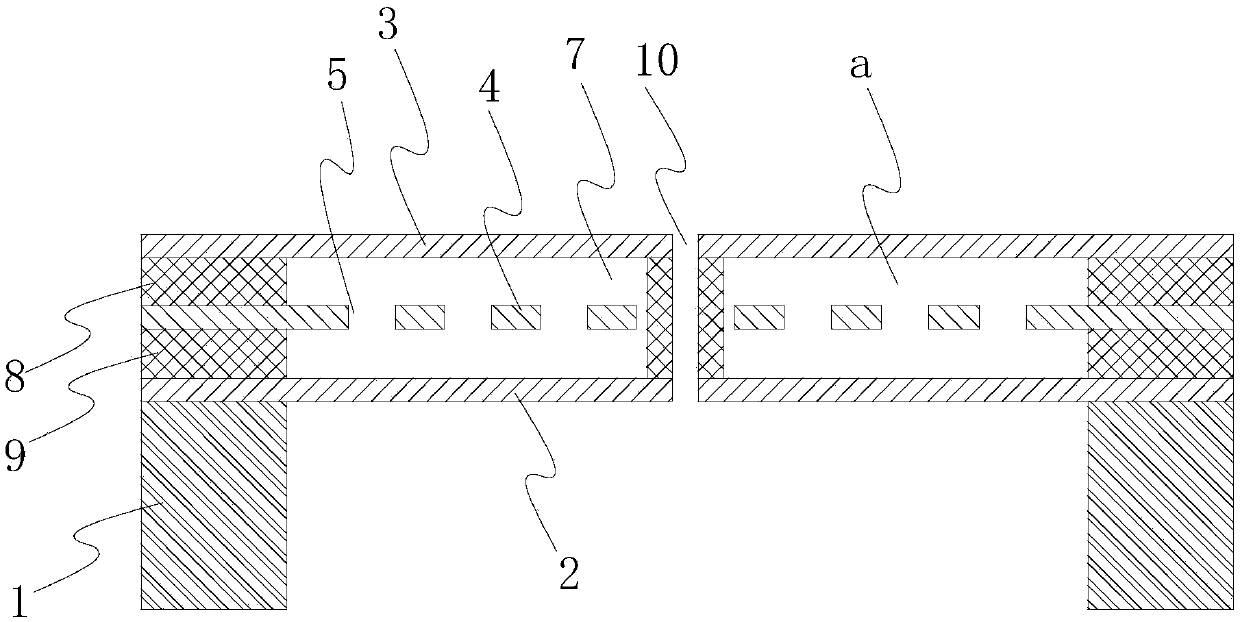

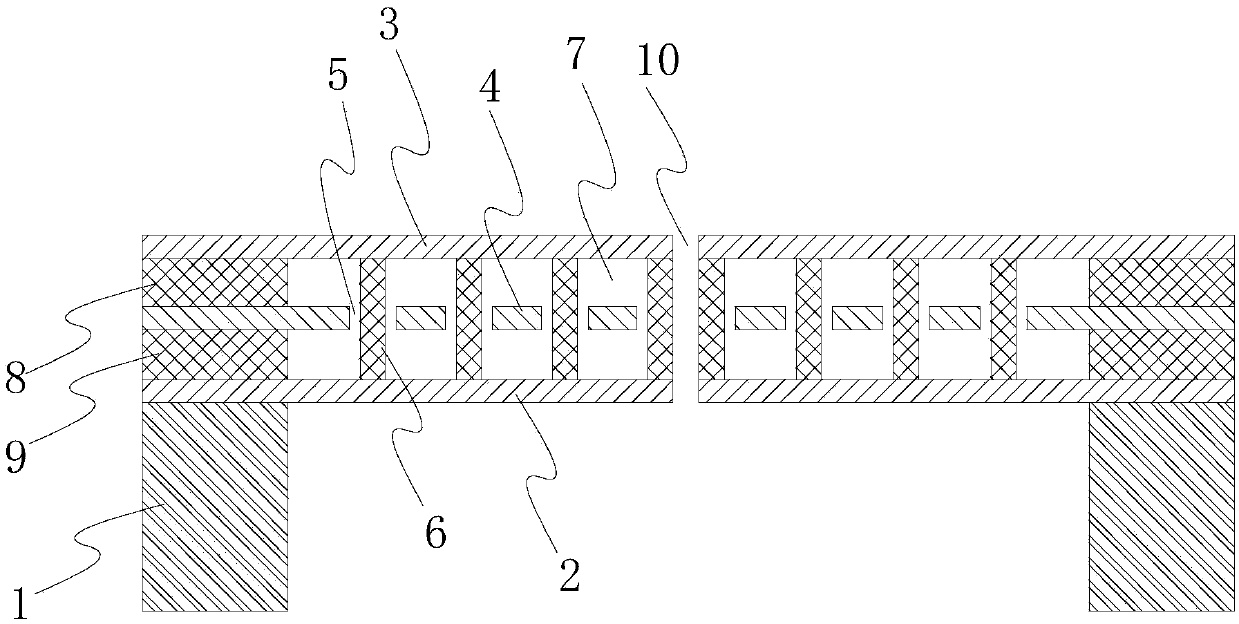

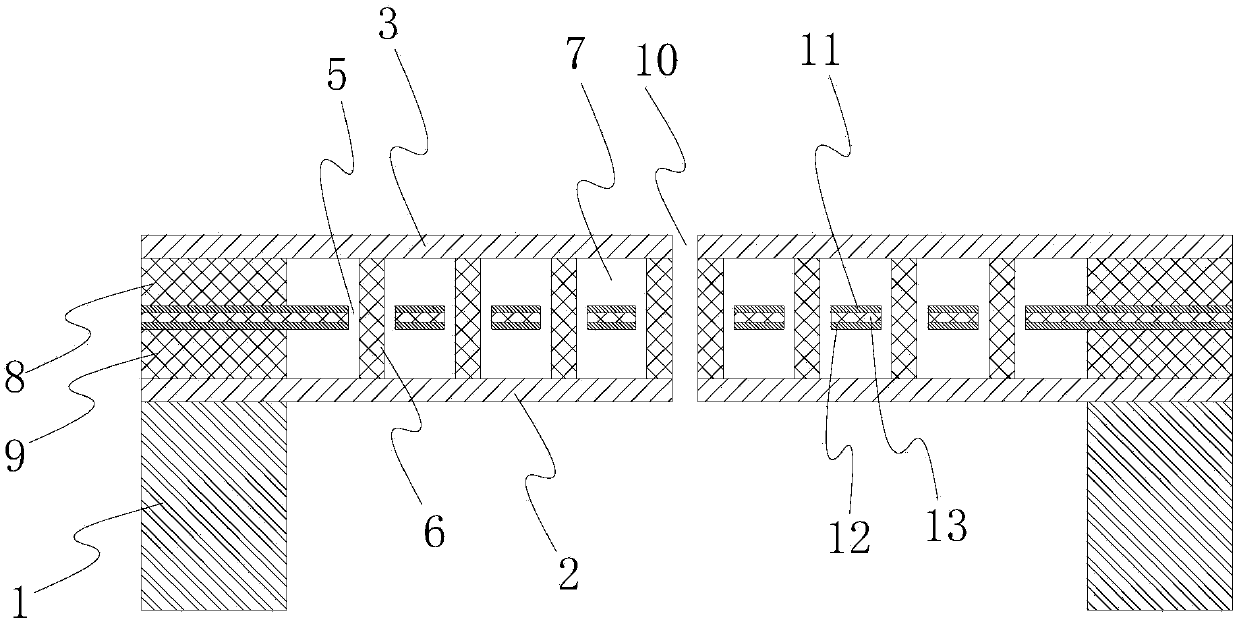

Micromechanical device and method of manufacturing micromechanical device

InactiveUS7972884B2Wave amplification devicesElectrostatic/electro-adhesion relaysEngineeringConductive materials

An example of the present invention is a micromechanical device including, a substrate in which a signal line is provided, a micromachine which is mounted on the substrate, is formed of a conductive material into a beam-like shape, is elastically deformed by a function of an electric field in such a manner that the beam-like part moves closer to or apart from the signal line, and changes the electric characteristics concomitantly with the deformation, a deformation restraint section constituted of a material having a higher viscosity coefficient than the conductive material, provided on the opposite side of the micromachine to the signal line, for restraining deformation of the micromachine in a direction in which the micromachine is separated from the signal line, and a sealing body provided on the principal surface of the substrate, for covering the micromachine with a hollow section located therebetween.

Owner:KK TOSHIBA

Micromechanical device and method of manufacturing micromechanical device

ActiveUS20090236114A1High viscosity coefficientWave amplification devicesElectrostatic/electro-adhesion relaysEngineeringConductive materials

An example of the present invention is a micromechanical device including, a substrate in which a signal line is provided, a micromachine which is mounted on the substrate, is formed of a conductive material into a beam-like shape, is elastically deformed by a function of an electric field in such a manner that the beam-like part moves closer to or apart from the signal line, and changes the electric characteristics concomitantly with the deformation, a deformation restraint section constituted of a material having a higher viscosity coefficient than the conductive material, provided on the opposite side of the micromachine to the signal line, for restraining deformation of the micromachine in a direction in which the micromachine is separated from the signal line, and a sealing body provided on the principal surface of the substrate, for covering the micromachine with a hollow section located therebetween.

Owner:KK TOSHIBA

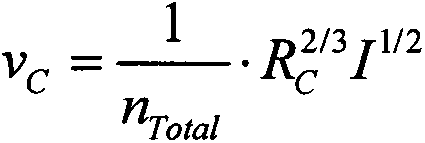

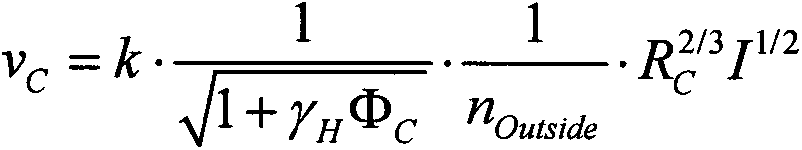

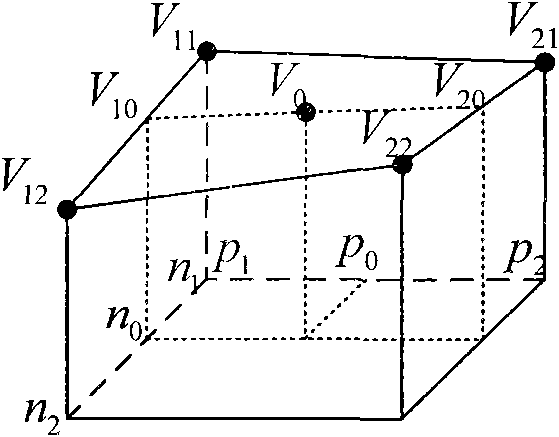

Calculation method for debris flow section mean flow rate and application

ActiveCN104794362AAccurate average velocityFluid speed measurementSpecial data processing applicationsDebris flowCalculation methods

The invention discloses a calculation method for the debris flow section mean flow rate and the application. The calculation method comprises the steps that parameters such as the debris flow fluid volume weight, the debris flow solid material volume weight, the debris flow channel or drainage groove gradient, the debris flow section hydraulic radius, the debris flow channel or drainage groove external roughness and the debris flow viscosity coefficient are determined by the means such as field investigation and measurement, actual sampling and actual volume weight measurement and indoor rheological experiments, the obtained parameters are substituted into a calculation formula for the debris flow section mean flow rate, and therefore the accurate debris flow section mean flow rate can be obtained. According to the method, the external roughness variations caused by the debris flow channel or drainage groove shape variations and the internal roughness generated by the debris flow fluid property are comprehensively taken into account, the debris flow section mean flow rate can be reasonably determined, a basis is provided for the debris flow exploration and the prevention engineering design, and the method is suitable for the requirements of the outdoor debris flow exploration and the actual engineering design.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

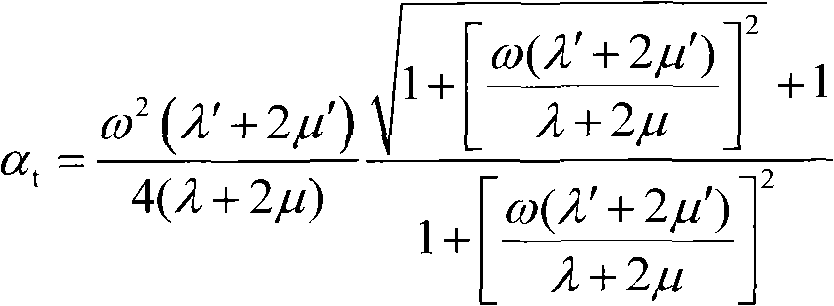

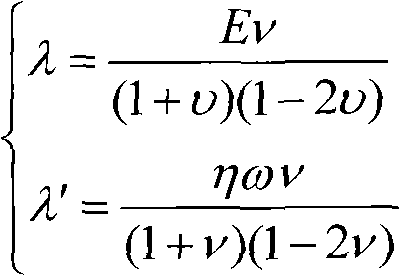

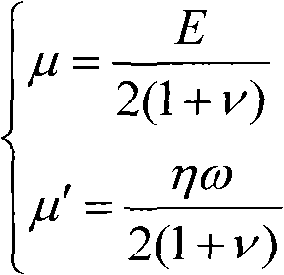

Method for testing rock mass mechanics parameters based on explosion seismic wave space-time attenuation law

ActiveCN102141545AGuaranteed reliabilitySave human effortAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSlope stability analysisSpacetime

The invention relates to a technology for testing rock mass mechanics parameters, in particular to a method for testing rock mass mechanics parameters based on an explosion seismic wave space-time attenuation law. The method comprises the steps of data testing and test data processing; and geometric parameters and mechanics parameters of rock mass can be obtained by corresponding testing and calculating. The parameters mainly comprise the viscosity coefficient of the rock mass, the equivalent elastic modulus of the rock mass, an azimuth angle of a structural plane, the rigidity of the structural plane, the thickness of the structural plane, and the elastic modulus of the structure plane; and the relevant parameters of the rock mass are given for analysis of slope stability.

Owner:FUJIAN MAKENG MINING CO LTD

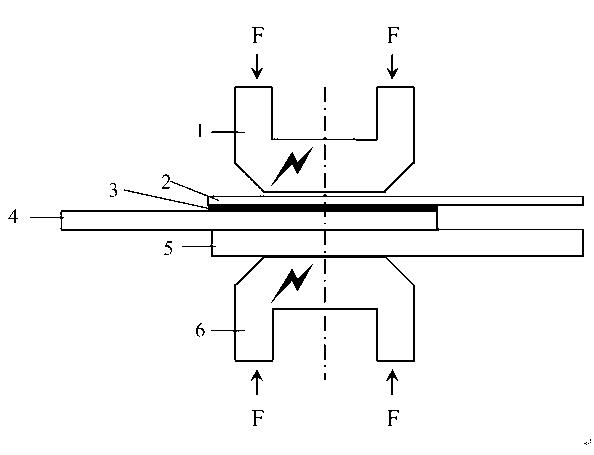

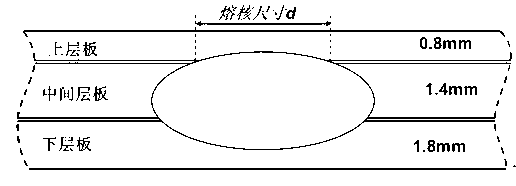

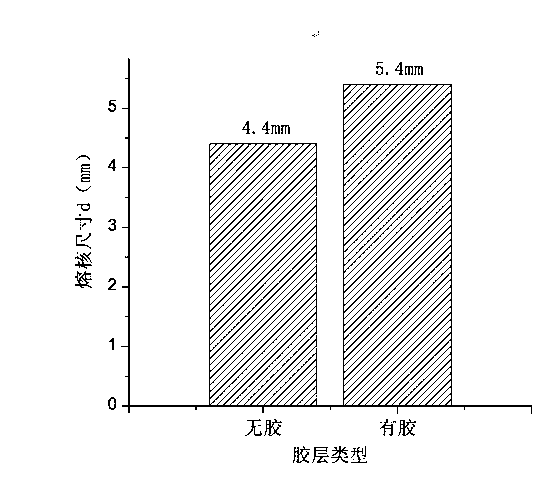

Method for increasing size of resistance spot weld nugget on thin-plate side of multilayer plates in different thickness

The invention relates to a method for increasing size of a resistance spot weld nugget on a thin-plate side of multilayer plates in different thickness. When the resistance spot welding connection for the multilayer plates in different thickness is performed, an epoxy resin structural glue is applied between upper or lower-layer to-be-welded metal plate and a middle-layer to-be-welded metal plate, wherein the epoxy resin structural glue is a single-component thermo-curing epoxy resin glue and has a density of 1.03-1.20g / mm3, a viscosity coefficient @50 DEG C (Pa.s) of 20-50 and a thickness of 0.2-1.2mm. According to the method provided by the invention, a glue-layer membrane resistor is formed after the structural glue is applied, so that a contact resistance between metal plates is increased and the generation and growth of a spot weld nugget are boosted, and meanwhile, the influence of the structural glue on a path of outward radiating through air on the surface of a steel plate is reduced and the heat required by the generation of the spot weld nugget is increased, so that the size of the resistance spot weld nugget on the thin-plate side is increased and the strength requirement for a spot-welded joint on the thin-plate side of the multilayer plates in different thickness is ensured.

Owner:SHANGHAI JIAO TONG UNIV +1

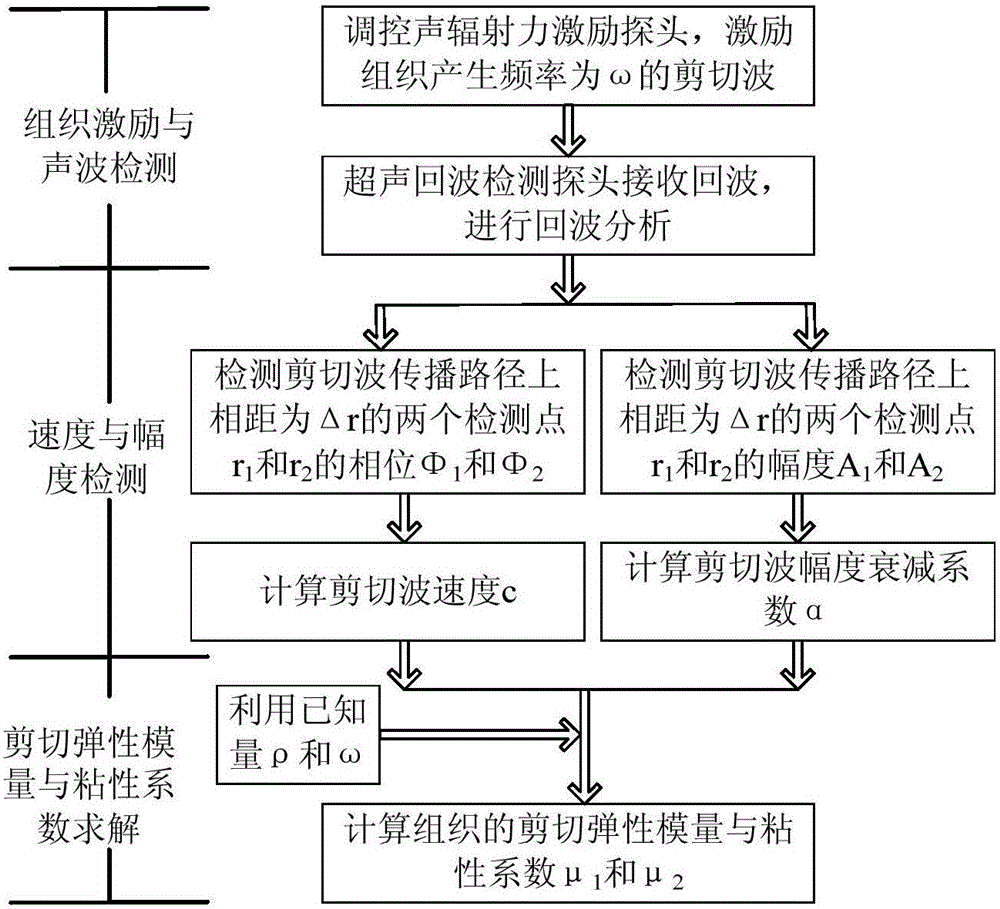

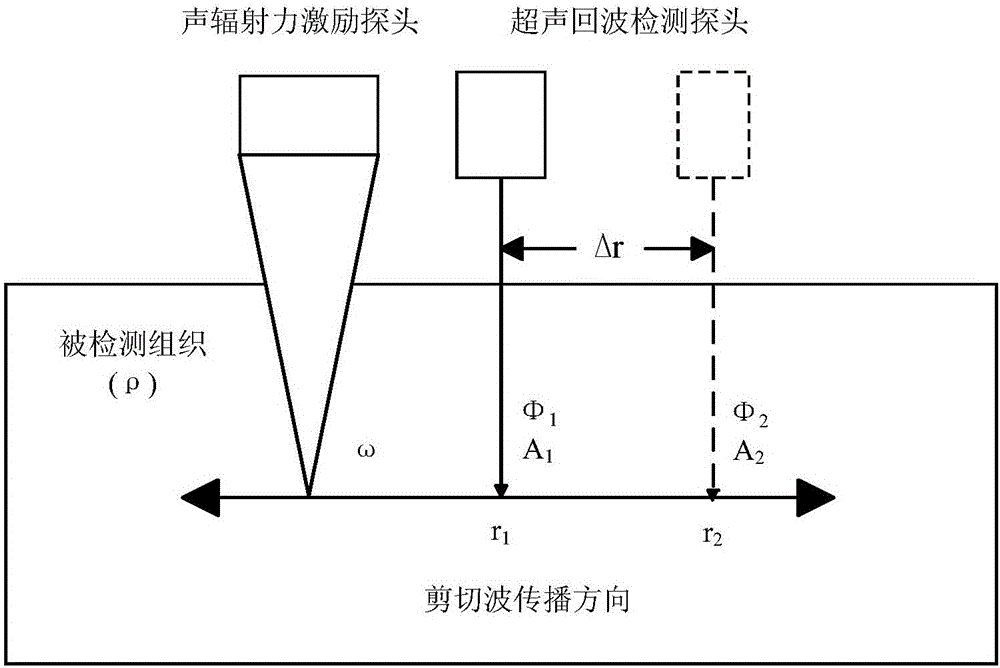

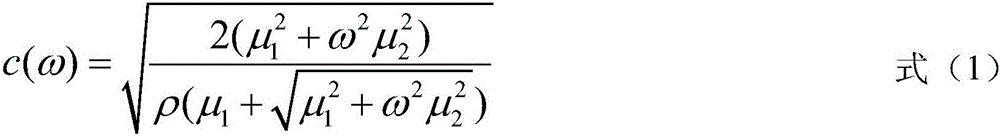

Tissue viscoelasticity measuring method based on shear wave amplitude and phase detection

ActiveCN106175831AGood for expanding the scopeGood for leveling upOrgan movement/changes detectionInfrasonic diagnosticsDiseaseViscoelasticity

The invention provides a tissue viscoelasticity measuring method based on shear wave amplitude and phase detection. An acoustic radiation force excitation probe and an ultrasonic echo detection probe are used for detection at the same time, the acoustic radiation force excitation probe generates push wave beams, tissue generates shear waves at certain frequency, the ultrasonic echo detection probe generates detection wave beams to detect amplitude attenuation and phase change of the shear waves on a propagation path, the elasticity modulus and viscosity coefficient of the tissue are estimated through an amplitude attenuation coefficient and a speed detection value, in other words, the elasticity modulus and viscosity coefficient of the tissue can be quantitatively detected at the same time, precise and rich mechanical parameter information is provided for diagnosis of multiple diseases, the clinical application range of ultrasonic elastography can be widened, and the level of ultrasonic elastography can be improved. The method can carry out detection through the shear waves at one frequency, the system complexity and design cost are reduced, detection efficiency is improved, phase detection noise caused by high-frequency shear waves is avoided, and the accuracy of mechanical tissue parameter detection is improved.

