Patents

Literature

38results about How to "Low cleaning temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer wax-removal degreasing cleaning agent and preparation method thereof

InactiveCN104560447AEasy to cleanUnique nanoporous structureOrganic detergent compounding agentsSurface-active detergent compositionsSilicon oxideLotion

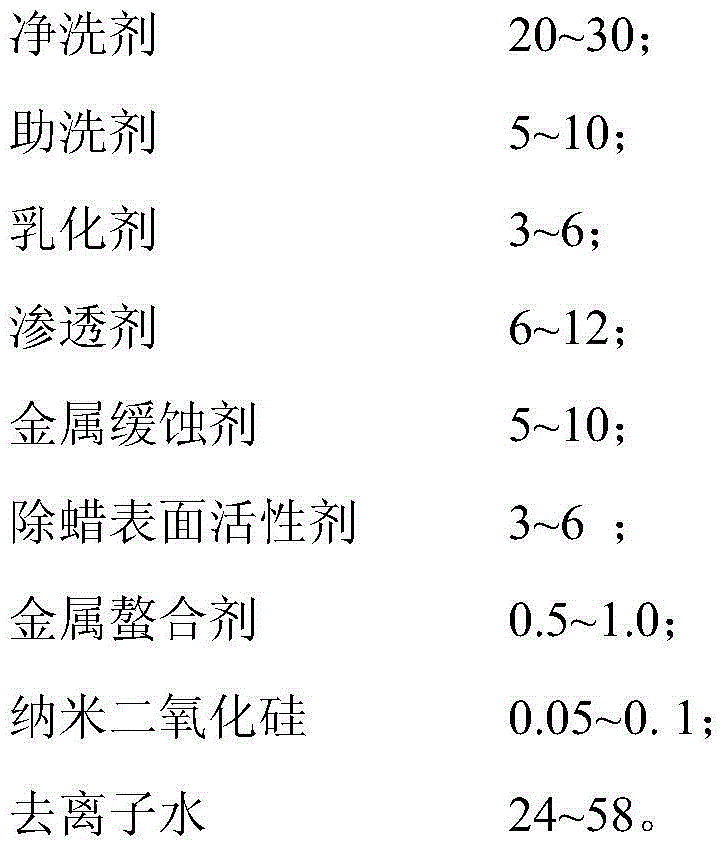

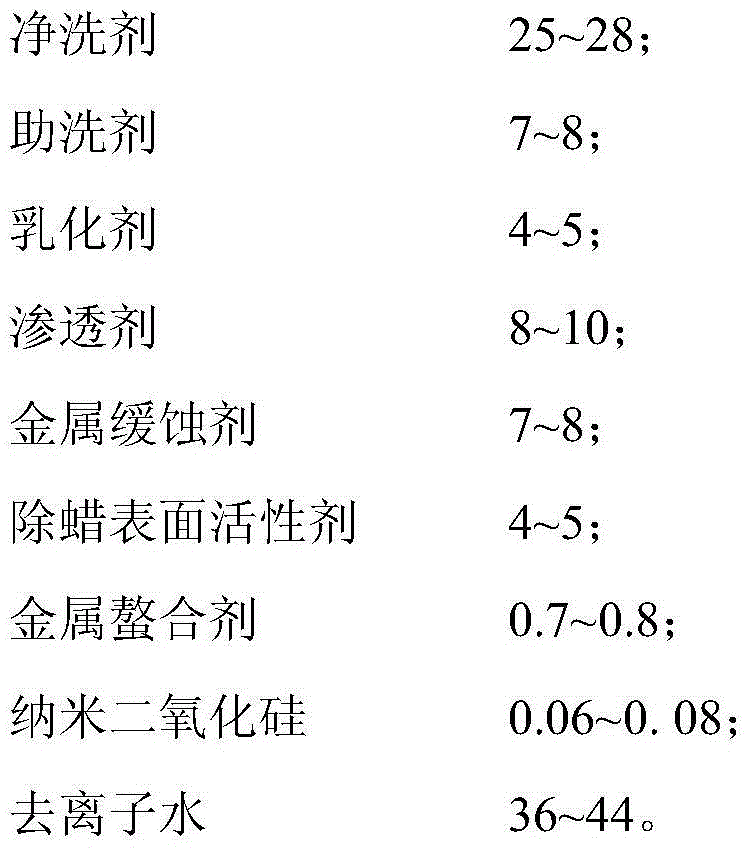

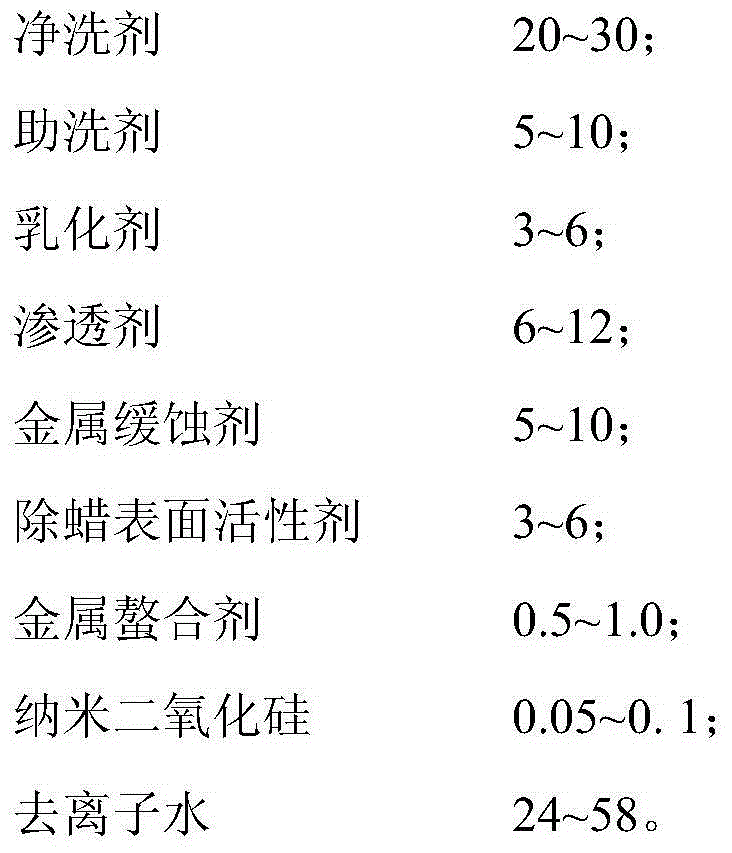

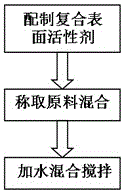

The invention relates to a nanometer wax-removal degreasing cleaning agent and a preparation method thereof and relates to cleaning agents. The nanometer wax-removal degreasing cleaning agent is prepared from the following raw materials in mass ratio: 20-30 of detergent, 5-10 of a builder, 3-6 of an emulsifier, 6-12 of a penetrating agent, 5-10 of a metal corrosion inhibitor, 3-6 of a wax-removal surfactant, 0.5-1.0 of a metal chelating agent, 0.05-0.1 of nanometer silicon oxide and 24-58 of deionized water. The preparation method comprises the following steps of (1) adding the metal chelating agent in deionized water to obtain an aqueous solution of the metal chelating agent; and 2) adding the emulsifier, the metal corrosion inhibitor and the nanometer silicon oxide into a reactor, adding deionized water and the detergent, adding the penetrating agent, the wax-removal surfactant and nanometer silicon oxide, stirring and adding the aqueous solution of the metal chelating agent obtained in the step (1), supplementing the residual deionized water and further stirring to obtain the nanometer wax-removal degreasing cleaning agent. The cleaning agent has the advantages of high wax-removal and degreasing speeds, long application period, good cleaning effect and environmental friendliness.

Owner:XIAMEN UNIV

Cleaning agent for ceramic membrane for oilfield produced water and cleaning method thereof

InactiveCN102716674AStrong targetingEfficient removalSemi-permeable membranesCleaning methodsCleansing Agents

The invention discloses a cleaning agent for a ceramic membrane for oilfield produced water, and overcomes the deficiency that the ceramic membrane for the oilfield produced water does not have an effective cleaning method and an effective cleaning formula. The cleaning agent comprises a component A, a component B and a component C, wherein effective constituents of the component A are sodium hydroxide and sodium alkyl benzene sulfonate; effective constituents of the component B are sodium hydroxide, sodium alkyl benzene sulfonate, ethylene diamine tetraacetic acid sodium salt, triethanol amine and sodium tripolyphosphate; and effective constituents of the component C are sodium hydroxide, sodium alkyl benzene sulfonate and hydrogen peroxide. The cleaning agent aiming at characteristics of the oilfield produced water has the advantages that dirt on the surface of the membrane and in membrane holes can be removed rapidly and efficiently, the cleaning frequency of the membrane is reduced, the cleaning temperature and the cleaning time are greatly reduced, the permeation flux of the ceramic membrane is recovered rapidly and efficiently, and the regeneration of a system is accelerated.

