Cutter wear identification and prediction method based on high and low frequency acoustic emission sensor fusion

A technology of acoustic emission sensor and tool wear, which is applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc. It can solve the problems of inconsistent data structure, poor data interaction, and difficult construction of processing and training models. The method is simple , the result is accurate, and the effect of avoiding low-frequency environmental noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] For the rough machining of a certain type of steam turbine rotor and blade produced by Shanghai Electric Group Shanghai Turbine Factory, the material is Inconel182. The complex shape of the blade profile requires that it is not allowed to stop the machine to change the tool before the cutting process is completely completed, and it is not allowed to damage the machined surface due to the wear and failure of the tool in the middle, and then cause the parts to be scrapped. Considering the tool cost, it is hoped that the tool life can be fully utilized.

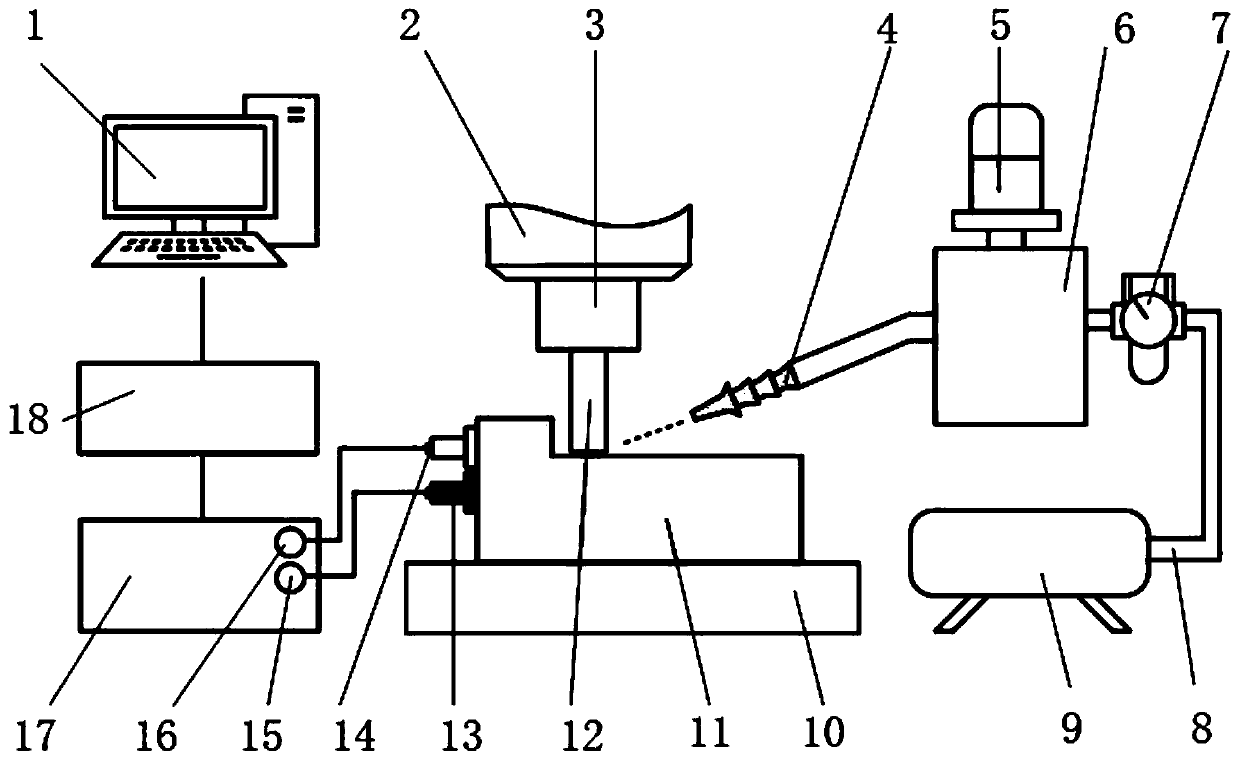

