Enteromorpha absorbent and preparation technology thereof

A technology of adsorbent and enteromorpha, which is applied in the field of enteromorpha adsorbent and its preparation, can solve the problems of high energy consumption, high cost, serious pollution, etc., and achieve the effect of simple preparation process, sufficient raw materials and fast preparation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Wash the Enteromorpha, dry it in an oven at 70°C for 4 hours, pulverize it into a powder in a magnetic pulverizer, and pass through a 100-mesh sieve to obtain a dry sample of Enteromorpha powder for future use. Prepare a 0.2mol / L sodium chloride solution, mix the dry sample of Enteromorpha powder with a 0.2mol / L sodium chloride solution at a mass ratio of 1:150, and stir and extract in a constant temperature water bath at 25°C for 6 hours. After the leached solution was filtered under reduced pressure, the filter cake was dried at 70°C for 4 hours to obtain the Enteromorpha adsorbent. The average pore diameter measured by a specific surface area analyzer is 7.8-9.4 nm.

Embodiment 2

[0025] Wash the Enteromorpha, dry it in an oven at 70°C for 6 hours, pulverize it into a powder in a magnetic pulverizer, pass through a 40-mesh sieve, and obtain a dry sample of Enteromorpha powder for future use. Prepare a 0.5mol / L calcium chloride solution, mix Enteromorpha powder and 0.5mol / L calcium chloride solution at a mass ratio of 1:200, stir and extract in a constant temperature water bath at 25°C for 8 hours. After the leached solution was filtered under reduced pressure, the filter cake was dried at 60°C for 4 hours to obtain the Enteromorpha adsorbent.

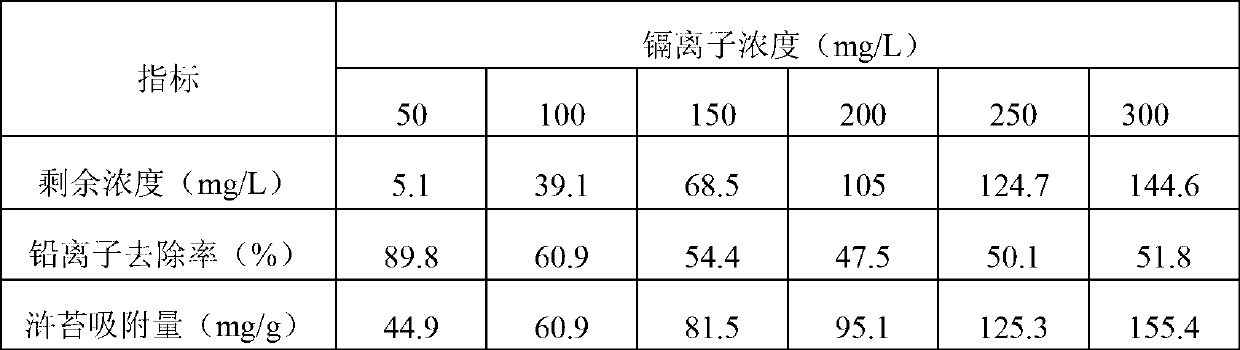

[0026] The above-mentioned Enteromorpha adsorbent was directly applied to the heavy metal wastewater treatment process to treat the simulated wastewater of heavy metal lead and cadmium, and achieved good results.

experiment example 1

[0028] The Enteromorpha adsorbent of Example 1 was used to treat heavy metal wastewater samples, and lead nitrate dissolved in deionized water was used to simulate lead-contaminated wastewater.

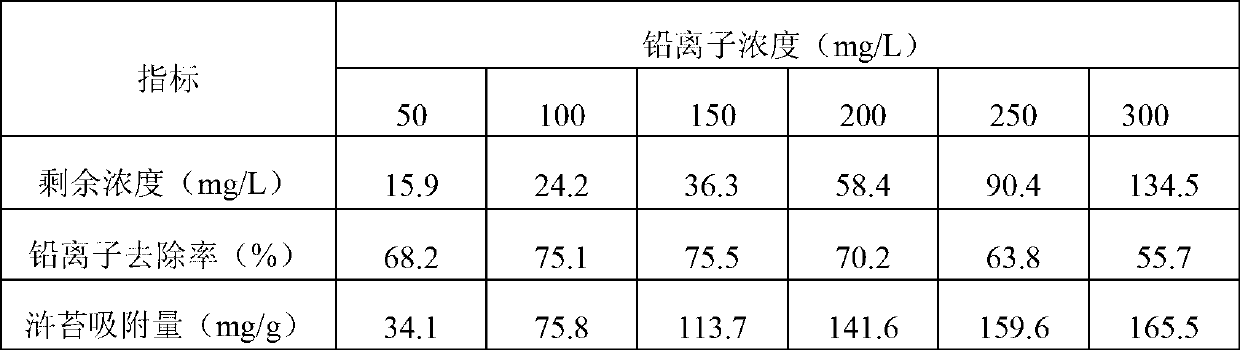

[0029] The Enteromorpha adsorbent prepared in Example 1 is used for the treatment of lead-contaminated wastewater with different concentrations. The dosage of Enteromorpha is 1g / L. The adsorption was shaken for 3 hours, and the results obtained after adsorption are listed in Table 1.

[0030] Table 1 Effects of Enteromorpha adsorbents on simulated water samples treated with lead pollution

[0031]

[0032] From the above treatment results, it can be seen that at the dosage of 1g / L, Enteromorpha adsorbent has good adsorption effect in the treatment of lead ion simulated water samples at low and high concentrations, and the adsorption capacity increases with the concentration of pollutants. It is suitable for treating high-concentration heavy metal polluted wastewater, and its adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com