Owner:CHONGQING UNIV OF TECH

Self-seepage concrete crack repairing glue and method for making same

InactiveCN101230244ALow viscosityShort curing timeBarrages/weirsNon-macromolecular adhesive additivesEpoxySilanes

The invention discloses a self-permeating concrete crack repairing glue and the preparing method thereof, which is characterized in that after mixing and stirring evenly 10-15 percent vinyl polyurethane with 10-60 percent vinyl monomer, 10-60 percent unsaturated epoxy resin, 0.1-10 percent accelerant, and 0.01-1 percent polymerization inhibitor according to the weight proportions each constituent accounting for, the main constituent A is obtained when the above mixture is discharged; after mixing and stirring evenly 60-90 percent plasticizing agent with 1-35 percent silane resin acceptor and 1-5 percent evocating agent, and then the accessory constituent B is obtained after the above mixture is discharged. Before in use, main constituent A and accessory constituent B are required to be packed separately, and during in use, the main constituent A and accessory constituent B are required to be mixed together by mixing proportion according to requirements. The invention integrates the advantages of the polyurethane, the epoxy resin, and the acrylic ester into a whole; has the advantages of low viscosity coefficient, self-permeability, quick firming, high strength, high durability and simple operation; can be used for repairing the cracks of the road, the dam or the airdrome.

Owner:ANHUI UNIVERSITY

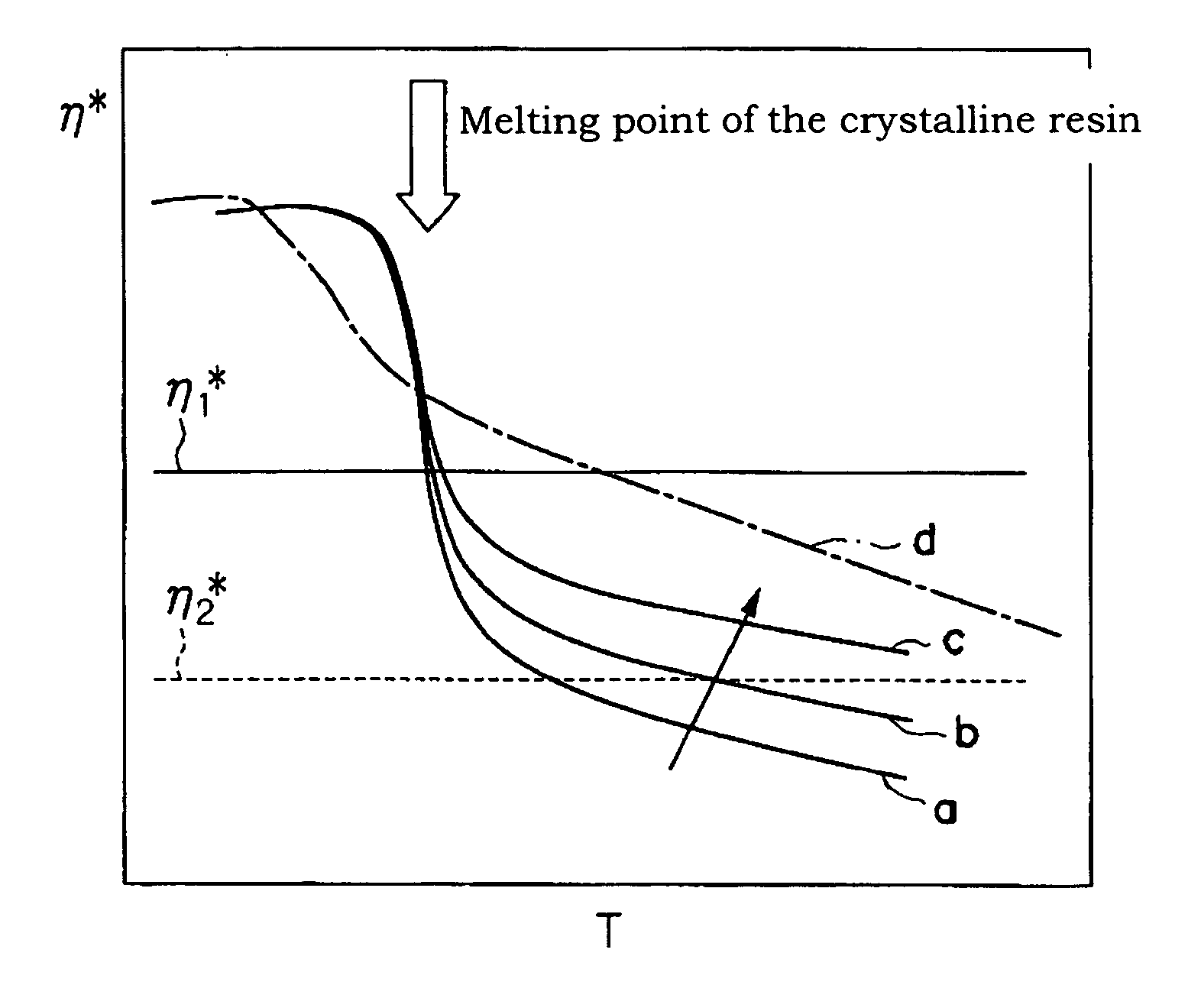

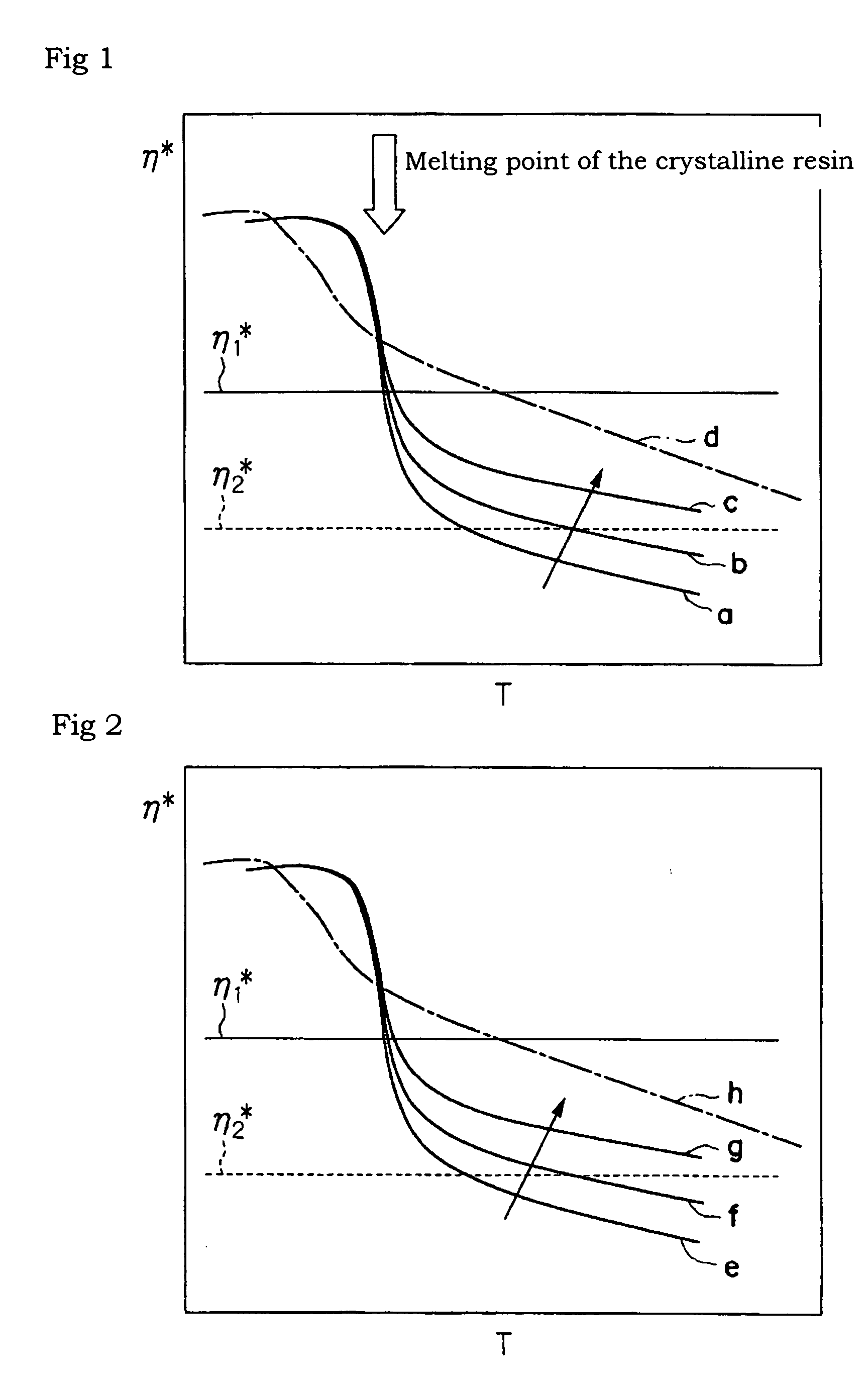

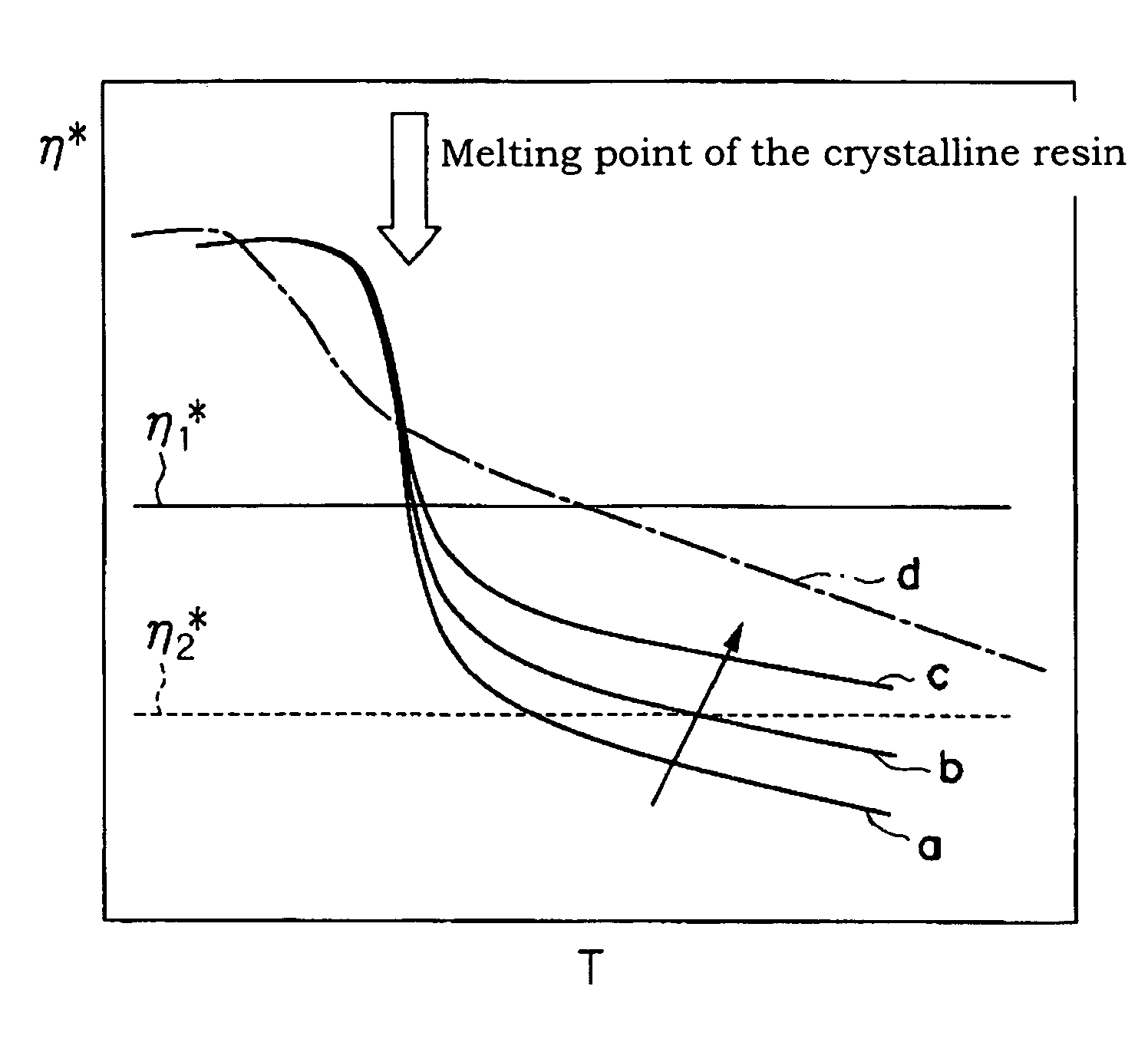

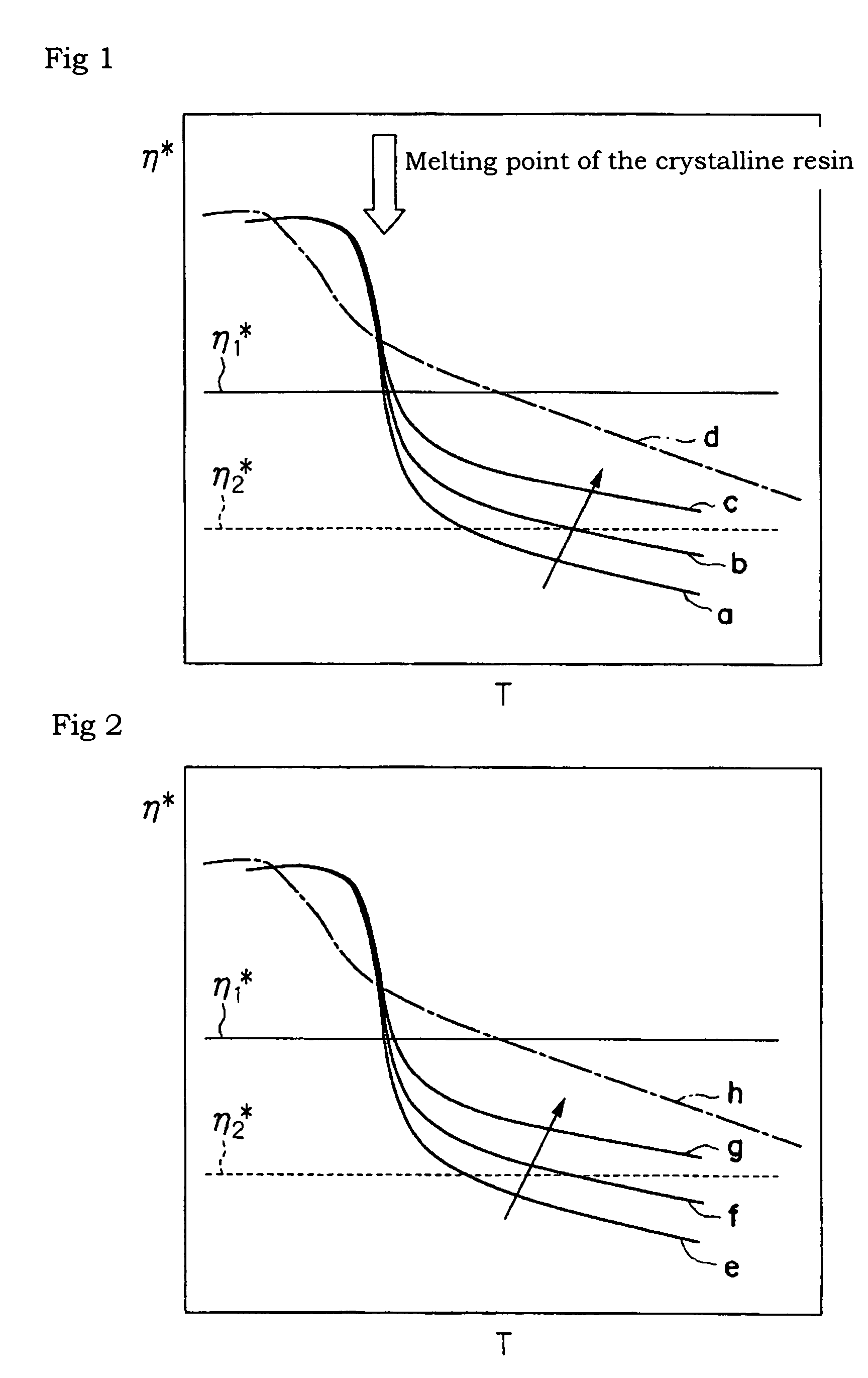

Electrophotographic toner, method for producing the same, electrophotographic developer, and image forming method

An electrophotographic toner having a core-shell structure including a crystalline resin in its core region or a sea-island structure including a crystalline resin in its island region, wherein the toner has 1) a resistance of 5.0×1012 Ω·cm or higher, 2) a dynamic viscosity coefficient of 3×103 Pa·s or higher at a temperature which is 50° C. higher than a melting point of the crystalline resin, and 3) a dynamic viscosity coefficient of 1×105 Pa·s or lower at a temperature which is 10° C. higher than the melting point of the crystalline resin.

Owner:FUJIFILM BUSINESS INNOVATION CORP

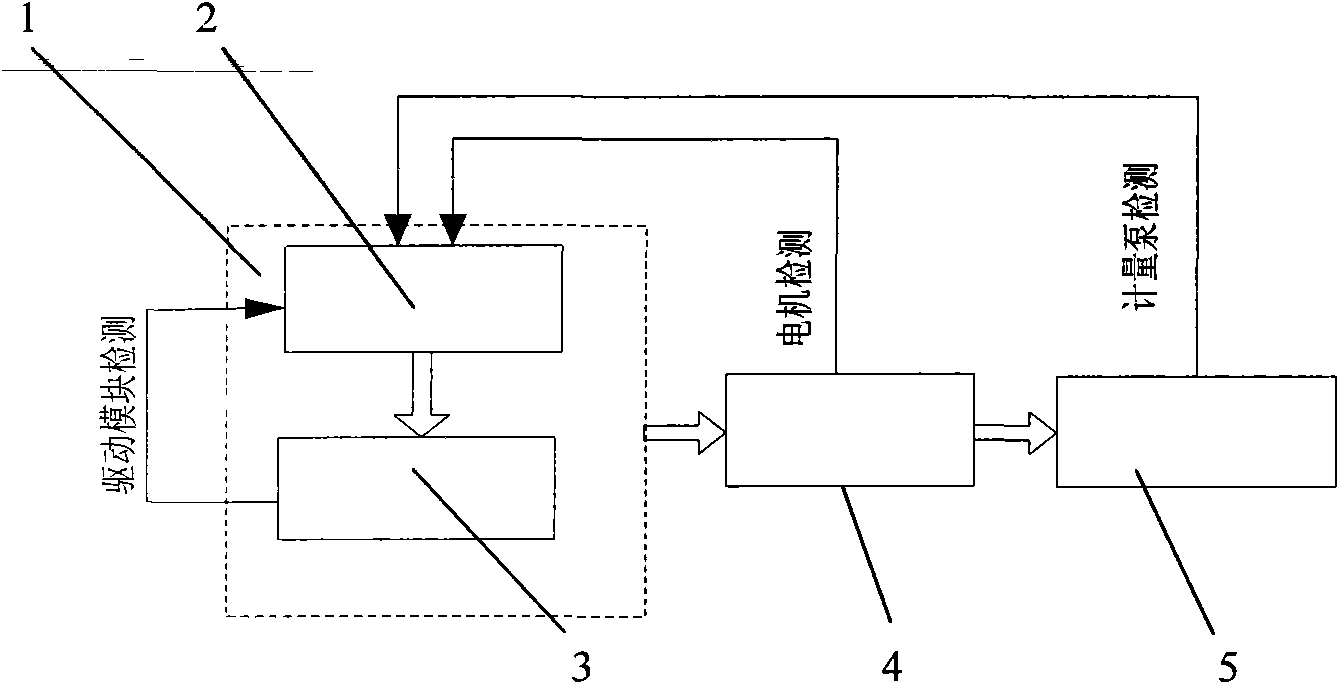

Flow compensation technology of digital frequency conversion metering pump

InactiveCN102032167AImprove output accuracyPrecise proportional dosingPump testingPositive-displacement liquid enginesFluid viscosityFrequency conversion

The invention belongs to the technical field of metering pumps, and particularly relates to the flow compensation technology of a digital frequency conversion metering pump. The flow compensation technology is characterized by comprising a method for determining and compensating for the error of manufacturing accuracy, a method for determining and compensating for rotate speed and outlet pressure, a method for determining and compensating for fluid viscosity coefficients and a method for determining and compensating for working hours. In the technology, error values of theoretical displacement caused by four factors of the manufacturing accuracy, the rotate speed and outlet pressure, the fluid viscosity coefficients and the working hours are calculated, and the theoretical displacement is compensated for according to the error values to obtain accurate actual displacement finally, so that the flow is calculated accurately by using the actual displacement in actual flow control; and in the technology, the manufacturing accuracy, the rotate speed and outlet pressure, the fluid viscosity coefficients and the working hours which influence the output displacement of the metering pump can be compensated, so the output accuracy of the metering pump is improved effectively, and the accurate constant-ratio addition of fluid is realized.