Owner:PETROCHINA CO LTD +1

Water-based cleaning agents for automobile parts and preparation method for water-based cleaning agents

The invention provides water-based cleaning agents for automobile parts and a preparation method for the water-based cleaning agents. The water-based cleaning agents include, by weight, 8.5-12% of composite surfactants, 6-10% of compound additives, 5-8% of mixed inorganic salt, 8-10% of solubilizers of diethylene glycol diethylether, 0.25-0.4% of inhibiters of benzotriazole, 0.05-0.1% of organic silicon defoamers and 59.5-72.2% of deionized water. The preparation method includes the following steps of (a) preparation of the composite surfactants, (b) weighing and mixing of raw materials and (c) water addition, mixing and stirring. The water-based cleaning agents are low in cleaning temperature, long in service life and free of toxin and pollution and have high cleaning efficiency and good anti-rust and anti-corrosion capacity, and the cleaning efficiency for automobile parts can be more than 99%.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

Chemical for cleaning boiler

InactiveCN102418103ALow cleaning temperatureShorten the timeCetyldimethylbenzylammonium chlorideAcid washing

The invention relates to a chemical for cleaning a boiler, and belongs to the technical field of the chemical cleaning of equipment. The chemical comprises a corrosion-inhibiting acid-washing agent, a bleaching agent and a passivant, wherein the corrosion-inhibiting acid-washing agent consists of 1,3,5,7-tetraaza-adamantane, ethylenediamine tetracetic acid, hydrochloric acid, phosphoric acid, silicon fluoride, hydrazine hydrate, sodium silicate, cetyl dimethyl benzyl ammonium chloride, ammonium thiocyanate, sodium dodecyl benzene sulfonate and the balance of water; the bleaching agent is citric acid solution; and a passivant consists of ethidene diamine, formaldehyde, diammonium phosphate, hydrogen peroxide, sodium nitrite and the water. The chemical has stable chemical properties, low toxicity, a good sustained-release effect and high scale dissolving capacity, and does not have the damage of sour corrosion to the boiler.

Owner:CHANGSHA BLUECLEAN TECH

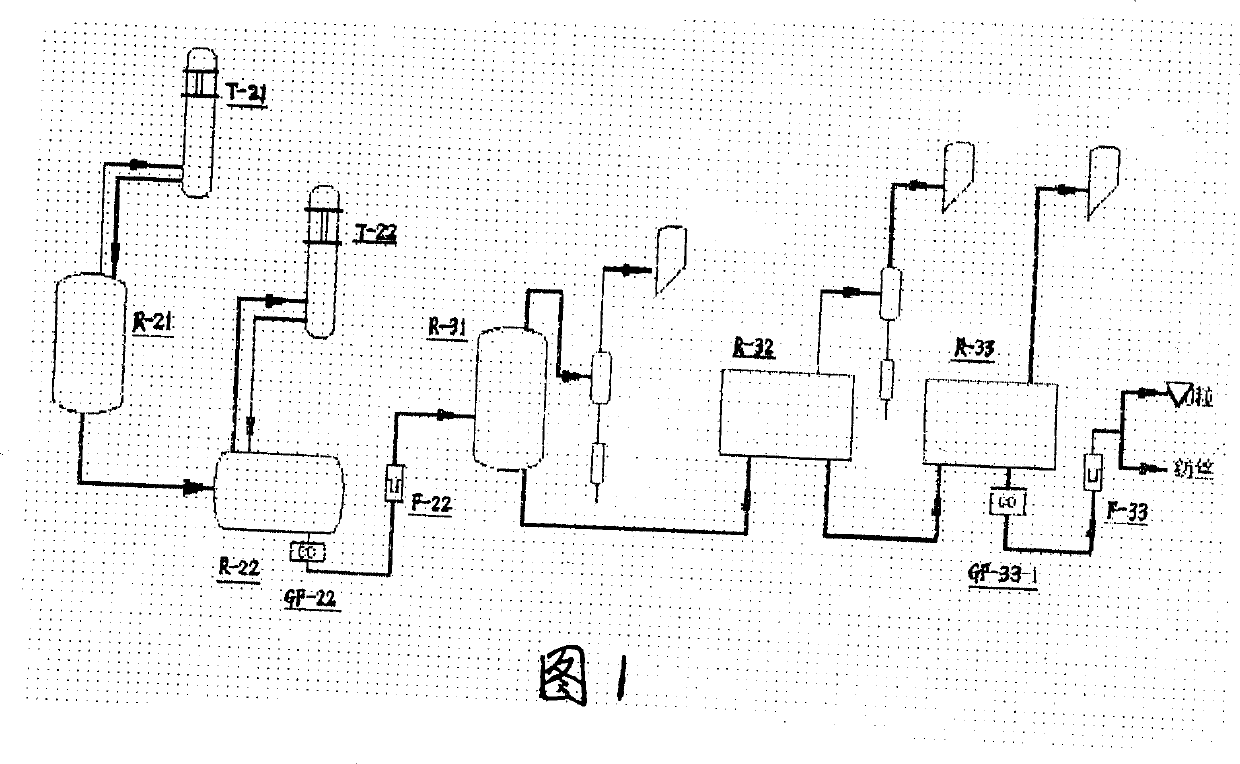

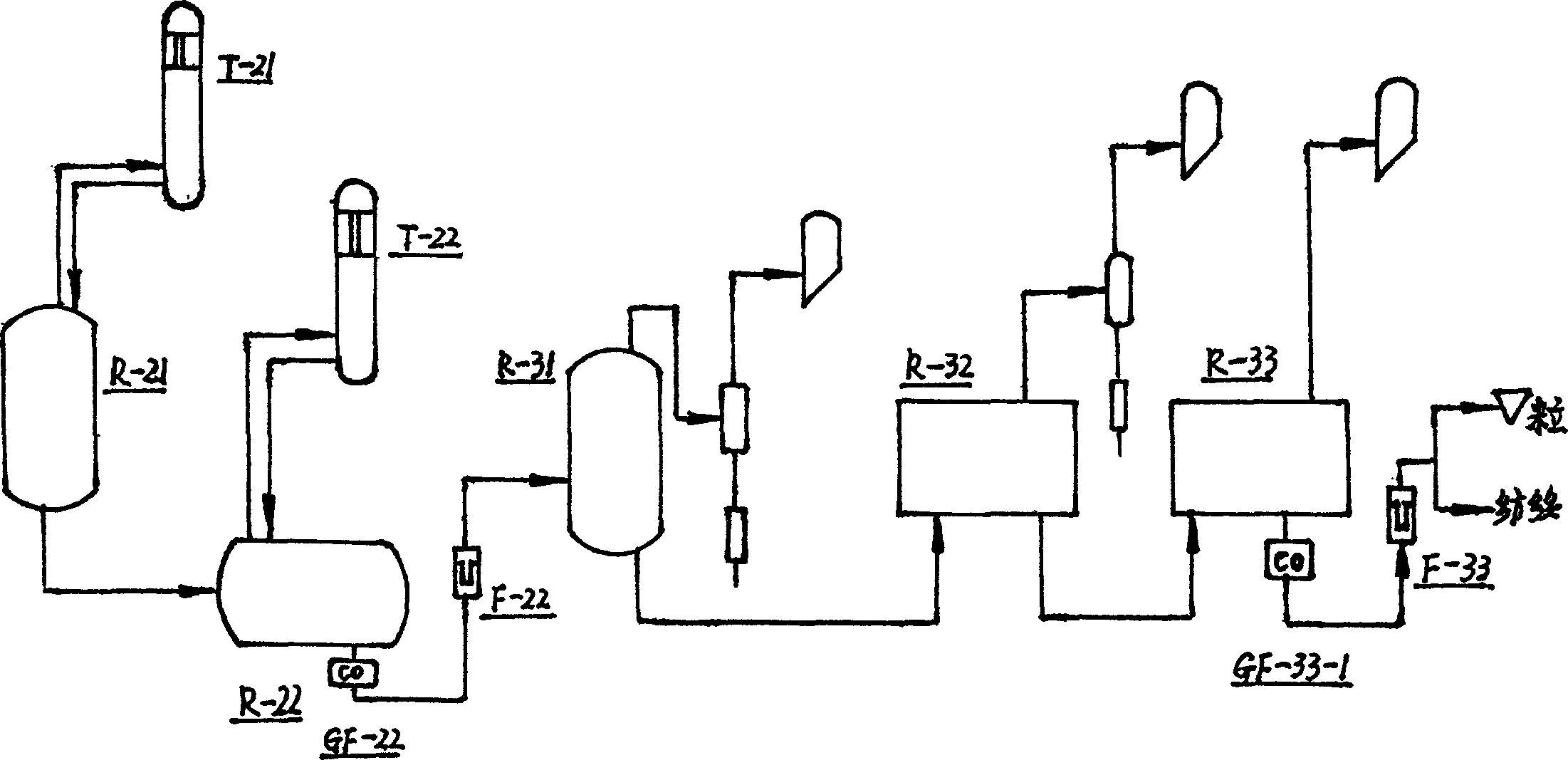

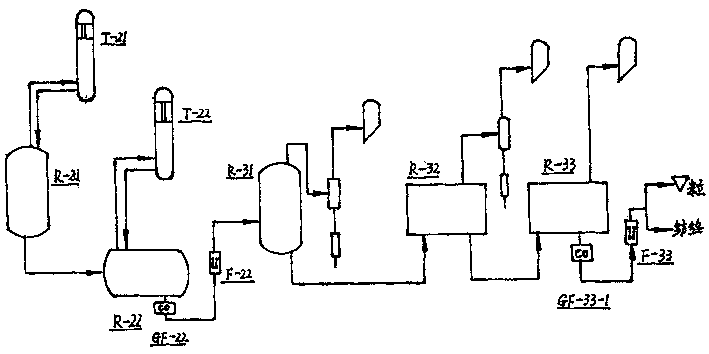

Cleaning method of esterifying polycondensation step for polyester preparing equipment

A cleaning method for the esterifying polycondensation step of polyester preparing equipment incldues adding the ethanediol solution of potassium hydroxide to system, controlling temp at 200-230 deg.C, stirring for alcoholysis, discharging the residual material and delivering it to recovery step, cooling the system to 100 deg.C and adding water for water washing.

