Patents

Literature

431results about How to "Compliance with emission standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

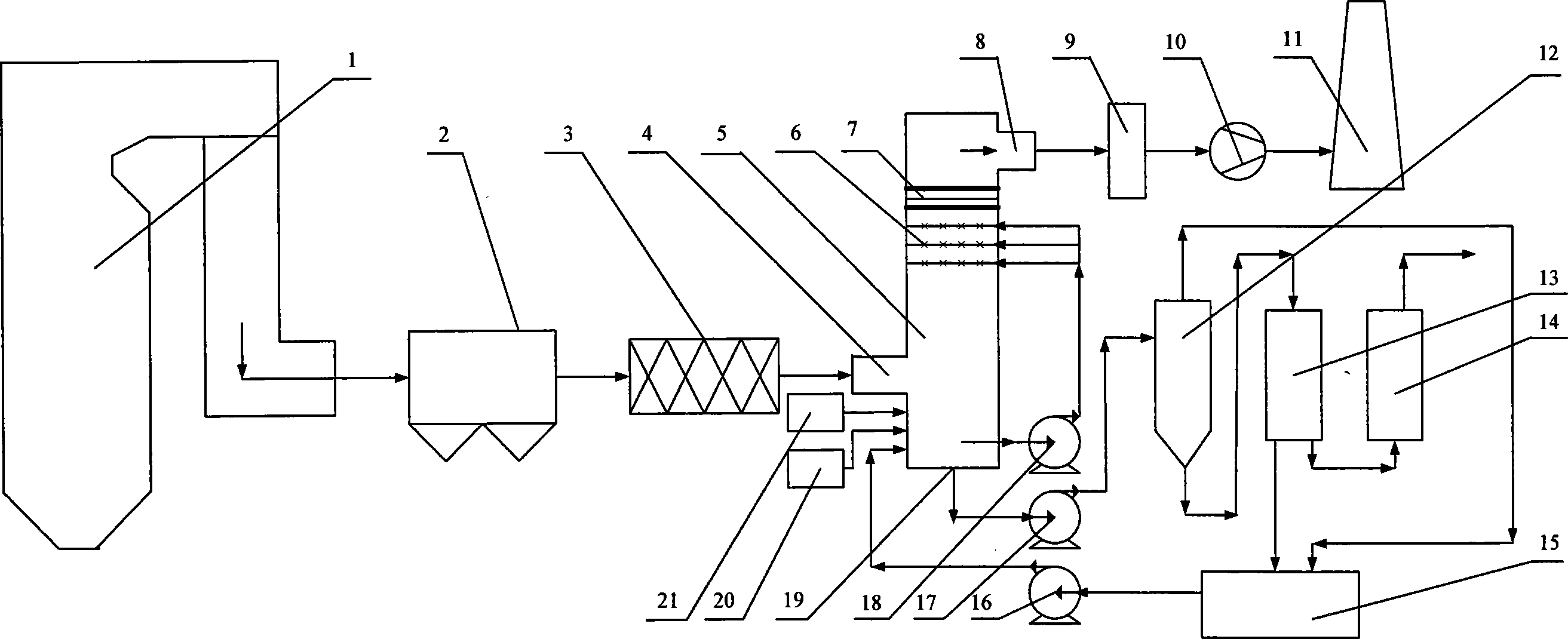

Simultaneously desulfurization and denitration wet ammonia flue gas cleaning technology and system thereof

InactiveCN101053747ASimple processSmall footprintDispersed particle separationFertilizerNitric oxide

A wet ammonium flue gas cleaning process for desulfurizing and denitrifying and a system thereof are disclosed. The process oxidates NO in the flue gas to be NO2, makes SO2 and NO2 in the flue gas react with ammonium to product ammonium sulfite, ammonium nitrate and ammonium nitrite, then oxidates ammonium sulfite and ammonium nitrite therein to product the byproduct that is ammiaonia sulfate and ammonium nitrate, and lastly gets the clear flue gas after demisting to the desulfurizing and denitrifying flue gas. The system comprises a dust pre-collector, a hydrogen peroxide or ozone sprayer, and a desulfurizing and denitrifying tower, which are connected in turns, wherein ammonia replenishment system and an air feeding device are mounted at the bottom of the desulfurizing and denitrifying tower, sprinkling layer which can cycle sprinkle is mounted at the middle, and a demister is mounted at the upper. The invention has a simple process, a simplified system, a low investment and operation cost. The invention not only has a high efficiency in desulfurizing and denitrifying, but also a high utilance of desulfurizing and denitrifying absorbent, and byproduct of desulfurization and denitration can be utilized as chemical fertilizer of ammiaonia sulfate and ammonium nitrate.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

Acid-cleaning inhibiter for cleaning boiler and use method thereof

ActiveCN101634030ASlow down the dissolution rateIncrease activation energyBoiler cleaning apparatusThioureaPhosphoric acid

The invention discloses an acid-cleaning inhibiter for cleaning a boiler and a use method thereof. The acid-cleaning inhibiter comprises the following components by weight percent: 2.0%-10.0% of acid liquor, 0.08-0.25% of urotropine, 0.04-0.15% of dimethylbenzene thiourea or thiourea, 0.01-0.05% of thiocyanate, 0.03-0.12% of dodecyl-cetyl phenmethyl chloride or bromide, 0.05-0.12% of a surface active agent and the balance of water. Acids suitable for the acid-cleaning inhibiter include hydrochloric acid, citric acid, sulphuric acid, hydrofluoric acid, aminosulfonic acid and phosphoric acid, which are suitable for boiler steel, mild steel, alloy steel and steam steel. The inhibition effect of the invention is over 98% with less toxicity under the boiler chemical cleaning condition, the value of LD50 (orally taken by mice) is 5.74 g / kg. The invention can be stored for 2 years, resistant Fe<3+> ion is 800 mg / kg in the acid cleaning. The preparation method has simple steps, easily obtained raw materials and convention operation.

Owner:湖南省湘电试验研究院有限公司 +2

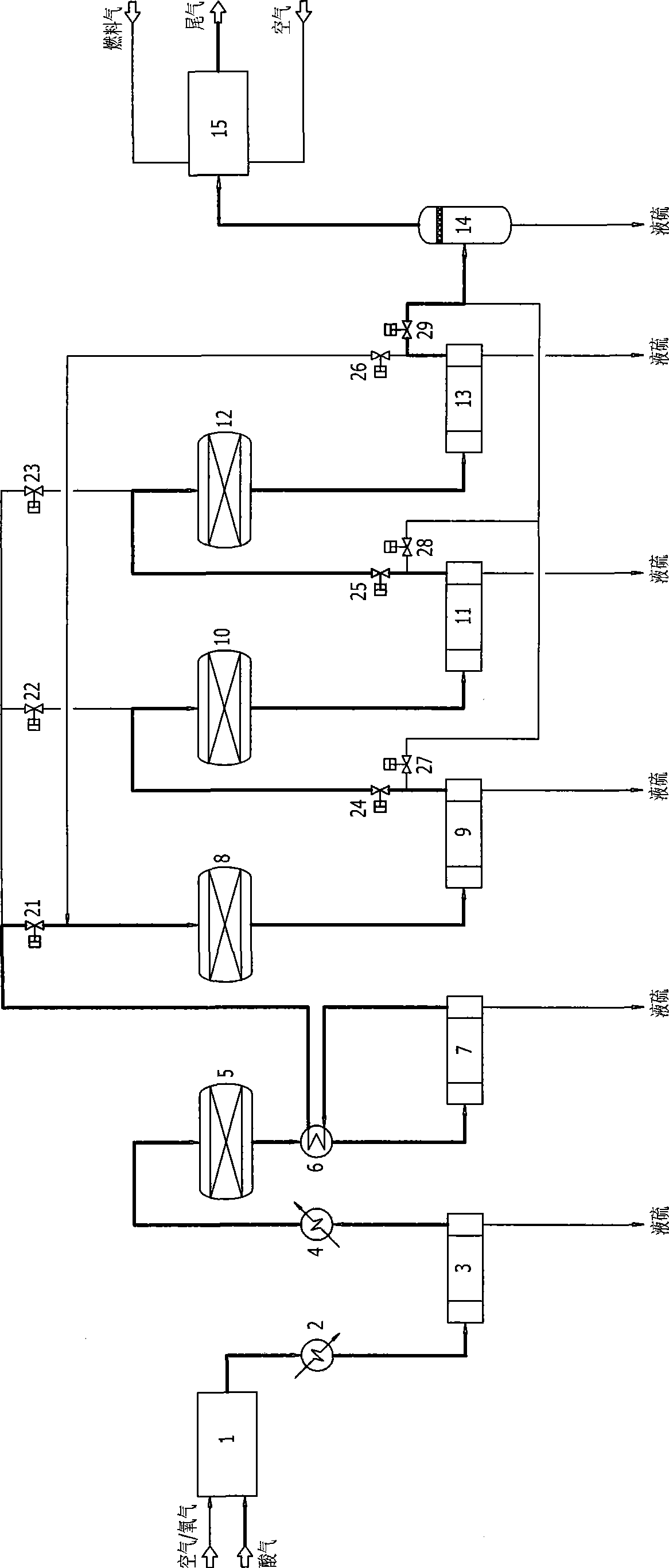

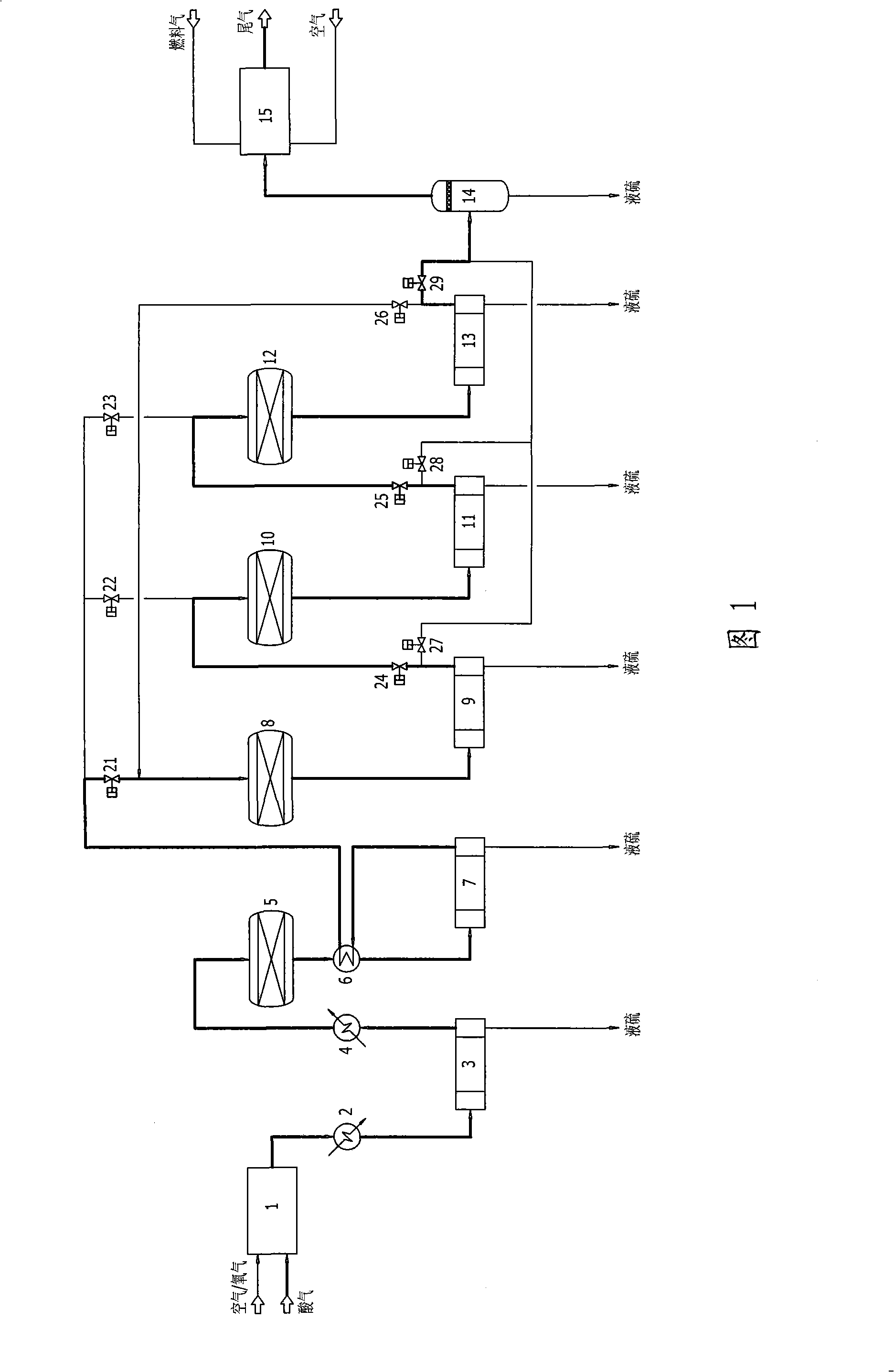

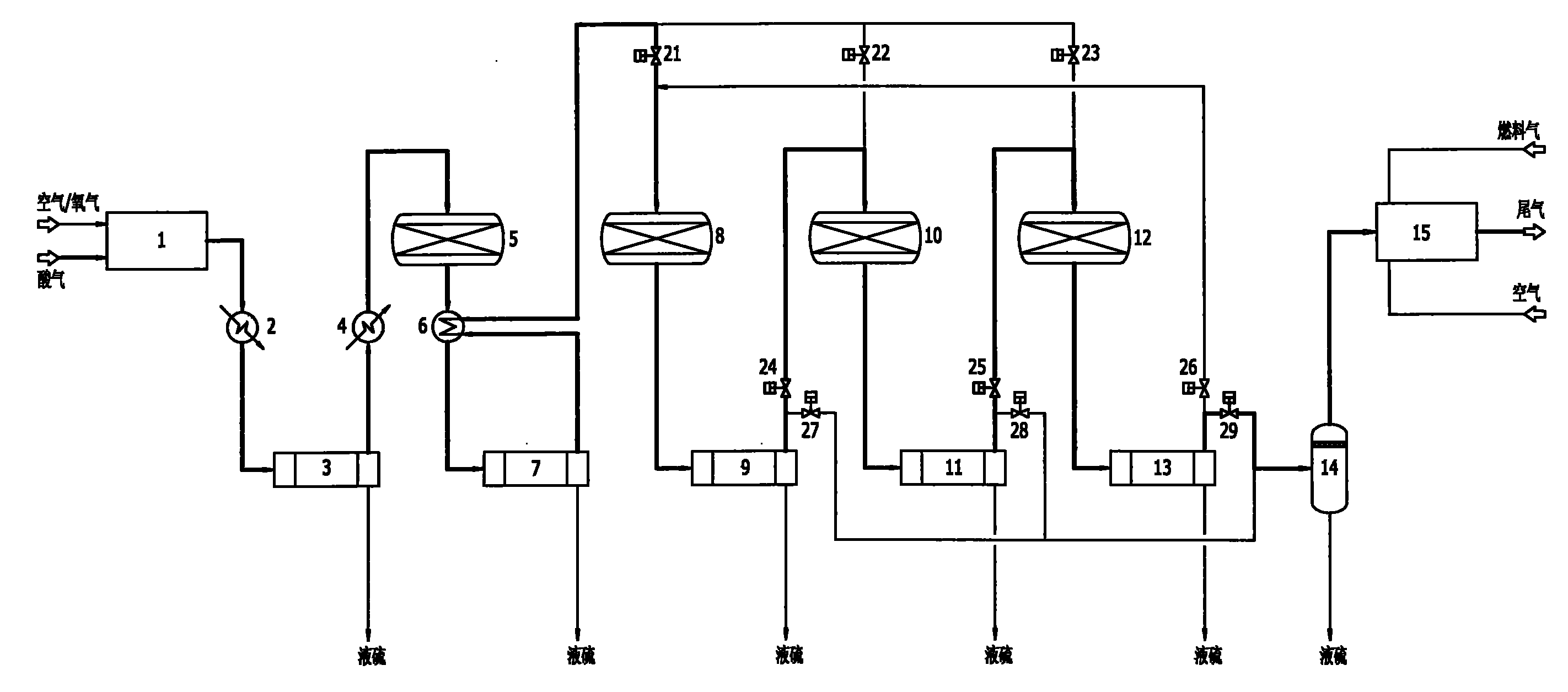

Low temperature Claus sulfur recovery process and device therefor

InactiveCN101519192AAchieve regenerationImprove conversion rateEnergy inputSulfur preparation/purificationReaction temperatureOxygen

