Patents

Literature

47results about How to "Improve surface mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-entropy alloy composite powder and method for strengthening magnesium alloy through ultrahigh-speed laser cladding

ActiveCN111996435AHigh bonding strengthHigh hardnessMetallic material coating processesAl powderHigh entropy alloys

The invention discloses high-entropy alloy composite powder and a method for strengthening magnesium alloy through ultrahigh-speed laser cladding. The high-entropy alloy composite powder comprises nickel powder, chromium powder, cobalt powder, iron powder, copper powder, titanium powder, vanadium powder, aluminum powder and ceramic particles, and the mass fraction of the ceramic particles is 10-20% of that of the high-entropy alloy composite powder. The method for strengthening the magnesium alloy through laser cladding comprises the following steps of (1) setting the technological parametersof ultra-high speed laser cladding; (2) loading the high-entropy alloy composite powder on an ultra-high-speed laser cladding machine, so that the energy of a laser beam acts on the powder materials;and (3) feeding the powder materials to the position above the surface of the magnesium alloy to be treated in a synchronous powder feeding mode, melting the high-entropy alloy composite powder into liquid drops which drop into a molten pool on the surface of the magnesium alloy, and forming a cladding layer which is metallurgically combined with the magnesium alloy matrix after solidification. The high-entropy alloy composite powder and the method for strengthening the magnesium alloy through ultrahigh-speed laser cladding avoid over-melting or over-burning of the magnesium alloy, improve thesurface treatment efficiency of the magnesium alloy, and have the advantages of small deformation and high surface smoothness.

Owner:CHONGQING UNIV OF TECH

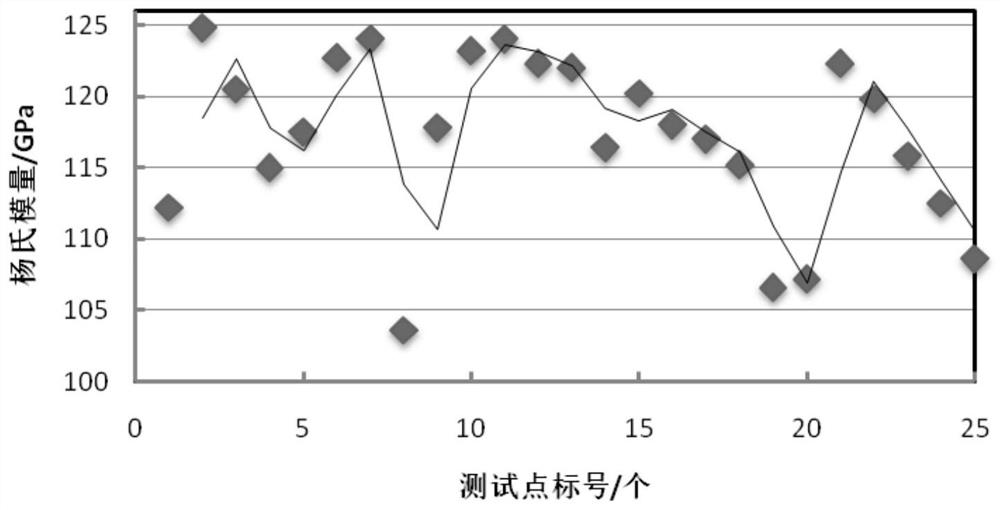

Technology for strengthening high surface hardness of TC4 titanium alloy by electrical spark

The invention discloses a method for improving surface hardness of a TC4 titanium alloy and relates to a method for strengthening the surface of the TC4 titanium alloy by electrical spark, belonging to the technical field of nontraditional machining. Different solid powder materials are added in a near-dry working medium to implement the technology for strengthening the high surface hardness of the TC4 titanium alloy. The method for improving the surface hardness of the TC4 titanium alloy is implemented by the following steps: the TC4 titanium alloy is strengthened by a powder-mixture near-dry electrical spark surface-strengthening method; and the solid powder materials mixed in the working medium respectively are C powder, B4C powder, and a mixture of the C powder and the B4C powder. Experiment parameters in the process of strengthening the surface by powder-mixture near-dry electrical spark are that the pulse interval toff is equal to 150Mus, the pulse width ton is equal to 150Mus, the pulse current ie is equal to 14A, the interelectrode discharge voltage is 120V, the machining depth h is equal to 0.1mm and a tool electrode used is graphite. The technology has the advantages that a strengthened layer and a matrix are combined well, the surface mechanical property is improved remarkably, and the like. The TC4 titanium alloy with the surface being strengthened by the method is up to 1382HV in microhardness, which is increased by 300% compared with that of the original alloy.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

