Process for comprehensively recovering liquid alkali roasting resource of mixed rare earth concentrate

A mixed rare earth and concentrate technology, applied in the direction of improving process efficiency, can solve the problems of discontinuous liquid alkali decomposition process of rare earth concentrate, unrecovered valuable resources in minerals, etc., to achieve clean production and solve environmental problems. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

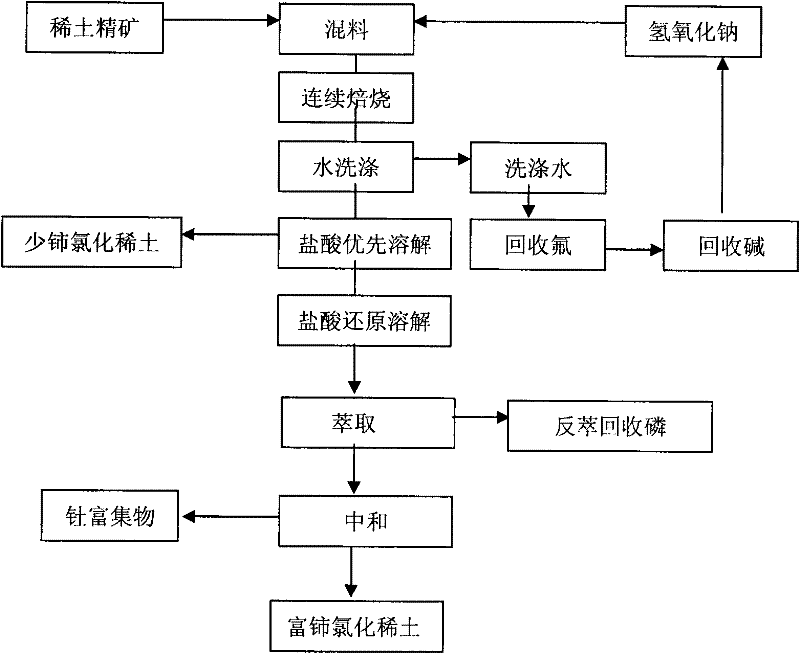

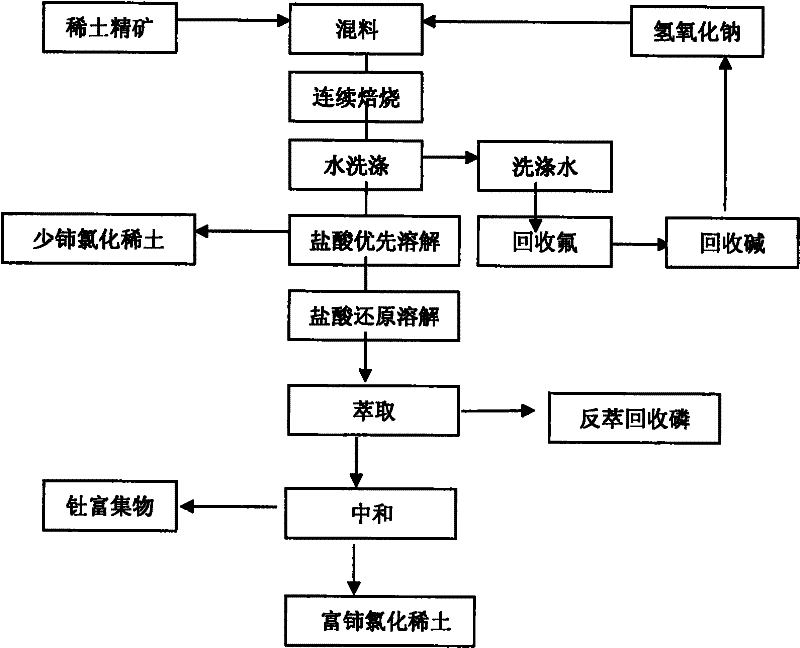

Image

Examples

Embodiment 1

[0032] Embodiment 1: get 500g sodium hydroxide and be made into 65wt% solution, add 500g mixed rare earth ore (REO55wt%), after mixing, go in and out continuously in the rotary kiln, stay in the kiln for 1.5~2.0 hours, temperature in the rotary kiln kiln is 300 ℃. The roasted ore after roasting enters the collecting hopper at the outlet of the rotary kiln. Then wash with water to pH 8-9, preferentially dissolve in hydrochloric acid to obtain a cerium-less rare earth chloride solution, and then perform reduction and dissolution with hydrochloric acid to obtain a fully soluble rare earth chloride solution and acid-dissolved slag. The fully dissolved rare earth chloride solution is extracted with TBP, and the raffinate is neutralized to pH=4~5 to obtain the ceric rare earth chloride solution and thorium enrichment; the extracted organic phase is back-extracted with sodium hydroxide solution to obtain sodium phosphate; the washing solution Causticization to get calcium fluoride. ...

Embodiment 2

[0033] Embodiment 2: Get 500g sodium hydroxide and make 70wt% solution, add 500g mixed rare earth ore (REO55wt%), after mixing, enter and exit continuously in the rotary kiln, stay in the kiln for 1.5~2.0 hours, and the temperature in the rotary kiln is 350 ℃. The roasted ore after roasting enters the collecting hopper at the outlet of the rotary kiln. Then wash with water to pH 8-9, preferentially dissolve in hydrochloric acid to obtain a cerium-less rare earth chloride solution, and then perform reduction and dissolution with hydrochloric acid to obtain a fully soluble rare earth chloride solution and acid-dissolved slag. The fully dissolved rare earth chloride solution is extracted with TBP, and the raffinate is neutralized to pH=4~5 to obtain the ceric rare earth chloride solution and thorium enrichment; the extracted organic phase is back-extracted with sodium hydroxide solution to obtain sodium phosphate; the washing solution Causticization to get calcium fluoride. The...

Embodiment 3

[0034] Embodiment 3: get 500g sodium hydroxide and be made into 70wt% solution, add 500g mixed rare earth ore (REO55wt%), after mixing, enter and exit continuously in the rotary kiln, stay in the kiln for 1.5~2.0 hours, and the temperature in the rotary kiln is 400 ℃. The roasted ore after roasting enters the collecting hopper at the outlet of the rotary kiln. Then wash with water to pH 8-9, preferentially dissolve in hydrochloric acid to obtain a cerium-less rare earth chloride solution, and then perform reduction and dissolution with hydrochloric acid to obtain a fully soluble rare earth chloride solution and acid-dissolved slag. The fully dissolved rare earth chloride solution is extracted with TBP, and the raffinate is neutralized to pH=4~5 to obtain the ceric rare earth chloride solution and thorium enrichment; the extracted organic phase is back-extracted with sodium hydroxide solution to obtain sodium phosphate; the washing solution Causticization to get calcium fluori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com