Owner:CHENGDU SEPMEM SCI & TECH

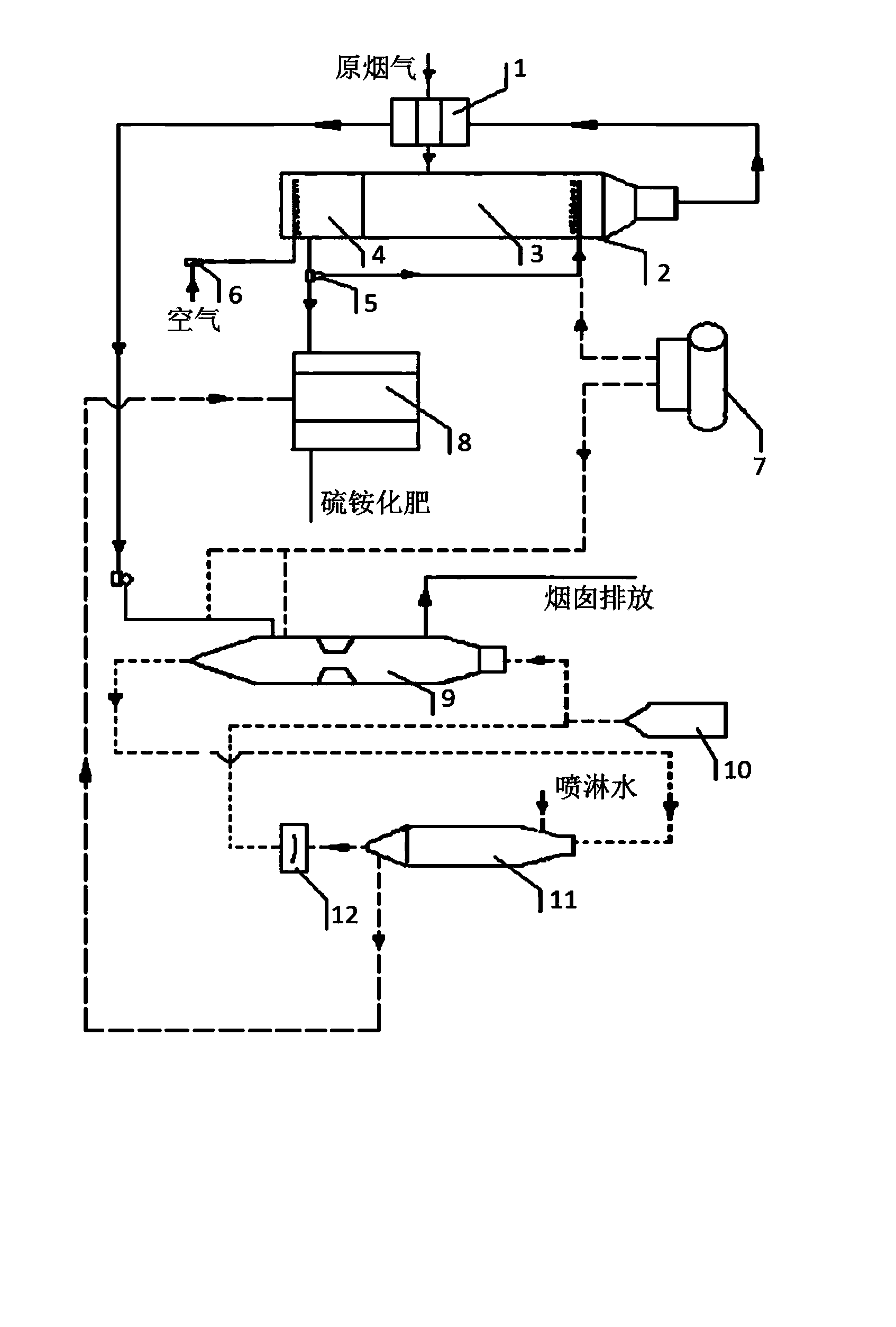

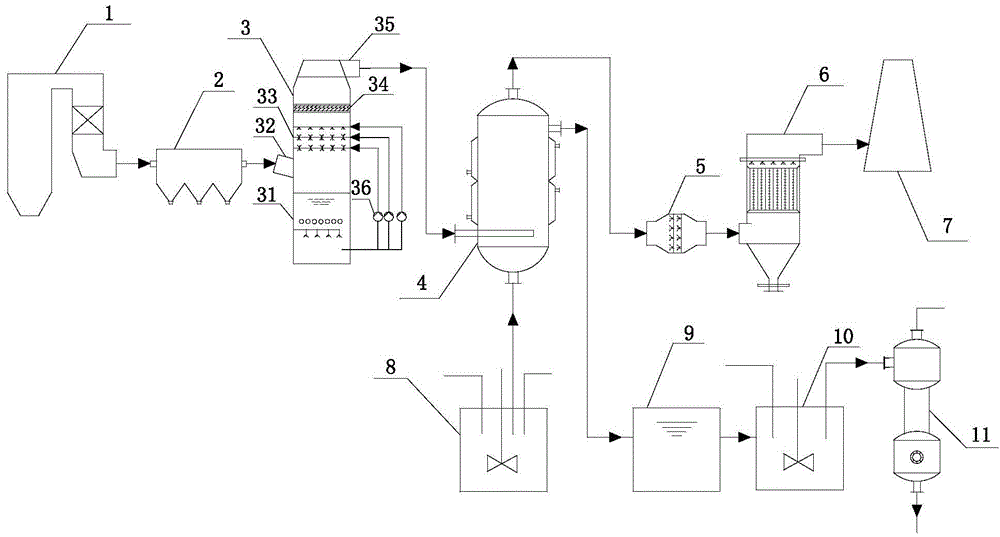

Method for simultaneously desulfurizing, denitrating and purifying flue gas

InactiveCN103861439ACompliance with emission standardsAdaptableAmmonium nitratesProductsFuranChemical industry

The invention discloses a method for simultaneously desulfurizing, denitrating and purifying flue gas and belongs to the field of flue gas purification. The method comprises the following steps: spraying the flue gas at the temperature of 50-90 DEG C by using ammonia absorption liquid to obtain a solution, and aerating and oxidizing the solution to obtain an ammonium sulfate solution; exchanging heat between the obtained flue gas and the original flue gas, heating to 120-350 DEG C, and supplementing ammonium hydroxide; converting NO and NO2 in the flue gas into N2 by addition or non-addition of an activated carbon material of a catalyst; performing reaction on the remaining SO2, ammonia and water vapor to generate ammonium sulfate; adsorbing mercury, dioxin, furan, a volatile organic compound, ammonia sol and other trace toxic substances by activated carbon; and regenerating the activated carbon after absorption and adsorption by using washing and heating methods. The method has the advantages that the process is simple and convenient, and the desulfurizing and denitrating efficiency is high; various toxic substances and fine particles in the flue gas can be adsorbed, a good prevention effect on PM2.5 pollution of industrial flue gas is achieved, ammonium sulfate and ammonium nitrate fertilizer byproducts are obtained, and resources can be recycled. The method can be applied to purification of sulfur-containing and nitrate-containing flue gas in the fields of boilers, metallurgy, chemical industry, thermoelectricity and garbage incineration power generation.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

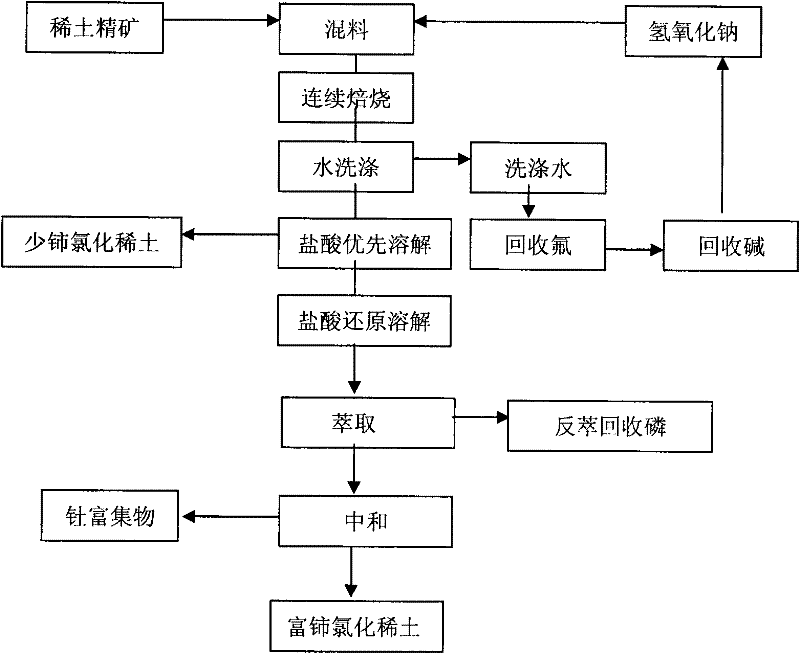

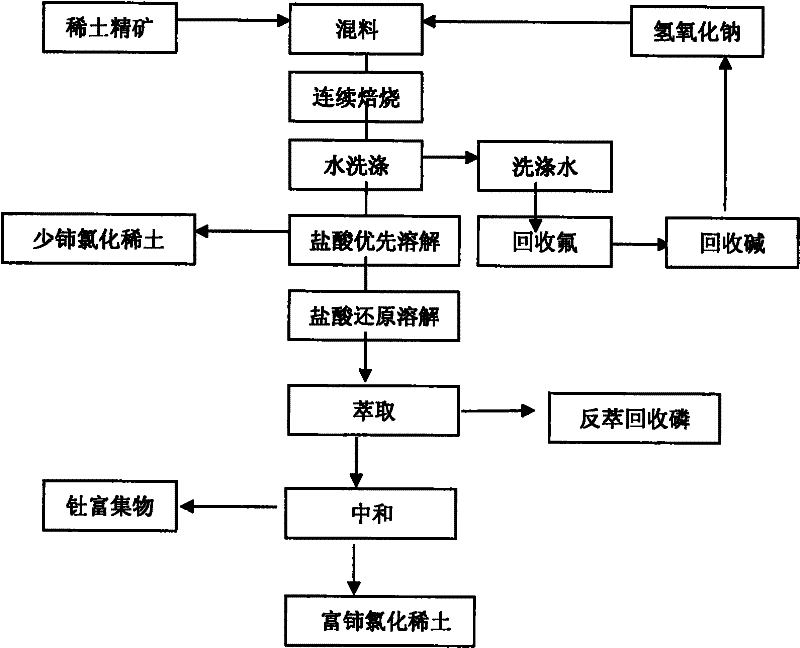

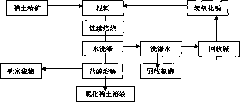

Process for comprehensively recovering liquid alkali roasting resource of mixed rare earth concentrate

InactiveCN102212674ASolve environmental pollutionRealize clean productionProcess efficiency improvementDecompositionCerium

The invention relates to a decomposition process for comprehensively recovering a liquid alkali roasting resource of mixed rare earth concentrate, comprising the following steps of: mixing and roasting the mixed rare earth concentrate and sodium hydroxide according to a weight ratio, wherein the roasting temperature is 200-600 DEG C, and the roasting time is 0.5-4 h; watering the roasted mineral water to be neutral; preferentially dissolving an alkali cake by using hydrochloric acid to obtain a less cerium chlorinated rare earth solution; reducing and dissolving residues by using hydrochloric acid after the hydrochloric acid is preferentially dissolved to obtain a rich cerium chlorinated rare earth solution; after extracting and recovering phosphorus of the rich cerium chlorinated rare earth solution, neutralizing the rich cerium chlorinated rare earth solution to obtain thorium enrichment content; recovering fluorine and sodium hydroxide in a roasted mineral water solution; and after extracting and separating the less cerium chlorinated rare earth solution, recovering calcium chloride. The mixed rare earth concentrate is processed by using the method disclosed by the invention. The continuous production of liquid alkali roasting mixed rare earth concentrate is realized. Tetravalent cerium and trivalent rare earth are separated preferably. Rare earth, thorium, fluorine, phosphorus, calcium and the like are comprehensively recovered. Waste gas and radioactive waste residues are avoided. Cleaner production and resource comprehensive recovery are realized.

Owner:BAOTOU RES INST OF RARE EARTHS

Water-based airplane surface cleaning agent and preparation method thereof

ActiveCN101955854AGood protectionThe formula is scientific and reasonableInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsIonChemistry

The invention relates to a water-based airplane surface cleaning agent, which is prepared by uniformly mixing the following components in percentage by weight: 21 to 30 percent of degradable surfactant, 5 to 7 percent of metal corrosion inhibitor, 0.3 to 2 percent of pH regulating agent, 1.7 to 5 percent of stabilizer, and the balance of deionized water. A preparation method comprises the following steps: (1) weighing the pH regulating agent, the degradable surfactant, the metal corrosion inhibitor, the stabilizer and the deionized water according to the ratio of weight percent; (2) adding the pH regulating agent, the metal corrosion inhibitor, the degradable surfactant and the stabilizer into the deionized water at the room temperature of between 23 and 25 DEG C; and (3) stirring the liquid at constant speed of 60 to 80r / min for 20 to 40 minutes to ensure that no bubble is generated in the liquid to prepare the cleaning agent after uniform mixing. The invention has scientific and reasonable formula and simple process without special equipment, and the cleaning agent has the advantages of strong cleaning capability, short cleaning time, low cost, high efficiency and is safe and reliable for use.

Owner:北京凯兰航空技术有限公司

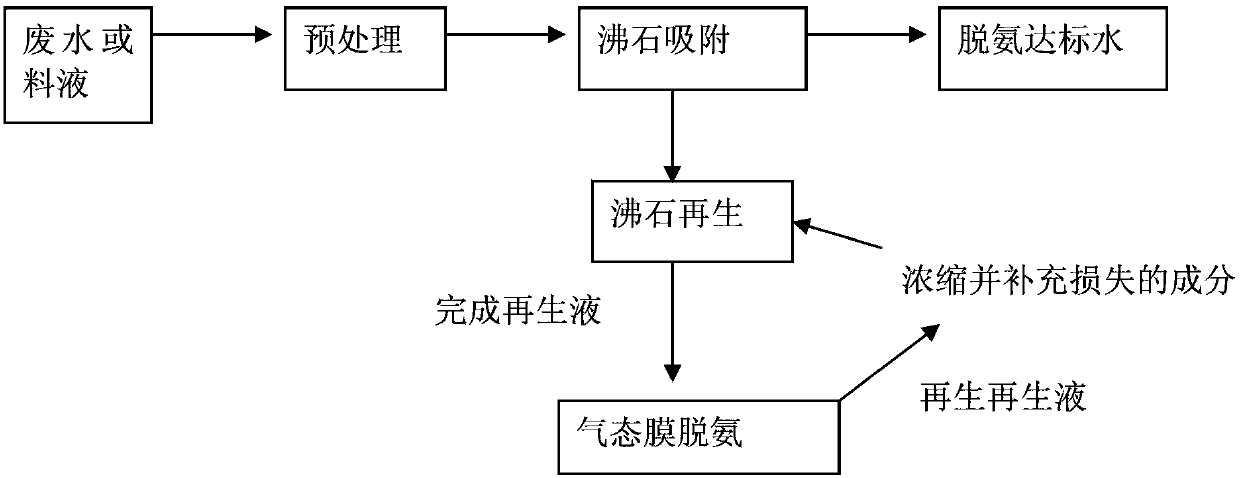

Method for treating low-concentration ammonia-nitrogen wastewater or feed liquid

ActiveCN104211246ACompliance with emission standardsDoes not increase processing difficultyMultistage water/sewage treatmentEnvironmental resistancePre treatment

The invention relates to a method for treating a low-concentration ammonia-nitrogen wastewater or feed liquid. The method comprises the steps: firstly, pre-treating the low-concentration ammonia-nitrogen wastewater or feed liquid, removing impurities in the wastewater or feed liquid, adjusting the pH of the wastewater or feed liquid to 6-7.5, and increasing the surface tension to 40 mN / m or even 65 mN / m or more; then carrying out selective adsorption treatment on the pretreated low-concentration ammonia-nitrogen wastewater or feed liquid with zeolite, making the ammonia-nitrogen average concentration of the wastewater or feed liquid subjected to adsorption less than a predetermined value, when the ammonia-nitrogen average concentration of the wastewater or feed liquid after the adsorption treatment reaches the predetermined value, carrying out regeneration treatment on zeolite by utilizing a regeneration liquid, and thus obtaining an ammonia-nitrogen enriched regeneration liquid; followed by allowing the ammonia-nitrogen enriched regeneration liquid to enter a gas membrane separation device, and carrying out deamination treatment; and finally carrying out concentration treatment on the ammonia-nitrogen removed regeneration liquid, and thus obtaining a recyclable regeneration liquid. The method has the advantages of simple operation, small energy consumption, low operation cost, no secondary pollution, economy and environmental protection.