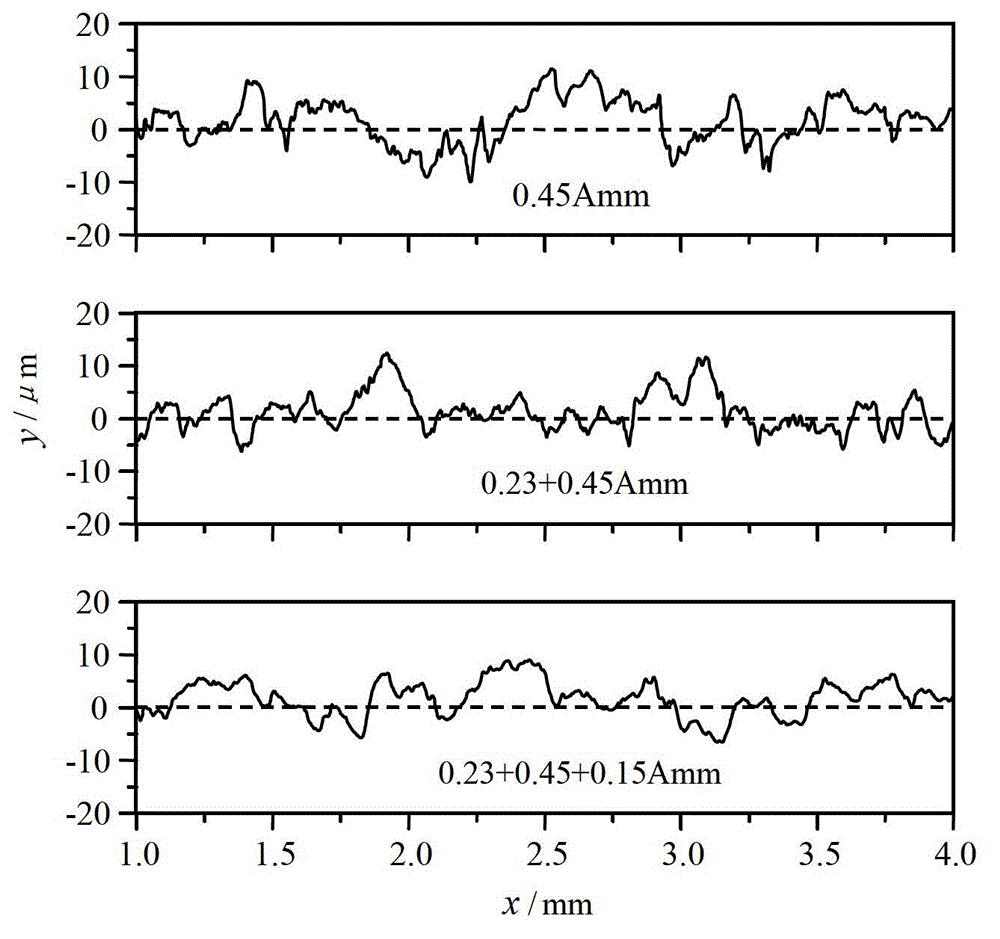

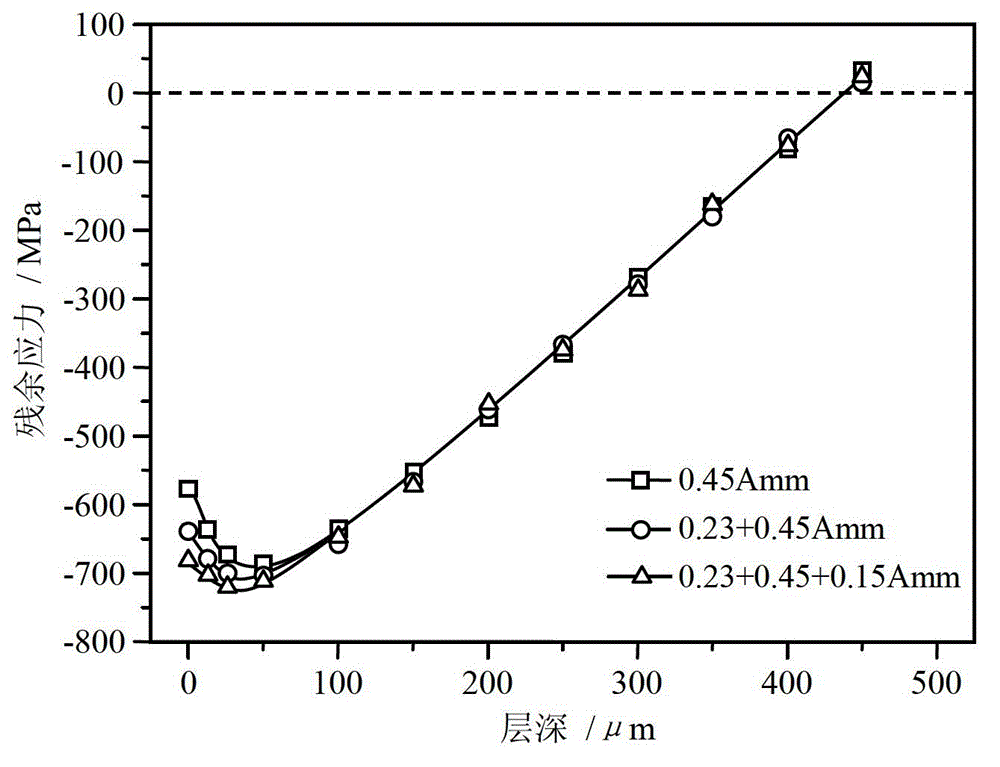

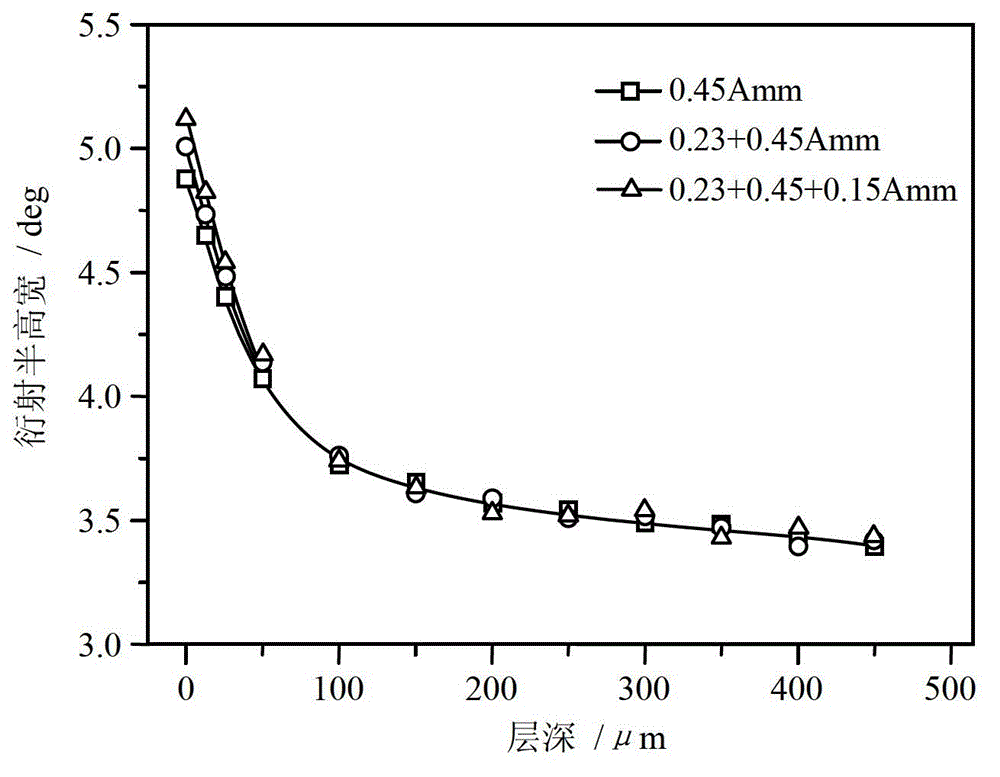

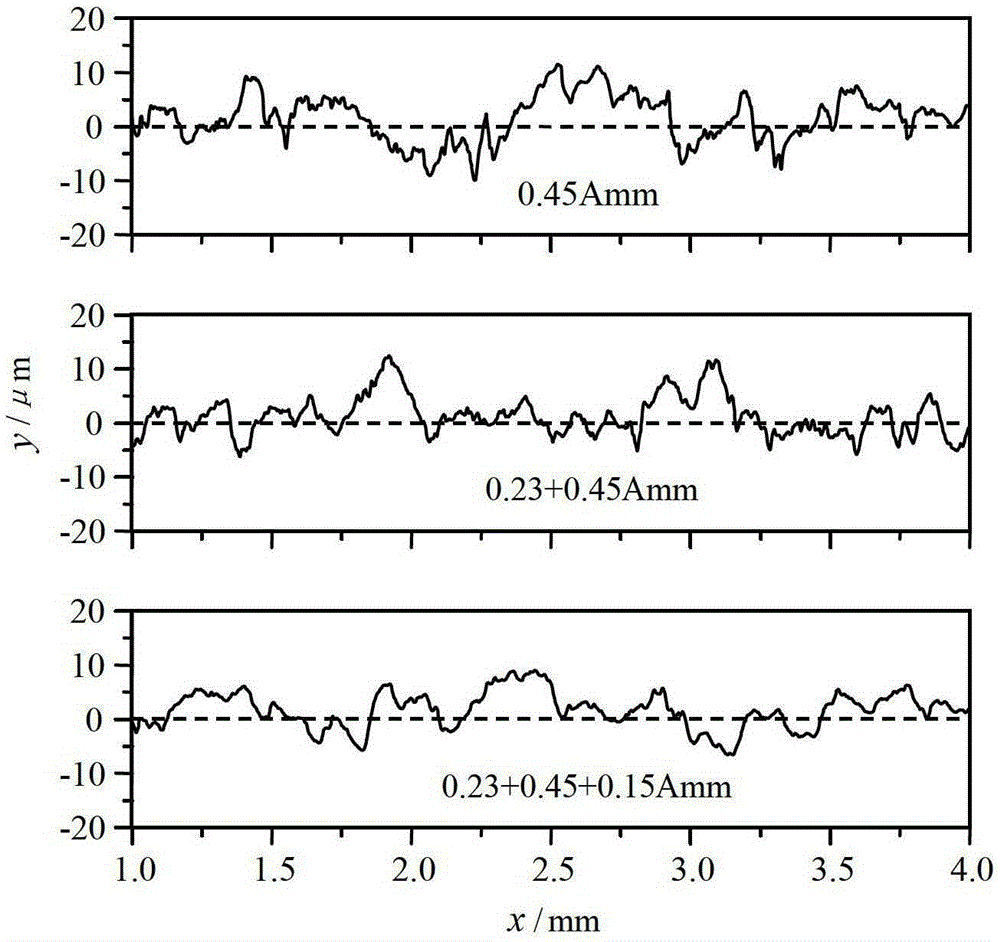

Novel spring pre-strengthening finishing composite shot blasting method

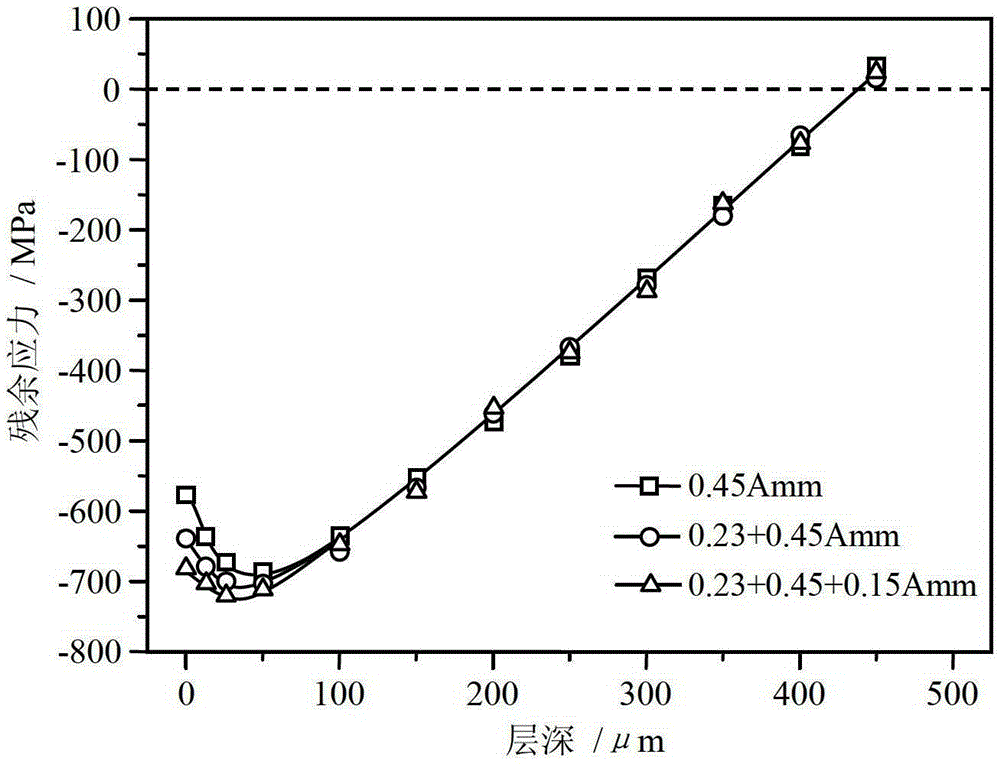

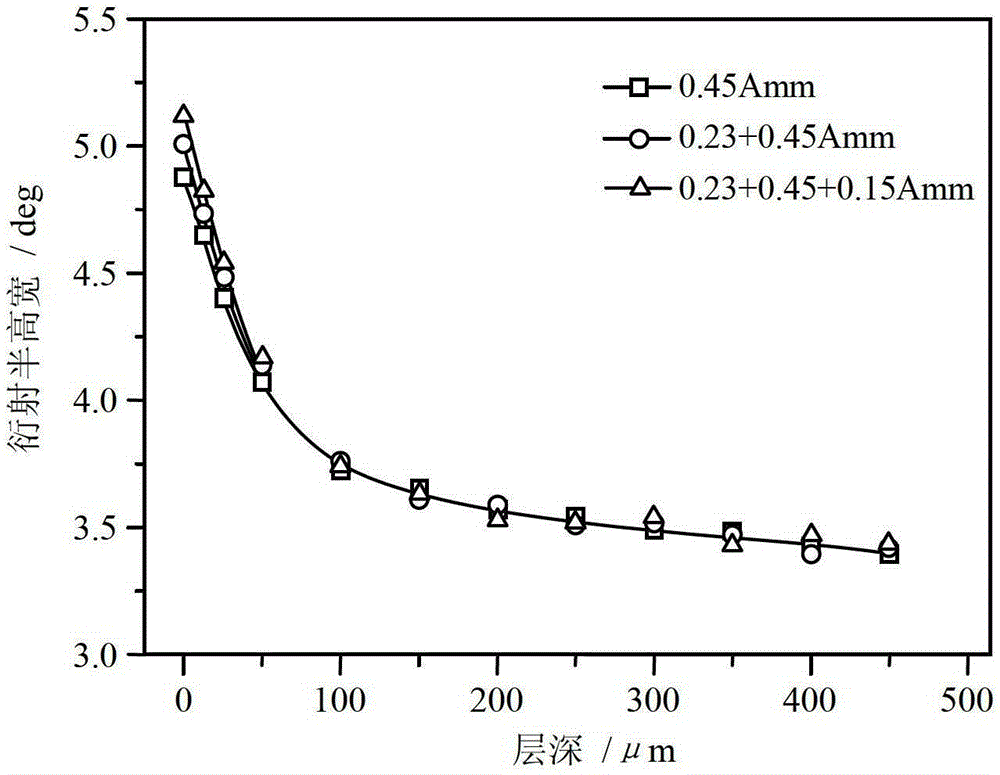

InactiveCN102941536AImprove mechanical propertiesHigh hardnessAbrasion apparatusSurface roughnessUltimate tensile strength

The invention relates to a novel spring pre-strengthening finishing composite shot blasting method. The method includes that a spring is subjected to pre-strengthening finishing composite shot blasting by a shot blasting machine, the pre-strengthening finishing composite shot blasting includes three processes, the shot blasting strength is 0.23Amm in the first process, the shot blasting strength is 0.45Amm in the second process, the shot blasting strength is 0.15Amm in the third process, and shot blasting mediums of three-time shot blasting are same to obtain a processed spring product. Compared with shot blasting methods in prior art, the novel spring pre-strengthening finishing composite shot blasting method has the advantages that the beneficial effect of residual compressive stress is increased, and negative influences caused by surface roughness of a part can be avoided to greatest degree.

Owner:SHANGHAI JIAO TONG UNIV

Chromium carbide ceramic thermal-spraying flux-cored wire

InactiveCN102400083AHigh hardnessHigh bonding strengthMolten spray coatingWelding/cutting media/materialsChromium carbideCarbon steel

The invention provides a chromium carbide ceramic thermal-spraying flux-cored wire. The weight percentages of chemical compositions of the flux-cored wire are that 75 to 85 wt% of Cr2C3, 10 to 15 wt% of NiCr, 1 to 3 wt% of La2O3 and 4 to 7 wt% of graphite; and the powder size is minus 120 to plus 80 meshes. The raw materials are put into an agitator to be evenly mixed, a H08 low-carbon steel belt is adopted by a scarfskin, flux-cored wire production equipment is adopted, and the ceramic flux-cored wire of which the outer diameter is F4 to F6 is formed through curliness and extraction. When the flux-cored wire is used, the spraying distance is controlled within a range of 80 to 120mm and the coating thickness is 0.1 to 0.3mm. The flux-cored wire has the advantages that the cost is low, a large bonding strength reaching 15 to 20MPa exists between a sprayed coating and a low-carbon steel substrate, the sprayed coating has higher hardness reaching 600 to 1000HV within a certain spraying distance range and has higher wear resistance.

Owner:YANSHAN UNIV

Surface mixed and modified powder infiltration technology of magnesium diecast alloy

InactiveCN101698229AImprove surface mechanical propertiesImprove corrosion resistanceConcentration gradientMechanical property

The invention relates to a novel surface modification technology of die cast magnesium alloy. Concentration gradient of surface layer alloy of the magnesium alloy is formed by an infiltration technology; the modified power mixture with different granularity specifications, such as SiC, Al302, Si, Sn, Cr, Al, Zn and Cu and the like, is simultaneously sprayed inside and on the surface of a closed die casting mold cavity evenly; and a surface modified layer is formed in the die casting forming process of the magnesium alloy. The modified layer comprises a sub-surface modified layer and a surface modified layer, and is distributed inwards in a gradient shape along the magnesium alloy surface. The surface modified alloying layer of the invention is continuous and compact, has favorable corrosion resistance and abrasive resistance, and the mechanical property of the casting surface is also improved; the modified alloying layer and the magnesium alloy matrix are metallurgical combination with high combination strength, and surface layer cracking or stripping is not easy to emerge. The modified technology is simple,features easily controlled parameters, environment protection, no pollution, no sticky mold and no injury on a mould, and can be widely used in industrial production.

Owner:DALIAN JIAOTONG UNIVERSITY

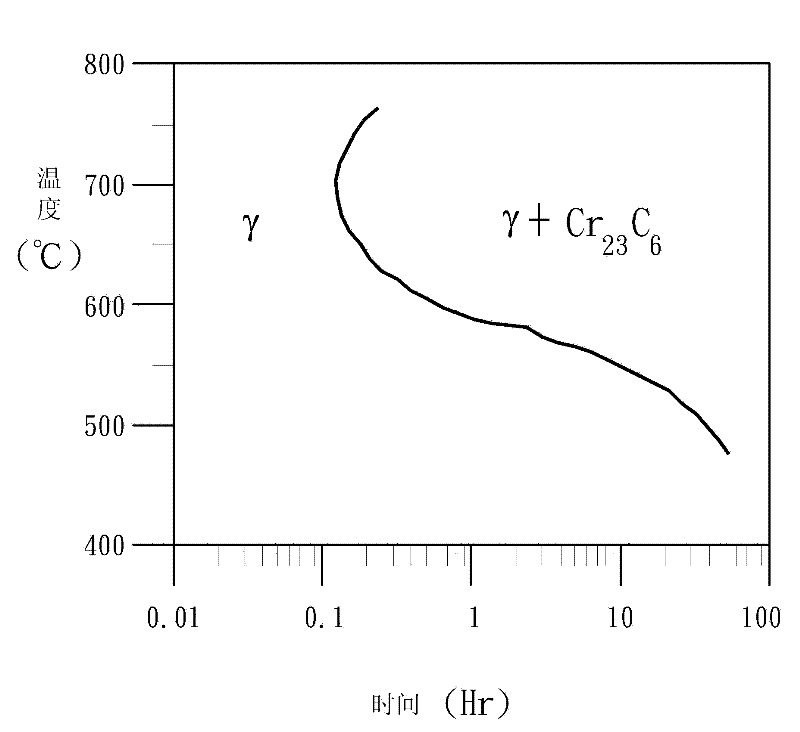

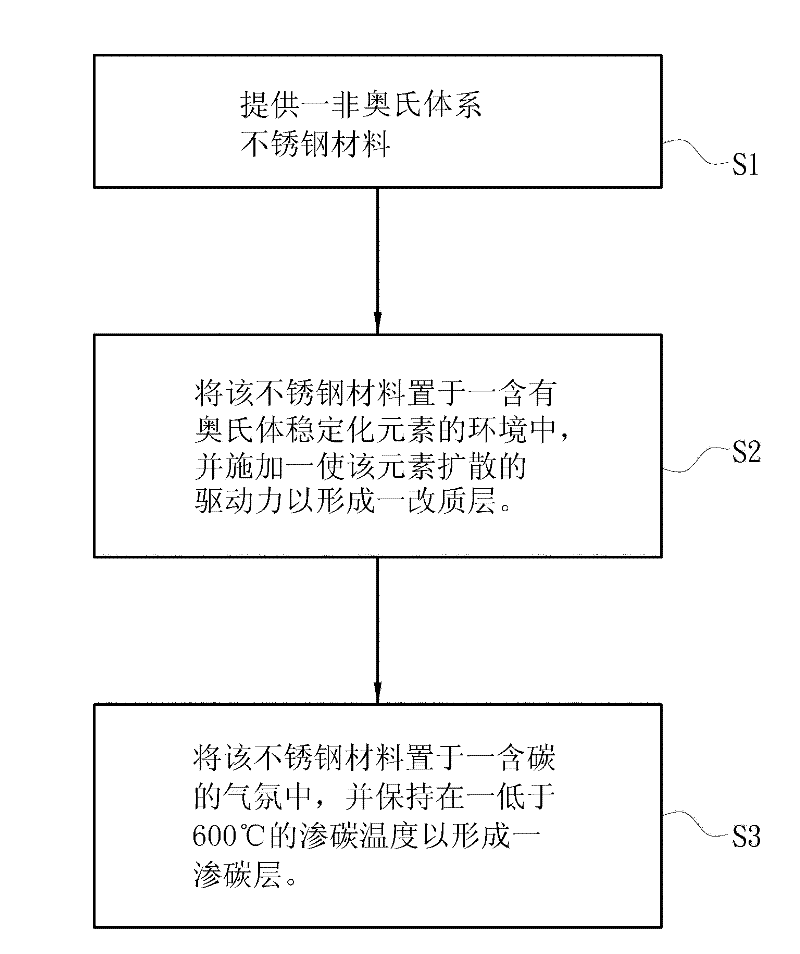

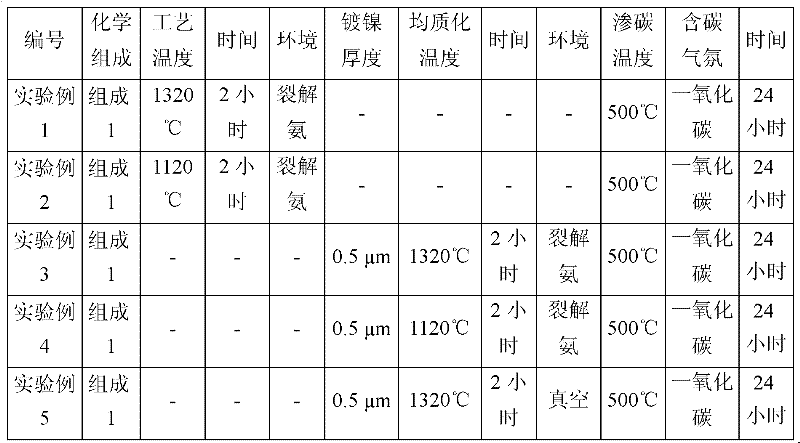

Method for improving mechanical properties of surface of non austenitic stainless steel

ActiveCN102676978AImprove surface mechanical propertiesImprove corrosion resistanceSolid state diffusion coatingHigh surfaceHardness

The invention provides a method for improving mechanical properties of the surface of non austenitic stainless steel. The method comprises the following steps: putting a non austenitic stainless steel material into an environment comprising at least one austenitic stabilizing element, and making the austenitic stabilizing element disperse to the surface of the stainless steel material to form a modified layer, wherein the modified layer is rich in the austenitic stabilizing element; and putting the stainless steel material into a carbon-containing atmosphere, making the modified layer contact the carbon-containing atmosphere, keeping carburizing temperature of lower than 600DEG C, and making carbon enter the modified layer to form a carburized layer. By the carburized layer, the mechanical properties of the surface of the non austenitic stainless steel material can be improved, and the non austenitic stainless steel material can be applied to appearance products and structural parts, which require high wear resistance, high surface hardness and high corrosion resistance.