Owner:ZHEJIANG UNIV OF TECH

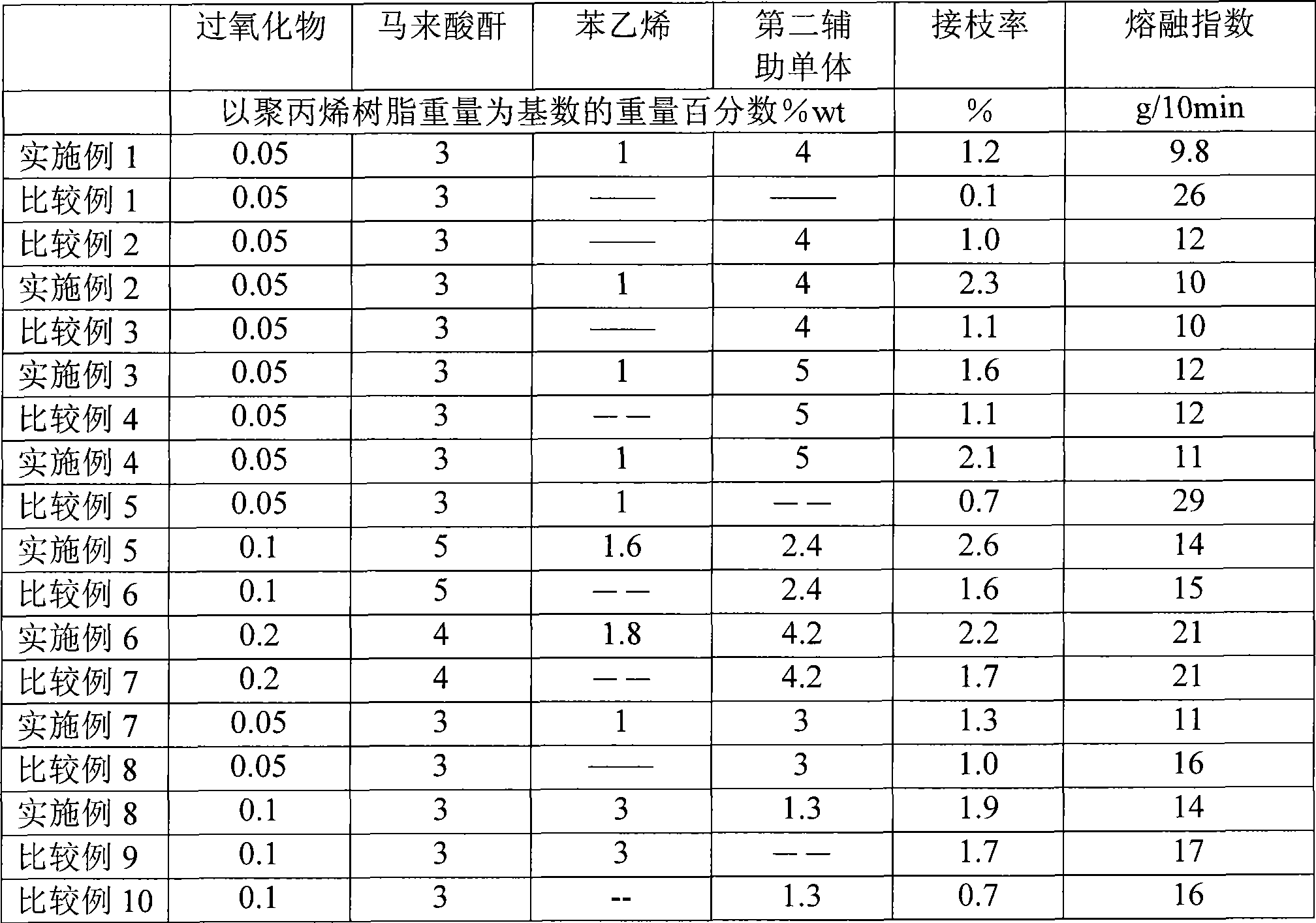

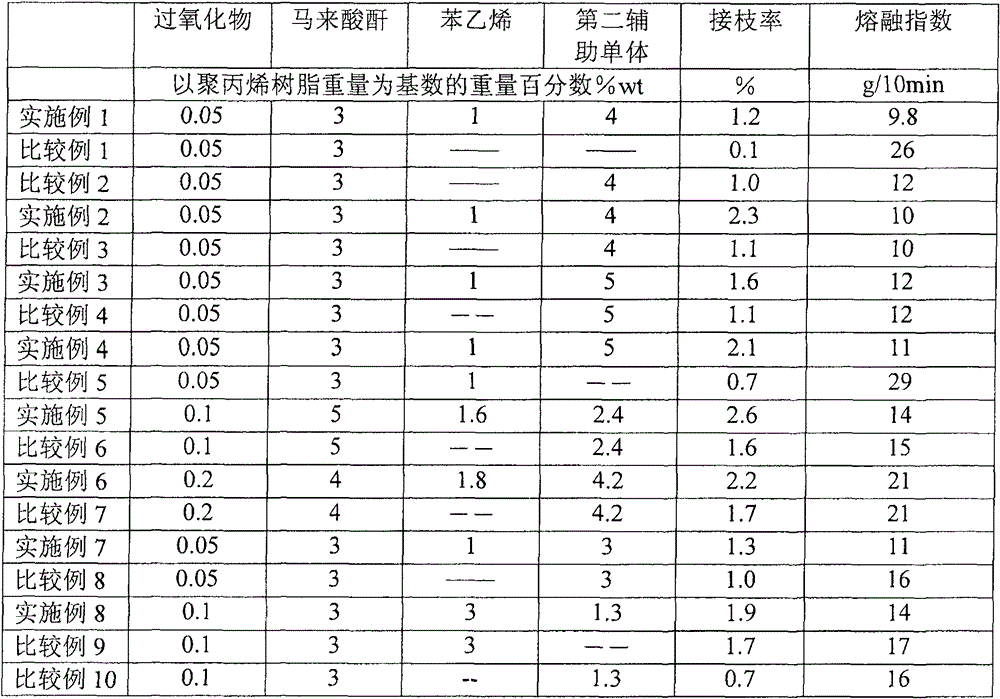

Method for grafting maleic anhydride onto polypropylene resin

The invention provides a method for preparing grafted polypropylene resin, relating to the technology of melt-grafting maleic anhydride onto polypropylene resin. In the method, a melt free radical grafting reaction is adopted to graft a maleic anhydride monomer onto a molecular chain of the polypropylene resin. Polypropylene resin adopts powder without an antioxidizer, wherein an auxiliary monomer is introduced in a melt grafting reaction triggered by a peroxide initiator besides the addition of the maleic anhydride monomer. The auxiliary monomer consists of a first auxiliary monomer and a second auxiliary monomer. The first auxiliary monomer is a styrene monomer and the second auxiliary monomer is an organic matter monomer with molecules including two or more carbon-carbon double bonds. The consumption of the auxiliary monomer accounts for 1%wt to 10%wt of the weight of the polypropylene resin and the proportion of the first auxiliary monomer and the second auxiliary monomer in the auxiliary monomer ranges from 5:95 to 70:30; the consumption of the maleic anhydride accounts for 1%wt to 8%wt of the weight of polypropylene. The method for grafting maleic anhydride onto polypropylene resin can obtain the grafted polypropylene resin with relatively high grafting ratio, molecular weight and viscosity coefficient.

Owner:CHINA PETROLEUM & CHEM CORP +1

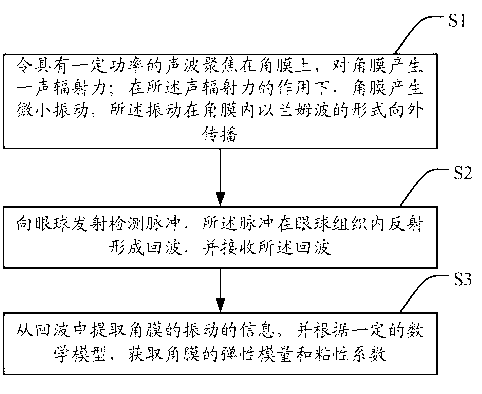

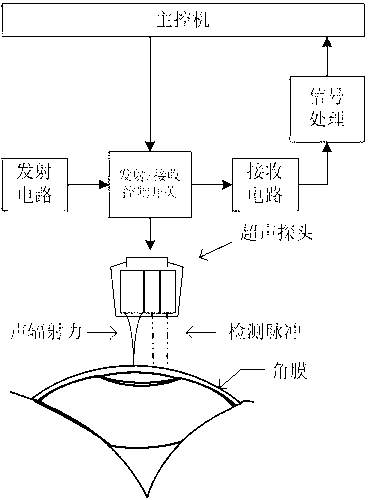

Method and system for ultrasonic detection of cornea viscoelasticity

InactiveCN103006274AComprehensive description of mechanical propertiesSimple structureEye diagnosticsEye inspectionMathematical modelViscoelasticity

The invention discloses a method and system for ultrasonic detection of cornea viscoelasticity. The method comprises the following steps of firstly, focusing sound waves with certain power onto a cornea to generate a sound radiant force on the cornea; under the action of the sound radiant force, the cornea generating slight vibration, and the vibration propagating outwards in the cornea in a Lamb wave way; then, transmitting a detection pulse to an eyeball, the pulse reflecting in the tissues of the eyeball to form echo, and receiving the echo; and finally, extracting the vibration information of the cornea from the echo, and according to a certain mathematical model, obtaining an elastic module and a viscosity coefficient of the cornea. The elastic module and the viscosity coefficient can be simultaneously and quantitatively measured, and mechanical properties of the cornea are fully described. Meanwhile, the system has the advantages that the structure is simple, easy implementation is realized, the cost is low, and the like. The system can be used as independent equipment, and also can be used as an additional function module to be loaded onto the existing color ultrasonic system for use, so the market population prospect is better.

Owner:SHENZHEN UNIV

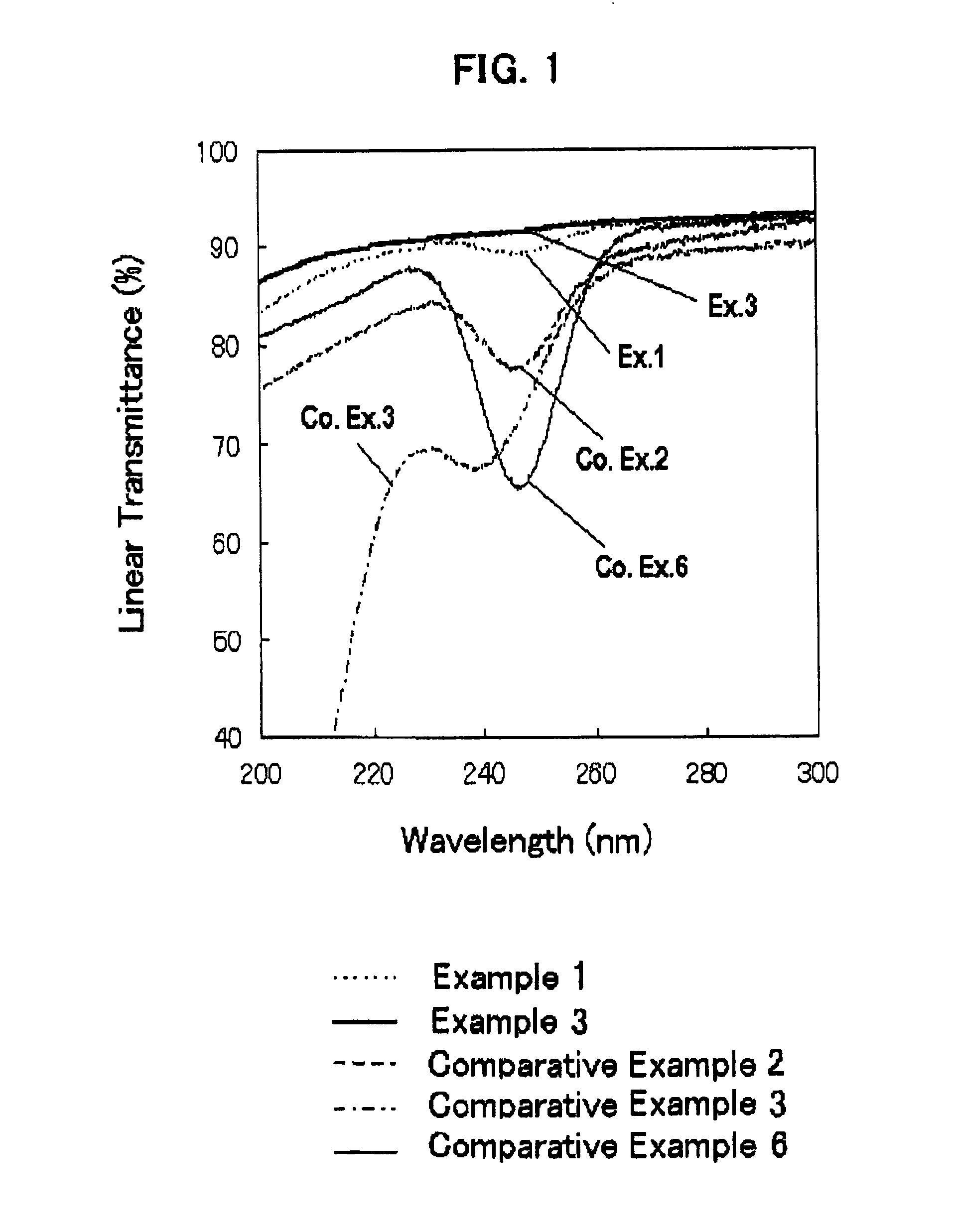

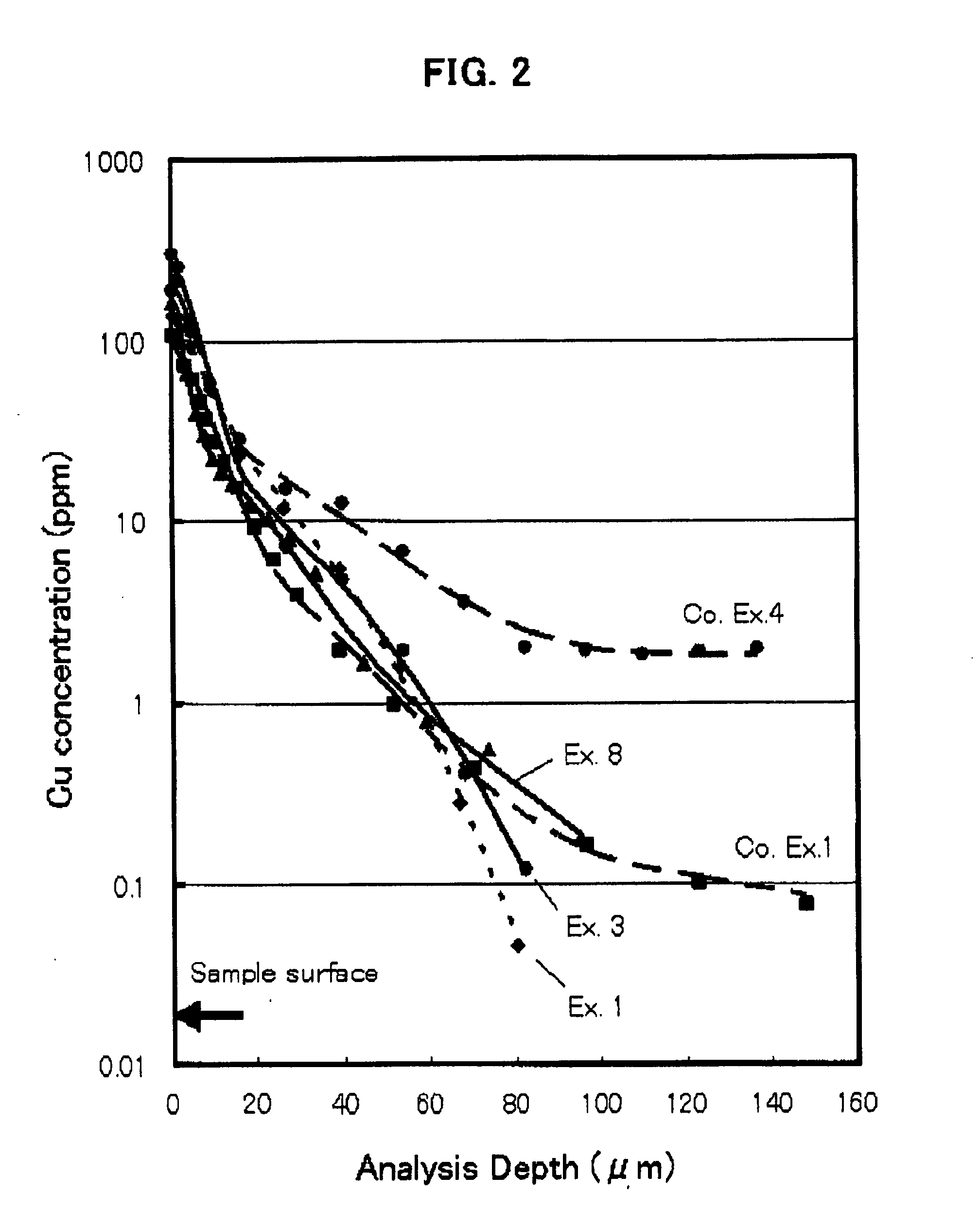

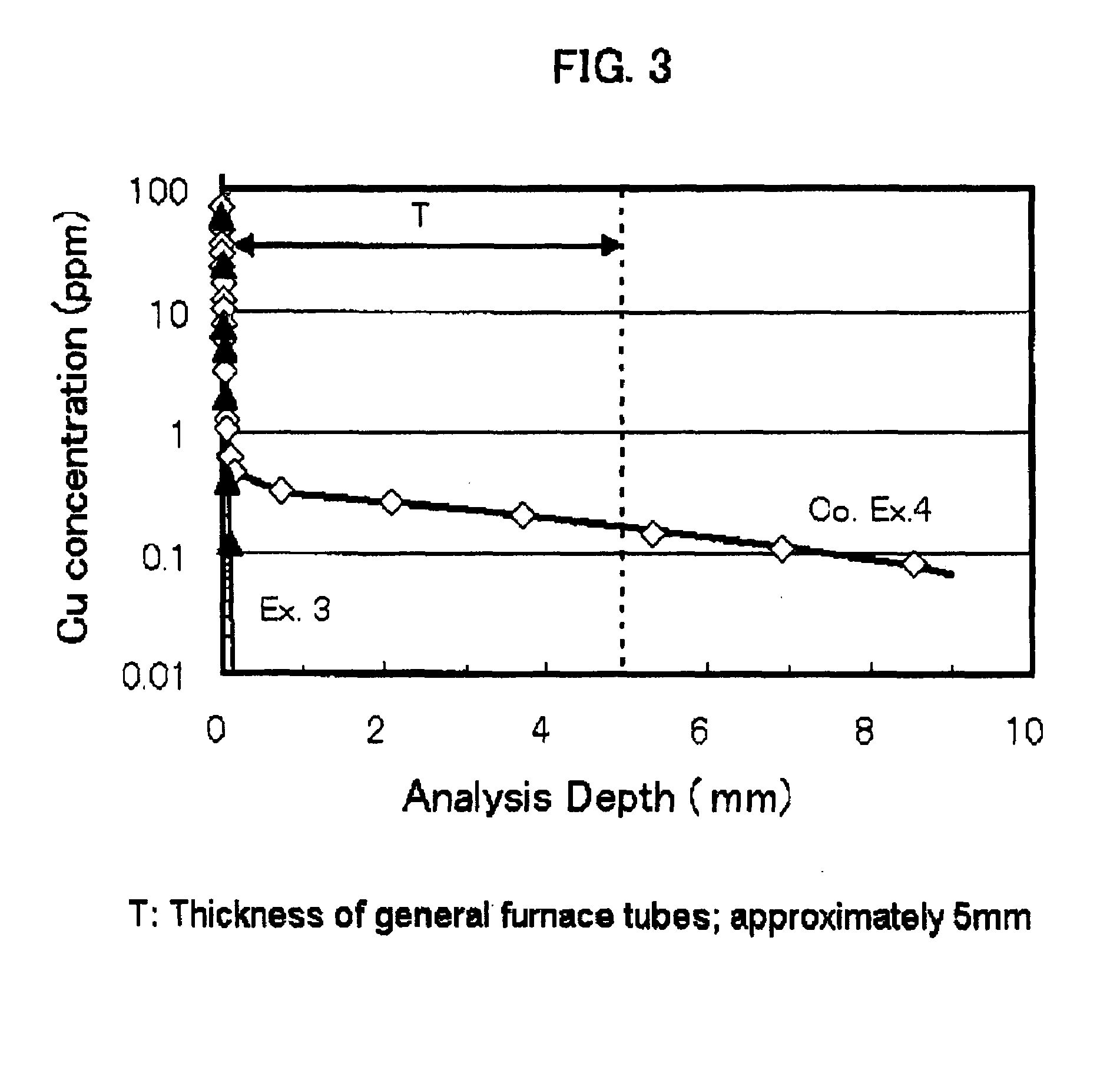

Fused silica glass and process for producing the same

ActiveUS20100041538A1High transparencyReduce the probability of spreadingGlass shaping apparatusGlass tempering apparatusMetal impuritiesUltraviolet

Fused silica glass having an internal transmittance of UV with 245 nm wavelength, being at least 95% at 10 mm thickness, a OH content of not larger than 5 ppm, and a content of Li, Na, K, Mg, Ca and Cu each being smaller than 0.1 ppm. Preferably the glass has a viscosity coefficient at 1215° C. of at least 1011.5 Pa·s; and a Cu ion diffusion coefficient of not larger than 1×10−10 cm2 / sec in a depth range of greater than 20 μm up to 100 μm, from the surface, when leaving to stand at 1050° C. in air for 24 hours. The glass is made by crystobalitizing powdery silica raw material; then, fusing the crystobalitized silica material in a non-reducing atmosphere. The glass exhibits a high transmittance of ultraviolet, visible and infrared rays, has high purity and heat resistance, and exhibits a reduced diffusion rate of metal impurities, therefore, it is suitable for various optical goods, semiconductor-production apparatus members, and liquid crystal display production apparatus members.

