Zr-based amorphous coating, preparation process thereof and application of Zr-based amorphous coating in electric purification

A technology of amorphous coating and preparation process, which is applied in the direction of electrode cleaning, electrostatic separation, chemical instruments and methods, etc., can solve the problems of destroying the oxide layer on the surface of the aluminum plate, difficult to clean the dirt on the surface of the aluminum plate, and affecting the user experience, etc., to achieve Excellent glass forming ability, avoiding deposition and diffusion, and improving macroscopic mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

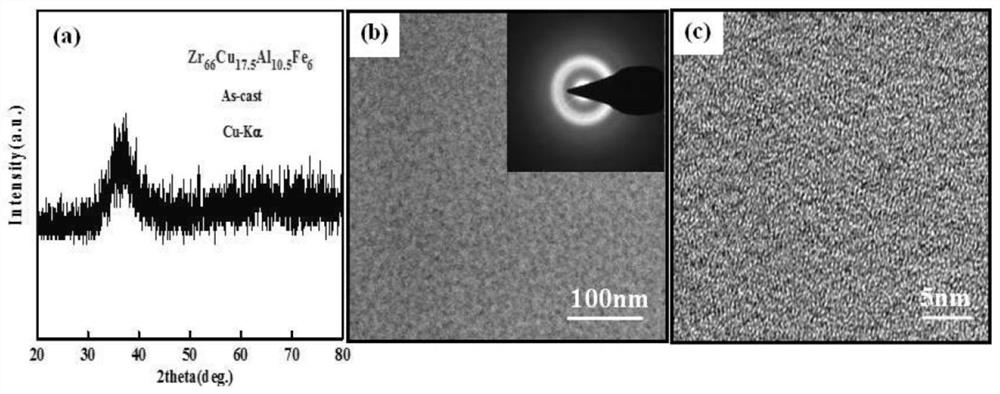

[0034] A Zr-based amorphous coating comprises the following raw materials in atomic mole percentages: Zr 66%, Cu 17.5%, Al 10.5%, Fe 6%.

[0035] The preparation process of the Zr-based amorphous coating is as follows:

[0036] Four elements of Zr (99.99%), Cu (99.99%), Al (99.99%), and Fe (99.99%) are selected, and the ratio is Zr66%, Cu17.5%, Al10.5%, and Fe6%. Amorphous powder, the particle size of the amorphous powder is 11-16 μm, and the amorphous component has strong glass forming ability, which is convenient for the preparation of the amorphous coating.

[0037] Using an aluminum plate with a size of 90mm×37mm×0.8mm as the substrate, first use alcohol to clean the stains and rust spots on the surface of the substrate to remove organic matter adhered to the surface and prevent residual pollutants from affecting the combination of the coating and the substrate material. Then, use shot peening technology to roughen the surface of the substrate, so that the surface roughne...

Embodiment 2

[0042] A kind of application of Zr-based amorphous coating in electric purification, using the Zr-based amorphous coating prepared in Example 1 to carry out electric purification environmental test, the details are as follows:

[0043] The present invention adopts the Zr-based amorphous coating in Example 1 to take a TEM image in an electric purification environment. The temperature of the electric purification environment is 25℃±2, the humidity is about 50%±10, the ozone content of the whole machine is controlled within 500ppb, and the microcurrent varies in the range of mA level, and it is about 0.1mA when it is stable. 3 Cigarette particles were selected for CADR testing in the purification experimental chamber, and the particle size range was 0.09-1 μm. The obtained TEM image is as follows Figure 4 shown. through the Figure 4 It can be seen from the TEM image in Figure 4 The inset is a selected-area diffraction pattern, which consists of concentric rings with differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com