Ladle roughing slag detection, control method and system

A detection method and detection system technology, which are applied in general control systems, control/regulation systems, program control, etc., can solve the problems of the influence of vibration detection accuracy, difficulty in meeting actual needs, and the influence of system vibration characteristics. The effect of high accuracy and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

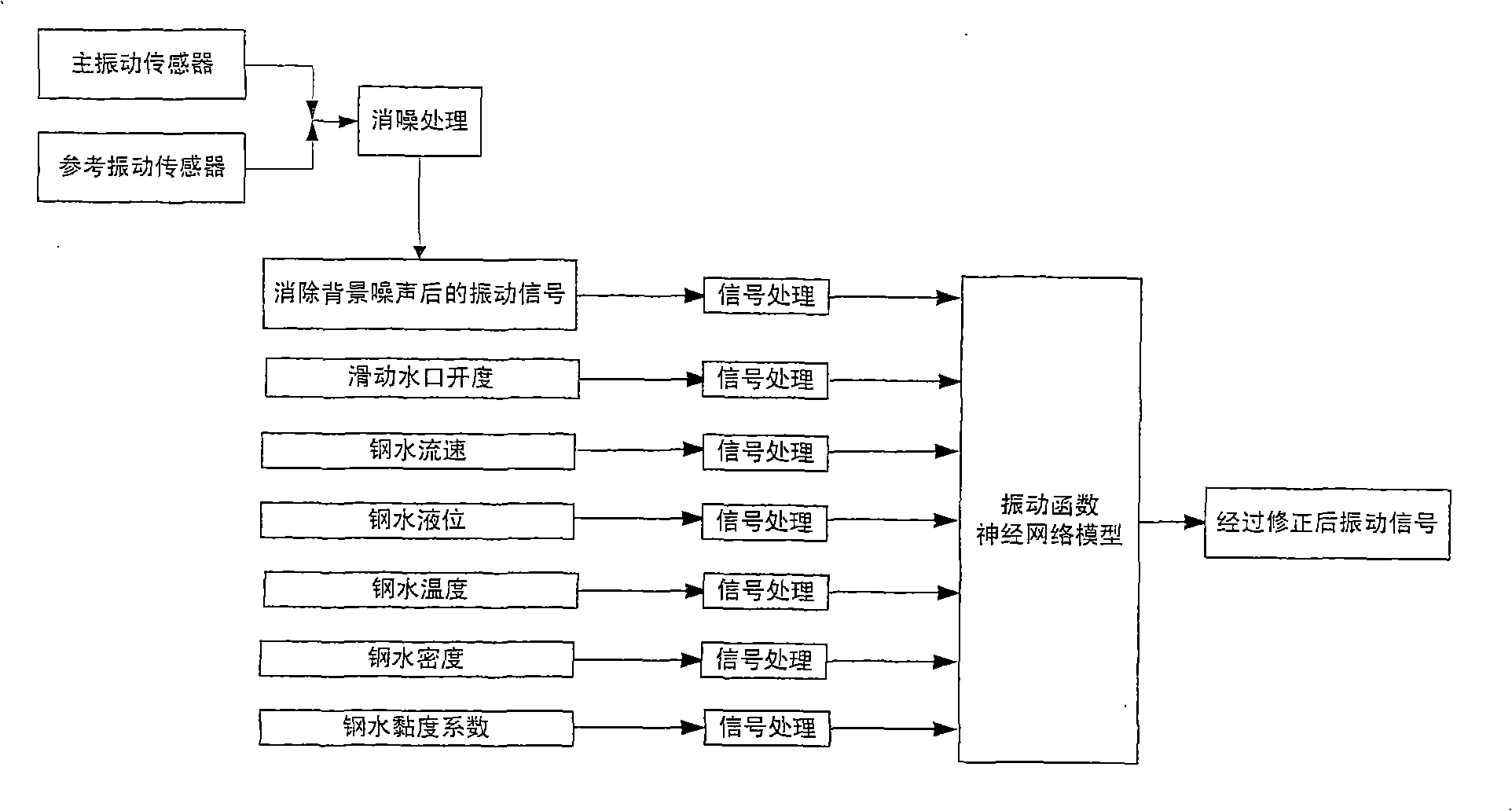

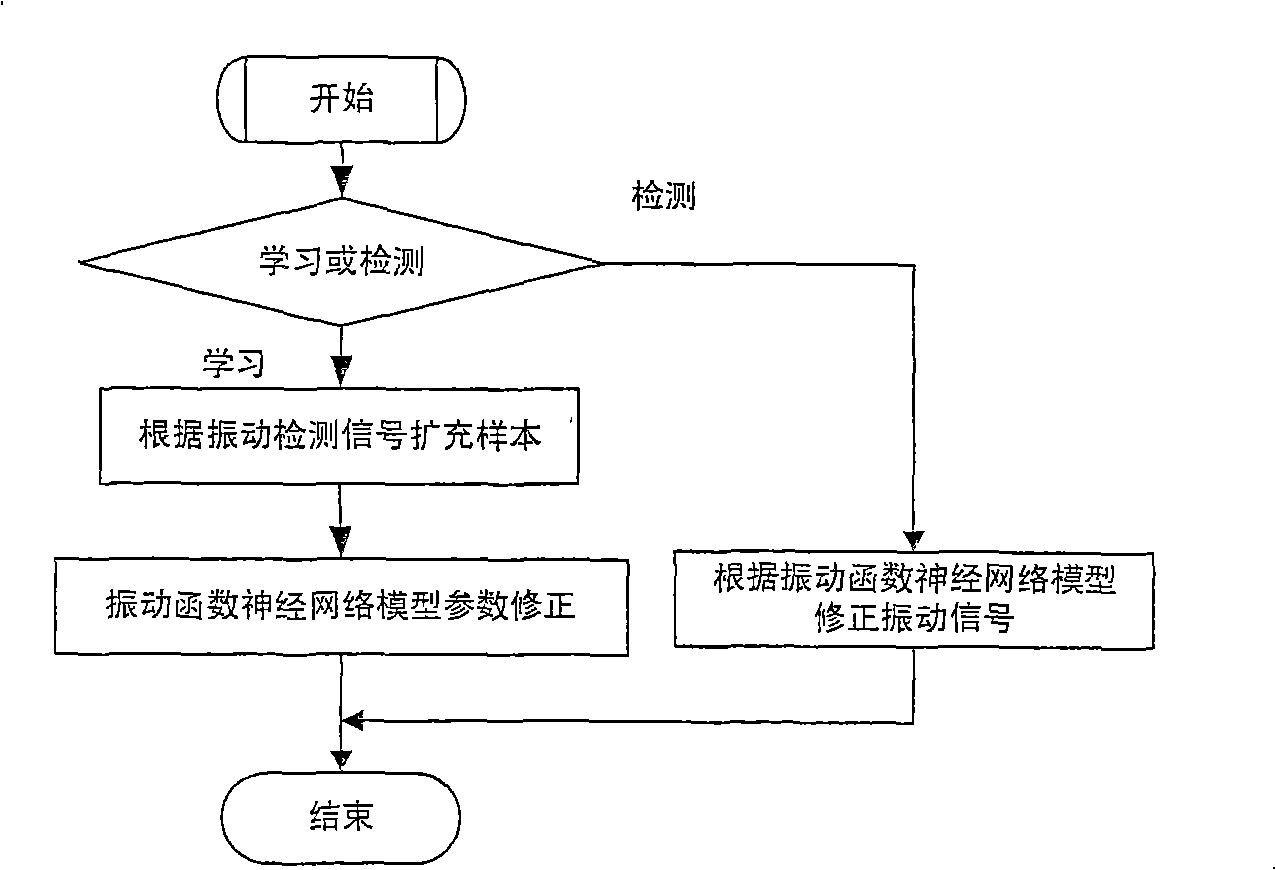

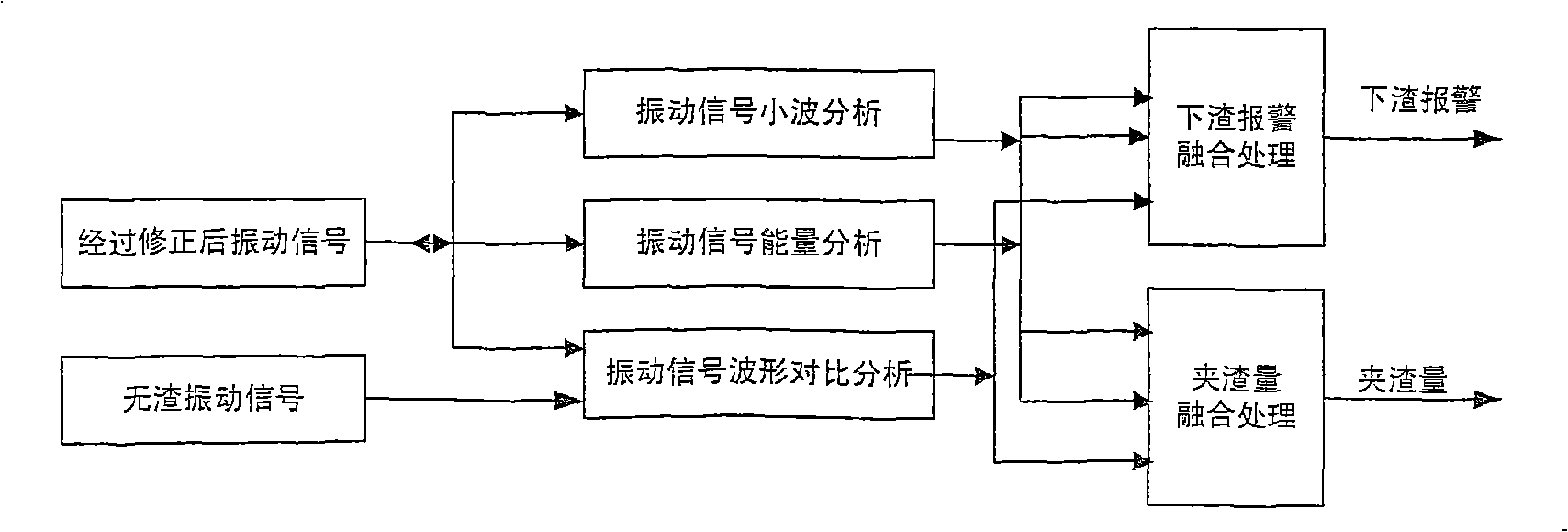

[0052] The vibration sensor of the ladle slag detection system adopts the speed sensor model PCB 640B01, the ICP power supply adopts the SCXI-1530 of NI Company, the detection station adopts the PXI computer composed of NI Company’s PXI-8186 P4 and PXI-1042Q, and the data acquisition selects NI Company PXI-6122 data acquisition card. Based on data communication, the opening of the sliding gate, the flow rate of molten steel, the liquid level of molten steel, and the weight of the ladle are obtained. Among them, the density and viscosity of molten steel can also be directly input to the detection station. The detection system has data communication function to output slag lowering alarm signal and slag inclusion amount signal. The slag lowering station control software is based on LabView8.0 software, which realizes human-computer interaction, including operation and parameter modification; realizes comprehensive processing of data; realizes storage and query of historical data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com