Owner:TOSOH CORP +1

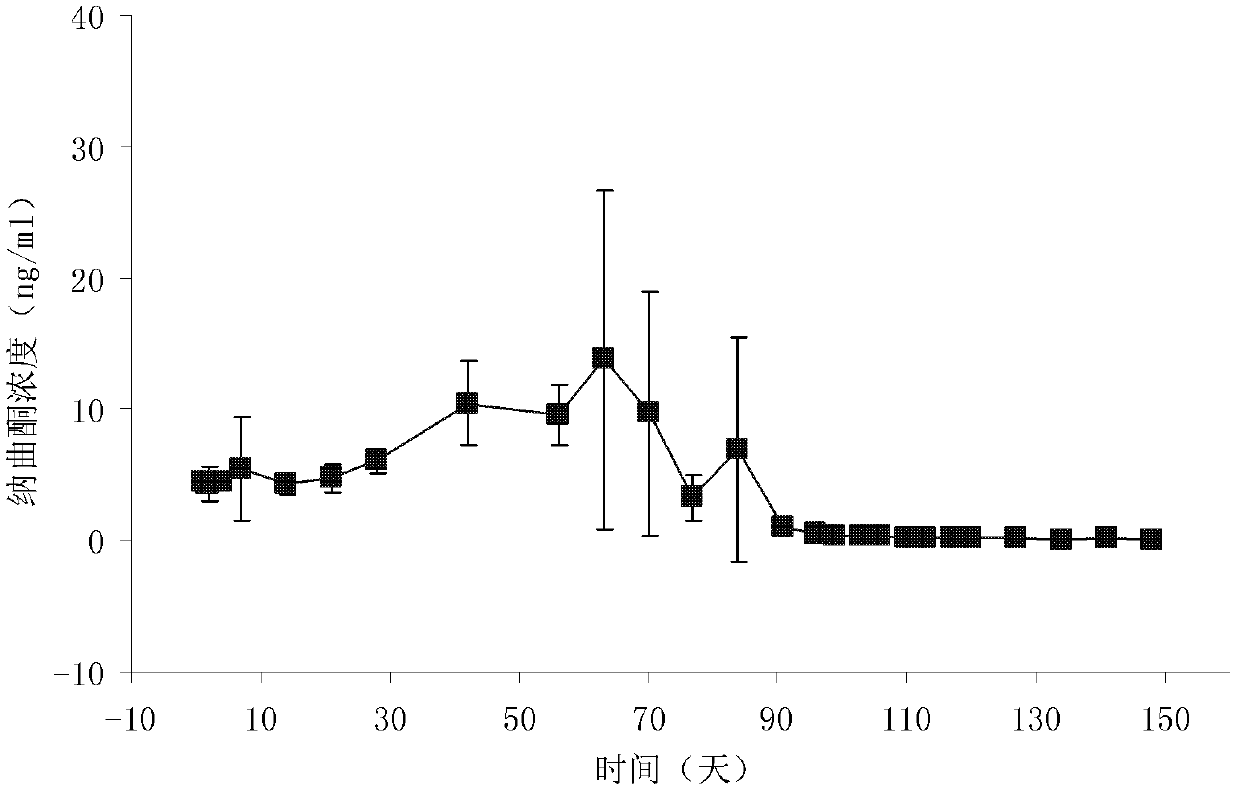

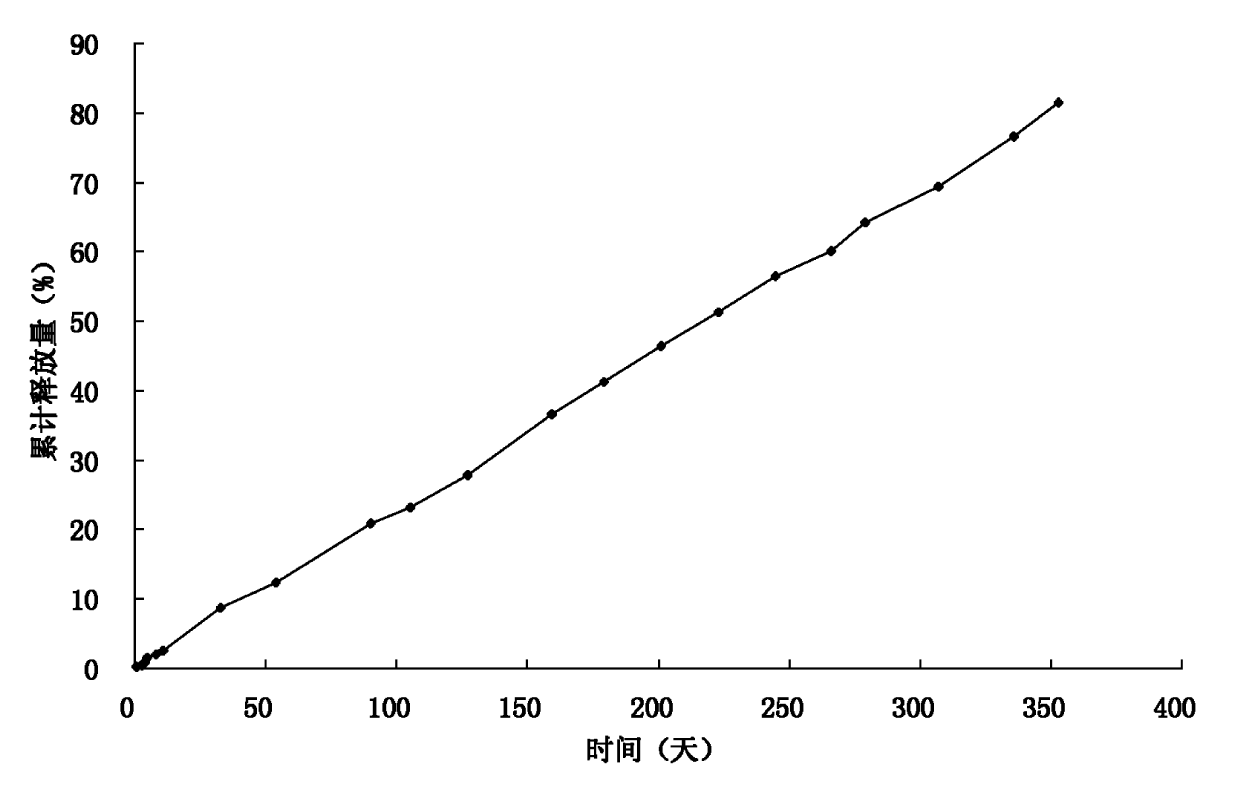

Long-acting naltrexone implant and preparation method thereof

ActiveCN102512399AFacilitated releaseRelease stabilityOrganic active ingredientsNervous disorderSide effectCurative effect

The invention relates to a long-acting naltrexone implant and a preparation method thereof, which belong to the field of pharmaceutical preparations. The long-acting naltrexone implant comprises a polylactic acid and naltrexone, and is characterized in that the viscosity coefficient of the polylactic acid is 0.5-2.5dl / g (chloroform, 30 DEG C); the ratio of the polylactic acid to the naltrexone is1:(0.5-1.8) in parts by weight; the composition structure of the long-acting naltrexone implant is a particle tabletted and coated structure; coated particles are slow release pellets which can be sieved by a 20-60 mesh screen in particle size; the slow release pellets comprise the polylactic acid and the naltrexone; the ratio of the polylactic acid to the naltrexone in the slow release pellets is 1:(1-2) in part by weight; and a coating layer is a DL-polylactic acid. The long-acting naltrexone implant has a good curative effect, better drug-loading rate and better drug release completeness, and has small side effect on human bodies.

Owner:SHENZHEN SCIENCARE MEDICAL INDUSTRIES CO. LTD.

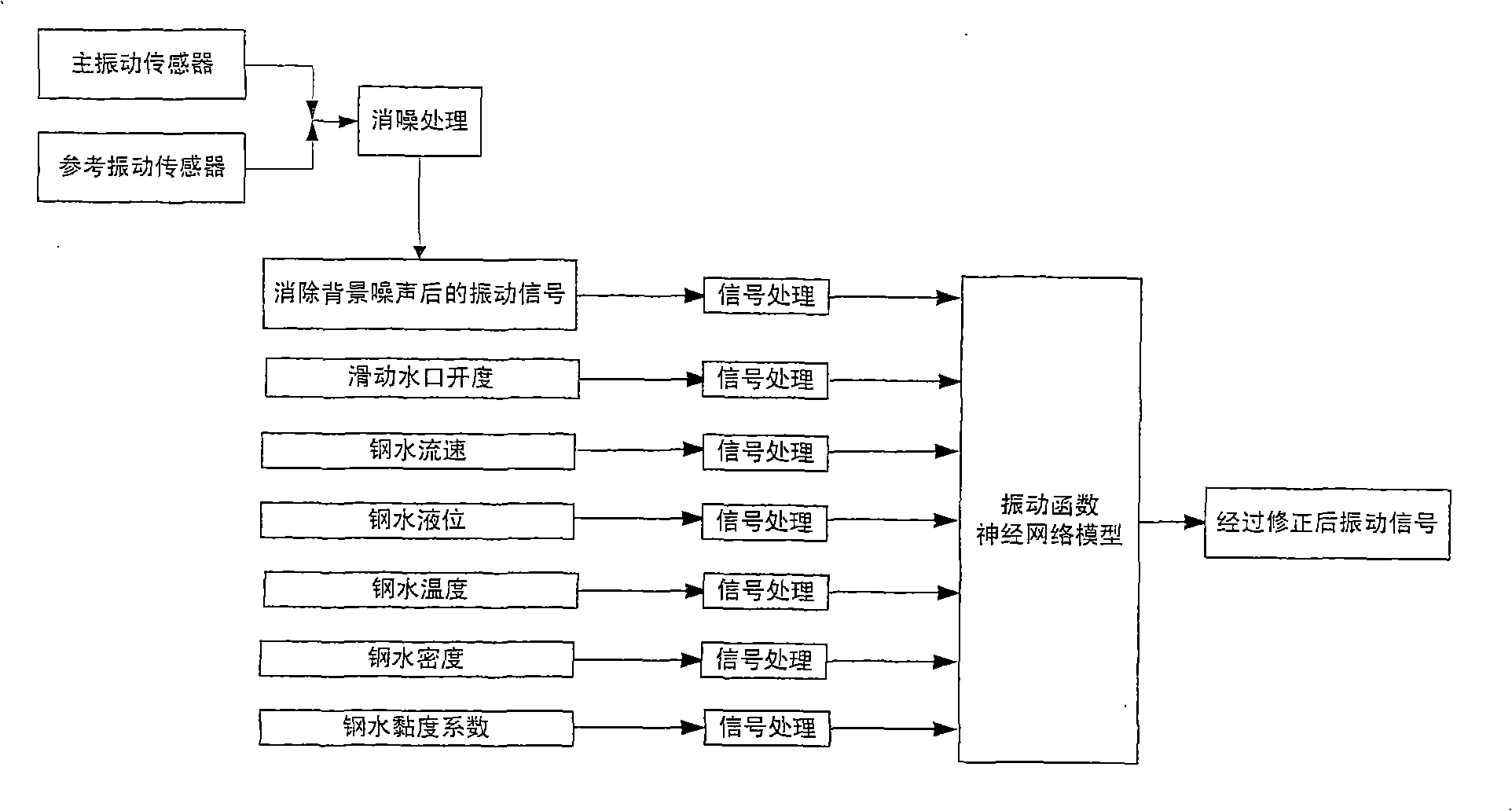

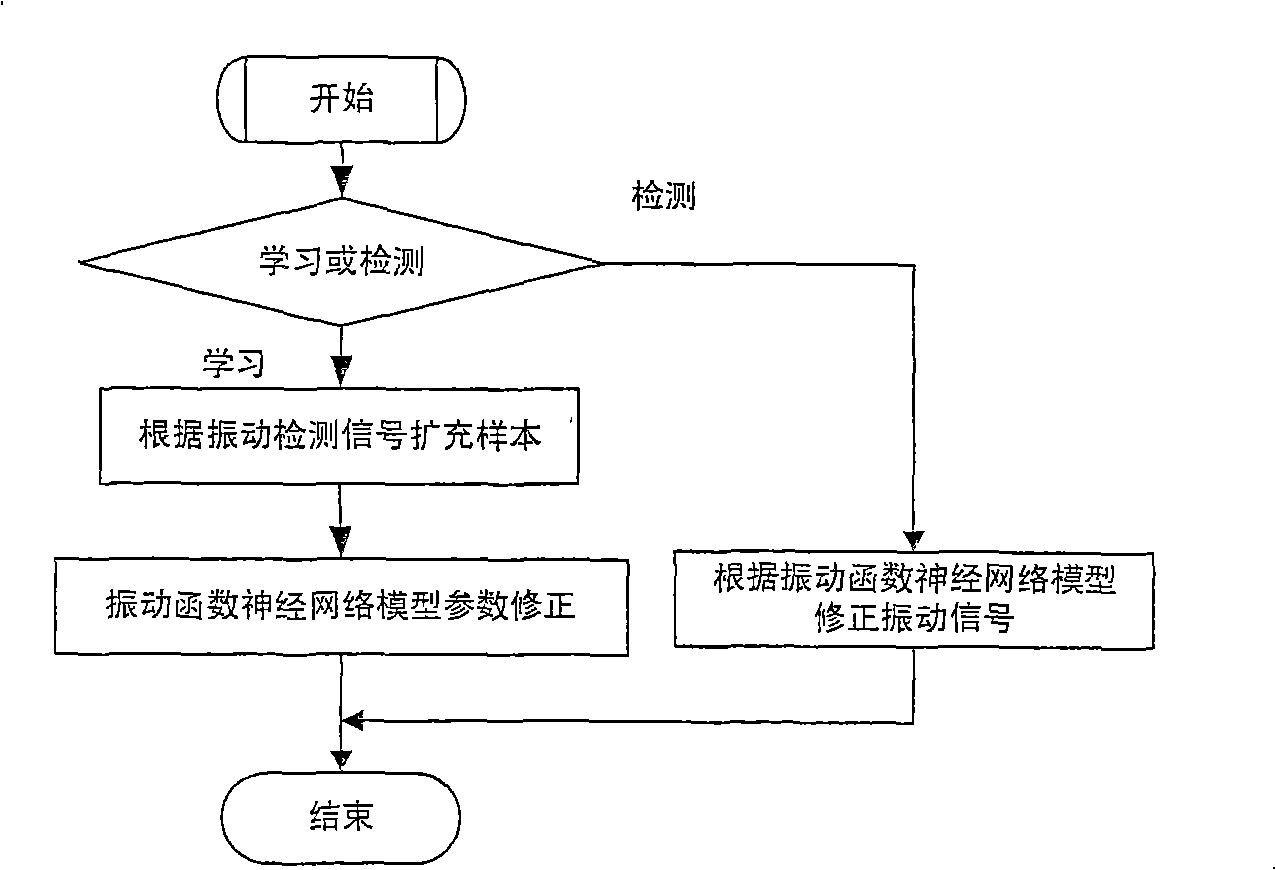

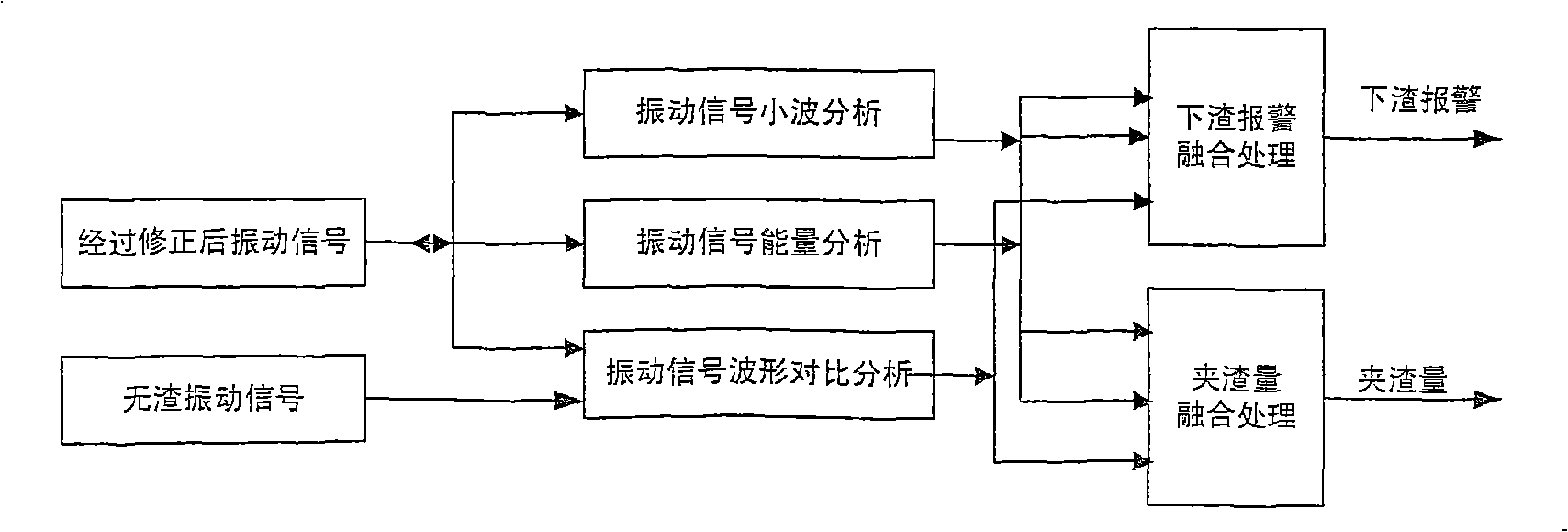

Ladle roughing slag detection, control method and system

InactiveCN101251749AReduce investmentReduce maintenance costsProgramme controlMelt-holding vesselsAutomatic controlSlag

The present invention discloses a detection / control method and a system for steel ladle roughing slag. The method comprises contents in two aspects as follows: according to vibration signals, molten steel flow velocity, molten steel liquid level, slide gate opening degree, molten steel density and molten steel viscosity coefficient, the detection of steel ladle roughing slag state in casting process is realized, so as to get the roughing slag state of the steel ladle, as well as roughing slag amount; according to the detected steel ladle roughing slag state, a slide gate is automatically controlled to be closed with the preset roughing slag sensitivity. The method improves the instability and inaccuracy of adopting single vibration signal for detection in the prior art, improves the precision and reliability of roughing slag detection systems, can close the slide gate in time, prevent excessive steel ladle roughing slag and improve molten steel purity through automatic control, and improves molten steel yielding rate on the premise of guaranteeing molten steel quality. The system is low in cost, high in reliability and low in maintenance cost, which is extensively applied to metallurgical industry.