Owner:SUZHOU ZHONGYAO TECH CO LTD

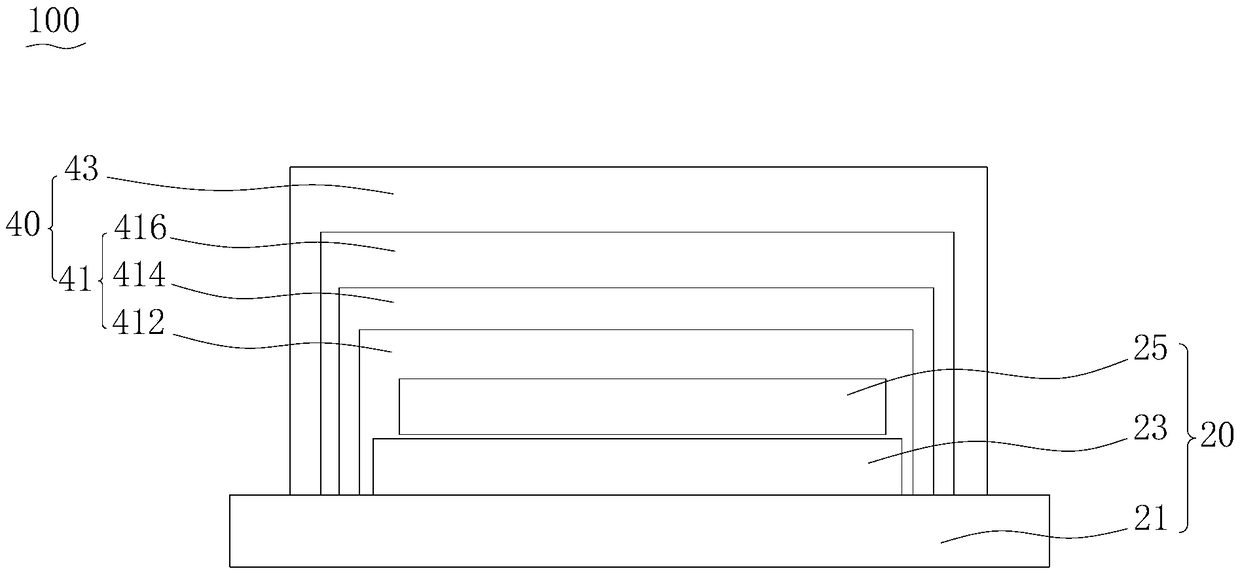

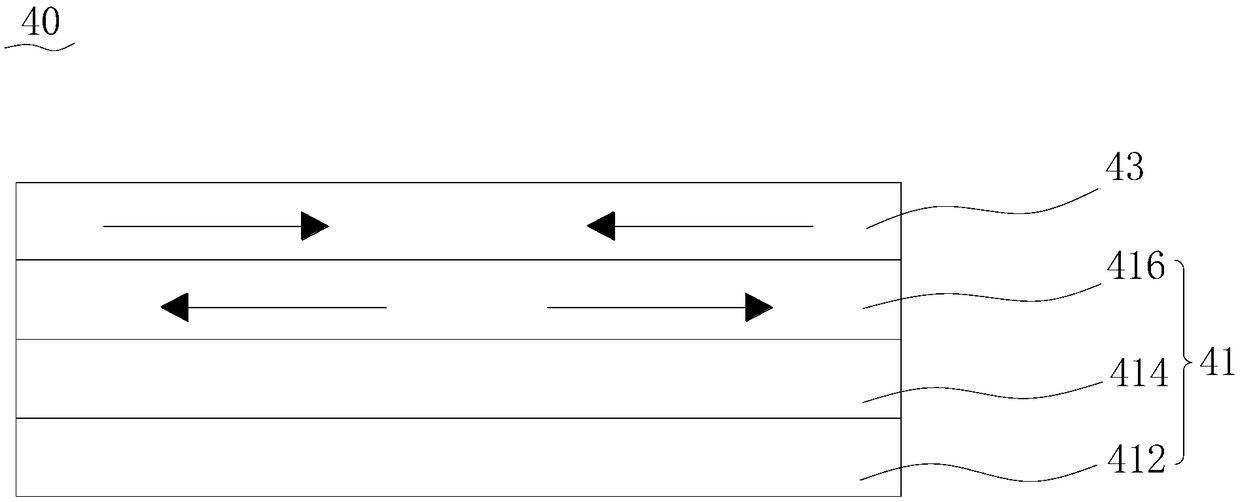

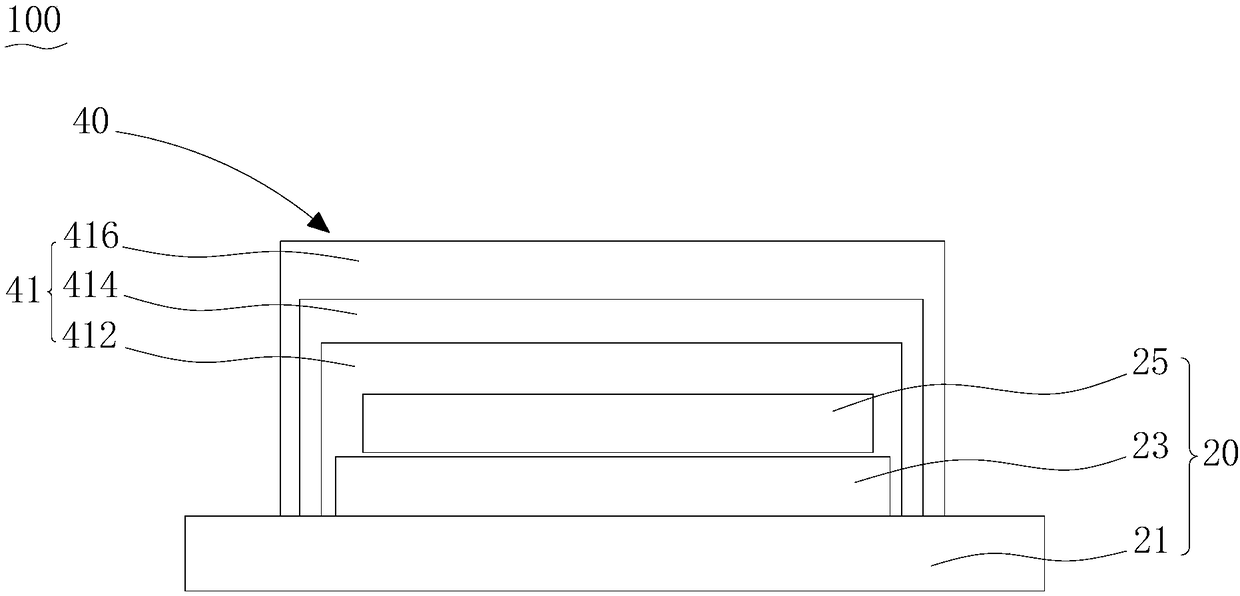

Display panel, display device provided with display panel and display panel forming method

InactiveCN108922982ASmall coefficient of thermal expansionImprove surface mechanical propertiesSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceTension stress

The invention relates to a display panel, a display device provided with the display panel and a display panel forming method. The display panel comprises a display base plate and a packaging unit forpackaging the display base plate. The surface of the side, away from the display base plate, of the packaging unit has residual compressive stress used for offsetting at least part of mechanical force. According to the display panel, the existence of residual compressive stress optimizes the mechanical properties of the surface of the side, away from the display base plate, of the packaging unit,and the impact resistance of the packaging unit is improved. When a falling ball hits the display panel provided with the packaging unit in a reliability test, at least part of the tensile stress generated by cracks formed by the falling ball on the packaging unit is offset with the residual compressive stress on the surface of the packaging unit, so that the impact force on the display base plate positioned below the packaging unit is effectively reduced, and the display base plate is prevented from being damaged.

Owner:YUNGU GUAN TECH CO LTD

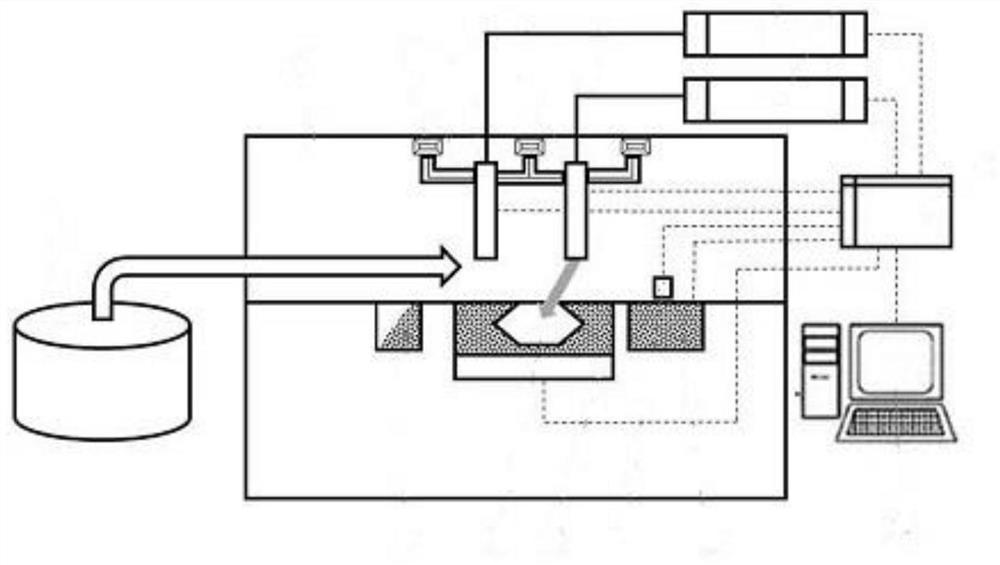

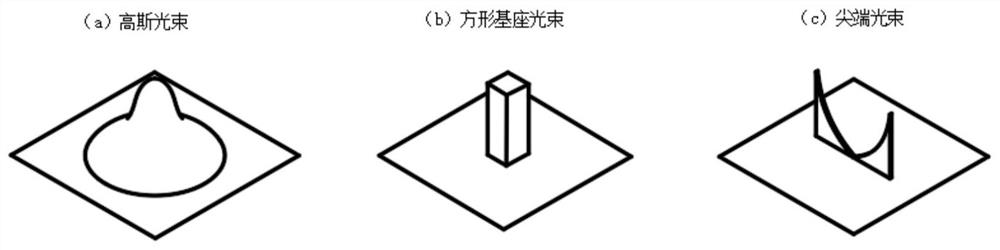

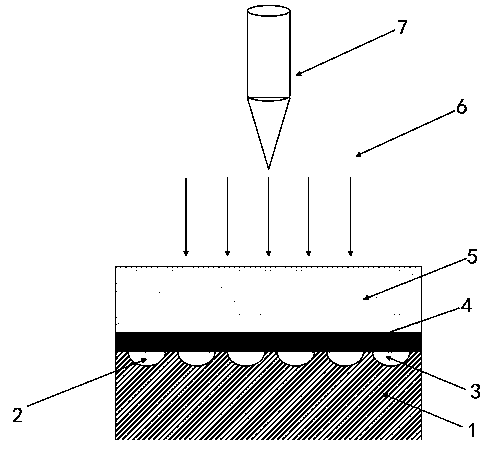

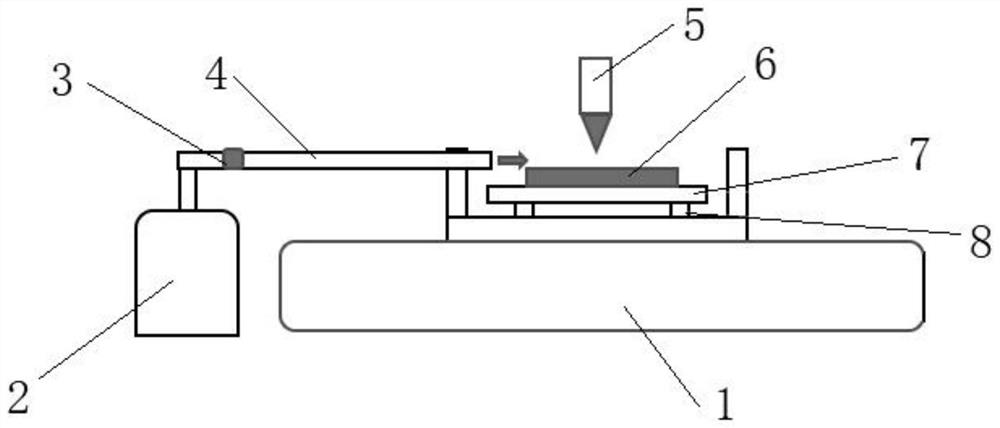

Laser additive-polishing integrated machining method and device

PendingCN112620943AImprove surface accuracyImprove surface mechanical propertiesAdditive manufacturing apparatusLaser beam welding apparatusLight beamLaser additive manufacturing

The invention discloses a laser additive-polishing integrated machining method and device. The method can be used for surface polishing of laser additive-manufactured parts, in the additive-manufacturing process, additive manufacturing and polishing are conducted synchronously, laser polishing is utilized, and a flat and smooth surface is quickly obtained, so that the integration of additive machining and polishing machining is realized. The device mainly comprises a mechanical arm, a barrel, a reflector, a holographic optical element, a cooling system and a wire feeding pipe, and is characterized in that a circular incident laser beam is reflected to the surface of the holographic optical element through the reflector and diffracted into two focused beams by the holographic optical element, and the focused beams I and an alloy wire are used for additive forming; and the focused beam II is used for additive forming subsequent polishing. The method and the device have the advantages that (1) the surface quality of the material can be effectively improved, and the mechanical property of the material surface is improved; and (2) the device adopts alloy wires for additive manufacturing, so that the problems of powder splashing and the like are avoided.