Owner:TIANJIN PURESEA SPRING MEMBRANE TECH CO LTD

Water-based type environment protection cleaning agent and preparation method thereof

ActiveCN101225346AThe formula is scientific and reasonableSimple production processSurface-active detergent compositionsDetergent compounding agentsWater basedMan-hour

The invention relates to a water based environment-friendly cleaning agent and the preparation method, which is characterized in that the agent comprises natural plant extract, degradable surface active agent, inhibiter and de-ionized water. The preparation method is as follows: (1) preparing materials according to the weight ratio, (2) adding the raw material orderly in series, (3) stirring at even pace and (4) evenly mixing to make the finished cleaning agent ultimately. The preparation method for the water based environment-friendly cleaning agent has the advantages of scientific prescription, simple production technique, strong cleaning ability, short cleaning time, low labor and man-hour, high work efficiency, low causticity to the equipment, good safety and low equipment cost. The water based environment-friendly cleaning agent is degradable liquid and can be biologically degraded into harmless material in nature completely. The waste liquid after be cleaned cab be directly discharged without polluting the environment and reach the sewage discharge standard. The water based environment-friendly cleaning agent is provided with the surface active agent and the inhibiter which can form a rustproof protecting film on the metal surface after cleaning, and ensures that the part after cleaning has an advantage of good rust protection.

Owner:北京凯兰航空技术有限公司

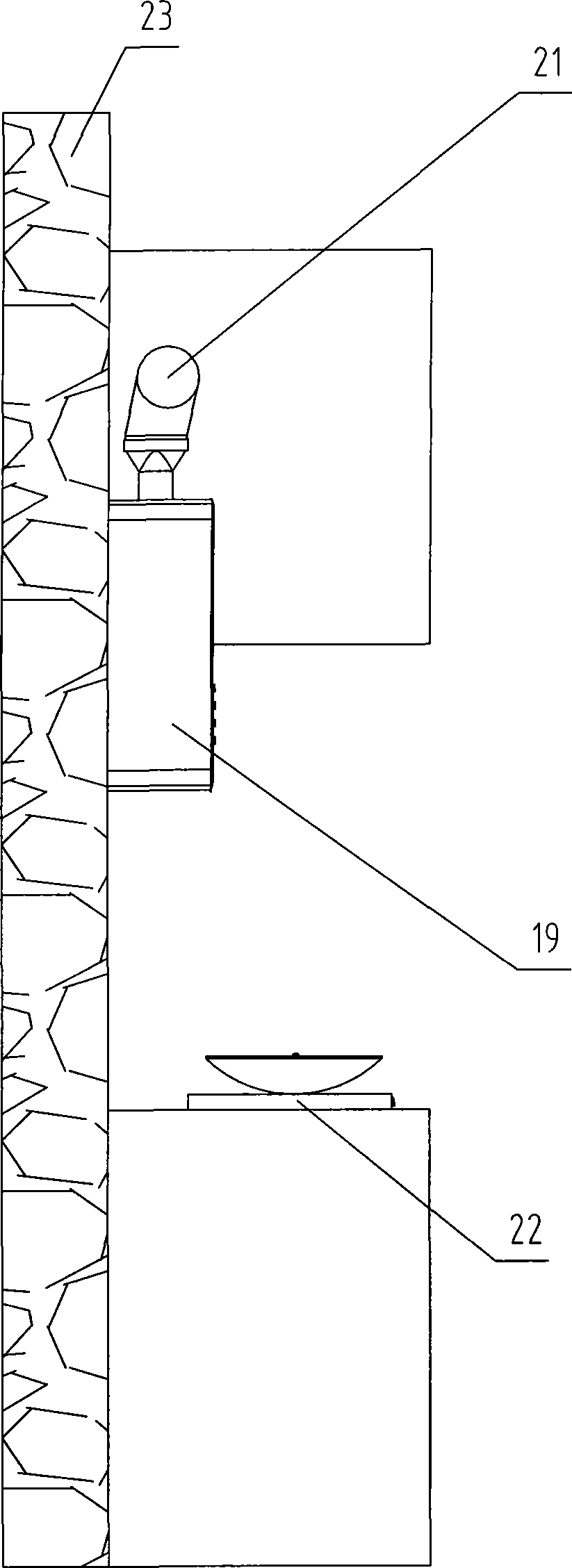

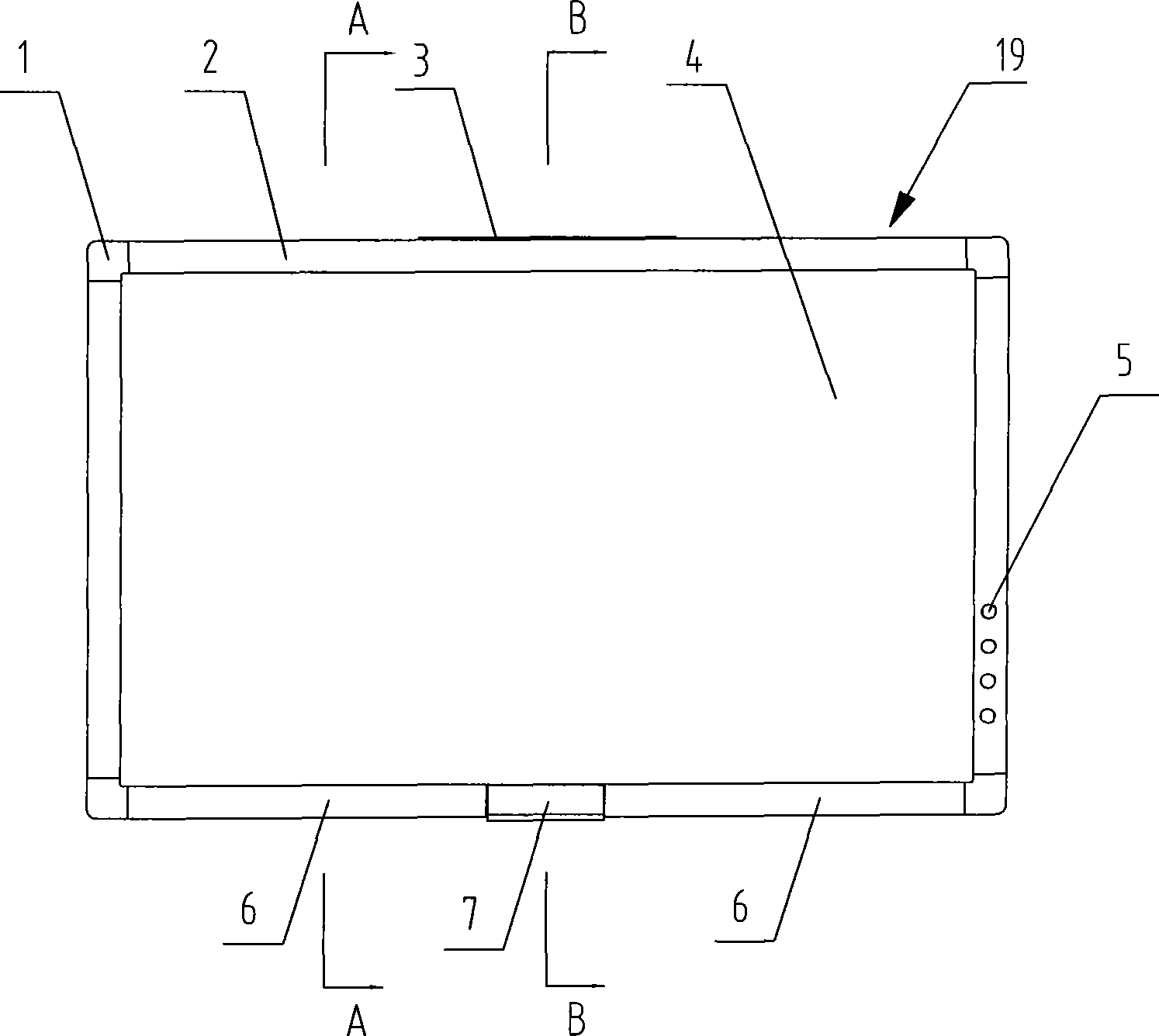

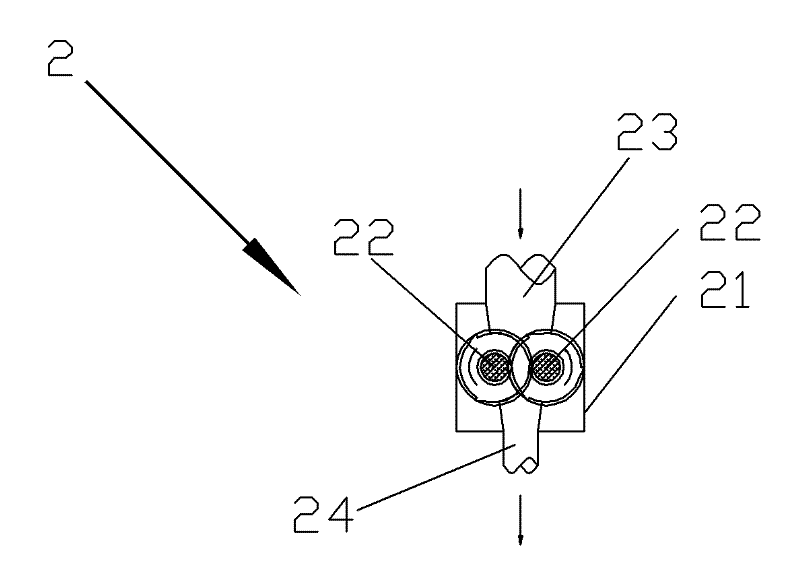

Wall-hung thin type lampblack depurating machine

ActiveCN101545651AImprove purification efficiencyCompact structureDomestic stoves or rangesLighting and heating apparatusEngineeringOperating life

The invention discloses a wall-hung thin type lampblack depurating machine, which is provided with flat cuboid-shaped shell, wherein a double-volute is arranged in the shell, and two isolated chambers of the double-volute share an air outlet passage on the top of the shell; a turbo-fan with a horizontal output shaft is arranged in the two isolated chambers of the double-volute respectively, and the front end of the output shaft of the turbo-fan extends out of the double-volute and is connected with at least one vertical rotary centrifugal filter screen plate; and the outside of the rotary centrifugal filter screen plate is provided with an annular oil guide ring, the bottom of the annular oil guide ring is provided with an oil leak opening, a fume flow distribution plate is arranged below the annular oil guide ring, an oil guide tank is arranged on the fume flow distribution plate, and the bottom of the shell is provided with an air inlet passage and an oil collection box. The wall-hung thin type lampblack depurating machine has ultra-high efficiency for holding up and collecting lampblack, can basically put an end to the pollution caused by the lampblack to the air, the shell and the external wall of a building, and has the characteristics of overall closure, simple structure, convenient cleaning, energy saving and noise reduction, large cooking space, safe running and long service life.

Owner:武汉创新环保工程有限公司

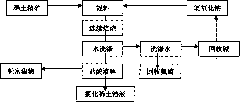

Liquid alkali roasting decomposition extraction process of mixed rare earth concentrates

ActiveCN101824554AReduce consumptionEliminate pickling and decalcification processDecompositionRare earth

The invention relates to a liquid alkali roasting decomposition extraction process of mixed rare earth concentrates, which comprises the following steps of: (1) mixing mixed rare earth concentrates and sodium hydroxide (prepared solution) in the weight ratio of 1:0.5 to 1.5; (2) roasting the rare earth ore mixed with the sodium hydroxide at the roasting temperature of between 150 and 500 DEG C for 0.5 to 4 hours; (3) performing size mixing on roasted ore hot water obtained by roasting, adding oxidant simultaneously for oxidation, and performing washing until the mixture is neutral after the oxidation; (4) dissolving trivalent rare earth preferentially in washed alkali cakes in hydrochloric acid, and controlling the pH value to be between 4 and 5 to prepare rare earth chloride solution with less cerium; and (5) performing reductive dissolution of the hydrochloric acid on cerium dregs dissolved preferentially in the hydrochloric acid, and controlling the pH value to be between 4 and 5 to prepare cerium-rich chloride solution. The mixed rare earth concentrates are processed by adopting the extraction process, so that the continuous production of the alkali-decomposing mixed rare earth ore can be realized, cerium-rich products are extracted preferentially, the treatment capacity of the follow-up extraction separation is relieved, and the pollution-free production and comprehensive utilization of resources are realized.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

Pipeline cleaning agent

InactiveCN103740489AEfficient removalKeep clean for a long timeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBetaineActive agent

The invention relates to a pipeline cleaning agent which comprises the following components by weight: 15-28 parts of organic acid, 20-35 parts of an asurface active agent, 18-30 parts of a penetrating agent and 0.5-3 parts of an acorrosion inhibitor, wherein the surface active agent comprises one or more ofpolyether, butyl cellosolve, coconut oil fatty acid diethanol amide and fatty alcohol-polyoxyethylene ether sulfate sodium; the penetrating agent comprises one or more of alcohol, sodium dodecyl sulfate, sodium dioctyl sulfosuccinate,dodecyl dimethyl betaine, sodium oleoyl methylamine ethanesulfonate and calcium chloride; the corrosion inhibitor comprises one or more of imidazolinequaternary ammonium salts or imidazoline amides. The pipeline cleaning agent can effectively remove grease and dirt in a pipeline to keep the pipeline unblocked, is safe and non-toxic, cannot corrode equipment, is harmless tohuman skin and conforms to emission standards.

Owner:BEIJING DAISI SCI & TECH

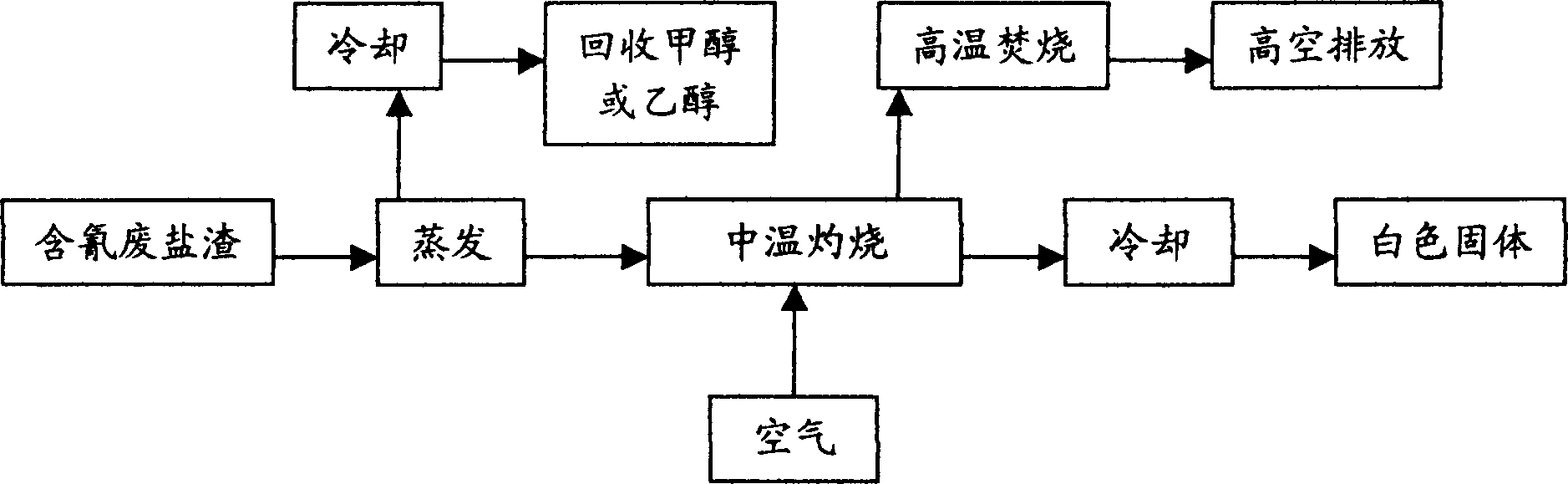

Method for treating waste salt dregs containing cyanogen

The invention relates to a processing method for cyanogens contained waste salt dredge, the process steps are: the cyanogens contained waste salt dredge is put into the drier to be heated; the heating temperature is controlled with 60-120deg.C, the carbinol and the alcohol volatilize from the dredge, the carbinol and the alcohol are reclaimed with high purity after beings cooled in the condenser; the cyanogens contained waste salt dredge without carbinol and alcohol is baked in oxygen condition, the oxide in the dredge is fully oxidized, the organic is oxidized or volatilized off, thus eliminates the cyanogens and organic in the salt dredge; the gas generated in the baking process is transmitted to the burning furnace, the temperature is not lower than 1100deg.C, thus the tail gas may accord the discharging standard.