Owner:SHAANXI AIBEIER ELECTRIC POWER EQUIP

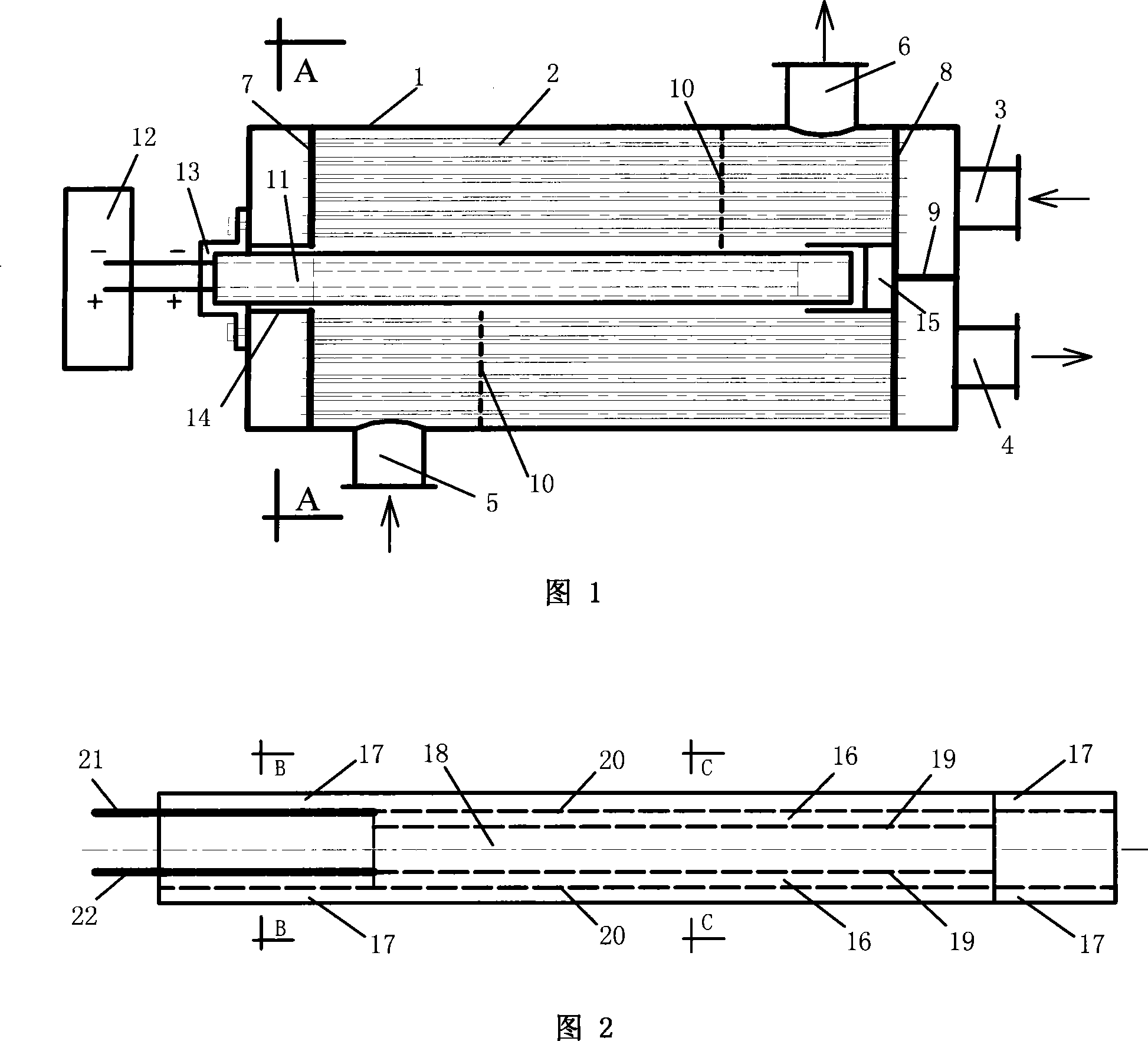

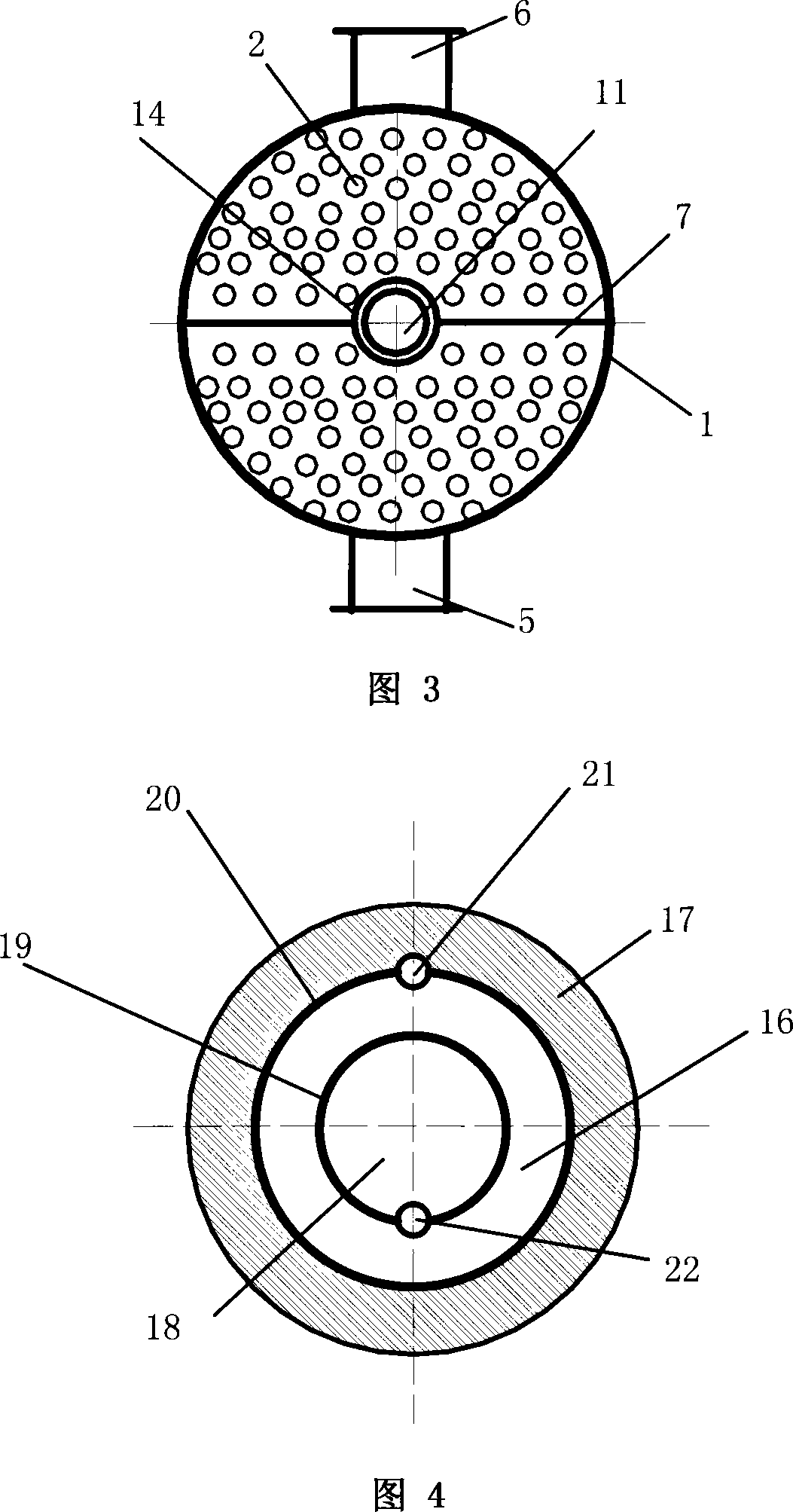

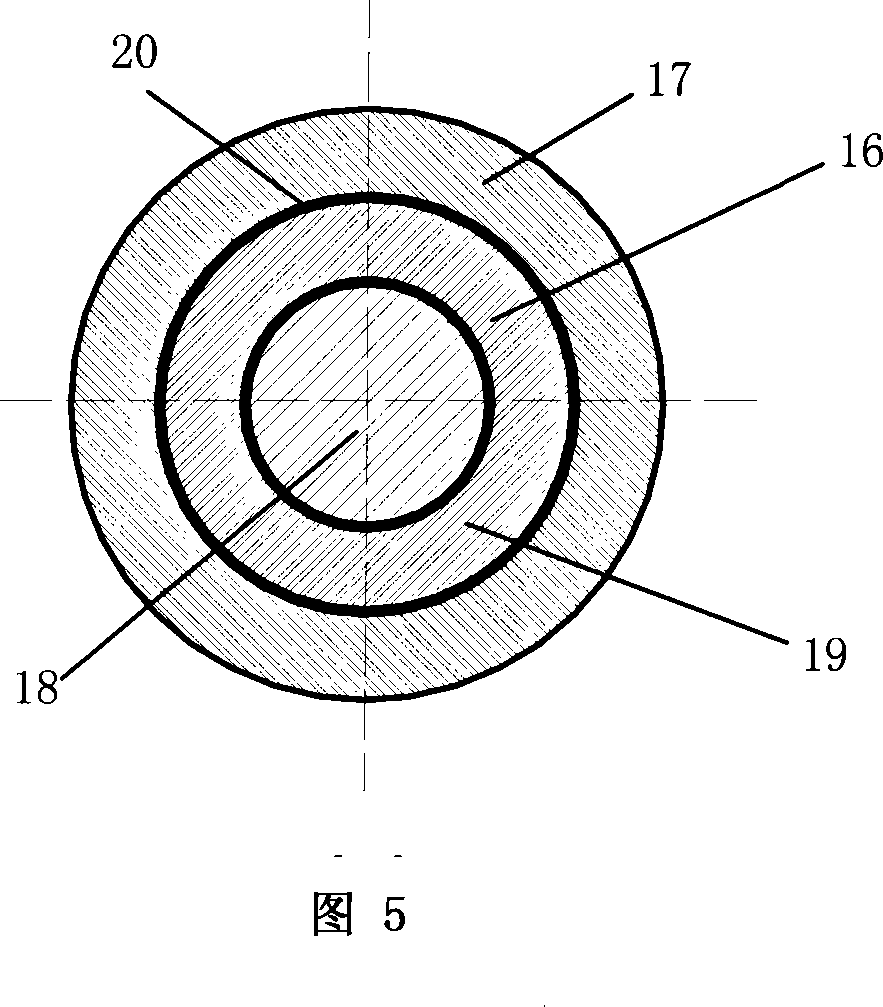

Pipe type heat exchanger with heat exchange shell intensified by ultrasonic wave

InactiveCN101196380AImprove heat transfer effectLower Kinematic Viscosity CoefficientStationary tubular conduit assembliesCavitationUltrasonic sensor

An ultrasonic heat transfer enhancing tube shell heat exchanger is provided, which belongs to the technology field of energy-saving of heat exchanger of industry. The heat exchanger comprises a shell, a heat exchanger tube, a tube side inlet, a tube side outlet, a shell side inlet, a shell side outlet, a first tube plate, a second tube plate, a clapboard, a baffle and a power ultrasonic transducer. The power ultrasonic transducer inserts from the central circular hole of the left end surface of the shell, passes through a circular casing and the central circular hole of a first tube plate in sequence, penetrates a circular hole support and is sealed in the shell side space of the heat exchanger by a sealing cover plate. The ultrasonic wave is projected radially along the power ultrasonic transducer, intensifies liquid oscillation adopting ''cavitation effect'' produced by the ultrasonic wave when spreading in the liquid, reduces liquid motion viscosity coefficient, enhances the heat exchange efficiency of the heat exchanger tube under the condition of low flow velocity of liquid, greatly reduces energy consumption of power plant and has obvious energy-saving effect. In addition, the ''cavitation effect'' of the ultrasonic wave can prevent the surface of the heat exchanger tube from scale formation and has strong adaptability and operability.

Owner:SHANGHAI JIAO TONG UNIV

MEMS microphone

ActiveCN107835477AReduce noiseGuaranteed performanceMicrophonesLoudspeakersDifferential pressureMems microphone

The invention discloses a MEMS microphone, which comprises a substrate, a first vibrating diaphragm and a second vibrating diaphragm. A sealing cavity is formed between the first vibrating diaphragm and the second vibrating diaphragm. A back electrode unit is arranged in the sealing cavity and forms a capacitor structure together with the first vibrating diaphragm and the second vibrating diaphragm. A plurality of through holes penetrating through the two sides of the back electrode unit are formed in the back electrode unit. A gas with the viscosity coefficient thereof smaller than that of air is filled in the sealing cavity. According to the MEMS microphone, the gas with the viscous coefficient thereof smaller than that of air is filled in the sealing cavity, so that the sound resistanceof the two vibrating diaphragms when the vibrating diaphragms are moving relative to the back electrode can be greatly reduced. The noise of the microphone is reduced. Meanwhile, the gas with the lowviscosity coefficient is used for filling, so that the pressure in the sealing cavity can be consistent with the pressure of the external environment. The problem of diaphragm deflection caused by differential pressure is avoided, and the performance of the microphone is guaranteed.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

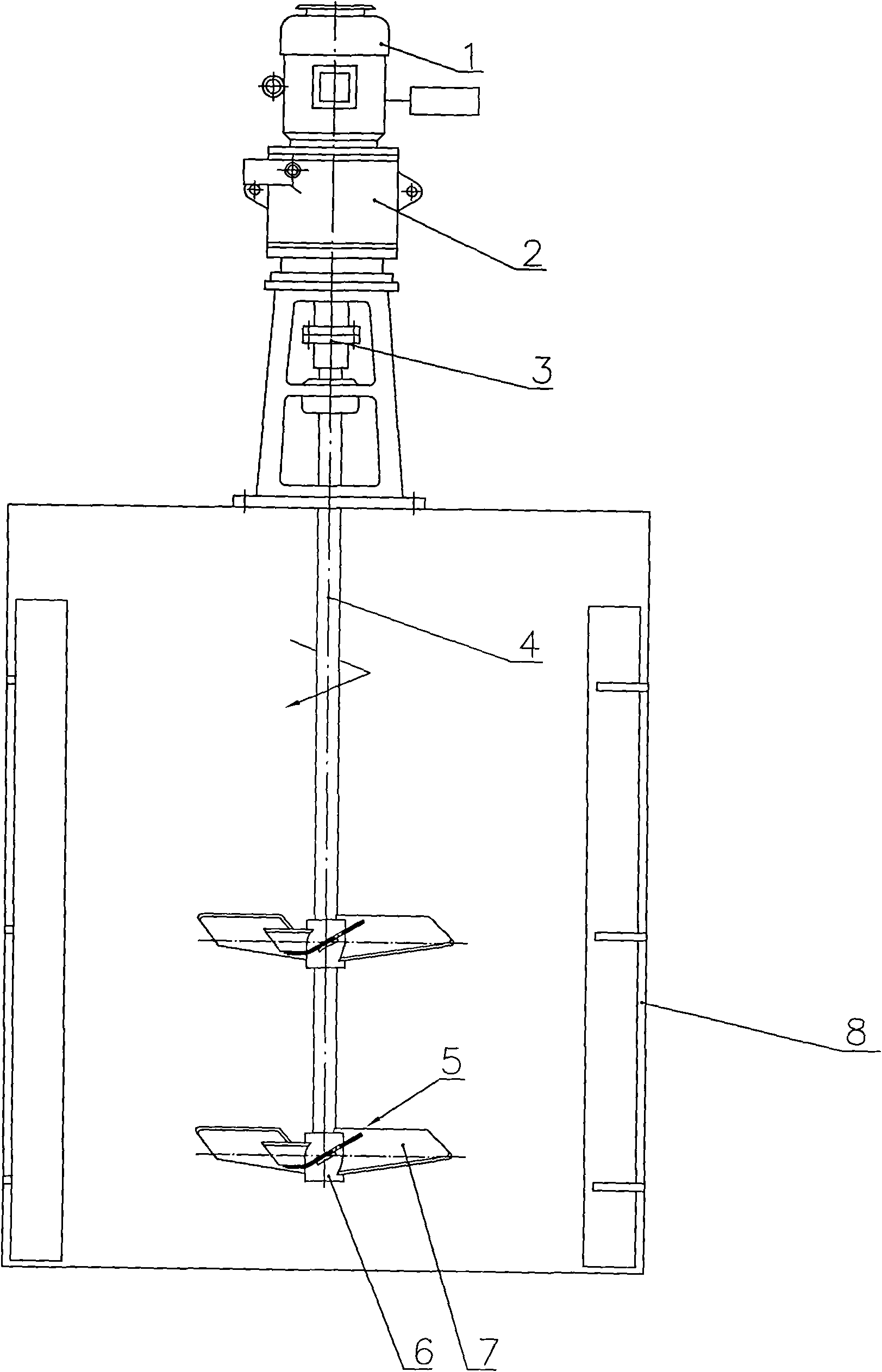

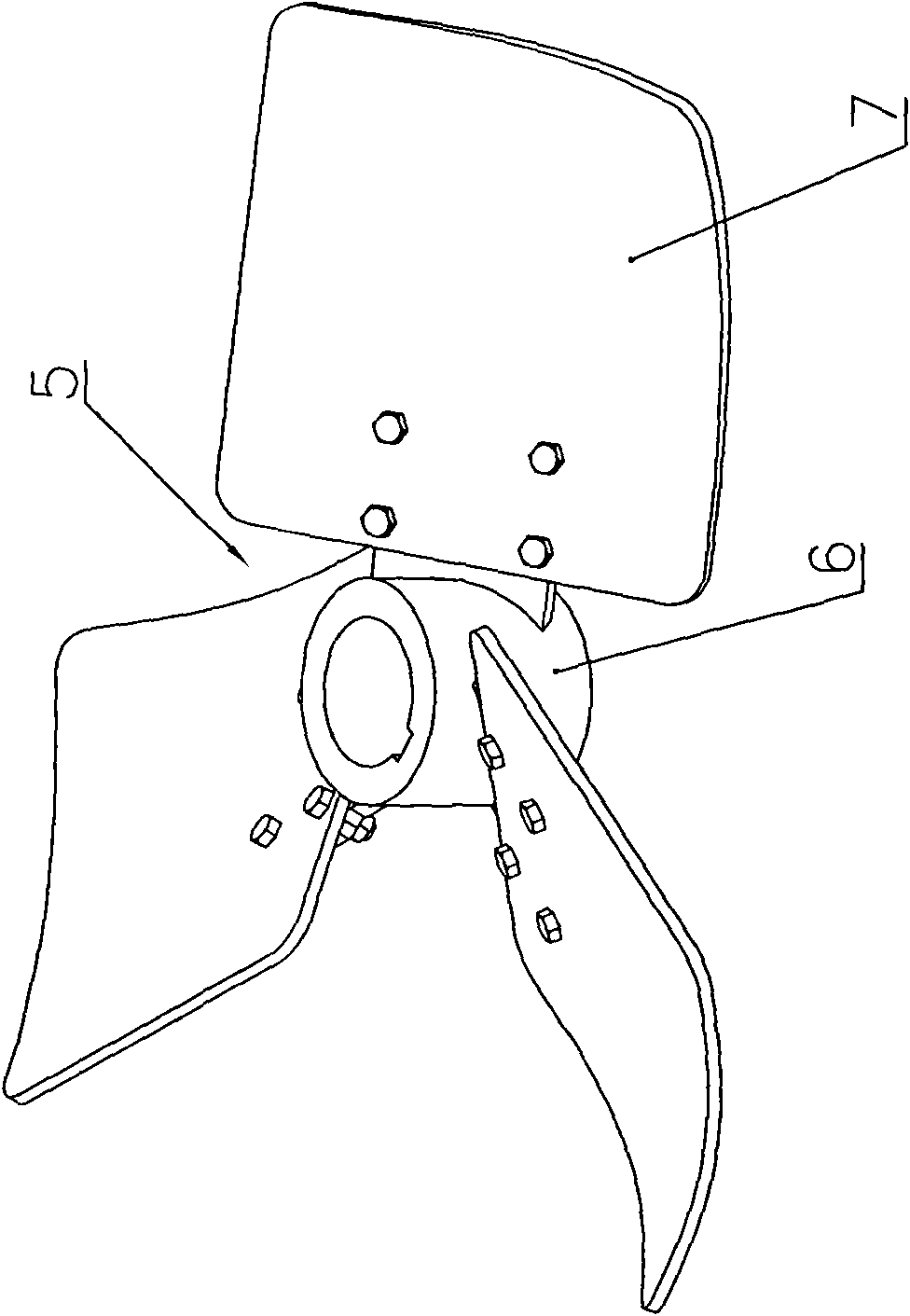

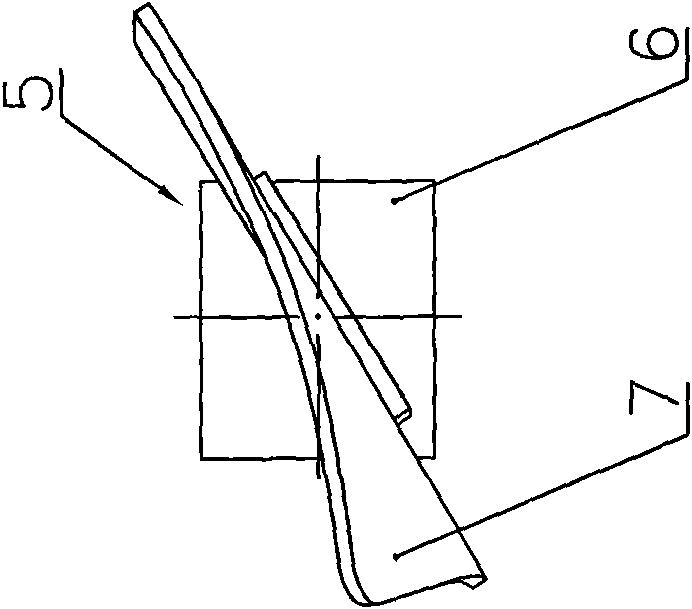

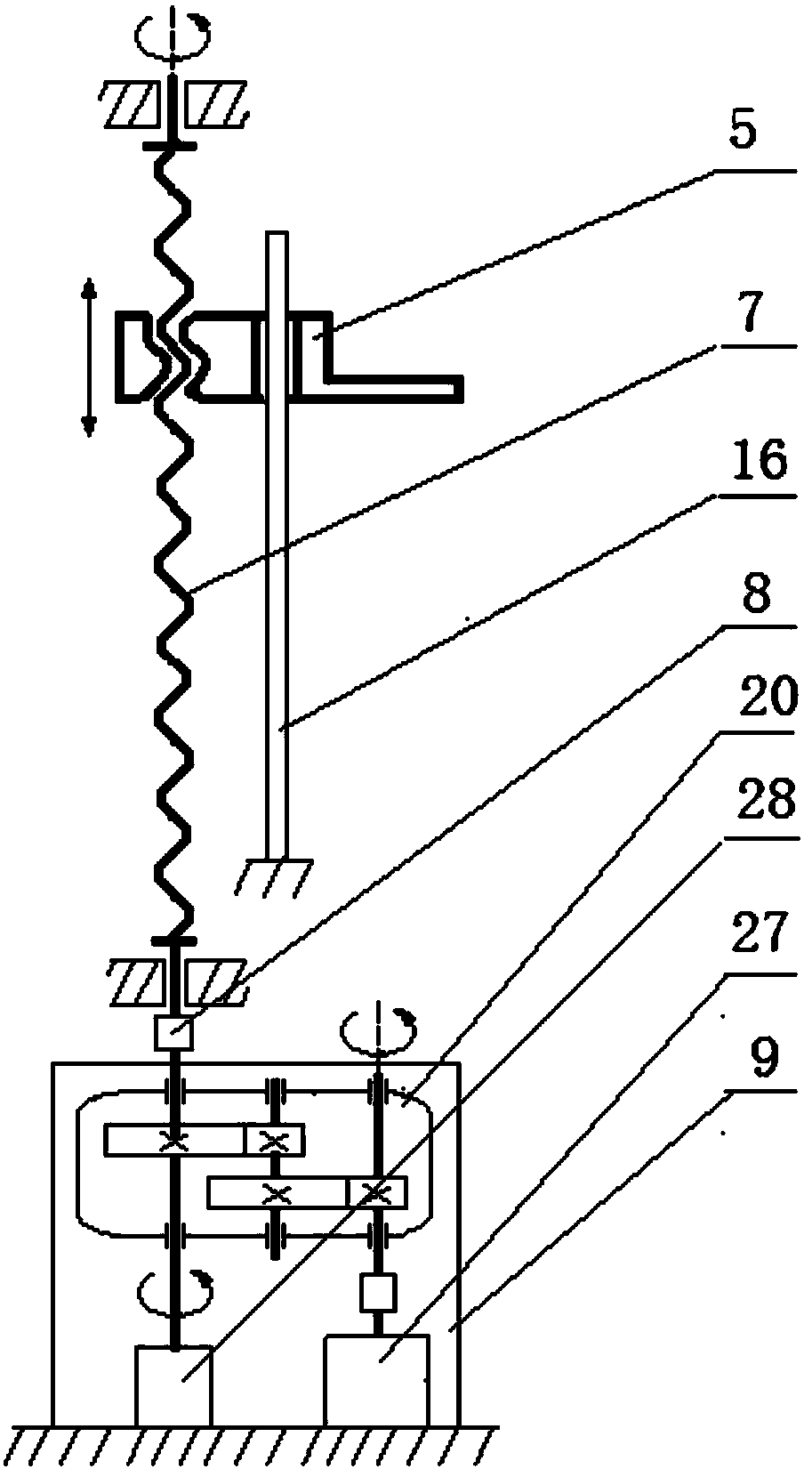

Device for dissolving, curing and stirring hydrophobic associating polymer

InactiveCN101642688AIncrease viscosityWell mixedRotary stirring mixersMixing methodsPolymer dissolutionEngineering

The invention relates to a device for dissolving, curing and stirring hydrophobic associating polymer, comprising a driving device, a stirring and driving decelerating mechanism, a stirring shaft anda stirring paddle arranged on the stirring shaft. The device is characterized in that the stirring paddle is a push-up type wide blade axial flow paddle. By adopting the push-up type wide blade axialflow stirring device, the device can obviously improve axial circular flow, evenly and uniformly dissolves the polymer, and can keep higher viscosity coefficient, thereby accelerating the dissolving and the curing of the polymer and being capable of greatly improving the oil displacement efficiency of the polymer.

