A kind of steel rim wheel surface treatment process

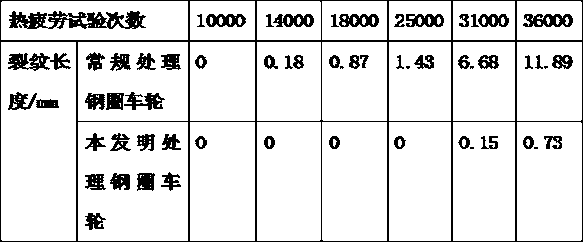

A surface treatment and wheel technology, used in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc., can solve the problems of large use environment span, can not meet long-term work and other problems, achieve short cleaning time, dimensional stability, dry friction The effect of coefficient reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A surface treatment process for steel rim wheels includes the following steps:

[0019] 1) Cleaning

[0020] Put the rim wheel in the cleaning agent, soak it for 20 minutes, then use ultrasonic vibration at 36-40℃ for 15 minutes, then boil the cleaning agent to boiling, let the rim wheel soak in the boiling cleaning agent for 30 minutes Minutes later, take out the steel rim wheel and dry it at 42-48°C; the cleaning agent is prepared from the following parts by weight of raw materials: sodium lauryl sulfate 4, sodium N-acyl glutamate 3, sodium lactate 2 , Sodium lignosulfonate 1, alkyl alcohol amide 2, triethanolamine 4, sodium laurate 0.1, sodium citrate 2, turpentine 1, isopropanol 0.2, chlorophyll 0.01, capsaicin 0.01, water 70;

[0021] 2) Surface preheating

[0022] Put the rim wheel in a vacuum and adjust the temperature to 36-40°C. After 50s, put the rim wheel in a nitrogen environment at a temperature of 220-230°C and heat preservation for 30-40 minutes;

[0023] 3) Surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com