Owner:邱滔 +1

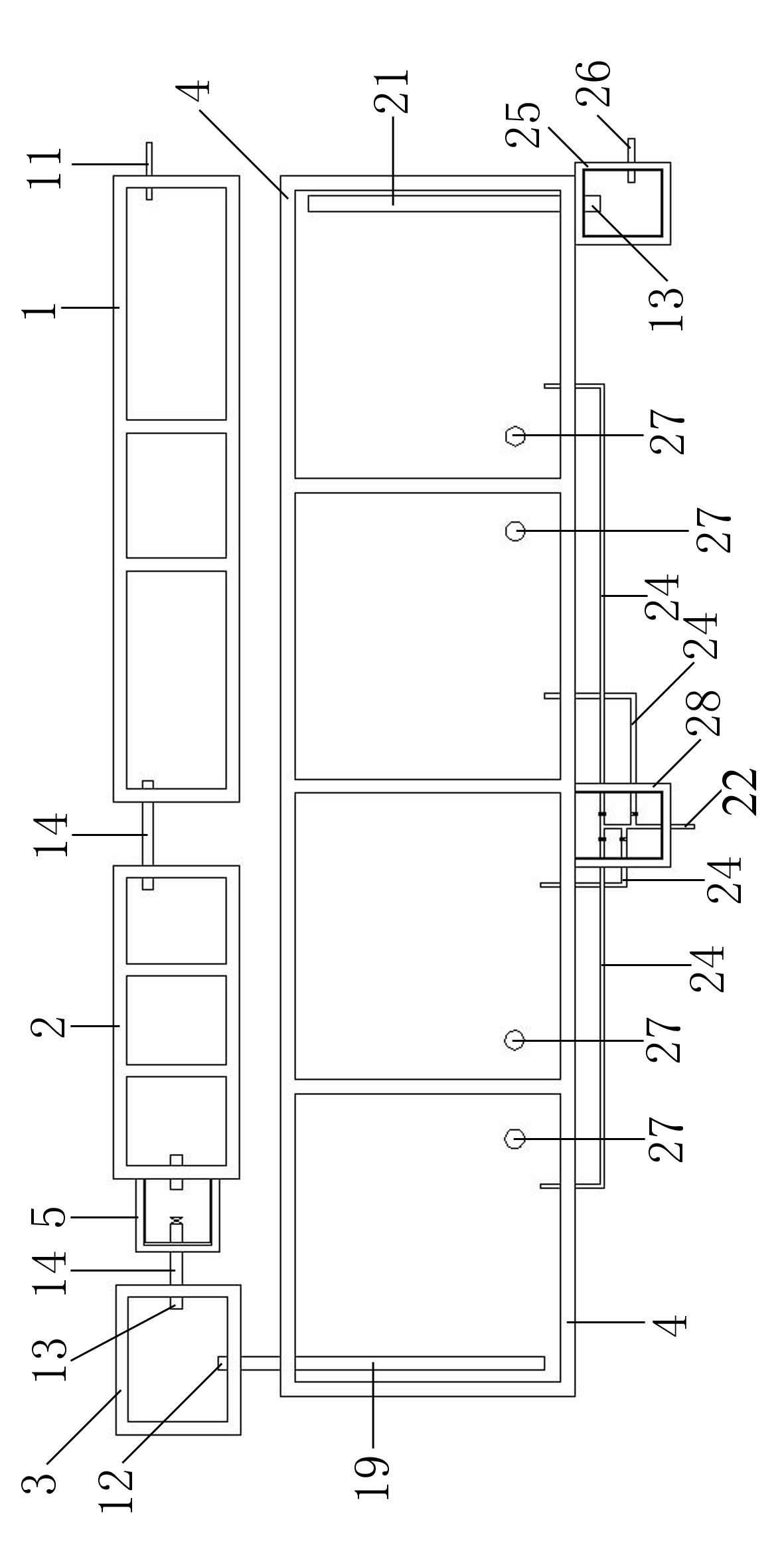

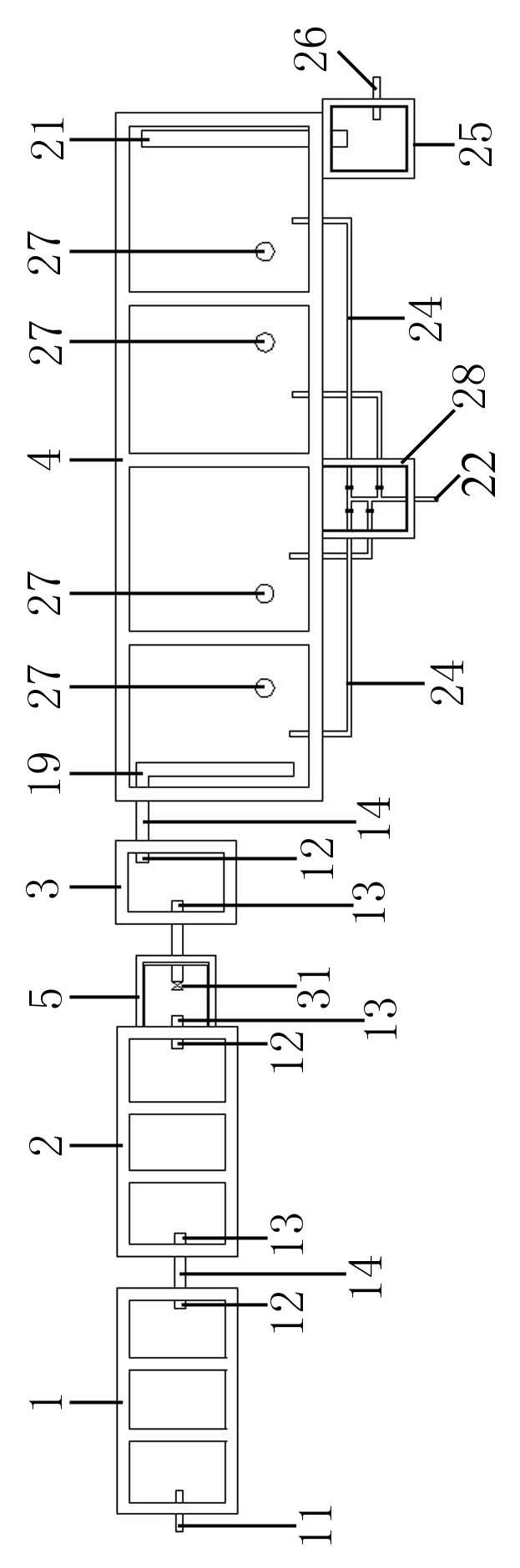

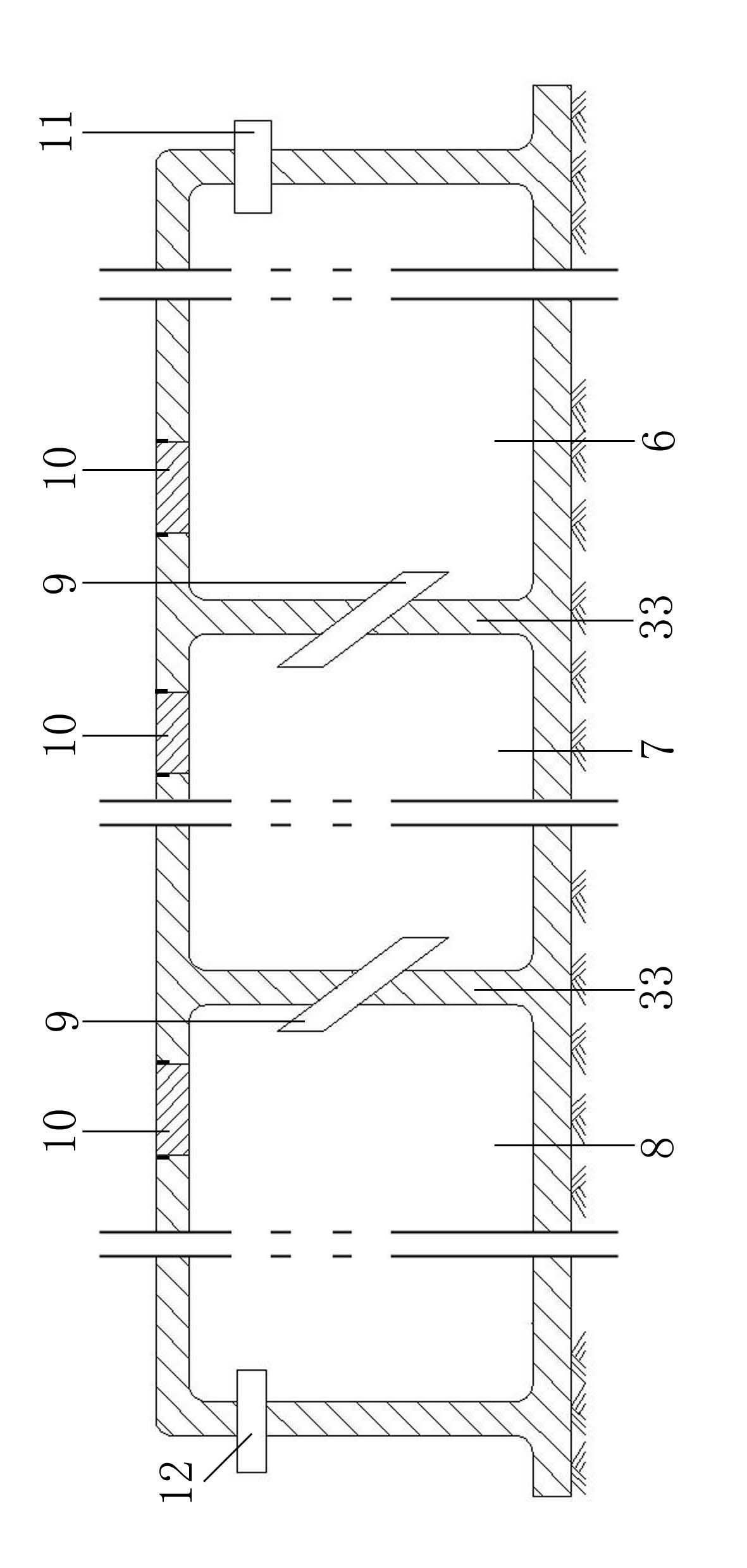

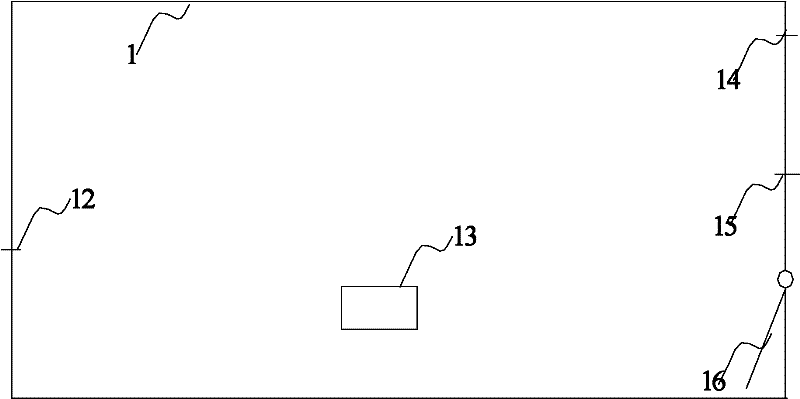

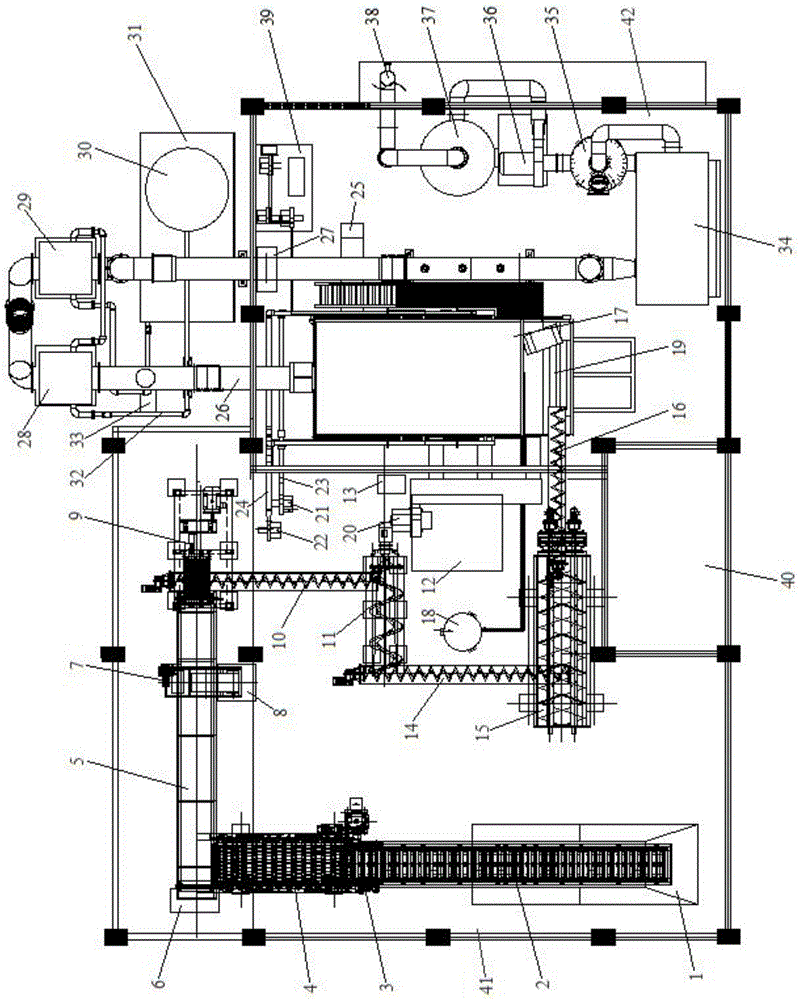

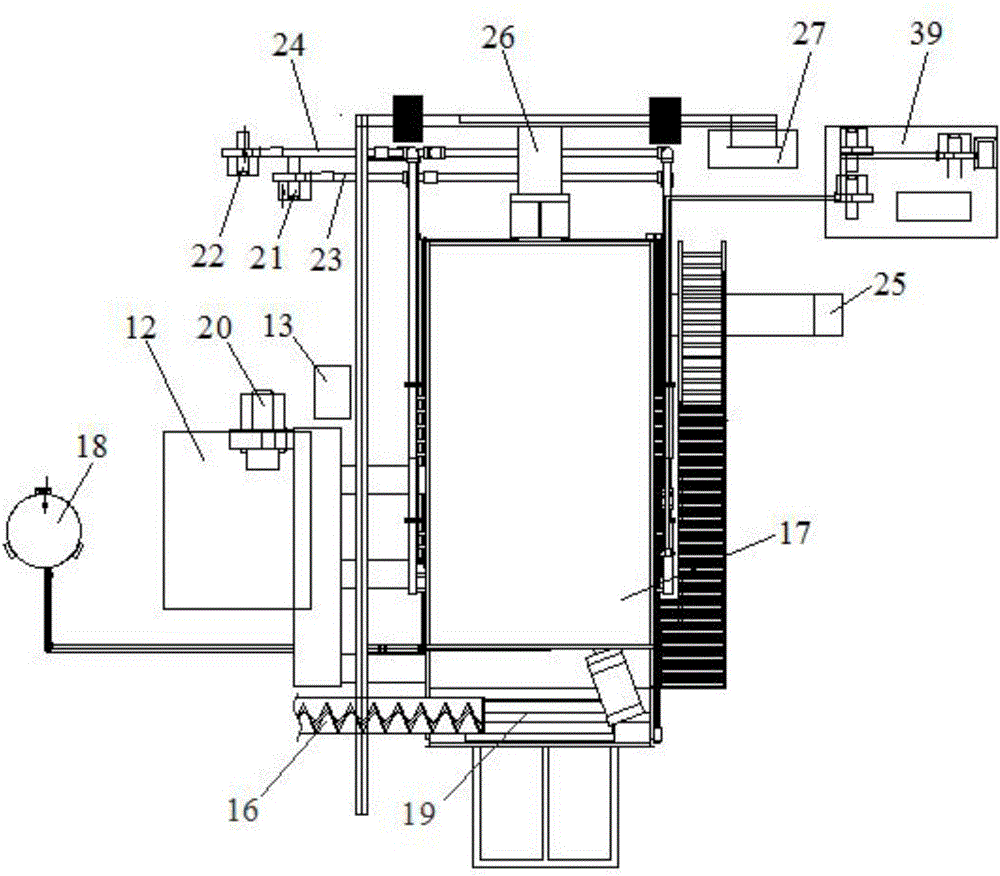

Biological response system for multistage sewage treatment as well as manufacturing method and sewage treatment method

InactiveCN102120677AEasy to handleIncrease the permeability coefficientMultistage water/sewage treatmentDecompositionEngineering

The invention discloses a biological response system for multistage sewage treatment as well as a manufacturing method and a sewage treatment method. The biological response system is formed by connecting a multistage precipitation pretreatment unit, a multistage hydrolysis and acidizing treatment unit, an aeration oxygenation treatment unit and a multistage undercurrent wetland treatment unit through pipelines; the multistage undercurrent wetland treatment unit comprises a water inlet wetland pool, two groups of decomposition and percolation wetland pools and a water outlet wetland pool which are sequentially arrayed; and the multistage precipitation pretreatment unit, the multistage hydrolysis and acidizing treatment unit and the aeration oxygenation treatment unit are sequentially arranged on one side of the multistage undercurrent wetland treatment unit in parallel and are connected with one another through pipelines. The biological response system provided by the invention has the advantages of scientific design, reasonable structure, fewer electromechanical devices due to the adoption of an automatic flow mode, low operation cost, low sewage treatment expense, small floor area, obvious sewage treatment effect, convenience for operation and maintenance management, low cost on project capital construction and operation, and capability of carrying out purification treatment all the year round, ; the treated sewage can be directly discharged into reservoirs, rivers and lakes and is in accordance with discharge standards in China; and a bioecological technology has stronger self-regulation capability and repair capability.