Owner:SHANDONG JIANZHU UNIV

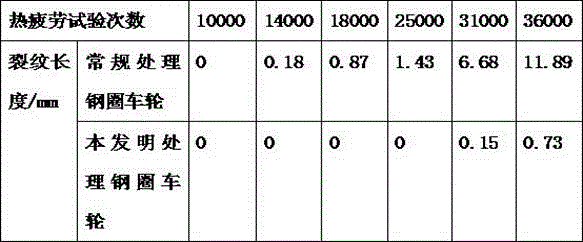

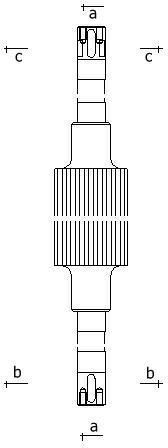

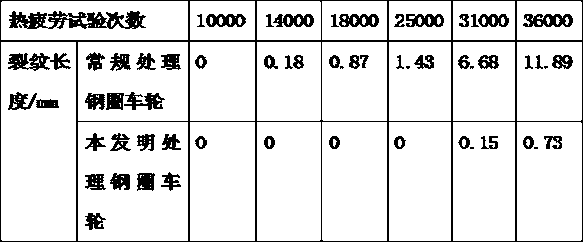

Steel ring car wheel surface treatment process

ActiveCN106222680AEfficient removalImprove surface mechanical propertiesFurnace typesMetallic material coating processesHigh resistanceShock resistance

The invention discloses a steel ring car wheel surface treatment process. The steel ring car wheel surface treatment process comprises the following steps of (1) cleaning, (2) surface preheating, (3) surface modification treatment, (4) cleaning and cold standing and (5) quenching treatment. The steel ring car wheel surface treated through the process has the high abrasion resistance, high hardness, high toughness and high shock resistance, subsequent quenching treatment is matched, the optimal quenching time and quenching temperature are optimized, and the tempering time and tempering temperature are adjusted, so that the impact toughness and hardness of a steel ring car wheel are improved; and inner hardness and outer hardness are balanced, the microhardness of the surface of a steel ring car wheel coating is quite high, the salt corrosion resistance and stress corrosion cracking resistance can be further improved. In addition, the fatigue resistance of the steel ring car wheel is greatly improved, the service life of the steel ring car wheel is prolonged, and the service life of the steel ring car wheel is prolonged by three to four times compared with untreated steel ring car wheels.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

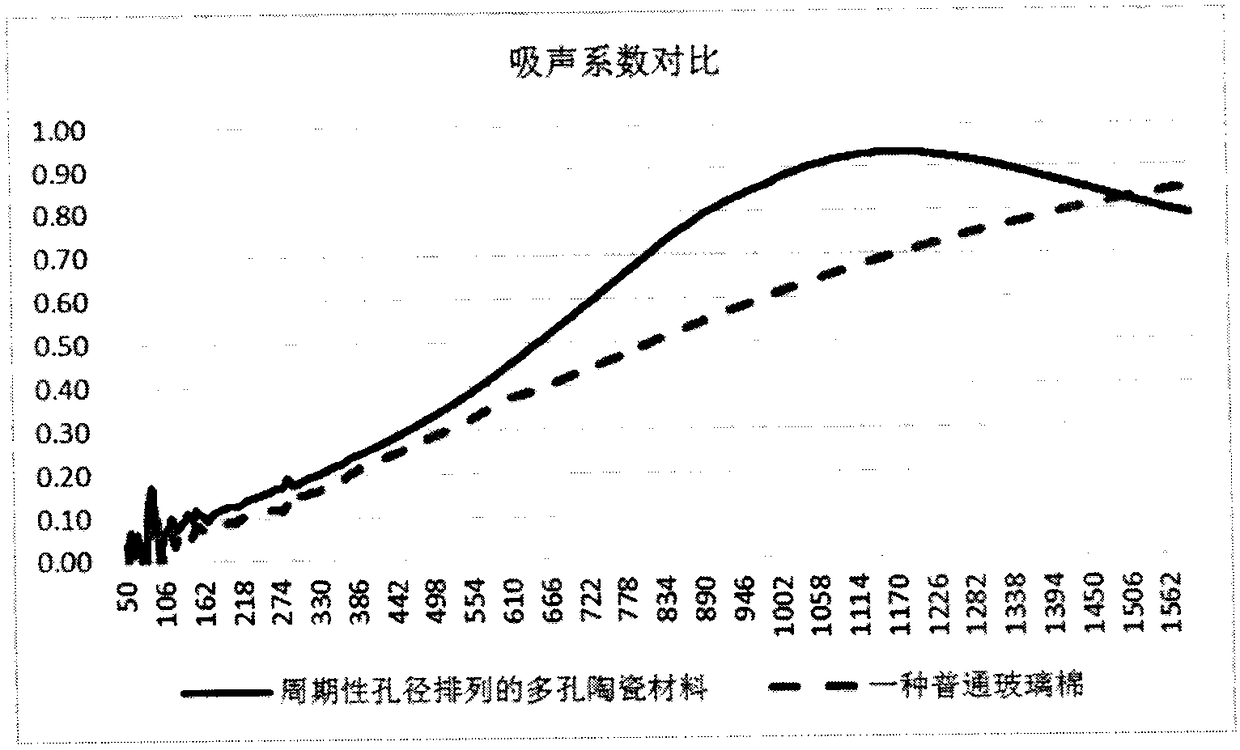

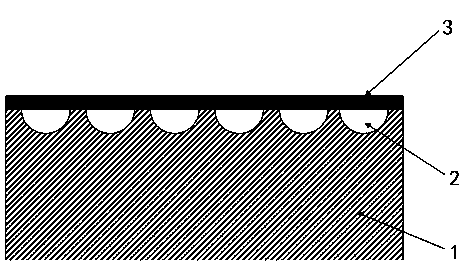

Porous ceramic sound absorption material designed on basis of photonic crystal theory and production method thereof

InactiveCN108455999AAvoid secondary environmental pollutionImprovement of design conceptCeramicwareFiberMaterial Design

The invention relates to a porous ceramic sound absorption material designed on basis of photonic crystal theory and a production method thereof. The porous ceramic sound absorption material is prepared from a ceramic framework, wherein micropores which are periodically arranged are formed in the ceramic framework; the porous ceramic sound absorption material is characterized in that the porosityis 40-70%, the pore diameter is 0.0001-0.001m, the flow resistance rate is 2500-12500Pa.s / m<2>, and the thickness is 20-100mm. The porous ceramic sound absorption material designed on basis of the photonic crystal theory can replace the traditional sound absorption material in multiple places, is capable of avoiding the secondary environment pollution of the inorganic fiber materials such as glasswool caused by dust formation, and can be applied to the outdoor environment; compared with other sound absorption materials, the porous ceramic sound absorption material has incomparable superiority.

Owner:张晓琳

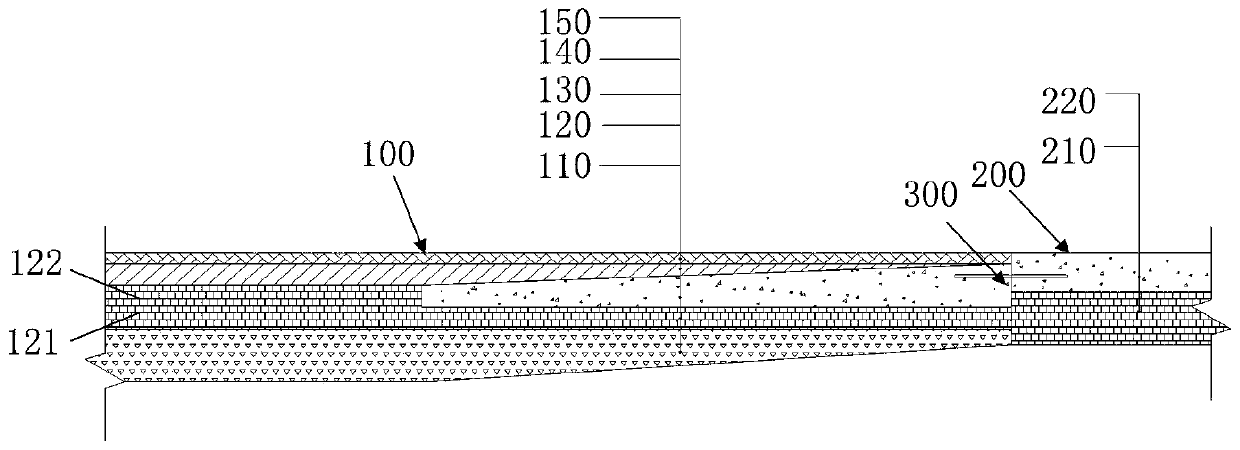

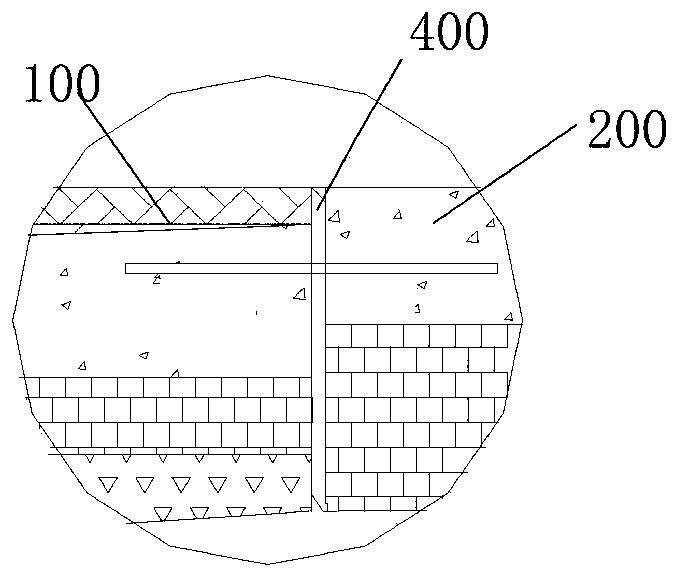

Roller compacted concrete and U-turn road structure prepared from same

PendingCN110846970AExtended service lifeMeet construction requirementsPaving reinforcementsIn situ pavingsRoller-compacted concreteArchitectural engineering

The invention relates to the technical field of building materials and constructional engineering, in particular to roller compacted concrete and a U-turn road structure prepared from the same. The roller compacted concrete is composed of cement, crushed stone, machine-made sand, a super set-retarding agent, a mortar extractant and water. The U-turn road structure includes a flexible asphalt concrete road structure and a rigid cement concrete road structure. The roller compacted concrete and an asphalt pavement can be simultaneously subjected to mortar extraction and rolling compaction construction. The U-turn road structure can reduce the quality problems such as sedimentation, subsidence, bulging and bleeding of a traditional asphalt concrete pavement under the action of a limit load, the carrying capacity and anti-strain ability of pavements such as U-turn lanes for vehicles, and the cumulative load of braking, parking and other operation of the vehicles are buffered to ensure driving safety.

Owner:SINOHYDRO ENG BUREAU 4

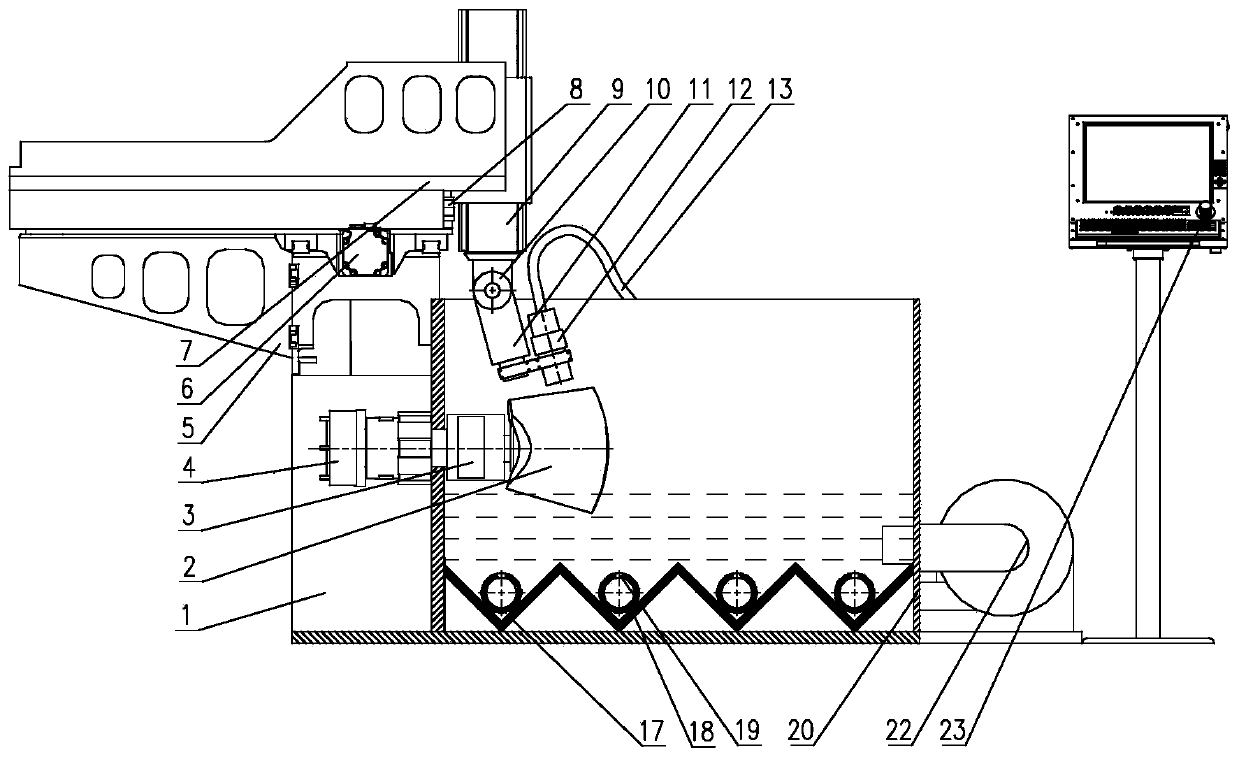

High-precision blade abrasive fluid surface polishing strengthening equipment

InactiveCN110977785AQuality improvementHigh degree of automationAbrasive feedersAbrasive blasting machinesComputer control systemPolishing

The invention relates to the field of polishing equipment, in particular to high-precision blade abrasive fluid surface polishing strengthening equipment which comprises a rack and an abrasive box arranged on the rack. The blade is arranged in the abrasive box through a clamping device and a B-axis servo driving system, the lower part of the blade is in contact with polishing turbid liquid, and therefore the B-axis servo driving system drives the blade to rotate; an X-axis servo driving system, a Y-axis servo driving system, a Z-axis servo driving system and a swing arm are arranged at the upper end of the rack, the X axis, the Y axis and the Z axis are straight axes, a polisher is arranged at the tail end of the swing arm, and therefore the polisher is driven by the A-axis servo driving system to rotate; the polisher is connected with a polishing centrifugal pump through a hose, and an input shaft of the polishing centrifugal pump is connected with a filter arranged in the abrasive box; the polishing centrifugal pump sucks the polishing turbid liquid through the filter, and the polishing turbid liquid is pressurized and then conveyed to the polisher through a hose; and the high-precision blade abrasive fluid surface polishing strengthening equipment further comprises a computer control system arranged on the outer side of the rack. By means of the equipment, blade machining abrasive fluid surface polishing strengthening equipment and process are developed, and the surface quality and geometric accuracy of the blade can be remarkably improved.

