Method for preparing high-wear resistance paper-based friction material

A paper-based friction material, high wear resistance technology, applied in paper coatings, papermaking, textiles and papermaking, etc., can solve the problems of reduced friction stability, poor mechanical properties and wear resistance of paper-based friction materials, etc. The degree of structural compactness, the improvement of mechanical properties, and the effect of improving the densification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

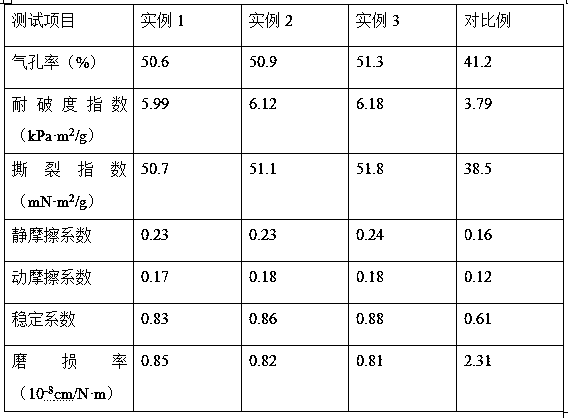

Examples

Embodiment Construction

[0022] In terms of parts by weight, weigh 3 to 5 parts of bamboo fiber, 20 to 25 parts of propylene glycol, 0.5 to 0.8 parts of citric acid particles, and 7 to 8 parts of ferrous sulfate solution with a mass fraction of 5 to 8% and put them into a beaker. Mix and stir with the agitator at a speed of 300-350r / min for 3-4 hours. After the stirring is completed, filter to obtain a filter cake, wash the filter cake with distilled water for 3-5 times, and then put it in an oven to dry for 100-120 minutes to obtain a dry product; Immerse the product in a conical flask with distilled water, add dropwise a copper sulfate solution with a mass fraction of 30 to 40% of the dry product and a mass fraction of 10 to 15% into the conical flask, place the conical flask in an ultrasonic oscillator, and Oscillate for 3 to 4 hours at a frequency of 40 to 45 kHz. After the oscillation is over, filter the filter residue and wash the filter residue 3 to 5 times with distilled water; Put the mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com