Owner:浙江长城搅拌设备股份有限公司

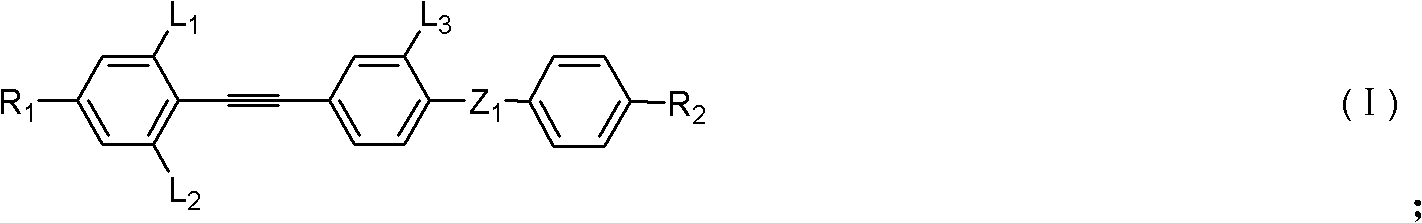

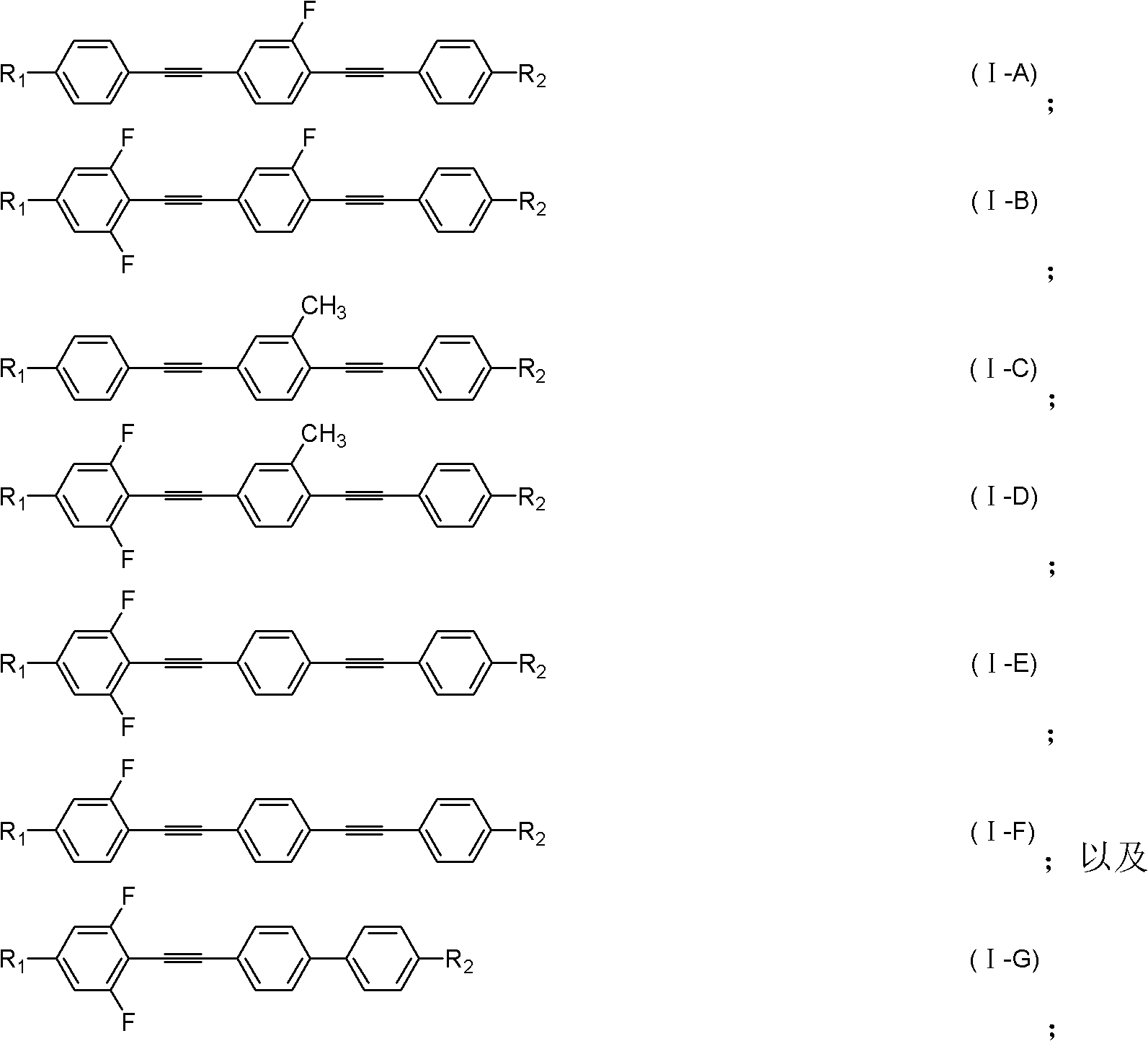

Liquid crystal composition with high optical anisotropy and liquid crystal display element

ActiveCN102634347ALiquid crystal compositionsNon-linear opticsLiquid-crystal displayViscosity coefficient

The invention provides a liquid crystal composition. The liquid crystal composition comprises 5-80 percent by weight of a compound of general formula (I), 5-85 percent by weight of a compound of general formula (II) and 5-45 percent by weight of a compound of general formula (III). The liquid crystal composition has low viscosity coefficient, high optical anisotropy, high specific resistance, wide nematic phase range and excellent low-temperature intersolubility, is suitable for 3D display mode, and is especially suitable for 2D / 3D conversion. The invention also provides a liquid crystal display element comprising the liquid crystal composition.

Owner:JIANGSU HECHENG DISPLAY TECHCO +1

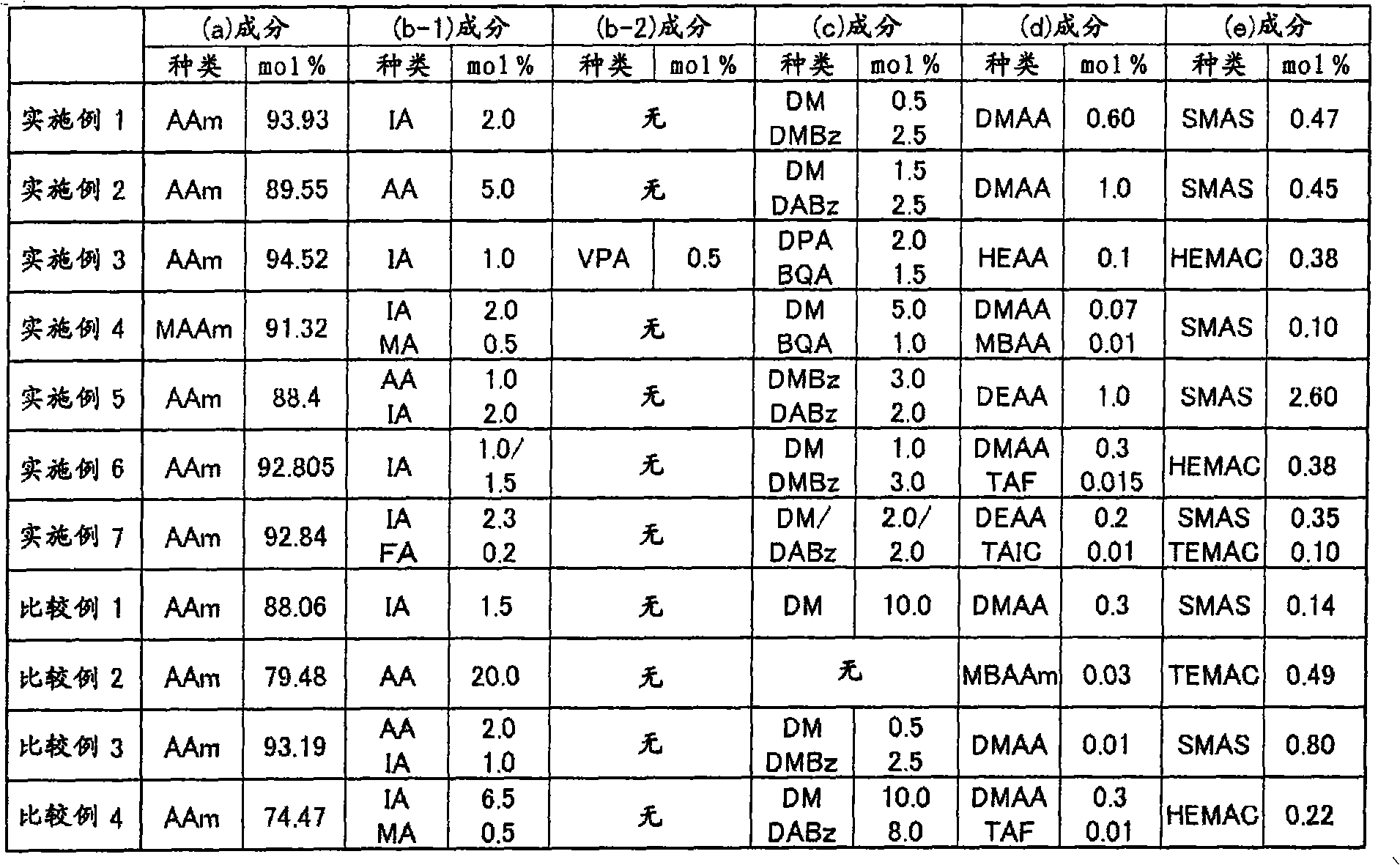

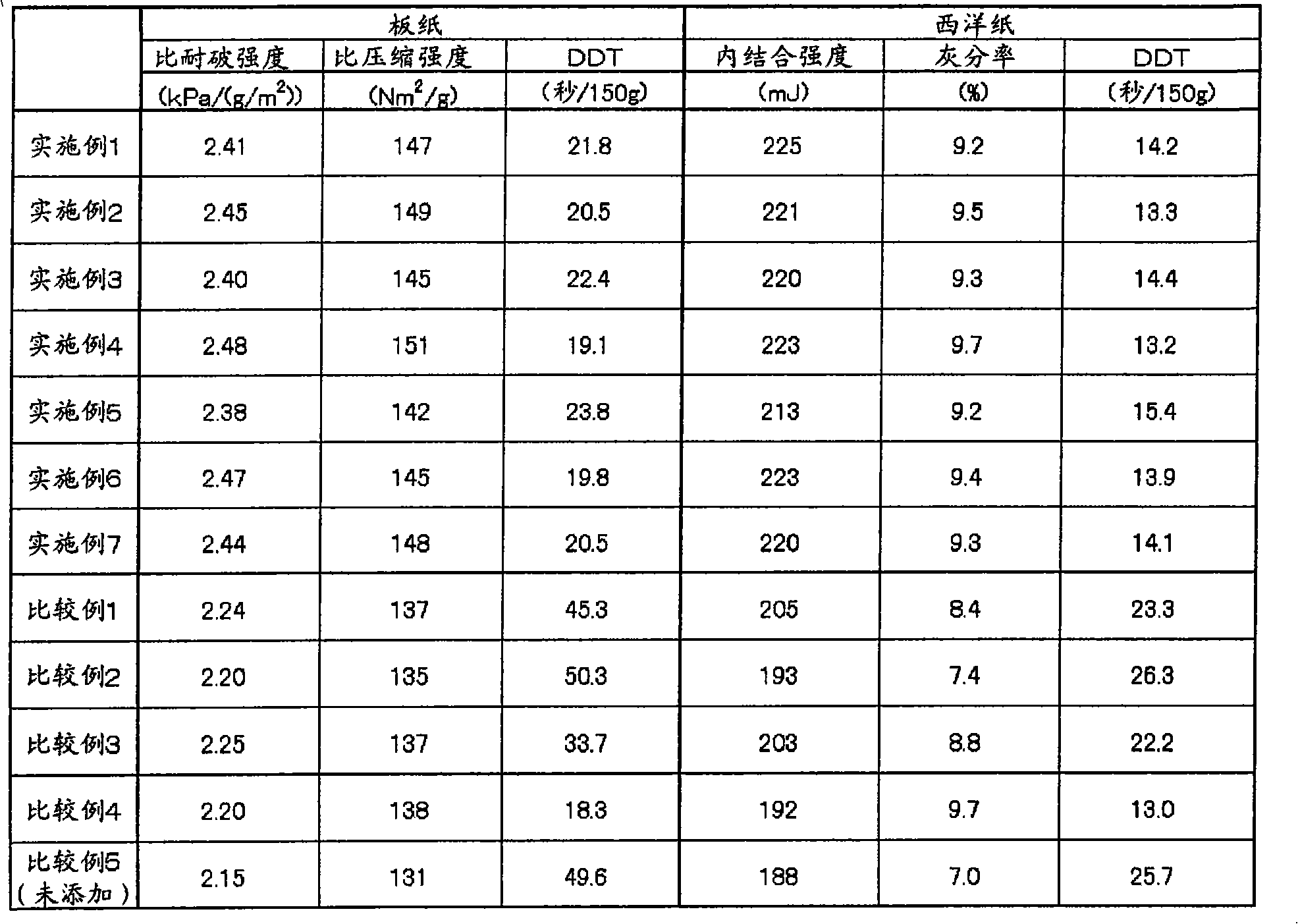

Additive for papermaking

InactiveCN101906734AExcellent paper strength improvement effectGood filterabilityNon-fibrous pulp additionPaper/cardboardFiltrationTransmittance

An object of the invention is to provide an additive for papermaking containing amphiprotic acrylamide polymer, which has excellent paper force improvement effect, excellent water filtration character and stuffing preserving rate. The additive for papermaking containing amphiprotic acrylamide polymer is characterized in that it has a specific relationship, the weight average molecular weight / average number molecular weight, intrinsic viscosity, gyroradius, solid content, viscosity coefficient, PH and light transmittance ratio are specific scope, and is obtained by performing polymerization using specific amount of specific monomer.

Owner:SEIKO PMC CORP

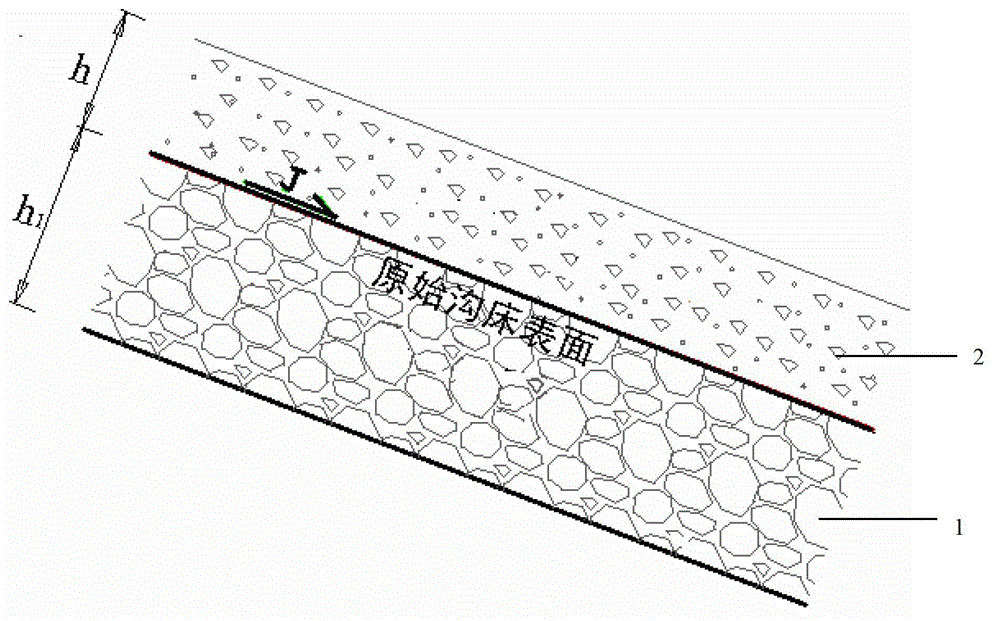

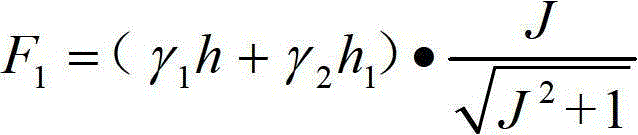

Method for measuring maximum scour depth of viscous debris flow gully bed and application thereof

ActiveCN102943450AIncrease resistance to movementAvoid destructionHydraulic engineering apparatusVertical gradientPrevention project

The invention discloses a method for measuring the maximum scour depth of a viscous debris flow gully bed and the application thereof. The method comprises the following steps: weight Gamma1, depth h and a dynamic friction angle Beta of a viscous debris flow body, weight Gamma2, an internal frictional angle Phi and a viscosity coefficient C of cumulus deposits of an original gully bed, and vertical gradient J of the gully channel are determined by means of survey, measurement and sampling of the debris flow gully, testing of debris flow characteristic parameters and the like; and the obtained parameters are substituted into a calculation formula to obtain the maximum scour depth of the viscous debris flow gully bed. The method is applicable to the design of foundation embedded depth in a viscous debris flow prevention project, and the obtained maximum scour depth of the viscous debris flow gully bed serves as the minimum foundation embedded depth in the prevention project. Compared with the prior art, as the method is based on rigorous theory derivation, the maximum scour depth of the viscous debris flow gully bed can be reasonably determined, and references on the design of the foundation embedded depth in the prevention project are provided; and the method is high in result accuracy and can meet the requirements of the practical project.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