Owner:CENT RES INST OF TIANJIN BENEFO MECHANICAL EQUIP GRP CO LTD

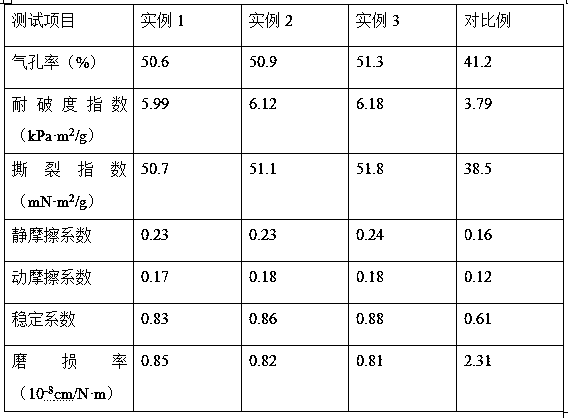

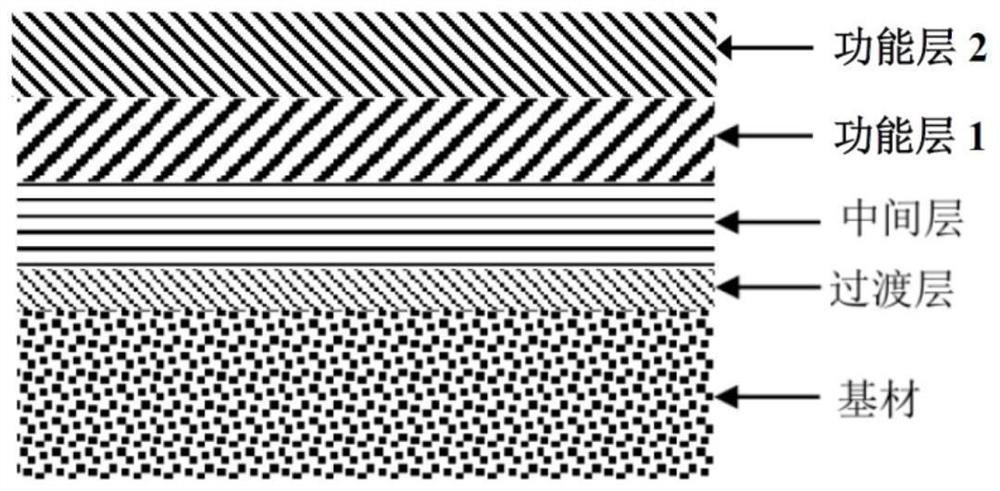

Method for preparing high-wear resistance paper-based friction material

ActiveCN109024055AImprove surface mechanical propertiesImprove mechanical propertiesPaper coatingCoatingsFiberBond energy

The invention relates to a method for preparing a high-wear resistance paper-based friction material, and belongs to the technical field of preparation of paper-based friction materials. The preparation method comprises the following steps: mixing bamboo fibers with a ferrous sulfate solution, filtering and drying the obtained fibers to obtain a dried product, reacting the dried product with a copper sulfate solution to obtain filter residues, mixing the filter residues with ethyl orthosilicate, and carrying out microwave heating to obtain modified bamboo fibers. The bamboo fibers are mixed with ferrous ions, the excellent mechanical properties of elemental metals make the mechanical properties of the modified bamboo fibers improved; pores in the bamboo fibers are filled to the compactnessand improve the tightness of the microstructure of the bamboo fibers, so the toughness and the mechanical properties of the bamboo fibers are further improved; and a silicon dioxide film is formed onthe surface of the bamboo fibers to protect iron and copper elements, and the film contains S-O bonds with large bond energy, so the strength of the paper-based friction material is improved, and thematerial has a broad application prospect.

Owner:深圳市永霖科技有限公司

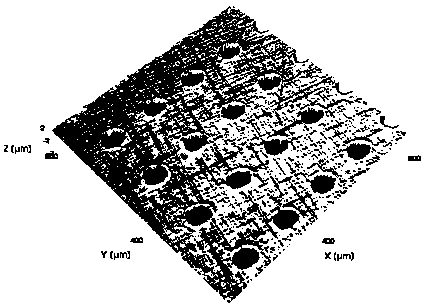

A solid lubrication coating preparing method utilizing laser thermal-mechanical coupled texturing

ActiveCN108893733AFully lubricatedEasy to operateLaser beam welding apparatusHeat inorganic powder coatingShock waveThermal effect

The invention discloses a solid lubrication coating preparing method utilizing laser thermal-mechanical coupled texturing, and relates to the technical field of lubrication and antifriction of the material surface. A micro pit texture is processed on the metal matrix surface by utilizing a laser thermal effect, the matrix is pre-coated with a layer of solid lubrication powder after the matrix is polished, then impact reinforcement processing is performed on the matrix surface by utilizing a shock wave force effect formed by laser impact, pits are filled with a solid lubricant agent, the matrixsurface is covered with a layer of a compact solid lubrication coating simultaneously, after a friction pair works for a period of time, the solid lubricant agent in the pits is transmitted between the pits, and therefore, the solid lubrication coating of the matrix surface is supplemented. The method is a novel surface coating preparing method, a surface lubrication state can be fully improved,and metal surface mechanical properties of the metal surface can be substantially improved simultaneously. The technology is simple and reliable, automatization production can be realized, and the preparing method is suitable for industrialization popularization.

Owner:JIANGSU UNIV

Hydrophobic oxyfluorinated-graphene composite polyimide powder paint and preparation method thereof

InactiveCN106800882AImprove hydrophobicityImprove interface performancePowdery paintsPotassium persulfateSebacic acid

The invention discloses a hydrophobic oxyfluorinated-graphene composite polyimide powder paint which is prepared from the following raw materials in parts by weight: 100-110 parts of polyimide, 10-14 parts of fluoridized graphite, 0.1-0.3 part of potassium persulfate, 1-2 parts of sodium nitrate, 0.1-0.4 part of potassium permanganate, 4-6 parts of sebacic acid, 0.5-1 part of phosphorus pentoxide, 0.1-0.2 pat of dicyclohexylcarbodiimide, 0.1-0.2 part of 4-dimethylaminopyridine, 0.4-1 part of zinc pyrithione, 0.6-1 part of dibenzothiazyl disulfide, 2-3 parts of alkenyl succinic anhydride, 1-2 parts of polyoxyethylene oleate, 2-4 parts of beeswax, 0.1-0.4 part of hexamethyl phosphoryl triamide, 6-8 parts of montmorillonite powder, 0.3-1 part of butyl tin mercaptide, and right amounts of dimethylformamide, sulfuric acid and anhydrous ethanol. The powder paint has the advantages of favorable hydrophobicity, high seepage resistance, high surface strength, favorable toughness and excellent comprehensive properties.

Owner:ANHUI RONGJIU OPTICAL FIBER COMM

A kind of preparation method of high abrasion resistance paper-based friction material

ActiveCN109024055BImprove surface mechanical propertiesImprove mechanical propertiesPaper coatingCoatingsFiberSilicic acid

The invention relates to a method for preparing a high-wear resistance paper-based friction material, and belongs to the technical field of preparation of paper-based friction materials. The preparation method comprises the following steps: mixing bamboo fibers with a ferrous sulfate solution, filtering and drying the obtained fibers to obtain a dried product, reacting the dried product with a copper sulfate solution to obtain filter residues, mixing the filter residues with ethyl orthosilicate, and carrying out microwave heating to obtain modified bamboo fibers. The bamboo fibers are mixed with ferrous ions, the excellent mechanical properties of elemental metals make the mechanical properties of the modified bamboo fibers improved; pores in the bamboo fibers are filled to the compactnessand improve the tightness of the microstructure of the bamboo fibers, so the toughness and the mechanical properties of the bamboo fibers are further improved; and a silicon dioxide film is formed onthe surface of the bamboo fibers to protect iron and copper elements, and the film contains S-O bonds with large bond energy, so the strength of the paper-based friction material is improved, and thematerial has a broad application prospect.

Owner:深圳市永霖科技有限公司

Solidification contraction-free high-hardness casting magnesium alloy and process thereof

The invention discloses a solidification contraction-free high-hardness casting magnesium alloy and a process thereof. The alloy comprises the following components in percentage by weight: 0.6-0.8wt.%of Li, 2.0-3.0wt.% of Sb, 5.0-8.0wt.% of In, 4.0-6.0wt.% of Bi, 1.0-2.0wt.% of Pb, 3.0-5.0wt.% of Ge, 1.2-1.5wt.% of Si, 5.0-8.0wt.% of Sn and the balance of magnesium. By adopting the magnesium alloy, casting defects are effectively eliminated, formation of casting pores and looseness is reduced, and excellent mechanical properties of a cast alloy part are achieved. Therefore, the invention provides a lightening solving scheme of a magnesium alloy substitution product, and updating and industry updating requirements of novel materials in China are effectively promoted in the implementation and industrialization process.

Owner:GUANGZHOU YUZHI TECH CO LTD

UV gravure white ink for food packaging BOPP film, and preparation method of UV gravure white ink

The invention belongs to the field of ultraviolet curing ink, and relates to UV gravure white ink for a food packaging BOPP film, and a preparation method thereof. The UV gravure white ink is preparedfrom the following raw materials by weight: 8 to 15 parts of polyether polyol aliphatic polyurethane acrylate, 8 to 15 parts of polyester acrylate, 30 to 40 parts of dipropylene glycol diacrylate, 2to 6 parts of pentaerythritol triacrylate, 1 to 3 parts of 819, 1 to 3 parts of 1173, 0.3 to 0.8 part of Tego-Foamex N, 0.8 to 1.5 parts of DC-57, 0.3 to 0.8 part of Tego-655, 3-8 parts of talcum powder, 3-8 parts of light calcium carbonate, and 15-30 parts of titanium dioxide. The ink is applied to food packaging BOPP films, the printing speed can reach 200 m / min or above while the low cost is guaranteed, and the ink is good in adhesive force and resistant to abrasion and is environment-friendly UV photocuring ink.

Owner:河南功能高分子膜材料创新中心有限公司

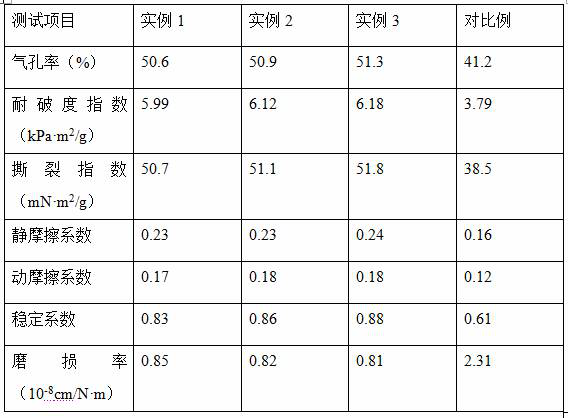

Preparation method of CrAlVSiN coating

ActiveCN114351087AReduce adverse effectsImprove bindingVacuum evaporation coatingSputtering coatingSurface engineeringIon beam

The invention belongs to the technical field of surface engineering, and particularly relates to a preparation method of a CrAlVSiN coating, the CrAlVSiN coating comprises a transition layer, a middle layer and a functional layer, the transition layer is deposited on the surface of a base material, the middle layer is deposited on the transition layer, and the functional layer is deposited on the middle layer; the transition layer is TiAlN, and the middle layer is CrAlTiN; and the functional layer is CrAlTiN. According to the method, high-energy ion beams are introduced for activating treatment by introducing glow discharge such as radio frequency, pulse and the like or Hall discharge modes, process parameters are optimized, the film-substrate binding force of the CrAlVSiN hard coating is improved, and the prepared CrAlVSiN coating is high in hardness, high in wear resistance, resistant to high-temperature oxidation and good in corrosion resistance. And when the coating is used as a surface functional coating of a cutter, a mold and a bearing, the coating has good cutting life, adhesion resistance and reinforced protection effect.

Owner:SOUTHWESTERN INST OF PHYSICS +1

Cobalt based metal powder

The invention discloses a cobalt based metal powder. The metal powder is prepared from, by weight, 13-15% of tungsten carbide, 0.2-0.4% of carbon, 2-4% of calcium fluoride, 2-4% of silicon nitride, 18-23% of chromium, 2-4% of boron, 0.2-0.4% of vanadium, 5-8% of iron, 4-6% of silicon, 9-12% of molybdenum, 1.2-1.6% of manganese, and the balance cobalt. The cobalt based metal powder can be sufficiently fused with a lathe tool base material, the ingredients can be evenly distributed into a cladding layer, ultrahigh hardness ceramic granules are adopted for improving the harness of a lathe tool, in addition, some micro elements are selected for improving the corrosion resistance, strength and heat resistance of the lathe tool, and therefore the cobalt based metal powder is used for performinglaser fusion covering on the lathe tool, and the cost is lowered while the mechanical performance of the surface of the lathe tool can be improved.

Owner:JIANGSU VILORY ADVANCED MATERIALS TECH CO LTD

Environment-friendly plastic film and preparation method thereof

InactiveCN111004450AGood antibacterial effectImprove surface mechanical propertiesPolymer scienceEmulsion

The invention discloses an environment-friendly plastic film, which is prepared from the following raw materials in parts by weight: 140 to 180 parts of a pretreated base material, 3 to 5 parts of diphenyl silanediol, 1 to 2 parts of zinc pyrithione, 2 to 4 parts of melamine, 0.3 to 1 part of fatty acid diethanolamide and 40 to 50 parts of antibacterial filler emulsion. According to the invention,the filler is high in strength and good in surface activity, can improve the surface mechanical property of a finished film, and has good compatibility with a polypropylene matrix; and the uniform stability of the finished film is good, and the film further has good antibacterial performance and excellent comprehensive performance.