Owner:TIANJIN WATER RESOURCES RES INST

Radioactive liquid waste treatment device

The invention relates to a radioactive liquid waste treatment device comprising a feeding device, a volume reducer of radioactive wastes, a tail gas and residual liquid treatment device and a conveyer. The feeding device, the tail gas and residual liquid treatment device and the conveyer are respectively connected with the volume reducer; the feeding device, the tail gas and residual liquid treatment device, the conveyer and the volume reducer are integrally arranged under a vacuum environment; the volume reducer comprises a macroscopic dehydration volume-reduction unit for macroscopically dehydrating and reducing volume of the radioactive liquid wastes and a heating-drying volume-reduction unit, and the heating-drying volume-reduction unit and the macroscopic dehydration volume-reductionunit for breaking the organization structure of the radioactive wastes are connected by a pipeline to form a seal system. A movable radioactive liquid waste treatment device disclosed by the invention has the advantages of little environment pollution, safe and reliable treatment process and reduced storage space, and reaches the state standard of effluent discharge.

Owner:HUANCHUANG XIAMEN TECH

Liquid alkali low-temperature roasting decomposition process of caustic soda liquid of mixed rare earth concentrates

InactiveCN101824531AEliminate pickling and decalcification processRealize continuous roasting decompositionDecompositionRare earth

The invention relates to a liquid alkali low-temperature roasting decomposition process of caustic soda liquid of mixed rare earth concentrates, which comprises the following steps of: (1) mixing mixed rare earth concentrates and sodium hydroxide in the weight ratio of 1:0.5 to 1.5; (2) roasting the mixed rare earth ore at the roasting temperature of between 150 and 550 DEG C for 0.5 to 4 hours; (3) washing roasted ore water obtained by roasting until the water is neutral; (4) dissolving washed alkali cakes in hydrochloric acid, and controlling the pH value to be between 4 and 5 to prepare rare earth chloride solution; (5) after washing thorium enrichment dissolved by the hydrochloric acid, performing sealing pile-up or extracting thorium and rare earth through further dissolution. The mixed rare earth concentrates are processed by adopting the low-temperature roasting decomposition process, so that the continuous production of the alkali-decomposing mixed rare earth ore can be realized, no waste gas or ammonia nitrogen waste water is generated in the process, and the pollution-free production and comprehensive utilization of resources are realized.

Owner:BAOTOU RES INST OF RARE EARTHS

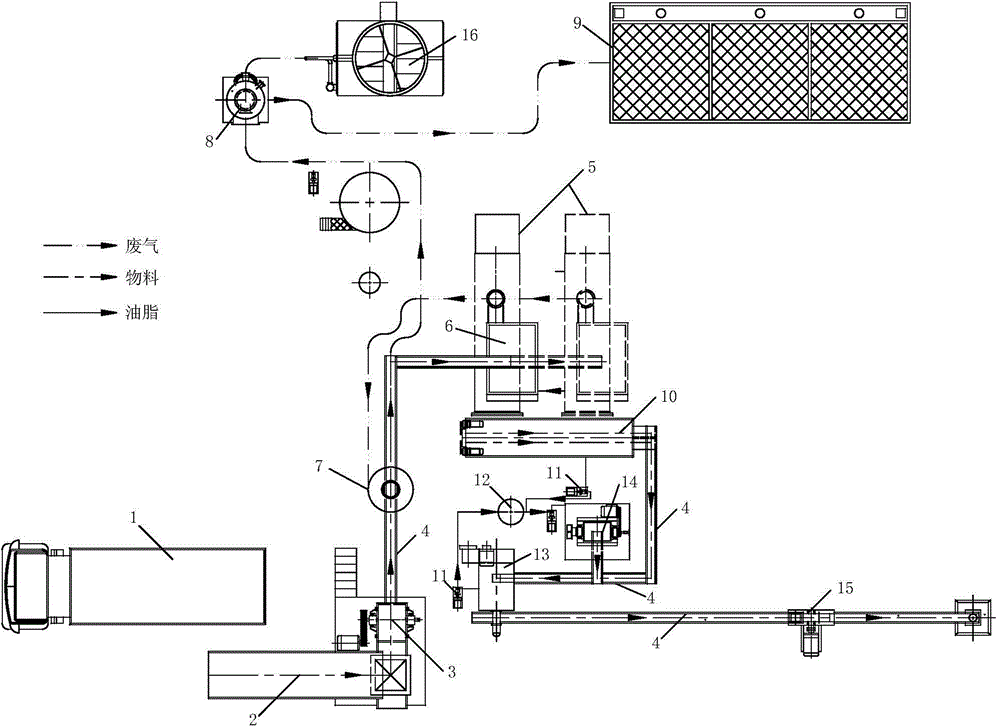

Innocent treatment process for livestock and poultry died from diseases

InactiveCN104941989AEfficient use ofAvoid pollutionSolid waste disposalClimate change adaptationEnvironmental resistanceOil and grease

The invention relates to an innocent treatment process for livestock and poultry died from diseases. The innocent treatment process comprises the following steps: disinfecting a transport vehicle; breaking livestock and poultry died from diseases, metering and weighing the broken materials, and then carrying out high-temperature and high-pressure sterilization treatment; collecting waste gas generated during the high-temperature and high-pressure sterilization treatment, removing a small amount of materials contained in the waste gas, condensing the waste gas obtained by separation, introducing the condensed waste gas into a biofilter and filtering; performing coarse filtering, namely, performing solid-liquid separation on a mixture of material and oil after high-temperature and high-pressure sterilization treatment, and storing the separated oil into an oil storage tank; performing refined filtering, namely, performing solid-liquid separation on the material obtained by solid-liquid separation again, and storing the separated oil into the oil storage tank; performing oil separation, namely, performing solid-liquid separation on the oil in the oil storage tank, so as to obtain high-purity oil which can be taken as bio-oil for production, wherein the separated tiny material is subjected to refined filtering again; and finally, grinding the material obtained after solid-liquid separation and bagging. According to the innocent treatment process, resource utilization is realized, waste is turned into valuable, energy is saved, and the environment protection purpose is achieved.

Owner:CHANGZHOU OLYMSPAN THERMAL ENERGY EQUIP

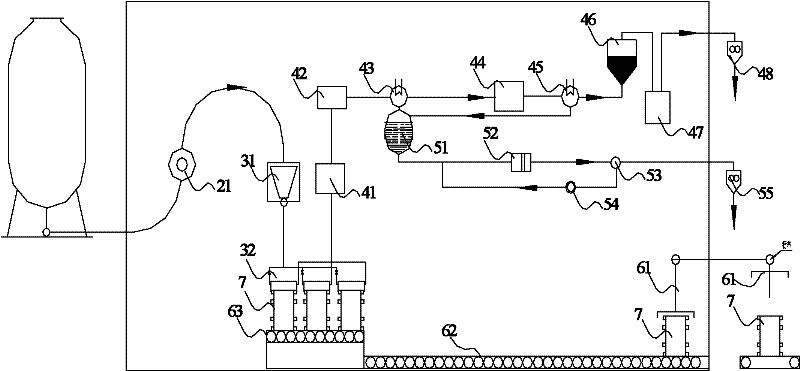

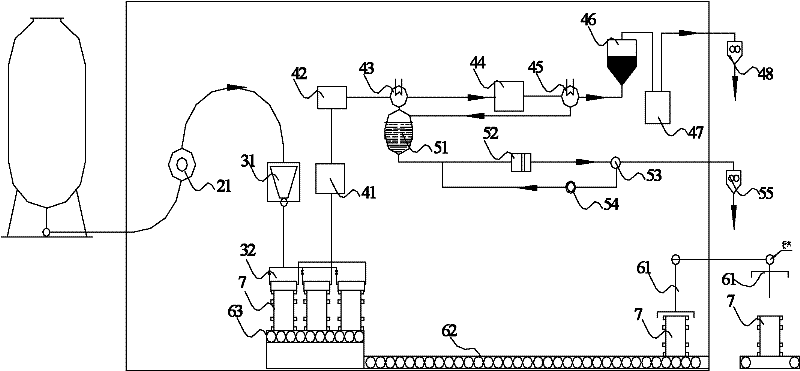

System and process for removing PM2.5 through wet flue gas demercuration and cooperative desulfurization

ActiveCN104014217AMeet low emission requirementsMeet emission requirementsCombination devicesLiquid wasteFlue gas

The invention discloses a system and process for removing PM2.5 through wet flue gas demercuration and cooperative desulfurization. The system comprises a bag type dust collector, a wet desulfurization absorption tower, an oxidation tower, a wet electric precipitator, an oxidizing agent preparation device and an integrated oxidation and demercuration byproduct preparation structure comprising a waste reservoir, a settling pond and a solid-liquid separator. The process comprises the following steps: dissolving and absorbing particulate mercury and Hg<2+> in flue gas on a slurry spraying layer during wet desulfurization, thus realizing first-stage demercuration; further oxidizing elemental Hg0 in the flue gas into Hg<2+> by adopting an oxidizing agent, and dissolving and removing the Hg<2+>; removing residual Hg<2+>, particulate mercury, PM2.5 and acid mist in the flue gas by adopting the wet electric precipitator; and preparing byproducts from oxidation and demercuration liquid wastes by adopting a precipitation separation method. According to the system and process, effective demercuration and cooperative desulfurization and fine particle removal are realized, the byproducts are effectively recycled, secondary pollution is avoided, and a comprehensive flue gas treatment effect is improved.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

Low temperature Claus sulfur recovery process and device therefor

InactiveCN101519192BImprove conversion rateReduce emission concentrationEnergy inputSulfur preparation/purificationReaction temperatureOxygen

The invention discloses a low temperature Claus sulfur recovery process. The process mainly comprises a thermal reaction section, a catalytic reaction section and a tail gas incineration section, wherThe invention discloses a low temperature Claus sulfur recovery process. The process mainly comprises a thermal reaction section, a catalytic reaction section and a tail gas incineration section, whertion temperature, contributes to performance of chemical equilibrium towards the direction of sulfur generation, so that conversion rate and recovery rate of sulfur are improved. Moreover, the processtion temperature, contributes to performance of chemical equilibrium towards the direction of sulfur generation, so that conversion rate and recovery rate of sulfur are improved. Moreover, the process has the advantages of simple process flow, relative small equipment and investment, low operation cost and more contribution to environmental protection. The invention also discloses a device for thehas the advantages of simple process flow, relative small equipment and investment, low operation cost and more contribution to environmental protection. The invention also discloses a device for the low temperature Claus sulfur recovery process.low temperature Claus sulfur recovery process.ein in a combustion furnace of the thermal reaction section, partial hydrogen sulfide reacts with oxygen to be converted into sulfur dioxide, the hydrogen sulfide and the sulfur dioxide undergo a Clauein in a combustion furnace of the thermal reaction section, partial hydrogen sulfide reacts with oxygen to be converted into sulfur dioxide, the hydrogen sulfide and the sulfur dioxide undergo a Claus reaction to generate sulfur, and process gas after sulfur separation enters the catalytic reaction section; in the reactor of each stage of the catalytic reaction section, the hydrogen sulfide and ts reaction to generate sulfur, and process gas after sulfur separation enters the catalytic reaction section; in the reactor of each stage of the catalytic reaction section, the hydrogen sulfide and the sulfur dioxide under conventional Claus reaction, catalyst reactivation, sub-dewpoint and sub-solid point low temperature Claus reaction in sequence; after the catalyst reaction section, the tail ghe sulfur dioxide under conventional Claus reaction, catalyst reactivation, sub-dewpoint and sub-solid point low temperature Claus reaction in sequence; after the catalyst reaction section, the tail gas which is subjected to sulfur separation enters the tail gas incineration section, and the tail gas is incinerated and exhausted in the tail gas incineration furnace. The process adopts a lower reacas which is subjected to sulfur separation enters the tail gas incineration section, and the tail gas is incinerated and exhausted in the tail gas incineration furnace. The process adopts a lower reac

Owner:CHENGDU SEPMEM SCI & TECH

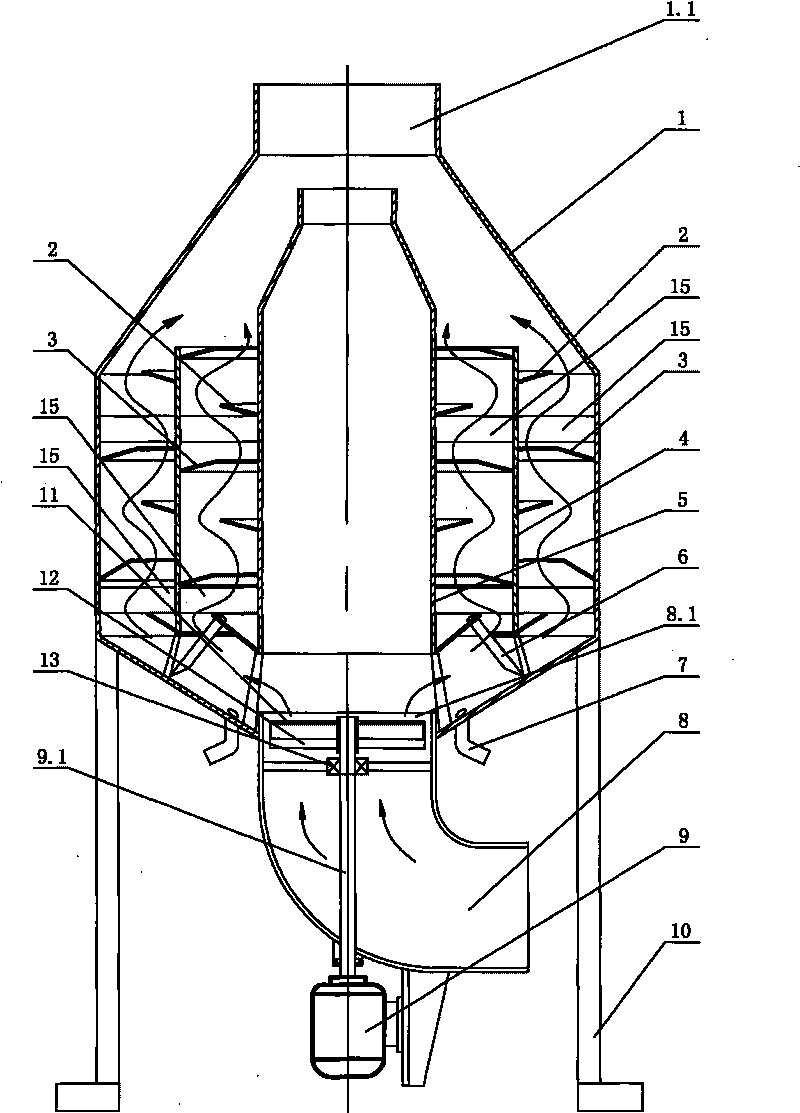

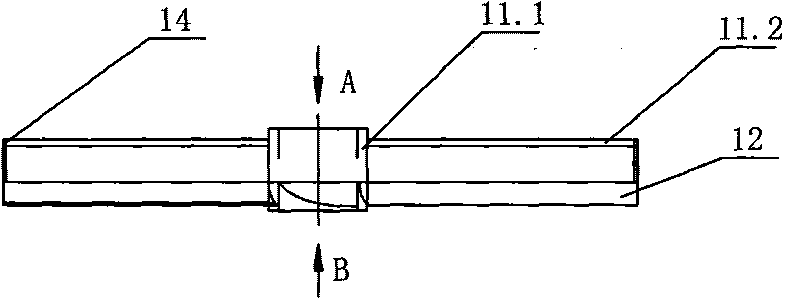

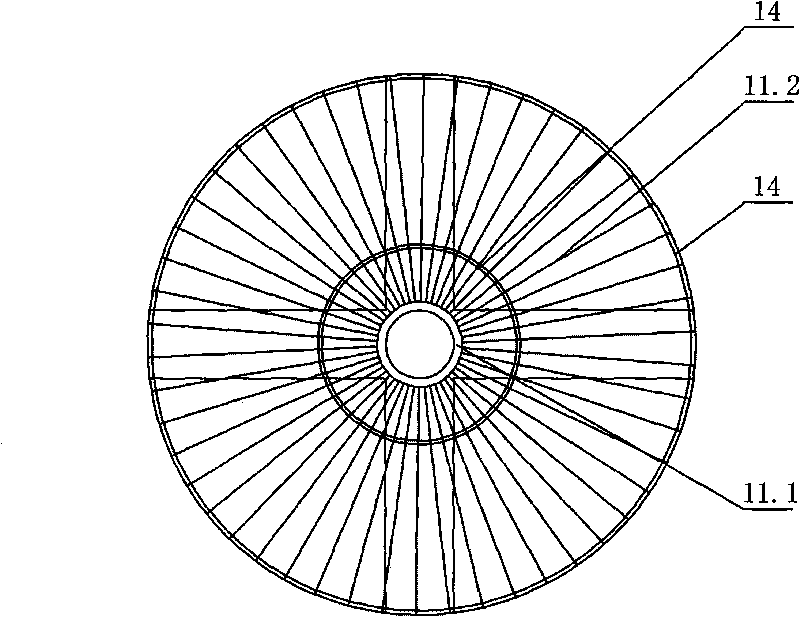

Wind speed-reducing water mist removing device

InactiveCN101693157ACongeal fastSlow down the flowDispersed particle separationIndustrial wasteAirflow

