Patents

Literature

56results about How to "Avoid Vibration Interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ladle roughing slag detection, control method and system

InactiveCN101251749AReduce investmentReduce maintenance costsProgramme controlMelt-holding vesselsAutomatic controlSlag

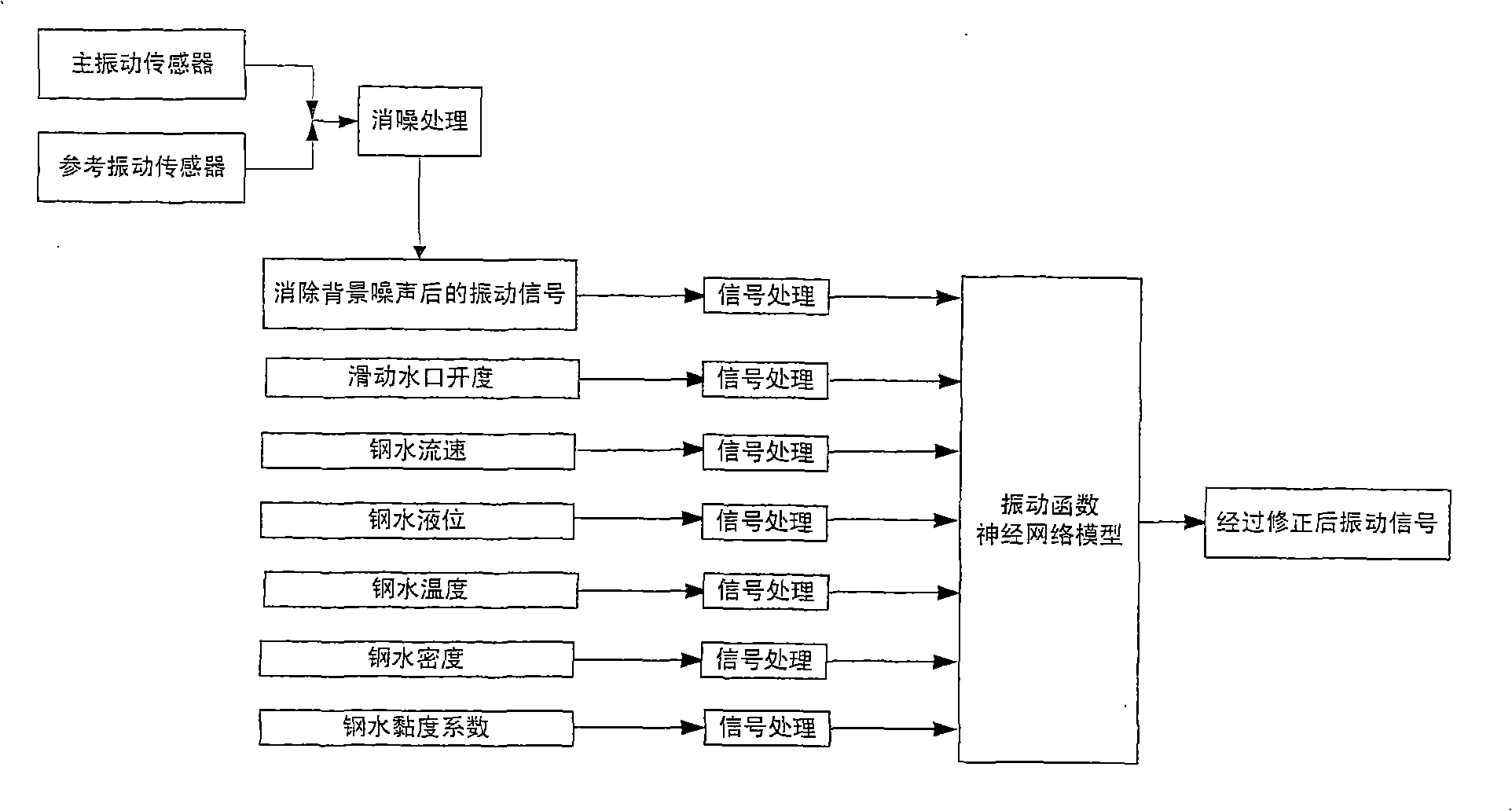

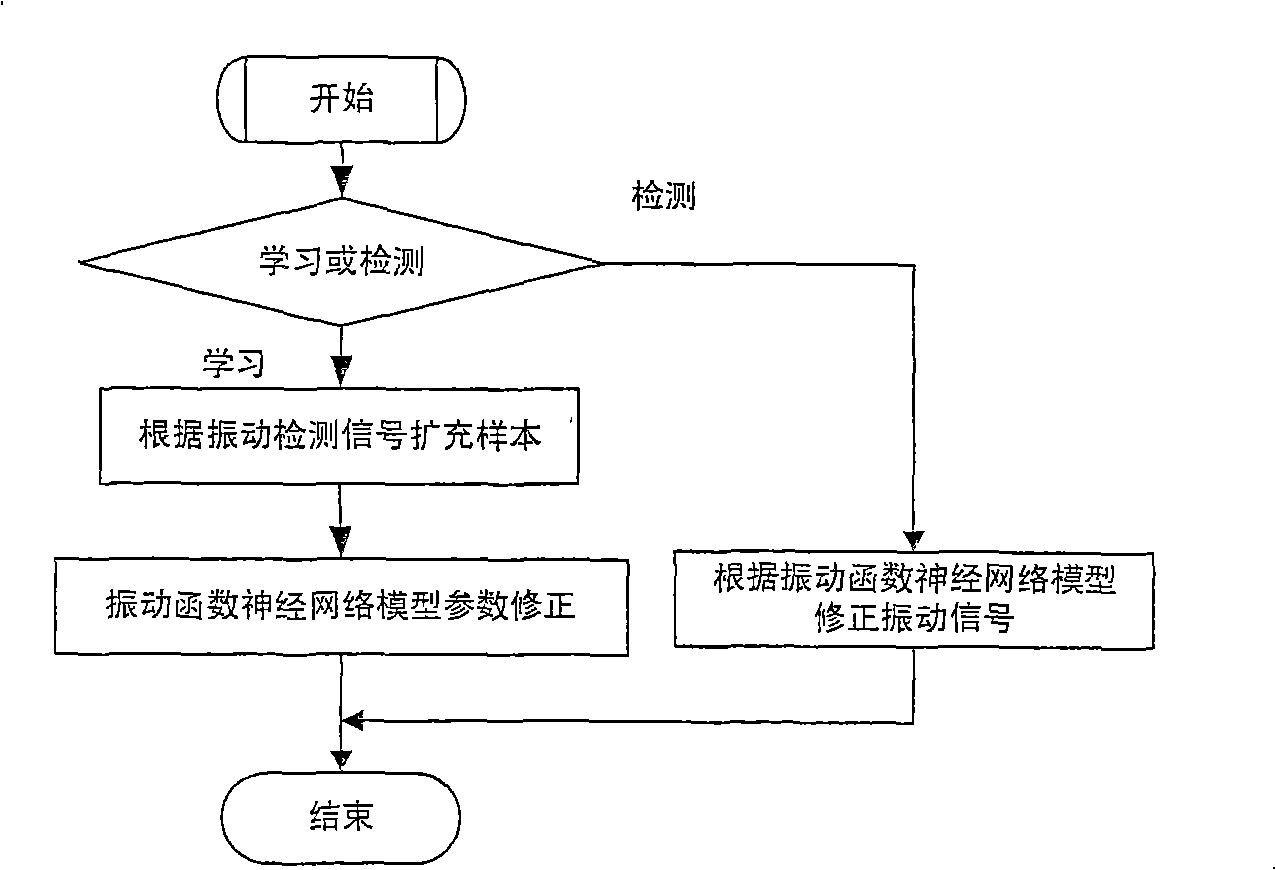

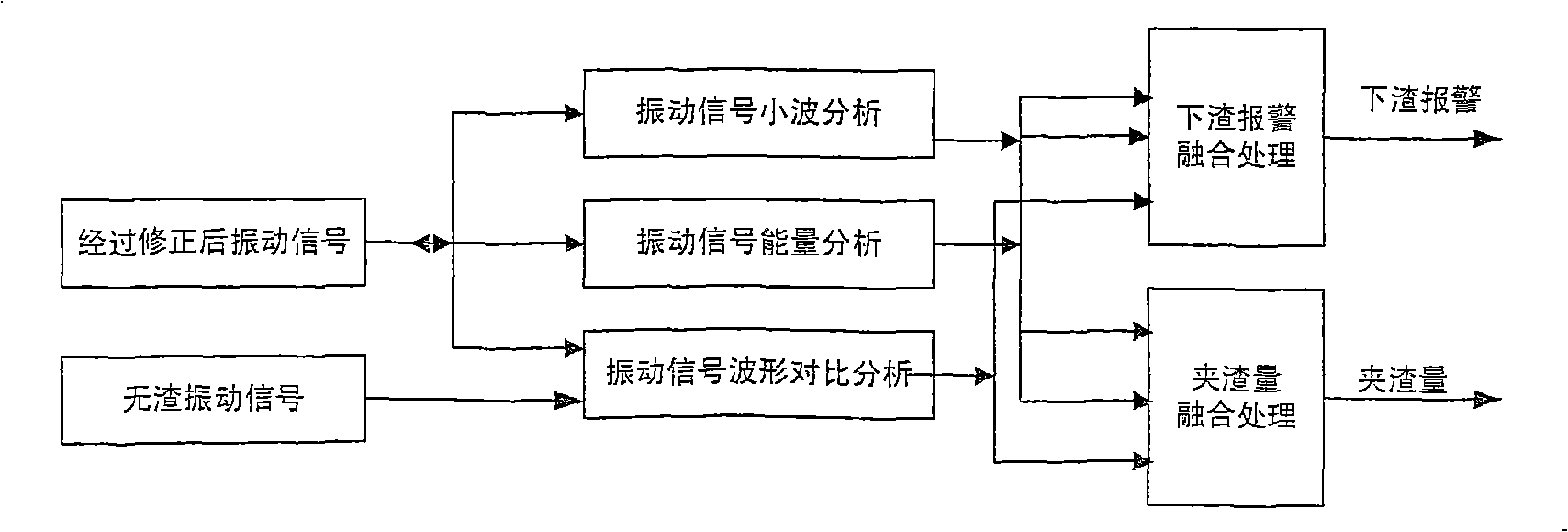

The present invention discloses a detection / control method and a system for steel ladle roughing slag. The method comprises contents in two aspects as follows: according to vibration signals, molten steel flow velocity, molten steel liquid level, slide gate opening degree, molten steel density and molten steel viscosity coefficient, the detection of steel ladle roughing slag state in casting process is realized, so as to get the roughing slag state of the steel ladle, as well as roughing slag amount; according to the detected steel ladle roughing slag state, a slide gate is automatically controlled to be closed with the preset roughing slag sensitivity. The method improves the instability and inaccuracy of adopting single vibration signal for detection in the prior art, improves the precision and reliability of roughing slag detection systems, can close the slide gate in time, prevent excessive steel ladle roughing slag and improve molten steel purity through automatic control, and improves molten steel yielding rate on the premise of guaranteeing molten steel quality. The system is low in cost, high in reliability and low in maintenance cost, which is extensively applied to metallurgical industry.

Owner:SHAANXI AIBEIER ELECTRIC POWER EQUIP

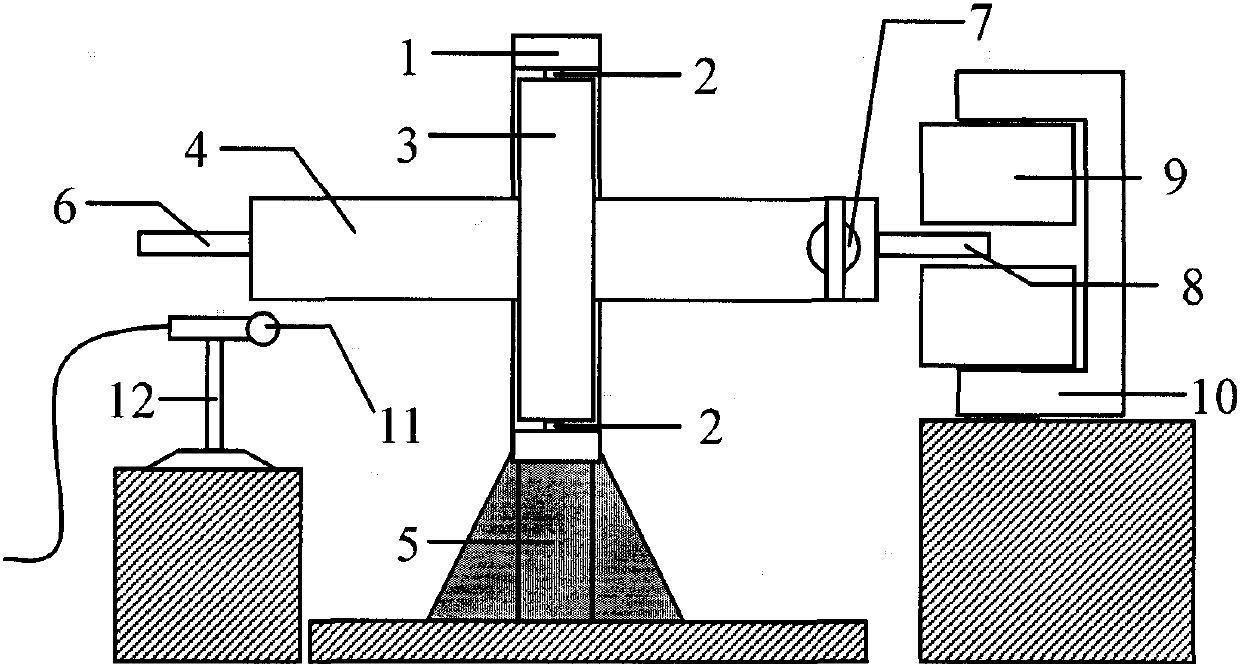

Reynolds test instrument

InactiveCN101051427AAvoid Vibration InterferenceImprove presentationEducational modelsEngineeringPermeation

The present invention discloses a Reynolds experiment instrument. It is characterized by that in the constant pressure zone of its constant pressure water tank a permeation cover is set, said permeation cover can be used for covering upper portion of water inlet of experiment tube, the space covered by said permeation cover is formed into a water-stabilizing zone, and the water body in the water-stabilizing zone of said experiment instrument can not be interfered by water of water inlet tube.

Owner:SOUTHWEST JIAOTONG UNIV

Agitator tank

InactiveCN105478027AAvoid damageSmooth rotationRotary stirring mixersTransportation and packagingRubber ringElectric machinery

The invention relates to an agitator tank. The agitator tank comprises an agitator tank body and an agitator motor. The agitator tank body is provided with support legs. The support leg comprises an upper section and a lower section. A damper spring for supporting the upper section is arranged in the lower section. The upper section is provided with a connection ring. An inner ring goes through the connection ring. The inner ring is connected to the connection ring through a rubber ring. A connection pin goes through the inner ring. The upper section is connected to the agitator tank body through the connection pin. A lead inlet / outlet and a tube head are arranged at a compressor. The tube head is provided with a spherical head. A spherical cavity is arranged at the lead inlet / outlet. The tube head is clamped in the spherical cavity through the spherical head and is hinged to the lead inlet / outlet. The tube head is fixedly connected to the lead inlet / outlet through a puller bolt. The agitator tank realizes adjustment of a lead inlet / outlet direction and a less vibration transmitting amount and solves the problem that the existing agitator tank has poor vibration isolation effects.