Owner:袁水清

A new spring pre-strengthening and finishing compound shot peening method

InactiveCN102941536BImprove mechanical propertiesHigh hardnessAbrasion apparatusSurface roughnessUltimate tensile strength

The invention relates to a novel spring pre-strengthening finishing composite shot blasting method. The method includes that a spring is subjected to pre-strengthening finishing composite shot blasting by a shot blasting machine, the pre-strengthening finishing composite shot blasting includes three processes, the shot blasting strength is 0.23Amm in the first process, the shot blasting strength is 0.45Amm in the second process, the shot blasting strength is 0.15Amm in the third process, and shot blasting mediums of three-time shot blasting are same to obtain a processed spring product. Compared with shot blasting methods in prior art, the novel spring pre-strengthening finishing composite shot blasting method has the advantages that the beneficial effect of residual compressive stress is increased, and negative influences caused by surface roughness of a part can be avoided to greatest degree.

Owner:SHANGHAI JIAO TONG UNIV

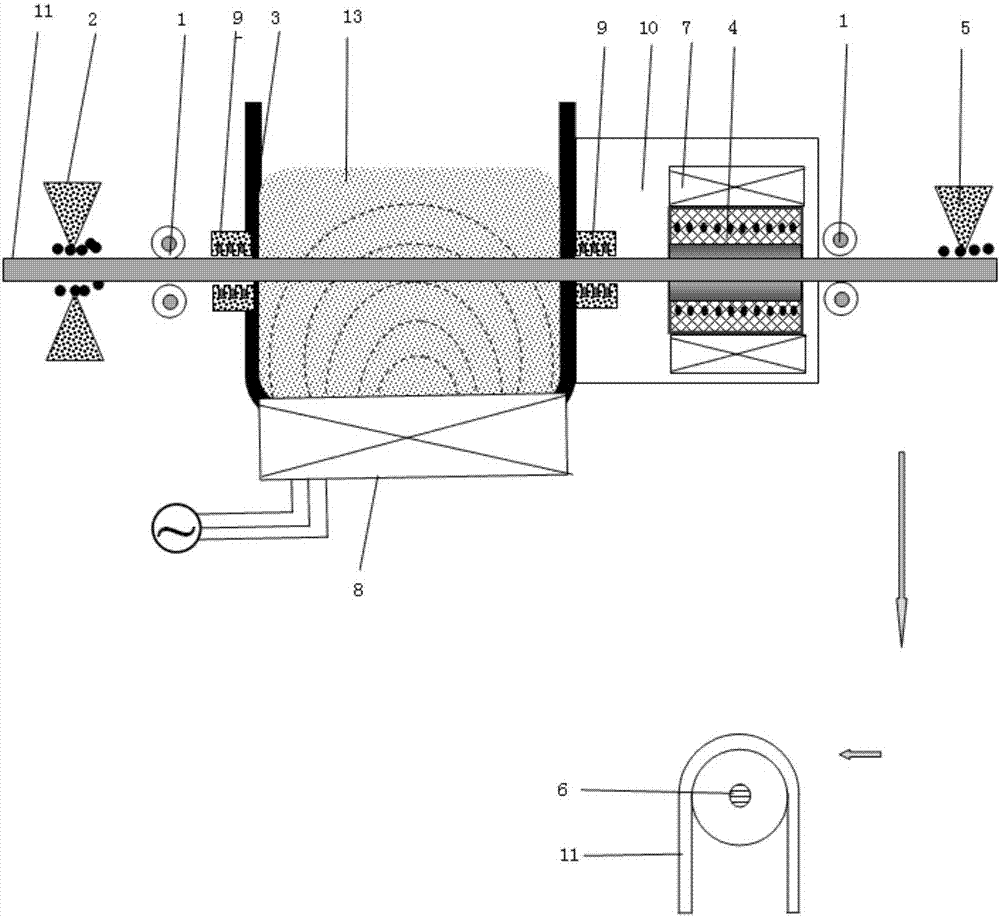

Method and device for preparing arc figured steel

ActiveCN106967940AFully contactedEvenly distributedHot-dipping/immersion processesProcess efficiency improvementRare earthRoll forming

The invention provides a method and device for preparing arc figured steel. An aluminum plating layer containing microelements such as rare earth is plated on the surface of the figured steel in an immersion manner, and an interface between the aluminum plating layer and the figured steel is alloyed through heat treatment under a magnetic field; then an obtained figured steel surface is subjected to shot blasting strengthening treatment; and then the figured steel obtained through surface strengthening treatment is directly subjected to cold roll forming, and arc joint steel used in special fields such as tunnel bridges is obtained. By means of the method and device for preparing the arc figured steel, the figured steel surface and immersion plating liquid can be in sufficient contact through electromagnetic stirring, meanwhile, the immersion plating liquid can be evenly distributed to prevent segregation, then the figured steel with the aluminum plating layer is subjected to heat treatment under the magnetic field, and due to the fact that a hot dip coating is formed on the surface and the shot blasting strengthening treatment is conducted, the good-mechanical-performance arc figured steel used in the special fields such as tunnel bridges is obtained. By means of the method and device for preparing the arc figured steel, operation is simple, the cost is low, the yield is high, and the good-mechanical-performance arc figured steel used in the special fields such as tunnel bridges can be continuously prepared. The method and device for preparing the arc figured steel belong to the field of metallurgy technology and material science.

Owner:GUIZHOU INST OF TECH

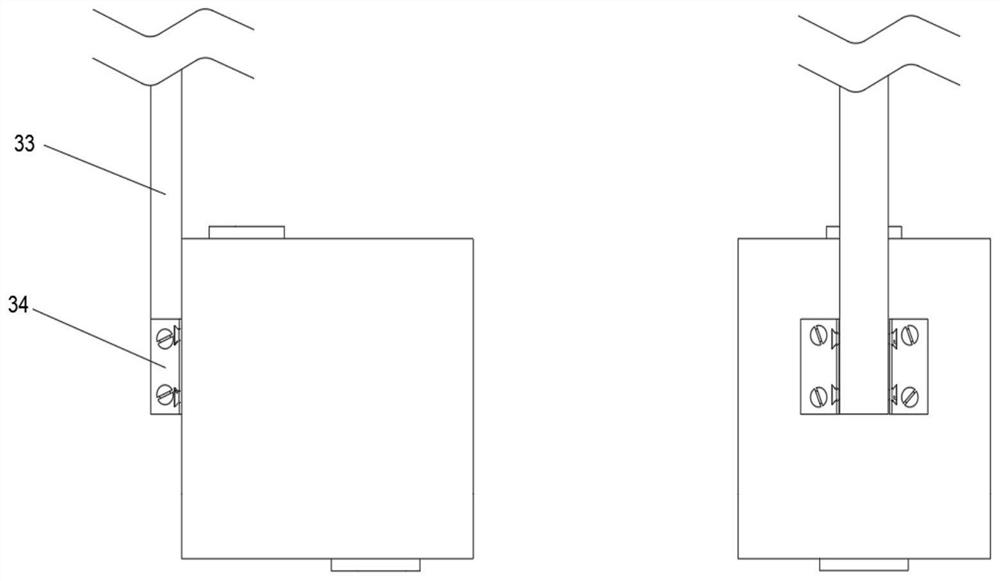

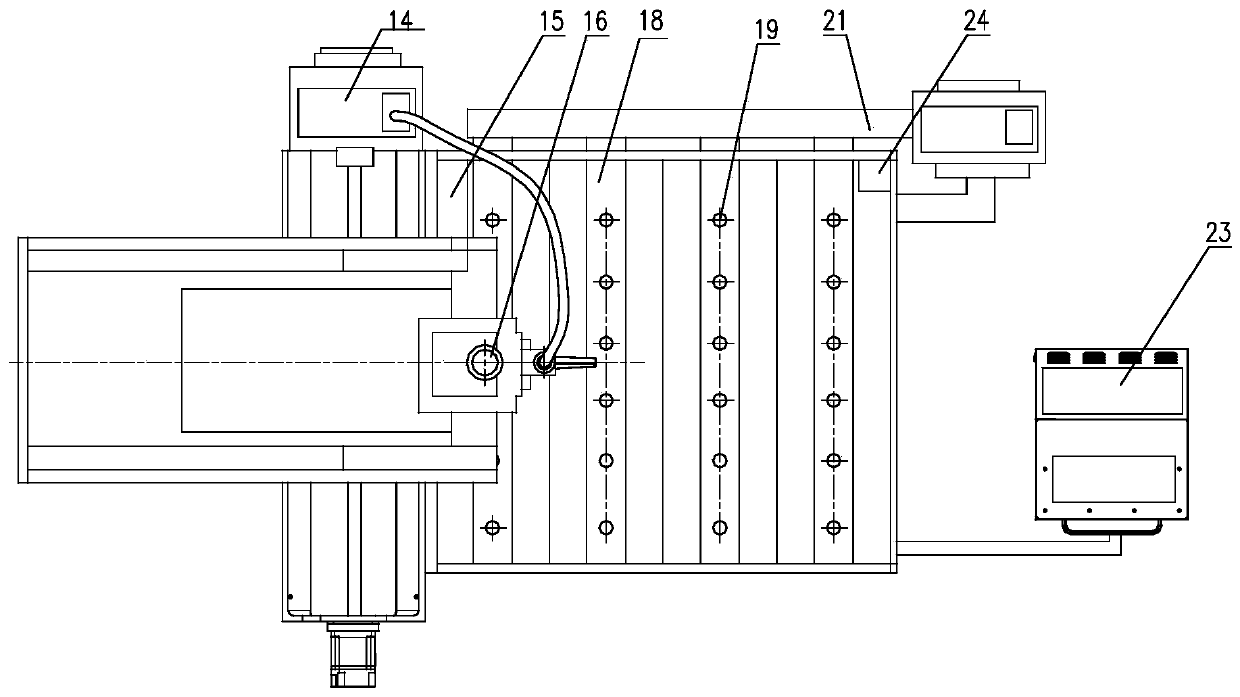

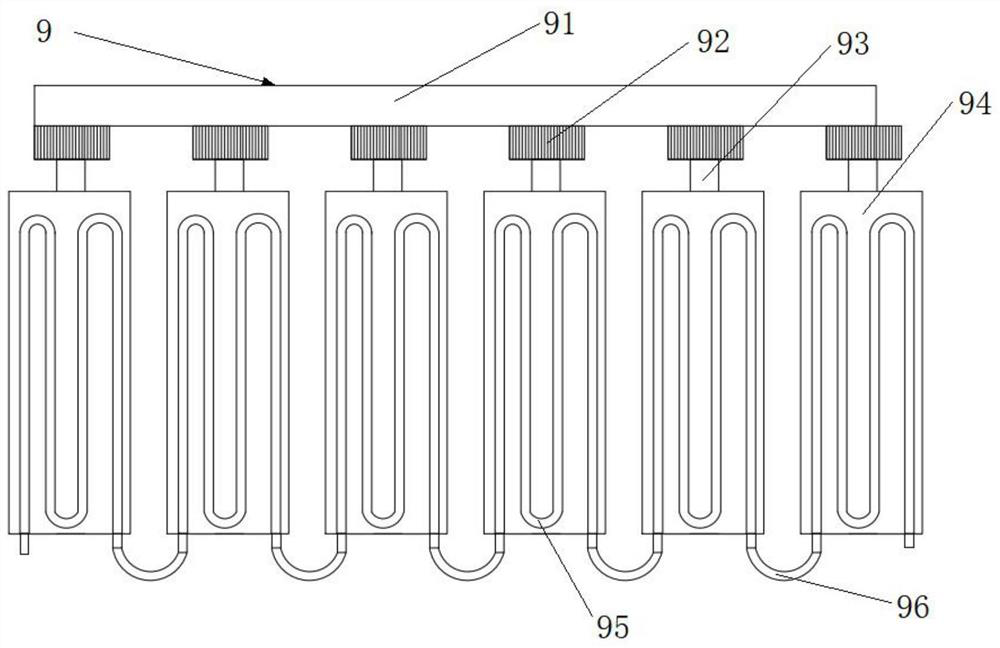

Temperature control assisted ultrasonic rolling surface strengthening device and method

ActiveCN114686647AImprove surface mechanical propertiesStrengthening the mechanical properties of metal surfacesHeat treatment process controlTemperature controlMetal machining

The invention relates to a temperature control assisted ultrasonic rolling surface strengthening device and a temperature control assisted ultrasonic rolling surface strengthening method, belongs to the technical field of metal processing, and solves the problem that the material performance of a processed metal workpiece cannot reach the expectation due to the fact that most existing surface ultrasonic rolling processes are carried out at normal temperature. The surface strengthening device comprises an ultrasonic rolling module and a temperature control module. The temperature control module comprises a cold field loading module and a thermal field loading module; the cold field loading module comprises a liquid nitrogen tank and a liquid nitrogen pipe and is used for cooling a metal workpiece to be treated; the thermal field loading module comprises a heating component, and the heating component is used for heating the metal workpiece; the ultrasonic rolling module comprises a machine tool and a machining tool and is used for achieving ultrasonic rolling machining of the metal workpiece. The surface ultrasonic rolling technology is carried out on the metal workpiece under different temperature conditions, and different material properties are obtained.

