Tooth form cold extrusion forming method for blowing-carding roller

A technology of blowing-carding roller teeth and cold extrusion, which is applied in the field of cold-extrusion forming of blowing-carding roller teeth, can solve the problems of no improvement in mechanical properties, achieve improved mechanical properties, improve fatigue strength, and save processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

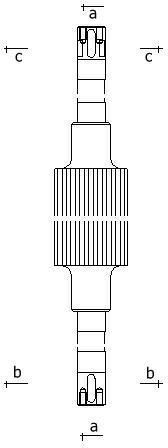

Image

Examples

Embodiment Construction

[0014] The following specific implementation methods are only for better illustration of this patent, and do not limit the rights of the patent application.

[0015] A cold extrusion forming method for blowing and combing roller teeth. The roller blank is clamped on the cold extrusion equipment, the equipment is started, and the power traction roller parts rotate and move axially at the same time; the left and right sides of the roller blank The cold head is continuously extruding the roller blank under the guidance of the tool holder. The roller with different tooth shape adopts different cold head. The groove shape of the roller can be saw tooth, arc tooth or trapezoidal tooth. The groove shape of the roller is extruded on the periphery of the workpiece at the same time.

[0016] First, clamp the roller blank on the cold extrusion equipment, rotate under the traction of the power, and also move axially at the same time, the cold heads on the left and right sides of the rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com