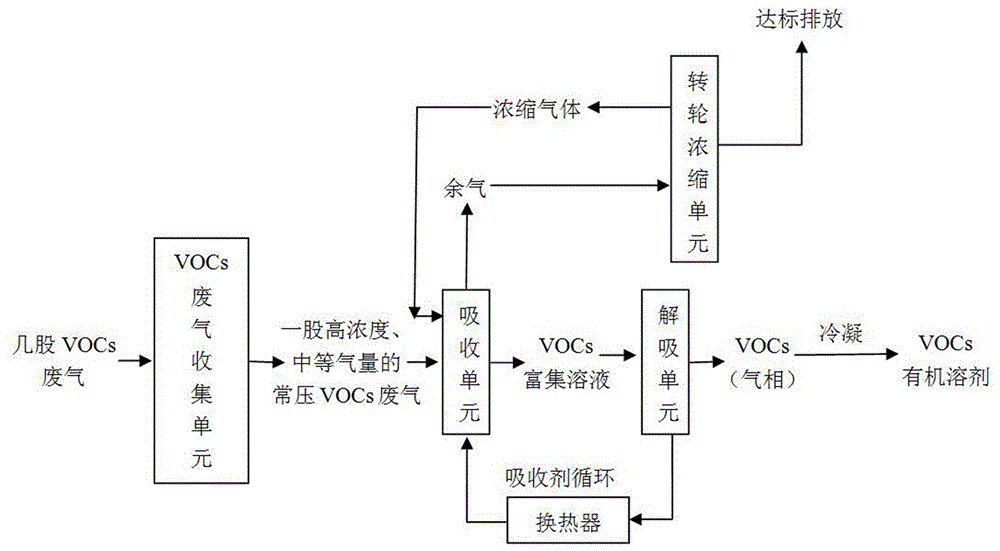

VOCs waste gas treatment method

A technology for waste gas treatment and waste gas, which is applied in separation methods, chemical instruments and methods, air quality improvement, etc., and can solve problems such as low absorption rate and non-standard discharge of tail gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

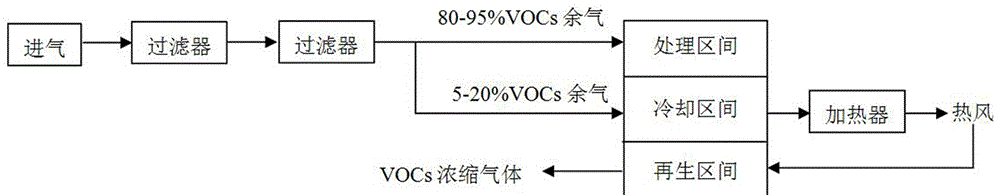

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A high-concentration, medium-volume ethyl acetate waste gas recovery treatment method comprises the following steps:

[0024] (1) Ethyl acetate waste gas collection

[0025] Collect the ethyl acetate waste gas discharged from each discharge point to obtain high-concentration and medium-volume ethyl acetate waste gas. The ethyl acetate content in the waste gas is 10g / L, and the gas volume is 10000Nm 3 / h.

[0026] (2) Absorption unit

[0027] The ethyl acetate waste gas collected in step (1) is sent from the bottom to the absorption tower for absorption, and the absorbent is sent from the top. Under the condition of a temperature of 30°C and normal pressure, the ethyl acetate waste gas and the absorbent are subjected to gas-liquid countercurrent contact , ethyl acetate is dissolved in the absorbent to obtain an ethyl acetate enriched solution, and the residual gas after absorption is discharged from the top of the tower, and the concentration of ethyl acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com