The invention relates to a wind speed-reducing water mist removing device which comprises a toggle joint and a purifying cylinder, wherein the toggle joint is connected with an air inlet pipeline, and the purifying cylinder is connected with an air outlet of the toggle joint; the purifying cylinder comprises an outer cylinder body with an air outlet, a middle cylinder body and an inner cylinder body, wherein the outer cylinder body is installed above the air outlet of the toggle joint and the middle cylinder body and the inner cylinder body are installed in the outer cylinder; multiple layers of damping disks are arranged in both an annular passage between the outer cylinder body and the middle cylinder body and an annular passage between the middle cylinder body and the inner cylinder body; multiple layers of damping disks are formed by mutually spacing at least two small damping disks and at least two big damping disks; and a drain pipe is installed at the bottom of the outer cylinder body. The invention is used for the purification processing of industrial waste gases, and the water mist and the waste gases after being mixed are rapidly discharged into the toggle joint by the air inlet pipeline through an induced draft fan; after carrying out centrifugal shunting, the water mist mixed with smoke and poisonous substances is condensed in the purifying cylinder and separated from an airflow, thus purified air is discharged; and the invention has the advantages of low cost and obvious purifying effect.

Owner:张宏生

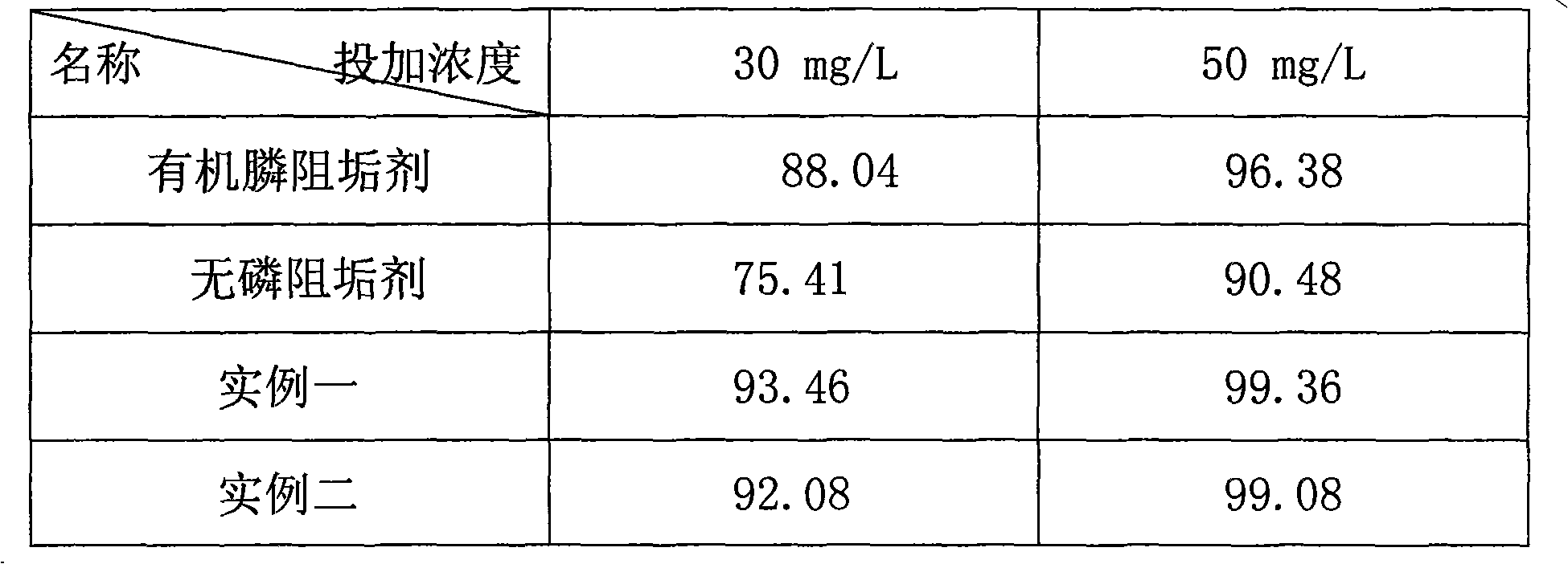

Low-phosphorous environment-friendly scale inhibitor adapting to 'three-high' water quality and preparation thereof

InactiveCN101913712AInhibition formationHigh charge densityScale removal and water softeningPhosphateWater quality

The invention provides a low-phosphorous environment-friendly scale inhibitor adapting to 'three-high' water quality and preparation thereof. The scale inhibitor is prepared from the following raw materials in part by weight: 1, 1.0 to 2.5 parts of polyamino polyether methylene phosphonic acid (PAPEMP); 2, 1.5 to 3.0 parts of polyepoxysuccinic acid (PESA); 3, 1.5 to 2.5 parts of acrylic acid-hydroxypropyl acrylate-AMPS terpolymer; 4, 1.5 to 2.5 parts of liquid caustic soda; 5, 0.5 to 1.0 part of hydrolyzed plymaleic anhydride; and 6, the balance of water. The scale inhibitor is prepared by the following steps of: pumping the raw materials 1, 2 and 3 into a reaction kettle during synthesis, and continuously stirring; and adding the material 4 into 5 and 6, pumping into the reaction kettle, continuously stirring for 35 to 45 minutes, and discharging to prepare the product. The scale inhibitor has good scale-inhibiting effect on carbonate and phosphate and the scale-inhibiting time of 100 hours, and is suitable for a high-hardness high-alkalinity high-mineralization circulating cooling water system and oil field water treatment. Therefore, the original concentration times is improved from 3 times to 5-6 times, the new water can be saved by 10 to 30 percent per year, and the phosphorus content of sewage treated by the scale inhibitor is 1.5 to 3ppm and accords with the national phosphorus discharge standard.

Owner:URUMQI KEFAZHAN FINE CHEM

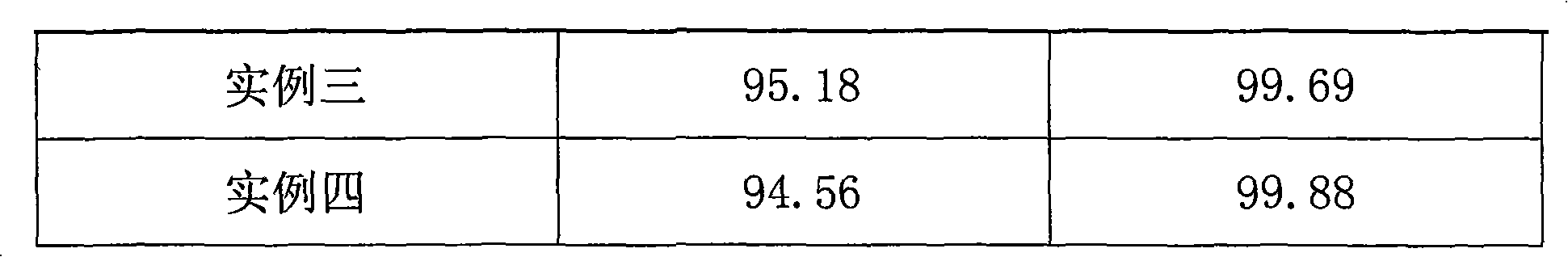

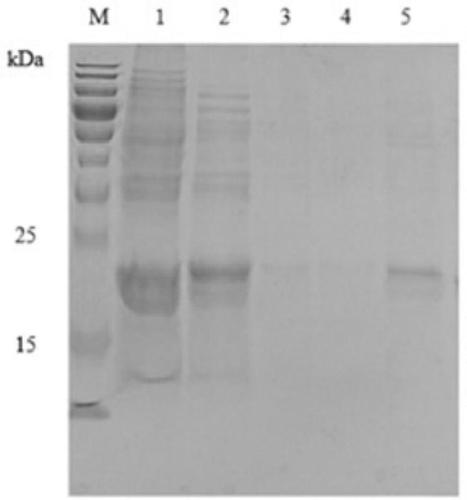

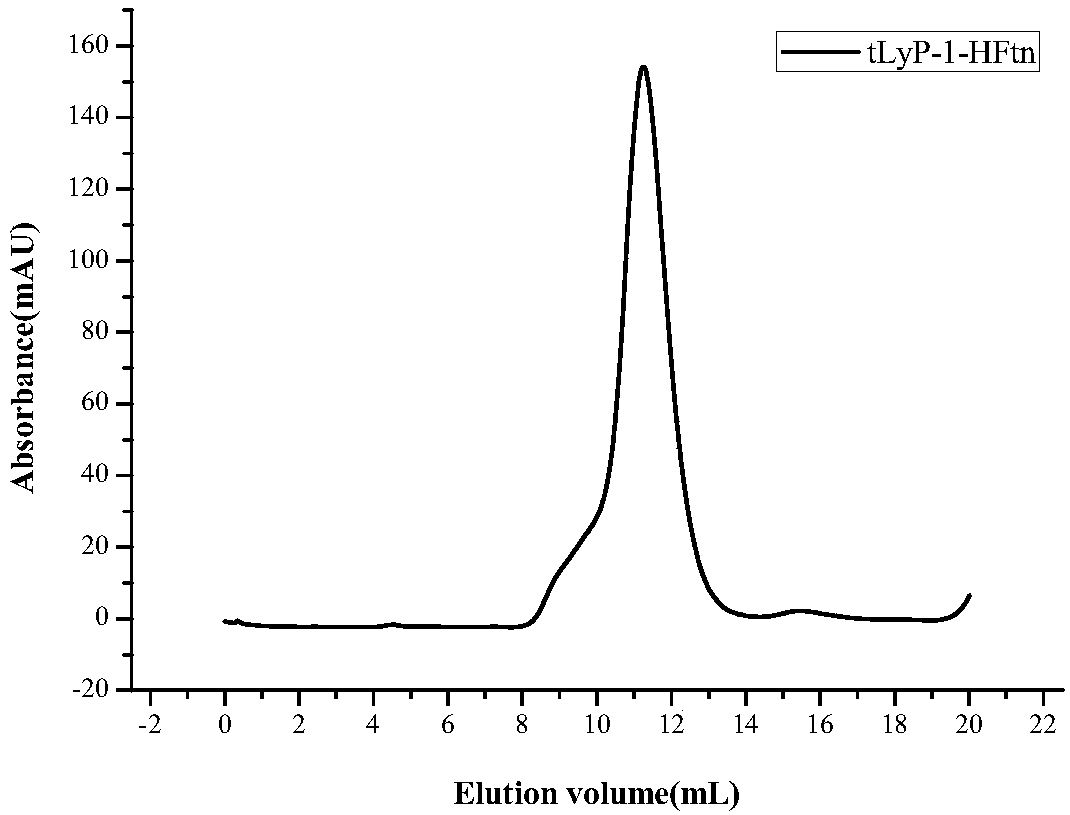

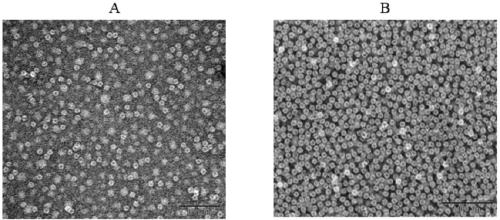

Tumor homing cell-penetrating peptide tLyP-1 modified apoferritin nano-cage and preparation method thereof

InactiveCN109486827ACompliance with emission standardsAchieve dual targetingPeptide preparation methodsFermentationTumor therapyFerritin

The invention discloses a tumor homing cell-penetrating peptide tLyP-1 modified apoferritin nano-cage and a preparation method thereof. The protein nano-cage is hollow cage-shaped protein formed by self-assembling 24 protein subunits; and one tumor homing cell-penetrating peptide tLyP-1 is modified on an N end of each protein subunit by utilizing a gene recombination technology to obtain a recombinant human body heavy-chain ferritin nano-cage with a tLyP-1 modified surface. According to the protein nano-cage provided by the invention, a medicine is loaded into the nano-cage through adjusting depolymerization and recombination of the protein subunits; the nano-cage has good water solubility and biocompatibility, has excellent stability in a human body and has a uniform size; the nano-cage can be specifically combined with a lot of neuropilin receptors 1 (NRP-1) which are expressed in tumor neovascularization and tumor cells of malignant tumors including gliomas, breast cancer, pancreatic cancer, gastric cancer, colorectal cancer, non-small cell lung cancer and the like; and types of the tumors treated by the nano-cage are greatly increased and the targeting ability of tumor treatment is improved. The protein nano-cage provided by the invention has an extremely great application prospect in the aspects of tumor diagnosis and treatment and the like.

Owner:NANJING FORESTRY UNIV

Strong effective decoloring decontaminating purifying agent for wastewater of dyestuff, and preparation method

InactiveCN101050007ARaw materials are easy to getLow priceWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationTherapeutic effectPolyacrylamide

This invention relates to a method for preparing high-efficiency water purifier for decolorizing printing wastewater. The water purifier is polymerized from: melamine 2.5 parts, aluminum sulfate 0.1 part, ammonium chloride 2 parts, formaldehyde 2 parts, urea 1 part, 20-60 wt.% soluble starch aqueous solution 1 part, and 1-6 wt.% cationic polyacrylamide solution 0-0.5 part. The water purifier has good treatment effect on printing wastewater.

Owner:WUHAN UNIV OF TECH

High-organic-content dredged silt composite curing material

ActiveCN106673569AHigh strengthImprove stabilitySolid waste managementFixation/solidifcation sludge treatmentPotassiumPERMANGANATE ION

The invention discloses a high-organic-content dredged silt composite curing material. The curing material has the advantages of being low in cost and excellent in performance, and capable of utilizing industrial waste materials, effectively curing silt with a high organic content and achieving comprehensive utilization of silt and solid waste. The high-organic-content dredged silt composite curing material of the invention is prepared from the following ingredients in mass percent: 6% to 9% of cement, 5% to 7.5% of coal ash, 4% to 6% of mineral waste residue, 4% to 6% of lime, 3% to 5% of ardealite, 2% to 4% of excitant and 0.6% to 1.8% or 1.2% to 8% of strong oxidant, wherein the use amount of each ingredient is the percent of the ingredient mass to the dredged silt mass, the strong oxidant is potassium sulphate or potassium permanganate or H oxidant, the use amount of the strong oxidant is 0.6% to 1.8% when the strong oxidant is the potassium sulphate or the postassium permanganate, and the use amount of the strong oxidant is 1.2% to 5% when the strong oxidant is the H oxidant.