Owner:济南齐鲁化纤集团有限责任公司

Efficient degreasing cleaning agent

InactiveCN103571663AGood removal effectHigh decontamination rateSurface-active non-soap compounds and soap mixture detergentsSodium metasilicateFatty acid glycerol esters

The invention discloses an efficient degreasing cleaning agent, which consists of the following components in parts by weight: 5 to 15 parts of fatty glyceride, 2 to 5 parts of borax, 10 to 12 parts of mono ethanol amine, 5 to 10 parts of sodium metasilicate, 2 to 5 parts of sulfonic acid, 3 to 6 parts of borax, 1 to 2 parts of sodium silicate, 5 to 8 parts of starch and 20 to 40 parts of distilled water. According to the efficient degreasing cleaning agent, a reasonable formula is adopted; the efficient degreasing cleaning agent has good using effects, and is low in production cost, small in using amount, short in cleaning time, low in cleaning temperature, high in degreasing rate, low in toxicity, small in irritation and high in old viscous grease dirt removal capability.

Owner:QINGDAO HUARUI RUBBER IND EQUIP

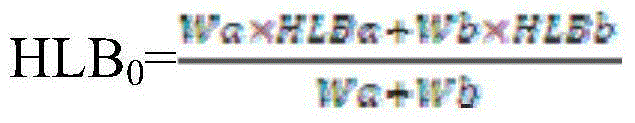

Method for recycling iron powder in magnetic filters of cold rolling factory

The invention discloses a method for recycling iron powder in magnetic filters of a cold rolling factory. The method includes steps of pre-treating the magnetic filters of the cold rolling factory; cleaning obtained iron powder with oil by cleaning agent and rinsing the iron powder with oil cleaned by the cleaning agent by deionized water; and finally drying the iron powder. The iron powder with oil is cleaned by the cleaning agent and rinsed by the deionized water by the aid of an ultrasonic cleaning method. Oil stain on the surface of the iron powder can be peeled off by the aid of a cavitation effect of ultrasonic waves, on the one hand, vibration of the iron powder is caused by the ultrasonic waves, peeling speed of the oil stain of the surface of the iron powder is increased, cleaning time is shortened, and cleaning temperature is reduced. In addition, the method has the advantages of short cleaning time and low temperature and energy consumption, purity of the obtained nanometer iron powder is high, and the quality of the obtained nanometer iron powder is high.

Owner:石家庄市宏晟环保科技有限公司

Cleaning agent used for high-wax crude oil volume tube, preparation method and use method

ActiveCN107723145AEasy to cleanImprove cleaning efficiencyOrganic detergent compounding agentsSurface-active detergent compositionsEmulsionChloride

The invention provides a cleaning agent used for a high-wax crude oil volume tube, a preparation method and a use method, and belongs to the technical field of wax removal. According to the technicalscheme, the cleaning agent is prepared from, by volume, 10-20 parts of solvent, 4-10 parts of co-solvent, 2-8 parts of surface active agent, 2-8 parts of emulsifying agent and 50-90 parts of water. The invention further provides the preparation method and the use method. The cleaning agent has the advantages that the wax dissolving rate of the emulsion type cleaning agent reaches 0.4 g / min or above, the closed-cup flash point is higher than 25 DEG C, the cleaning agent contains neither organic chloride nor carbon disulfide, the wax precipitation on the volume tube can be effectively cleaned, and the cleaning agent is good in safety and stability and especially suitable for wax removal of the high-wax crude oil volume tube.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluorine-free cleaning agent as well as preparation method and application thereof

ActiveCN114317127AReduce corrosionAvoid destructionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOrganic solventAlcohol

The invention provides a fluoride-free cleaning agent. The fluoride-free cleaning agent is a water-based cleaning agent; the fluoride-free cleaning agent comprises water, an organic solvent and an amine compound, the mass of the organic solvent is 15-85% of the mass of the fluoride-free cleaning agent; the mass of the amine compound is 5-50% of the mass of the fluoride-free cleaning agent; the corrosion inhibitor further comprises one or more of a corrosion inhibitor, an acid and an alcohol compound. Compared with the prior art, the fluoride-free cleaning agent provided by the invention also has better cleaning capacity under the condition of not containing fluorine element through the synergistic effect of the specific amine compound and one or more of the corrosion inhibitor, the acid and the alcohol, and meanwhile, the corrosion of the cleaning agent to metal can be reduced, the damage to a substrate medium is prevented, and the service life of the cleaning agent is prolonged. And the weather resistance of the cleaned wafer is improved. Compared with existing similar products, the fluoride-free cleaning agent provided by the invention has the obvious advantages that the cleaning temperature is reduced, the cleaning time is shortened, the cost performance is higher, and the like.

Owner:TAN KAH KEE INNOVATION LAB

Environment-friendly and multifunctional glass bottle washing agent and preparation method thereof

InactiveCN108300599AAvoid decompositionPenetrate fastInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsFoaming agentWash bottle

The invention provides an environment-friendly and multifunctional glass bottle washing agent and a preparation method thereof. The environment-friendly and multifunctional glass bottle washing agentis characterized by being prepared from an anionic surfactant, a non-ionic surfactant, a washing assisting agent, a de-foaming agent, a water treatment agent, fungicide and the like according to a certain ratio, a certain technology and required reaction. The environment-friendly and multifunctional glass bottle washing agent is mainly used for industrially washing beer, beverage and seasoning recycled glass bottles; the environment-friendly and multifunctional glass bottle washing agent has the characteristics of no phosphorus, strong washing capability, capability of finishing sterilizationand disinfection in one step and the like; the environment-friendly and multifunctional glass bottle washing agent does not adopt an organic silicon de-foaming agent, and a condition that the organicsilicon de-foaming agent is decomposed in strong alkali to generate a green viscous object for polluting a bottle body is avoided; the environment-friendly and multifunctional glass bottle washing agent can rapidly permeate through a binding agent and dirt on a glass bottle body under the condition that the temprature is 20 DEG C lower than common washing temperature; the washed bottle has high transparency and the washing agent is not remained in the bottle, so that the consumption of energy sources is greatly reduced.

