Temperature control assisted ultrasonic rolling surface strengthening device and method

A technology of ultrasonic rolling and surface strengthening, applied in the direction of heat treatment process control, heat treatment equipment, manufacturing tools, etc., can solve the problem of metal workpiece material performance not meeting expectations, etc. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

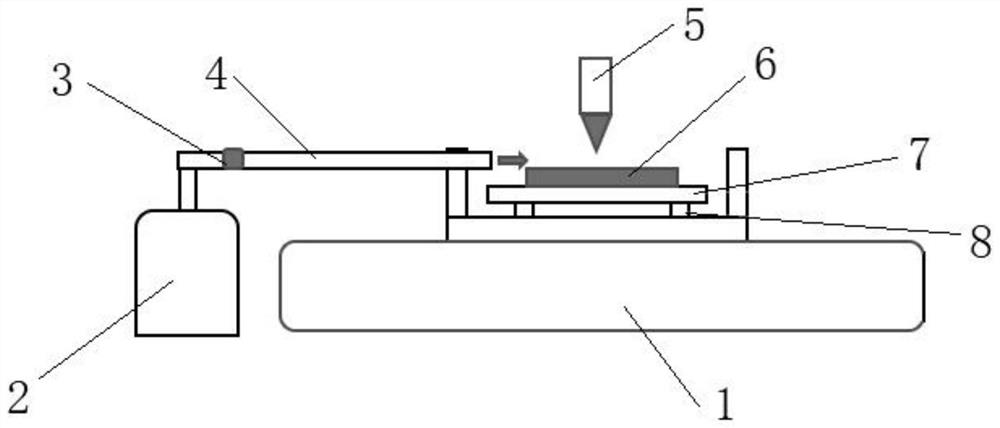

[0045] A specific embodiment of the present invention discloses a temperature control-assisted ultrasonic rolling surface strengthening device, comprising: an ultrasonic rolling module and a temperature control module; the temperature control module includes: a cold field loading module and a hot field loading module; The cold field loading module includes a liquid nitrogen tank 2 and a liquid nitrogen tube 4 for cooling the metal workpiece to be processed; the thermal field loading module includes a heating member, and the heating member is used for heating the metal workpiece 6; the The ultrasonic rolling module includes: a machine tool 1 and a machining tool 5 , which are used to realize the ultrasonic rolling process of the metal workpiece 6 .

[0046] Further, the ultrasonic rolling process is performed by applying a rolling load to the metal workpiece through an ultrasonic rolling module.

[0047] In a specific embodiment of the present invention, the ultrasonic rolling ...

