A solid lubrication coating preparing method utilizing laser thermal-mechanical coupled texturing

A technology of solid lubricating coating and thermal coupling, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as friction and wear failure, achieve simple operation, easy industrialization, and solve lubrication and wear problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example example 1

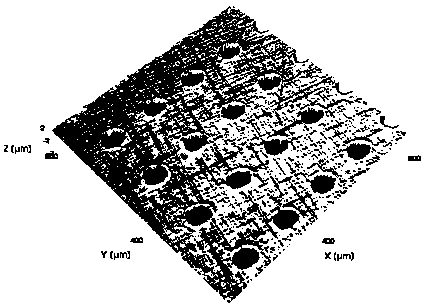

[0029] 1. Polish the surface of the bearing substrate to ensure that the surface roughness Ra of the substrate is lower than 0.1 μm. The SPI nanofiber laser is used for laser microtexture treatment on the surface. The texture morphology is pits. The pit parameters are 100 μm in diameter, 20 μm in depth, and 30% in texture density. The laser parameters are power of 50W, pulse width of 500ns, and the same point is cycled multiple times for processing, and the number of repetitions is 10 times. The shape of the pit is as figure 1 shown. Use a polishing machine to post-process the substrate to remove slag and flash.

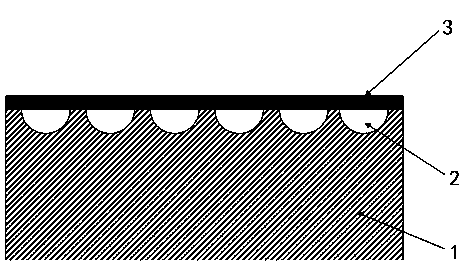

[0030] 2. Pre-coat a layer of solid lubricating powder on the surface of the substrate. The powder is Gr (nano): MoS2 (nano): CNTs mixed at 4:1:0.4. The solid lubricant covers the surface with a thickness of 100 μm. Schematic such as figure 2 shown.

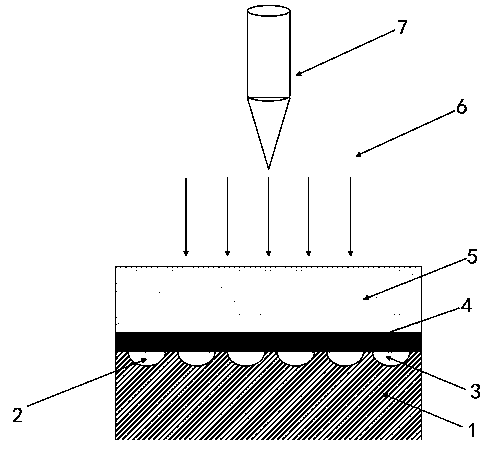

[0031] 3. Apply black paint on the surface of the substrate to form an absorption layer, wrap the substrate co...

example example 2

[0035] 1. Polish the surface of the engine plunger pump substrate to ensure that the surface roughness Ra of the substrate is lower than 0.1 μm. The SPI nanofiber laser is used for laser micro-texture treatment on the surface. The texture morphology is pits. The pit parameters are 50 μm in diameter, 10 μm in depth, and 20% of the texture density. The laser parameters are 30W power, 100ns pulse width, and the same point is cycled multiple times for processing, and the number of repetitions is 5 times. Schematic such as figure 1 As shown, the shape of the pit is as figure 2 shown. Use a polishing machine to post-process the substrate to remove slag and flash.

[0036] 2. Pre-coat a layer of solid lubricating powder on the surface of the substrate. The powder is mixed with nano-indium powder and nano-nickel powder at a ratio of 1:1. The solid lubricant covers the surface with a thickness of 0.5 μm. Schematic such as image 3 shown.

[0037] 3. Apply black paint on the sur...

example example 3

[0041] 1. Polish the surface of the engine valve lifter to ensure that the surface roughness Ra of the substrate is lower than 0.1 μm. The SPI nanofiber laser is used for laser micro-texture treatment on the surface. The texture morphology is pits. The pit parameters are 200 μm in diameter, 50 μm in depth, and 50% of the texture density. The laser parameters are as follows: the power is 100W, the pulse width is 2000ns, and the same point is cycled multiple times for processing, and the number of repetitions is 15 times. Schematic such as figure 1 As shown, the shape of the pit is as figure 2 shown. Use a polishing machine to post-process the substrate to remove slag and flash.

[0042] 2. Pre-coat a layer of solid lubricating powder on the surface of the substrate, the powder is Gr (nano): MoS2 (nano): CNTs: WS 2 (Nano): Nano indium powder and nano nickel powder are mixed according to 4:1:0.4:1:1:1. The solid lubricant covers the surface with a thickness of 2mm. Schemat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com