Owner:河南绿澳化工科技有限公司

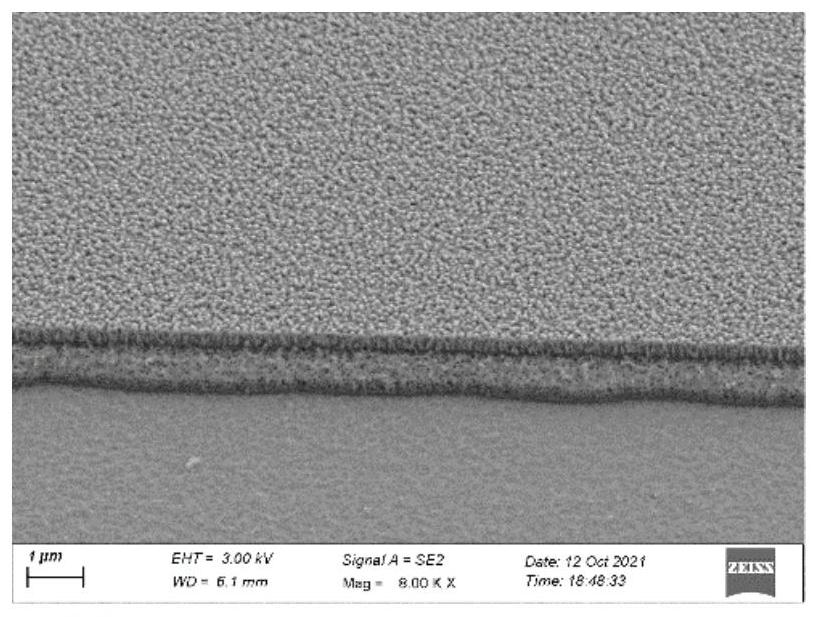

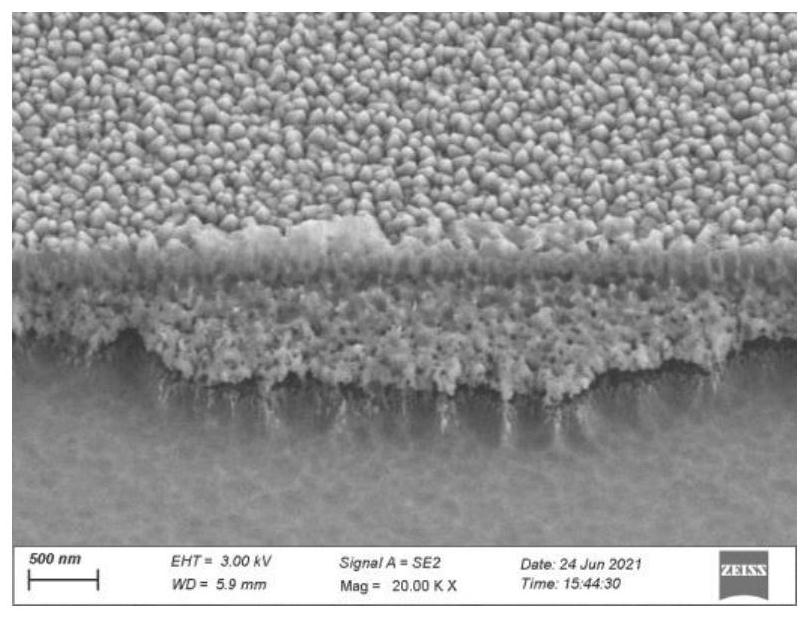

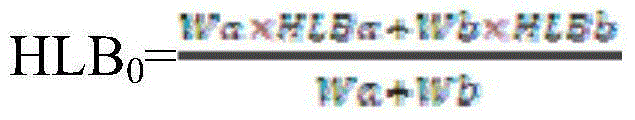

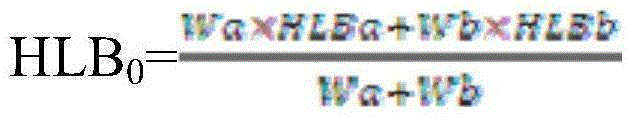

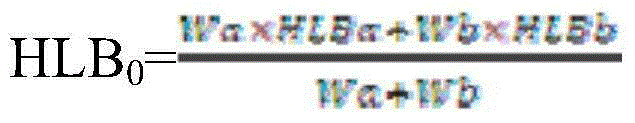

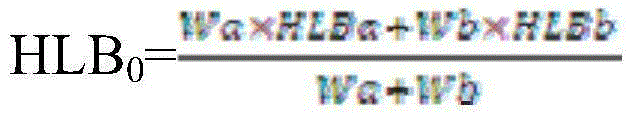

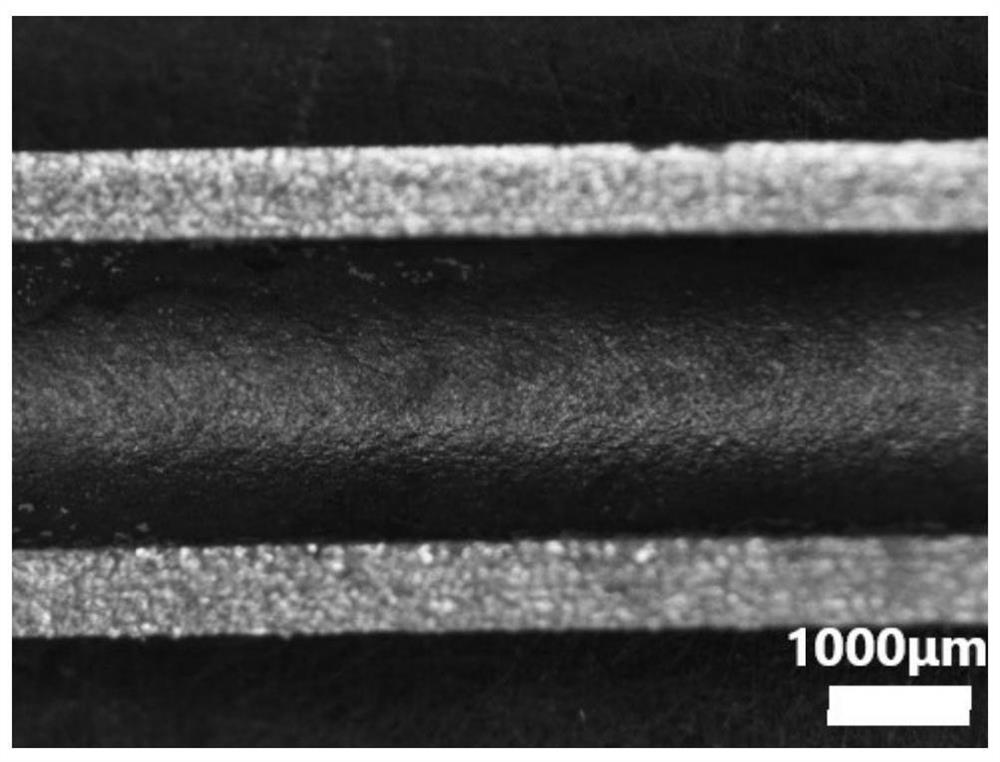

Water-soluble soybean oil

InactiveCN105176646AImprove cleaning efficiencyLow cleaning temperatureLubricant compositionSOYBEAN SEED OILWater soluble

The invention belongs to the technical field of lubricating oil for metal machining and discloses water-soluble soybean oil. The water-soluble soybean oil is prepared from, by mass, 4%-6% of mixed surfactant and the balance soybean oil. The mixed surfactant is prepared by mixing two kinds of dodecyl polyoxyethylene ether with different HLB values, and the HLB value of the mixed surfactant ranges from 7 to 9. According to the water-soluble soybean oil, the mixed surfactant formed by mixing the two kinds of dodecyl polyoxyethylene ether is added into the common soybean oil, and the water-soluble soybean oil is applied to the manufacturing industry of engines, and can improve cleaning efficiency, decrease cleaning temperature and reduce the use amount of cleaning agents, washing cost and emission pollution.

Owner:STATE RUN NO 616 FACTORY

Method for removing deposited carbon from aero-engine thrust augmentation fuel manifold

InactiveCN110961405AHardness does not decreaseNo damage to performanceCleaning using liquidsProcess engineeringCarbon deposit

The invention discloses a method for removing deposited carbon from an aero-engine thrust augmentation fuel manifold, and belongs to the technical field of aero-engines. According to the method basedon the oxidation-reduction effect of high-temperature alkali liquor, deposits as deposited carbon in the surface of a part is loosened by oxidation-reduction and thus peeled from the matrix surface, deposited carbon in the thrust augmentation fuel manifold is separated from the pipe wall by oscillation and taken away from an oil inlet pipe connecting nozzle through oil by means of an ultrasonic oscillation reverse suction force, and the deposited carbon is removed. Via the method, it is guaranteed that a chromium layer of the oil inlet pipe connecting nozzle is not damaged, deposited carbon ofthe novel engine thrust augmentation fuel manifold can be efficiently removed in a quality-guaranteeing mode, and the qualified rate of deposited carbon removal of the thrust augmentation fuel manifold reaches 95%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

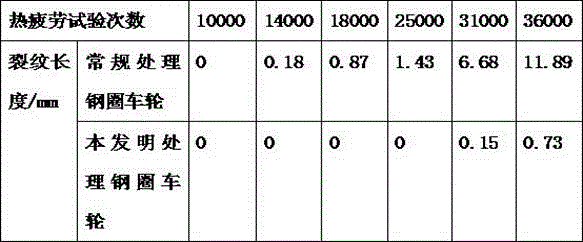

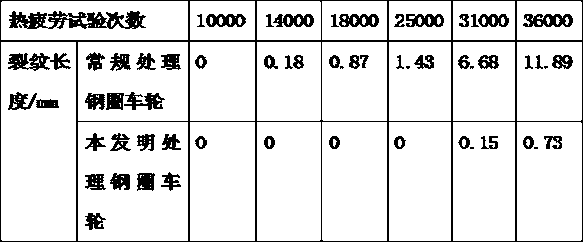

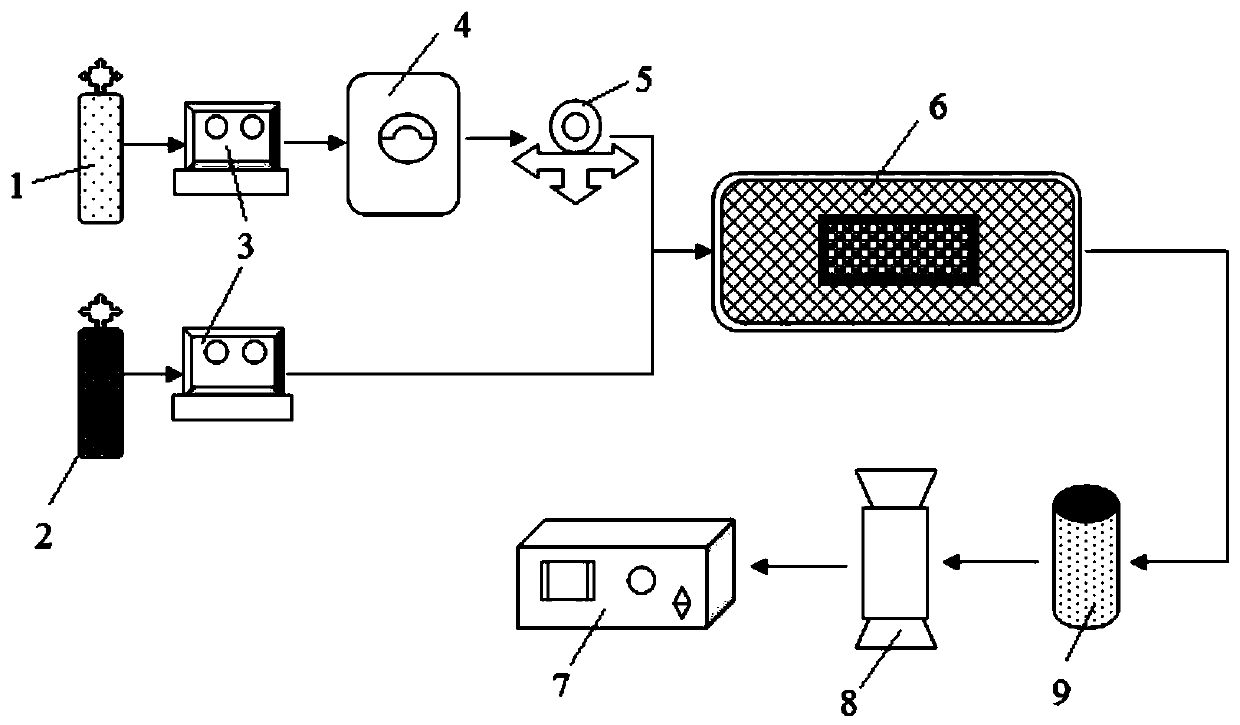

Steel ring car wheel surface treatment process

ActiveCN106222680AEfficient removalImprove surface mechanical propertiesFurnace typesMetallic material coating processesHigh resistanceShock resistance

The invention discloses a steel ring car wheel surface treatment process. The steel ring car wheel surface treatment process comprises the following steps of (1) cleaning, (2) surface preheating, (3) surface modification treatment, (4) cleaning and cold standing and (5) quenching treatment. The steel ring car wheel surface treated through the process has the high abrasion resistance, high hardness, high toughness and high shock resistance, subsequent quenching treatment is matched, the optimal quenching time and quenching temperature are optimized, and the tempering time and tempering temperature are adjusted, so that the impact toughness and hardness of a steel ring car wheel are improved; and inner hardness and outer hardness are balanced, the microhardness of the surface of a steel ring car wheel coating is quite high, the salt corrosion resistance and stress corrosion cracking resistance can be further improved. In addition, the fatigue resistance of the steel ring car wheel is greatly improved, the service life of the steel ring car wheel is prolonged, and the service life of the steel ring car wheel is prolonged by three to four times compared with untreated steel ring car wheels.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

