Method for improving mechanical properties of surface of non austenitic stainless steel

A mechanical property, stainless steel technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problem of limited improvement of surface mechanical properties, achieve excellent corrosion resistance, improve mechanical properties, and improve surface mechanical properties effect of nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

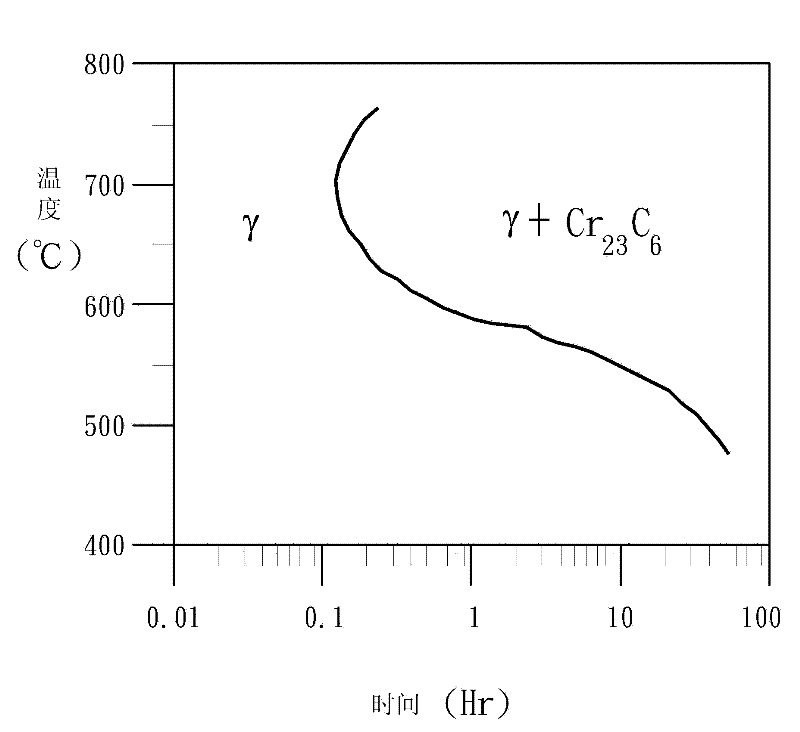

Problems solved by technology

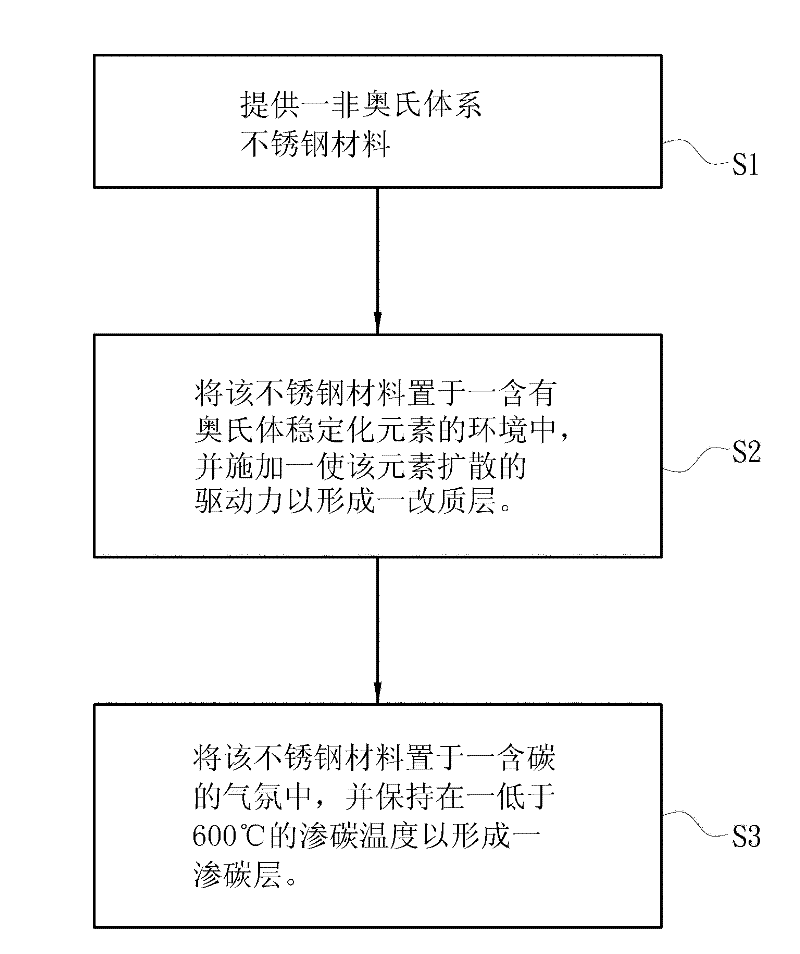

Method used

Image

Examples

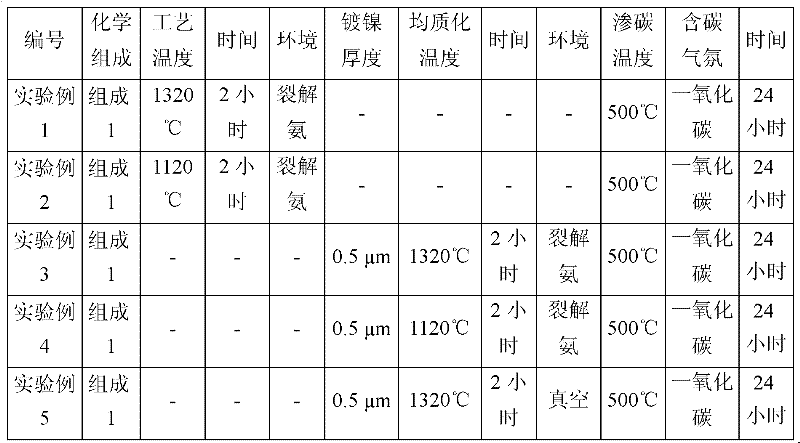

experiment example 1

[0050] In this experimental example, a stainless steel workpiece of composition 1 was first put into an atmosphere sintering furnace and passed through cracked ammonia, and kept at a process temperature of 1320°C for 2 hours to form a nitrogen-rich layer with a thickness of about 50 μm on the surface of the stainless steel workpiece. Then, the stainless steel workpiece is taken out from the atmosphere sintering furnace, and placed in a carburizing furnace, and carbon monoxide gas is passed through the furnace, and the temperature in the furnace is lowered to 500 ° C, and the temperature is maintained for 24 hours. The surface of the stainless steel workpiece A carburized layer with a thickness of about 21 μm can be formed, the surface hardness is about HV 650, and the core hardness is about HV 370. The corrosion resistance is qualified and can withstand 40 hours in the salt spray test.

experiment example 2