Owner:JIANGSHAN XIANJIN ELECTRICAL & MECHANICAL TECH SERVICES CO LTD

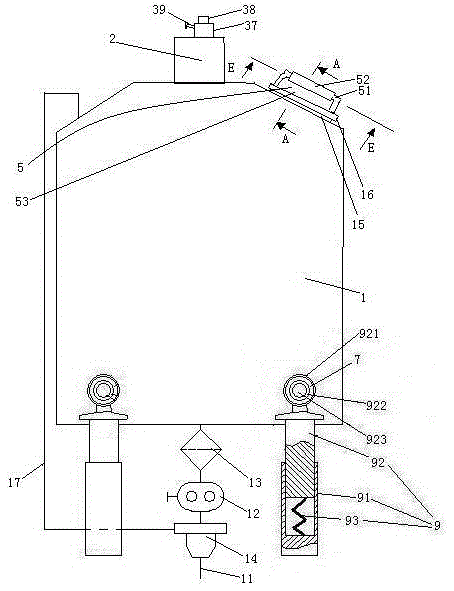

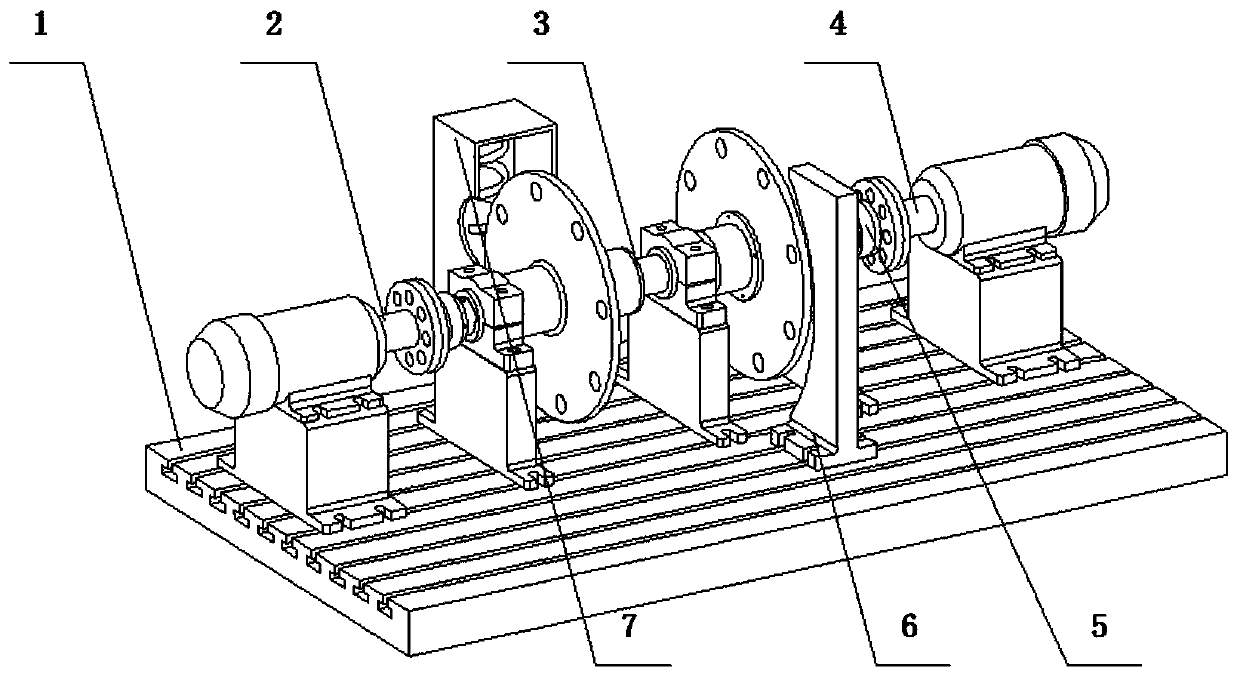

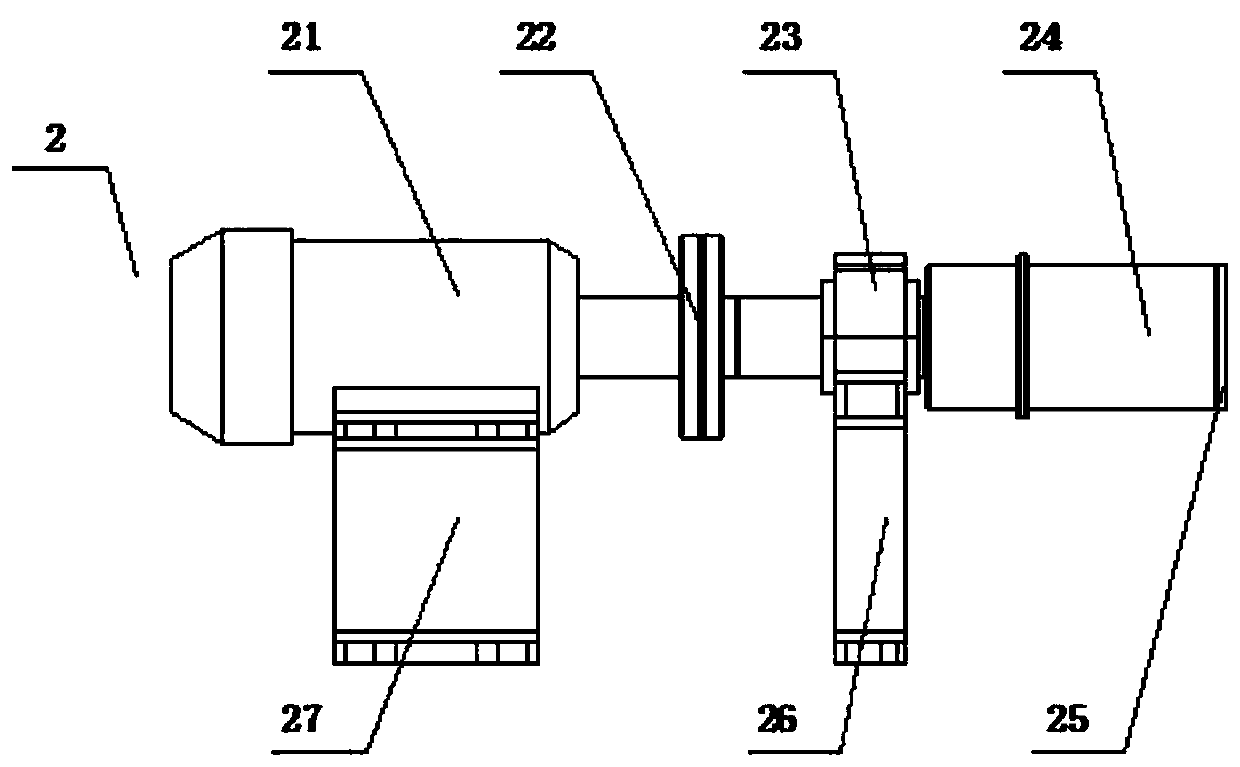

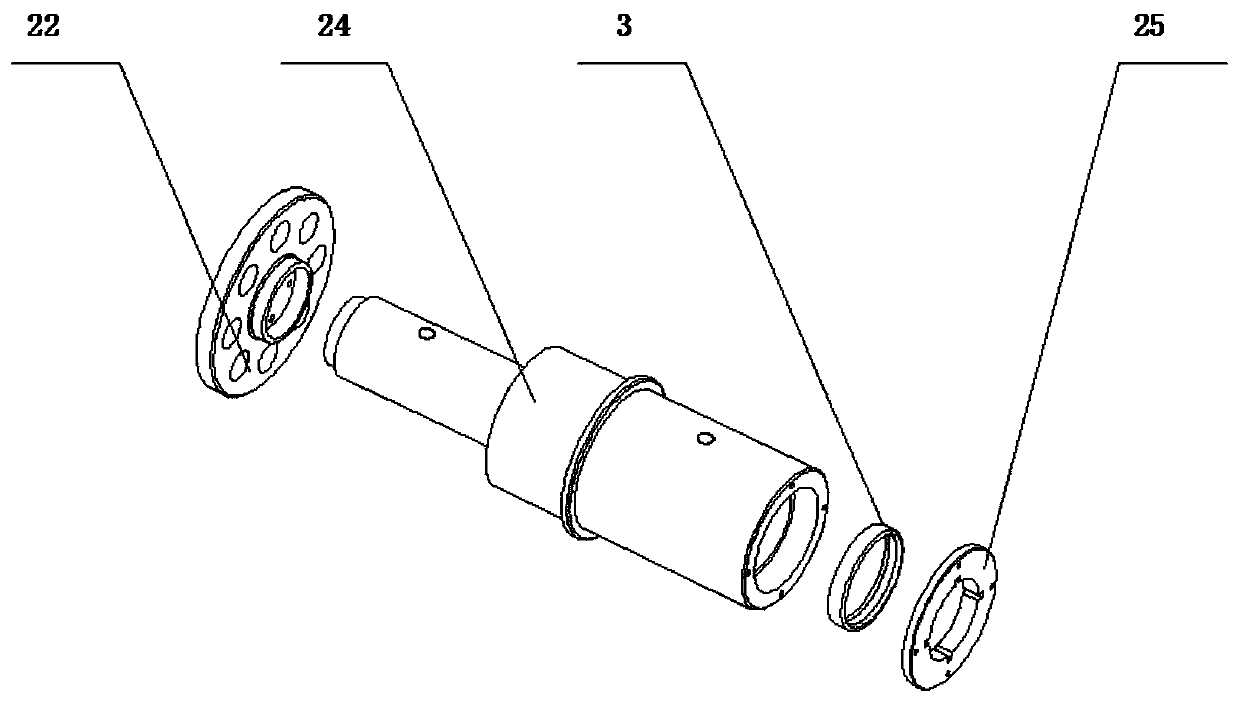

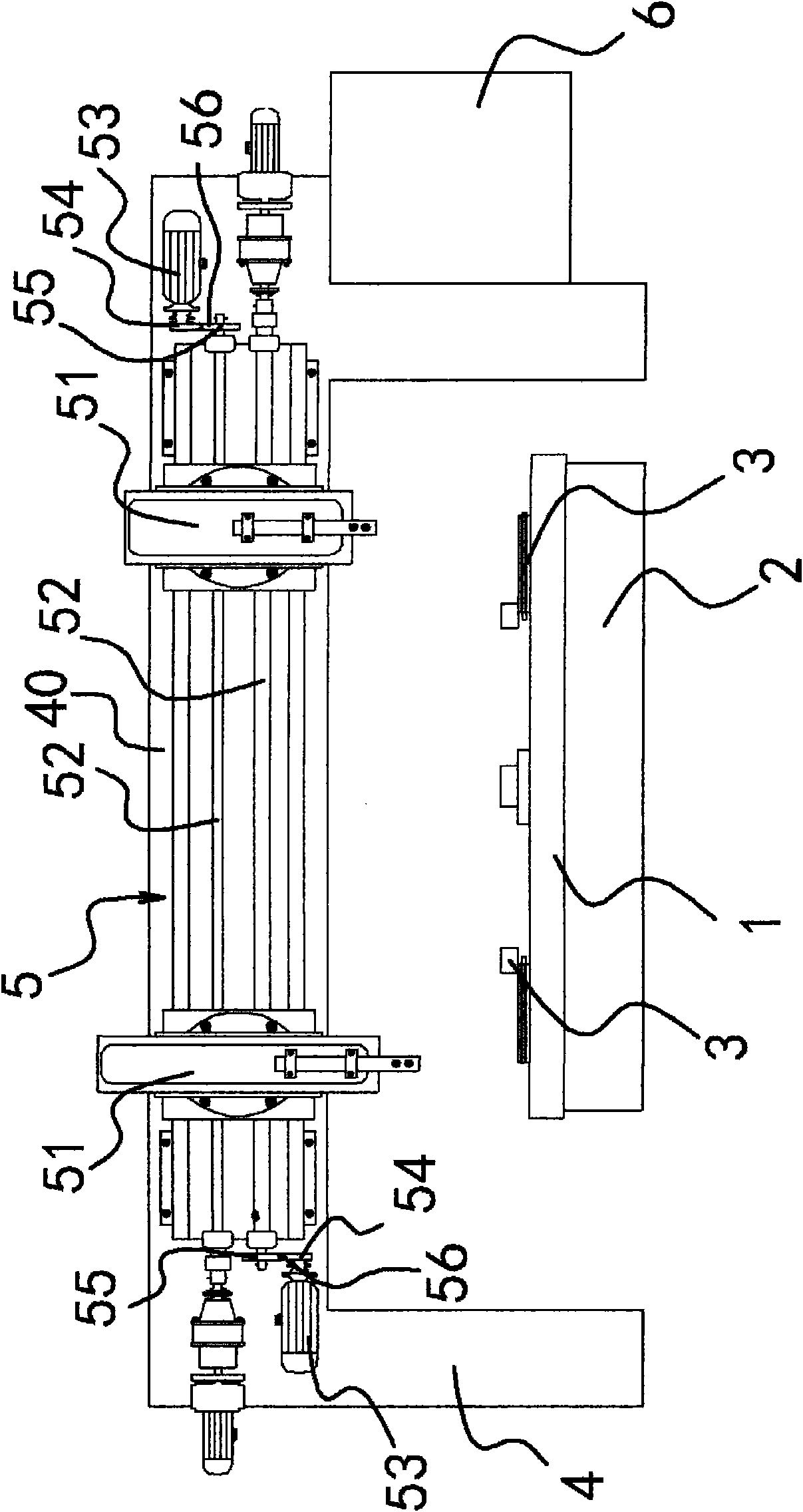

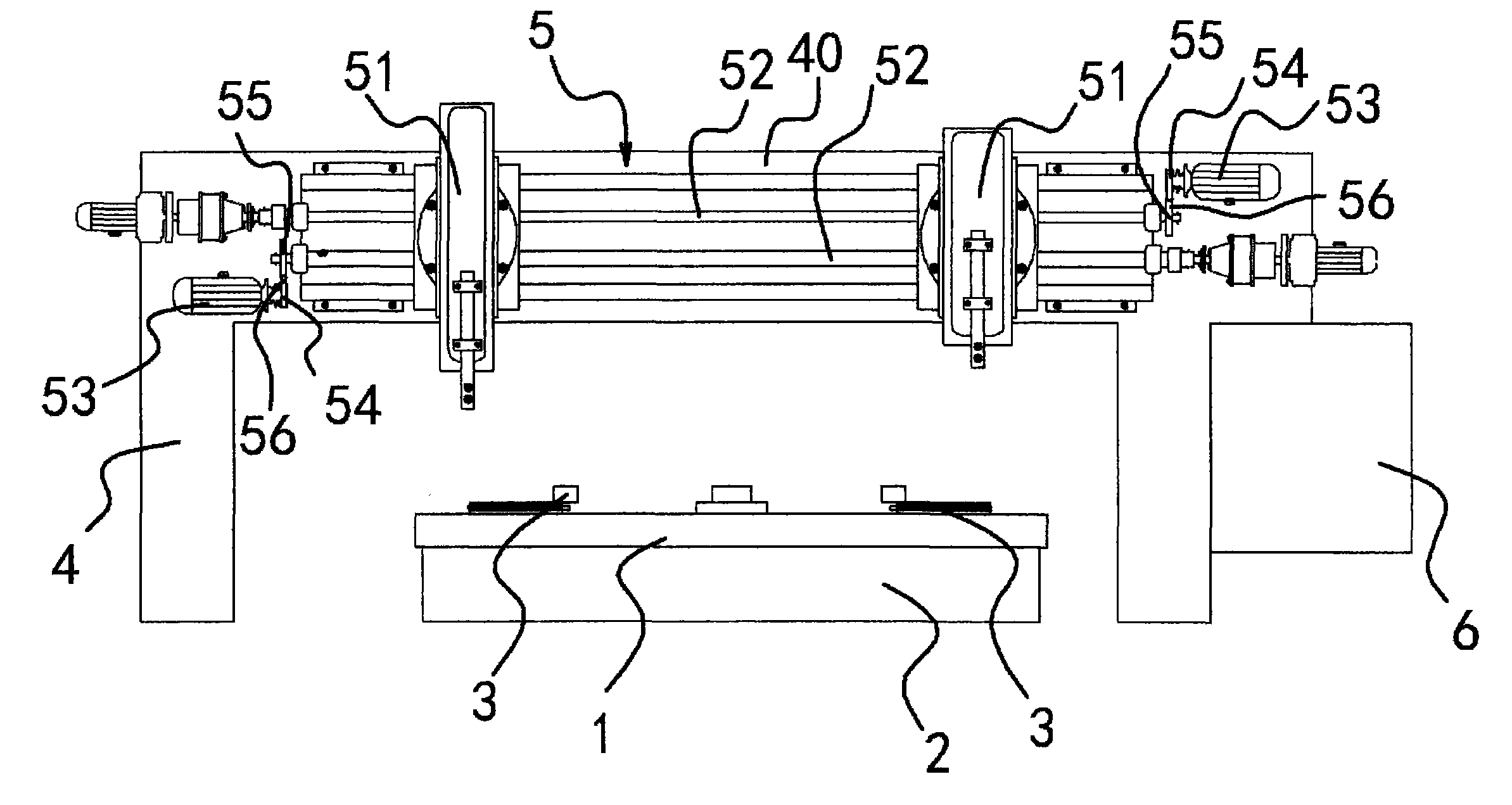

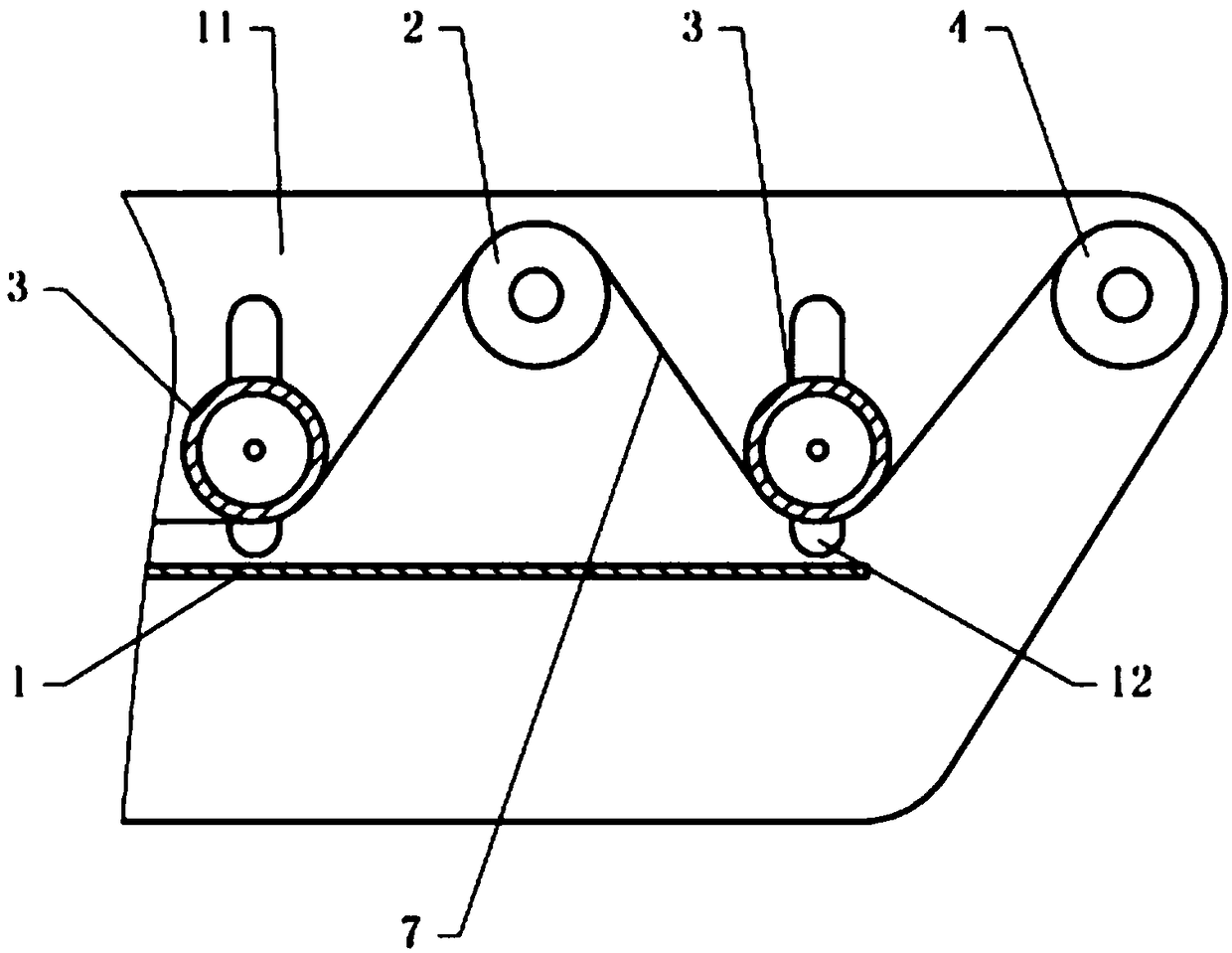

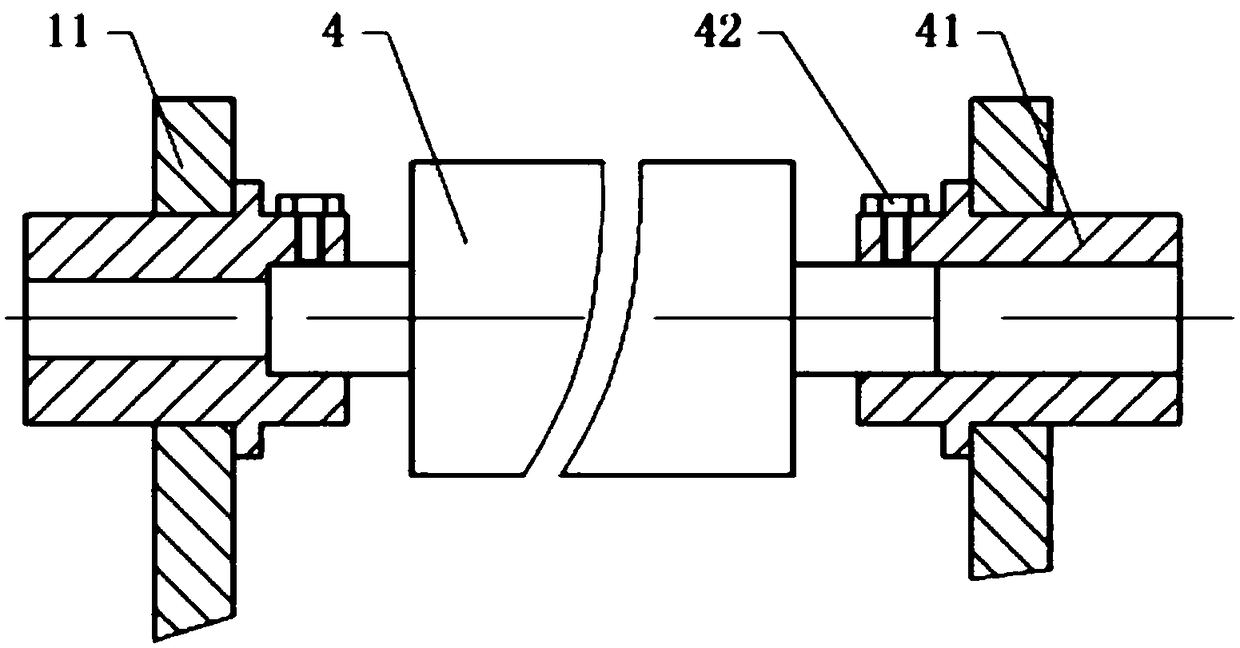

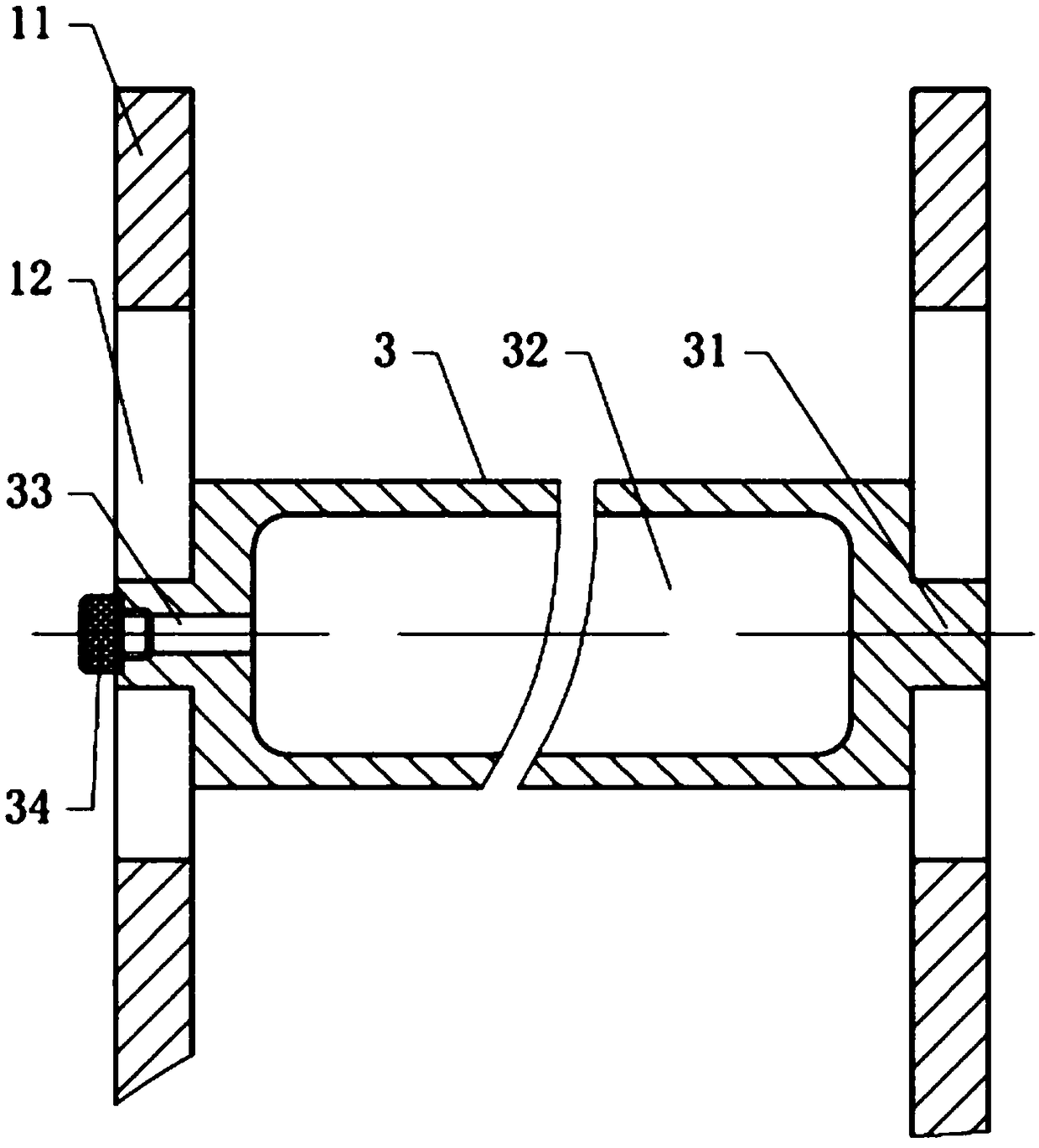

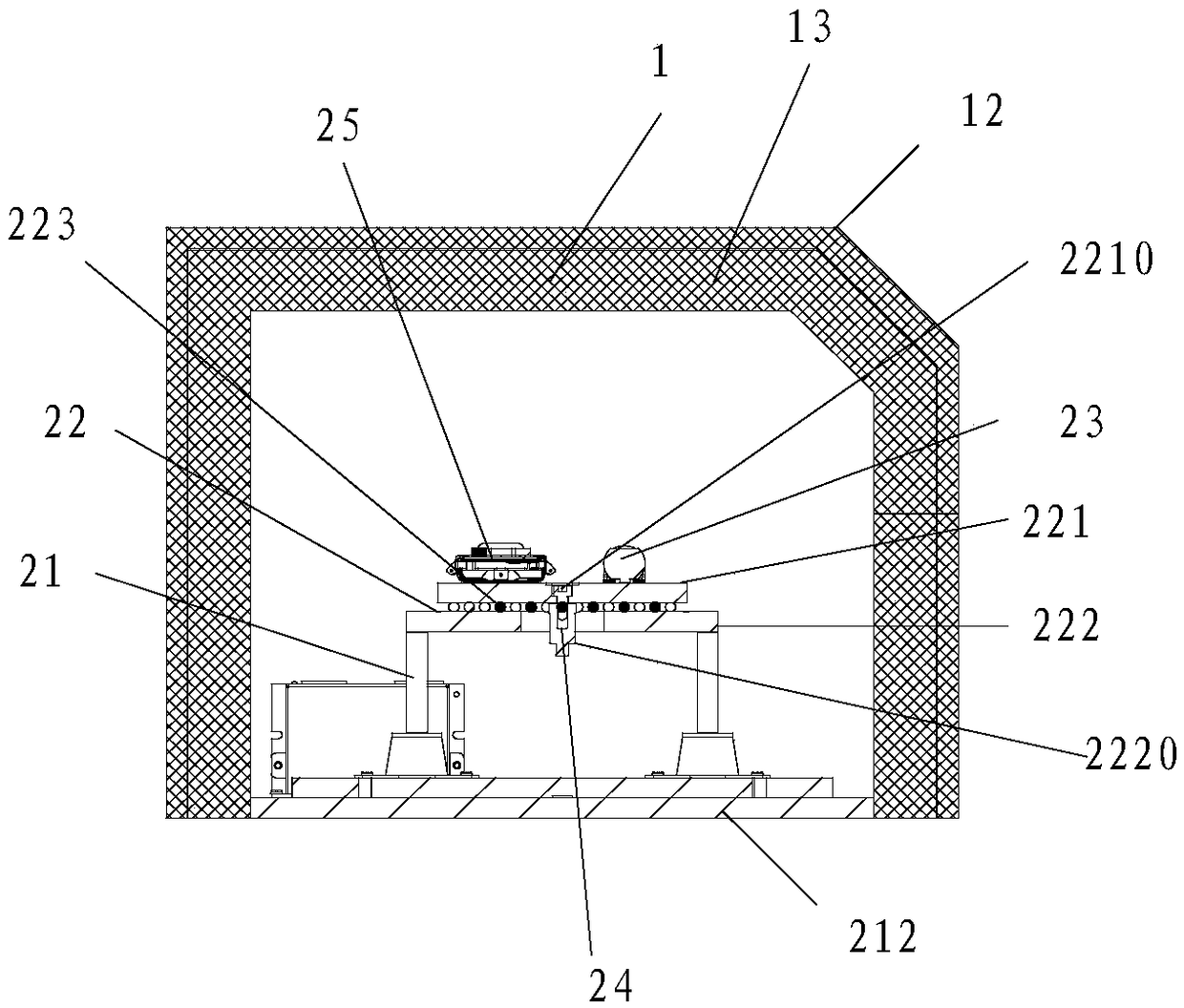

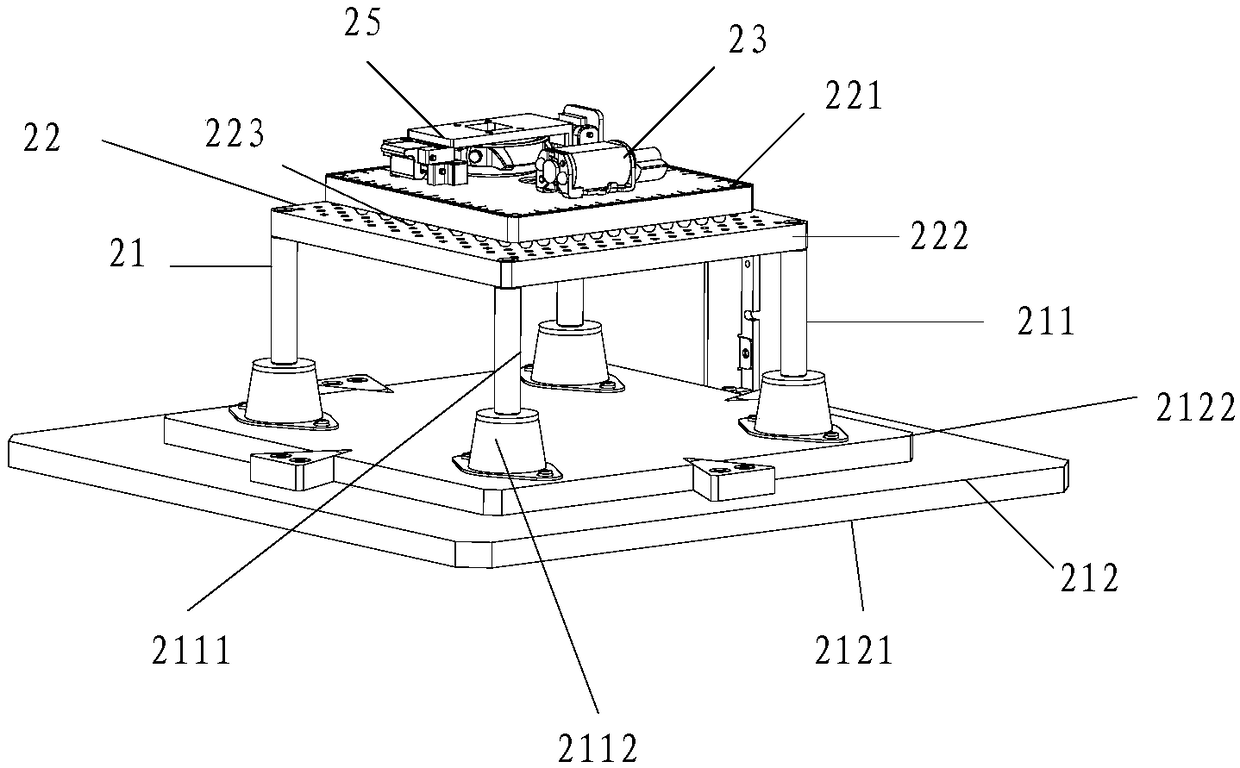

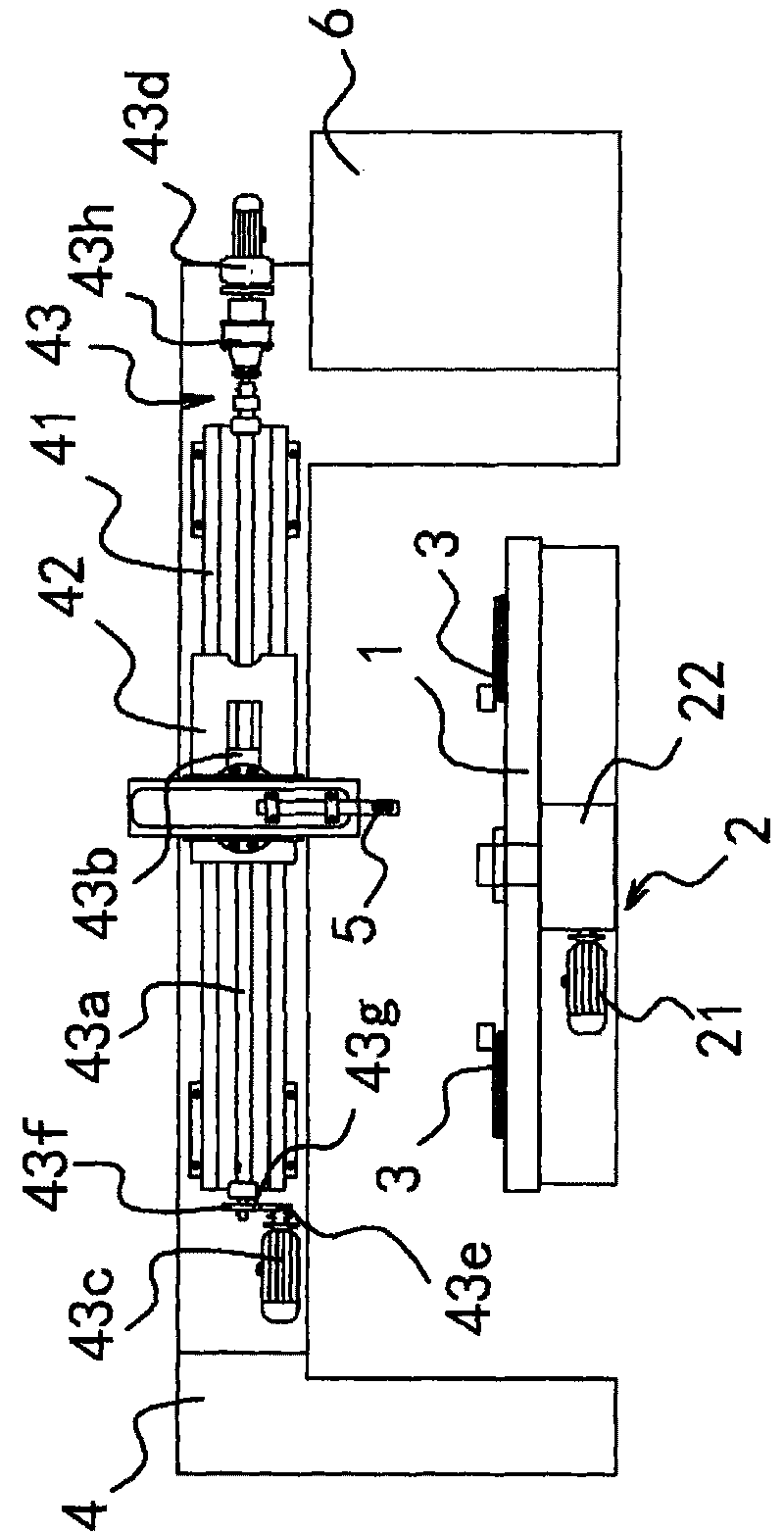

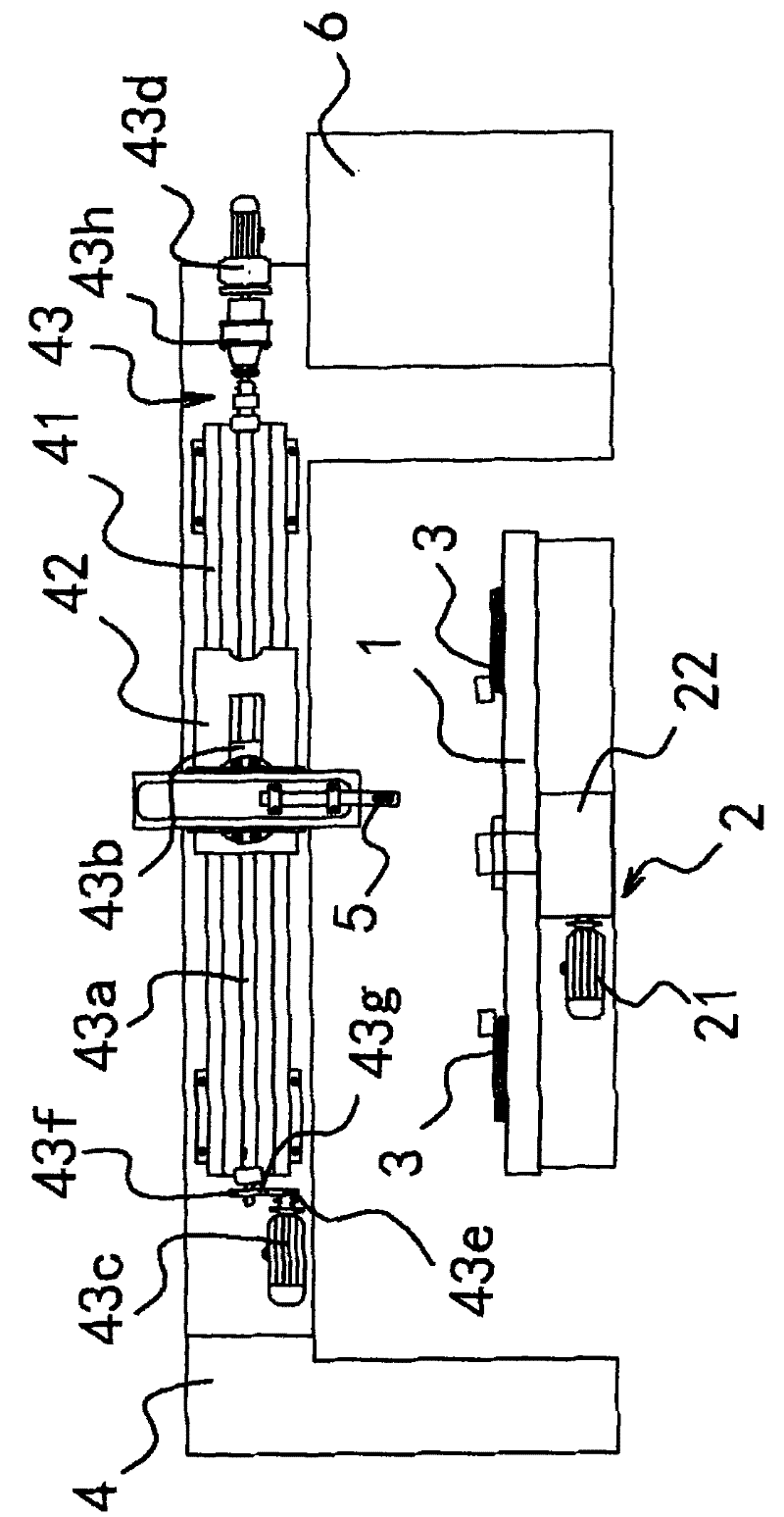

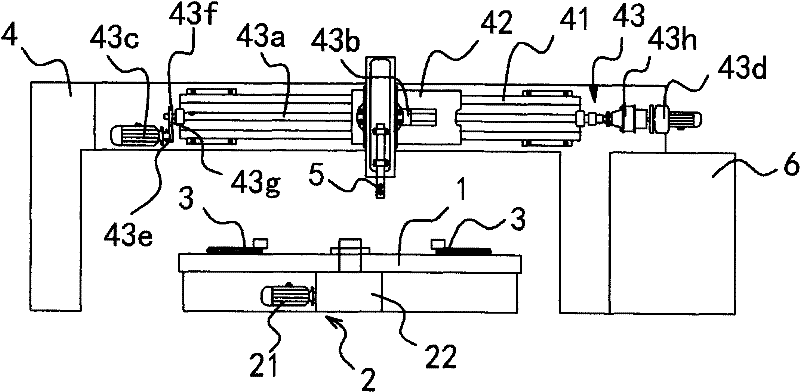

Intershaft bearing vibration experiment device

ActiveCN110243604AAvoid Vibration InterferenceAchieve vibration isolationMachine part testingBearing vibrationEngineering

The invention provides an intershaft bearing vibration experiment device. The intershaft bearing vibration experiment device comprises an experiment table base, a high-pressure rotor system, a low-pressure rotor system, a test system, a load simulation device and a temperature environment simulation device, wherein the high-pressure rotor system and the lower-pressure rotor system are used for allowing an inner sleeve ring and an outer sleeve ring of an intershaft bearing to rotate at different speeds, the test system is used for testing, transmitting and acquiring a vibration signal of the intershaft bearing, the load simulation device is used for simulating a centrifugal load and a radial load which are borne by the intershaft bearing, and the temperature environment simulation device is used for simulating a high-temperature environment of the intershaft bearing. In the intershaft bearing vibration experiment device provided by the invention, the simulation of the temperature environment and the load characteristic of the intershaft bearing is achieved, and meanwhile, the interference of other parts on the vibration signal of the intershaft bearing is prevented; and the proposed intershaft bearing test method is used for directly testing surface vibration of an inner circle and an outer circle of a bearing body, and the vibration characteristic of the intershaft bearing body can be effectively analyzed.