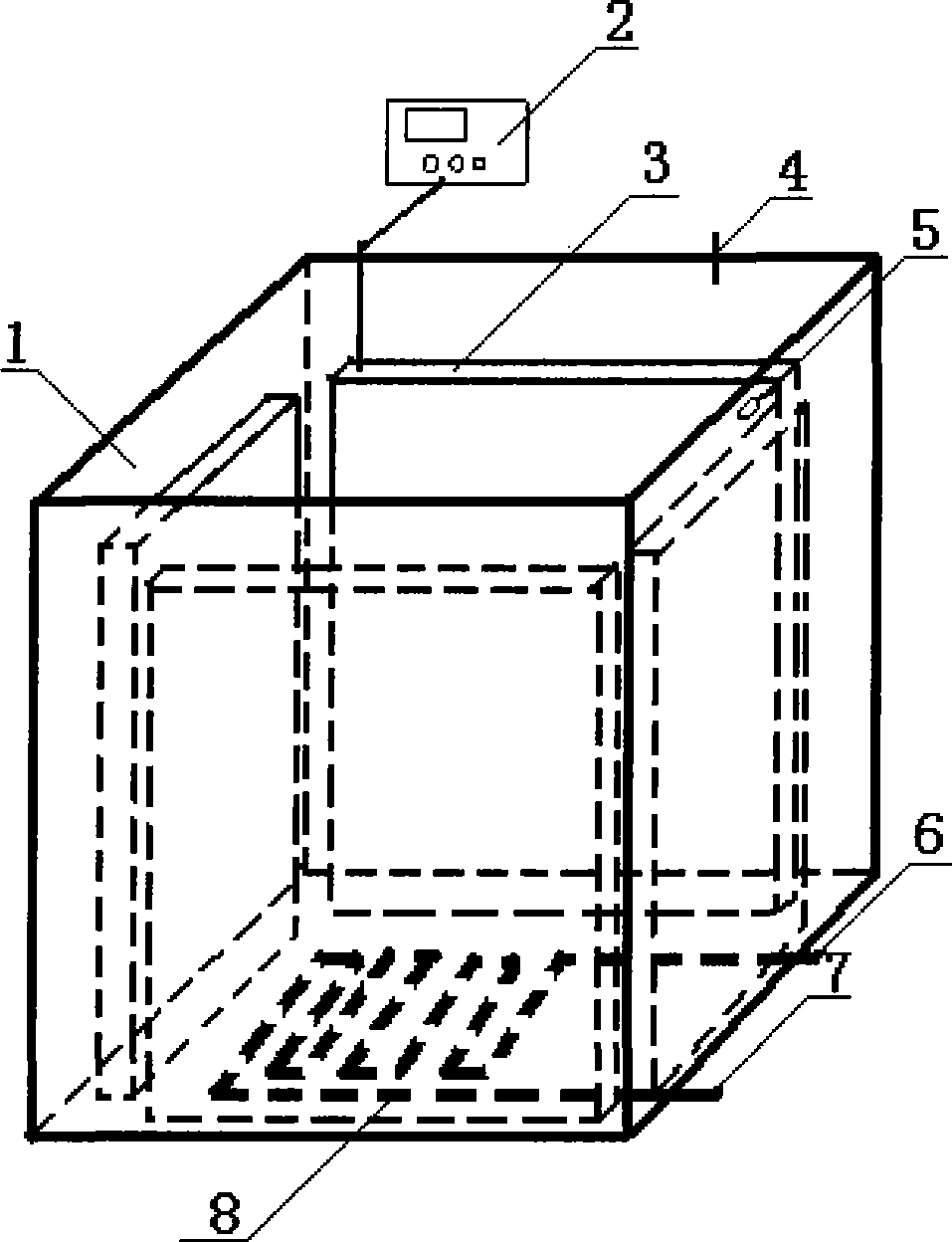

Cathode copper ultrasonic cleaning groove

InactiveCN101429670ASolve residual problemsSolve the crystallization problemPhotography auxillary processesElectrolysis componentsMegasonic cleaningEngineering

The invention provides a cathode copper ultrasonic cleaning bath which mainly comprises a stainless steel cleaning bath, ultrasonic shaking plates, a steam coil and an electric control device. The ultrasonic shaking plates are arranged on the four side edges of the stainless steel cleaning bath; a water inlet pipe is arranged on the top of the stainless steel cleaning bath; an overflow gate is arranged on one side plate of the bath; the steam coil is spirally arranged on the bottom of the bath; and the ultrasonic shaking plates are controlled by the electric control device. The cathode copper ultrasonic cleaning bath realizes the effective removal of electrolyte residue and crystals on the surface of cathode copper and in the tiny gaps of the cathode copper, and avoids the copper sulphate crystallization phenomenon caused by the long-time storage of the cathode copper.

Owner:DONGYING FANGYUAN NONFERROUS METALS

Environment-friendly type cleaning agent for mineral oil stains on surface of fabric and preparation method of environment-friendly type cleaning agent

ActiveCN106833929AEasy to cleanReduce cleaning costsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium bicarbonateSODIUM METHYL COCOYL TAURATE

The invention provides an environment-friendly type cleaning agent for mineral oil stains on the surface of a fabric and a preparation method of the environment-friendly type cleaning agent and belongs to the technical field of chemical cleaning agents. The environment-friendly type cleaning agent is characterized by being prepared from the following components in parts by weight: 20 to 30 parts of an anionic surfactant, 30 to 50 parts of a non-ionic surfactant, 5 to 10 parts of a cleaning assistant, 0.1 to 0.5 part of a preservative, 0.05 to 0.08 part of essence, 0.01 to 0.03 part of a pigment and 30 to 60 parts of water; the anionic surfactant is one of alpha-sulfonated fatty acid methyl ester and sodium methyl cocoyl taurate; the non-ionic surfactant is selected from two of RQ-225, an isomeric alcohol and ethylene oxide condensation compound and alkyl glucoside; the cleaning assistant comprises sodium chloride and sodium hydrogen carbonate; the preservative is sodium benzoate. The environment-friendly type cleaning agent takes the environment-friendly, toxin-free and harmless and easy-to-degrade surfactants as raw materials and a product completely meets environment-friendly requirements; a cleaning process is simple to operate and rapid in speed and has good cleaning effect on the mineral oil stains.

Owner:东阳市中南助剂有限公司

Metal surface cleaning agent and preparation method thereof

The invention discloses a metal surface cleaning agent. The metal surface cleaning agent comprises the following raw materials in parts by weight: 3-5 parts of a defoamer, 5-9 parts of hydrogen peroxide, 20-35 parts of deionized water, 2-4 parts of quartz powder, 5-8 parts of oxalic acid, 1-4 parts of ethyl alcohol, 10-15 parts of animal oleic acid, 3-4 parts of an emulgator, 5-8 parts of ethylene glycol mono-butyl ether, 2-5 parts of calcite powder, 1-3 parts of aluminum hydroxide, 1-2 parts of abietic acid polyoxyethylene ester, 6-8 parts of sodium gluconate, 3-6 parts of hydroxyethyl cellulose, 1-2 parts of ethylene glycol monostearate and 2-3 parts of nonyl phenol polyoxyethylene ether. The invention further discloses a preparation method for the cleaning agent. According to the metal surface cleaning agent, through improvement on a formula and a technology, the cleaning agent has a function of strong descaling; dirt on a metal surface can be effectively removed, so that the metal surface is shiny; cleaning time is short; cleaning temperature is low; the cleaning agent is suitable for different metal material surfaces and metals; besides, harm to a human body is small, and use is safer; and meanwhile, the cleaning agent is more environment-friendly. The metal surface cleaning agent is simple in raw materials, and production cost is lowered.

