Water-soluble line grinding oil

A water-soluble, row-grinding technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as increased difficulty in operation and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] For the preparation of mixed surfactants, in this example, two lauryl alcohol polyoxyethylene ethers with different HLB values are selected and mixed in different proportions to obtain lauryl alcohol polyoxyethylene ethers with HLB values between 9 and 11. ether.

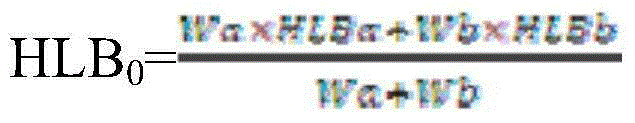

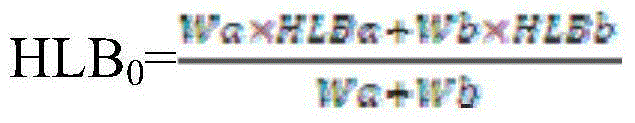

[0026] Among them, the mixing principle of two lauryl alcohol polyoxyethylene ethers with different HLB values is proportioned according to the following formula:

[0027] HLB 0 = W a × H L B a + W b + H L B b W a + W b

[0028] Where: HLB 0 - The HLB value of the mixed surfactant is between 9 and 11;

[00...

Embodiment 1

[0035] Mix 4 parts of lauryl alcohol polyoxyethylene ether with HLB=5 and 6 parts of lauryl alcohol polyoxyethylene ether with HLB=15 to obtain a mixed surfactant of HLB=11, which is added to the line mill at a mass percentage of 5% From kerosene, a water-soluble line grinding oil is obtained.

Embodiment 2

[0037] Mix 7 parts of lauryl alcohol polyoxyethylene ether with HLB=9 and 8 parts of lauryl alcohol polyoxyethylene ether with HLB=10 to obtain a mixed surfactant of HLB=9.53, which is added to the line mill at a mass percentage of 5.77% From kerosene, a water-soluble line grinding oil is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com