Owner:CHINA UNIV OF MINING & TECH

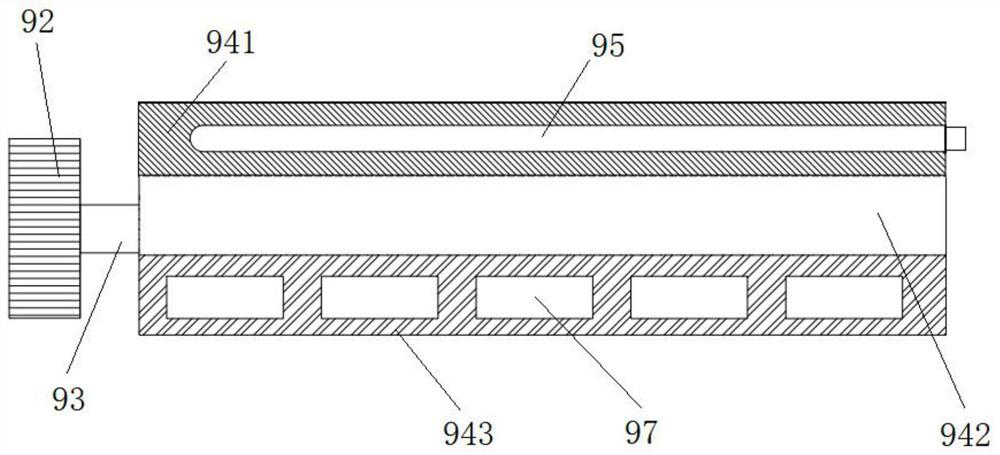

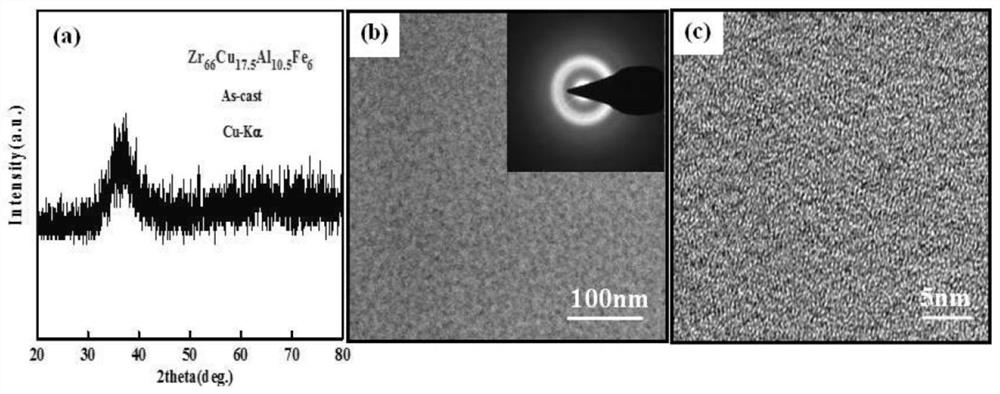

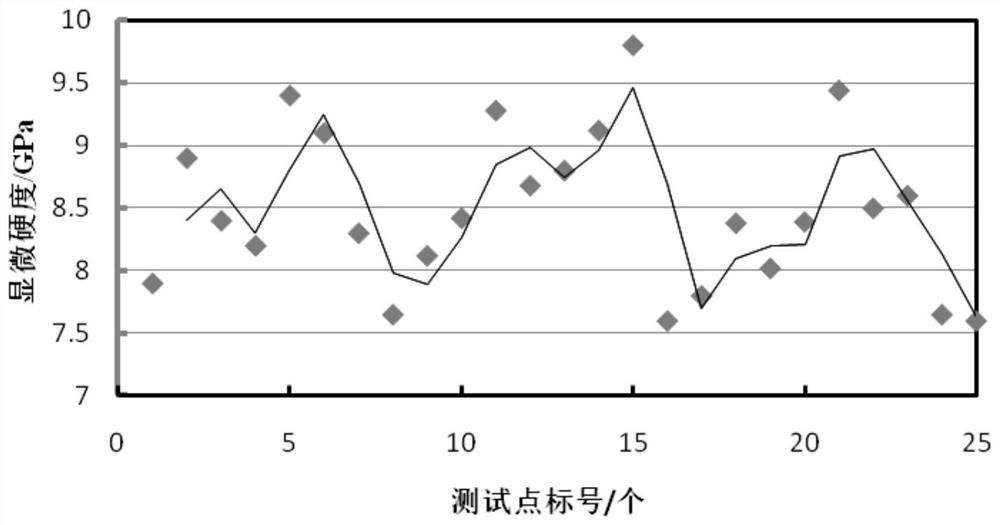

Zr-based amorphous coating, preparation process thereof and application of Zr-based amorphous coating in electric purification

ActiveCN113351372AHelps strengthenExtended service lifeDispersed particle separationPressure inorganic powder coatingMaterials scienceNanocrystalline composites

The invention discloses a Zr-based amorphous coating, a preparation process thereof and application of the Zr-based amorphous coating in electric purification. According to the application of the amorphous coating in electric purification, the amorphous coating is a Zr-based amorphous coating, and the Zr-based amorphous coating forms an amorphous-nanocrystalline composite structure in an electric purification environment, so the mechanical property is improved. According to the invention, a good anti-corrosion function is achieved; the cleaning is more convenient; moreover, when the Zr-based amorphous coating is applied to electric purification, an amorphous-nanocrystalline composite structure can be formed in an electric purification environment, so that the macroscopic mechanical property of the material is improved.

Owner:GREE ELECTRIC APPLIANCES INC

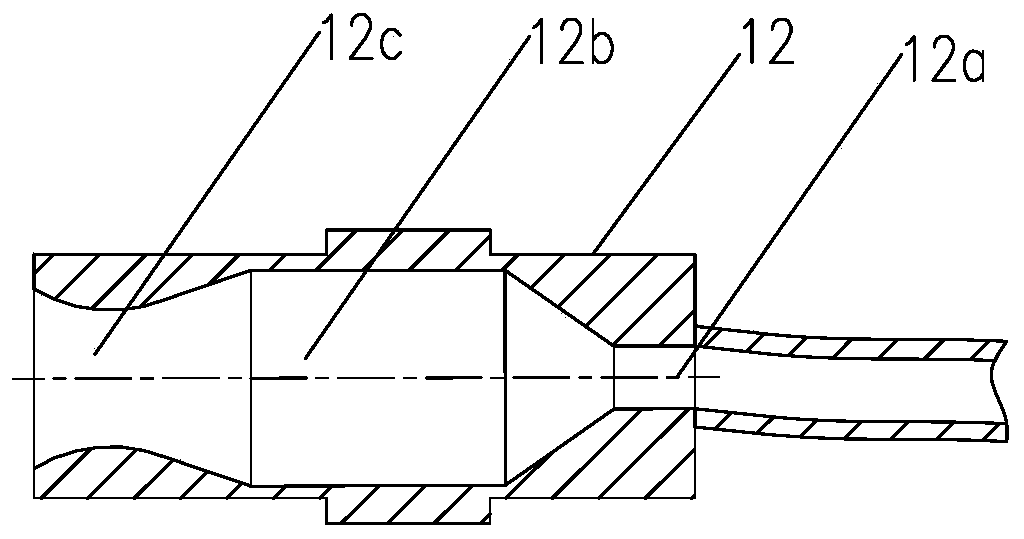

Tooth form cold extrusion forming method for blowing-carding roller

The invention relates to the technical field of processing of blowing-carding rollers and particularly relates to a tooth form cold extrusion forming method for a blowing-carding roller. The method comprises the steps as follows: a roller blank is clamped on cold extrusion equipment, the equipment is started, and the roller blank is rotated and is axially moved under the traction of a power force at the same time; cold heads on the left and the right sides of the roller blank extrude the roller blank continuously under the guide of a knife rest; different cold heads are adopted for different tooth forms of rollers, and roller grooves can be saw-shaped teeth, circular arc-shaped teeth or trapezoidal teeth and are formed by exchanging the cold heads to perform extrusion to the periphery of the roller blank simultaneously. The method provided by the invention has the advantages of saving material, improving the production efficiency, obtaining a roller with ideal precision and roughness, and improving the mechanical property of the surface of the roller; and the method is suitable for a blowing-carding solid roller as well as for a hollow roller like a spinning machine.

Owner:CHANGZHOU BRATI TEXTILE MACHINERY

A kind of steel rim wheel surface treatment process

ActiveCN106222680BEfficient removalImprove surface mechanical propertiesFurnace typesMetallic material coating processesHigh resistanceShock resistance

The invention discloses a steel ring car wheel surface treatment process. The steel ring car wheel surface treatment process comprises the following steps of (1) cleaning, (2) surface preheating, (3) surface modification treatment, (4) cleaning and cold standing and (5) quenching treatment. The steel ring car wheel surface treated through the process has the high abrasion resistance, high hardness, high toughness and high shock resistance, subsequent quenching treatment is matched, the optimal quenching time and quenching temperature are optimized, and the tempering time and tempering temperature are adjusted, so that the impact toughness and hardness of a steel ring car wheel are improved; and inner hardness and outer hardness are balanced, the microhardness of the surface of a steel ring car wheel coating is quite high, the salt corrosion resistance and stress corrosion cracking resistance can be further improved. In addition, the fatigue resistance of the steel ring car wheel is greatly improved, the service life of the steel ring car wheel is prolonged, and the service life of the steel ring car wheel is prolonged by three to four times compared with untreated steel ring car wheels.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

