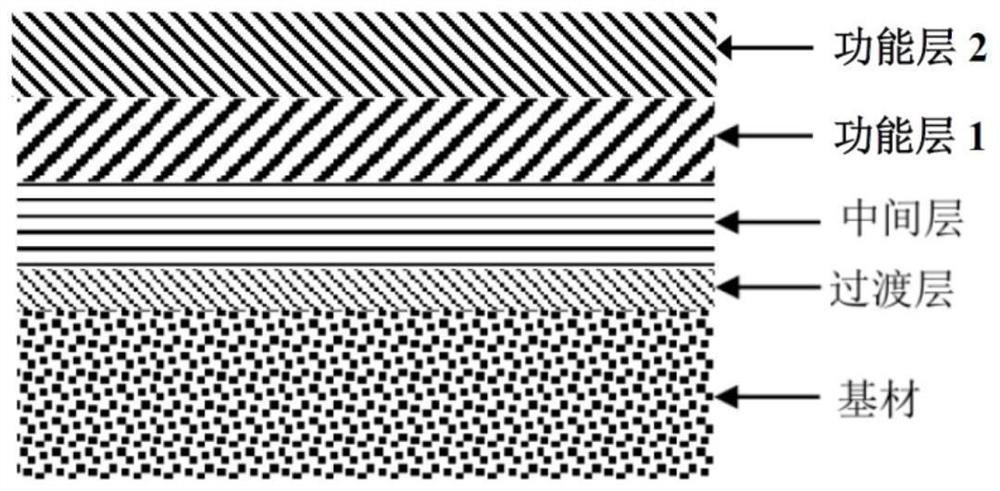

Preparation method of CrAlVSiN coating

A coating and functional layer technology, applied in the field of CrAlVSiN coating preparation, can solve the problems of poor oxidation resistance, weak wear resistance, short service life, etc., to reduce hardness difference, improve surface cleanliness, and reduce adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] After brushing the surface of the high-speed steel substrate with a soft brush, it is cleaned by 1005A organic solvent cleaning agent and anhydrous ethanol ultrasonically for 15 minutes each, and dried by hot air at 50°C for 10 minutes before being put into the furnace. Heating to 400°C, vacuuming to 3.0×10 -3 Below Pa, keep warm for 1.5 hours. Introduce Ar gas to make the vacuum degree 0.8Pa, set the bias voltage of the workpiece turret to -1200V, use the Hall ion source to activate the surface of the substrate, and the treatment time is 30min. Adjust the argon gas flow rate to 300 sccm, the bias voltage to -800V, turn on the Cr target, adjust the target current to 3A and carry out metal ion bombardment for 15 minutes. Using DC magnetron sputtering technology, open the nitrogen valve, send nitrogen 400sccm, adjust the flow rate of argon gas to 400sccm, adjust the bias voltage to -150V, open the Ti target and Al target at the same time, the target current is 3A, and de...

Embodiment 2

[0042] After brushing the surface of the high-speed steel substrate with a soft brush, it is cleaned by 1005A organic solvent cleaning agent and anhydrous ethanol ultrasonically for 15 minutes each, and dried by hot air at 50°C for 10 minutes before being put into the furnace. Heating to 400°C, vacuuming to 3.0×10 -3 Below Pa, keep warm for 1.5 hours. Oxygen was introduced to make the vacuum degree 0.1Pa, the bias voltage of the workpiece turret was set to -1200V, and the surface of the substrate was activated by Hall ion source, and the treatment time was 30min. Turn off the oxygen, feed the argon, adjust the argon flow rate to 300sccm, the bias voltage to -800V, turn on the Ti target, adjust the target current to 3A and carry out metal ion bombardment for 15min. Using pulse magnetron sputtering technology, open the nitrogen valve, send nitrogen 400sccm, adjust the flow of argon gas to 400sccm, adjust the bias voltage to -150V, open the Ti target and Al target at the same ti...

Embodiment 3

[0046] After brushing the surface of the high-speed steel substrate with a soft brush, it is cleaned by 1005A organic solvent cleaning agent and anhydrous ethanol ultrasonically for 15 minutes each, and dried by hot air at 50°C for 10 minutes before being put into the furnace. Heating to 400°C, vacuuming to 3.0×10 -3 Below Pa, keep warm for 1.5 hours. Oxygen was introduced to make the vacuum degree 0.1Pa, the bias voltage of the workpiece turret was set to -1200V, and the surface of the substrate was activated by Hall ion source, and the treatment time was 30min. Turn off the oxygen, feed in argon, adjust the argon gas flow rate to 300 sccm, the bias voltage to -1000V, turn on the Ti target, adjust the target current to 3A and carry out metal ion bombardment for 30 min. Using DC magnetron sputtering technology, open the nitrogen valve, send nitrogen 400sccm, adjust the flow rate of argon gas to 400sccm, adjust the bias voltage to -150V, open the Ti target and Al target at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com