Owner:NANJING UNIV OF TECH +2

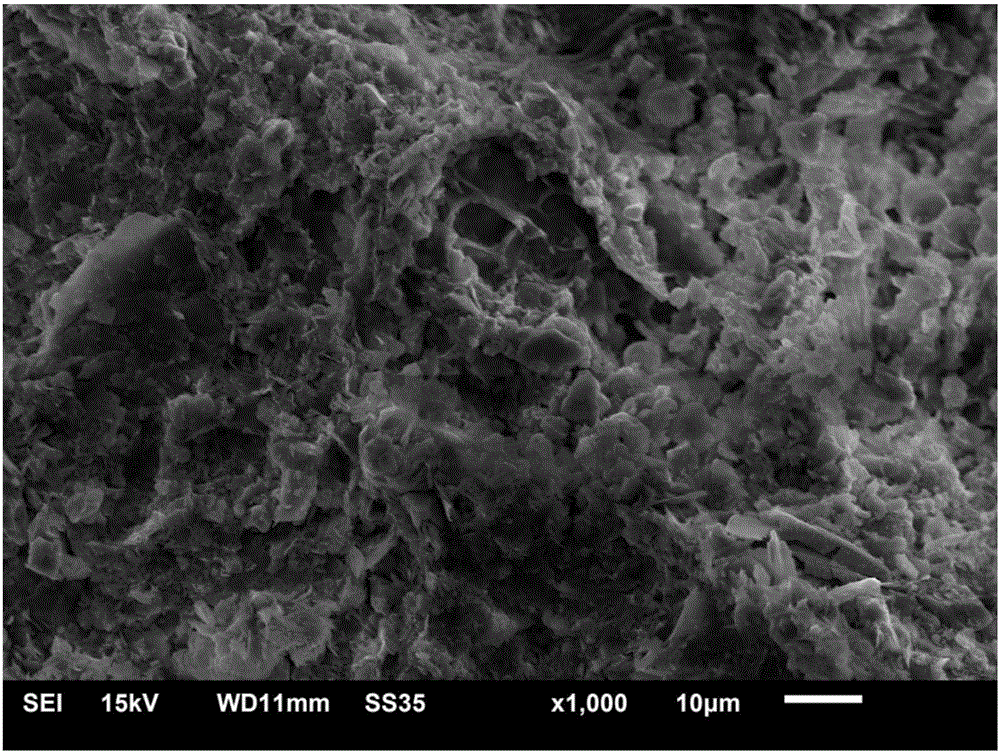

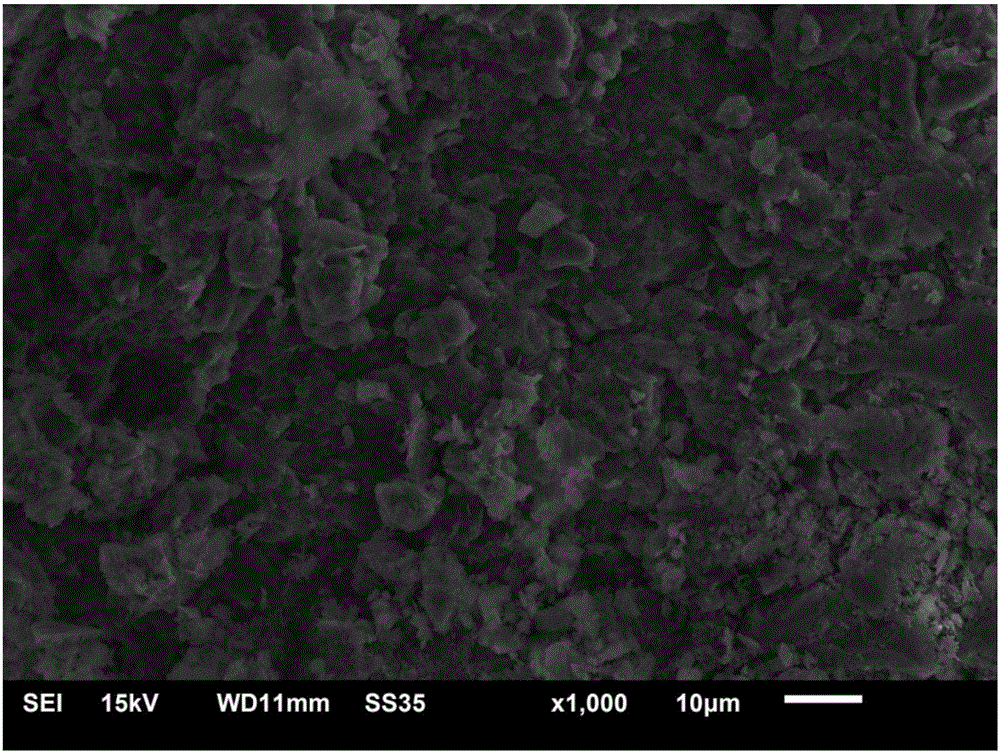

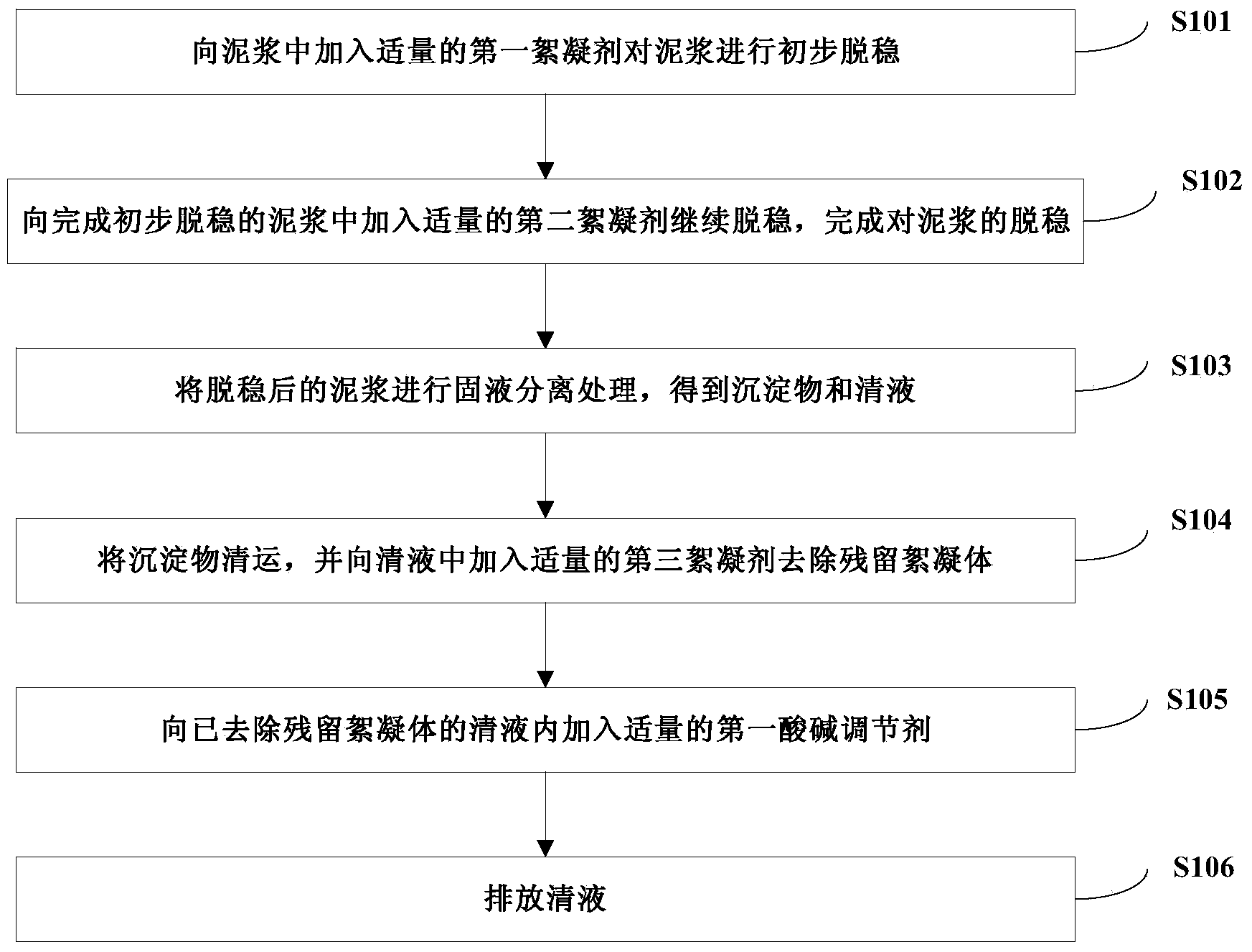

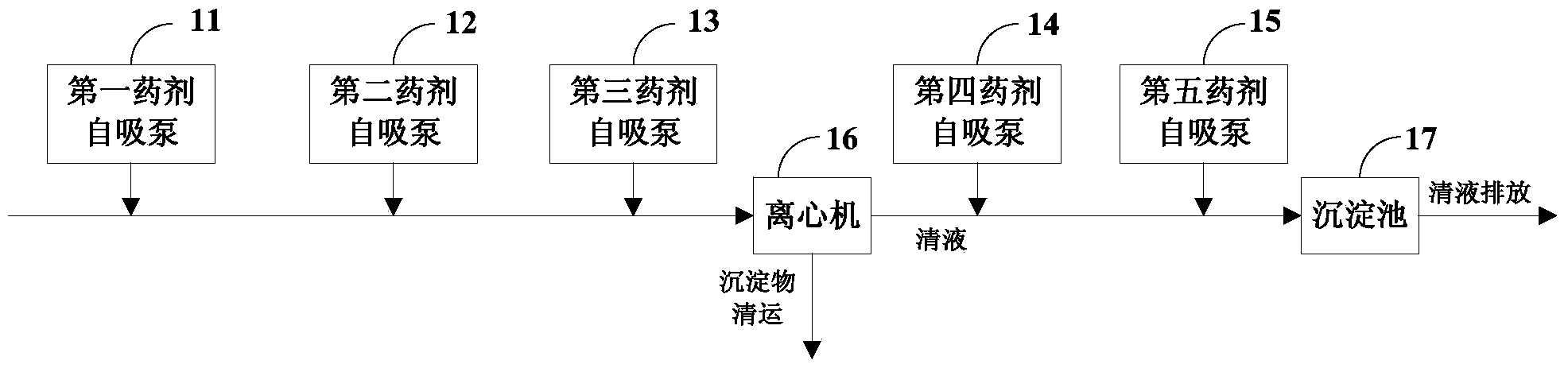

Waste drilling mud treatment process

InactiveCN104310747AReduce moisture contentNo residueSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFlocculationSediment

The invention discloses a waste drilling mud treatment process. The process comprises the following steps: adding a proper amount of a first flocculant into mud so as to primarily destabilize the mud; adding a proper amount of a second flocculant into the primarily destabilized mud for destabilizing continuously so as to complete the mud destabilization; performing solid-liquid separation treatment on the destabilized mud so as to obtain sediments and supernatant; clearing away the sediments and adding a proper amount of a third flocculant into the supernatant so as to remove residual flocculating constituents; adding a proper amount of a first pH regulator into the supernatant, in which the residual flocculating constituents are removed; discharging the supernatant. Compared with the prior art, the waste drilling mud treatment process has the advantages that through the combined flocculation of the first flocculant and the second flocculant, the flocculation effect is better and the water content of the sediments is lower.

Owner:HUNAN UNIV +1

Garbage disposal combustion furnace and garbage disposal system

PendingCN107525082AReduce moisture contentTo achieve the goal of zero emissionsCombustion technology mitigationAir/fuel supply for combustionCombustion chamberFlue gas

The invention discloses a garbage disposal combustion furnace and a garbage disposal system. The combustion furnace comprises a furnace body, a blower is arranged on one side of the furnace body to ventilate a fire grate, a first combustion chamber and a second combustion chamber are sequentially arranged above the fire grate, a first secondary blower and a second secondary blower are arranged on the outside of the furnace body to ventilate the first combustion chamber and the second combustion chamber respectively, and full combustion of garbage and flue gas is facilitated. When temperature of the first combustion chamber reaches a preset value, an extraction pump extracts a garbage leachate from a leachate filter tank to spray to the first combustion chamber for gasification disposal, and the purpose of zero discharge of the garbage leachate is achieved; after the garbage is combusted in the first combustion chamber, flue gas enters the second combustion chamber for secondary high-temperature combustion, harmful substances in the flue gas are fully pyrolyzed, the flue gas combusted is disposed through a flue gas disposal part, generation of dioxin can be greatly reduced, and the flue gas finally discharged is allowed to meet the national discharge standard.

Owner:珠海市云筒环保设备有限公司

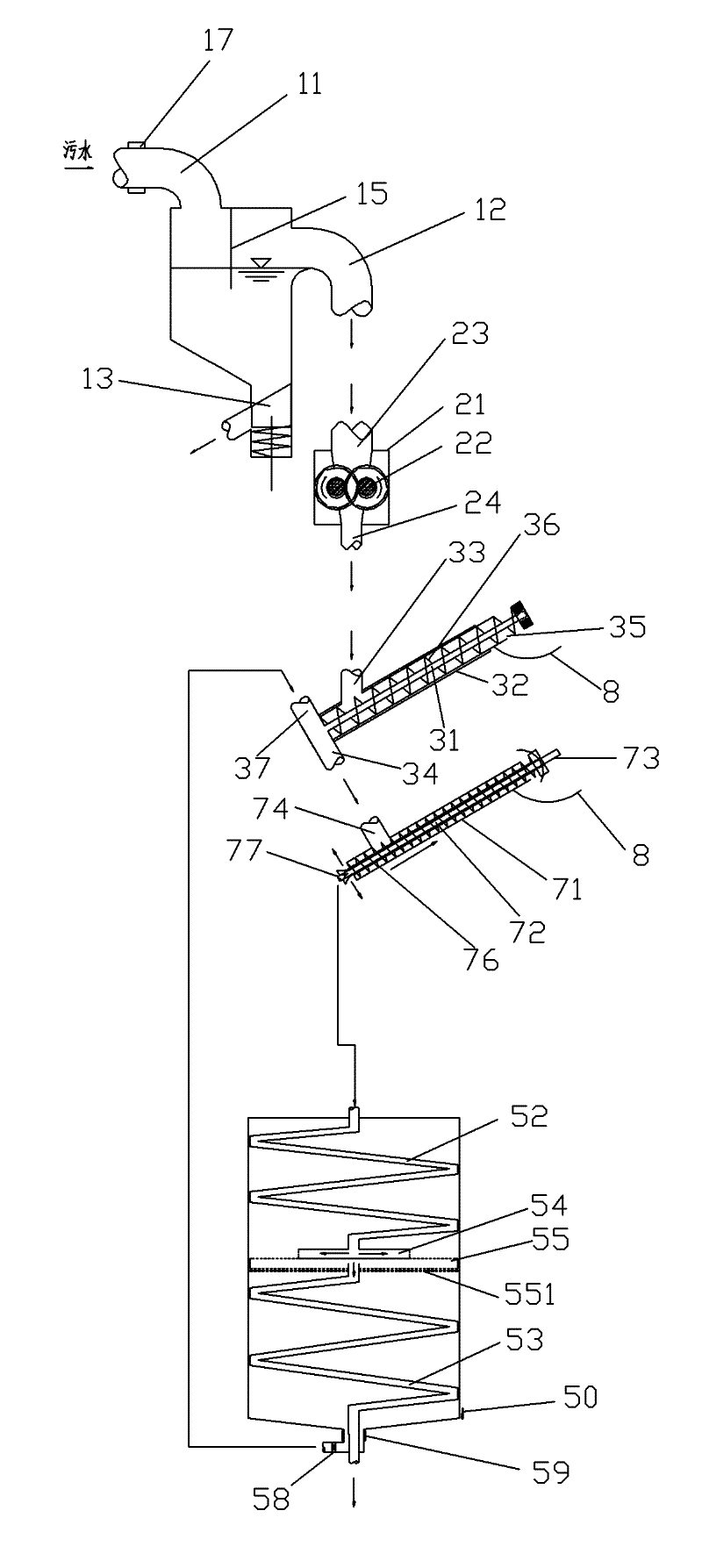

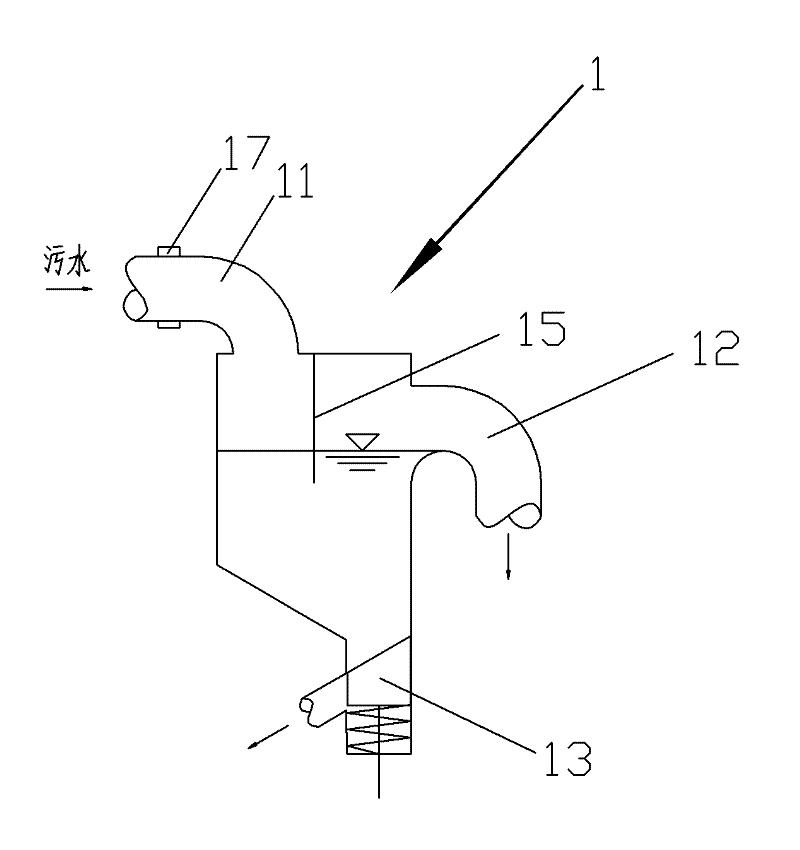

Physical sewage treatment system used for sewage treatment from source

InactiveCN102219319AEasy to separateEasy to handleMultistage water/sewage treatmentPollutionSewage sludge treatment

The invention discloses a physical sewage treatment system used for sewage treatment from the source, comprising a solid-liquid separation device and a settling device. The solid-liquid separation device is provided with a solid-liquid separator, and a separation water inlet, a separation water outlet and a separation sewage discharging port of the solid-liquid separator; the settling device comprises a settling shell the bottom of which is provided with a settling sewage discharging port, a water inlet hose and a water outlet hose are arranged in the settling shell, the water inlet end of the water inlet hose is connected with the separation water outlet of the solid-liquid separation device, the water outlet end of the water inlet hose is connected with a hollow floating disk, the outline of the floating disk adapts to that of the cross section of the settling shell, and a plurality of through holes are uniformly distributed in the annular area of the bottom surface, close to the edge; a floating disk water outlet is arranged on the bottom of the floating disk and is connected with the water inlet end of the water outlet hose, and the water outlet end of the water outlet hose extends out of the settling shell. The sewage treatment system can be used for treating sewage timely from the pollution sources, thus reducing or avoiding the phenomenon that sewage enters public water body.