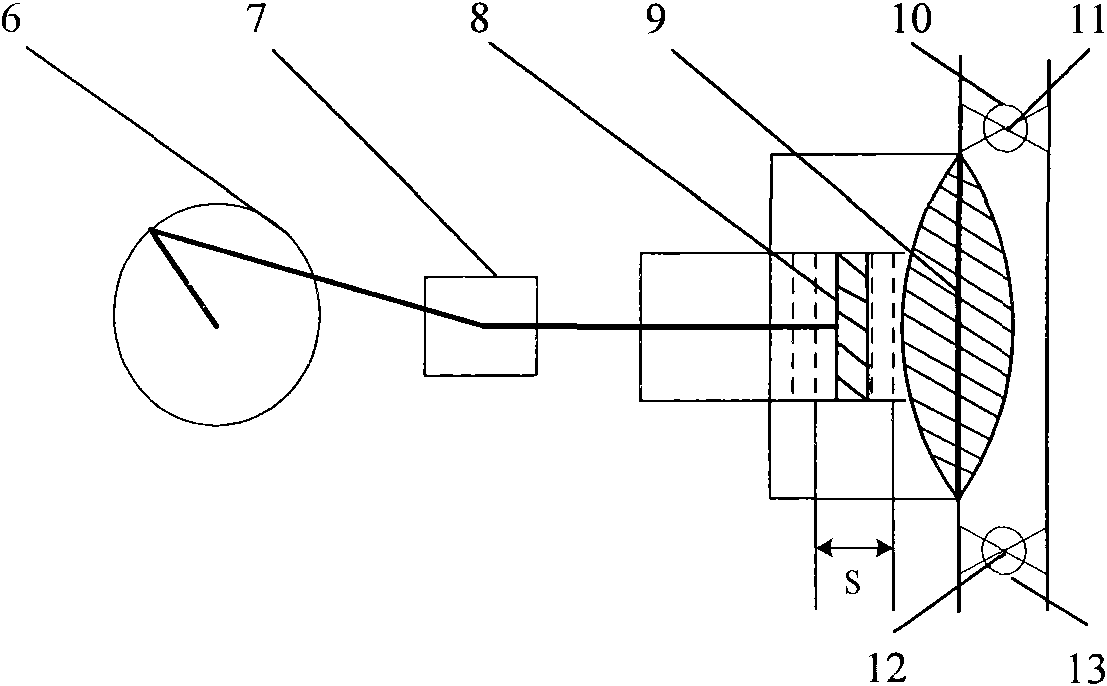

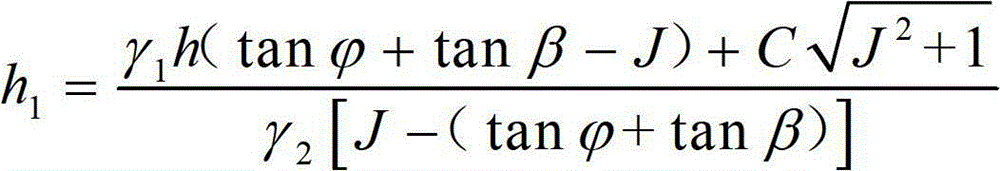

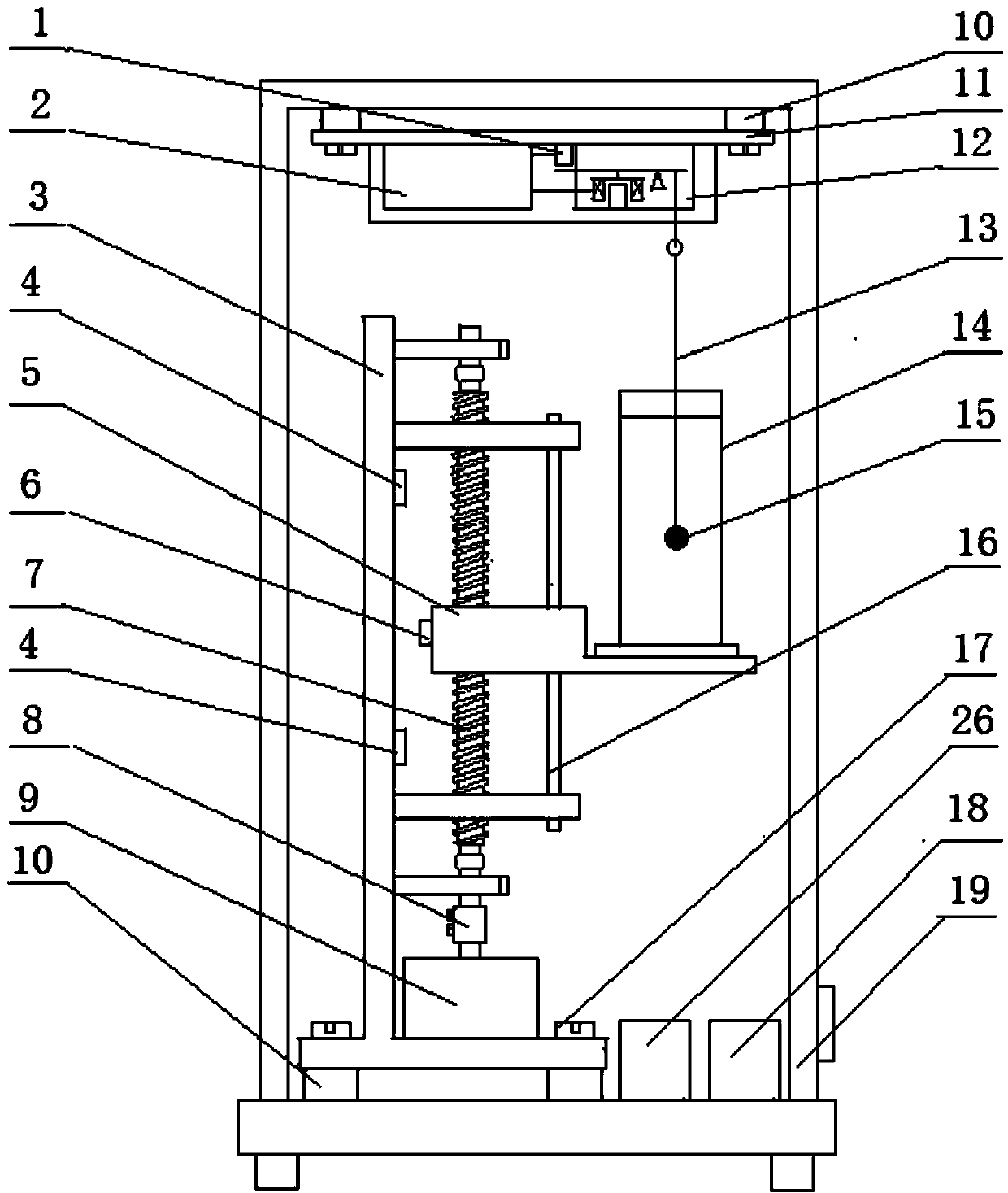

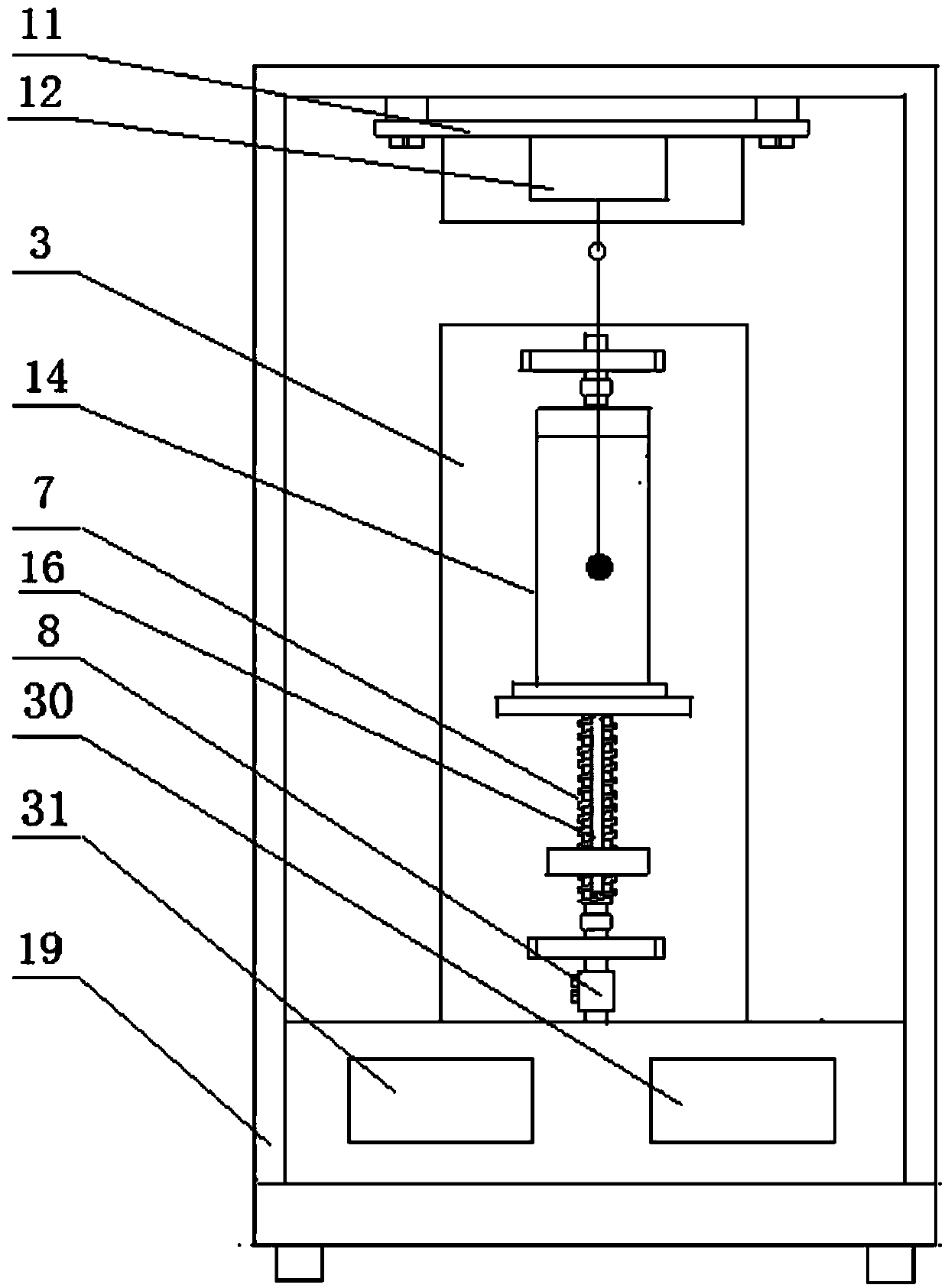

Ball-dragging-type viscometer

The invention discloses a ball-dragging-type viscometer. The ball-dragging-type viscometer is suitable for liquid with small viscosity coefficients as well as non-transparent liquid and high in measurement accuracy. According to the structure, the ball-dragging-type viscometer comprises a shell, a screw drive mechanism, a speed control system and a tension detection system are arranged in the shell, and the speed control system structurally comprises a controller, a servo motor, a motor driver and a rotary encoder, wherein the servo motor is connected with the controller through the motor driver and the rotary encoder is connected with the controller. According to the ball-dragging-type viscometer, a traditional ball falling method is replaced by a ball dragging method, namely, a ball is dragged at constant and low speed through the screw drive mechanism, so that the ball moves upwards at given speed and the viscosity of liquid is calculated according the Stokes formula shown in the specification according to measurement of tension borne by the ball. The ball-dragging-type viscometer has the advantages of being convenient to use, capable of immediately conducting repeated measurement, simple in structure, capable of easily achieving automatic measurement and the like.

Owner:SHANDONG UNIV

Method for grafting maleic anhydride onto polypropylene resin

The invention provides a method for preparing grafted polypropylene resin, relating to the technology of melt-grafting maleic anhydride onto polypropylene resin. In the method, a melt free radical graThe invention provides a method for preparing grafted polypropylene resin, relating to the technology of melt-grafting maleic anhydride onto polypropylene resin. In the method, a melt free radical grafting reaction is adopted to graft a maleic anhydride monomer onto a molecular chain of the polypropylene resin. Polypropylene resin adopts powder without an antioxidizer, wherein an auxiliary monomerfting reaction is adopted to graft a maleic anhydride monomer onto a molecular chain of the polypropylene resin. Polypropylene resin adopts powder without an antioxidizer, wherein an auxiliary monomer is introduced in a melt grafting reaction triggered by a peroxide initiator besides the addition of the maleic anhydride monomer. The auxiliary monomer consists of a first auxiliary monomer and a secis introduced in a melt grafting reaction triggered by a peroxide initiator besides the addition of the maleic anhydride monomer. The auxiliary monomer consists of a first auxiliary monomer and a second auxiliary monomer. The first auxiliary monomer is a styrene monomer and the second auxiliary monomer is an organic matter monomer with molecules including two or more carbon-carbon double bonds. Tond auxiliary monomer. The first auxiliary monomer is a styrene monomer and the second auxiliary monomer is an organic matter monomer with molecules including two or more carbon-carbon double bonds. The consumption of the auxiliary monomer accounts for 1%wt to 10%wt of the weight of the polypropylene resin and the proportion of the first auxiliary monomer and the second auxiliary monomer in the auhe consumption of the auxiliary monomer accounts for 1%wt to 10%wt of the weight of the polypropylene resin and the proportion of the first auxiliary monomer and the second auxiliary monomer in the auxiliary monomer ranges from 5:95 to 70:30; the consumption of the maleic anhydride accounts for 1%wt to 8%wt of the weight of polypropylene. The method for grafting maleic anhydride onto polypropylenexiliary monomer ranges from 5:95 to 70:30; the consumption of the maleic anhydride accounts for 1%wt to 8%wt of the weight of polypropylene. The method for grafting maleic anhydride onto polypropylene resin can obtain the grafted polypropylene resin with relatively high grafting ratio, molecular weight and viscosity coefficient.resin can obtain the grafted polypropylene resin with relatively high grafting ratio, molecular weight and viscosity coefficient.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing chitin and process for preparing chitosan by using chitin

The invention discloses a method for making crust element which comprises the following steps that: a crab shell which is cleaned and soaked for the first time is put into a sodium hydrate solution for heat preservation; the crab shell which is washed by tap water to the neutral is soaked for the second time, the acid liquor is scoured off by the tap water; the curst element soaked by hydrochloric acid is put into the sodium hydrate solution for heat preservation and then is fished out as well as is washed by the tap water to the neutral, and the crust element is obtained. The method for making chitosan by the crust element comprises the following steps that: the crust element is put into the sodium hydrate solution and is sealed, after temperature preservation and the reaction, the mixture is soaked by the tap water and is washed by the tap water; the processed chitosan is taken out to be dried and put into the sodium hydrate solution as well as be sealed while preserving the temperature, after the reaction, the chitosan is taken out and is soaked in the tap water as well as is taken out and dried, thereby obtaining the chitosan. By processing by the method, the reaction speed is increased by 30 times, the alkali liquor dosage is reduced by 50 percent; the made crust element has white color, the crust element is washed by water and soaked to produce the chitosan, the molecular weight is great, the deacetylation is more than or equal to 95 percent, and the viscosity coefficient is more than or equal to 2000MPa.S.

Owner:石勇

RANS/LES method based on tubulence energy and turbulence length scale truncation

InactiveCN106682398ASpecial data processing applicationsInformaticsViscosity coefficientKinetic energy

The invention discloses a RANS / LES method based on tubulence energy and turbulence length scale truncation. The method mainly establishes a novel truncation formula Fr of turbulent viscosity coefficient, and the truncation turbulent viscosity coefficient is obtained. Fr=1, calculation shows RANS; 0<Fr<1, a LES-like model is shown. According to the definition of molecular viscosity coefficient and the turbulence length scale energy spectrum which meets the formula ( the formula is shown in the description.), a Fr calculation formula is deduced. By the combination of a standard K-< model, the RANS / LES method can be achieved. In this way, the method can calculate velocity pulsation at the condition of less grids, and the obtained average velocity comparatively accords with a DNS result.

Owner:SOUTH CHINA UNIV OF TECH

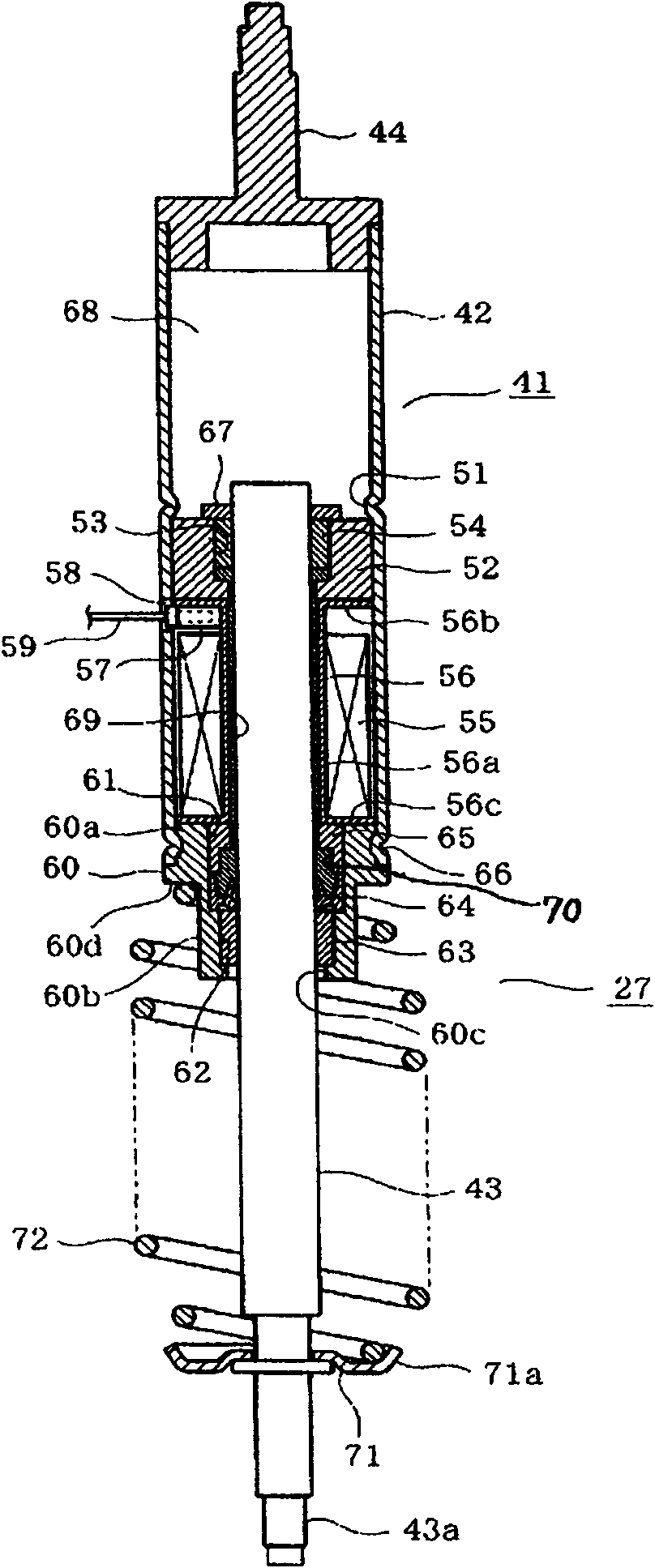

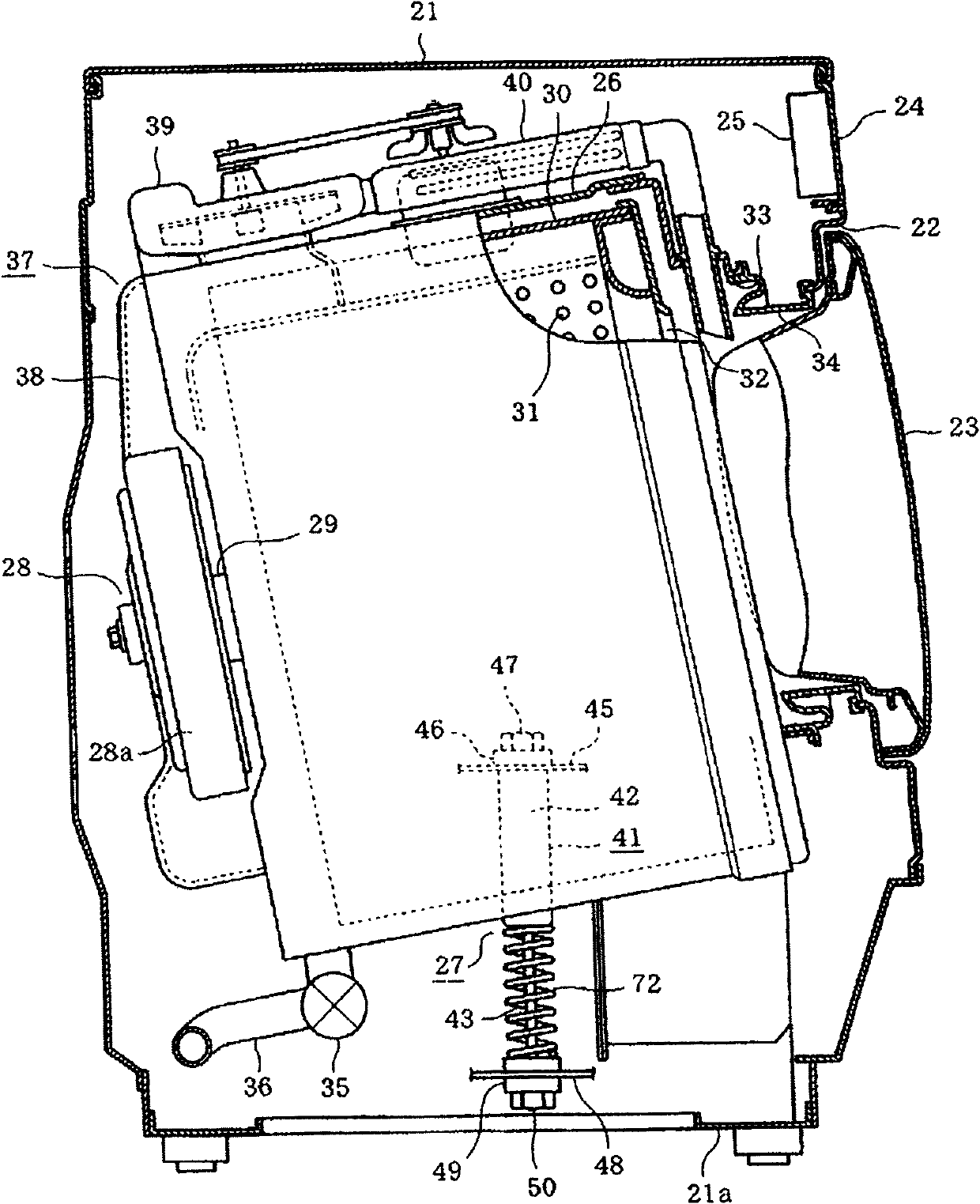

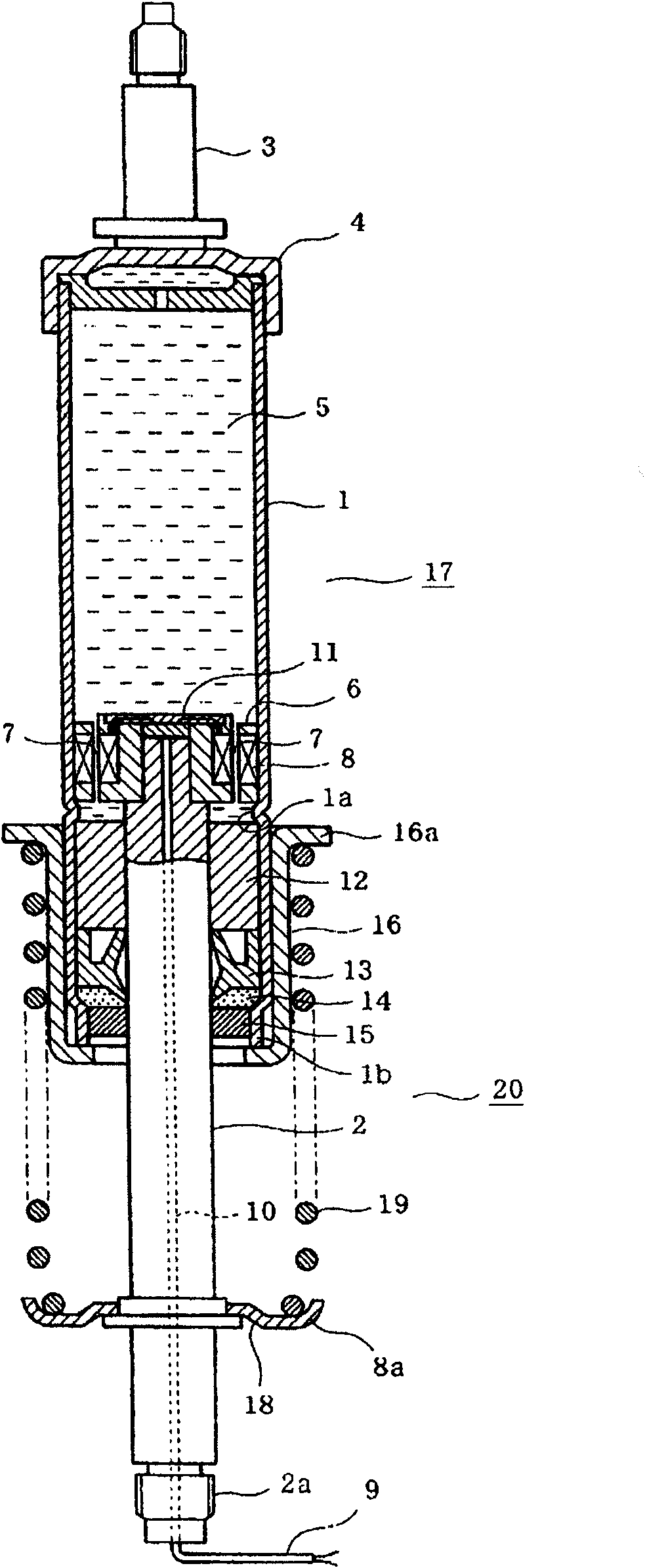

Drum-type washing machine and method for manufacturing hanger bracket with damper

The present invention provides a drum-type washing machine and a method for manufacturing a hanger bracket with a damper, in the damper by using magnetoviscous fluid to absorb vibration of a sink, assembly is easy, and structure is simple. A damping force of the damper (41) is controlled by changing viscosity coefficient of the magnetoviscous fluid (69) by energizing a coil (55). A cylinder (42) of the damper (41) is provided with the coil (55) coiled to a bobbin (56), and then provided with a holding member (60) for accepting a magnet yoke (65), a sealing member (64) and a bearing (63), a shaft (43) is inserted across, and the damper (41) is assembled by filling the magnetoviscous fluid (69) between the shaft (43) and the bobbin (56), between the shaft (43) and a magnet yoke (52), and between the shaft (43) and the magnet yoke (65). Then, a spring is mounted between the holding member (60) and a spring base (71a) of the shaft (43) to assemble the hanger bracket (27).

Owner:东芝家用电器制造(南海)有限公司 +1

Electrophotographic toner, method for producing the same, electrophotographic developer, and image forming method

Owner:FUJIFILM BUSINESS INNOVATION CORP

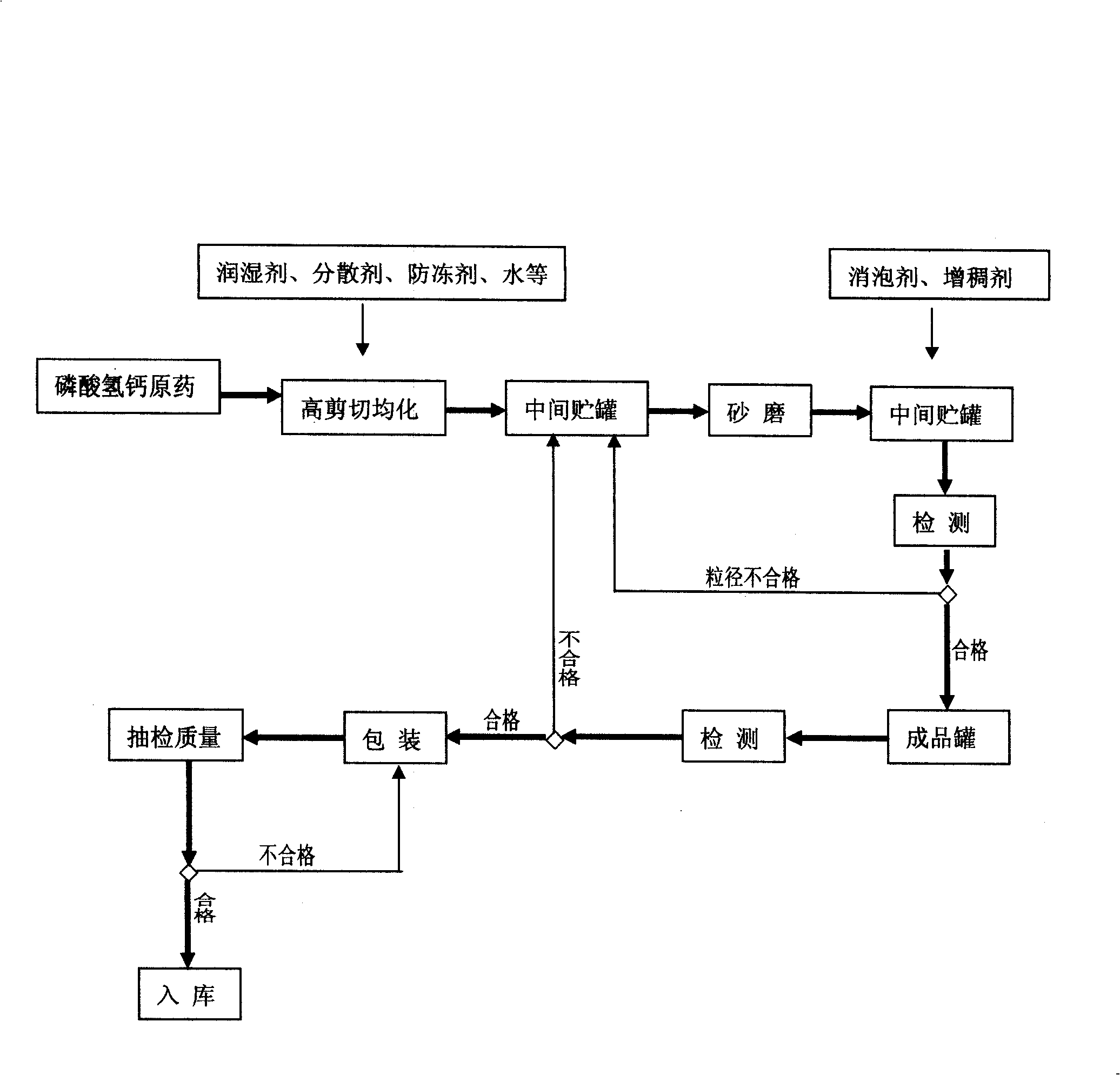

Calcium hydrophosphate suspending agent

ActiveCN101302129ACalcareous fertilisersDi-calcium phosphate fertilisersHigh concentrationHydrogen phosphate

The invention relates to a microelement fertilizer for agricultural use. The microelement fertilizer is calcium hydrogen phosphate suspending agent which is sticky with high concentration. The compositions by mass percent of the microelement fertilizer are: 20 to 80 percent of raw calcium hydrogen phosphate powder, 1 to 7 percent of wetting agent, 2 to 10 percent of dispersant, 2 to 6 percent of antifreeze, 0.2 to 1.0 percent of defoaming agent, 0.1 to 0.8 percent of thickening agent, and 2.2 to 76.7 percent of water. The compositions are mixed evenly with high shear and are grinded to the fineness between 0.5 and 6 micron; the viscosity coefficient of the mixture is adjusted by the thickening agent to obtain the calcium hydrogen phosphate suspending agent. The microelement fertilizer is prepared through adopting the high-performance addition agent and advanced technology. The microelement fertilizer is characterized by high content of activity components, good dispersion performance and stable heat storing performance. In the application, the microelement fertilizer has the advantages of rapid calcium supplement speed, good effect, small dosage of the fertilizer and environmental protection.