Owner:NANNING HEIJING INFORMATION TECH CO LTD

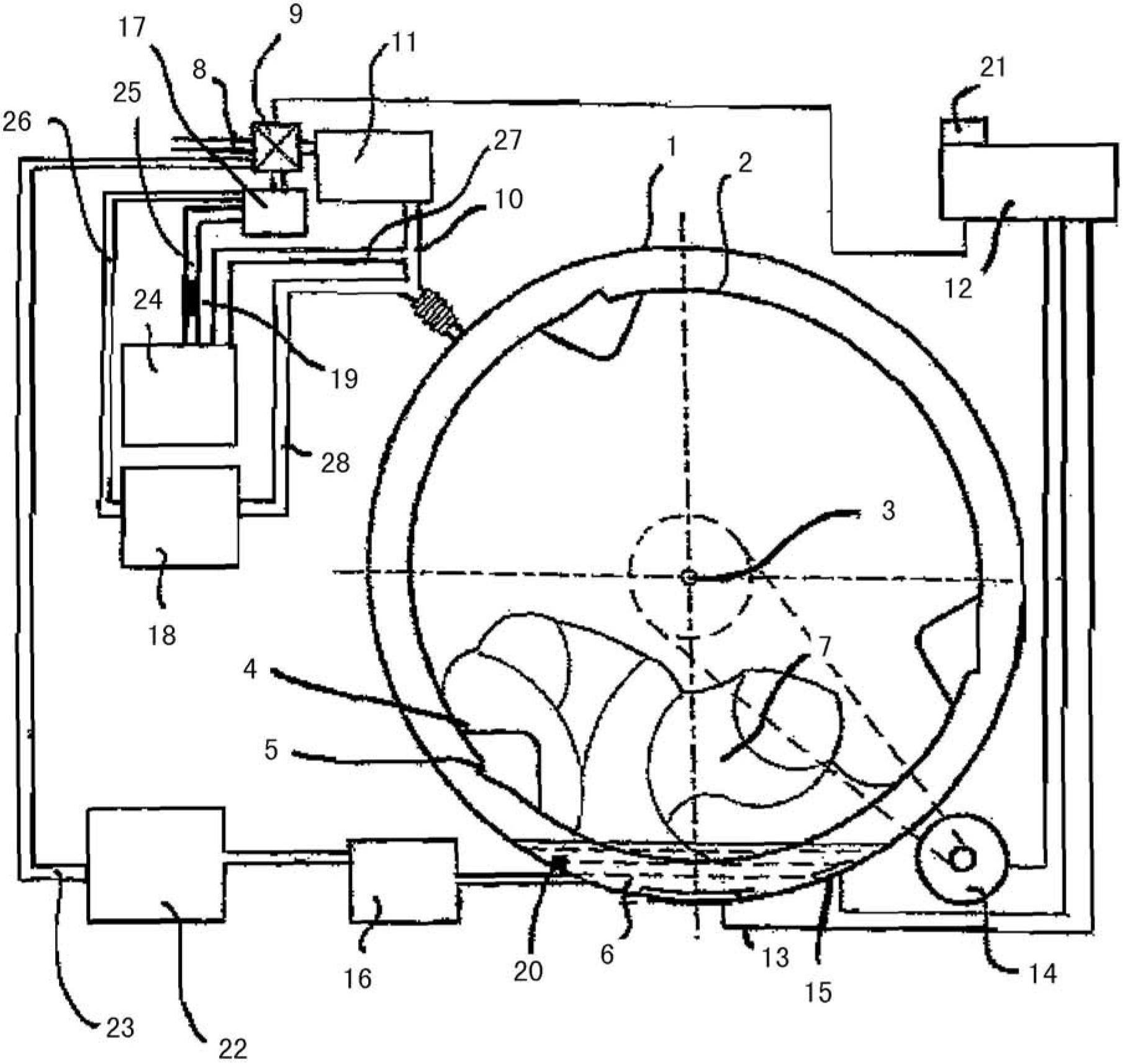

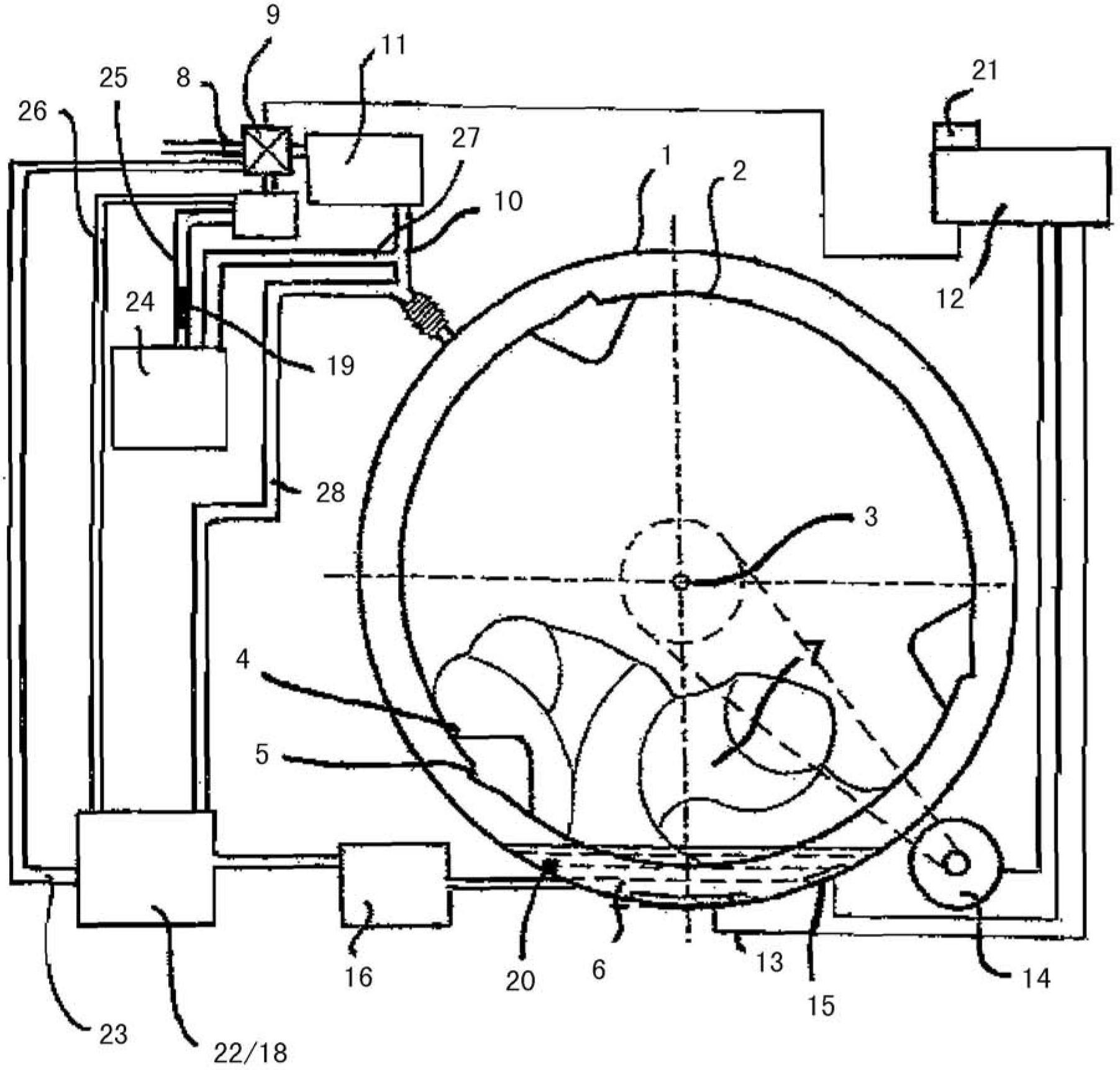

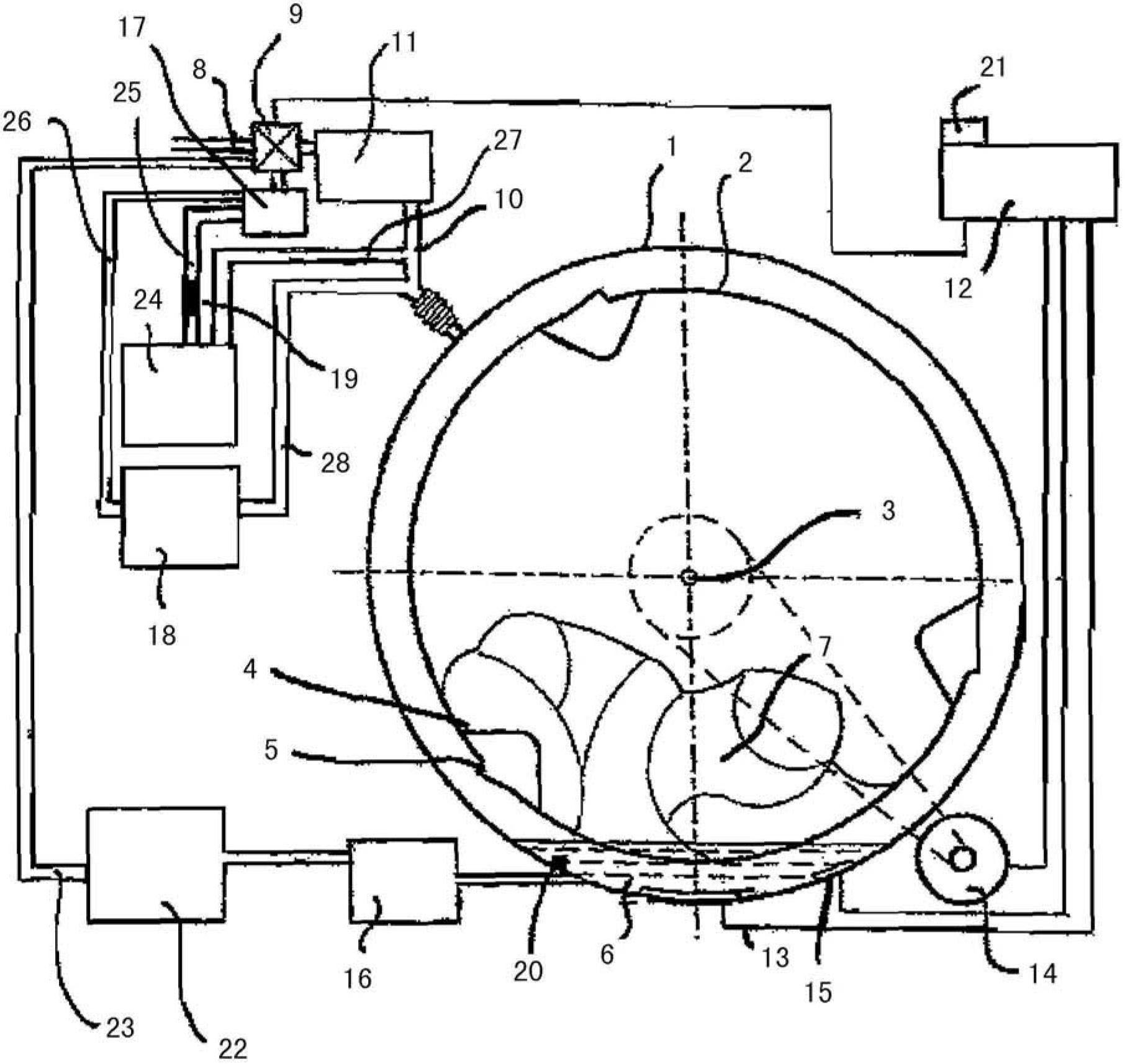

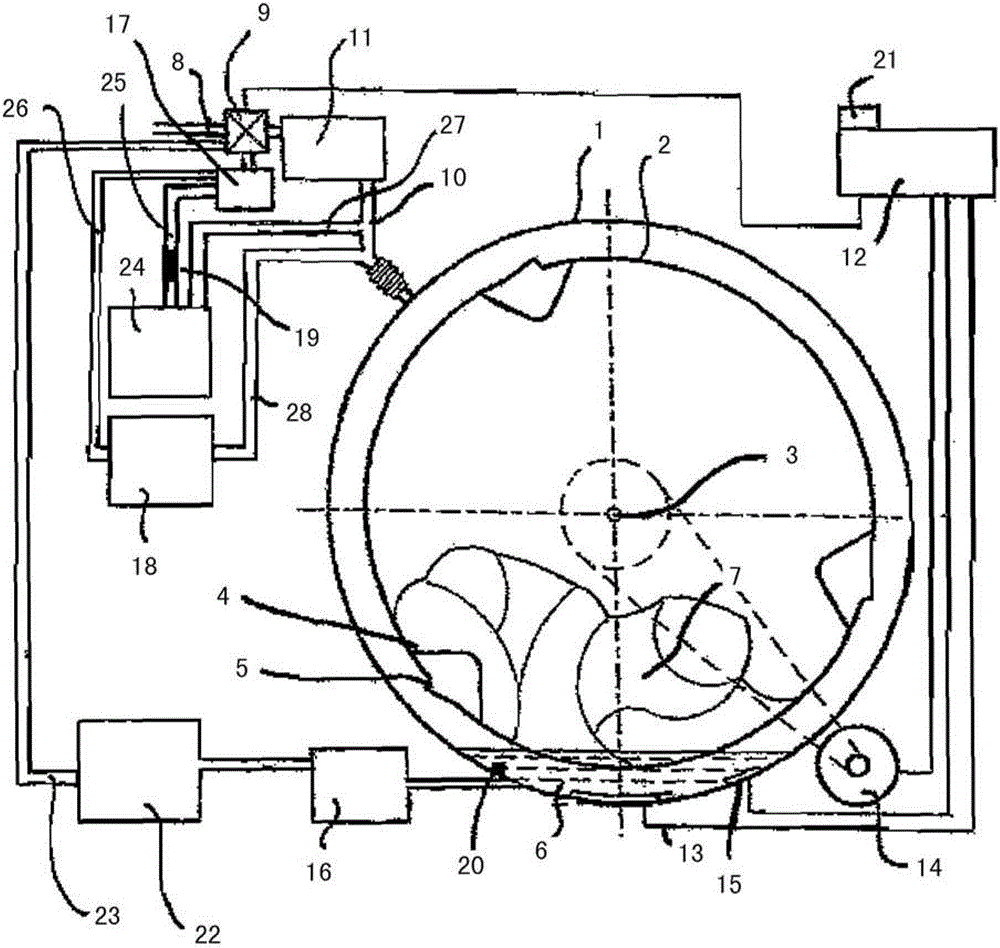

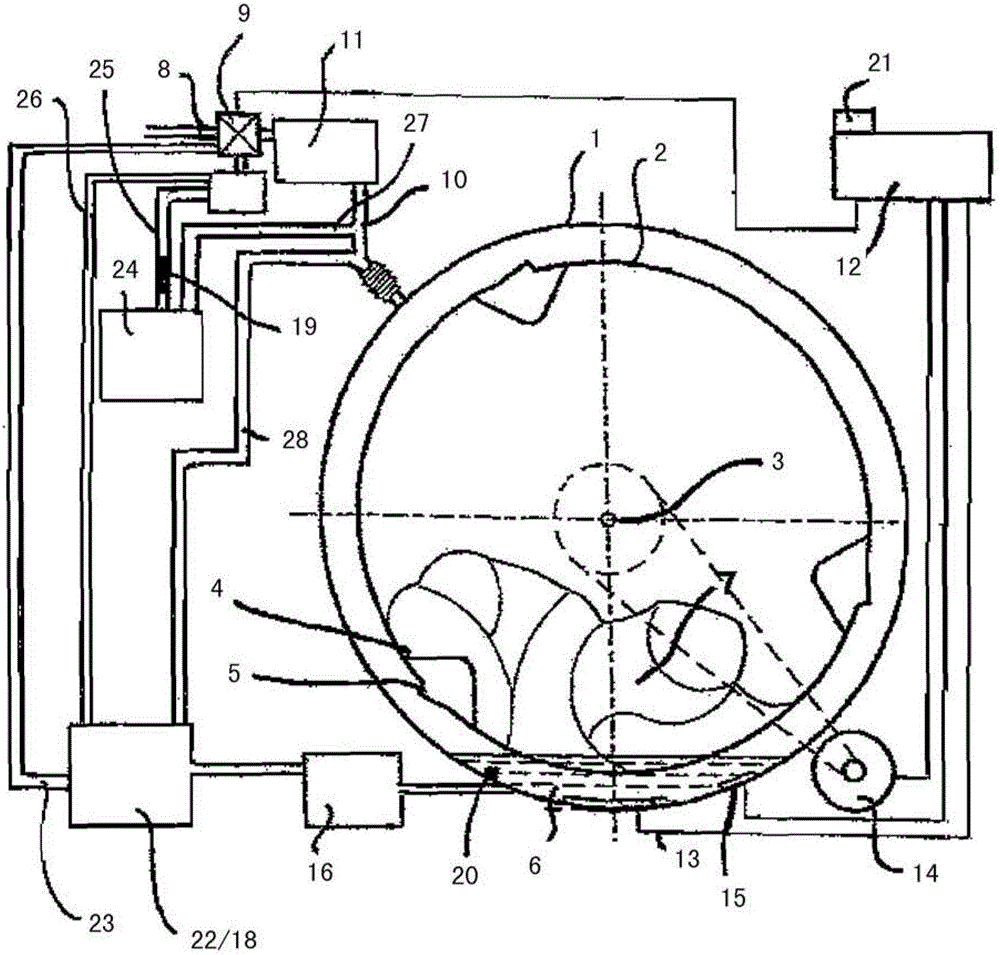

Washing machine having a desalination device

InactiveCN102666963AReduce loadUse reduce or avoidOther washing machinesTextiles and paperDesalinationRinse water

The invention relates to a washing machine having a suds container (1), a washing drum (2), a water inlet system (8, 9, 10) and a suds discharge system having a suds pump (16), a program control (12), a desalination device (17) for generating desalinated water, and a rinse water store (22), wherein the washing machine comprises a soft water tank (24) connected to the water inlet system (8, 9, 10) by means of the desalination device (17). The invention further relates to a method for treating laundry in such a washing machine.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Surface deoiling detergent for magnetic NdFeB material and its usage method

The present invention discloses one kind of surface cleaning detergent for magnetic NdFeB material and is usage. The surface cleaning detergent consists of sodium hydroxide, sodium carbonate, trisodium phosphate, sodium pyrophosphate, OP-10 emulsifier, sodium dodecyl sulfonate and thiourea. The surface cleaning detergent has stable performance and long use period, and may be used to deiol completely through soaking at 30-50 deg.c for 10-15 min, and the deioling period may be further shortened in ultraosonic deioling.

Owner:ZHEJIANG UNIV

A kind of environment-friendly cleaning agent for mineral oil pollution on fabric surface and preparation method thereof

ActiveCN106833929BEasy to cleanReduce cleaning costsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsActive agentSODIUM METHYL COCOYL TAURATE