Owner:SHANDONG KAIMEIRUI BEARING TECH CO LTD +1

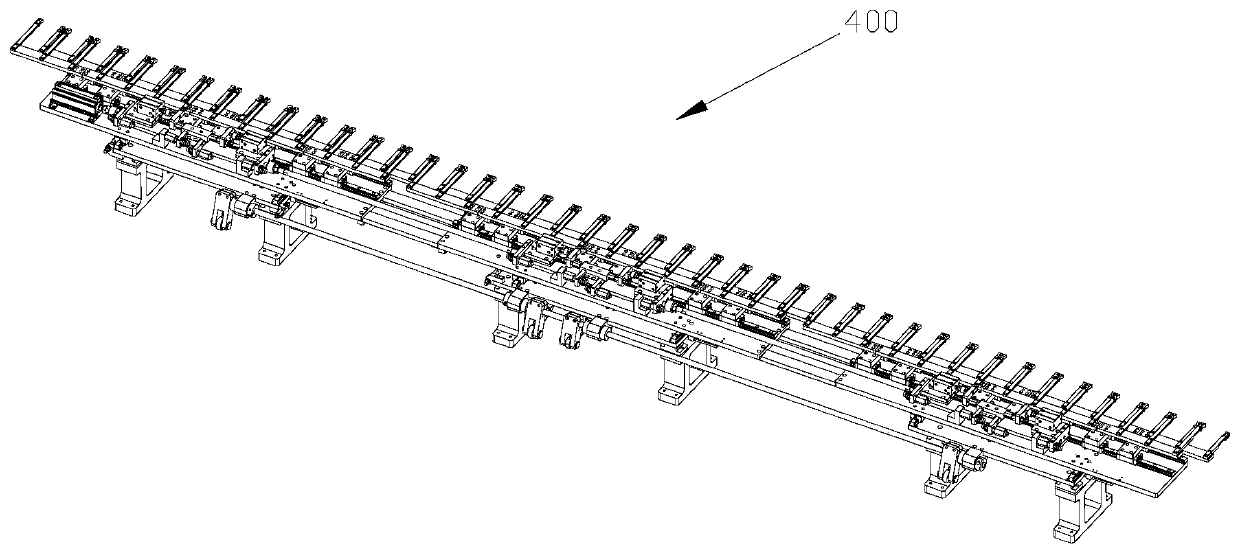

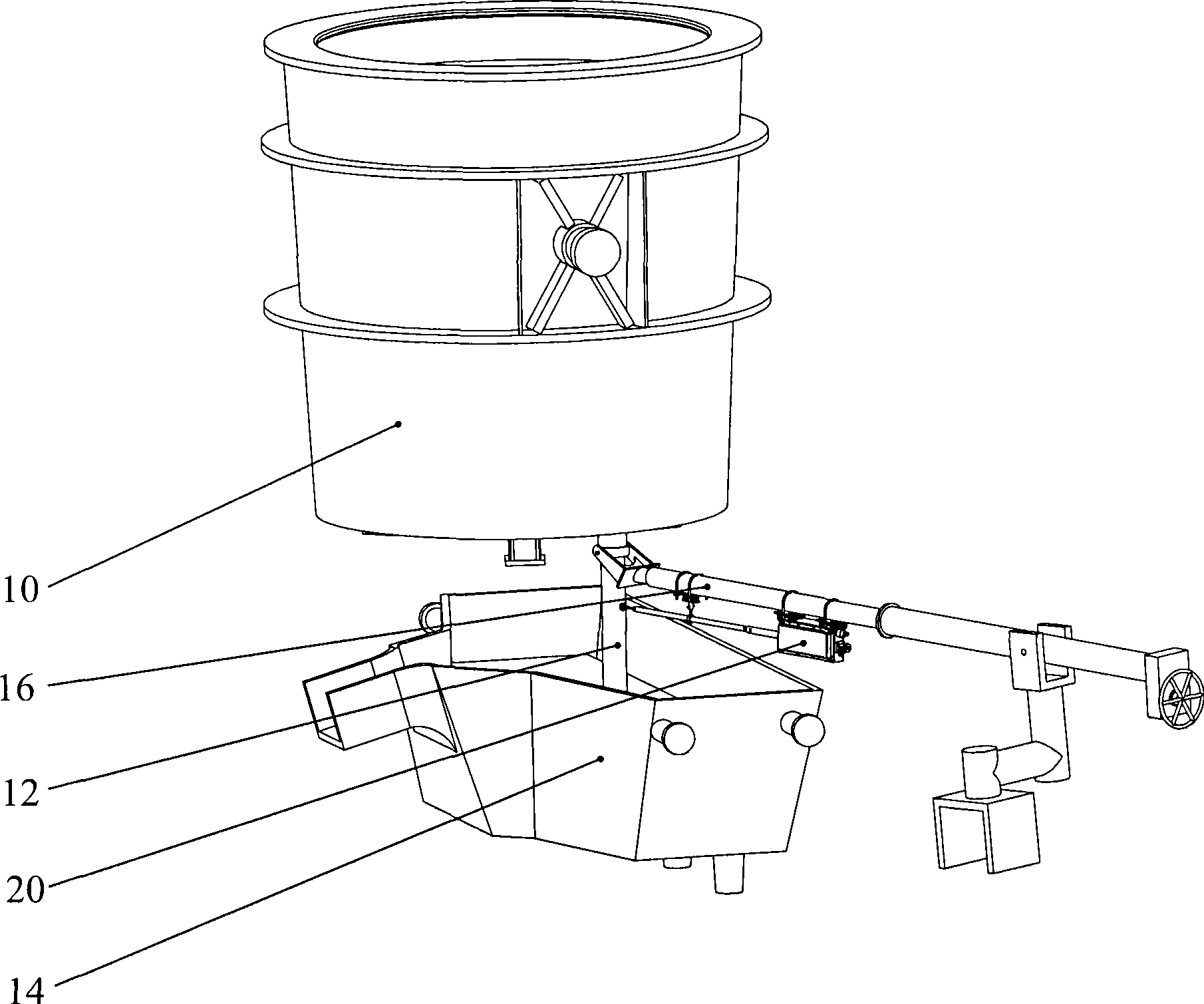

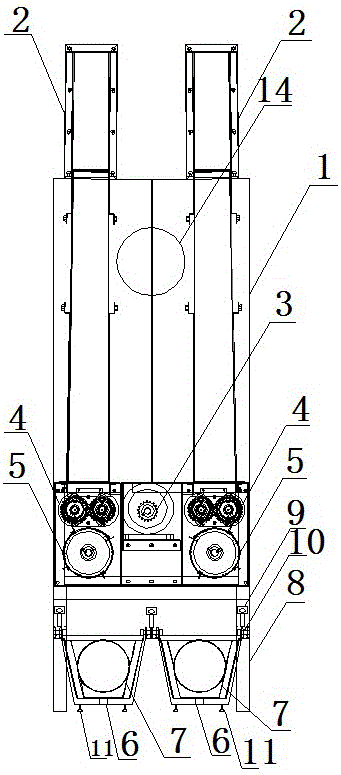

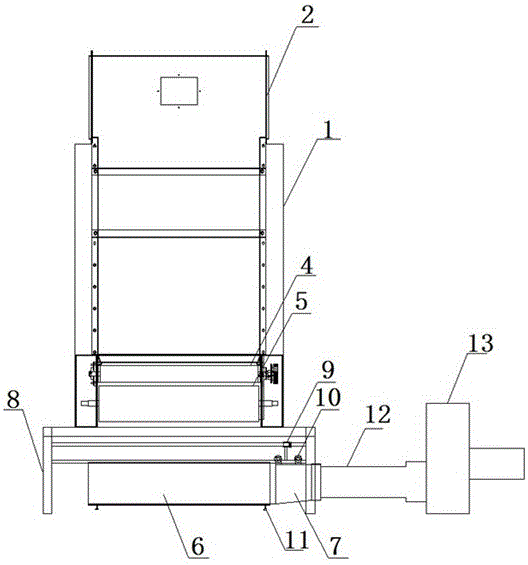

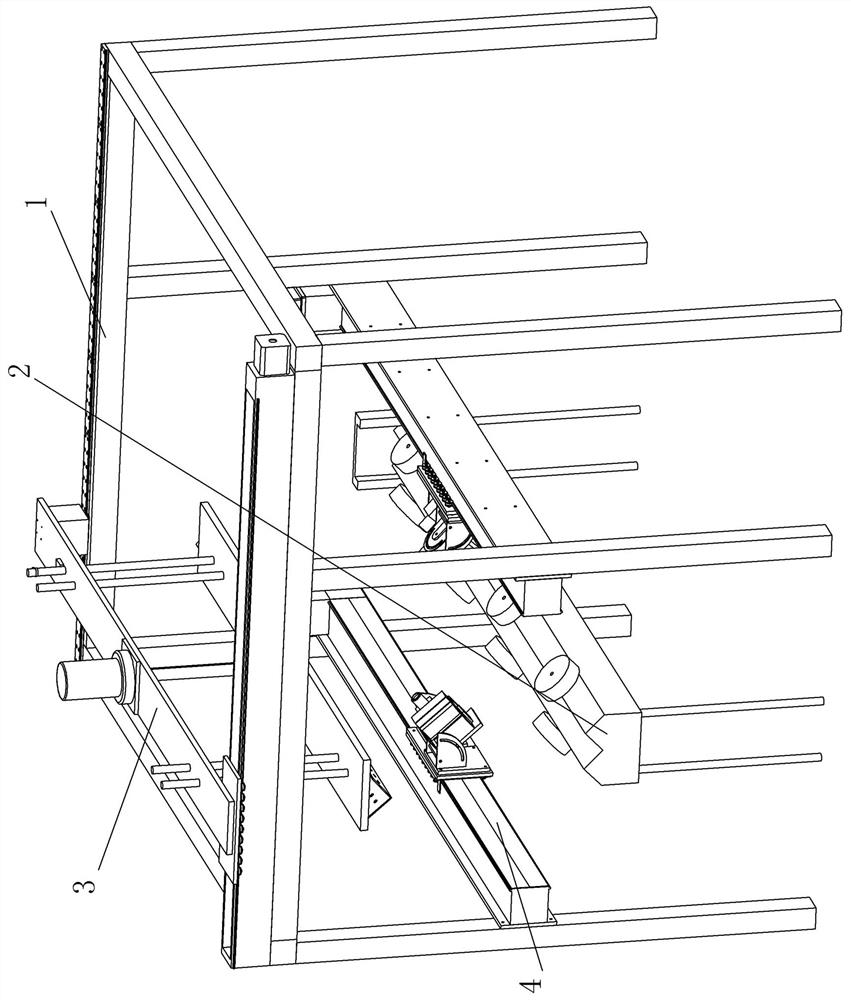

Angle steel detection device and detection method for electric iron tower

ActiveCN109013375ARealize sortingImprove detection efficiencySortingProduction lineImaging processing

The invention discloses an angle steel detection device and detection method for an electric iron tower. The angle steel detection device comprises an angle steel conveying mechanism, a vertical lifting device and an image acquisition system, wherein the angle steel conveying mechanism is connected with a production line, and used for conveying produced angle steel to the mechanism, and limiting the direction of the angle steel through a movement roll; the vertical lifting device is used for adsorbing the angle steel into air through an electromagnetic suction disc, and avoiding vibration interference of equipment and a transmission device; the image acquisition system controls a movement support through a screw rod and then drives a camera and a light source to rapidly move and shoot, theshot images are transmitted to an upper computer and image processing is carried out, and the angle steel is conveyed to a corresponding station according to a feedback result. The angle steel detection device and detection method for the electric iron tower are capable of realizing online automatic measurement and sorting for the angle steel, and high in automation degree, lower the labor intensity of manual detection and sorting, and greatly increase the detection efficiency for the angle steel and the production efficiency.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

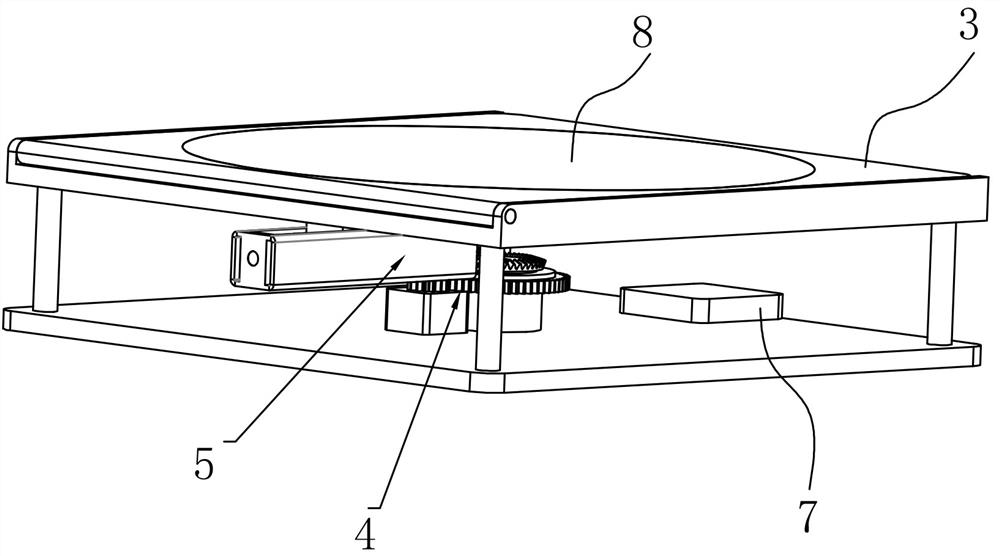

Automatic plate milling machine

InactiveCN101804477AHigh degree of automationEasy to processMilling equipment detailsMilling cutterEngineering

The invention relates to an automatic plate milling machine, which belongs to the technical field of processing equipment. The invention solves the problems of unreasonable design, low processing precision and the like in the prior art. The automatic plate milling machine comprises a turntable which is in horizontal arrangement, wherein the turntable is connected with a rotation motive power device capable of driving the turntable to rotate, a plurality of clamps used for fixing work pieces are arranged on the turntable, a support frame which is in arrangement independent from the turntable and positioned above the turntable comprises a cross beam in horizontal arrangement, at least one set of milling cutter assembly is arranged on the cross beam, a cutter capable of processing the work pieces is arranged on the milling cutter assembly, and both the milling cutter assembly and the rotation motive power mechanism are connected with an electric control box. The invention has the advantages that 1, the vibration interference does not exist during work, the processing precision is greatly improved, and the work noise is reduced; 2, because cement is adopted for manufacturing the support frame, the intensity is effectively improved, the occurrence of vibration is avoided and the processing precision is further improved; 3, the atomization degree is high, and the operation and the use are easy; and 4, the invention has multifunction, and can be applicable to the processing of plate materials made of various materials.

Owner:HANGZHOU LVDING FILTER PRESS MFG

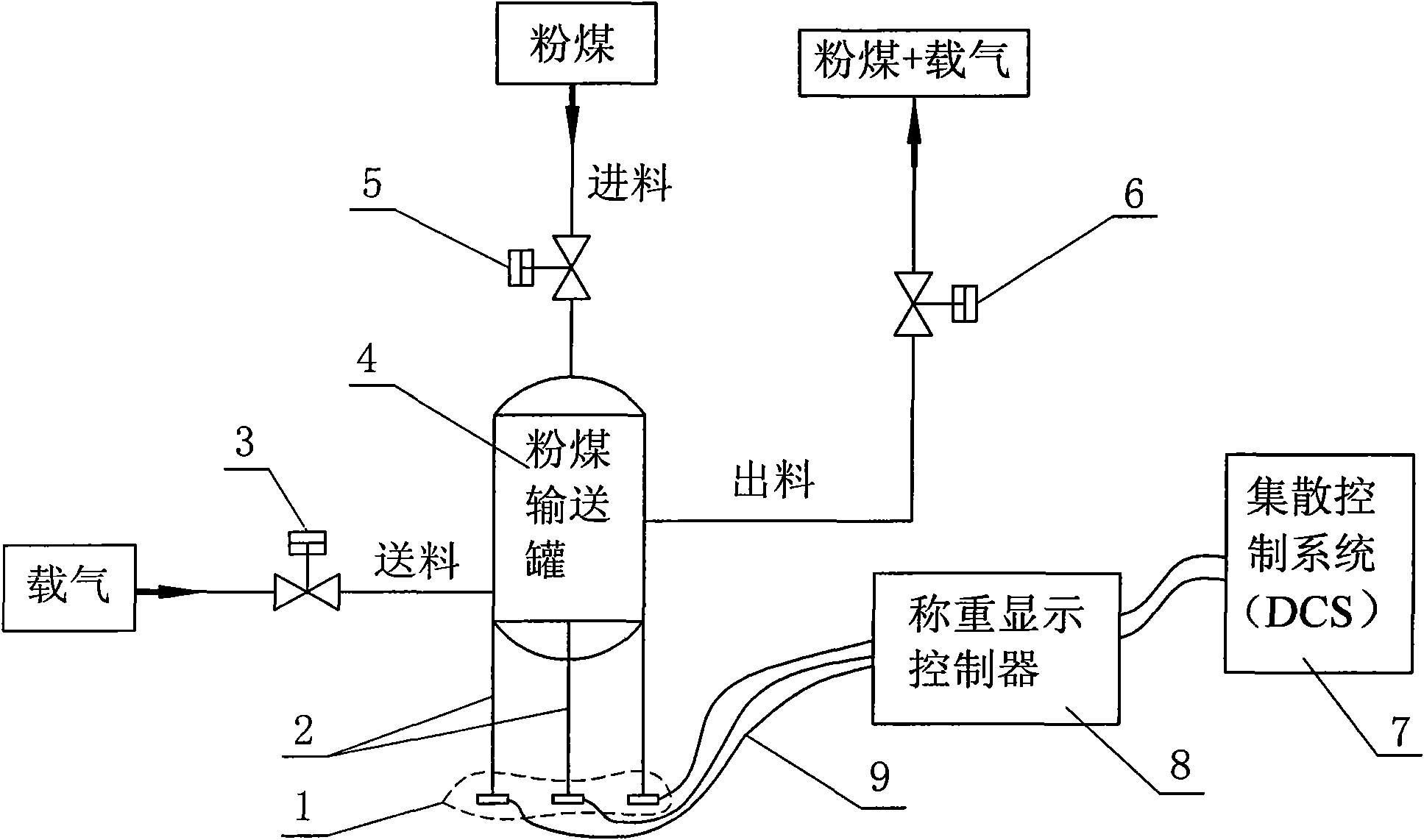

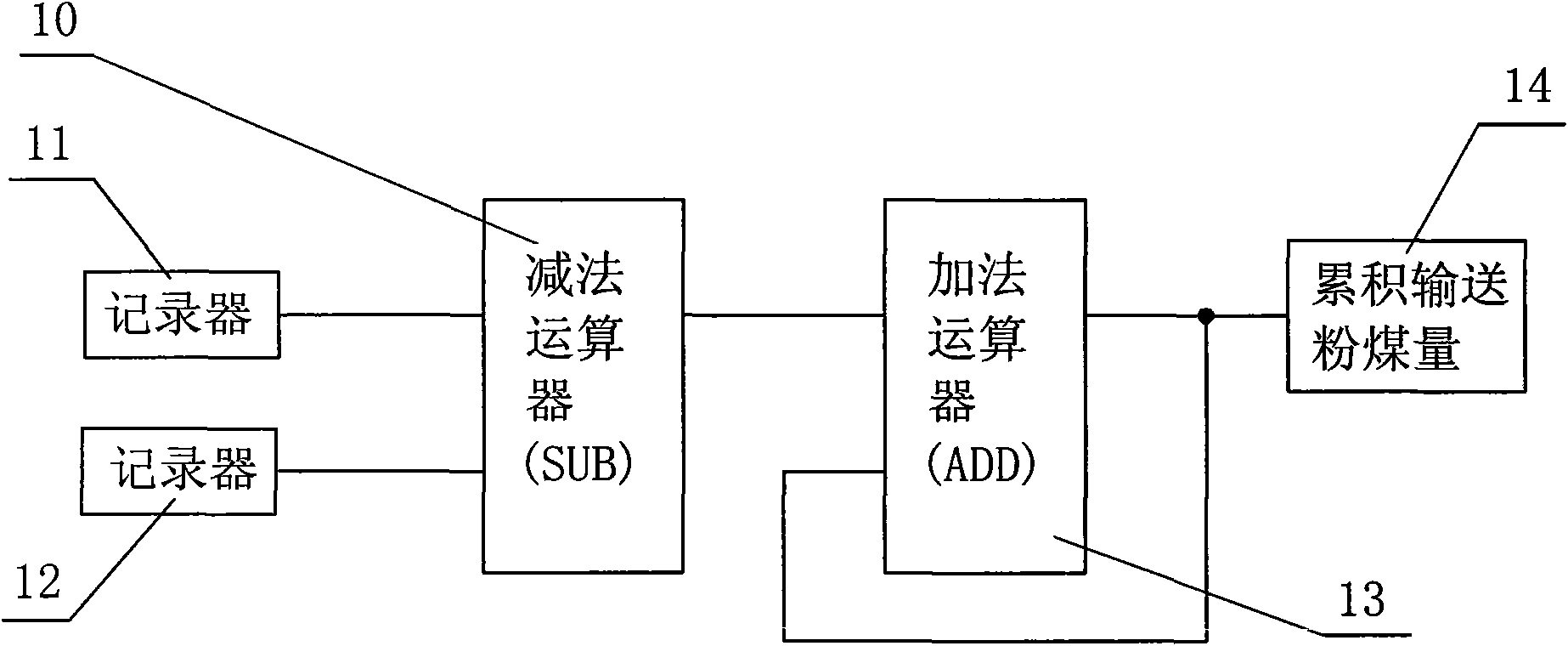

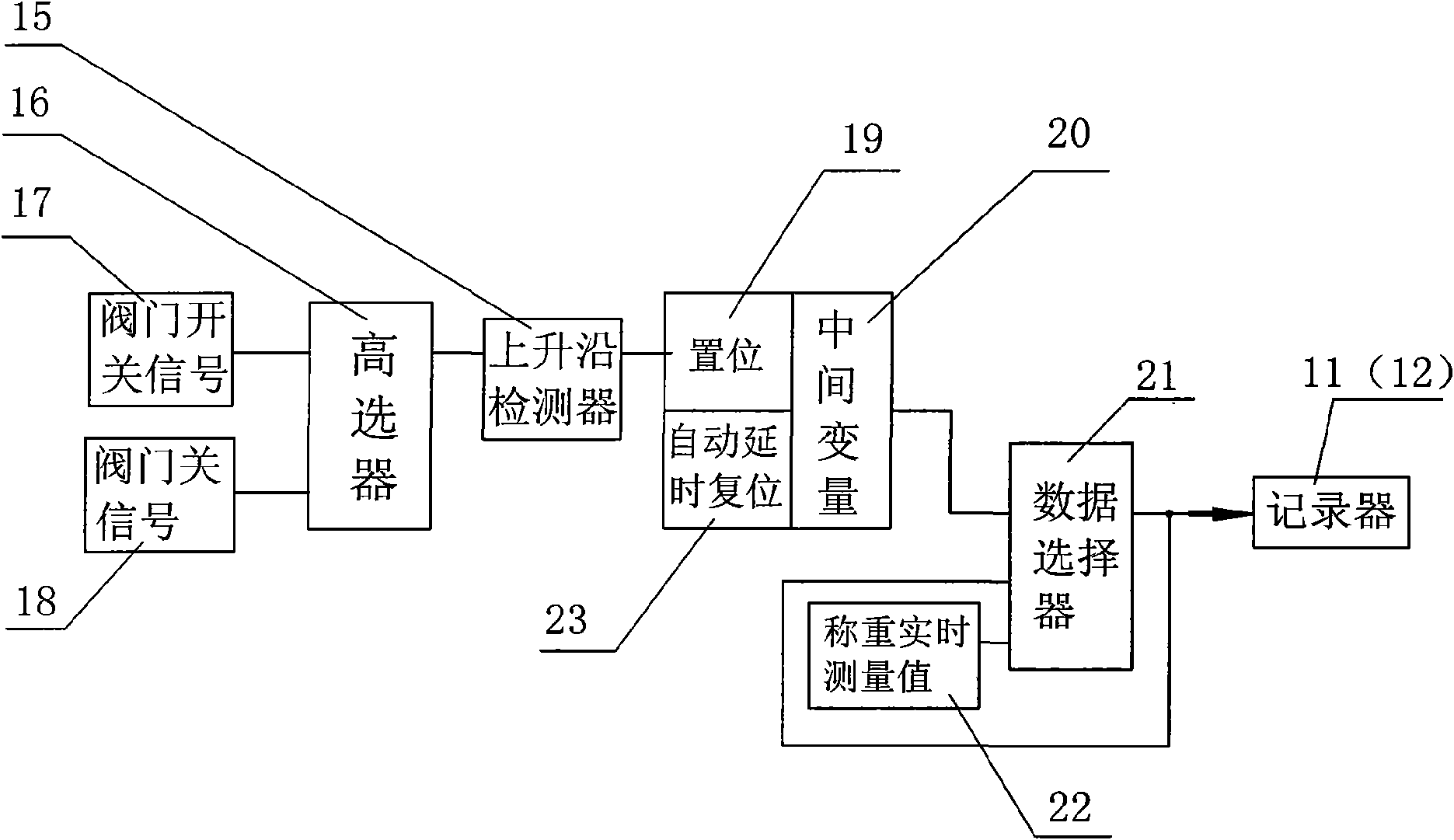

Method for automatically accumulating conveying capacity in powdered coal conveying process

ActiveCN101581592AAvoid unbalanced load failureAvoid interferenceVolume meteringWeighing apparatus with automatic feed/dischargeInterference factorDistributed control system

The invention relates to a method for automatically accumulating the conveying capacity in a powdered coal conveying process, which comprises the following steps that: a powdered coal conveying tank, a feed valve and a material conveying valve are used, a weighing sensor is arranged below each supporting leg of the powdered coal conveying tank, and a signal which is generated by the weighing sensor and has certain functional relation with the weight of the tank is transmitted to a weighing control display and is then converted into a standard direct current signal of 4 to 20 mA which is transmitted to a distributed control system through a signal cable; the distributed control system configures out two recorders, and the actions of the feed valve and the material conveying valve trigger the two recorders respectively; the recorders record the tank weight value when the feeding is finished and the tank weigh value when the material conveying is finished, subtract the two tank weight values to obtain the single-time conveying capacity, and perform superposition operations through an addition arithmetic unit to finally obtain the accumulated conveying capacity of the powdered coal. The method has high metering accuracy and few interference factors, can effectively relieve the problem of zero drift of an instrument and reduce the construction investment, and has high automatic degree and less maintenance workload.

Owner:水煤浆气化及煤化工国家工程研究中心

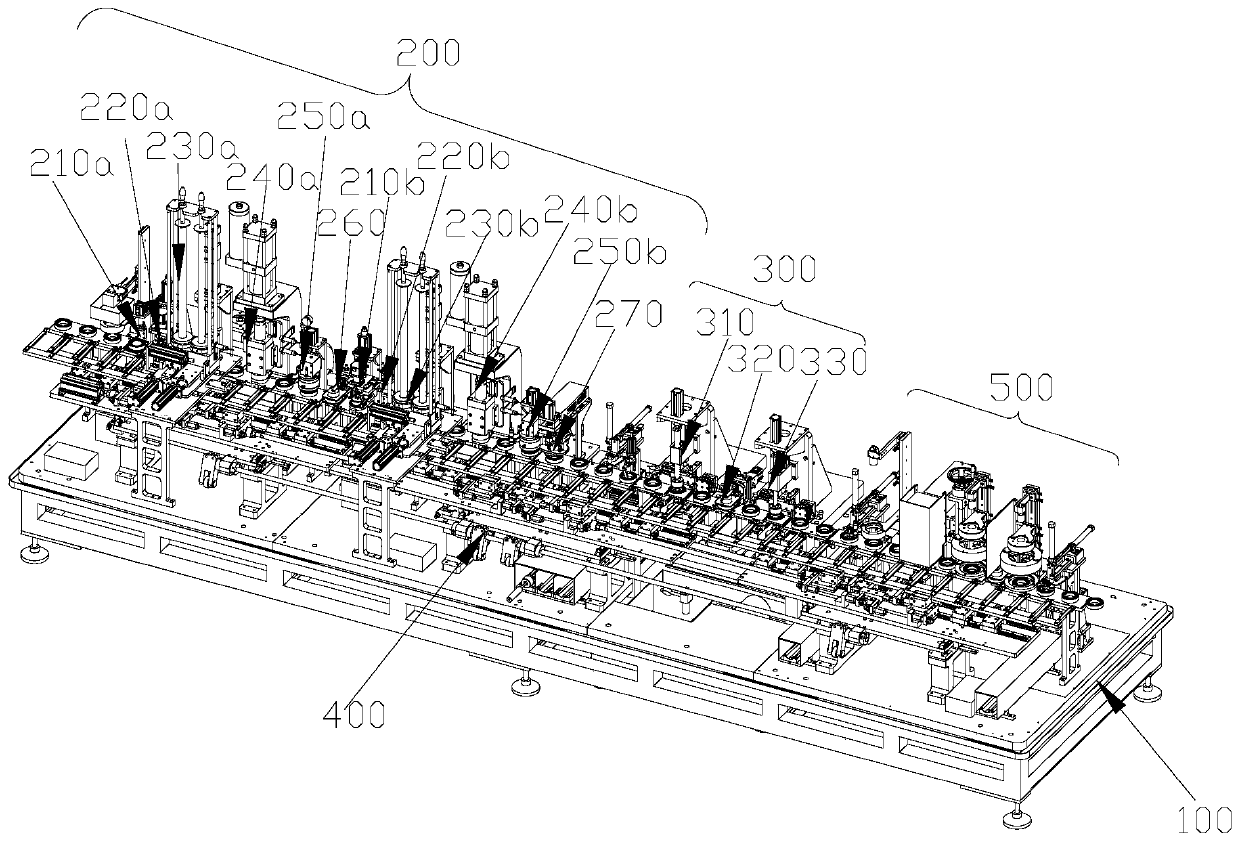

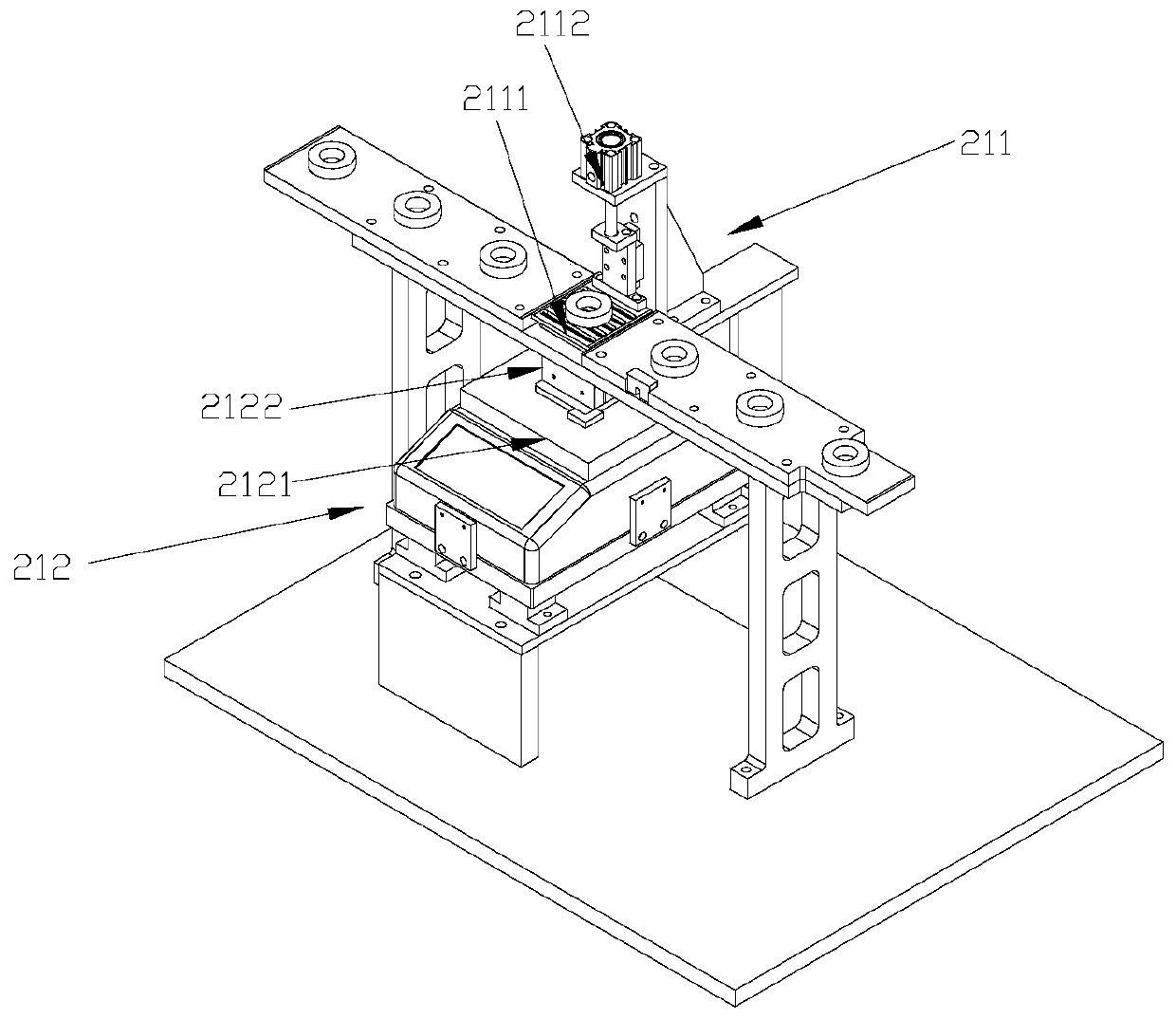

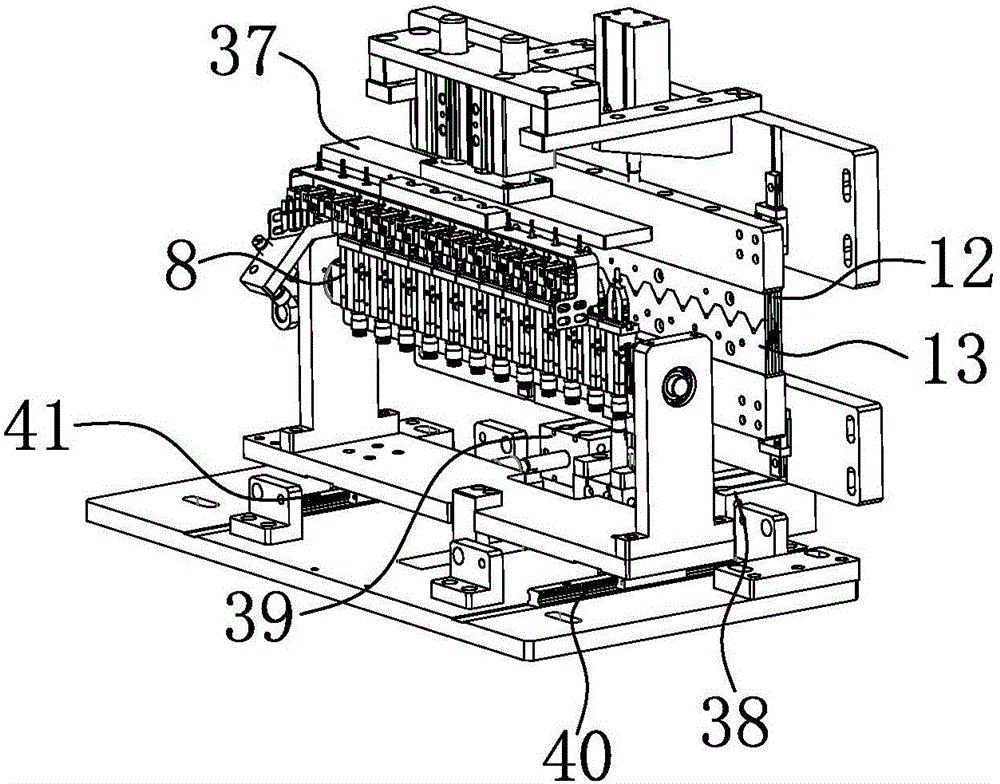

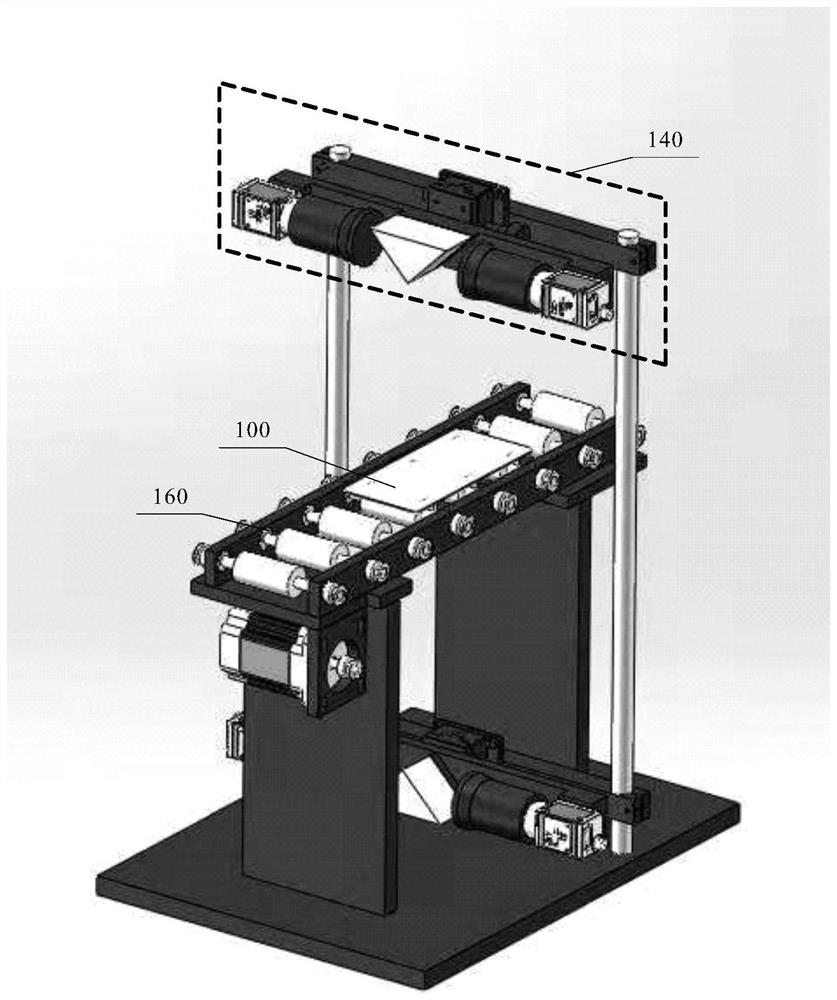

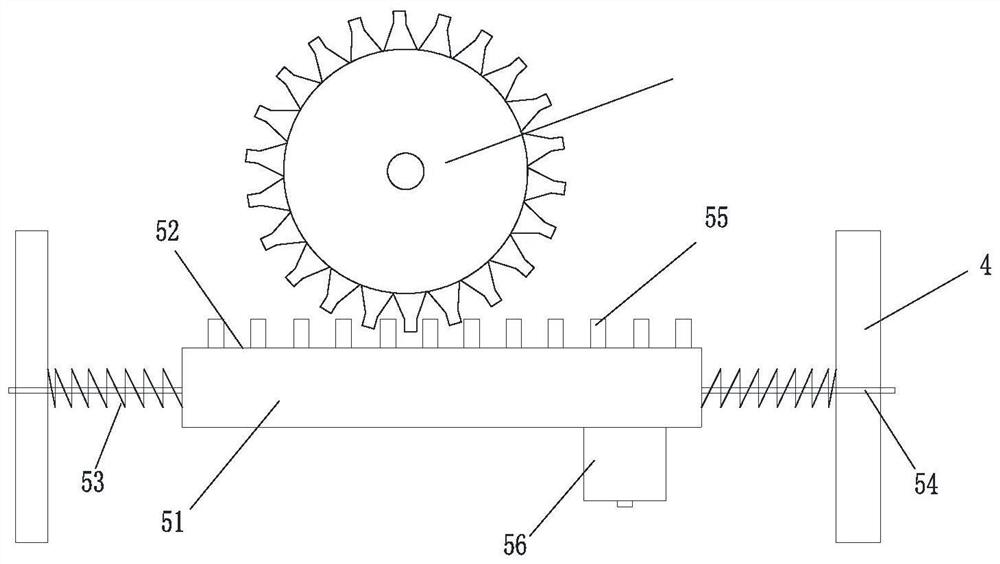

Bearing assembly detecting device

PendingCN110441062AReduce disorderly flowAchieve integrationMachine bearings testingMetal working apparatusEngineeringVibration detection

The invention relates to the technical field of processing and detection of bearings, and discloses an integrated bearing assembly detecting device. The integrated bearing assembly detecting device comprises a rack and a grease filling and cap pressing system, a vibration detecting system and a conveying system arranged on the rack; the grease filling and cap pressing system includes a first weighing mechanism, a first grease filling mechanism, a first cap adding mechanism, a first cap pressing mechanism, a first cap detecting mechanism, a first turning-over mechanism, a second weighing mechanism, a second grease filling mechanism, a second cap adding mechanism, a second cap pressing mechanism, a second cap detecting mechanism and a grease homogenizing mechanism which are sequentially disposed along a conveying direction of the bearing; the vibration detecting system is located on one side of the grease homogenizing mechanism, can be rigidly connected to the rack, and can be detached from the rack as needed; the vibration detecting system includes an A-face detecting mechanism, a second turning-over mechanism and a B-face detecting mechanism which are sequentially disposed along the conveying direction of the bearing; and the conveying system is configured to simultaneously perform material loading and material unloading on the grease filling and cap pressing system and the vibration detecting system.