Owner:东莞市施普旺生物科技有限公司

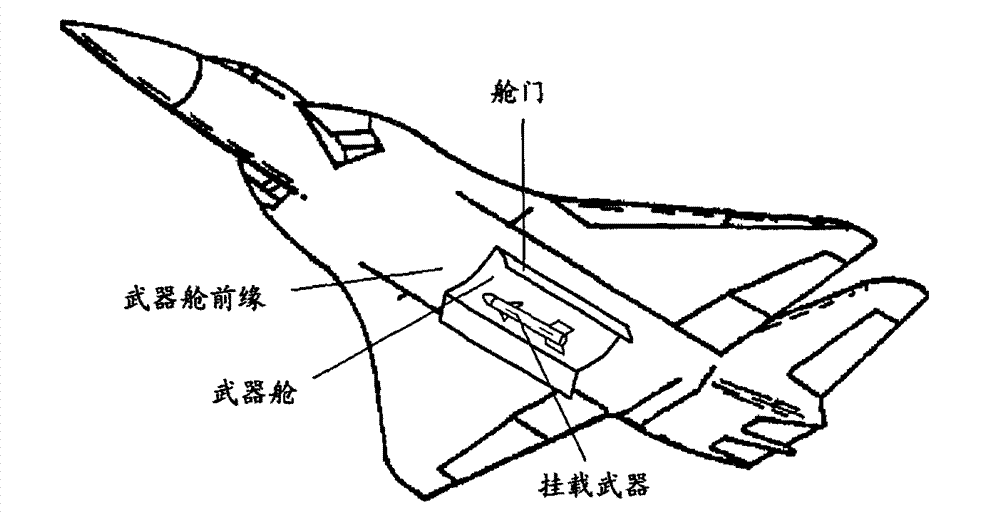

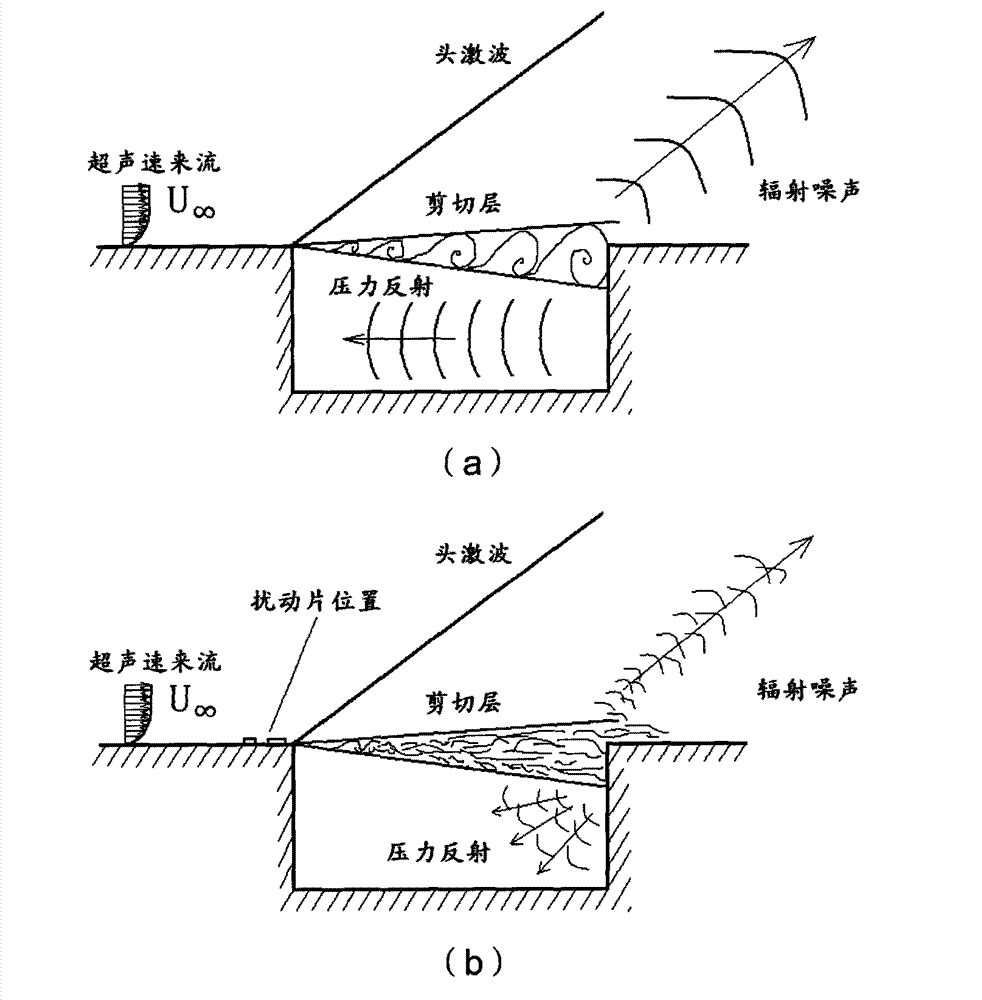

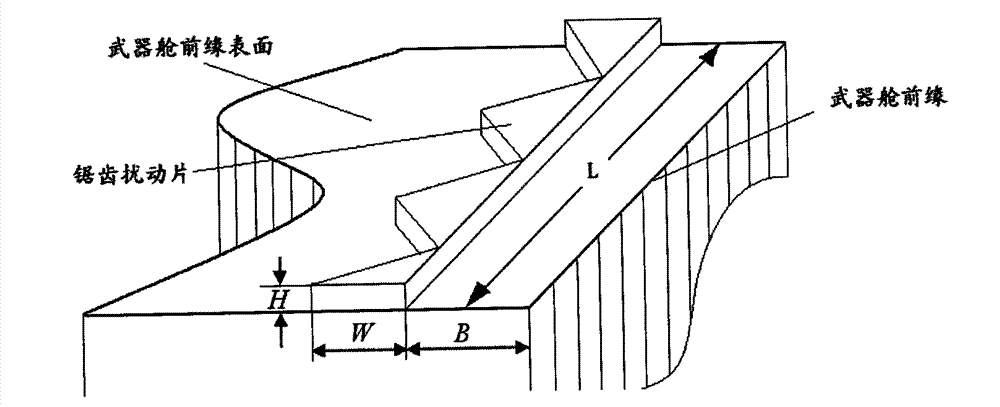

Noise reduction method for weapon cabin of supersonic aircraft on basis of turbulent flow on front-edge surface

ActiveCN102862676AReduced pressure for severe self-sustaining oscillation problemsAvoid disturbanceAir-flow influencersSustained oscillationsFundamental frequency

A noise reduction method for a weapon cabin of a supersonic aircraft on the basis of turbulent flow on a front-edge surface includes steps of (1), acquiring the flight speed, the incoming flow density, the incoming flow temperature, an incoming flow viscosity coefficient and the thickness of a boundary layer of the front-edge surface of the weapon cabin according to the flight condition of the supersonic aircraft, and computing an incoming Reynolds number on the basis of the thickness of the boundary layer of the front-edge surface of the weapon cabin; (2), selecting a fundamental-frequency disturbance sheet; (3), computing the ratio of the length to the depth of the supersonic aircraft according to the length, the depth and the width of the weapon cabin of the supersonic aircraft, reducing the thickness H of the fundamental-frequency disturbance sheet by 10-20% if the ratio is larger than 4, or increasing the thickness H of the fundamental-frequency disturbance sheet by 10-20% if the ratio is not larger than 4; and (4), fixing the fundamental-frequency disturbance sheet on the supersonic aircraft to complete noise reduction for the weapon cabin of the supersonic aircraft on the basis of the turbulent flow on the front-edge surface. The noise reduction method has the advantage that the problem of severe self-sustained oscillation of pressure of the inside of the cabin after the buried weapon cabin is opened during supersonic flight of the supersonic aircraft can be effectively solved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Environment protection type multifunction architecture adhesion agent and method for producing the same

ActiveCN101220250AImprove performancePromote degradationMonocarboxylic acid ester polymer adhesivesUnsaturated alcohol polymer adhesivesPolyvinyl alcoholAdhesive

The invention discloses an environment friendly and multi-functional building adhesive and the preparation method thereof, and is characterized in that: 4 to 5 percent of polyvinyl alcohol and 42 to 59.2 percent of water are taken by weight percentage, stired and heated to 80 plus or minus 2 DEG C until the polyvinyl alcohol is dissolved completely, then cooled to 70 plus or minus 2 DEG C, added with 10 to 20 percent of vinyl acetate-ethylene co-polymer emulsion and 0.4 to 0.6 percent of emulsifying agent; then the mixture is heated to 70 plus or minus 2 DEG C, added with 25 to 30 percent of winyl acetic ester and 0.5 to 1.5 percent of acrylic monomer, and further added with part of 0.25 to 0.3 percent of evocating agent which accounts for 35 to 45 percent of total amount of the evocating agent to carry out emulsion polymerization; the temperature is maintained at 70 plus or minus 2 DEG C, then the residual evocating agent which accounts for 55 to 65 percent of total amount thereof is added; the temperature is kept for 1-2 hours until no nomoner reflows, then the temperature raises to 90 plus or minus 2 DEG C, kept for 30 to 40 minutes, and finally reduced to 50 plus or minus 2 DEG C; the PH value is adjusted and the product is finished after stirring evenly. The invention has the advantages of steady performance, low viscosity coefficient, convenient operation, good stickiness property, good elasticity property, excellent film forming and water-proof property, high drying speed, uneasy going moldy and high biological degradability.

Owner:YANJIAN GRP CO LTD

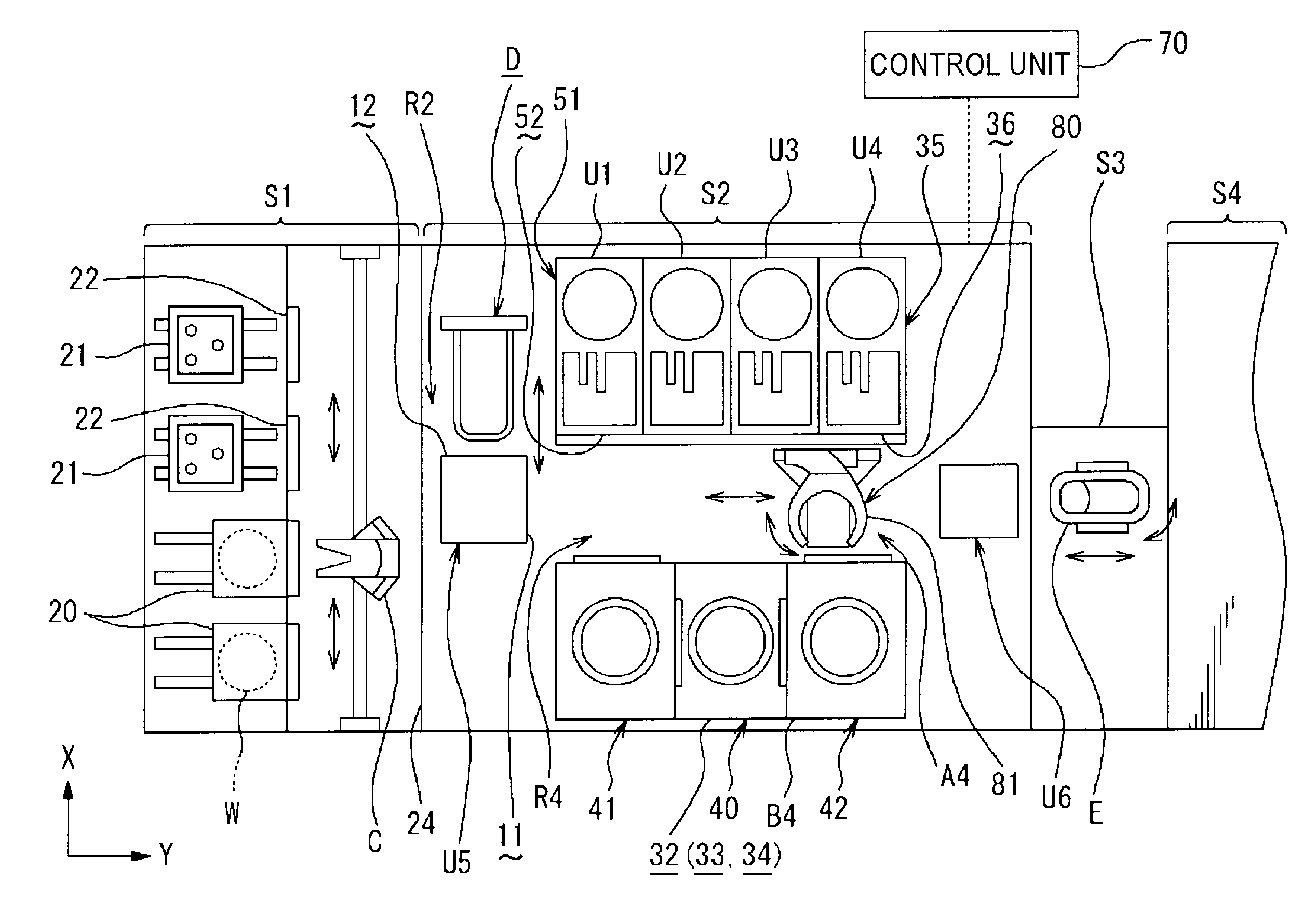

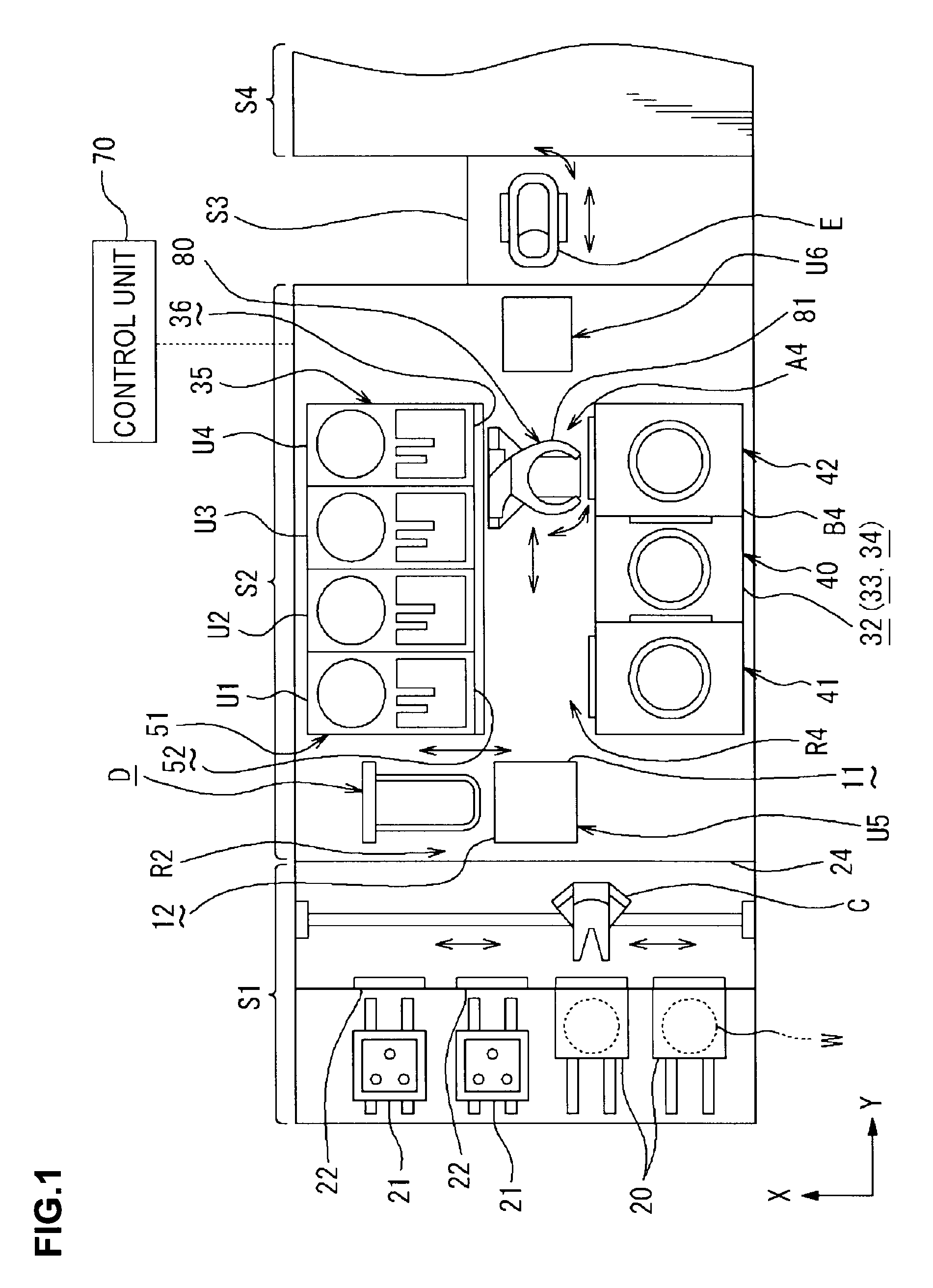

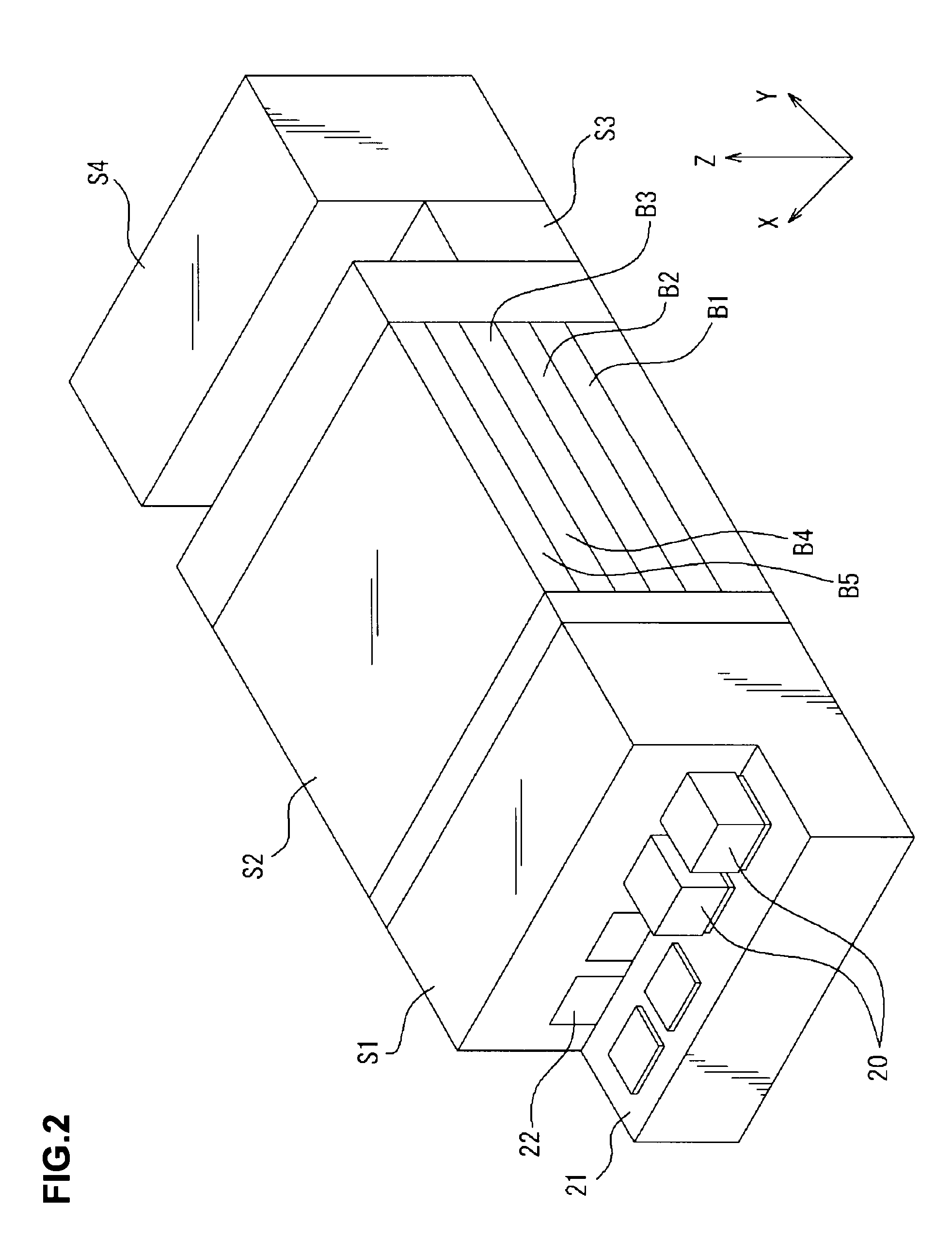

Substrate processing apparatus

ActiveUS20090013932A1Reducing apparatus operation rateImprove performanceLiquid surface applicatorsSpraying apparatusEngineeringGas supply

A substrate processing apparatus of the present invention includes a holding means for rotatably holding a substrate; a coating solution supply nozzle for supplying a coating solution onto a front surface of the substrate to be processed held by the holding means; a treatment chamber housing the holding means and the coating solution supply nozzle; a cooling means for cooling the substrate before the coating solution is supplied to the substrate, to a predetermined temperature; a heating means for heating the substrate coated with the coating solution to a predetermined temperature; and a transfer means for transferring the substrate between the treatment chamber, the cooling means and the heating means, wherein the treatment chamber, the cooling means and the heating means are partitioned from an ambient air, and wherein at least the treatment chamber is connected to a gas supply mechanism having a supply source of a gas having a kinematic viscosity coefficient higher than that of air and kept at a predetermined concentration of the gas.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com