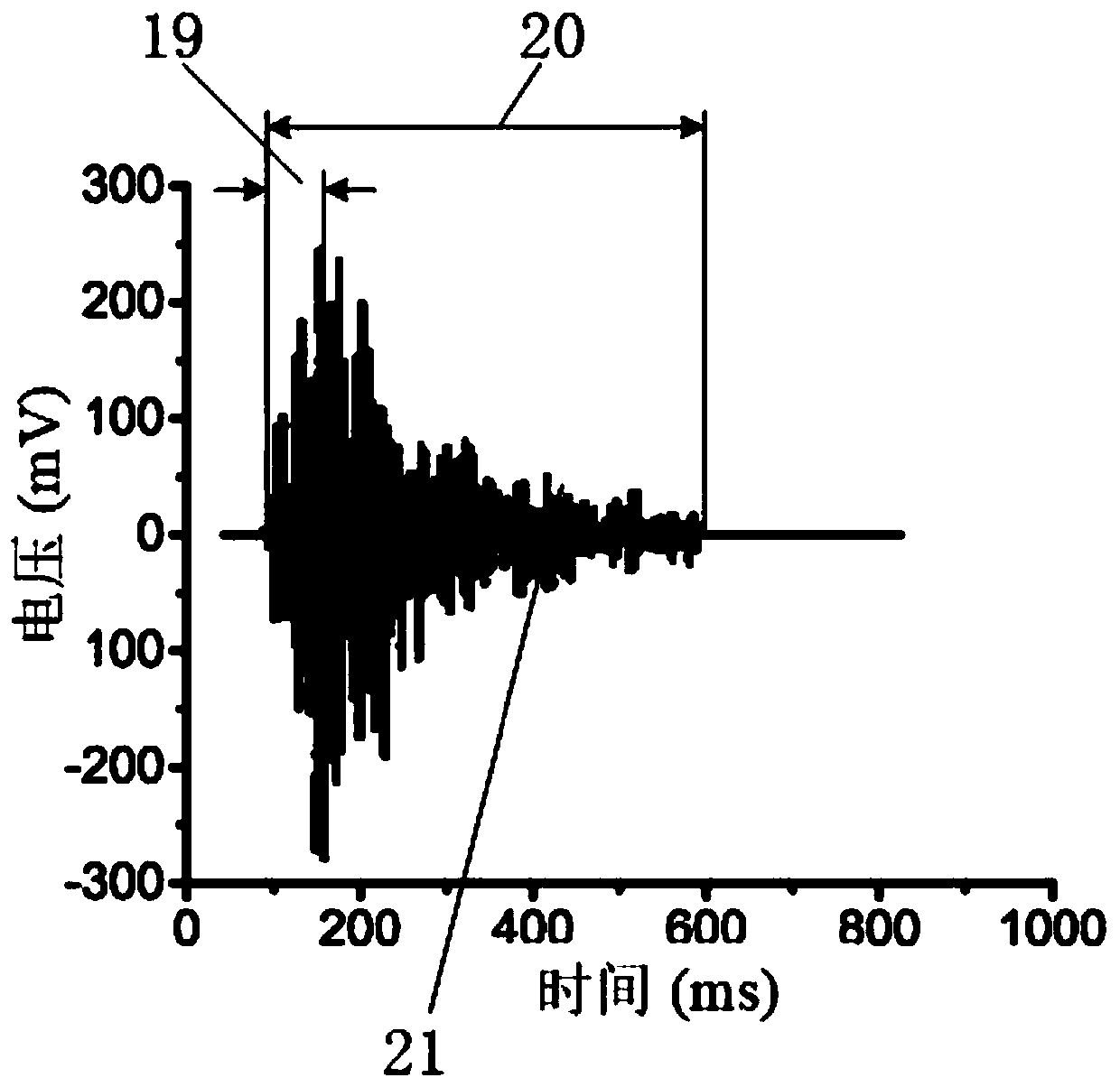

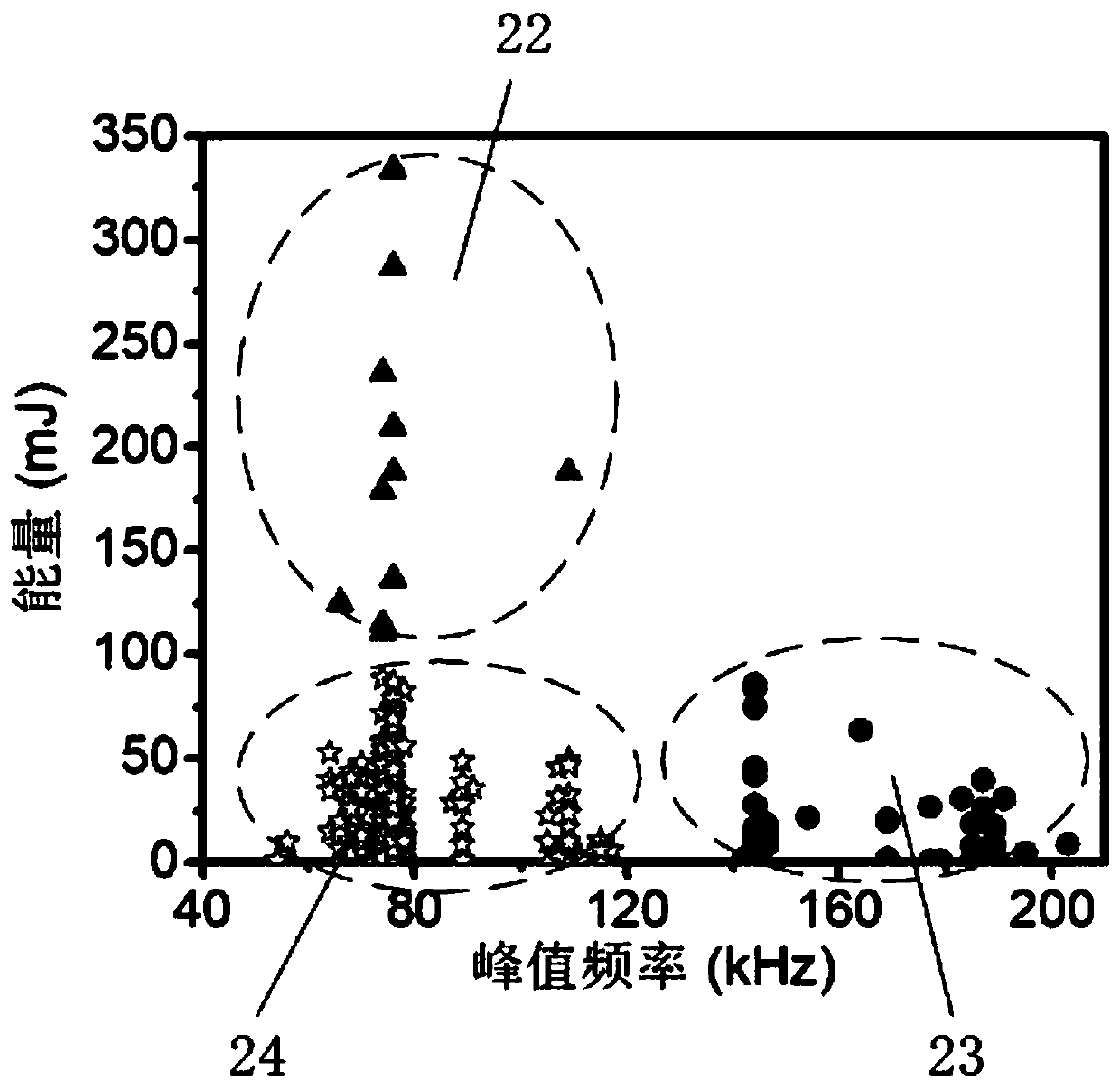

[0041] Applying a tool wear identification and prediction method based on the fusion of high and low frequency acoustic emission sensors provided by the present invention, combined with the attached figure 1 , attached figure 2 And attached image 3 , the specific operation is as follows:

[0042] 1) On the side of the workpiece 11 close to the milling cutter 12, a 100-1000kHz high-frequency acoustic AE sensor 13 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com