Embodiment 2

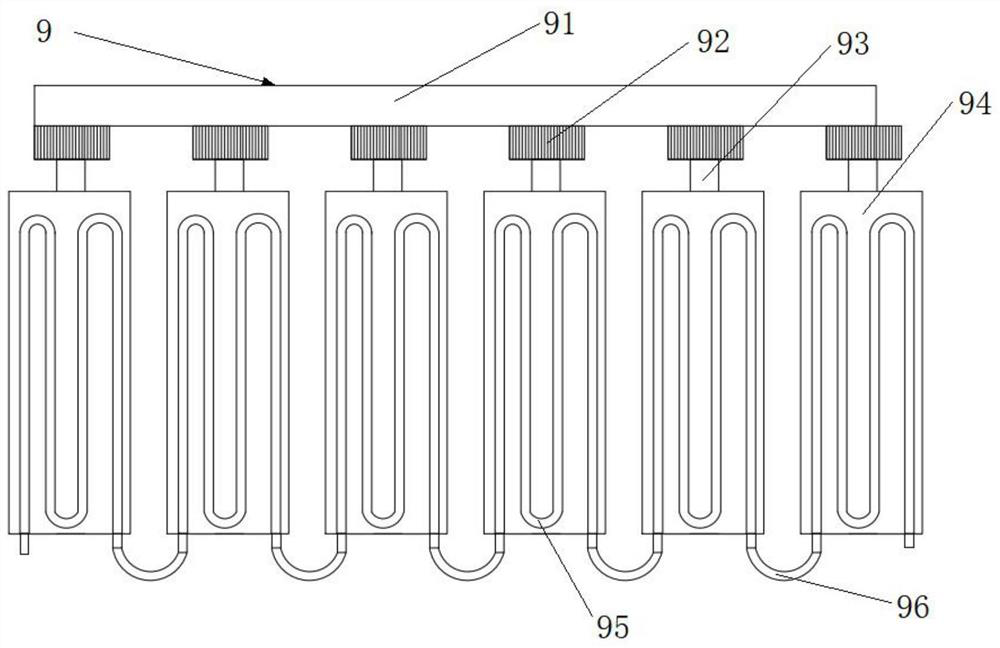

[0071] In a specific embodiment of the present invention, on the basis of Embodiment 1, the surface strengthening device for temperature control-assisted ultrasonic rolling is provided with a temperature control conversion mechanism 9 that can convert cold field loading or hot field loading.

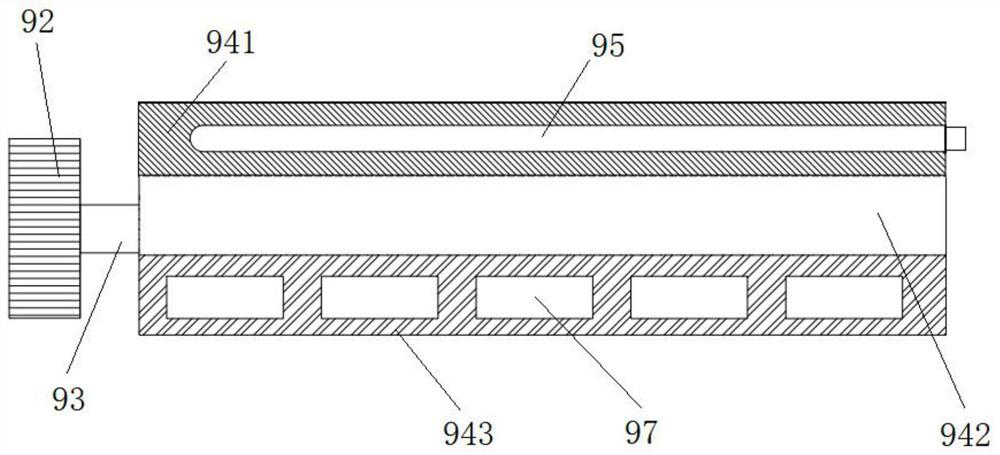

[0072] like Figure 2-4 As shown, the temperature control conversion mechanism 9 includes: the temperature control conversion mechanism 9 includes: a temperature control assembly 94 and a rotating shaft 93; the temperature control assembly 94 includes: a cooling layer 941 and a heating layer 943; the rotating shaft 93 can drive the temperature control assembly 94 to rotate, thereby switching the cooling layer 941 or the heating layer 943 to contact the metal workpiece 6 .

[0073] Further, the rotating shaft 93 is fixedly connected with the rotating wheel 92, and the rotating wheel 92 is driven to rotate by a motor.

[0074] Further, the rotating wheel 92 is rotatably mounted on the fix...

Embodiment 3

[0088] A surface strengthening method for temperature-controlled assisted ultrasonic rolling, using the surface strengthening device for temperature-controlled assisted ultrasonic rolling described in Embodiment 1 or 2 to perform ultrasonic rolling on a metal workpiece, specifically, comprising the following steps:

[0089] Step S1: select a cold field loading module or a hot field loading module to adjust the temperature of the metal workpiece 6 according to process requirements;

[0090] Step S2: monitor the surface temperature of the metal workpiece 6 through a temperature sensor;

[0091] Step S3: When the metal workpiece 6 reaches the preset temperature, the surface of the metal workpiece 6 is ultrasonically rolled by the ultrasonic rolling module.

[0092] In the step S1, the metal workpiece 6 is placed on the cold field loading module or the hot field loading module.

[0093] Further, when the temperature control-assisted ultrasonic rolling surface strengthening device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com