Owner:KUNSHAN AODELU AUTOMATION TECH

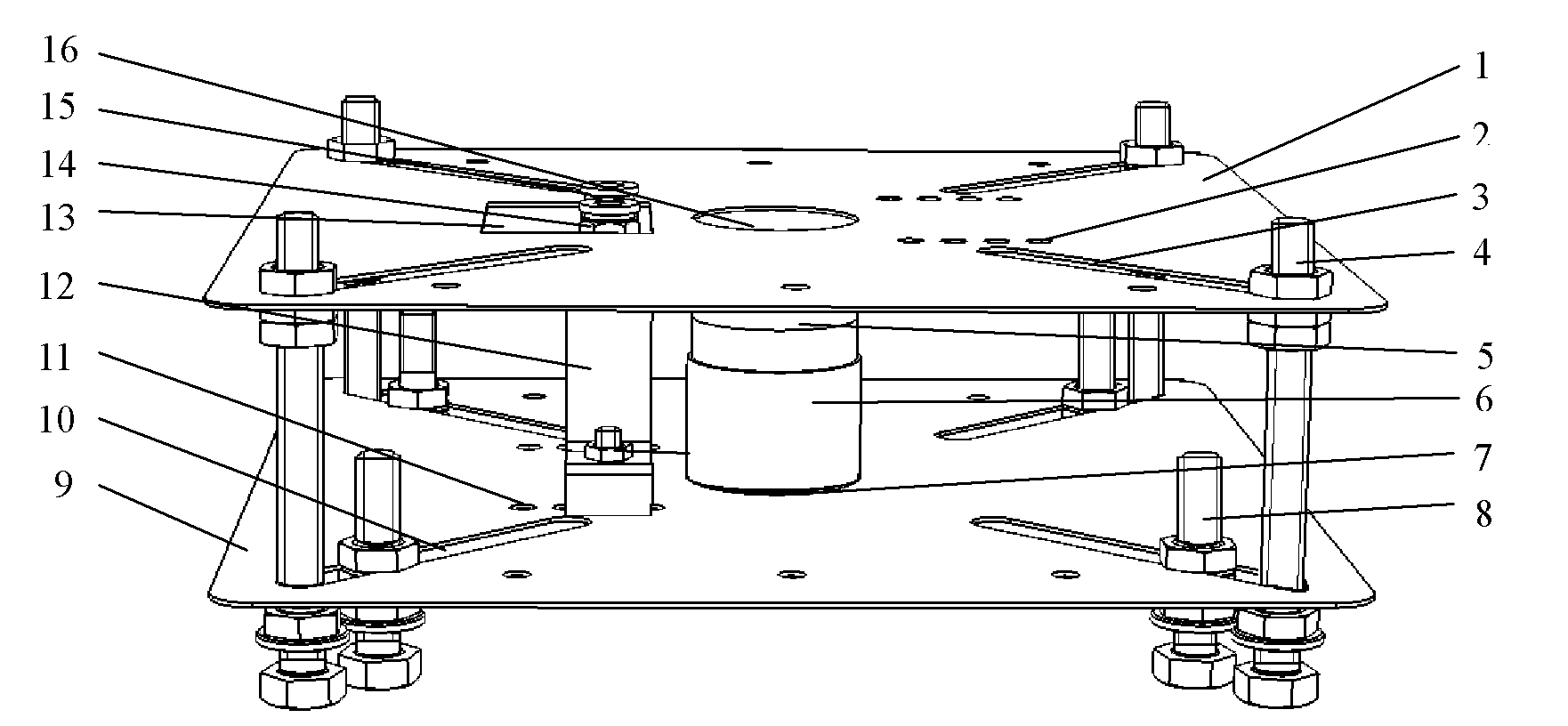

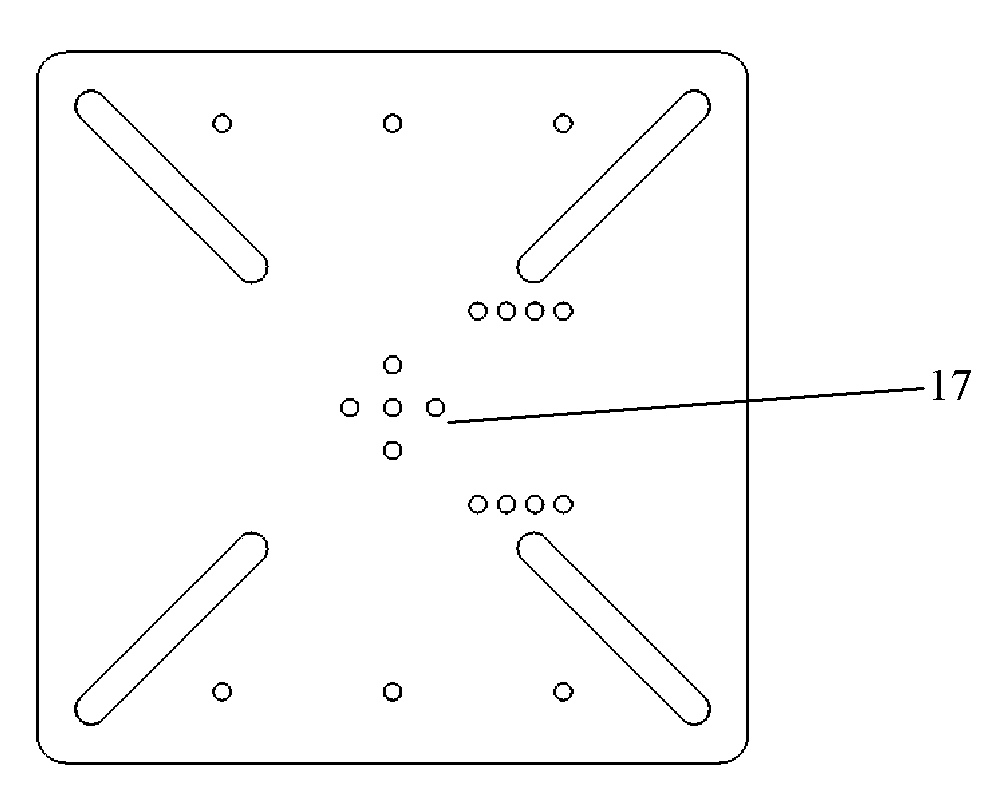

Detection device of contact stress distribution

InactiveCN101865738AAvoid Vibration InterferenceAvoid Quick Install DetectionForce measurementStress distributionEngineering

A detection device of contact stress distribution is composed of an upper workbench, a lower workbench, a pneumatic vibrator and a spherical indenter module, wherein the upper workbench and the lower workbench are respectively provided with a diagonal strip-shaped groove which is connected and fixed by fixed bolts and a linear shape array hole for installing the pneumatic vibrator, the position of the upper workbench dead against the spherical indenter module is provided with a round hole for installing a plane sample, the spherical indenter module comprises a spherical indenter which is arranged on the upper end of a retainer and is contacted with the plane sample, and the lower end of the retainer is attached with a pressure sensor for measuring the vibrating pressure of the spherical indenter module and a cross-shaped array hole which is vertically arranged on the lower workbench together with the pressure sensor. The invention has the beneficial effects of simple structure, easy manufacturing and installation and good combined properties, satisfies polytrope requirements and reduces interference caused by vibration.

Owner:ZHEJIANG UNIV OF TECH

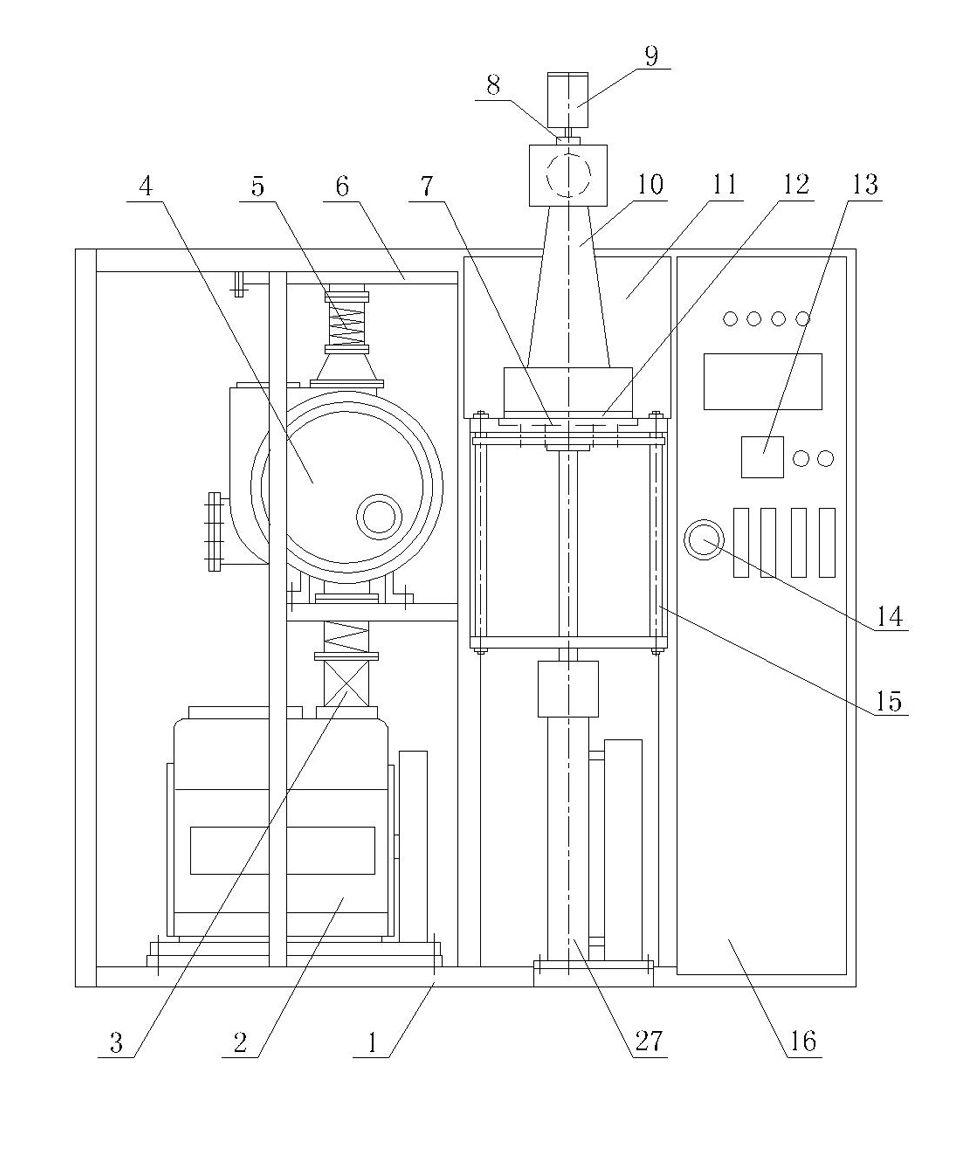

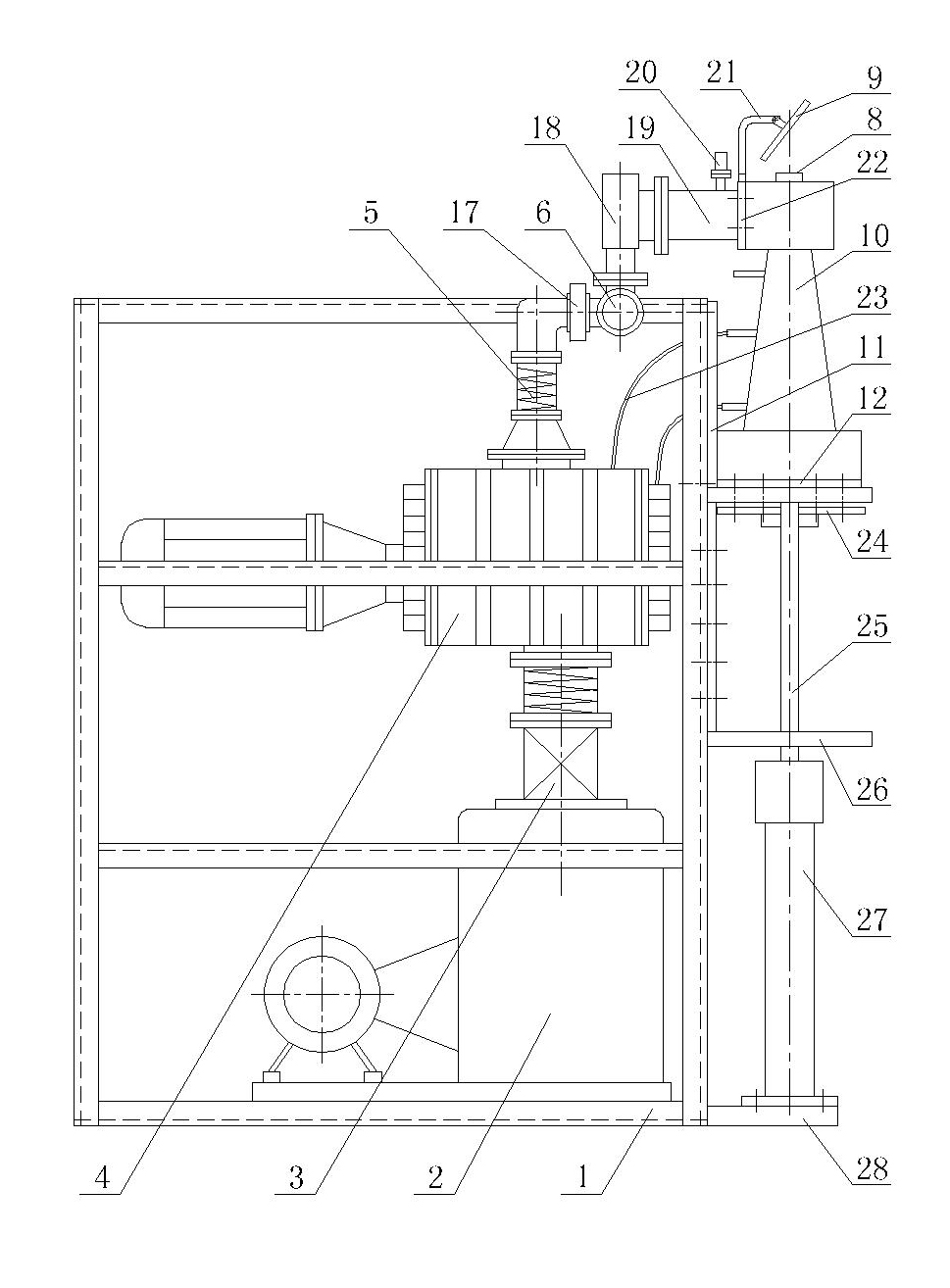

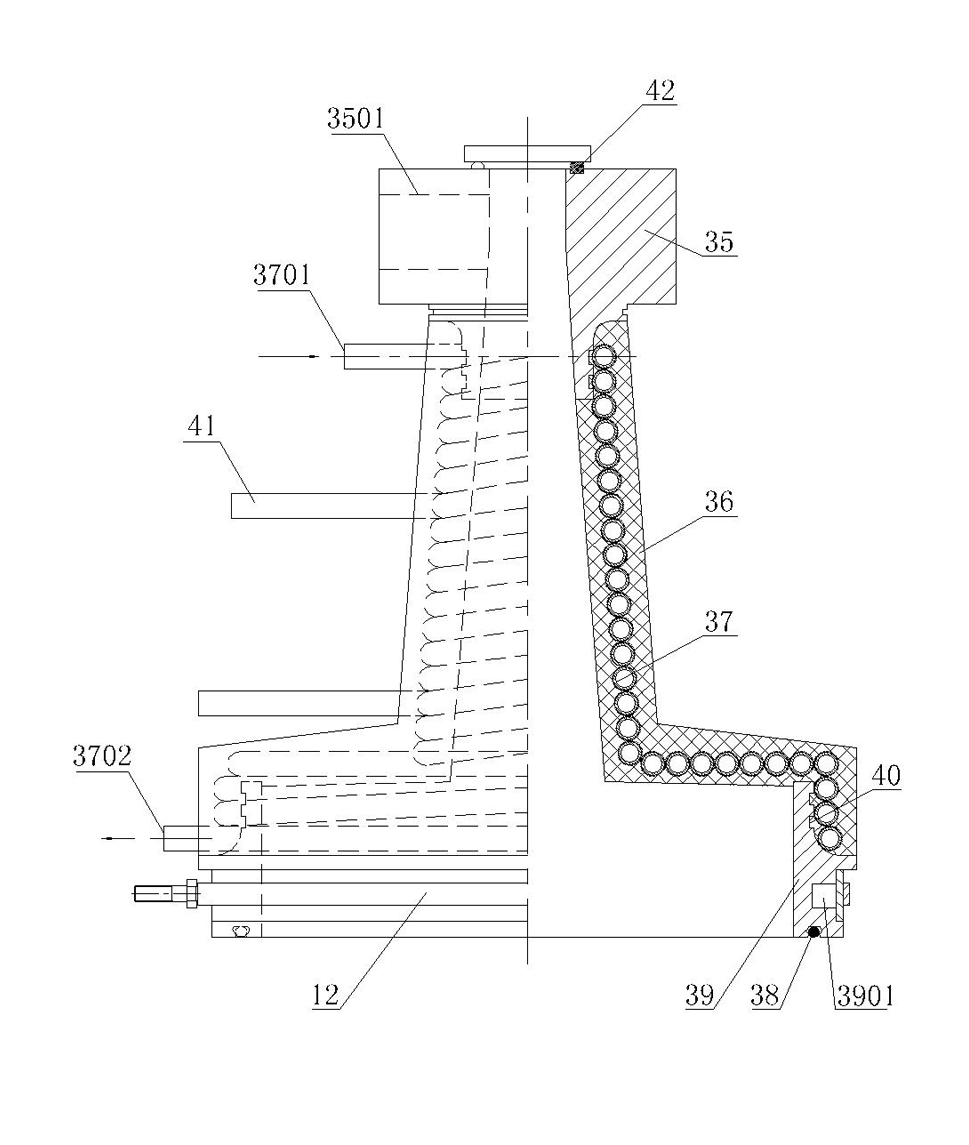

Rapid vacuum induction casting electric furnace

InactiveCN102042755AAvoid Vibration InterferenceReduce heat lossMaintainance of heating chambersCrucible furnacesElectric arc furnaceMedium frequency

The invention discloses a rapid vacuum induction casting electric furnace comprising a rack, wherein a vacuumizing system, a water cooling system and a medium frequency power supply are arranged on the rack. The electric furnace is characterized in that the rack is provided with a casting furnace, wherein the casting furnace is composed of an inspection microscope base, a base, an insulated furnace tube and an inductor copper pipe which is helically preinstalled in the insulated furnace tube; the inspection microscope base is hermetically connected with a vacuum pipeline of the vacuumizing system; the inspection microscope base is provided with an inspection microscope; the two ends of the inductor copper pipe are provided with a water inlet and a water outlet respectively and are respectively led out via the insulated furnace tube; the section, corresponding to the middle part of the casting furnace, of the inductor copper pipe is electrically connected with the medium frequency power supply; a reciprocating hoisting mechanism is arranged below the casting furnace on the rack; and the upper end of the reciprocating hoisting mechanism is provided with a tray. The electric furnace has the following advantages: smelting and casting can be carried out simultaneously, the yield of cast products is high and the product percent of pass can reach more than 85%, so the electric furnace is especially applicable to casting products with complex shapes; the casting time is short and the production efficiency is high; and the product density is high and the product quality is good.

Owner:JINZHOU GUXING TECH

Automatic extrusion device

The invention discloses an automatic material extruding device, which relates to the field of plastic manufacturing; the support of the automatic material extruding device, a feeding roller, a flattening roller and an output roller, and a drive motor for driving the rotation of the feeding roller and the output roller; the driving motor and the feeding roller and the output roller The rollers are driven by a chain, the feeding roller is located between the flattening rollers, and both the feeding roller and the output roller are located above the flattening rollers, and the output roller is set on either side of the left and right sides of the bracket; a set of opposite ear plates are fixed on the bracket , the feeding roller and the output roller are rotatably connected to the ear plate, and the ear plate is provided with a strip hole, and the two ends of the flattening roller are provided with a rotating pin that matches the strip hole, and the rotating pin is inserted into the corresponding strip hole. And the flattening roller can slide up and down relative to the strip hole. This device sets the tension roller in a floating state, and tensions the film by the gravity of the tension roller itself, so that the force on the film is always in a relatively constant state, so that the tension of the film is kept constant.

Owner:重庆敏驰塑胶有限公司

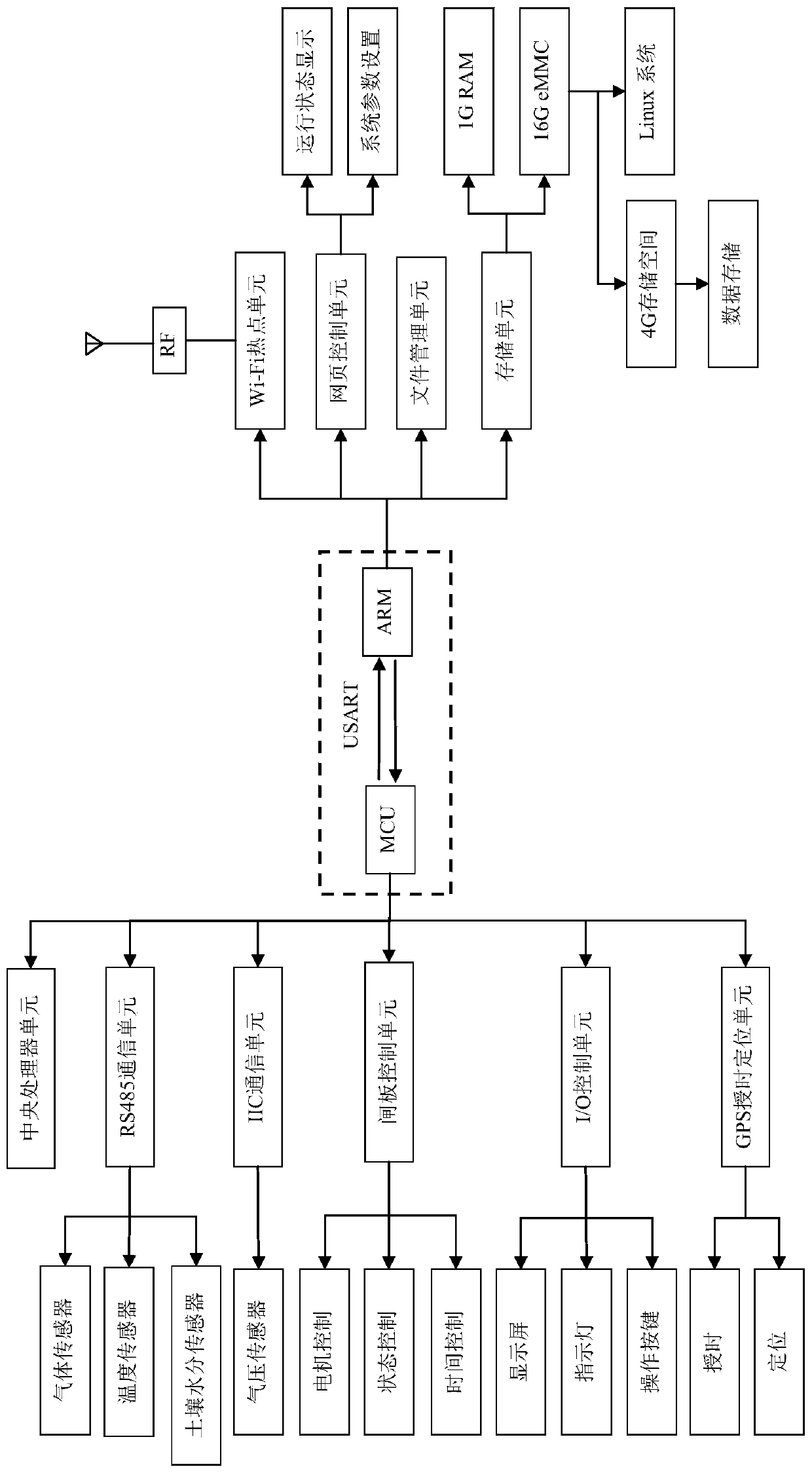

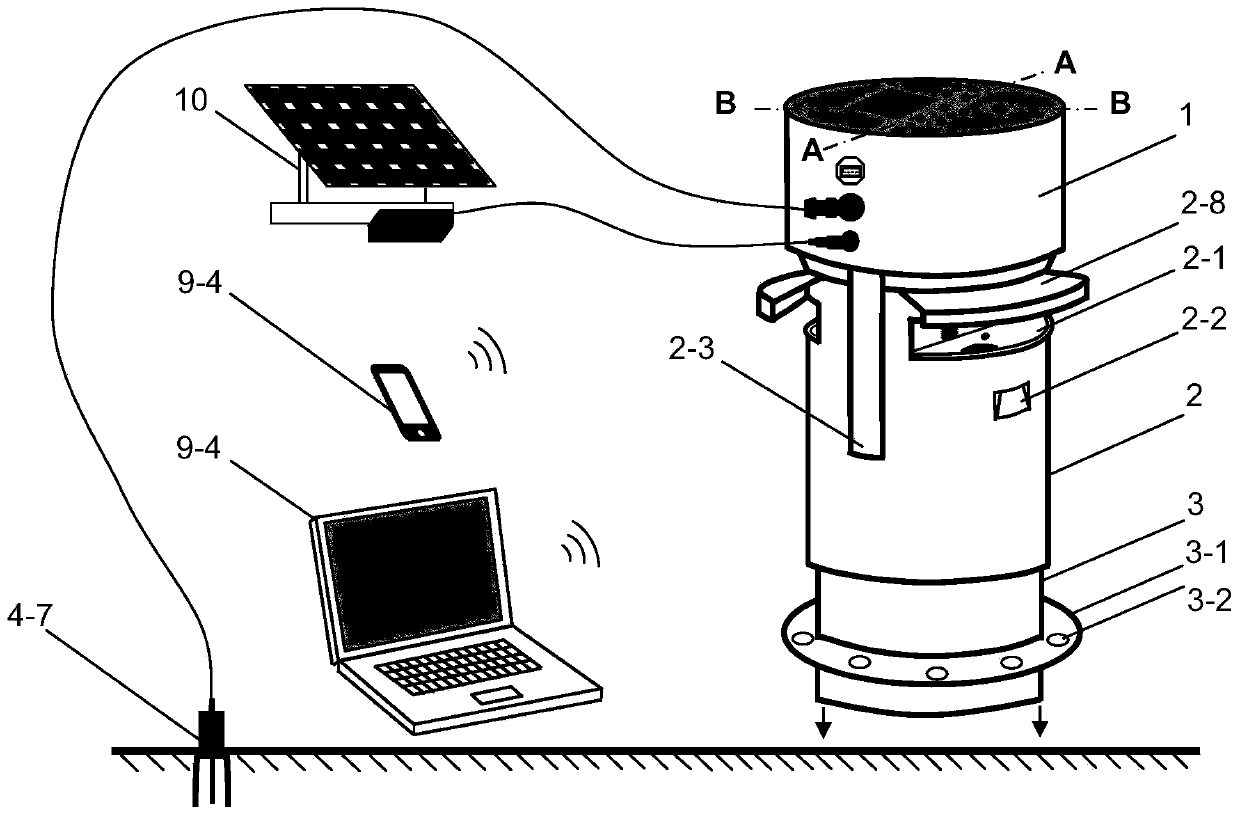

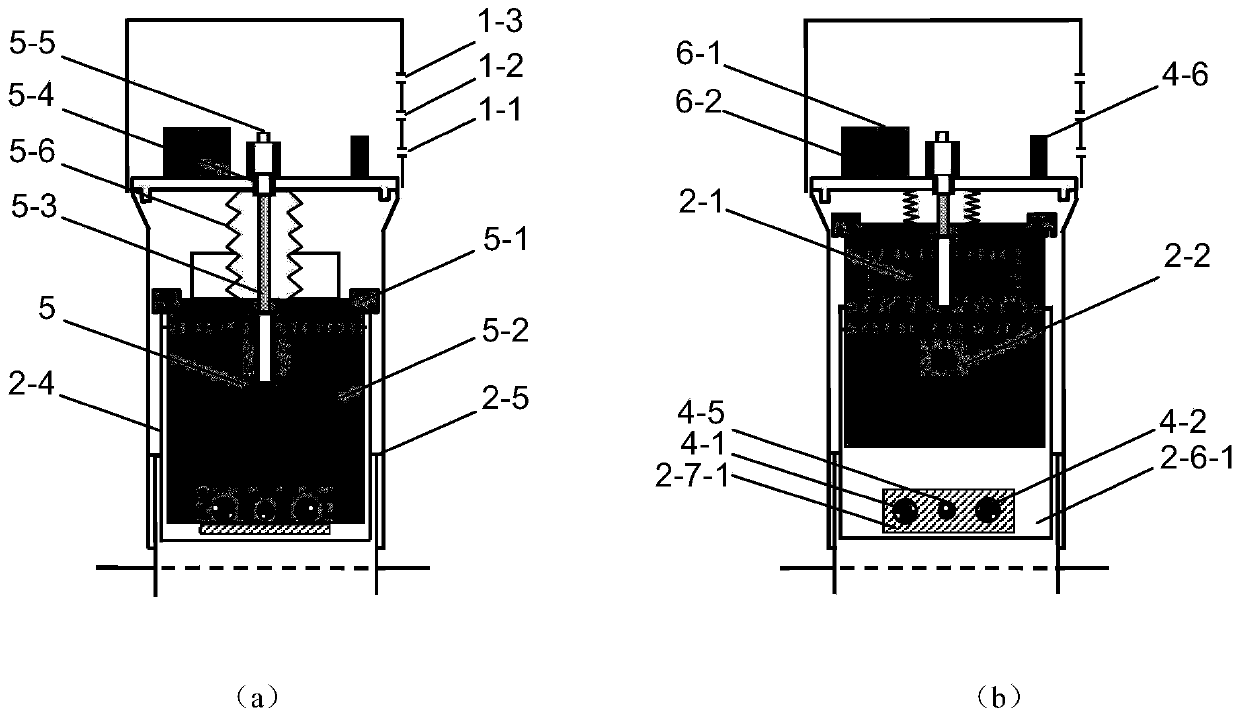

Multi-channel acquisition and control integrated soil gas flux monitoring system and monitoring method

PendingCN111505249ARealize synchronous online monitoringIncrease credibilityEarth material testingTemperature measurement of flowing materialsData displaySoil gas

The invention provides a multi-channel acquisition and control integrated soil gas flux monitoring system and a monitoring method. The system comprises a controller, a sensor unit, an air chamber unitand a human-computer interaction interface. An MCU, an ARM application processor and a Linux operating system are adopted in the controller. High integration of system control and data acquisition isrealized, visual man-machine interaction interface, GPS time service positioning, Wi-Fi wireless communication and PC / mobile phone webpage end remote control are supported, and arbitrary addition andcombination of CO2 / O2 / CO / CH4 and other gas sensors are supported. The user side supports the functions of monitoring parameter setting, real-time data display, file transmission management and the like. The system is based on the in-situ monitoring concept, the problem of air barrier and the problem of air pressure imbalance in an air chamber are avoided, and the influence of external force suchas an air pump on the air release rate is eliminated. The system can be widely applied to long-term continuous monitoring and scientific research experiments of soil gas flux in a complex environmentunder the field unattended condition.