Owner:ZHONGSHAN JUYA BATHROOM CO LTD

Chemical for cleaning boiler

InactiveCN102418103ALow cleaning temperatureShorten the timeCetyldimethylbenzylammonium chlorideAcid washing

The invention relates to a chemical for cleaning a boiler, and belongs to the technical field of the chemical cleaning of equipment. The chemical comprises a corrosion-inhibiting acid-washing agent, a bleaching agent and a passivant, wherein the corrosion-inhibiting acid-washing agent consists of 1,3,5,7-tetraaza-adamantane, ethylenediamine tetracetic acid, hydrochloric acid, phosphoric acid, silicon fluoride, hydrazine hydrate, sodium silicate, cetyl dimethyl benzyl ammonium chloride, ammonium thiocyanate, sodium dodecyl benzene sulfonate and the balance of water; the bleaching agent is citric acid solution; and a passivant consists of ethidene diamine, formaldehyde, diammonium phosphate, hydrogen peroxide, sodium nitrite and the water. The chemical has stable chemical properties, low toxicity, a good sustained-release effect and high scale dissolving capacity, and does not have the damage of sour corrosion to the boiler.

Owner:CHANGSHA BLUECLEAN TECH

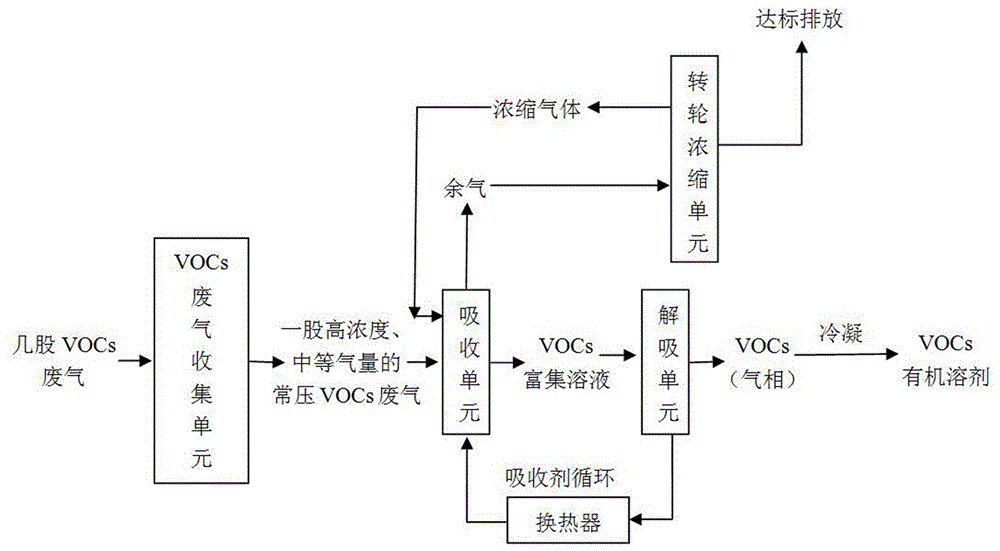

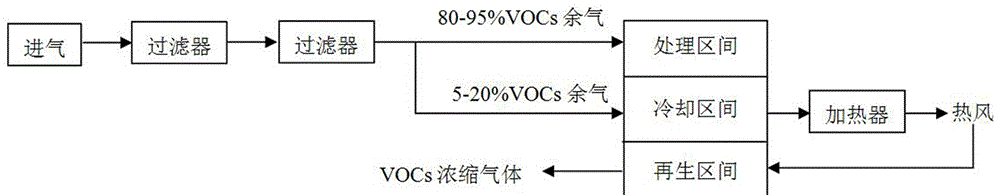

VOCs waste gas treatment method

InactiveCN105833666ACompliance with emission standardsRealize cleaner productionDispersed particle separationAir quality improvementChemical industryHigh concentration

The invention discloses a VOCs waste gas treatment method .High-concentration and low-medium-volume normal-pressure VOCs waste gas is discharged in the production process of medicine industry, chemical industry and other industries, and the waste gas is treated through the following steps of waste gas collecting, absorbing, desorbing, concentrating through a rotating wheel, recovering to obtain VOCs organic solvent, and purifying to achieve gas emission up to standard .By means of the method, absorbent can be recycled, emission of treated gas is up to standard, the recovery rate of VOCs is larger than or equal to 99%, the purity is larger than or equal to 95%, economic benefits are improved, and clean production is achieved .

Owner:河北美邦工程科技股份有限公司

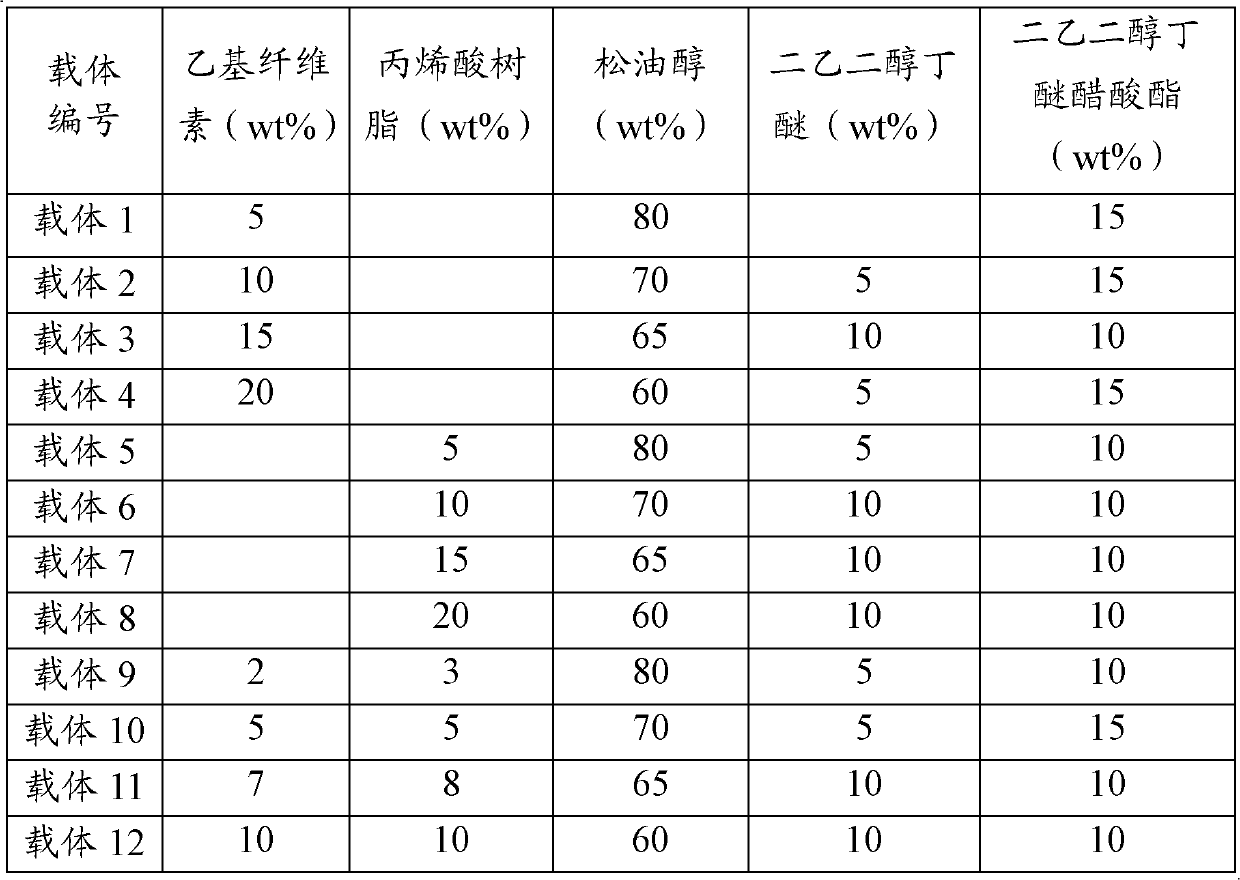

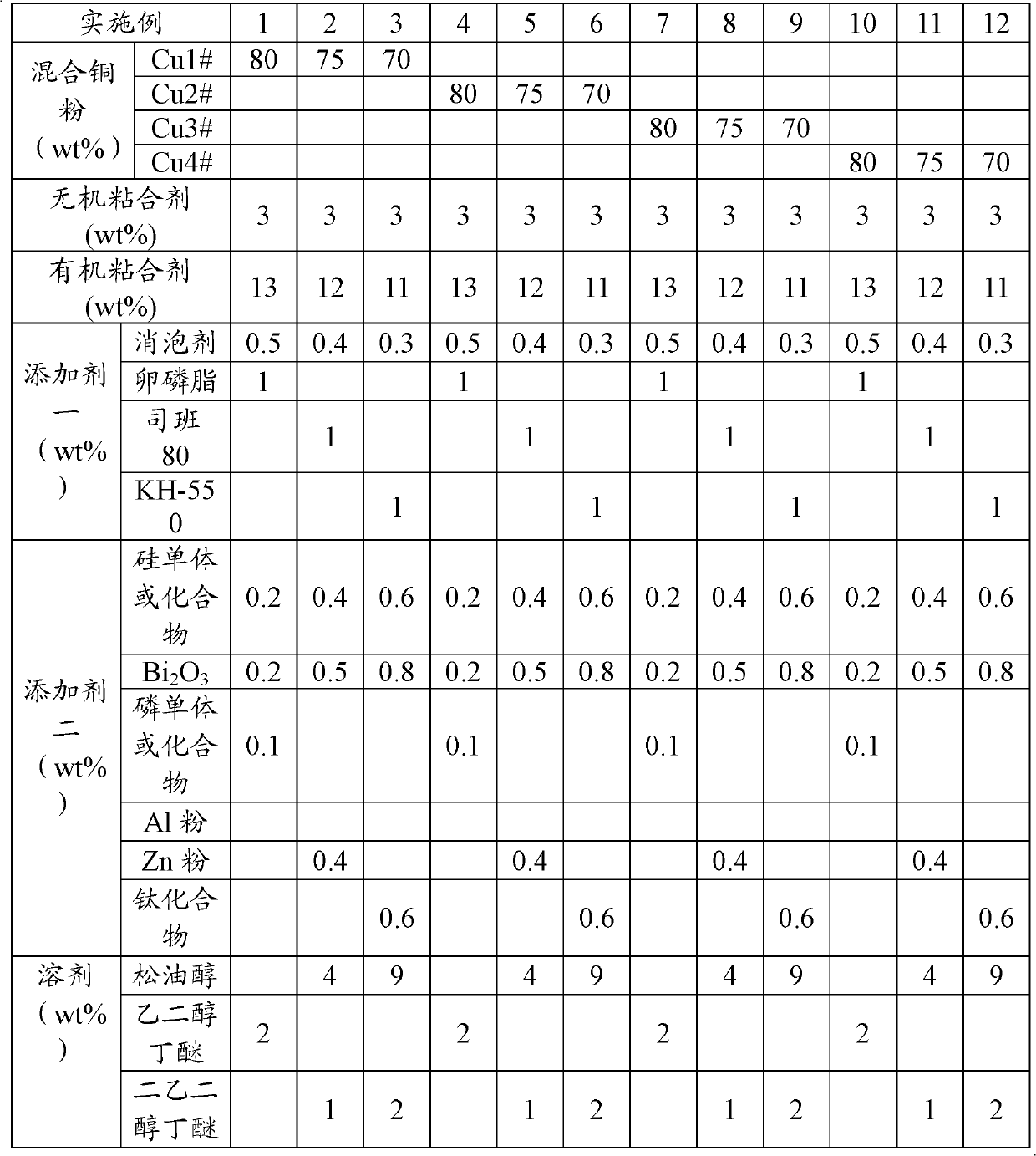

Lead-free copper slurry applied to silicon solar battery electrode and preparation method thereof

InactiveCN103310870AWide variety of sourcesLow priceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicon solar cellSlurry

The present invention provides lead-free copper slurry applied to a silicon solar battery electrode and a preparation method thereof. The lead-free copper slurry is prepared from, by mass, 60% to 85% of mixed copper powder, 1% to 10% of inorganic binder, 10% to 30% of organic binder, 1% to 30% of mixed additive and 5% to 20% of organic solvent. The mixed copper powder comprises copper powder A whose particle diameter distribution is 0.5 to 2 microns, copper powder B whose particle size distribution is 1 to 3 microns and copper powder C whose particle diameter distribution is 4 to 7 microns, wherein the mass ratio of the three kinds of copper powder is 5 to 8:1 to 4:1. The mixed additive is composed of a first additive and a second additive. The first additive is the mixture of one or more than two of a defoaming agent, a silane coupling agent KH-550 and lecithin or span. The second additive is one or more of elements or compounds of transition family or III, IV and V family elements. Ratio restriction on the additive amount of the first additive and the second additive does not exist, and adding is carried out according to the actual situation. The lead-free copper slurry has the advantages of low cost and excellent conductivity, weldability and ohmic contact property, and can be used as universal electrode slurry of electrodes on front and back of a solar battery.

Owner:SHENZHEN SENLONT ELECTRONICS

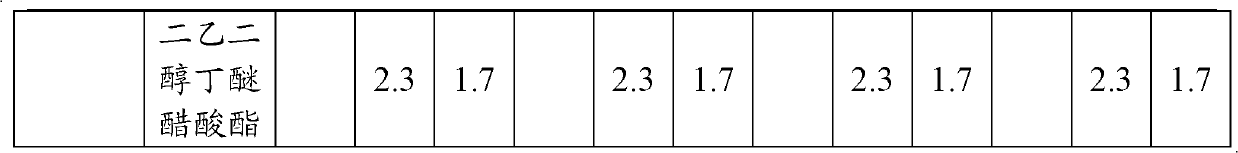

Water vapor electrolytic process based system for joint production of ammonia and nitric acid

ActiveCN106185984ARealize joint productionNot affected by market pricesElectrolysis componentsEnergy inputWater vaporEmission standard

The invention belongs to the technical field of chemical engineering and particularly relates to a water vapor electrolytic process based system for joint production of ammonia and nitric acid. The system comprises a nitrogen generation unit, an ammonia synthesis unit, a nitric acid generation unit, and a solid oxide electrolyzer. The ammonia synthesis unit is used to provide the material ammonia and process vapor for the nitric acid generation unit, no ammonia is externally purchased for the nitric acid generation unit, meanwhile, a heat recovery boiler is eliminated. The reaction heat of the ammonia synthesis unit and the nitric acid generation unit is used to produce high temperature vapor, the high temperature vapor is applied to the solid oxide electrolyzer, the solid oxide electrolyzer produces hydrogen and oxygen, the hydrogen and the oxygen are applied to the ammonia synthesis unit and the nitric acid generation unit, so that a mode of joint production of ammonia and nitric acid by taking air and water as raw materials is achieved, no materials or fuels are externally purchased, only electric energy is used, so that the system has the characteristics of high integration, low production cost, single and convenient energy consumption, reasonable recovery of energy, less environment pollution, conformity to the international emission standard and the like, and has an excellent economic benefit and an excellent application prospect.

Owner:陈志强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com