Pipe type heat exchanger with heat exchange shell intensified by ultrasonic wave

A shell-and-tube heat exchanger and enhanced heat transfer technology, applied in the field of industrial heat transfer and energy saving, can solve the problems of increased energy consumption of power equipment, increased fluid flow resistance, etc., to achieve enhanced heat transfer effect, reduced energy consumption, and significant energy saving effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

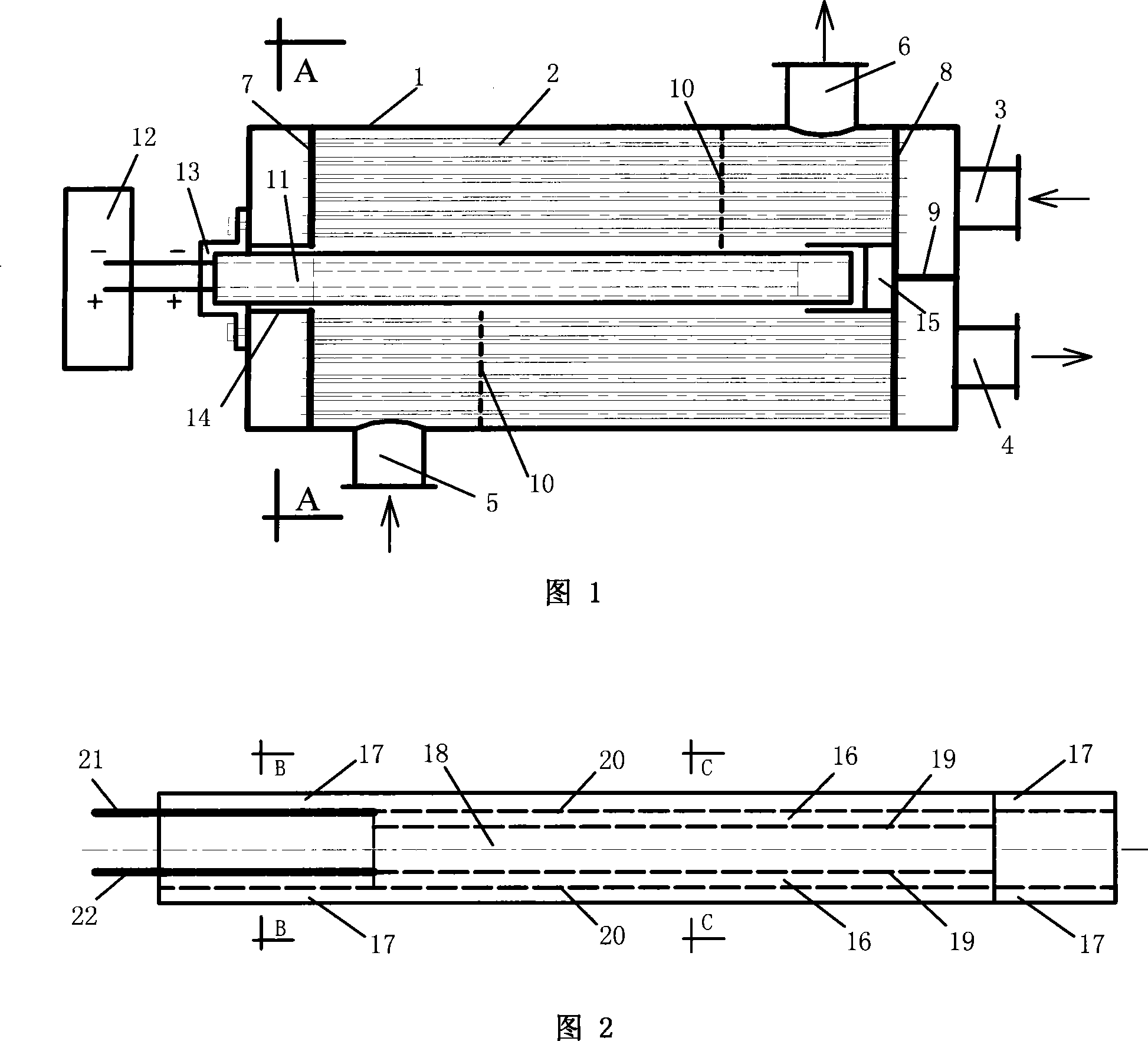