The invention provides an environment-friendly type cleaning agent for mineral oil stains on the surface of a fabric and a preparation method of the environment-friendly type cleaning agent and belongs to the technical field of chemical cleaning agents. The environment-friendly type cleaning agent is characterized by being prepared from the following components in parts by weight: 20 to 30 parts of an anionic surfactant, 30 to 50 parts of a non-ionic surfactant, 5 to 10 parts of a cleaning assistant, 0.1 to 0.5 part of a preservative, 0.05 to 0.08 part of essence, 0.01 to 0.03 part of a pigment and 30 to 60 parts of water; the anionic surfactant is one of alpha-sulfonated fatty acid methyl ester and sodium methyl cocoyl taurate; the non-ionic surfactant is selected from two of RQ-225, an isomeric alcohol and ethylene oxide condensation compound and alkyl glucoside; the cleaning assistant comprises sodium chloride and sodium hydrogen carbonate; the preservative is sodium benzoate. The environment-friendly type cleaning agent takes the environment-friendly, toxin-free and harmless and easy-to-degrade surfactants as raw materials and a product completely meets environment-friendly requirements; a cleaning process is simple to operate and rapid in speed and has good cleaning effect on the mineral oil stains.

Owner:东阳市中南助剂有限公司

Water-soluble line grinding oil

InactiveCN105154190AReduce dosageImprove cleaning efficiencyLubricant compositionKeroseneWater soluble

The invention belongs to the technical field of lubricating oil for metal processing and discloses water-soluble line grinding oil. The water-soluble line grinding oil is prepared from, by mass, 4%-6% of mixed surfactant, and the balance line grinding kerosene. The mixed surfactant is formed by mixing two kinds of dodecyl polyoxyethylene ether with different HLB values. The HLB value of the mixed surfactant ranges from 9 to 11. The mixed surfactant formed by mixing the two kinds of dodecyl polyoxyethylene ether is added to the common line grinding kerosene, when the water-soluble line grinding oil is applied to an engine manufacturing industry, cleaning efficiency can be improved, the cleaning temperature can be reduced, the use level of a cleaning agent can be reduced, the cleaning cost can be reduced, and emission pollution can be reduced.