[0052] In this experimental example, a stainless steel workpiece of composition 1 was first put into an atmosphere sintering furnace and passed through cracking ammonia, and kept at a process temperature of 1120°C for 2 hours to form a nitrogen-rich layer with a thickness of about 35 μm on the surface of the stainless steel workpiece. Then, the stainless steel workpiece is taken out from the atmosphere sintering furnace, placed in a carburizing furnace, and carbon monoxide gas is passed through the furnace, and the temperature in the furnace is lowered to 500 ° C, and the temperature is maintained for 24 hours. The stainless steel workpiece A carburized layer with a thickness of about 20 μm can be formed on the surface. The surface hardness is about HV 653, and the core hardness is about HV 365. The corrosion resistance is qualified and can withstand 40 hours in the salt spray test.

experiment example 3

[0054] In this experimental example, a stainless steel workpiece with composition 1 is used. A nickel layer with a thickness of about 0.5 μm is first plated on the surface of the stainless steel workpiece, and then a homogenization step is performed. The stainless steel material is put into an atmosphere sintering furnace, and cracked ammonia is passed through it and Raise the temperature to 1320°C, hold the temperature for 2 hours, then lower the atmosphere sintering furnace to room temperature, then put the stainless steel material into the carburizing furnace, pass through carbon monoxide gas and raise the temperature of the carburizing furnace to 500°C, and hold the temperature for 24 hours A carburized layer with a thickness of about 25 μm can be formed on the surface of the stainless steel workpiece. The surface hardness is about HV 710, and the core hardness is about HV 350. The corrosion resistance is qualified and can withstand 42 hours in the salt spray test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com