Laser additive-polishing integrated machining method and device

A technology of laser additive and additive forming, which is applied in the direction of additive processing, laser welding equipment, metal processing equipment, etc., to achieve the effect of improving surface accuracy, improving surface mechanical properties, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

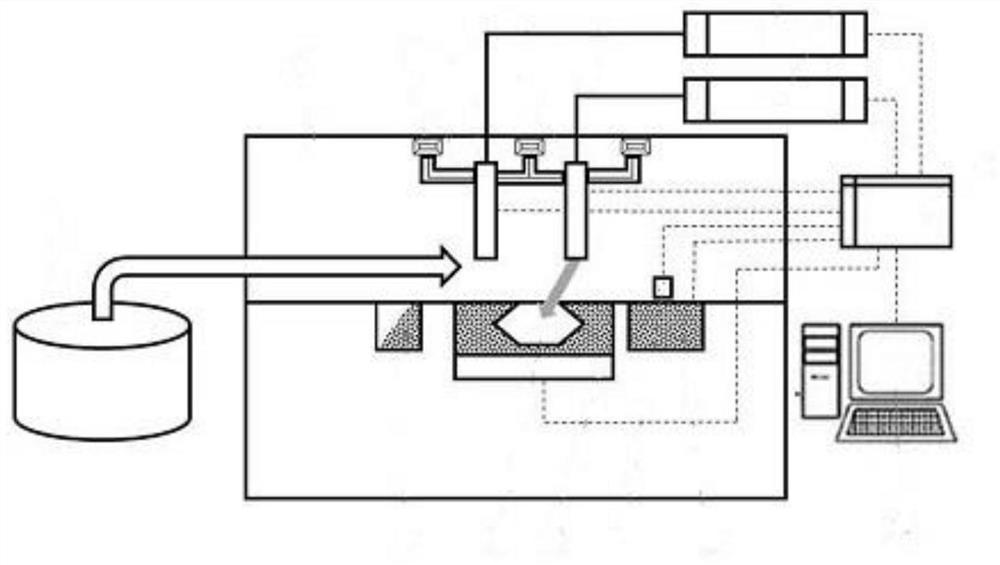

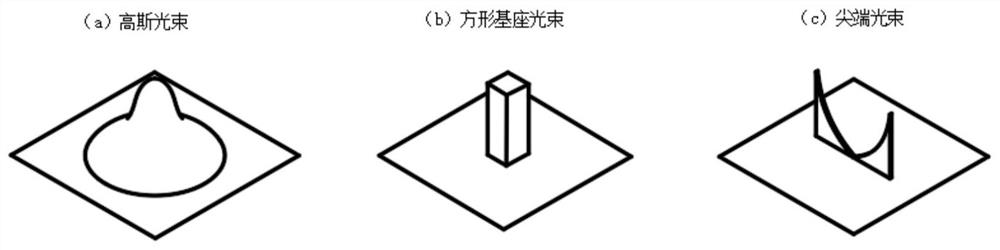

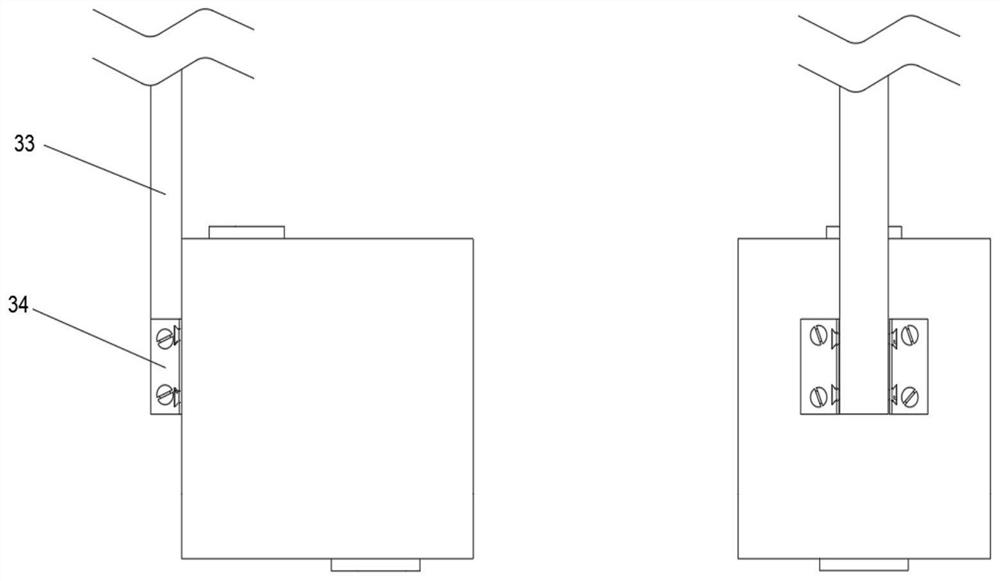

[0031] refer to image 3 , Figure 4 , Figure 5 , the reflector 22 and the holographic optical element 31 are sequentially installed inside the cylinder 19, and the circular incident laser beam 20 from figure 2 The light entrance 21 shown is incident on the reflector 22, and the reflector 22 reflects the circular incident beam 20 to the surface of the holographic optical element 31, and forms two focused beams through diffraction by the holographic optical element 31: focused beam I30, focused beam II29, The focused beam I30 and the alloy wire fed by the wire feed tube 27 are additively manufactured on the substrate, and the focused beam II29 is simultaneously laser polished.

[0032] During operation, the circular incident laser beam 20 is reflected to the surface of the holographic optical element 31 by the reflector 22, and is diffracted by the holographic optical element 31 to form two focused beams: focused beam I30 and focused beam II29. At this time, the wire feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com