Owner:阜新工大华联科技有限公司

Extrusion assembly of extrusion equipment

The invention discloses an extrusion assembly of extrusion equipment, and relates to the field of plastic manufacturing. The extrusion assembly of the extrusion equipment comprises a support, a feeding roller, flattening rollers, an output roller and a driving motor driving the feeding roller and the output roller to rotate. The driving motor is in chain transmission with the feeding roller and the output shaft, the feeding roller is located between the flattening rollers, and the feeding roller and the output roller are located above the flattening rollers. The output roller is arranged on any side of the left side and the right side of the support. The support is fixedly provided with a pair of oppositely-arranged lug plates, the feeding roller and the output roller are rotationally connected with the lug plates, the lug plates are provided with strip-shaped holes, rotating pin shafts matched with the strip-shaped holes are arranged at the two ends of the flattening rollers, the rotating pin shafts are inserted into the corresponding strip-shaped holes, and the flattening rollers can slide up and down relative to the strip-shaped holes. Tensioning rollers are set to be in a floating state, a film is tensioned through self-gravity of the tensioning rollers, the stress of the film is always in a relatively constant state, and thus the tension of the film keeps constant.

Owner:NINGBO ZHENHAI XIANGAO ELECTROMECHANICAL

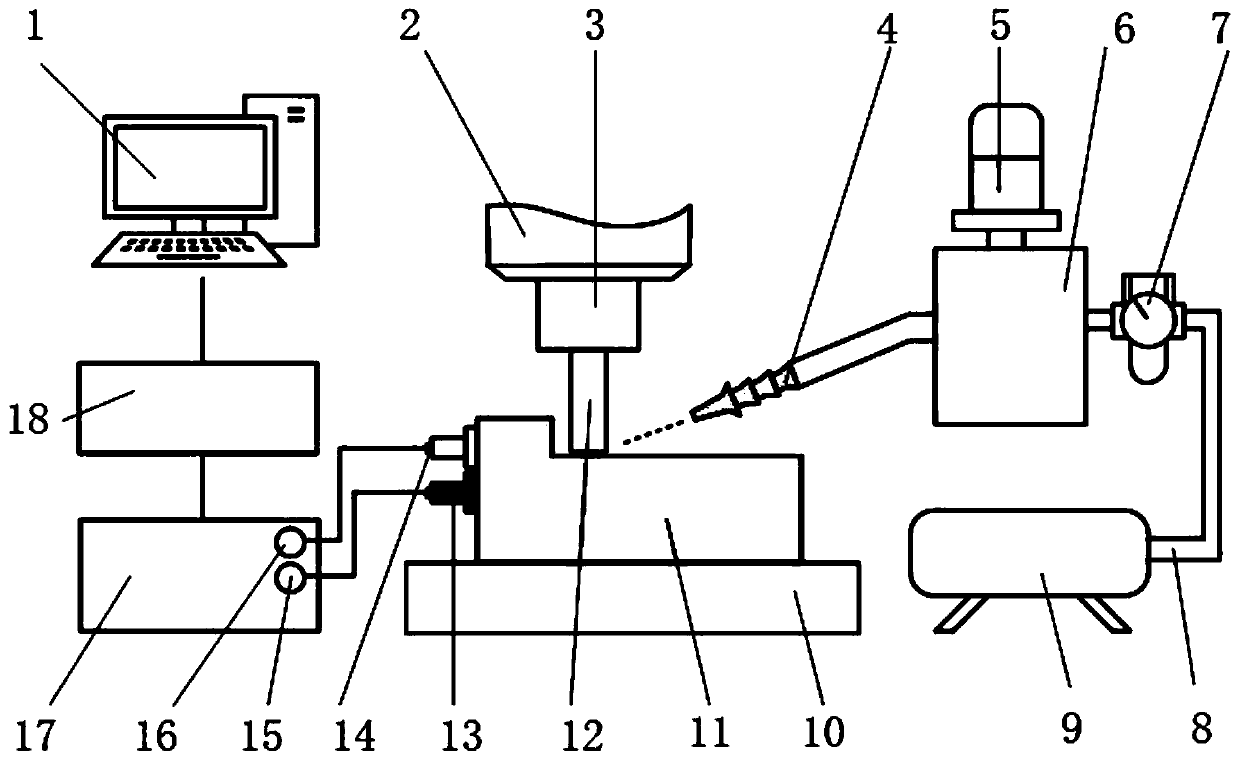

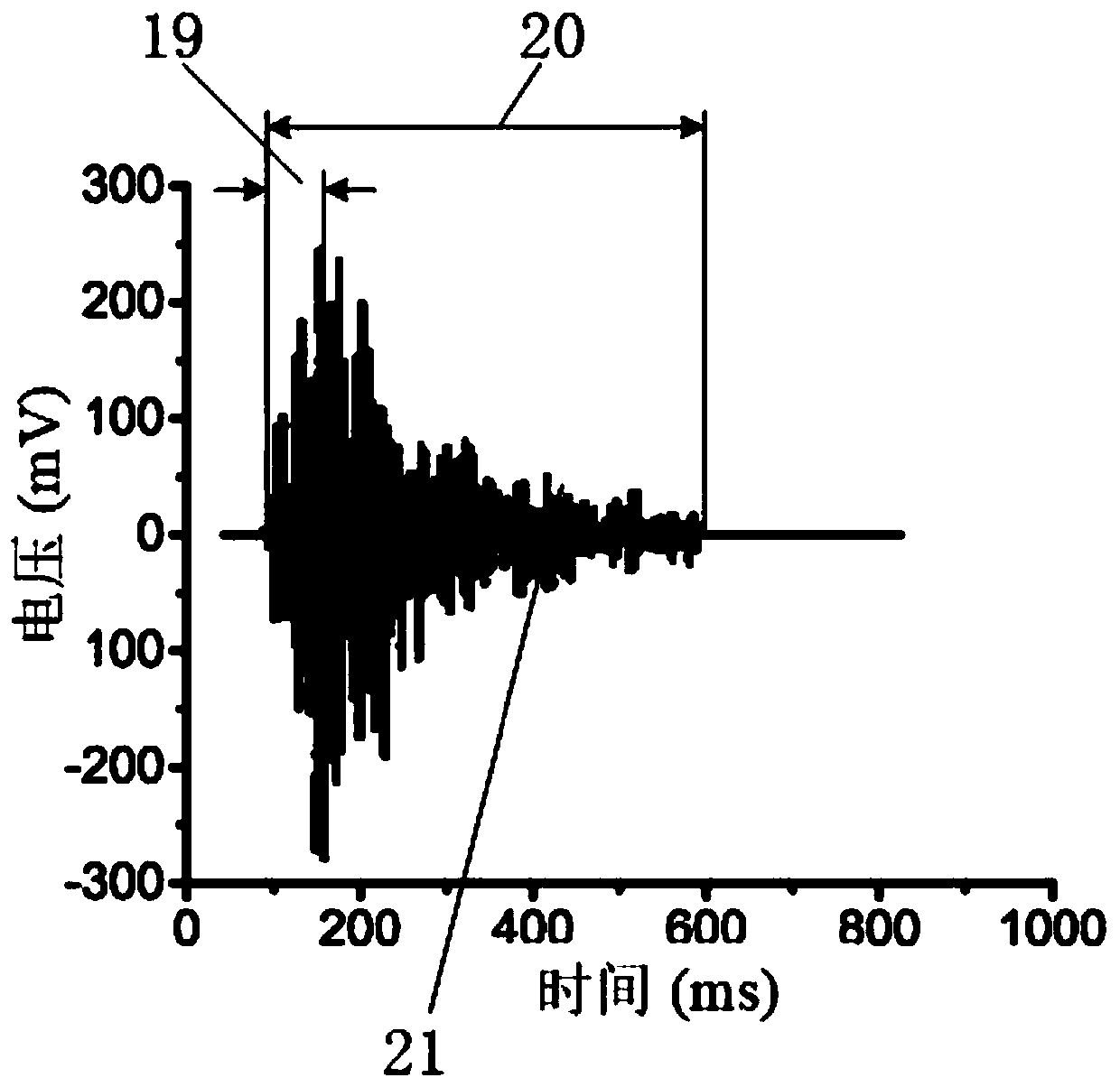

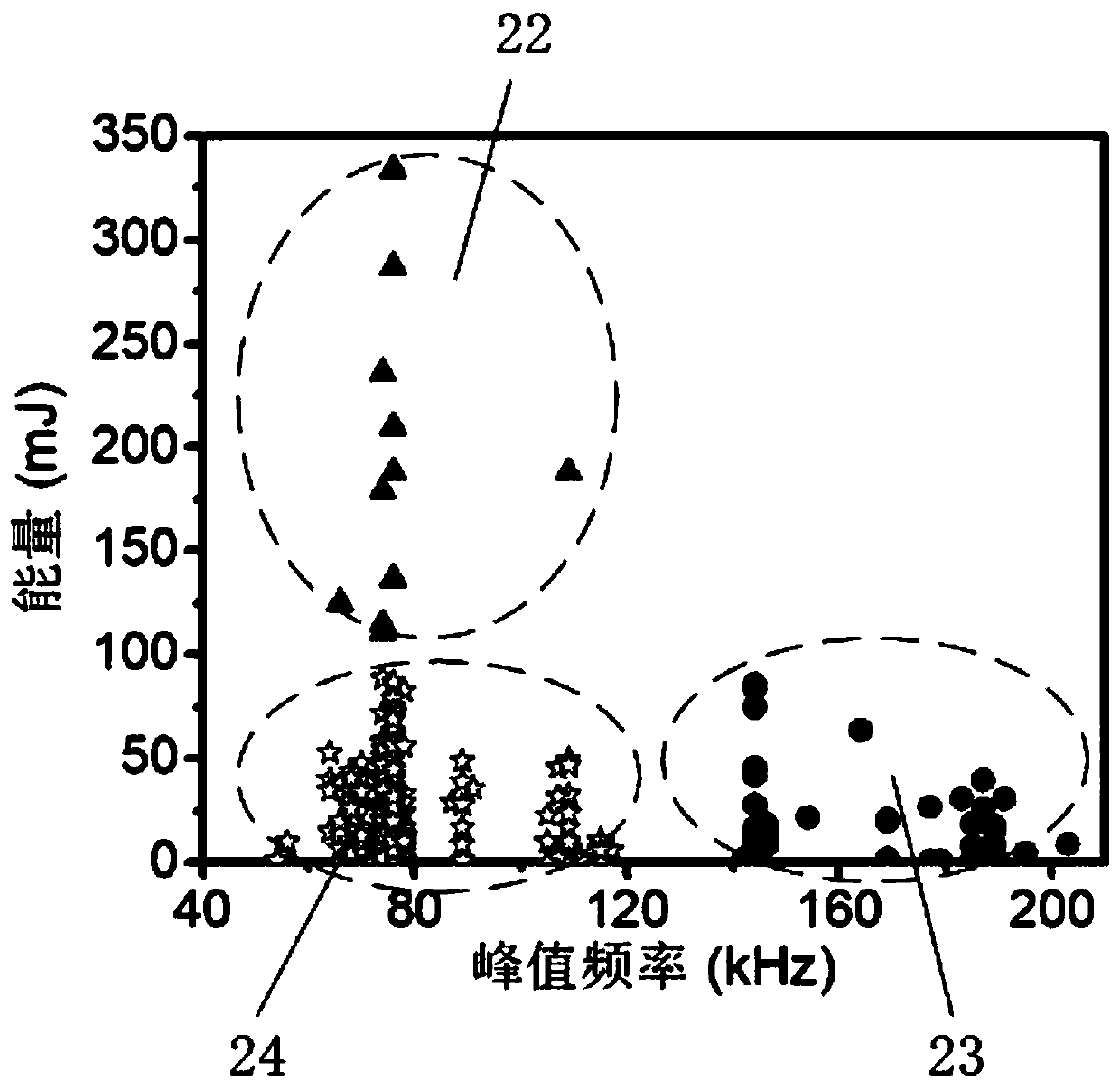

Cutter wear identification and prediction method based on high and low frequency acoustic emission sensor fusion

InactiveCN111590391ASimple methodEasy to operateMeasurement/indication equipmentsMaintainance and safety accessoriesNoiseEngineering

The invention discloses a cutter wear identification and prediction method based on high and low frequency acoustic emission sensor fusion. The method comprises the following steps that firstly, acoustic emission short wave parameters of high and low frequency sensors, including a threshold value, rising time and duration time, are set to eliminate interference signals; secondly, deep fusion, characterization and identification are carried out on the high-frequency and low-frequency acoustic emission signals, and the relation between cutter abrasion and acoustic emission pulse signals is established; and finally, through linear fitting of the total energy of acoustic emission blasting signals caused by brittle fracture and plastic deformation, an equation of the abrasion loss of the rear cutter face of the cutter and the total energy of acoustic emission is established, and accordingly the service life of the cutter is predicted. The method can effectively avoid low-frequency environment noise and machine tool vibration interference, is particularly suitable for cutter wear recognition and prediction under the working condition of minimum quantity lubrication green cutting machining, and is simple, convenient to operate and accurate in result.

Owner:ZHEJIANG ZHONGDE AUTOMATIC CONTROL VALVE

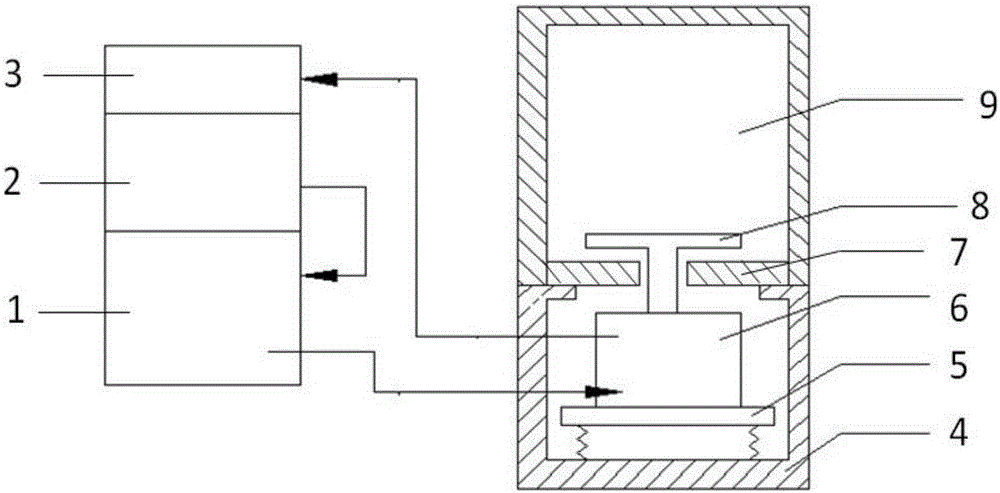

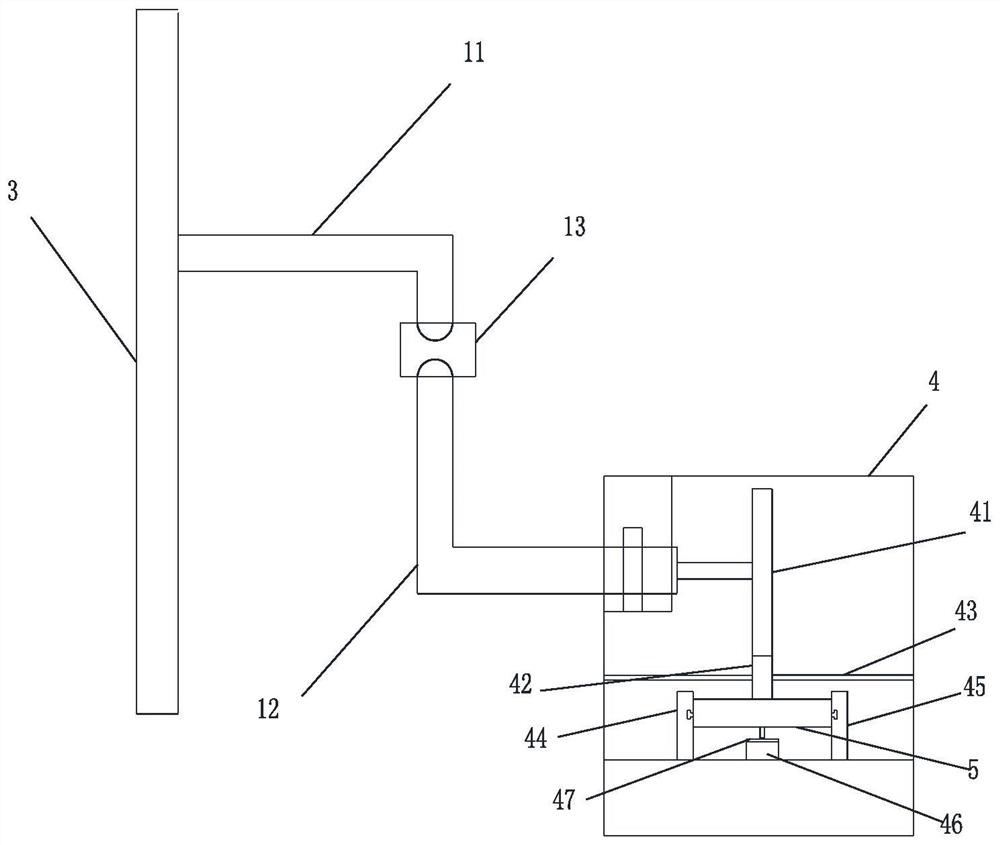

Cell culture box

ActiveCN106399096AAvoid Vibration InterferenceMeet training requirementsBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCultured Cell Line

The invention provides a cell culture box and relates to the technical field of biology experiment apparatus equipment and solves the problem of long-time placing of a culture body leaving the culture environment. The inside of an upper box body is a cell culture bin 9, and an excitation vibration device 6 provided with an elastic support base 5 is arranged inside a lower box 4; a through hole is formed in the middle of a bottom plate 7 of the upper box body, a vertical rod is arranged at the lower part of a vibration table board 8 which is located at the bottom of the cell culture bin 9, and the vertical rod penetrates through the through hole of the base plate 7 and is fixed with the excitation vibration device 6 in the lower box body; the output end of an excitation vibration power amplifier 1 is connected with the excitation vibration device 6, the vibration signal of the excitation vibration device 6 is connected with a vibration signal measuring apparatus 3 by a vibration sensor, and the output end of the vibration signal regulator 2 is in line connection with the excitation vibration power amplifier 1. The vibration table board 8 is made of an aluminum alloy plate, and equidistance screw holes in even number are formed in the vibration table board 8. The cell culture box is mainly used for providing micro-vibration stress simulation for cell culture under experiment environment.

Owner:SOUTHWEST JIAOTONG UNIV

Impulse Scale Apparatus for Measuring Laser Ablation Micro-Impulse

ActiveCN111373876BReduce preparation timeOvercoming the problem of vacuum evaporationApparatus for force/torque/work measurementEngineeringSensor holder

The invention provides an impulse balance device for measuring laser ablation micro-impulse, which comprises an impulse balance part, an electromagnetic damping part and a displacement measuring part. The impulse scale part includes a beam, a rotating bracket, a pivot, a pivot bracket, a fixed bracket, a counterweight and a damping plate; the middle part of the beam is fixed with a rotating bracket, and one end of the pivot is vertically connected to the rotating bracket, and the other end is vertically connected to the pivot frame ; Both ends of the beam are respectively fixed with counterweights and damping plates; the pivot frame is installed on the upper end of the fixed bracket, and the bottom end of the fixed bracket can be connected with the test bench or other adjustment mechanisms. The electromagnetic damping part includes a power supply, a bracket and an electromagnet; the electromagnet is fixed by the bracket; the displacement measurement part includes a displacement sensor, a sensor bracket, a controller and a data processing terminal.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

