Method and device for preparing arc figured steel

A special-shaped steel and arc-shaped technology, which is applied in the fields of metallurgical technology and material science, can solve the problems that it is difficult to prepare curved special-shaped steel, reduce the yield of curved special-shaped steel products, and crack, so as to increase corrosion resistance and mechanical properties , weaken cracking behavior, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

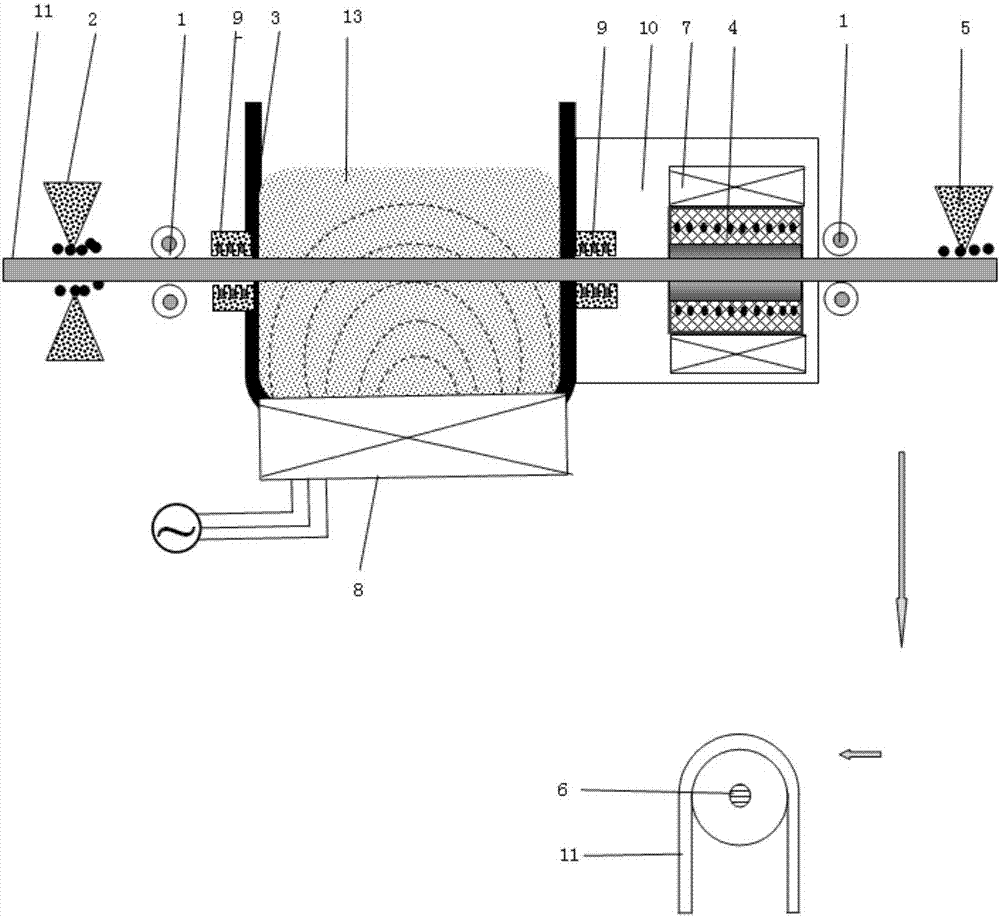

[0029] see figure 1 , the present embodiment provides a device for preparing arc-shaped special-shaped steel, including a conveying roller 1 for conveying the original special-shaped steel, and a shot blasting machine 2, a hot-dip coating pool 3, and a heat treatment furnace are sequentially arranged on the conveying path of the original special-shaped steel 4. The surface strengthening device 5 and the cold bending machine 6, the heat treatment furnace 4 is correspondingly provided with a magnetic field generator 7, and the magnetic field generator 7 acts on the heat treatment area of the heat treatment furnace 4, and the hot-dip coating pool 3 is correspondingly provided with an electromagnetic oscillation device 8 , the shot blasting machine 2 and the heat treatment furnace 4 are respectively arranged on opposite sides of the hot-dip coating pool 3, and the opposite sides of the hot-dip coating pool 3 are provided with electromagnetic sealing valves 9, and the heat treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com