Cleaning solution and cleaning method for coke on inner surface of renewable pipeline

An inner surface, cleaning liquid technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficult coke removal, difficult chemical reaction, pipeline corrosion damage, etc., to solve pipeline corrosion. Destruction problems, high operational safety, improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

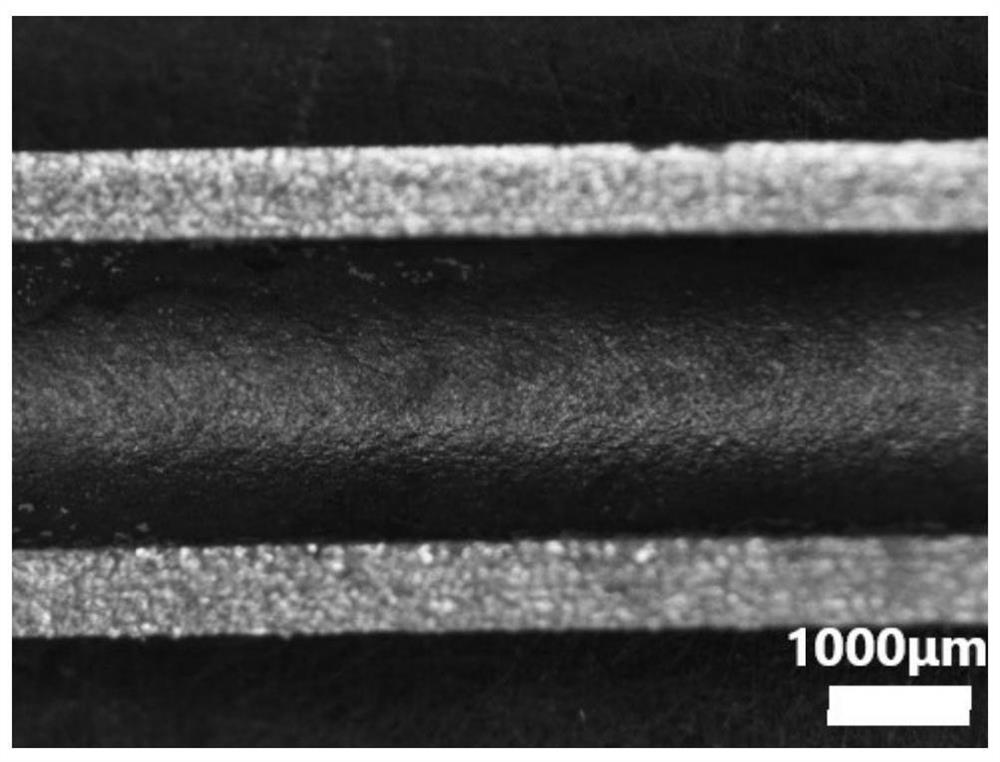

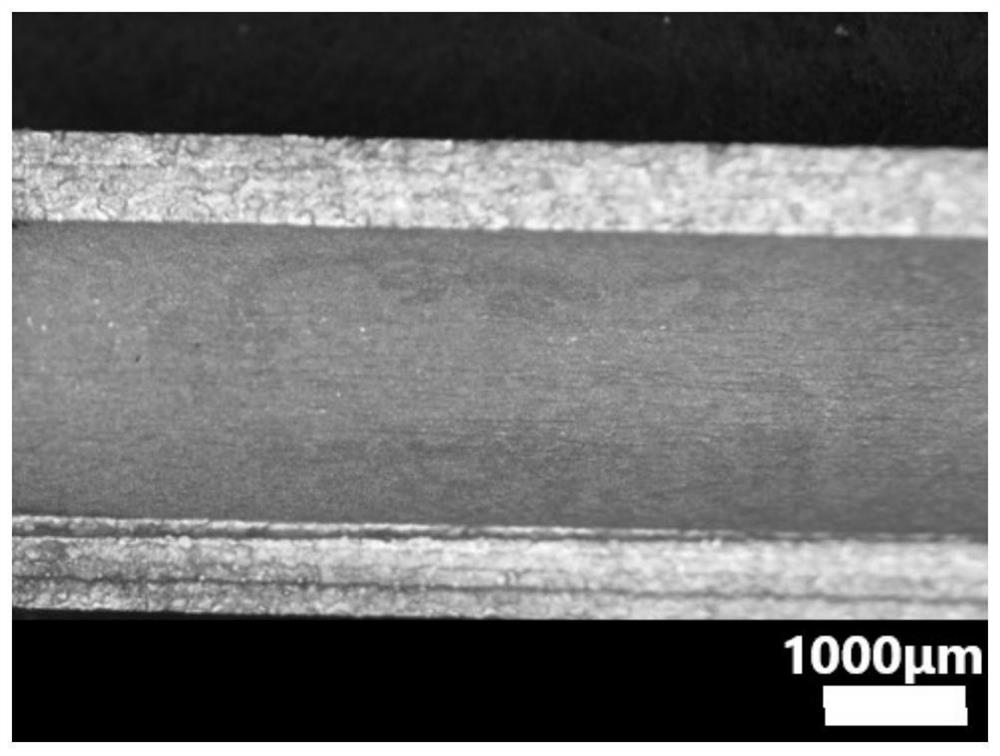

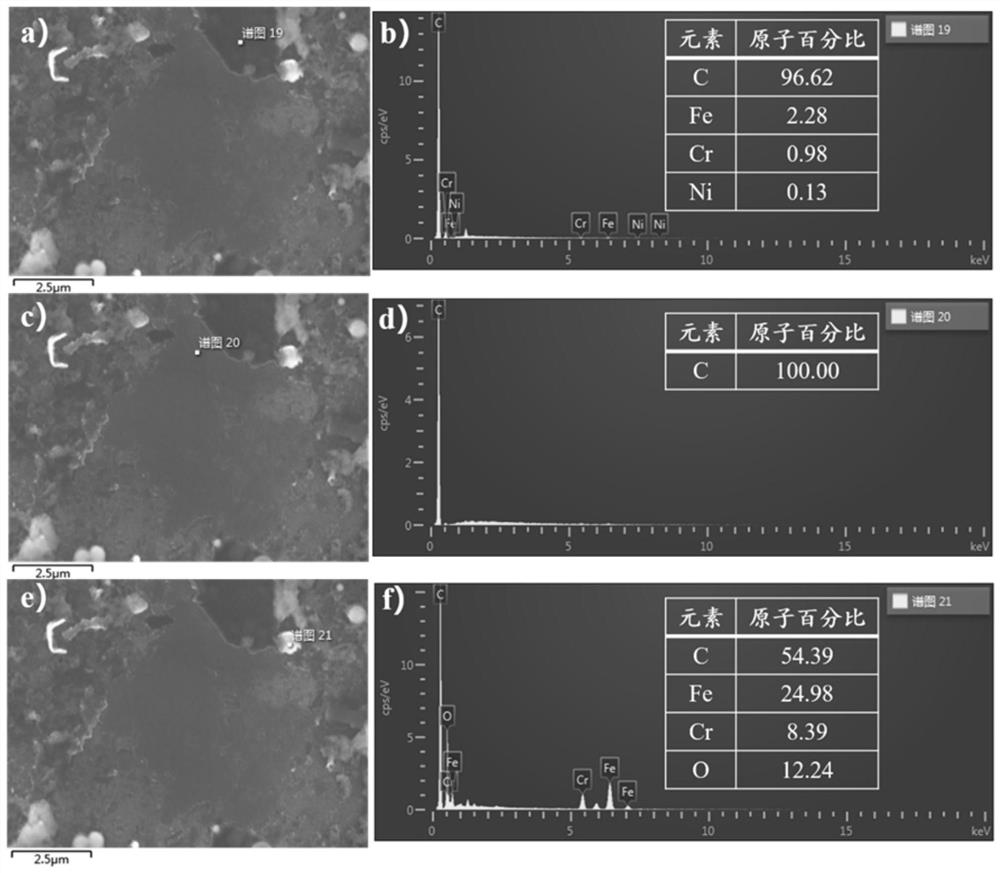

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The embodiments are used only to explain the present invention and not to limit the scope of protection of the present invention.

[0036] (1) The cleaning liquid of coke on the inner surface of the renewable cooling pipe

[0037] Preparation of cleaning solutions by weight: 87% of the alkali solution, 3% of the surfactant, 5% of the solubilizer and 5% of the chelating agent.

[0038]The mixed alkali solution consists of an aqueous sodium hydroxide solution with a mass fraction of 20% and an aqueous solution of potassium permanganate with a mass fraction of 20% (the weight ratio of aqueous sodium hydroxide solution and an aqueous solution of potassium permanganate is 1: 1). The surfactant is composed of a fatty alcohol polyethylene ether and sodium laurylbenzenesulfonate massager 1: 2 compounded. The solubilizer is isopropanol. The chelating agent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com