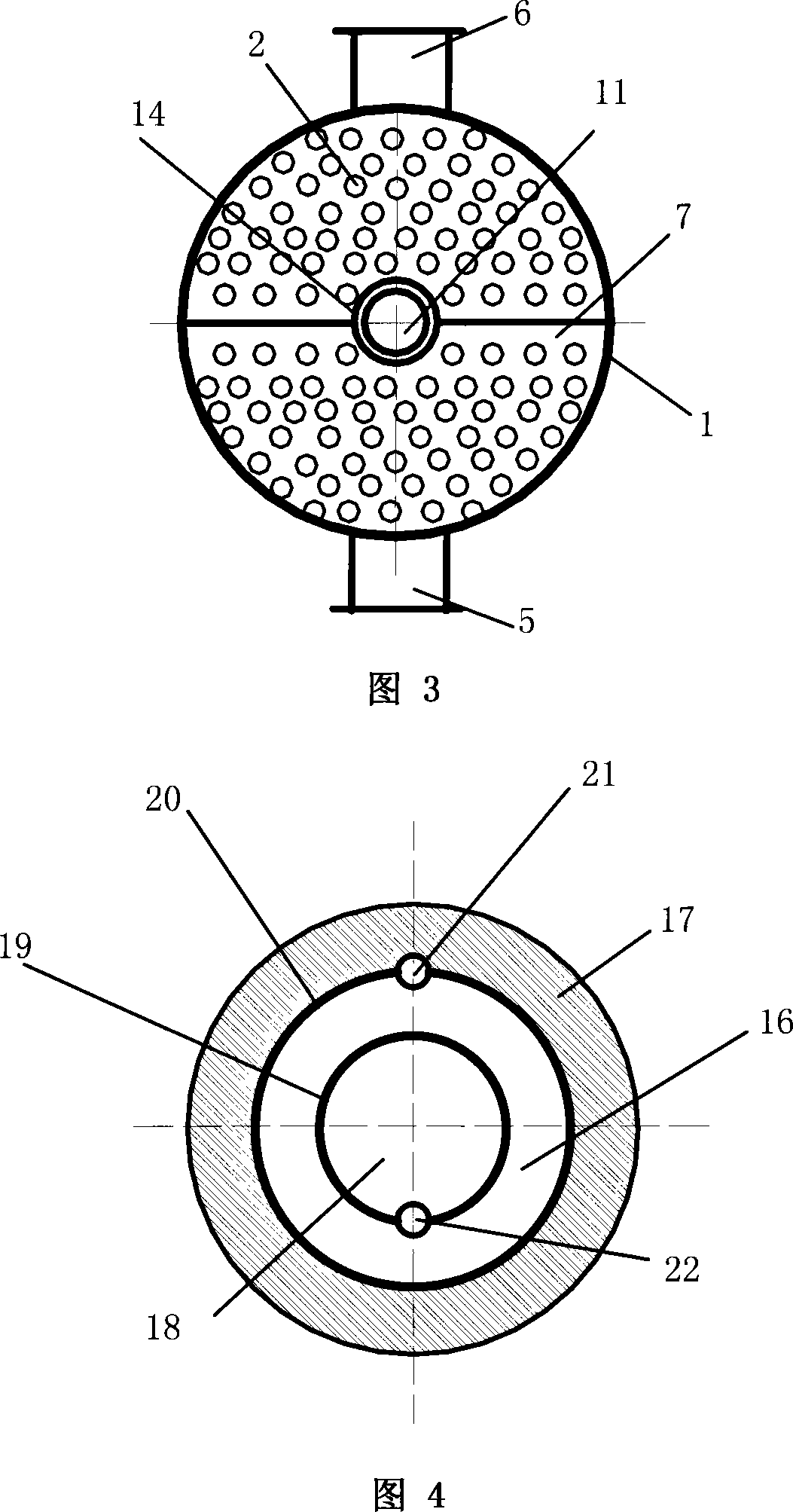

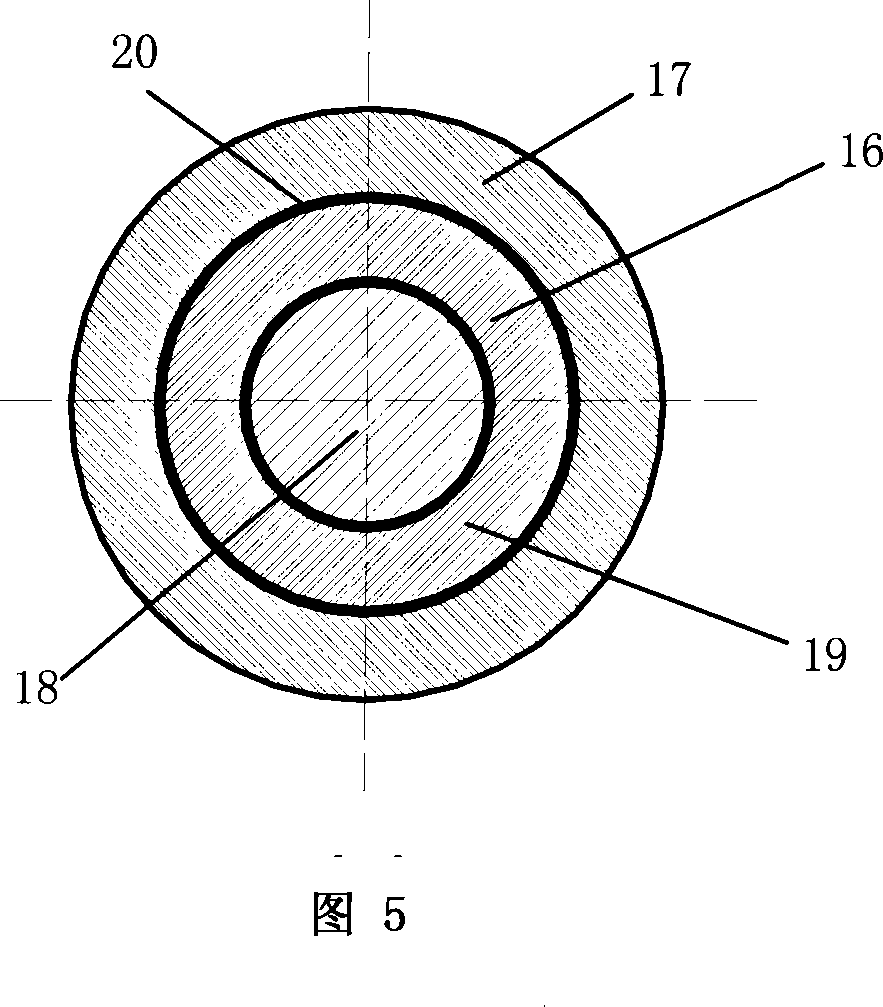

[0013] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, the invention of this embodiment includes a shell 1, a heat exchange tube 2, a tube side inlet tube 3, a tube side outlet tube 4, a shell side inlet tube 5, a shell side Cheng outlet pipe 6, first tube plate 7, second tube plate 8, partition plate 9, baffle plate 10, power ultrasonic transducer 11, power ultrasonic generator 12, sealing cover plate 13, circular sleeve 14, round hole Support 15, wherein the power ultrasonic transducer 11 includes ultrasonic vibration wafer 16, ultrasonic sealing radiation sleeve 17, fastening rod 18, positive electrode thin copper sheet 19, negative electrode thin copper sheet 20, negative electrode lead 21, positive electrode lead 22. The shell 1 is a closed cylindrical shell placed horizontally. The tube-side inlet pipe 3 and the tube-side outlet pipe 4 are located at the upper and lower parts of the right end face of the shell 1 respectively; The size is equal to the size of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com