Angle steel detection device and detection method for electric iron tower

A detection device and technology for electric power towers, applied in sorting and other directions, can solve problems affecting the quality of iron towers, high labor intensity, and unqualified hole positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

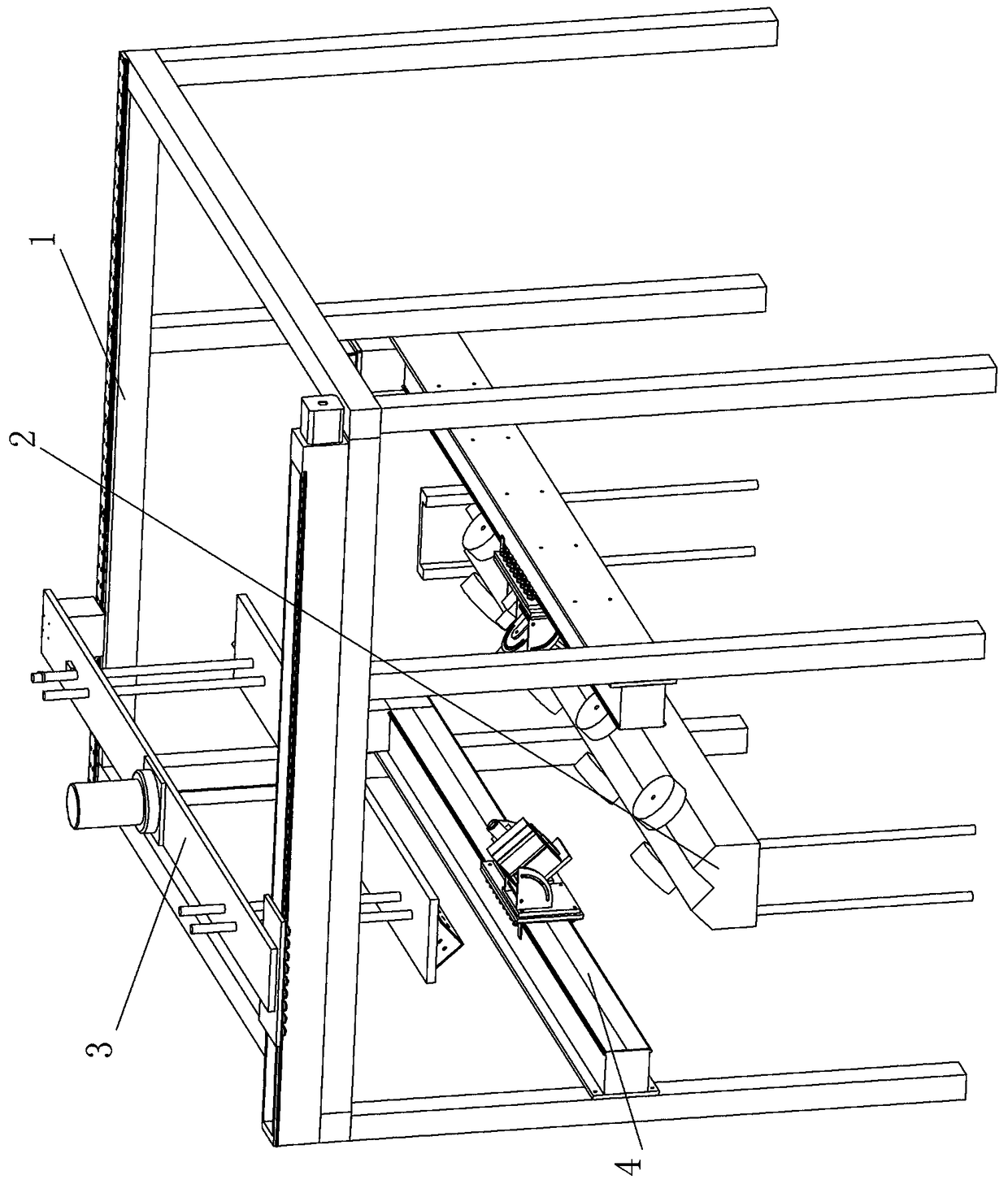

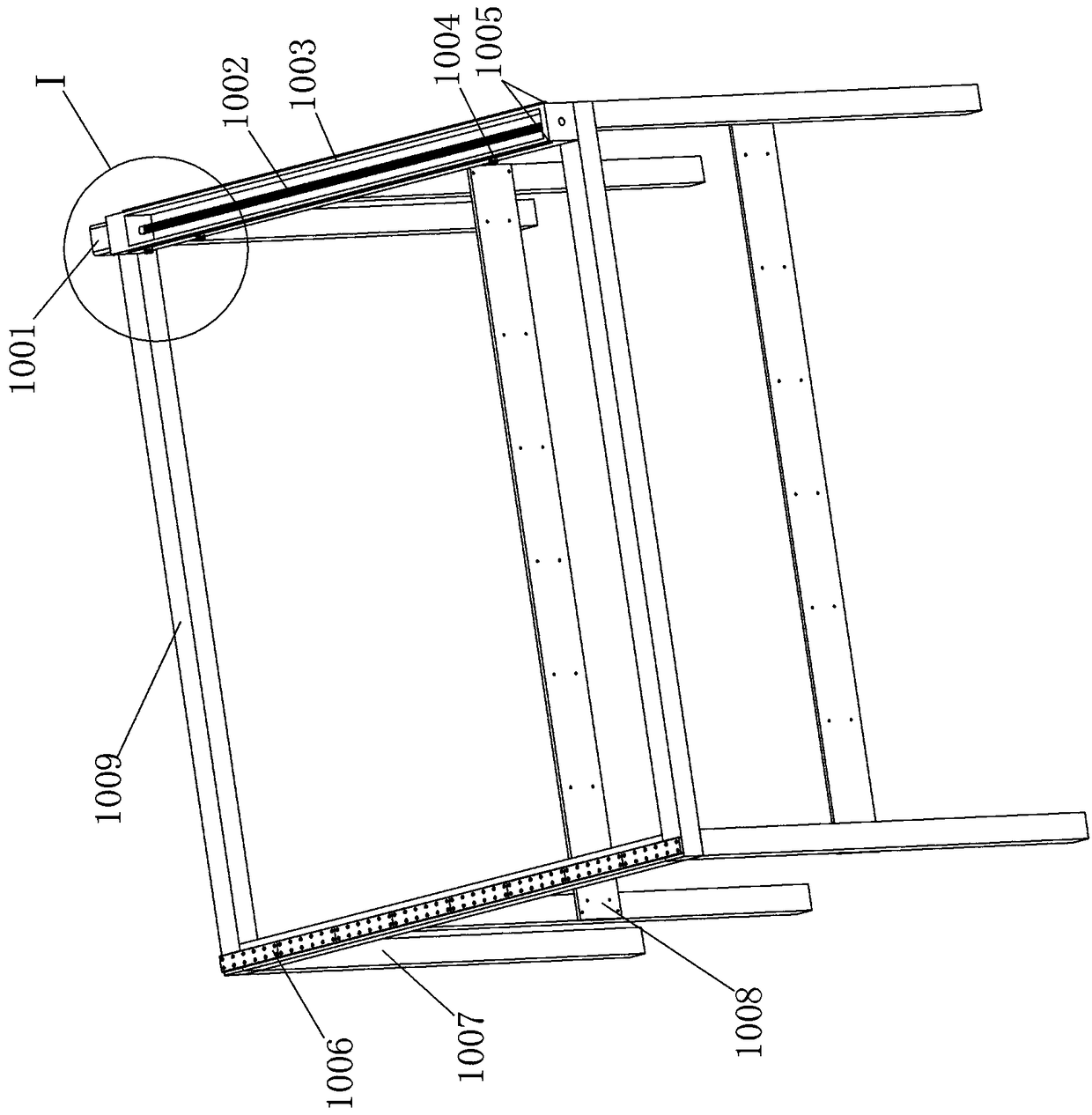

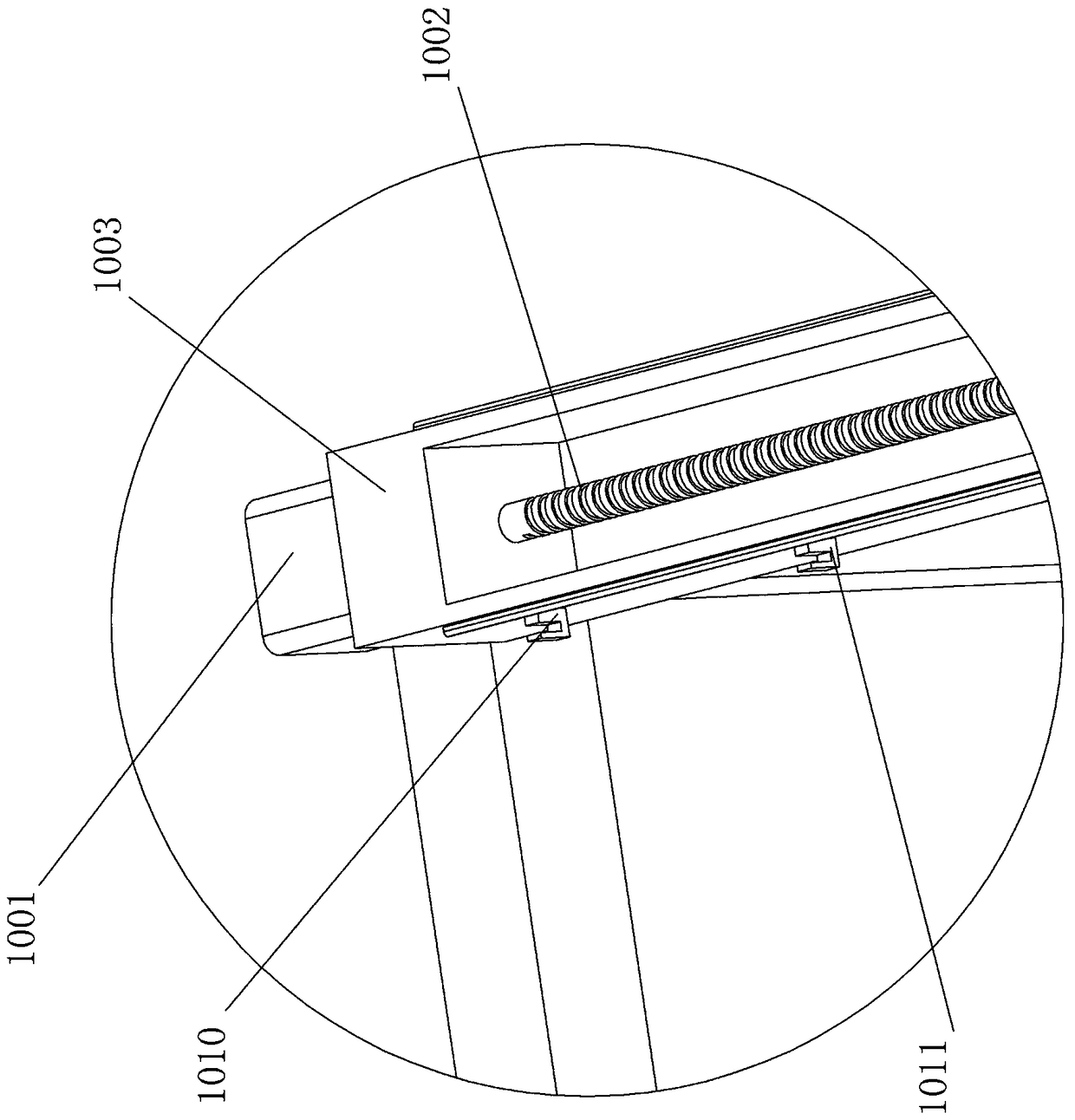

[0041] Embodiment one: see Figure 1-9 , a kind of electric tower angle steel detection device in the figure, comprises angle steel transmission mechanism, vertical lifting device, image acquisition system, is characterized in that:

[0042] The angle steel transmission mechanism includes a transmission seat, a baffle, and a transmission roller; four legs are fixed below the transmission seat for support, the main body of the transmission seat is a strip structure, and the upper surface is provided with a V-shaped groove. There are two rows of cylindrical transmission rollers arranged along the length direction on both sides. The top of the transmission rollers slightly exceeds the edge of the V-shaped groove. There is a baffle at the front end of the V-shaped groove, and a photoelectric sensor is installed on the baffle.

[0043] The vertical lifting device includes a fixed frame and a lifting mechanism; the upper part of the fixed frame is a rectangular frame, the lower part...

Embodiment 2

[0057] Embodiment two: a kind of detection method that utilizes the detection device in embodiment one to electric tower angle steel, its using method is:

[0058] ①. Select the angle steel sample, place it in the V-shaped groove, and use the vertical lifting device to lower the electromagnetic chuck to an appropriate height for adsorption. After the height is determined, fix the position of the upper limit switch; lift the sample to the detection position, and adjust the The lower limit switch, positioning screws A, B, and C of the line array camera system adjust the angle of the camera and the light source so that the center of the camera is facing the center of the side of the sample close to the camera, and the angle of the light source is determined by the quality of the image captured by the camera; the adjustment is completed Finally, fix the position of the lower limit switch, and fasten the positioning screws A, B, and C of the camera and light source accessories to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com