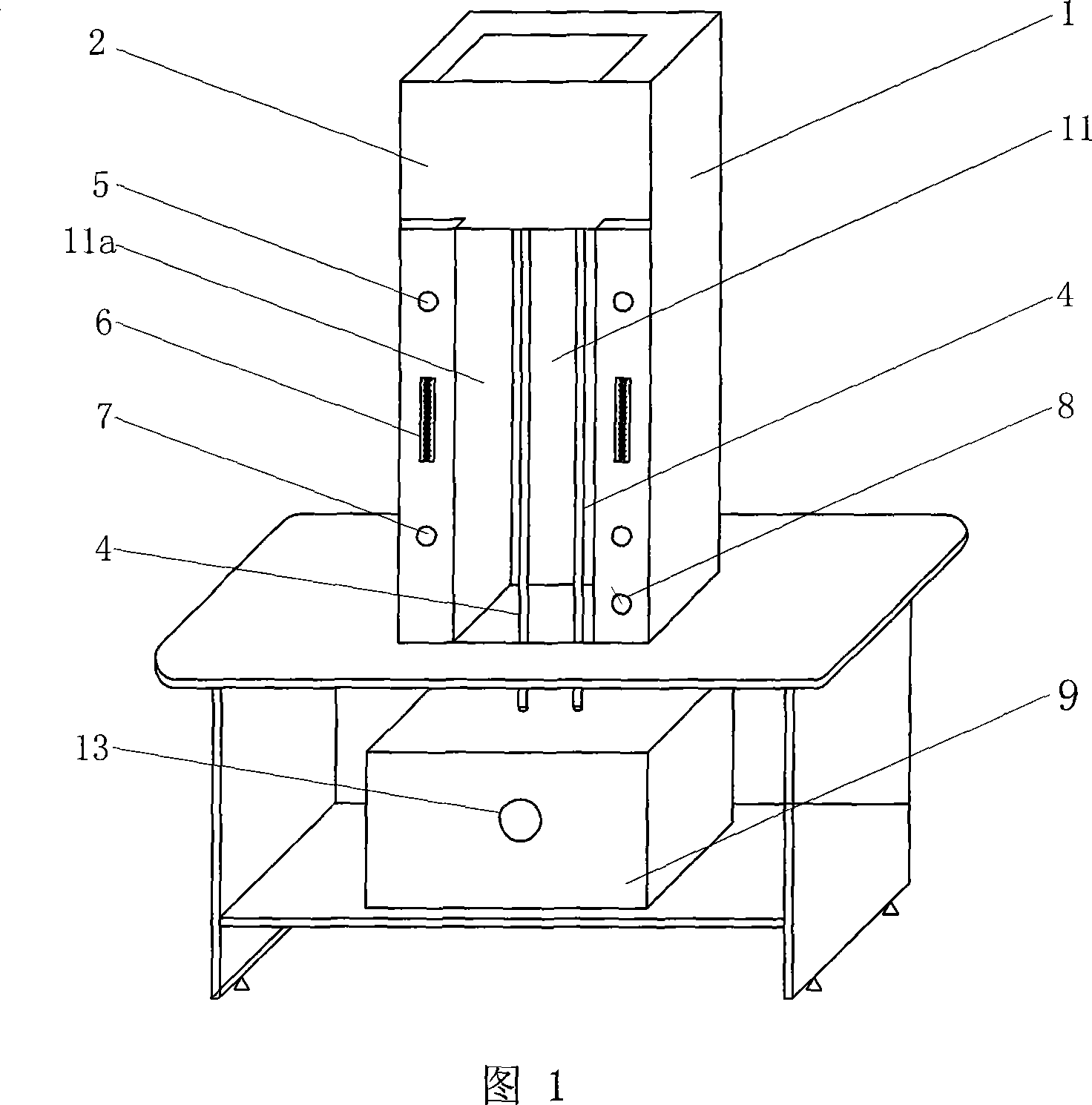

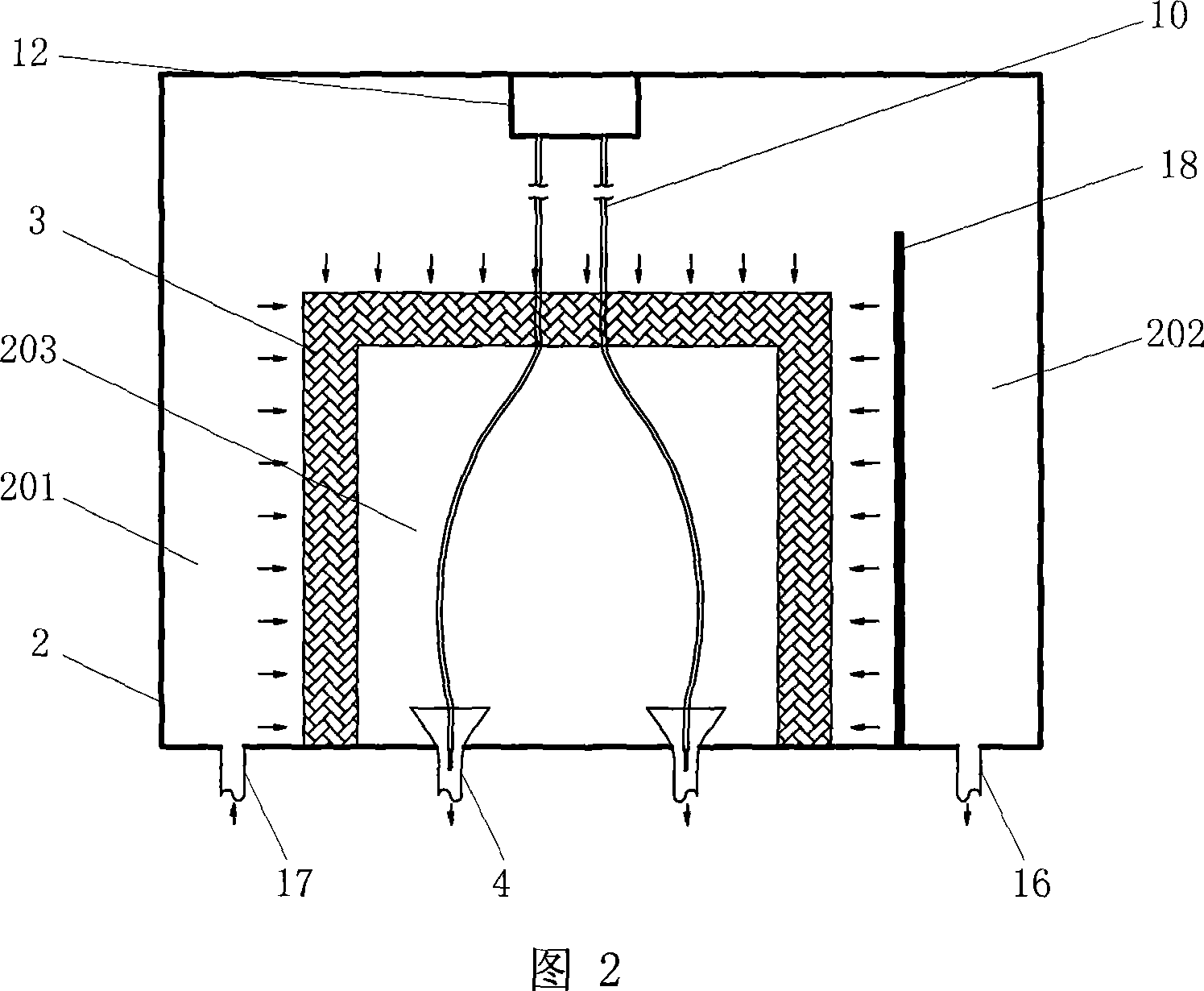

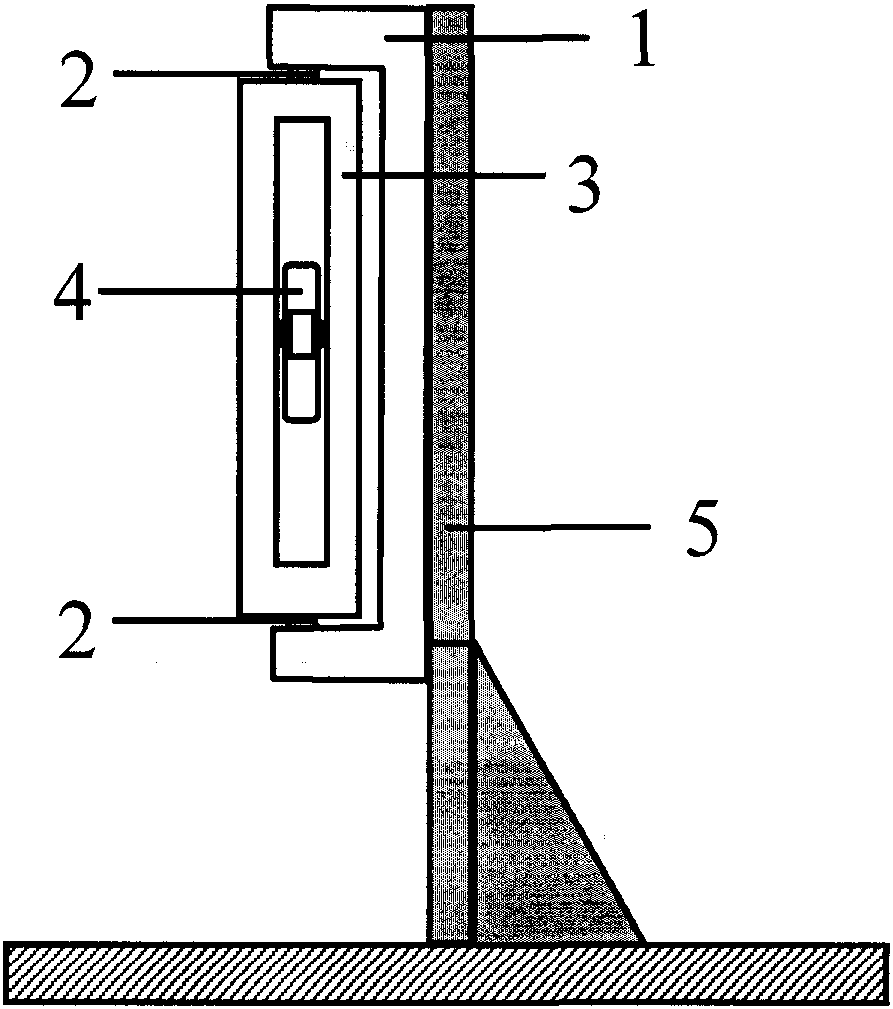

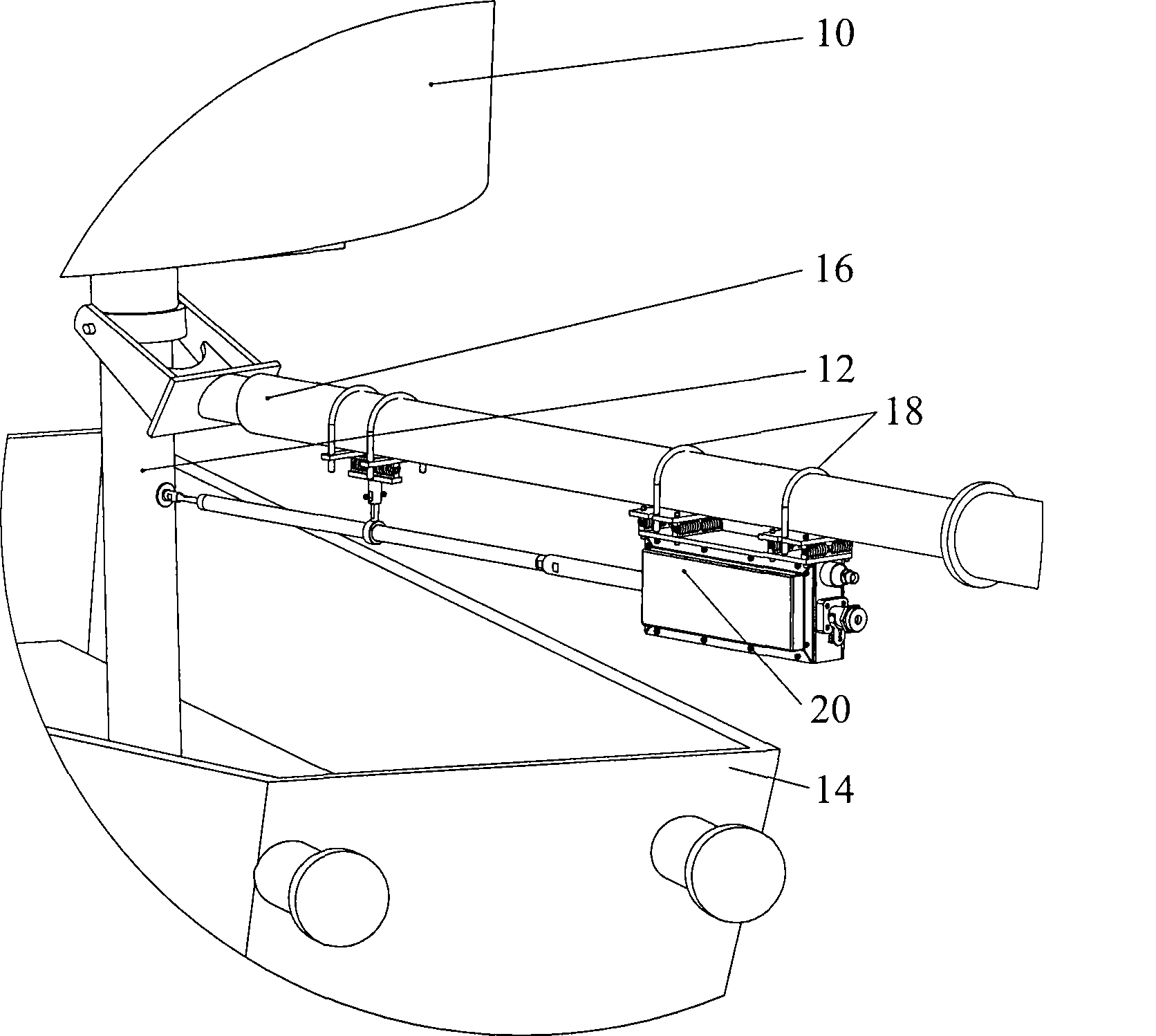

Detecting device of discharging slag from ladle

InactiveCN101393174AHigh precisionAvoid Vibration InterferenceUltrasonic/sonic/infrasonic wave generationProcessing detected response signalSlagEngineering

The invention provides a device for detecting the vibration of slag dropping in a large ladle. The device is used for detecting the vibration of a protective sleeve of a long water gap caused by molten steel which flows from the large ladle to a middle ladle through the protective sleeve of the long water gap during a metallurgical process, wherein the vibration detection device comprises a sensing mechanism, an actuating mechanism and a sensor, wherein the sensing mechanism is selectively contacted with the outer wall of the protective sleeve of the long water gap and senses the vibrating situation of the protective sleeve of the long water gap; the actuating mechanism is connected with the sensing mechanism and drives the sensing mechanism to protrude or withdraw; and the sensor is connected with the sensing mechanism and receives vibration signals transmitted by the sensing mechanism. The device for detecting the vibration of slag dropping in the large ladle is arranged on a slag dropping mechanical arm, fixed on the ground or arranged inside the mechanical arm; and a vibration isolator is arranged between the vibration detection device and the mechanical arm or between a box body and the ground.

Owner:HUNAN RAMON SCI & TECH

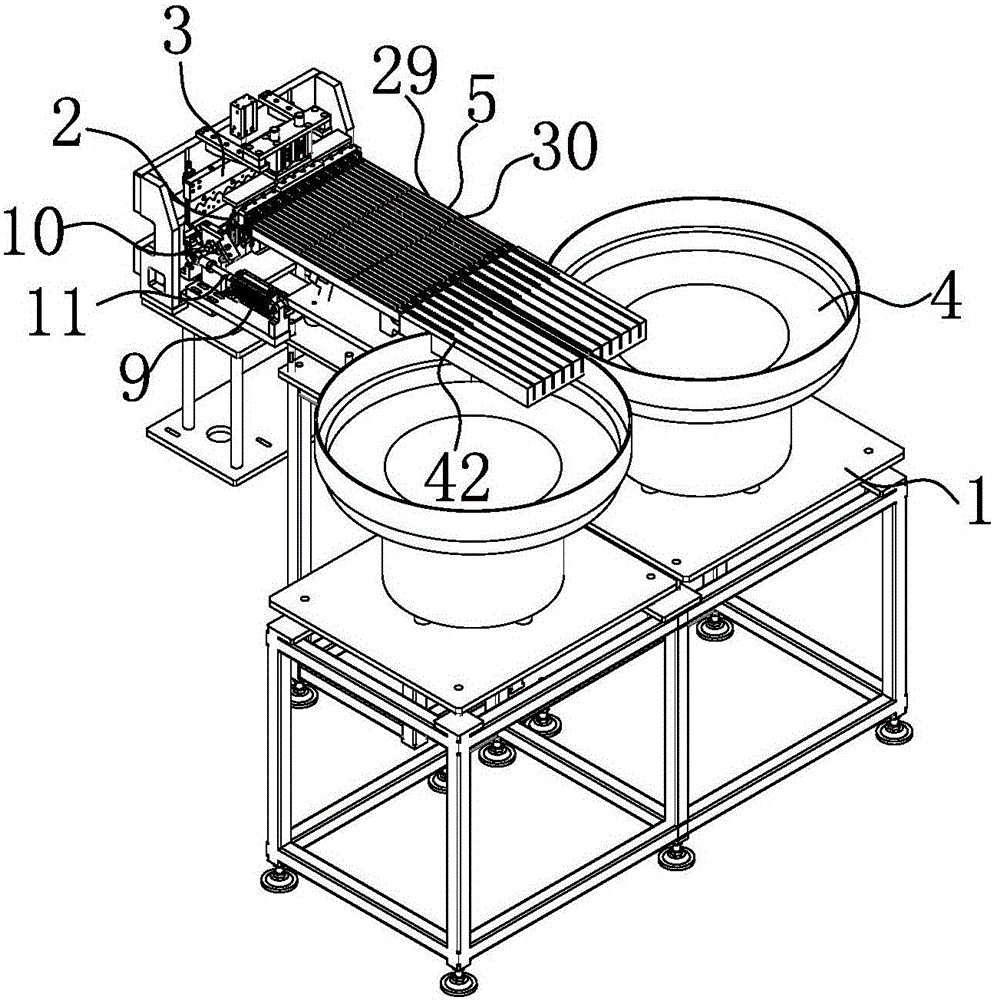

Two-way tube and catheter assembling device

PendingCN106064298ARealize the assemblyImprove accuracyMetal working apparatusMedical equipmentEngineering

The invention belongs to the technical field of medical equipment, and particularly relates to a two-way tube and catheter assembling device which comprises a rack. The two-way tube and catheter assembling device is characterized in that a two-way tube fixture and a catheter fixture are arranged in the rack; a vibrator bowl is arranged on one side of the two-way fixture; a two-way tube conveying mechanism capable of conveying a two-way tube on the vibrator bowl to the end where the two-way fixture is positioned is arranged between the vibrator bowl and the two-way fixture; the two-way fixture is connected with a rotary driving mechanism capable of driving the two-way fixture to be turned over, and further connected with a transverse driving mechanism capable of driving the two-way fixture to move horizontally; and after the two-way fixture is turned over in place, the two-way tube on the two-way fixture is positioned on the same axis with a catheter on the catheter fixture. The two-way tube and catheter assembling device has the advantages that the assembling accuracy between the two-way tube and the catheter is high, and the overall design is reasonable.

Owner:梁启明

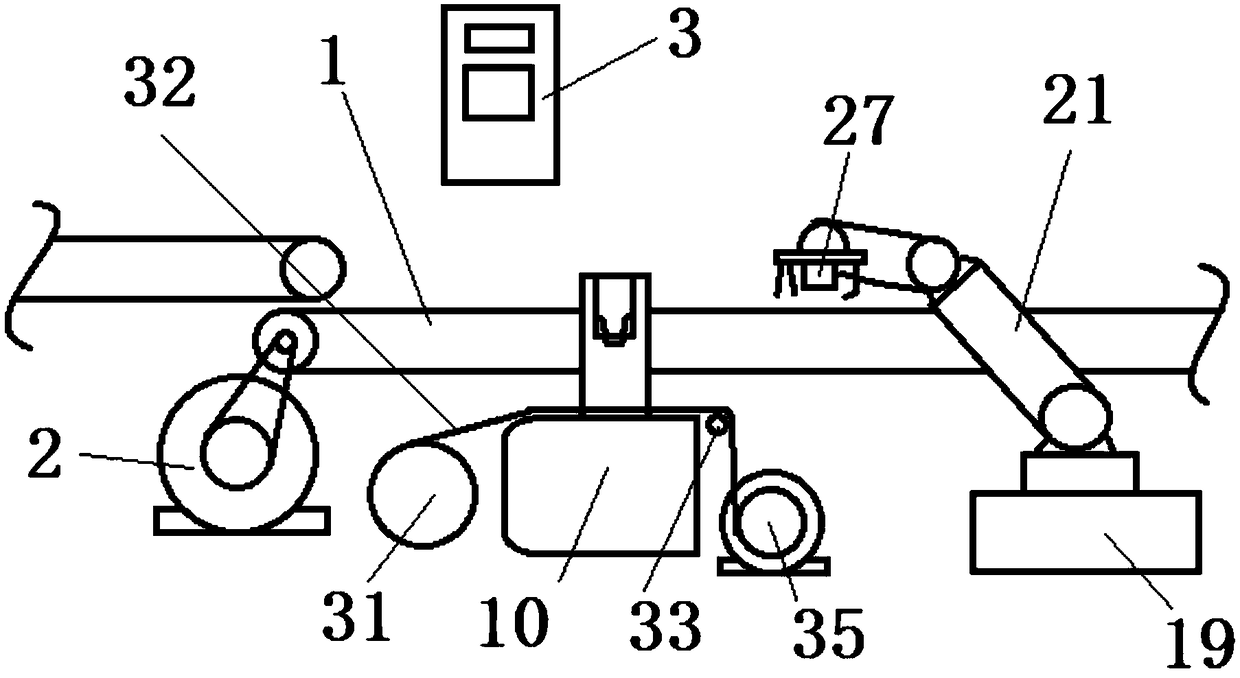

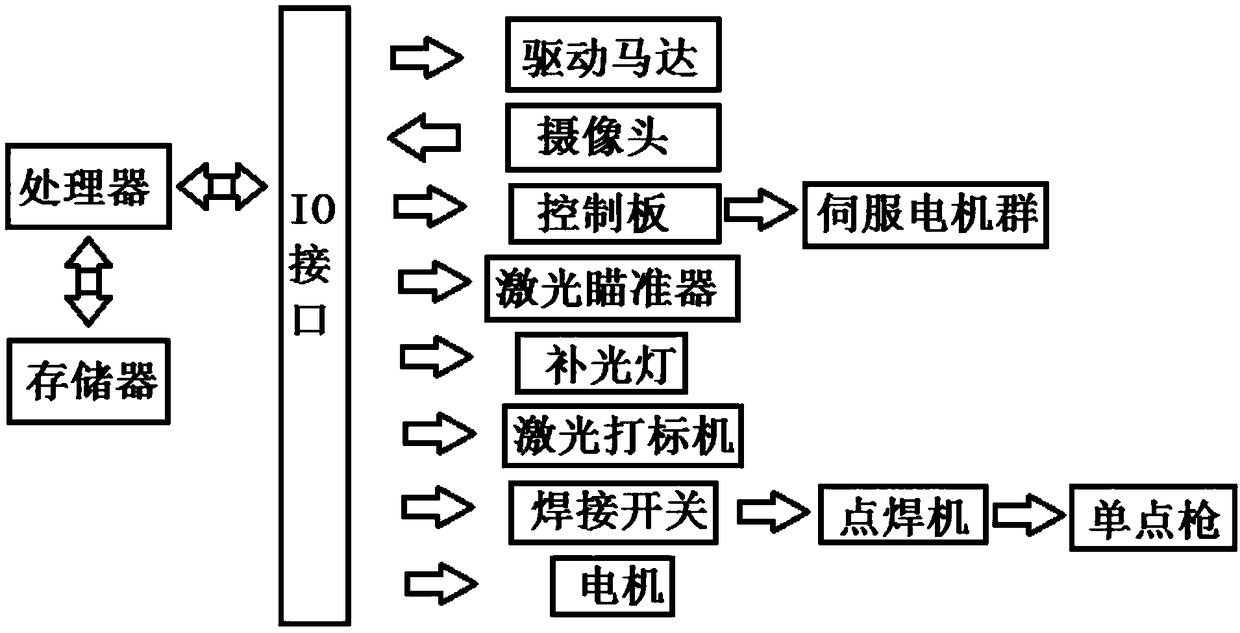

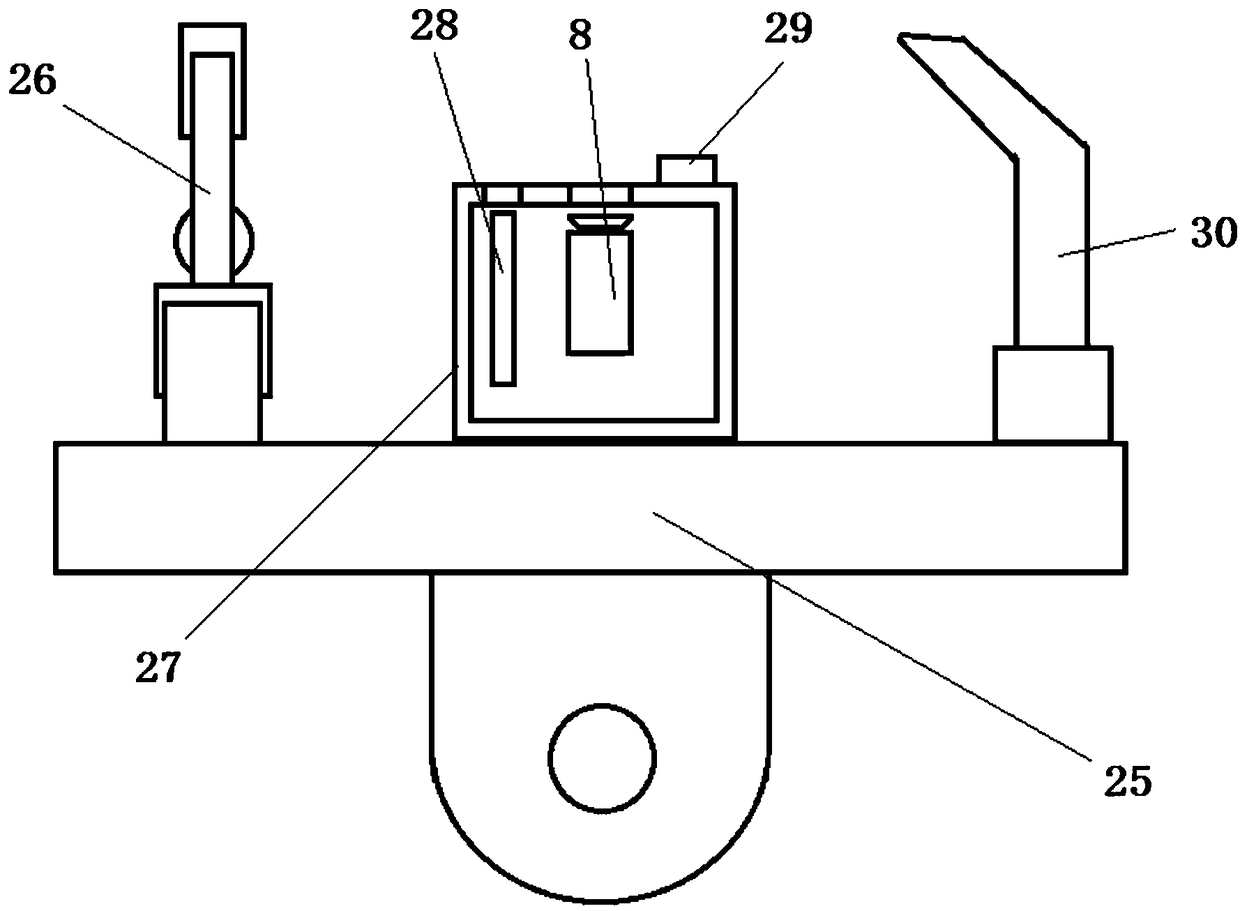

Mark welding system

ActiveCN108747008AGuaranteed efficiencyAvoid mistakesLaser beam welding apparatusReference imageVisual recognition

The invention relates to the field of production automation, in particular to a mark welding system. The mark welding system mainly includes a belt conveyor, a main control box, a robot, a visual recognition device and a spot welding machine, wherein the feeding end of the belt conveyor is located below a discharging opening of a production line, and a driving motor for driving the conveyor belt to convey in the horizontal direction is arranged on the belt conveyor; the main control box is fixedly arranged on any side of the belt conveyor, a processor is arranged in the main control box, the processor is connected with a memory and an IO interface, the memory is used for storing various product reference images and the nameplate contents corresponding to the reference images, and the IO interface is connected to the driving motor through a driving plate; and the visual recognition device and the spot welding machine are connected with the robot, and a laser marking machine is arrangedwithin the operating range of the robot. By means of the mark welding system, the robot can automatically manufacture and fix the nameplates, and various drawbacks caused by the manual nameplate hanging are avoided.

Owner:深圳市天圳自动化技术有限公司

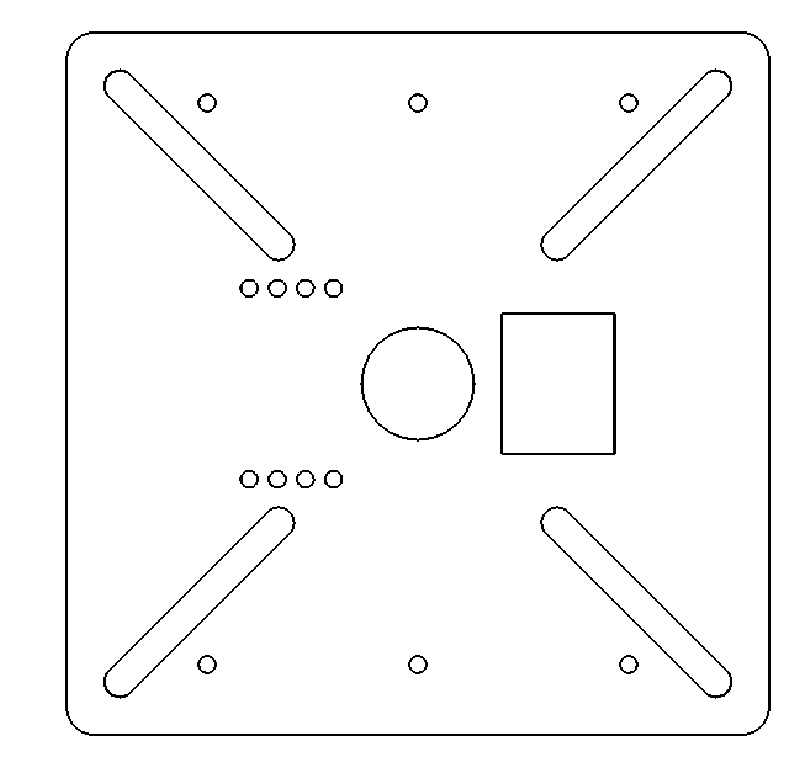

Precise cotton blending machine

ActiveCN106350906AReduce distractionsAvoid Vibration InterferenceFibre feedersDrive motorEngineering

The invention discloses a precise cotton blending machine. The precise cotton blending machine comprises a closed casing, a cotton feeding channel, a driving motor, a cotton pressing roller, a cotton stripping roller, a cotton storing tank, a material sucking hopper, a support, a connecting pipeline and a fan, wherein the cotton storing tank is arranged on the ground and is arranged in the support; a weighing device is arranged at the bottom in the cotton storing tank; a discharge opening is formed in the side face of the cotton storing tank; a driving device is arranged in the support; the material sucking hopper is fixed under the driving device; the material sucking hopper can be movably butted with and separated from the discharge opening by the driving device; the material sucking hopper is communicated with the fan through the connecting pipeline. According to the precise cotton blending machine disclosed by the invention, the cotton storing tank which is independently fixed and is provided with the weighing device is adopted, so that vibration and interference of other devices during working are avoided, and the weighing accuracy is greatly improved; meanwhile, the precise cotton blending machine is also provided with the material sucking hopper which can be movably butted and is only butted with a material sucking inlet of the cotton storing tank during working, so that the interference on weighing is further reduced.

Owner:常州市金坛志诚机械有限公司

Vibration source detecting facility and method

ActiveCN109000874AAvoid Vibration InterferenceWeak vibration is easy to detectVibration testingEngineeringVibration source

The embodiment of the invention provides a vibration source detecting facility and method. The vibration source detecting facility comprises a shielding case used for shielding outside noise, and a vibration source detecting device located in the shielding case. The vibration source detecting device comprises a damping support, a bearing table, a variable-frequency vibration motor, a vibration sensor and a fixing assembly used for fixing a to-be-detected product, wherein the bearing table is arranged on the damping support, and the variable-frequency vibration motor, the vibration sensor and the fixing assembly are arranged on the bearing table. According to the vibration source detecting facility and method, weak vibration of the to-be-detected product can be tested precisely under various outside interference situations.

