Liquid crystal composition with high optical anisotropy and liquid crystal display element

A liquid crystal composition and compound technology, applied in optics, liquid crystal materials, nonlinear optics, etc., can solve problems such as unsuitable 3D display mode, high viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

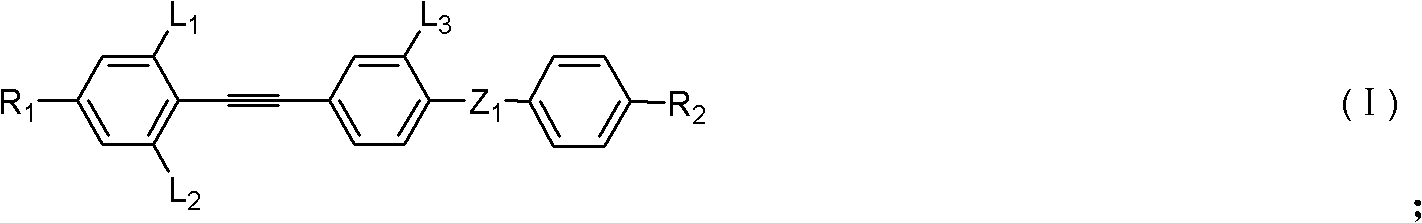

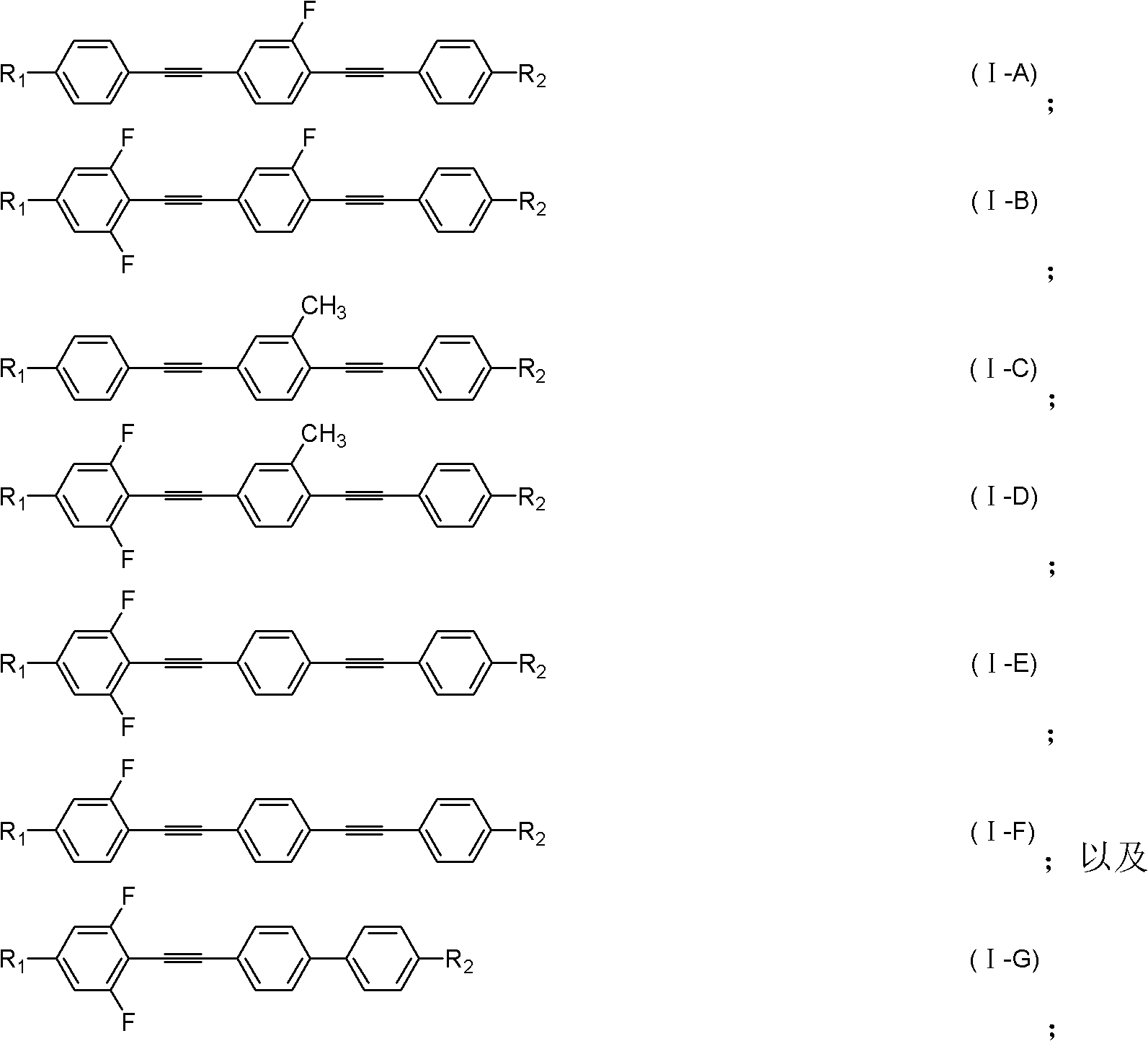

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0093] The specific synthetic steps of the prepared compound II-E-3 are as follows:

[0094]

[0095] 1) Synthesis of lithium diisopropylamide (LDA)

[0096] Add 115mL of diisopropylamine and 100mL of tetrahydrofuran (THF) into a 1000mL three-necked flask, under nitrogen protection, and add 320mL of n-butyllithium (n-BuLi, 2.4mol / L) dropwise under temperature control at 0°C to -20°C. Stir at ~-20°C for 1 hour to prepare LDA.

[0097] 2) Synthesis of trifluorovinyl zinc chloride

[0098]

[0099] Add 53g of anhydrous zinc chloride and 100mL THF to a 1000mL three-necked flask, protect it with nitrogen, cool down to -70°C, inject 54g of 1,1,1,2-tetrafluoroethane gas, and control the temperature from -50°C to -70°C Slowly inject LDA under the liquid surface through the needle tube, and stir for 2 hours after the addition, to obtain trifluorovinyl zinc chloride.

[0100] 3) compound of synthetic formula a

[0101]

[0102] The compound of formula b (45 g produced by ou...

Embodiment 1

[0127] Mix the following structural monomers with the matrix liquid crystal composition (Table 2) at a weight ratio of 1:9, the two have good miscibility and can be mixed well:

[0128]

[0129] The extrapolation performance of the structural monomer is as follows:

[0130] Δn: 0.43

Embodiment 2

[0132] Mix the following structural monomers with the matrix liquid crystal composition (Table 2) at a weight ratio of 1:9, the two have good miscibility and can be mixed well:

[0133]

[0134] The extrapolation performance of the structural monomer is as follows:

[0135] Δn: 0.47

[0136] Table 2 lists the components, proportions and performance test results of the above-mentioned matrix liquid crystal composition filled between the two substrates of the liquid crystal display, so as to compare the performance with the liquid crystal composition of the present invention.

[0137] Table 2 Matrix liquid crystal composition formula and its test performance

[0138]

[0139] Composition Control Example 1 (CN101712874):

[0140] Table 3 lists the components and proportions of the liquid crystal composition of Comparative Example 1 and the performance test results of filling between the two substrates of the liquid crystal display, so as to compare the performance with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com