Coal-dressing hydraulic bracket for caving coal working face

A technology of hydraulic support and working face, which is applied in the direction of mine roof support, solid separation, filter and screen, etc., which can solve the problems of low coal preparation efficiency, short operating life and high investment cost, so as to increase coal mining efficiency and save coal transportation cost , the effect of reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

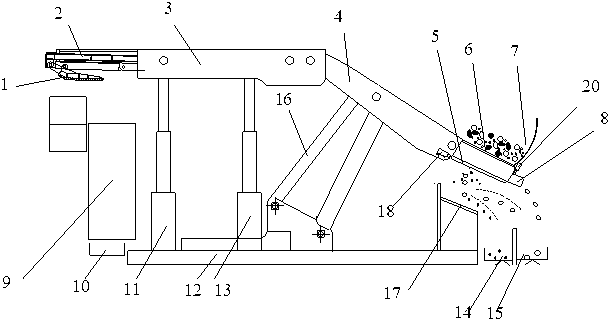

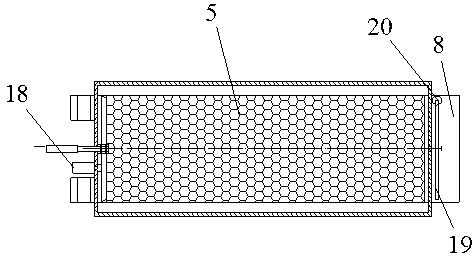

[0013] Such as figure 1 As shown, the coal preparation hydraulic support of the coal caving working face of the present invention comprises a top beam 3, a front beam 2 connected to the top beam 3, the front end of the front beam 2 is connected with a side guard 1, and the bottom of the front beam 2 is provided with a mining The coal machine 9 and the front scraper conveyor 10, the front column 11 and the rear column 13 are arranged under the top beam 3, the front column 11 and the rear column 13 are symmetrically fixed on the bottom plate 12, and the rear part of the top beam 3 is connected with a brace Shield beam 4, the lower part of shield beam 4 is diagonally braced with a link mechanism 16 fixed on the base plate 12, and the shield beam 4 is supported by link mechanism 16 to fix the coal discharge height. The rear end of the cover beam 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com