Owner:GOERTEK INC

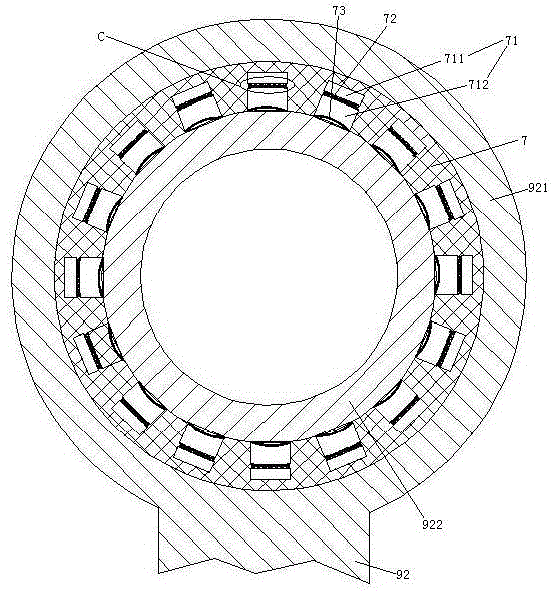

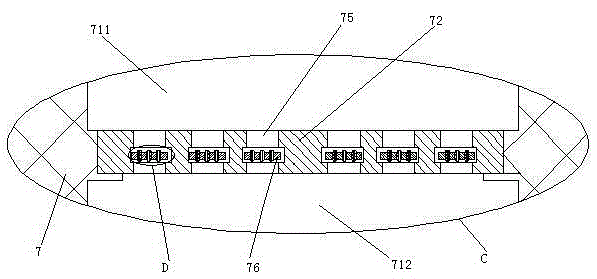

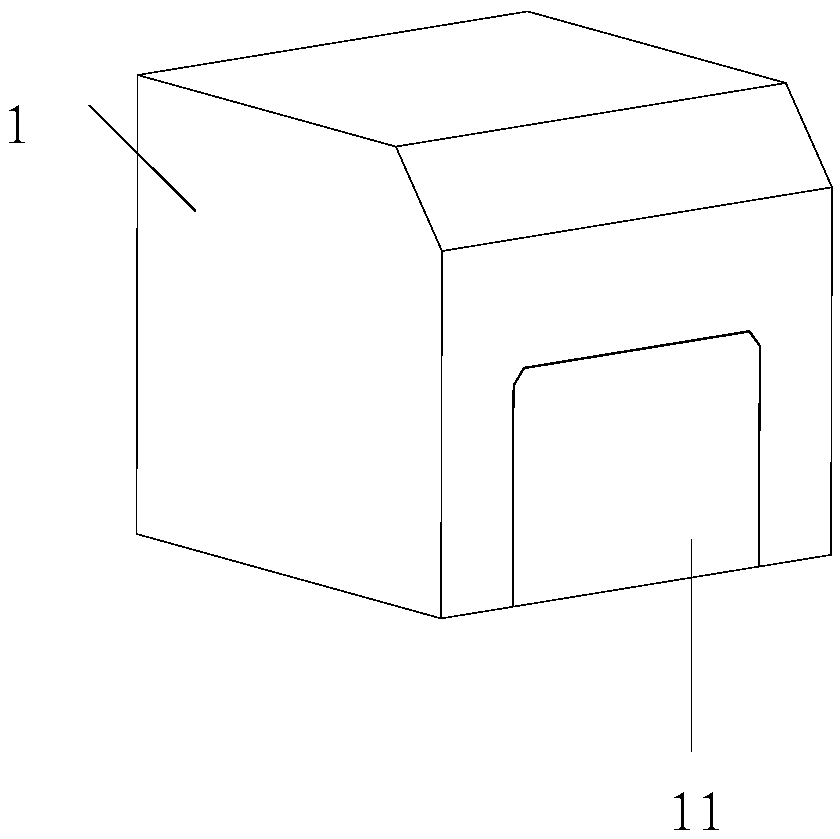

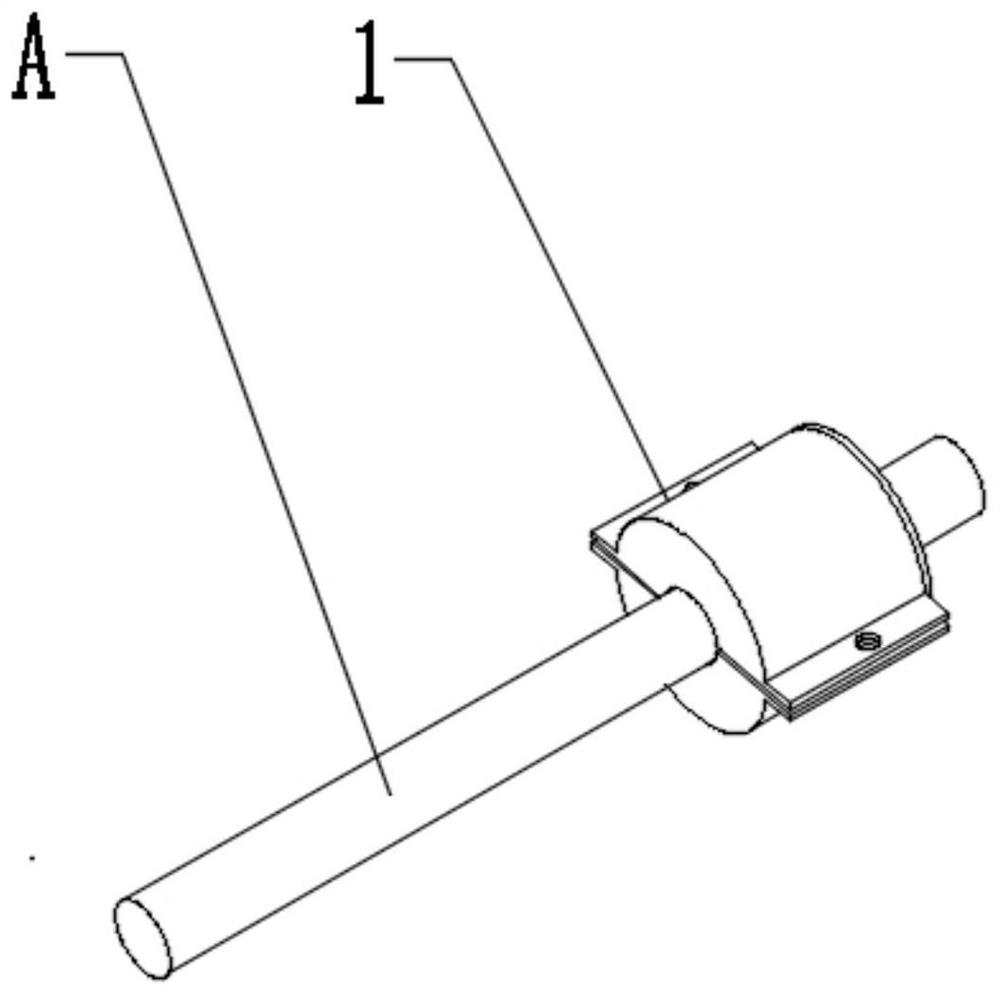

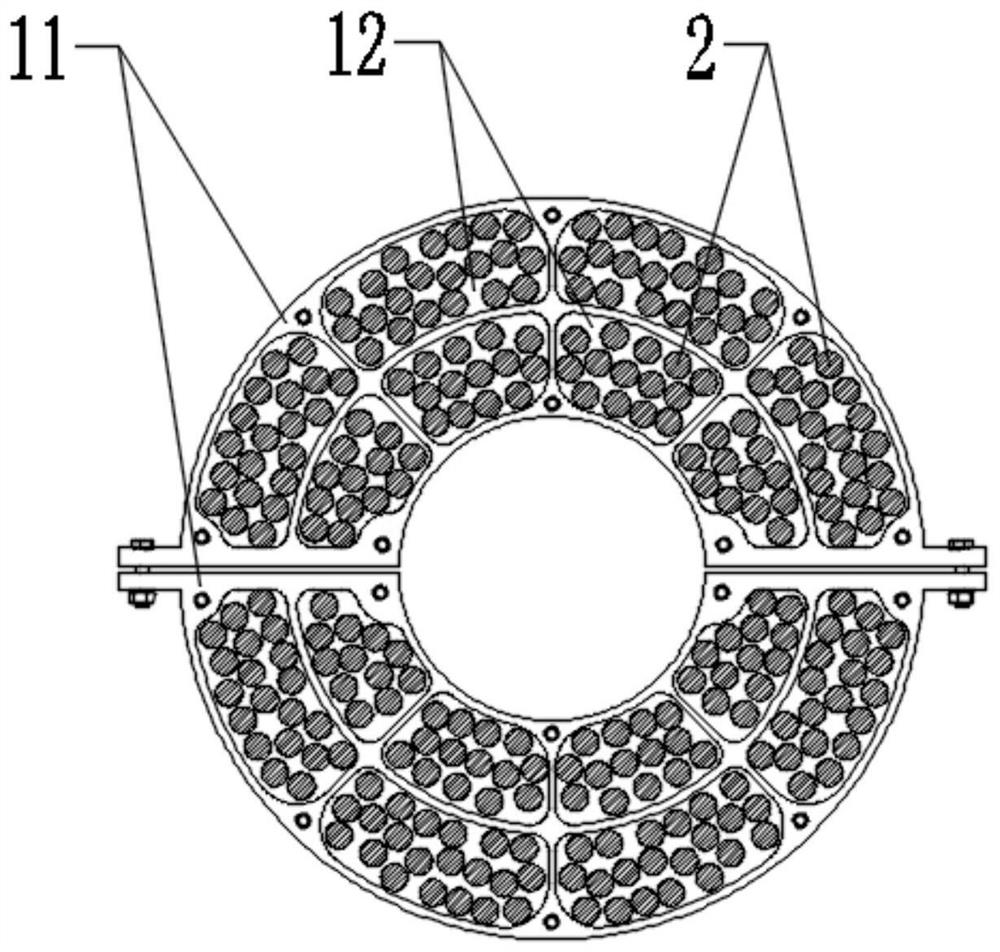

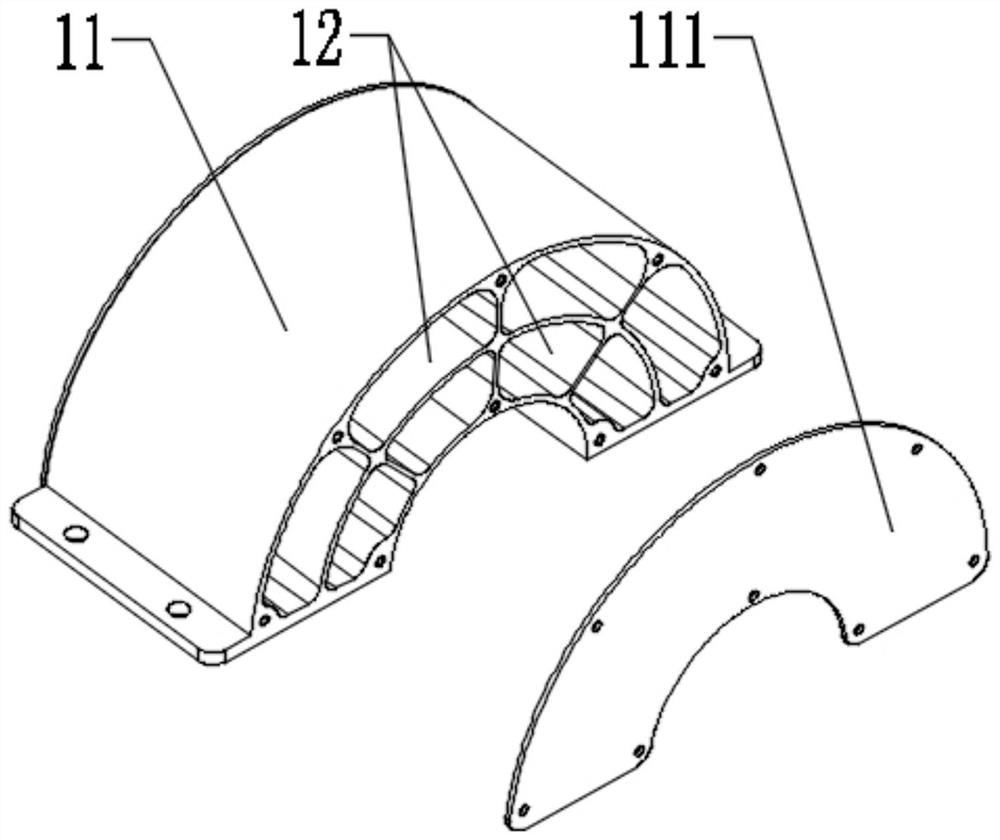

Shafting hoop type particle damping shock absorber and design method

ActiveCN113153947AAvoid failureGuaranteed freedom of movementGeometric CADDesign optimisation/simulationEngineeringShock absorber

The invention discloses a shafting hoop type particle damping shock absorber and a design method. The shock absorber comprises a body and a damping medium, wherein the body is arranged on the outer periphery of a shaft body in a sleeving mode, and the body is filled with the damping medium; the body is provided with a plurality of cavities which are used for containing the damping medium respectively; and the cavities are arranged in the body in a regular arrangement mode and surround the outside of the shaft body at intervals in the axial direction of the shaft body. The body filled with the damping medium is arranged on the outer periphery of the shaft body in a sleeving mode, so that vibration of the shaft body is reduced, stable operation of the shaft body is guaranteed, and safety and efficiency of a shafting transmission system in the working process are further guaranteed.

Owner:XIAMEN ZHEN-WEI TECH CO LED

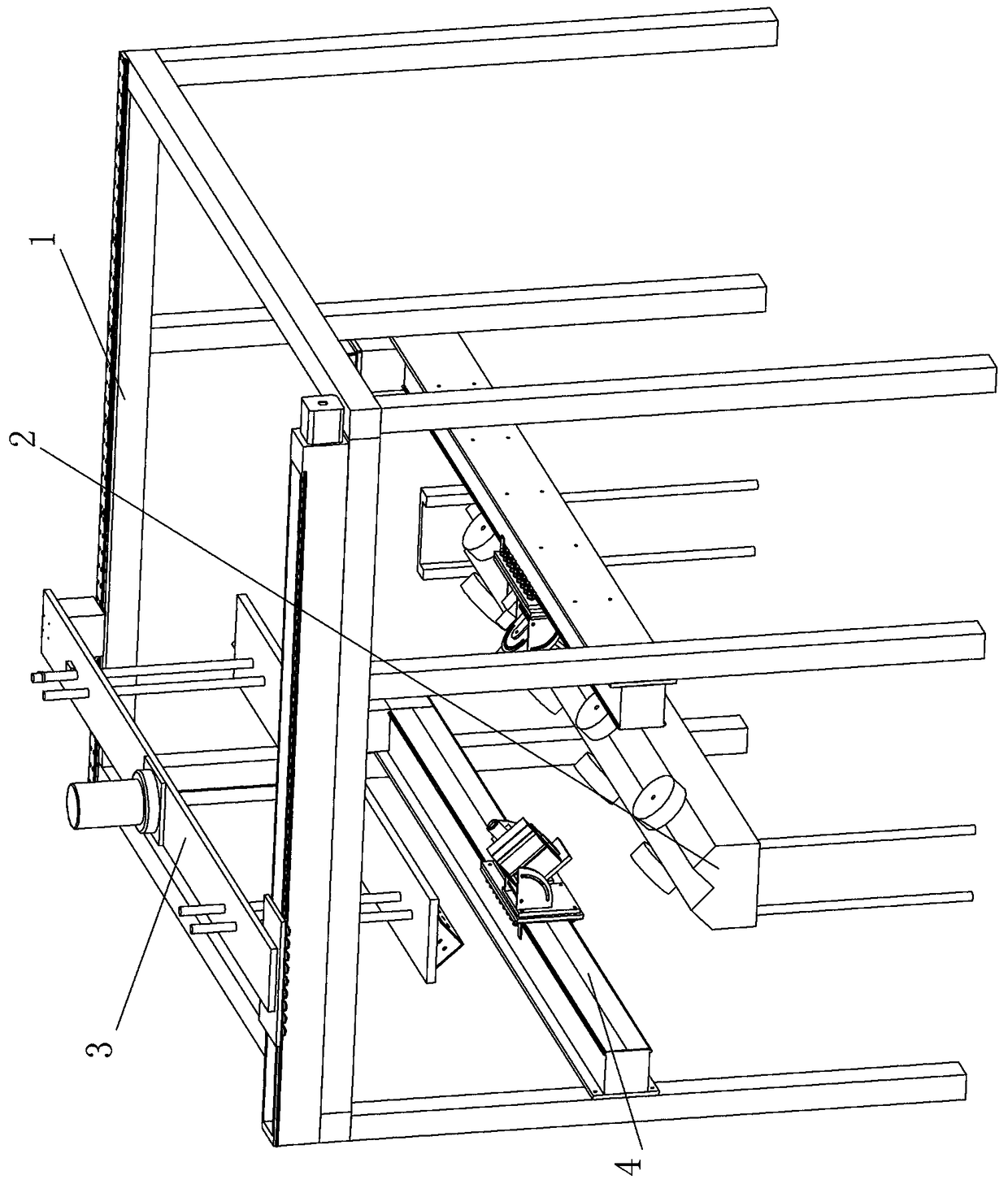

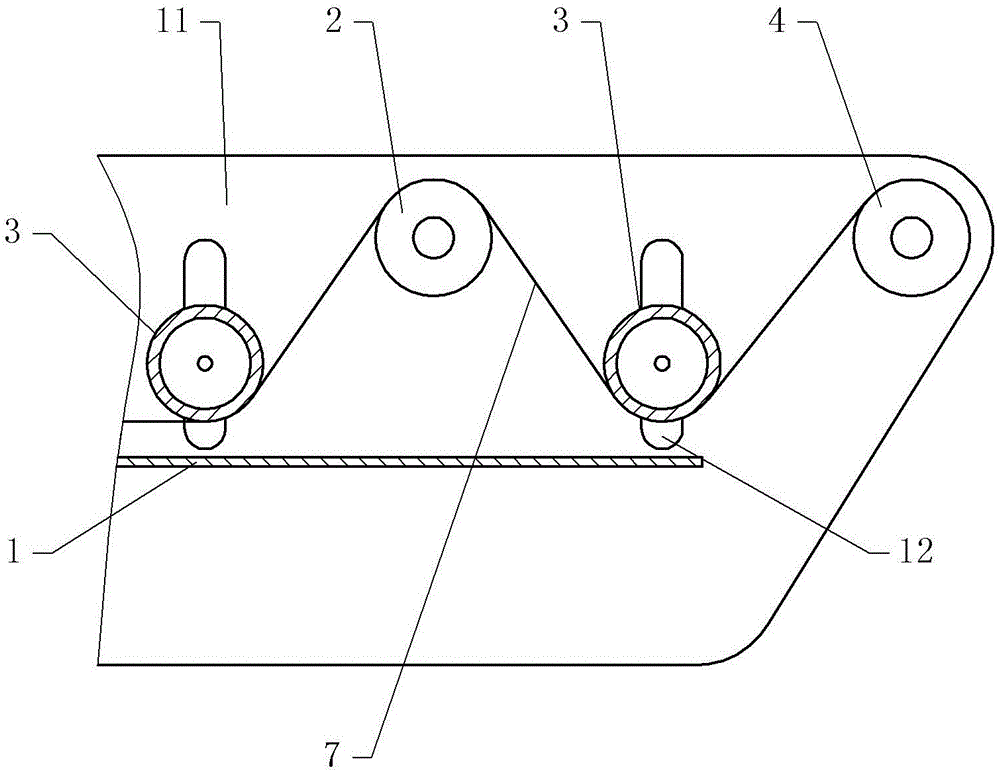

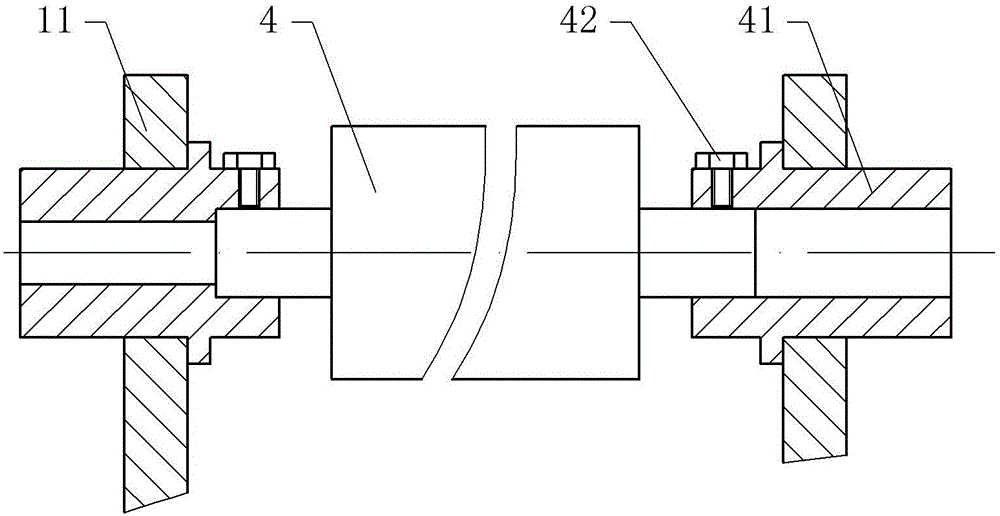

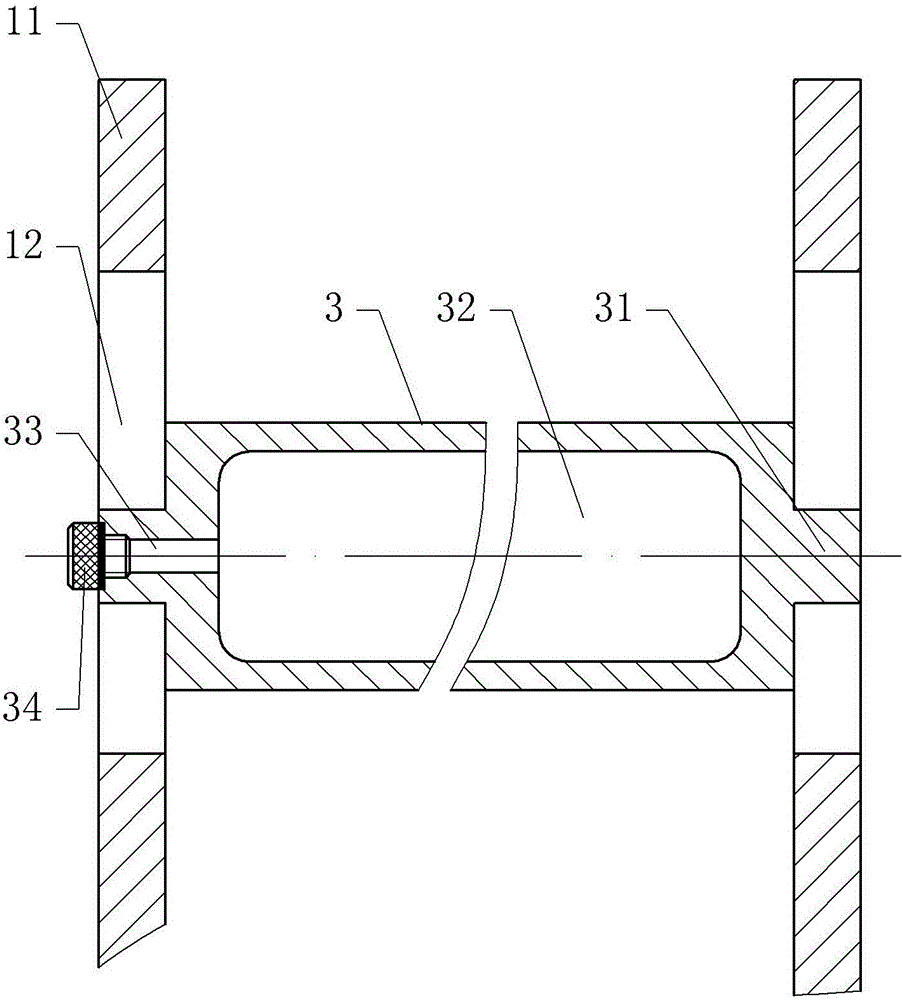

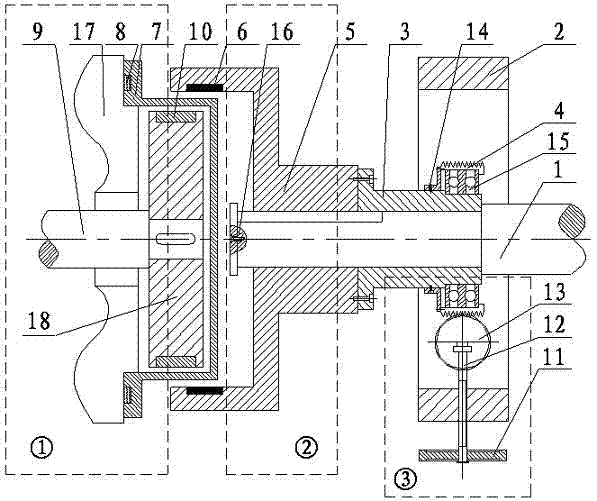

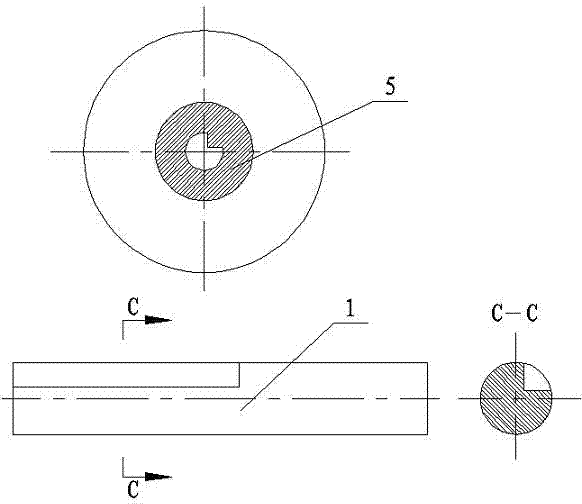

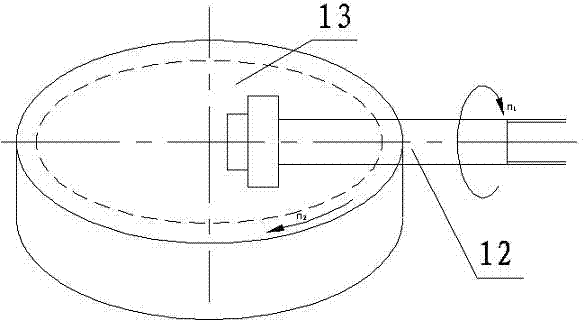

Adjustable axial asynchronous magnetic force coupler

InactiveCN102324829BAdjust the meshing areaRealize the purpose of online stepless speed regulationAsynchronous induction clutches/brakesAviationMagnetic tension force

The invention relates to the technical field of mechanical engineering transmission, in particular to an adjustable axial asynchronous magnetic force coupler. The adjustable axial asynchronous magnetic force coupler is mainly suitable for power transmission devices in the industries such as mines, metallurgy, aviation and the like. The coupler comprises an inner rotor assembly (1), an outer rotorassembly (2), a speed regulation device (3) and a distance sleeve (7), wherein the speed regulation device (3) is composed of a sleeve III (2), a sleeve I (3), a sleeve II (4), a rotation handwheel (11), a friction wheel driving wheel (12), a friction wheel driven wheel (13), a fixed sleeve (14) and double lines of angular contact ball bearings (15). The speed regulation device (3) of the adjustable axial asynchronous magnetic force coupler causes a meshed area between a permanent magnet (6) and a copper bar (10) to be changed by movement transmission between the friction wheel driving wheel and the friction wheel driven wheel, thereby realizing the purpose that the linearity of an output torque is stably changed, realizing the soft start function of the motor, and expanding the application range of the magnetic force coupler. In addition, the transmission mechanism formed by the inner rotor assembly and the outer rotor assembly is searched, the transmission mechanism which can provide stable torque, large power and high efficiency under different occasions is proposed, and the function of the magnetic force coupler is expanded.