Owner:STATE RUN NO 616 FACTORY

Water-soluble machine oil

InactiveCN105154189AReduce dosageImprove cleaning efficiencyLubricant compositionMetalworkingBalancing machine

The invention belongs to the technical field of lubricating oil for metal processing and discloses water-soluble machine oil. The water-soluble machine oil is prepared from, by mass, 4%-6% of mixed surfactant, and the balance machine oil. The mixed surfactant is formed by mixing two kinds of dodecyl polyoxyethylene ether with different HLB values. The HLB value of the mixed surfactant ranges from 10 to 12. The mixed surfactant formed by mixing the two kinds of dodecyl polyoxyethylene ether is added to the common machine oil, when the water-soluble machine oil is applied to an engine manufacturing industry, cleaning efficiency can be improved, the cleaning temperature can be reduced, the use level of a cleaning agent can be reduced, the cleaning cost can be reduced, and emission pollution can be reduced.

Owner:STATE RUN NO 616 FACTORY

A kind of steel rim wheel surface treatment process

ActiveCN106222680BEfficient removalImprove surface mechanical propertiesFurnace typesMetallic material coating processesHigh resistanceShock resistance

The invention discloses a steel ring car wheel surface treatment process. The steel ring car wheel surface treatment process comprises the following steps of (1) cleaning, (2) surface preheating, (3) surface modification treatment, (4) cleaning and cold standing and (5) quenching treatment. The steel ring car wheel surface treated through the process has the high abrasion resistance, high hardness, high toughness and high shock resistance, subsequent quenching treatment is matched, the optimal quenching time and quenching temperature are optimized, and the tempering time and tempering temperature are adjusted, so that the impact toughness and hardness of a steel ring car wheel are improved; and inner hardness and outer hardness are balanced, the microhardness of the surface of a steel ring car wheel coating is quite high, the salt corrosion resistance and stress corrosion cracking resistance can be further improved. In addition, the fatigue resistance of the steel ring car wheel is greatly improved, the service life of the steel ring car wheel is prolonged, and the service life of the steel ring car wheel is prolonged by three to four times compared with untreated steel ring car wheels.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

A coke cleaning method using ozone mixed gas

ActiveCN109251762BCreate pollutionReduce consumptionThermal non-catalytic crackingMixed gasChemistry

The invention discloses a decoking method adopting ozone mixed gas. The ozone content in the ozone mixed gas is 60-80 mg / L, the molar percentage of N2 accounting for the ozone mixture gas is 10-30%, and the decoking temperature is 160-220 DEG C. The method has remarkable decoking efficiency and does not cause damage to a catalytic device.

Owner:TIANJIN UNIV

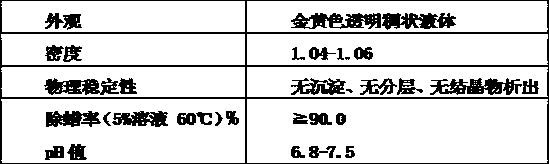

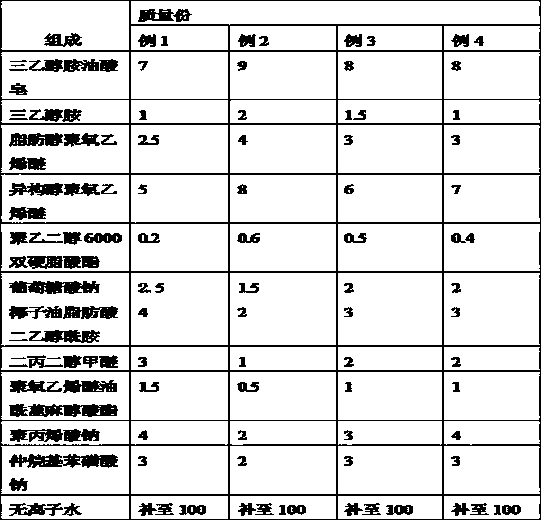

High-efficiency wax removal water for metal workpieces and preparation method thereof

The invention provides a high-efficiency wax removal water for metal workpieces and a preparation method thereof. Alcohol polyoxyethylene ether 6%, polyethylene glycol 6000 distearate 0.5%, sodium gluconate 2%, coconut oil fatty acid diethanolamide 3%, dipropylene glycol methyl ether 2%, polyoxyethylene ether oleoyl castor 1% oleic acid ester, 3% sodium polyacrylate, 3% sodium secondary alkylbenzene sulfonate, and deionized water to make up to 100%. It can have a good dewaxing effect on various metal parts and non-ferrous metal parts. In the process of dewaxing the parts, it can simultaneously play a good role in corrosion inhibition and oxidation prevention, and can well protect the metal Surface original color. The wax removal ability is extremely strong, the efficiency is high, the production process is simple, the cost is low, the working temperature is low, and the effect is good.

Owner:江西瑞思博新材料有限公司

Cleaning method of esterifying polycondensation step for polyester preparing equipment and pipeline

InactiveCN1203927CNo side effectsLow cleaning temperatureCleaning using liquidsPolyesterProcess equipment

The invention provides a method for cleaning the esterification polycondensation equipment and the pipeline system of the ester plant after parking. The esterification polycondensation production process of the ester unit is added to the equipment and pipeline system, the temperature of the cleaning liquid is controlled at 200-230°C, the residue after the alcoholysis and discharge is stirred, and then the equipment and pipeline system are led out to the recycling process, and finally the equipment and pipeline The temperature of the system is lowered to below 100°C, and then water is added for washing. The weight ratio of the potassium hydroxide to ethylene glycol is 1:90-110.

Owner:济南齐鲁化纤集团有限责任公司

Washing machine having a desalination device

InactiveCN102666963BReduce loadUse reduce or avoidOther washing machinesTextiles and paperDesalinationRinse water

The invention relates to a washing machine having a suds container 1, a washing drum 2, a water inlet system 8, 9, 10 and a suds discharge system having a suds pump 16, a program control 12, a desalination device 17 for generating desalinated water, and a rinse water store 22, wherein the washing machine comprises a soft water tank 24 connected to the water inlet system 8, 9, 10 by means of the desalination device 17. The invention further relates to a method for treating laundry in such a washing machine.

Owner:BOSCH SIEMENS HAUSGERATE GMBH

Industrial water washing method of antioxidant 300 crude product

InactiveCN108727236ALow cleaning temperatureImprove washing effectOrganic chemistryOrganic compound preparationPurification methodsAntioxidant

The invention relates to a purification method of an antioxidant, in particular to an industrial water washing method of an antioxidant 300 crude product. The industrial water washing method of the antioxidant 300 crude product comprises the following steps: firstly, adding No.150 solvent oil and No.200 solvent oil into a reaction still, and adding the antioxidant 300 crude product for dissolving;after the temperature is raised to 40 to 60 DEG C, adding a saturated sodium chloride solution, stirring, layering and separating to obtain an organic phase; secondly, cooling the organic phase to 5to 10 DEG C, filtering and collecting filtrate to obtain an antioxidant 300 product. By adopting the No.150 solvent oil and the No.200 solvent oil as washing solvents, the industrial water washing method of the antioxidant 300 crude product disclosed by the invention has the advantages of low cleaning temperature, good washing effect and suitability for industrialized production; in addition, theindustrial water washing method combines with cooling to remove partial impurities in a filtering mode, so that the washing effect is good and the obtained antioxidant 300 product has high purity.

Owner:张森

Composite passivant used for the boiler chemical cleaning of power plant and passivation method

ActiveCN101580937BEfficient removalSimple passivation processBoiler cleaning apparatusMetallic material coating processesEthylene diaminePower station

The invention discloses a composite passivant used for the boiler chemical cleaning of a power plant and a passivation method. The composite passivant consists essentially of components of the following mass percent: 0.010 percent to 0.025 percent of ethylene diamine tetraacetic acid (EDTA), 0.01 percent to 0.02 percent of trisodium phosphate, 0.2 percent to 0.5 percent of hydrogen peroxide, 0 percent to 0.01 percent of sodium nitrite, 9.2 to 9.6 pH value of chemical pure or analytically pure suitable ammonia adjustment solution, and the balance of water. The invention has the advantages of simple passivation process, safe and non-toxic agent, low washing temperature, short time, energy conservation and environmental protection, and fine passivation effect, does not generate acid corrosionhazard to the unit ignition, and is a novel passivation method. By adopting the passivation method, the copper fouling of the operating unit can be effectively removed.

Owner:湖南省湘电试验研究院有限公司 +2

Cleaning solution and cleaning method for coke on inner surface of renewable pipeline

ActiveCN112626528BImprove operational safetyMild conditionsCleaning using liquidsCokeProcess engineering

The invention discloses a cleaning solution and a cleaning method for coke on the inner surface of a renewable pipeline. Use a cleaning solution with sodium hydroxide and potassium permanganate as the main components to ultrasonically clean the inside of the pipeline at 80°C for 8 hours, which can remove the coke on the inner surface of the pipeline, and the cleaning process will not cause corrosion damage to the pipeline. The cleaning solution of the invention is suitable for cleaning the coke formed by various endothermic hydrocarbon fuels on the inner wall of metal pipelines.

Owner:XI AN JIAOTONG UNIV

Method for removing nickel on chemical nickel-plated surface of silicon wafer

The invention relates to a method for removing nickel on a chemically nickel-plated surface of a silicon wafer, which belongs to the field of semiconductor silicon wafer production, and the method is characterized by comprising the following steps of: putting a silicon wafer subjected to chemical nickel plating and nickel sintering into mixed acid, and performing cleaning at 46-50 DEG C, the mixed acid being a mixture of a 36-38% hydrochloric acid solution, a 69-71% nitric acid solution and pure water; the mixture of hydrochloric acid, nitric acid and pure water in a specific proportion is used for replacing concentrated nitric acid in the prior art for cleaning chemical nickel plating on the surface of the silicon wafer, the good cleaning effect can be achieved at the temperature of about 48 DEG C, the cleaning time is shortened to 90 s from 120 s in the prior art, the good cleaning effect can be achieved, and the problem of acid mist forming is well solved.

Owner:SHANDONG JINGDAO MICROELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com