Method for automatically accumulating conveying capacity in powdered coal conveying process

A technology of conveying volume and pulverized coal, which is applied in the field of automatic accumulation of pulverized coal conveying process, and can solve problems such as the inability to overcome the zero drift of the instrument measurement system, the large maintenance workload of the automatic control professional, and the large measurement error of the flowmeter. , to achieve the effect of reducing zero drift, high degree of automation, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0017] 1. The principle of the invention

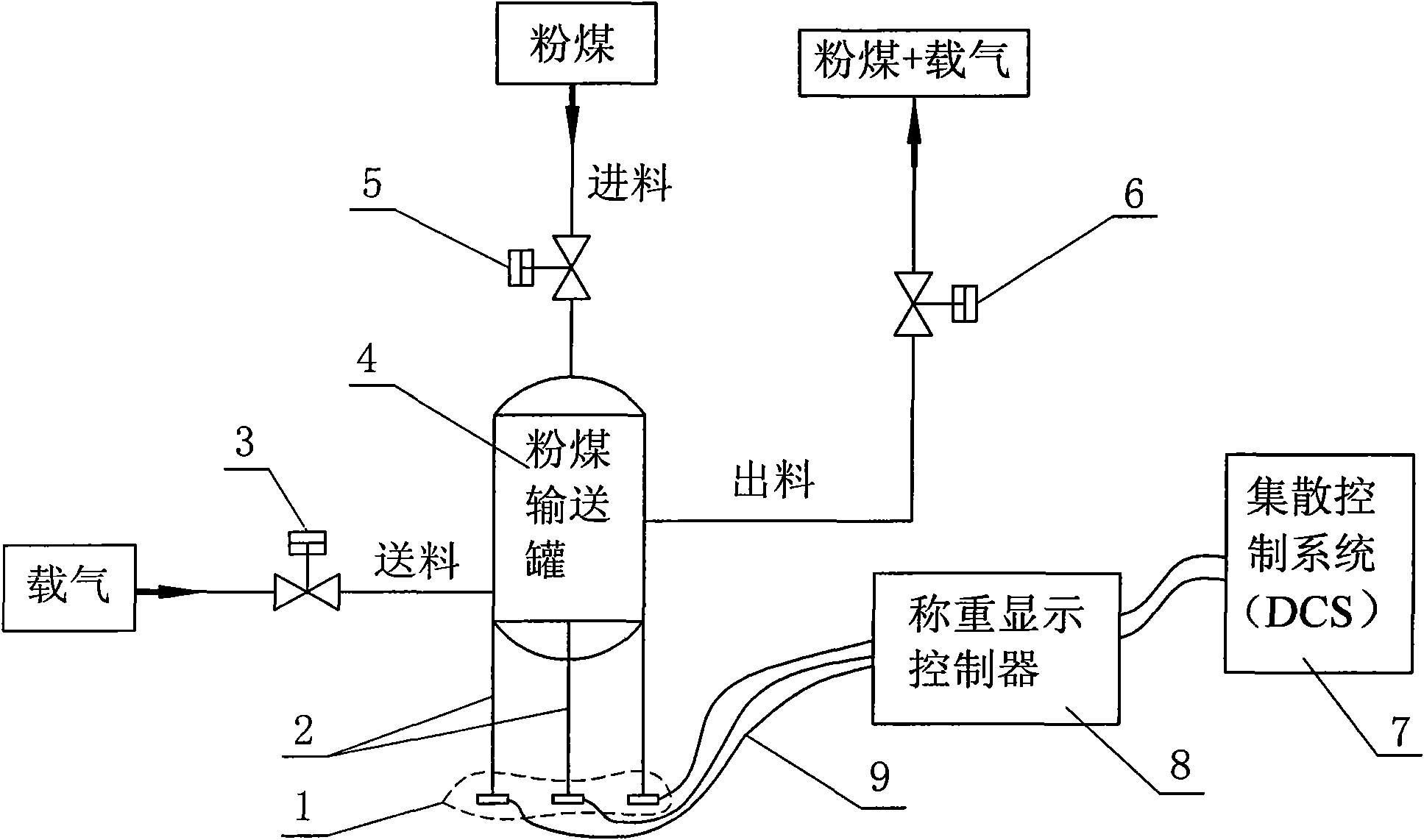

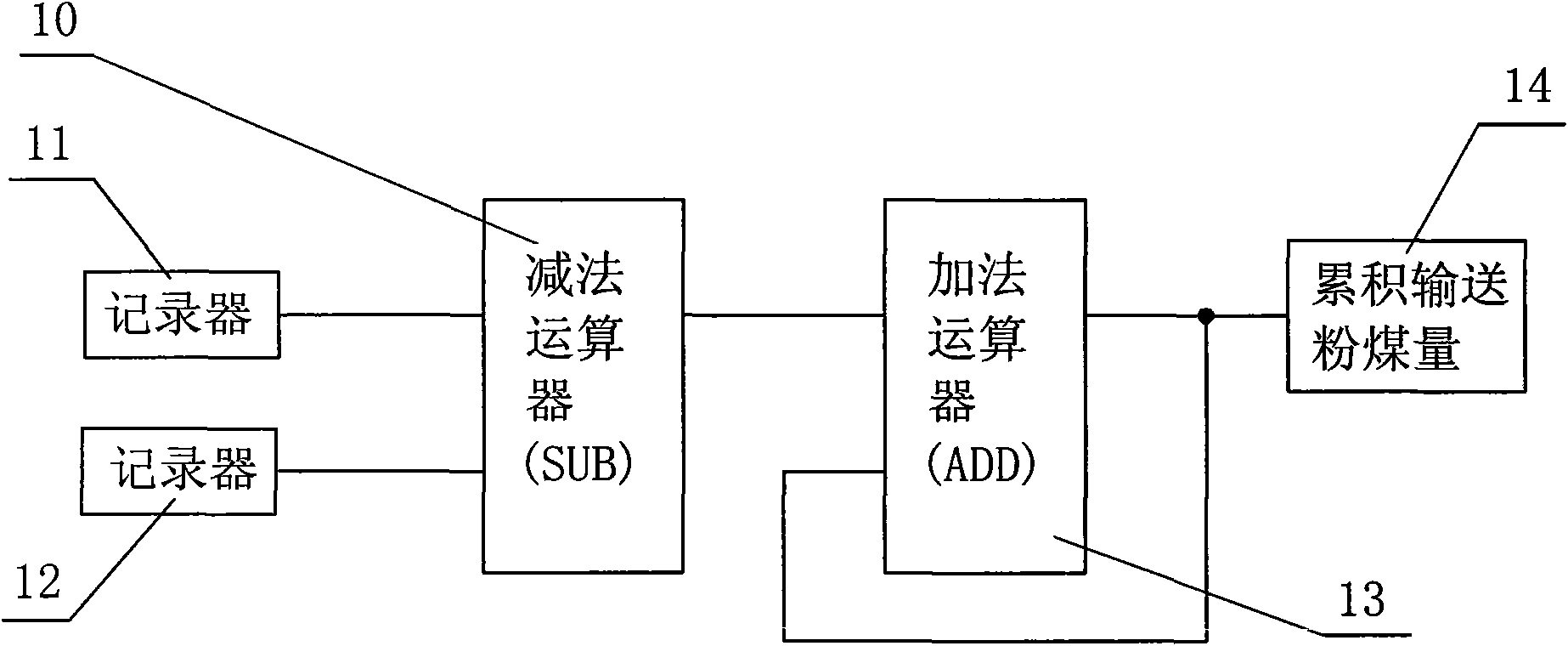

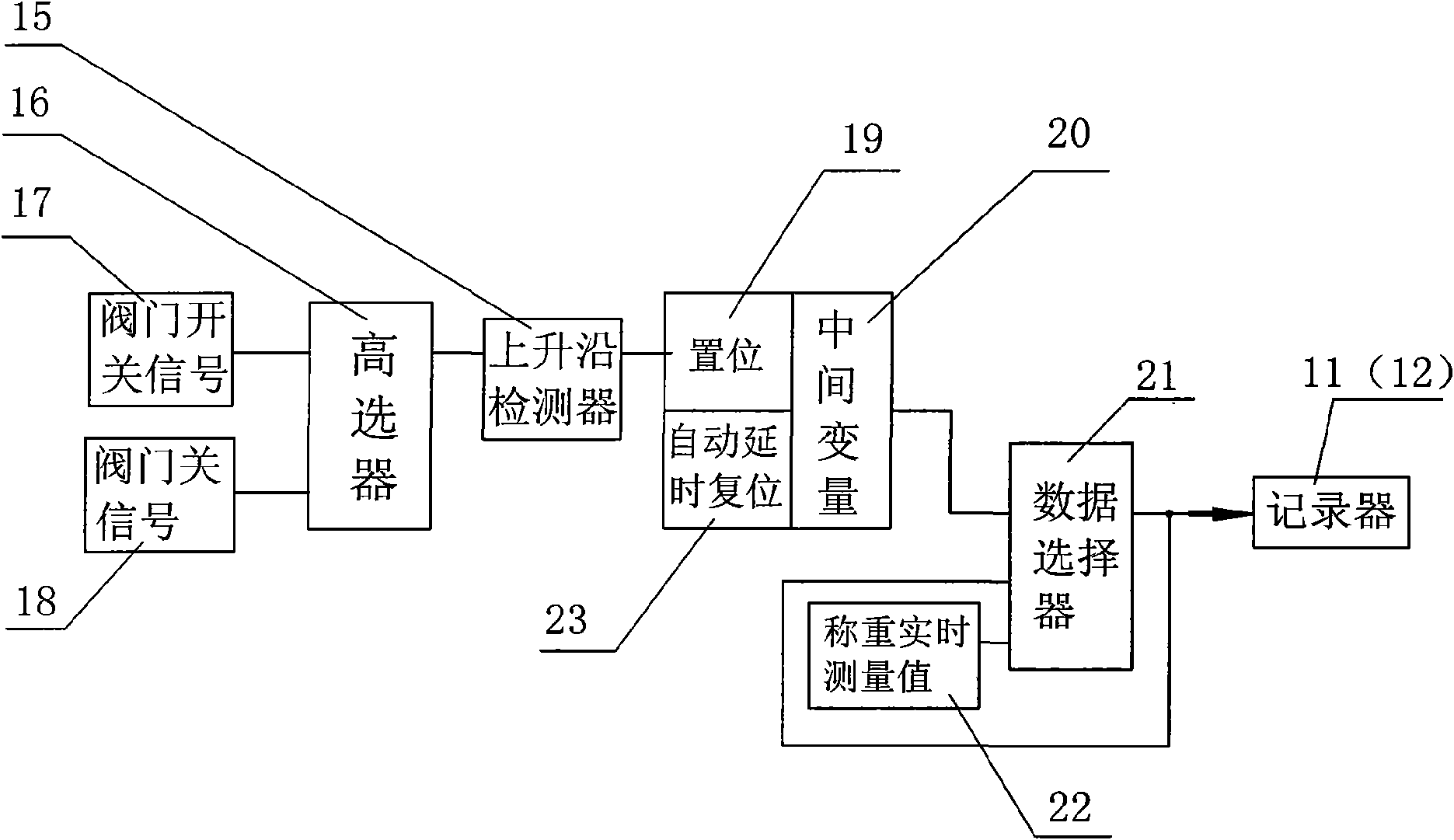

[0018] The invention as figure 1 As shown, the key equipment in the process of the present invention is the pulverized coal delivery tank 4, and the delivery process is made up of the feed operation and the feeding operation (or discharge) of the pulverized coal delivery tank, and these two operations are carried out at intervals. The characteristics of the process, the present invention adopts the weighing sensor instrument with more mature technology at present to weigh the weight of the pulverized coal delivery tank, and then uses the distributed control system to configure two recorders 11, 12, and the feed valve 5 and the feed valve 3 (or discharge valve 6) triggers recorders 11 and 12 respectively, records the tank weight value when feeding is completed and the tank weight value when feeding is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com