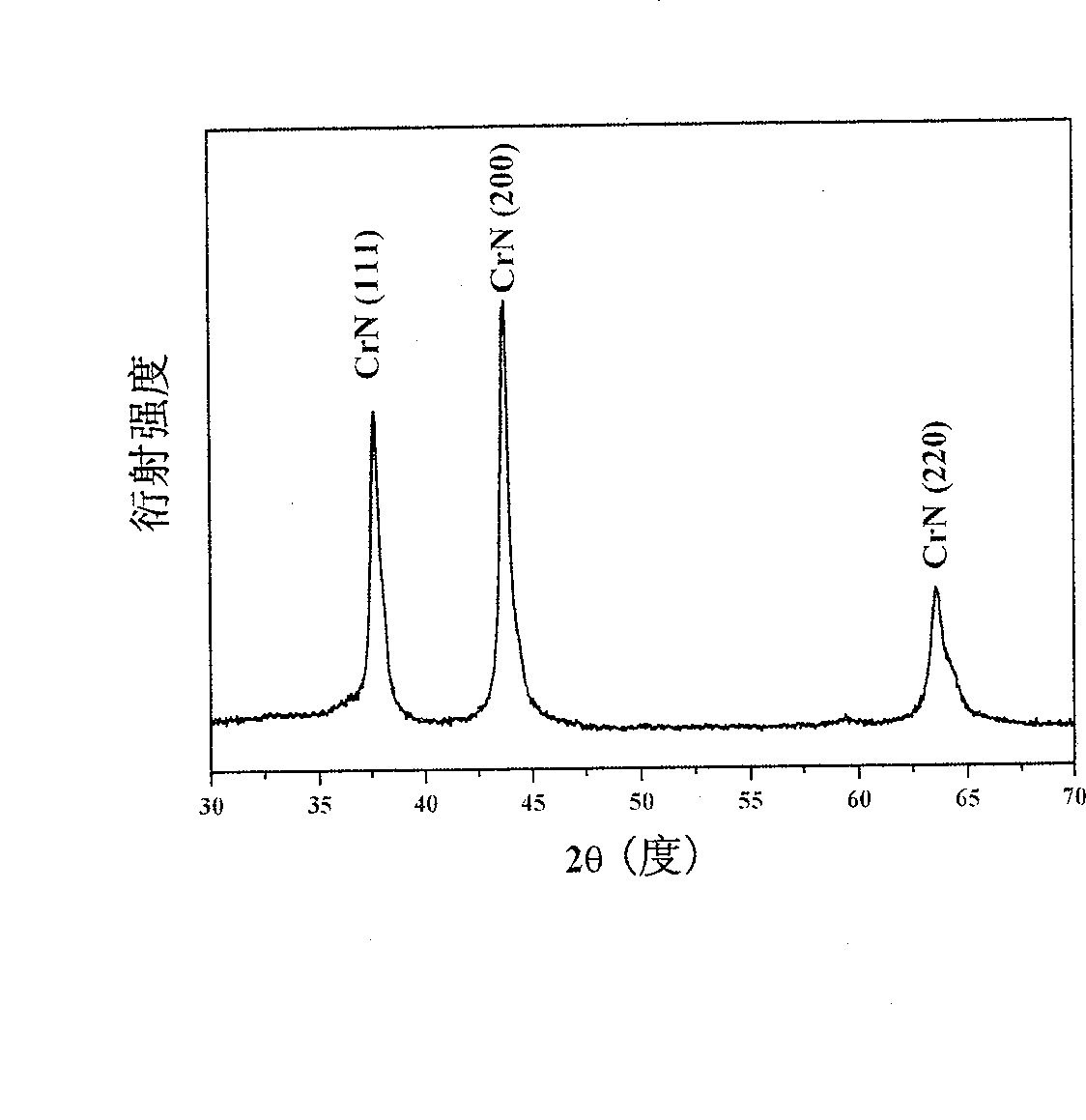

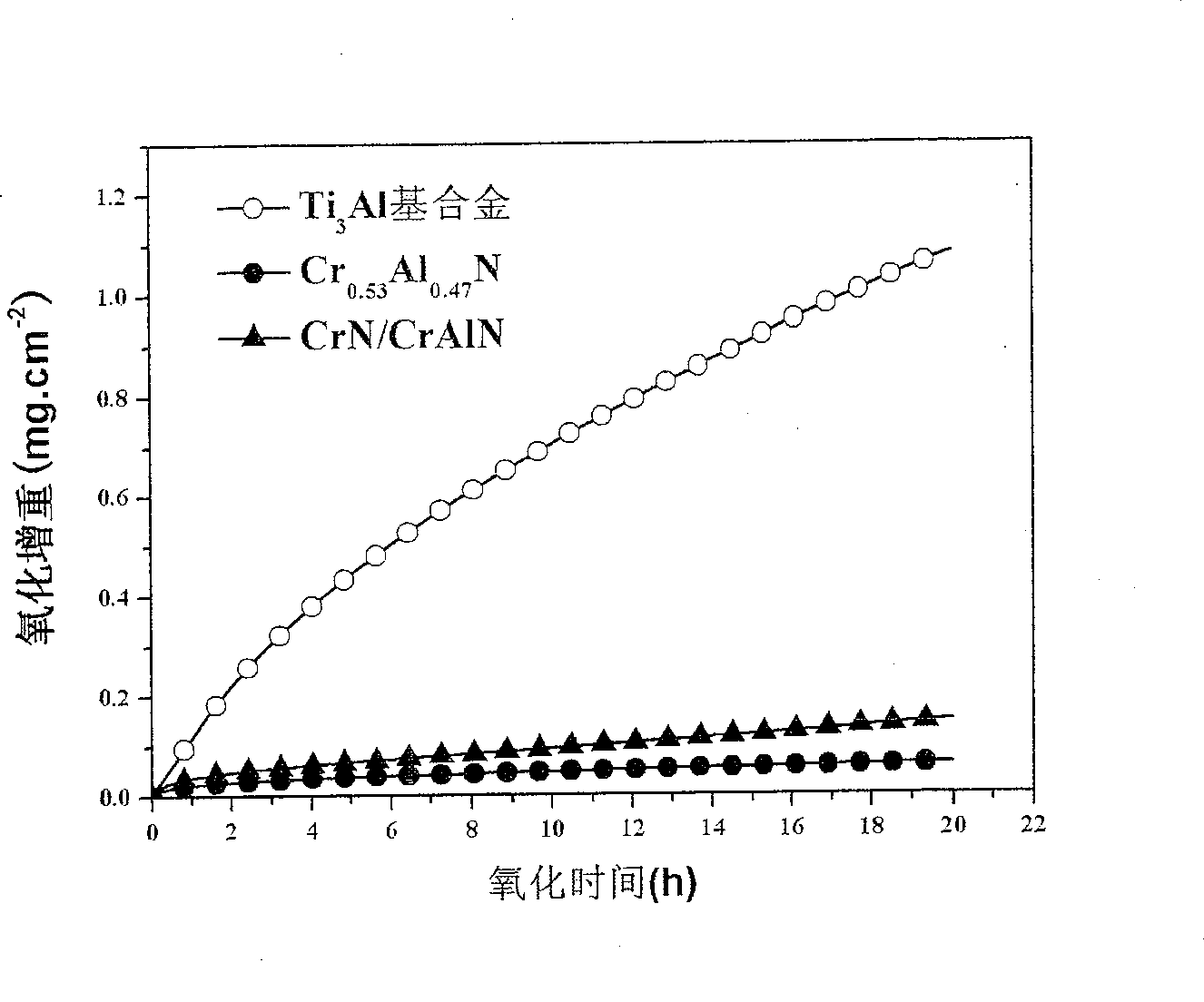

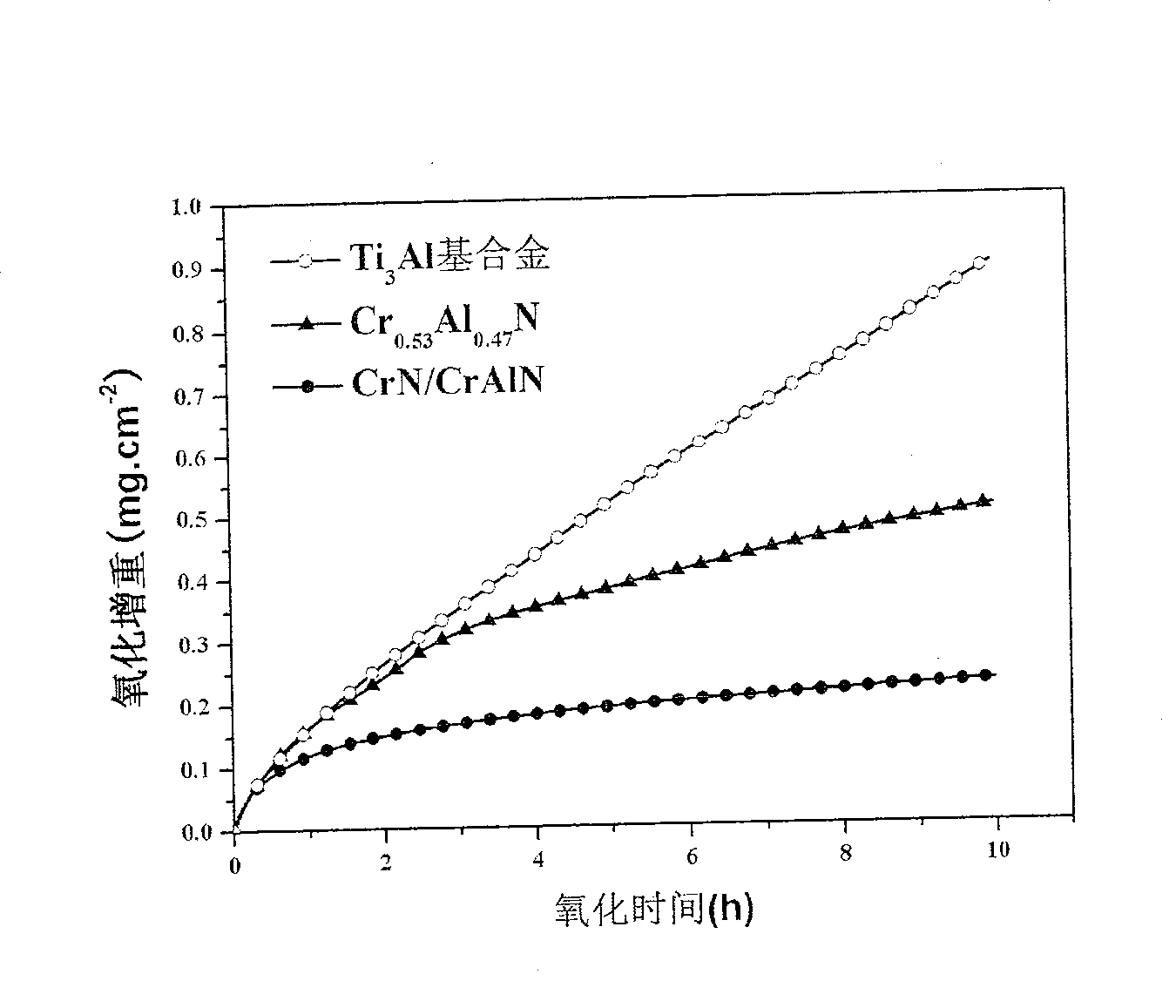

CrN/CrAlN protective coating capable of resisting high temperature corrosion in wide temperature range and preparing method

InactiveCN100482855CExcellent high temperature protection performanceEffective protectionVacuum evaporation coatingSputtering coatingRoom temperatureOxidation resistant

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

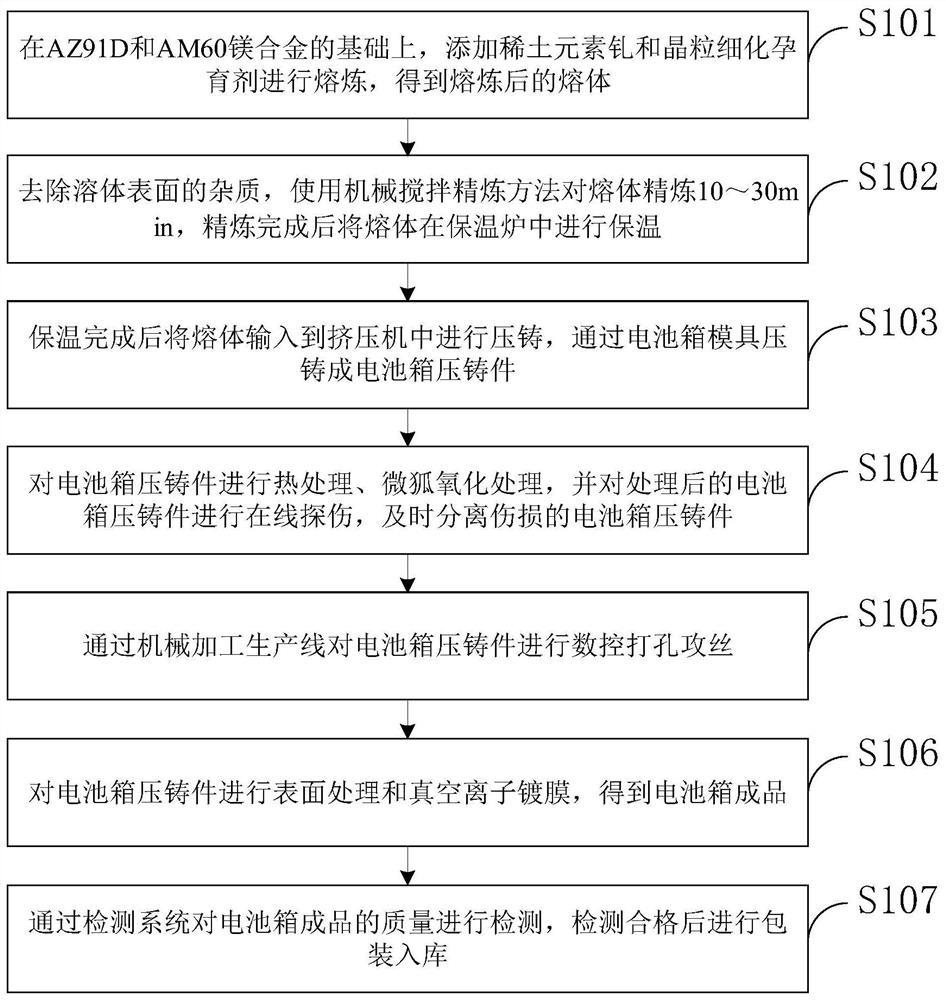

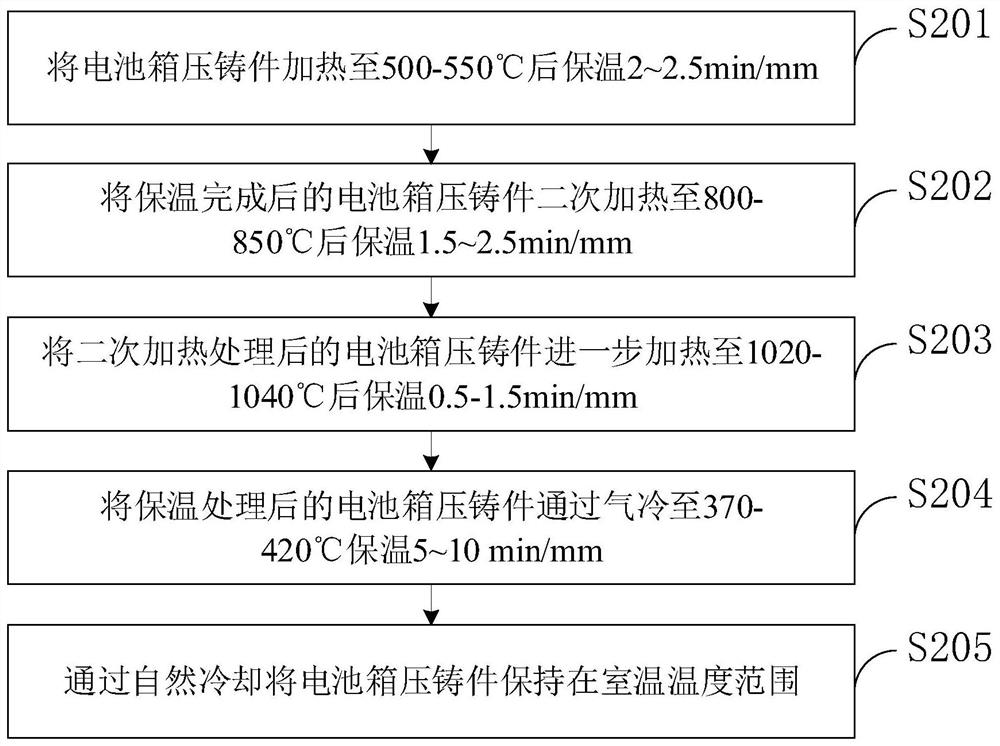

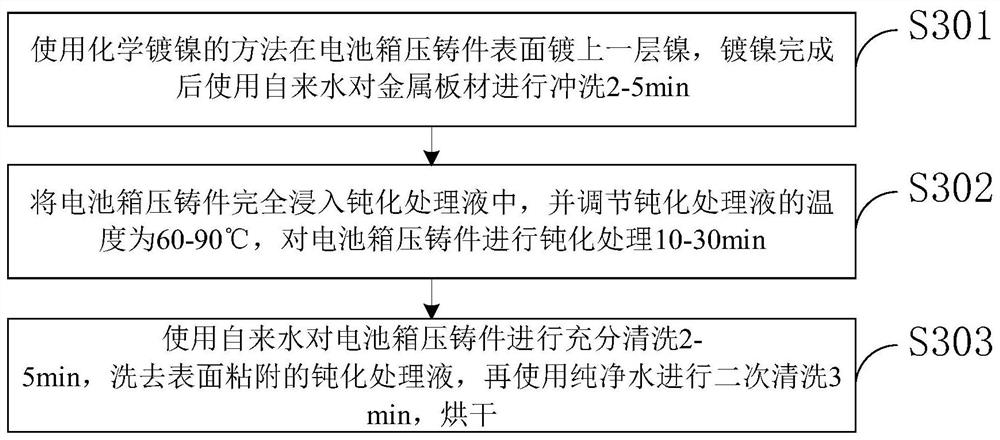

Preparation method of magnesium alloy new energy automobile battery box

PendingCN113275542AHigh strengthImprove toughnessAnodisationFurnace typesNumerical controlProduction line

The invention belongs to the technical field of mechanical manufacturing, and discloses a preparation method of a magnesium alloy new energy automobile battery box. On the basis of AZ91D and AM60 magnesium alloys, rare earth element gadolinium and a grain refinement inoculant are added for smelting, impurities on the surface of a melt are removed, the melt is refined and subjected to heat preservation, and a battery box die casting is formed through die casting of a battery box die; the battery box die casting is subjected to heat treatment and micro-fox oxidation treatment, the treated battery box die casting is subjected to online flaw detection, and the damaged battery box die casting is separated in time; numerical control punching and tapping are carried out on the battery box die casting through a machining production line; and surface treatment and vacuum ion plating are carried out on the battery box die casting to obtain a battery box finished product. The strength and toughness of the magnesium alloy are improved by adding the rare earth element gadolinium, the alloy is subjected to grain refining by adding the grain refining inoculant, and the plasticity of the magnesium alloy is improved, so that the qualified magnesium alloy is smelted, and subsequent treatment is facilitated by means of manners of surface pre-cleaning and the like.

Owner:陕西鸿泰元和镁业有限公司

Fiber oxyfluoridized-graphene composite polyimide powder paint and preparation method thereof

InactiveCN106800881AImprove hydrophobicityImprove interface performancePowdery paintsPotassium persulfateDispersity

The invention discloses a fiber oxyfluoridized-graphene composite polyimide powder paint which is prepared from the following raw materials in parts by weight: 2-4 parts of sodium myristate soap, 0.3-1 part of triethanolamine, 100-110 parts of polyimide, 10-14 parts of fluoridized graphite, 0.1-0.3 part of potassium persulfate, 1-2 parts of sodium nitrate, 0.1-0.4 part of potassium permanganate, 4-6 parts of sebacic acid, 0.5-1 part of phosphorus pentoxide, 0.1-0.2 part of dicyclohexylcarbodiimide, 0.1-0.2 part of 4-dimethylaminopyridine, 0.7-2 parts of hydroxyethyl cellulose, 3-4 parts of phosphorylated cotton, 0.5-1 part of calcium naphthenate, 0.8-1 part of saturated octadecacarbamide, 0.6-1 part of 1,2-dimethyl imidazole, 6-8 parts of dibutyl benzene dicarboxylate, 3-4 parts of titanium white, and right amounts of dimethylformamide, anhydrous ethanol and sulfuric acid. The hydroxyethyl cellulose and the like are added to improve the dispersity of the filler in the polymer and enhance the toughness of the finished product.

Owner:ANHUI RONGJIU OPTICAL FIBER COMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com