Owner:JIANGSU UNIV

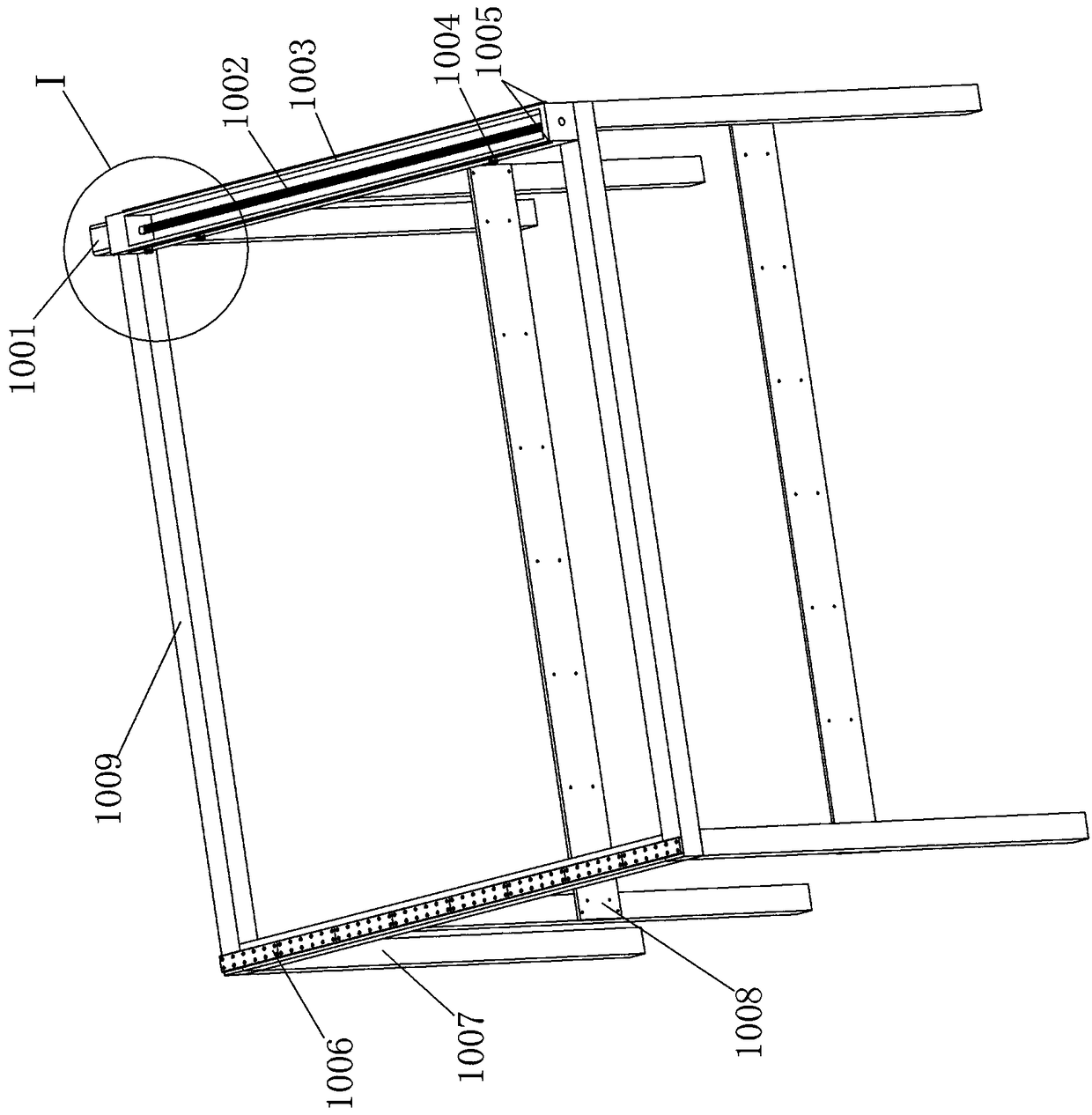

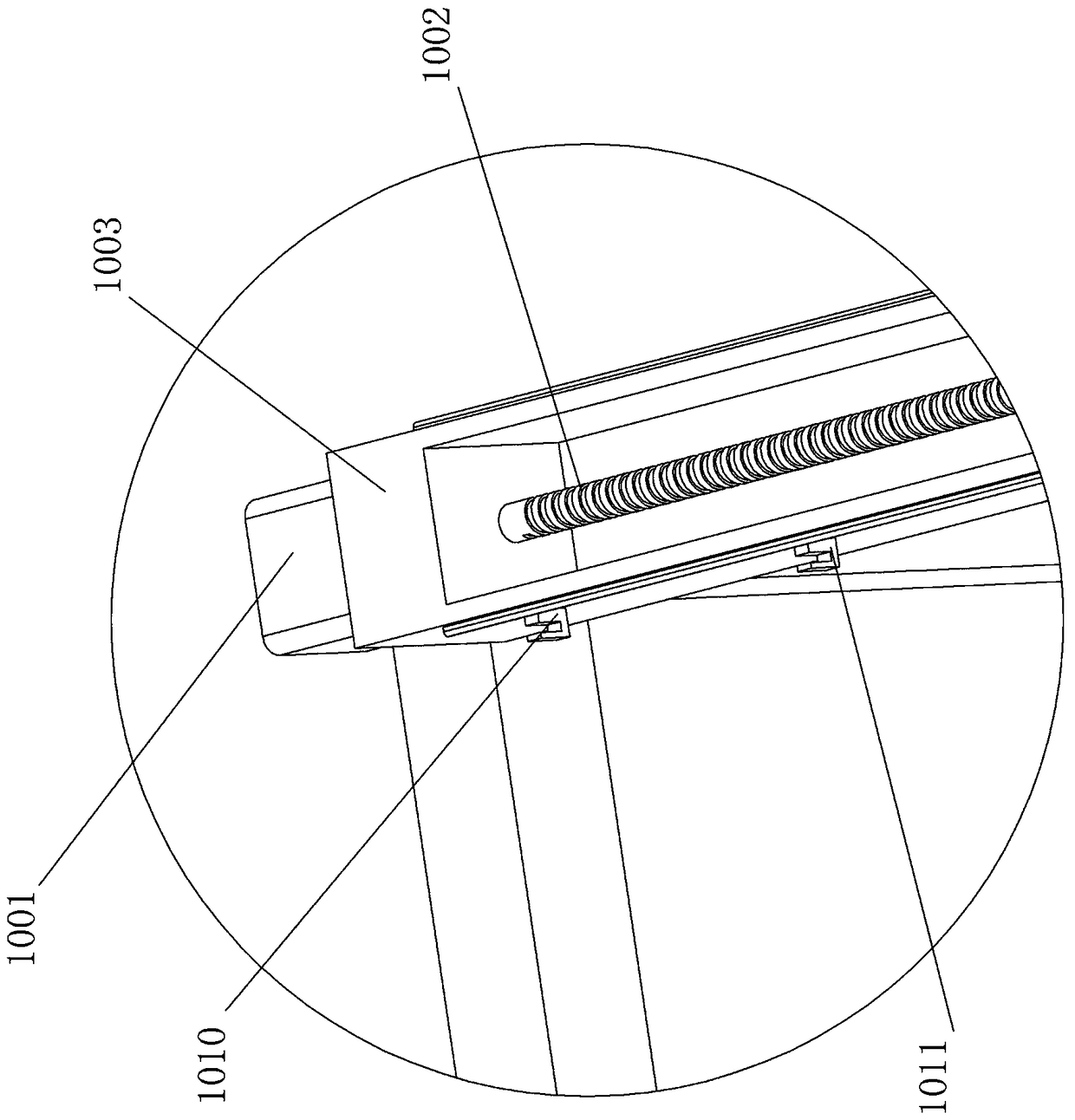

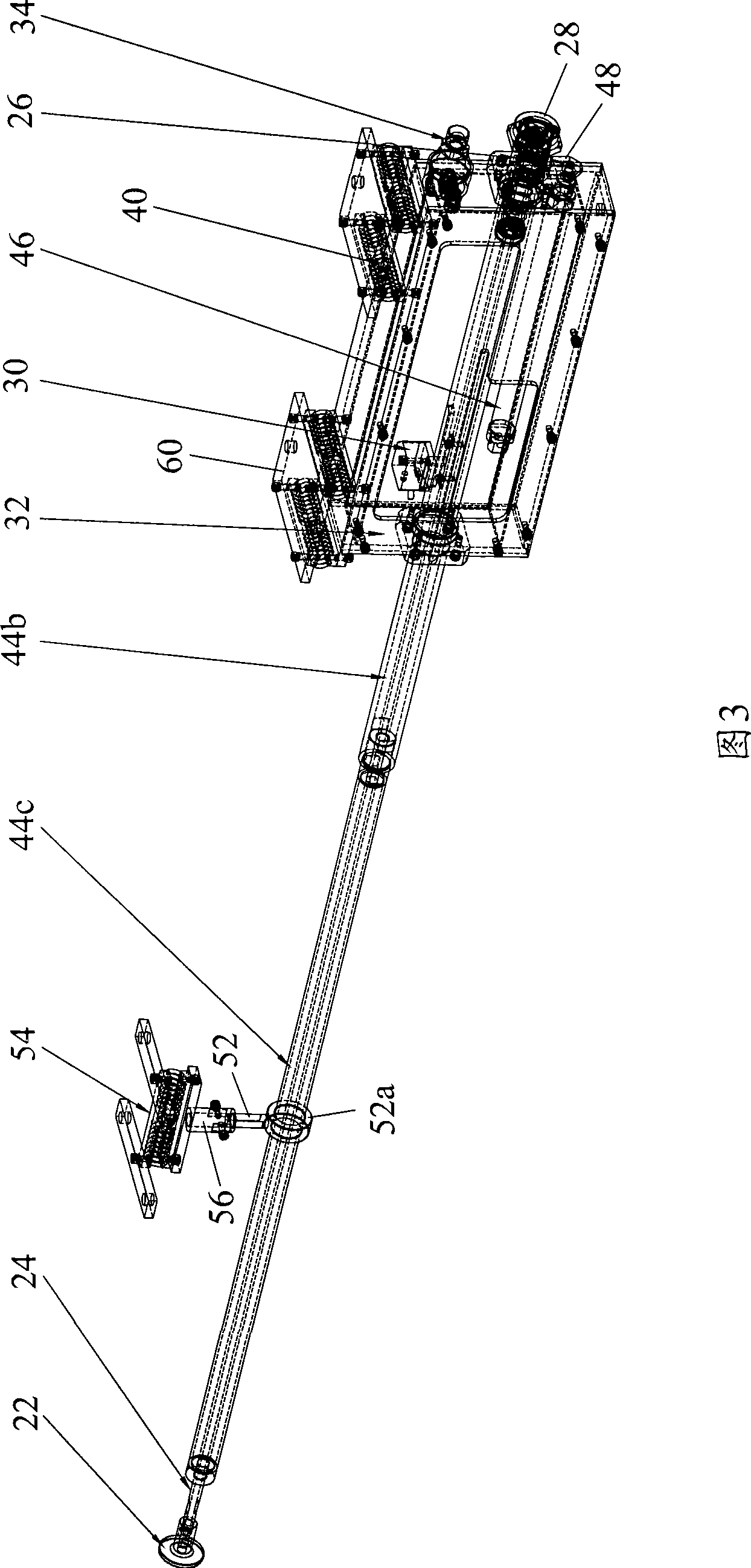

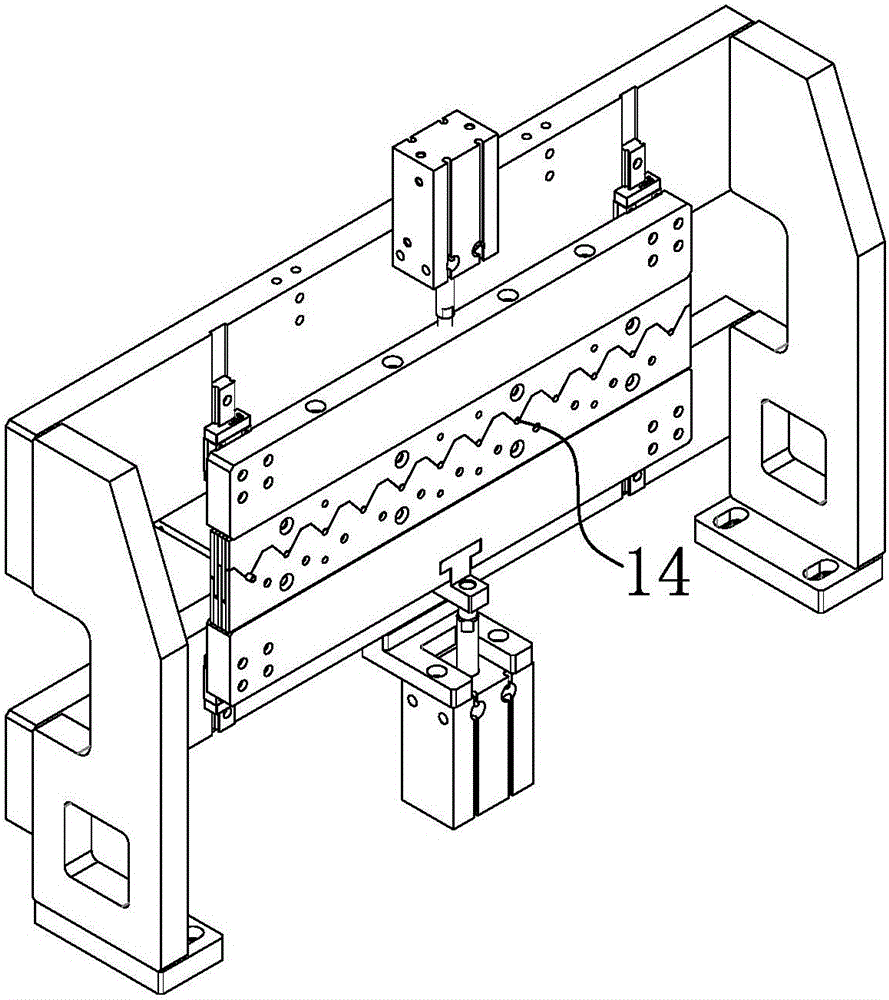

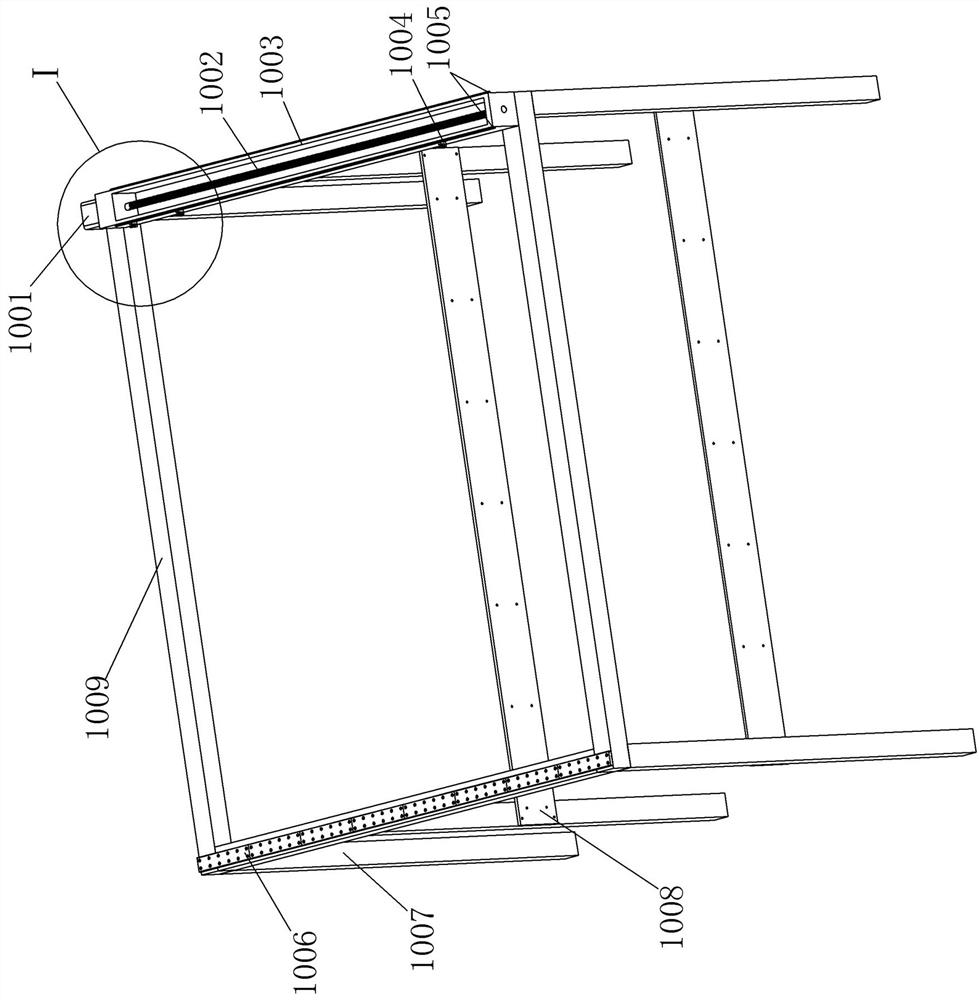

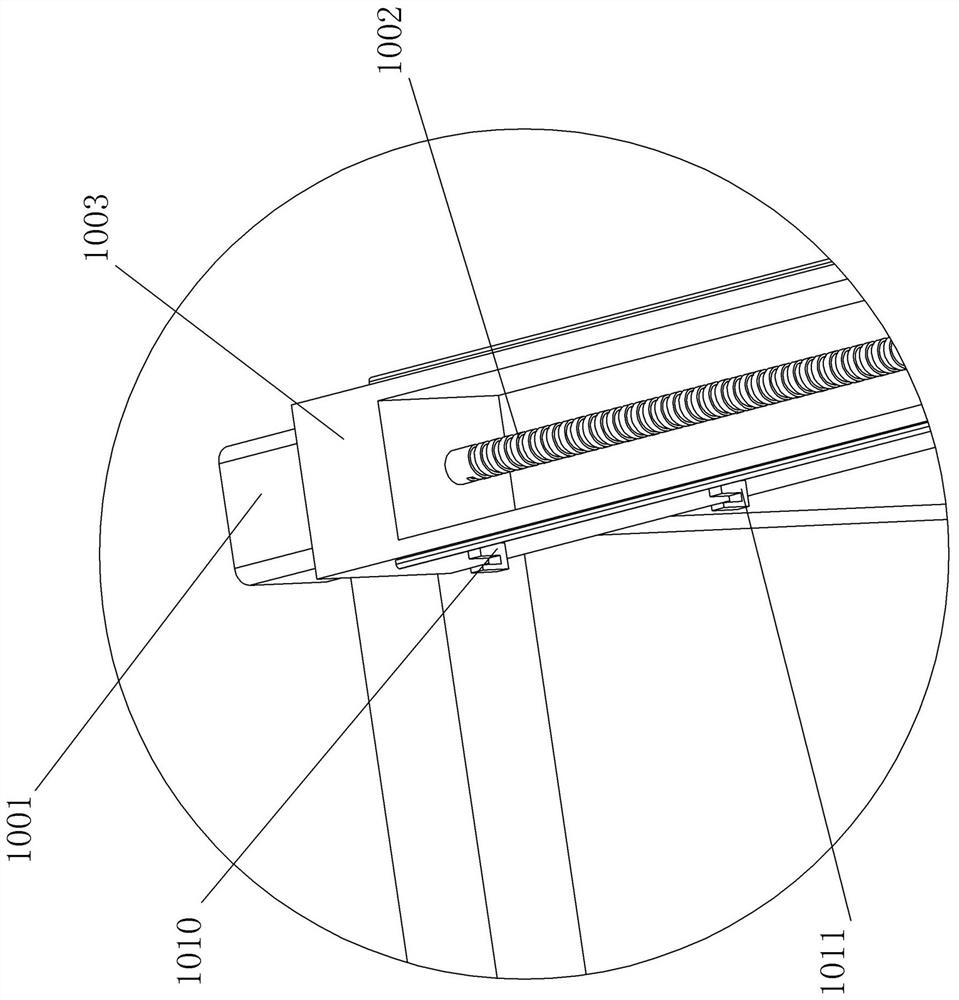

An electric power tower angle steel detection device and detection method

ActiveCN109013375BRealize sortingImprove detection efficiencySortingProduction lineImaging processing

The invention discloses an angle steel detection device and detection method for an electric iron tower. The angle steel detection device comprises an angle steel conveying mechanism, a vertical lifting device and an image acquisition system, wherein the angle steel conveying mechanism is connected with a production line, and used for conveying produced angle steel to the mechanism, and limiting the direction of the angle steel through a movement roll; the vertical lifting device is used for adsorbing the angle steel into air through an electromagnetic suction disc, and avoiding vibration interference of equipment and a transmission device; the image acquisition system controls a movement support through a screw rod and then drives a camera and a light source to rapidly move and shoot, theshot images are transmitted to an upper computer and image processing is carried out, and the angle steel is conveyed to a corresponding station according to a feedback result. The angle steel detection device and detection method for the electric iron tower are capable of realizing online automatic measurement and sorting for the angle steel, and high in automation degree, lower the labor intensity of manual detection and sorting, and greatly increase the detection efficiency for the angle steel and the production efficiency.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

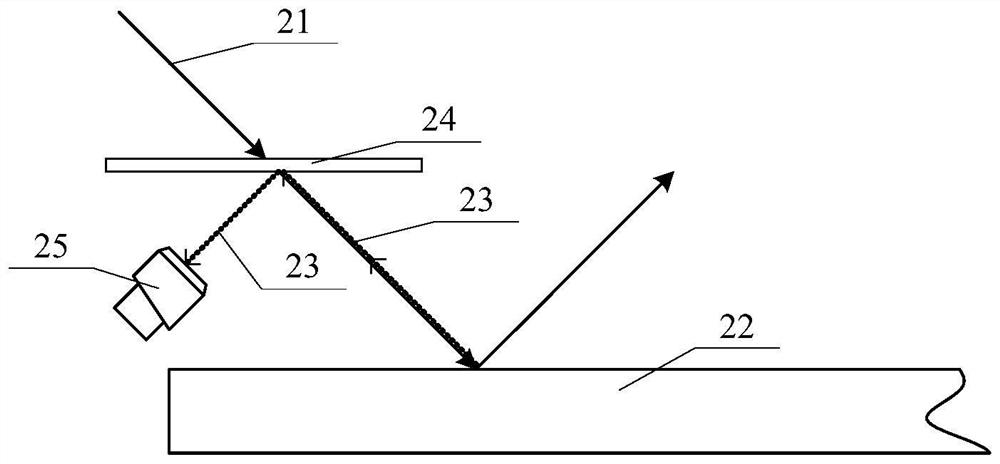

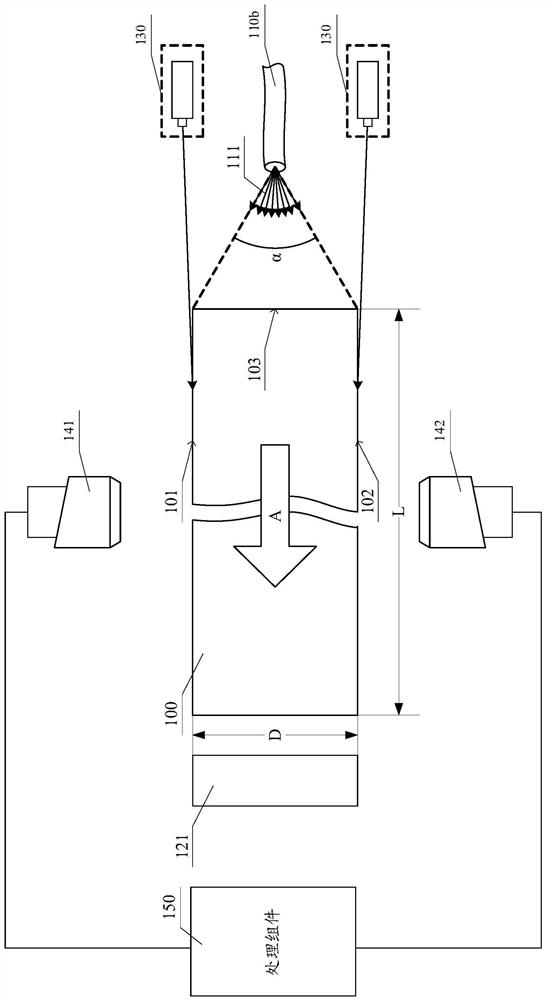

Subsurface defect detection device

PendingCN113008796AAvoid detectionAvoid Vibration InterferenceOptically investigating flaws/contaminationEngineeringWaveguide

A subsurface defect detection device comprises: a light source assembly suitable for generating illumination light, the illumination light being divergent light, wherein the illumination light is coupled into a to-be-detected piece to form waveguide light, and the waveguide light is propagated in the to-be-detected piece in a guided wave mode; an imaging assembly which comprises an area array image sensor, wherein the area array image sensor is suitable for collecting the scattered waveguide light to obtain a defect image; and a processing assembly which is suitable for processing the defect image. The detection device can realize multi-angle detection so as to improve the imaging efficiency; moreover, an area array image sensor is adopted in the imaging assembly to obtain defect images, and the defect images are matched with divergent illumination light, so that the introduction of a scanning mode can be avoided, mechanical vibration interference is avoided, and the synchronous control difficulty is reduced.

Owner:CHIBI JINGMAI OPTOELECTRONIC TECH CO LTD

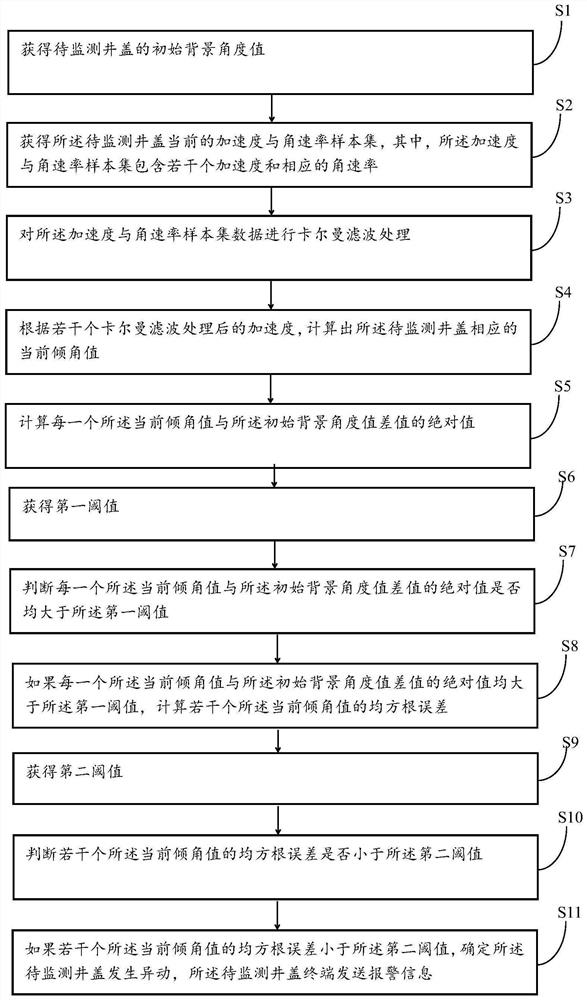

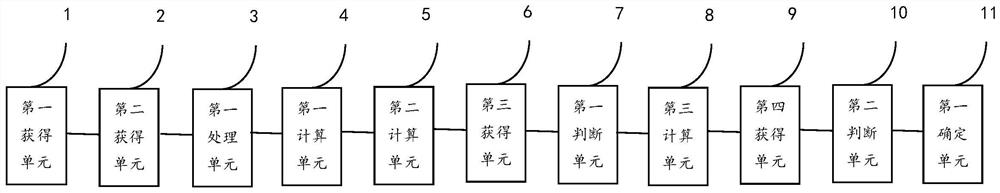

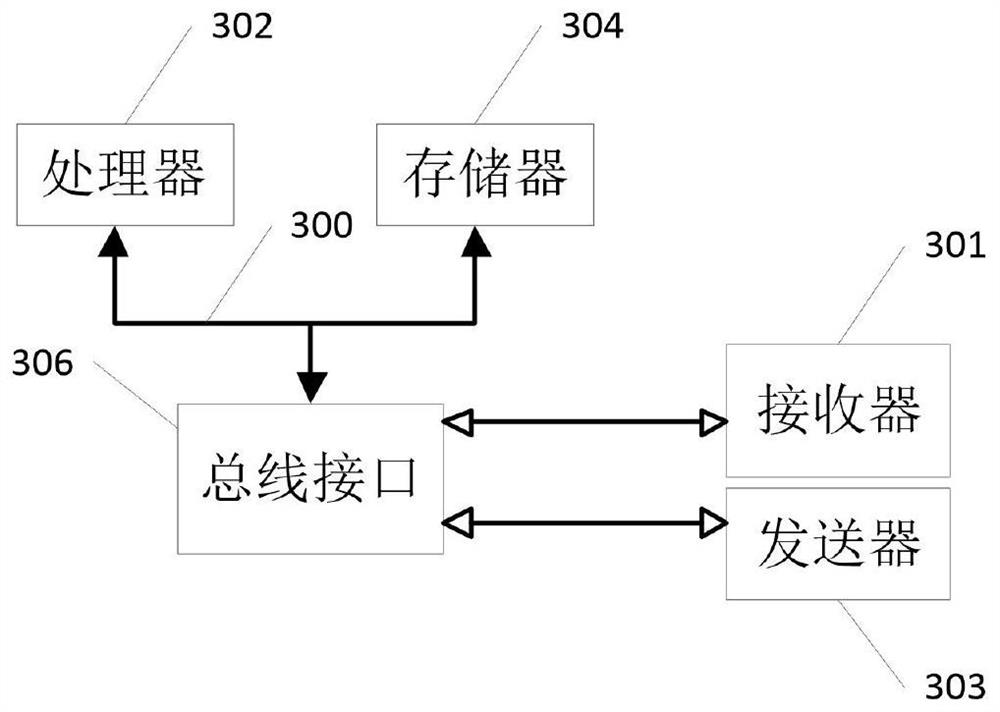

Well lid transaction monitoring method and device based on multi-data fusion filtering

PendingCN112781556ARealize real-time monitoringHigh precisionSpeed measurement using gyroscopic effectsIncline measurementEngineeringThresholding

The invention provides a well lid transaction monitoring method and device based on multi-data fusion filtering. The method comprises the steps of obtaining an initial background angle value and a current acceleration and angular rate sample set of a to-be-monitored well lid; performing Kalman filtering processing on the sample set data; calculating a current inclination angle value; calculating an absolute value of a difference value between each current inclination angle value and the initial background angle value; judging whether the values are greater than a first threshold value; if all the inclination angle values are greater than the first threshold value, calculating root-mean-square errors of the current inclination angle values; judging whether the root-mean-square error of the current inclination angle values is smaller than a second threshold value or not; and if the root-mean-square error of the plurality of current inclination angle values is smaller than a second threshold value, determining that the to-be-monitored well lid is abnormal, and sending alarm information by the to-be-monitored well lid terminal. Based on the Kalman filtering algorithm, the method achieves the technical effects of effectively avoiding the vibration interference problem, achieving the real-time monitoring of the inclination angle of the well lid, improving the dynamic detection precision and accuracy of the abnormal movement of the well lid, and having high applicability.

Owner:XIAN CHINASTAR M&C

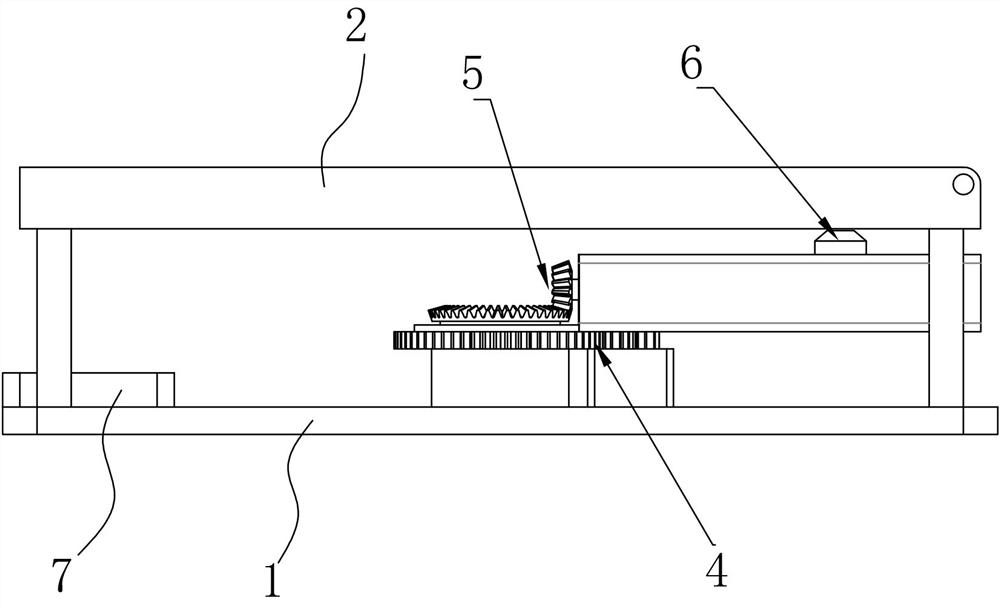

Vertical lathe

InactiveCN101745649AEasy to installEasy to disassembleTurning machinesStructural engineeringEngineering

The invention belongs to the processing equipment technical field, in particular to a vertical lathe. The invention solves the technical problems that processing error is large and structure design is unreasonable in the prior art. The vertical lathe comprises a rotary table arranged horizontally, an actuating unit which is connected on the rotary table and can drive the rotary table to rotate as well as a fixture which is arranged on the rotary table and used for fixing work pieces, and the vertical lathe also comprises a cutter rest arranged independently, and the cutter rest is provided with a cutter which can process the work pieces when the rotary table rotates. The vertical lathe has the advantages that: 1, the structure that the rotary table and cutter are separately arranged, thus avoiding vibration interference when the two are at work, greatly improving processing accuracy and reducing noise; 2, the cutter rest made by concrete is adopted, thus effectively improving strength, avoiding vibration and further improving processing accuracy; besides, concrete is easy to process and make; 3, automation degree is high, and the vertical lathe is easy to operate and use, thus greatly reducing labour intensity and improving labour efficiency.

Owner:HANGZHOU LVDING FILTER PRESS MFG

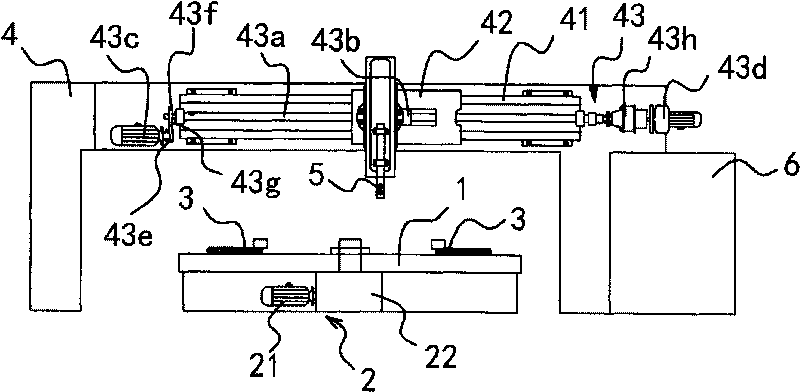

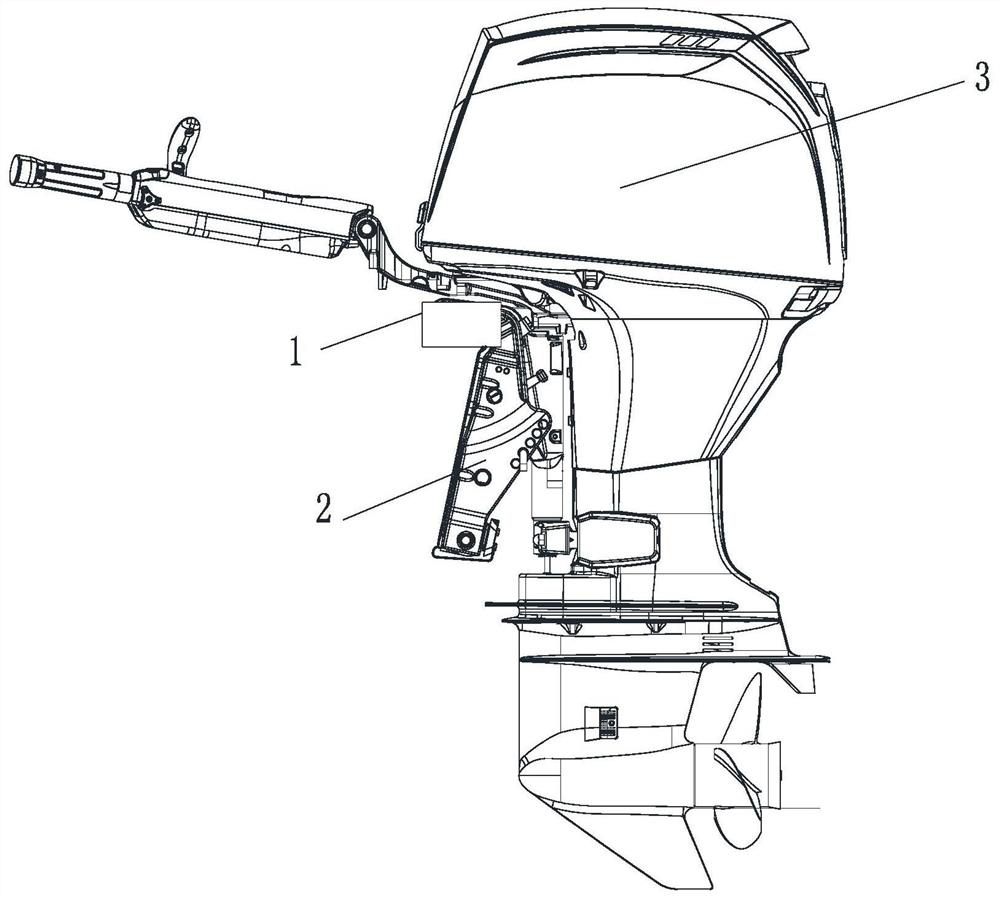

A monitoring system for tilting height of outboard motor

ActiveCN112520001BAvoid Vibration InterferenceEasy to drive safelyPropulsion power plantsOutboard propulsion unitsDriver/operatorFixed frame

The invention discloses a system for monitoring the tilting height of an outboard motor, which includes a fixed frame fixed on the edge of the hull and an outboard motor movably connected with the fixed frame, and also includes a tilting height sensing device, a controller, a central controller and display instrument; the tilting height sensing device is used to measure the tilting height information of the outboard motor, and is fixedly arranged on a fixed frame and is movably connected with the main body of the outboard motor; the controller calculates the tilting height of the tilting height sensing device Warp the height signal and send the warping height signal to the central controller, and communicate with the central controller; the central controller is used to control the warping of the outboard motor and receive the warping height signal, and convert the warping height signal into a pointer The signal is electrically connected to the display instrument; the display instrument is used for real-time display of the tilting height information of the outboard engine and is fixedly installed in the operating room. This scheme can display the warping height value of the outboard motor in real time through the display instrument, which brings great convenience to the driver's safe driving.

Owner:HANGZHOU HIDEA POWER MACHINERY

Vertical lathe

InactiveCN101745649BHigh degree of automationImprove work efficiencyTurning machinesStructural engineeringProcessing accuracy

The invention belongs to the processing equipment technical field, in particular to a vertical lathe. The invention solves the technical problems that processing error is large and structure design is unreasonable in the prior art. The vertical lathe comprises a rotary table arranged horizontally, an actuating unit which is connected on the rotary table and can drive the rotary table to rotate aswell as a fixture which is arranged on the rotary table and used for fixing work pieces, and the vertical lathe also comprises a cutter rest arranged independently, and the cutter rest is provided with a cutter which can process the work pieces when the rotary table rotates. The vertical lathe has the advantages that: 1, the structure that the rotary table and cutter are separately arranged, thusavoiding vibration interference when the two are at work, greatly improving processing accuracy and reducing noise; 2, the cutter rest made by concrete is adopted, thus effectively improving strength, avoiding vibration and further improving processing accuracy; besides, concrete is easy to process and make; 3, automation degree is high, and the vertical lathe is easy to operate and use, thus greatly reducing labour intensity and improving labour efficiency.

Owner:HANGZHOU LVDING FILTER PRESS MFG

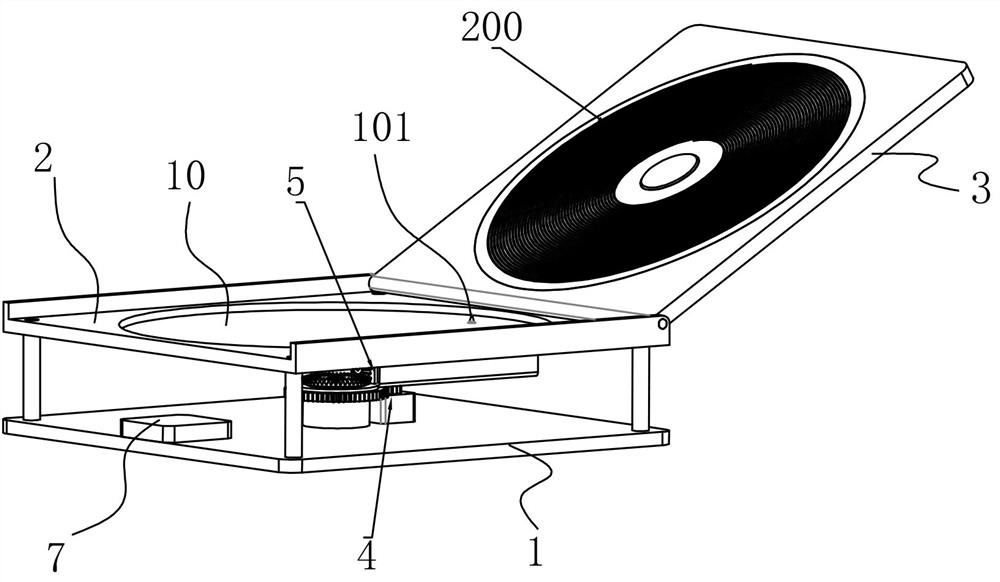

High-resolution sound pickup

ActiveCN113382346ARestore accuratelyImprove reading accuracyElectrical transducersMagnetorheological fluidSound quality

The invention discloses a high-resolution sound pickup, which comprises a bottom plate, a first seat body, a second seat body, a rotary driving mechanism, a radial driving mechanism, an ultrasonic sound pickup head and a signal processing unit; the first seat body is provided with an accommodating circular groove in which magnetorheological fluid is stored; the second seat body is provided with a disc mounting circular groove; the disc mounting circular groove and the accommodating circular groove are coaxial; the rotary driving mechanism is used for driving the ultrasonic sound pickup head to rotate circumferentially; the radial driving mechanism is connected with the output end of the rotary driving mechanism and is used for driving the ultrasonic sound pickup head to move in the radial direction; the ultrasonic sound pickup head is used for generating a vertically upward magnetic field to enable the magnetorheological fluid to form a conical magnetorheological fluid stylus, and is used for sending out an ultrasonic signal, receiving an ultrasonic reflection signal and feeding back the received ultrasonic reflection signal to the signal processing unit; and vibration interference in the pickup process is avoided, the sound information reading precision is improved, the playing sound quality is better, and sound can be accurately restored.

Owner:深圳市微语信息技术开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com