Vertical wind turbine comprising pitch motor with protruding rotor blades, kit for same, and method for operating same

A wind power generation equipment and vertical technology, which are applied to a vertical wind power generation equipment having a pitch motor carrying rotor blades, an installation kit for the same, and the field of operation thereof, and can solve the problem of a blade control device and a blade The driver cannot achieve the problems of energy output efficiency, efficiency and service life minimization, propeller drive consumption, etc., to achieve the effect of optimal energy output and low noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] For a better understanding of the invention, reference is now made to the accompanying drawings. The figures only show exemplary embodiments of the subject matter of the invention, wherein the features, as described above, can be combined with one another as desired or can also be omitted, depending on the respective requirements.

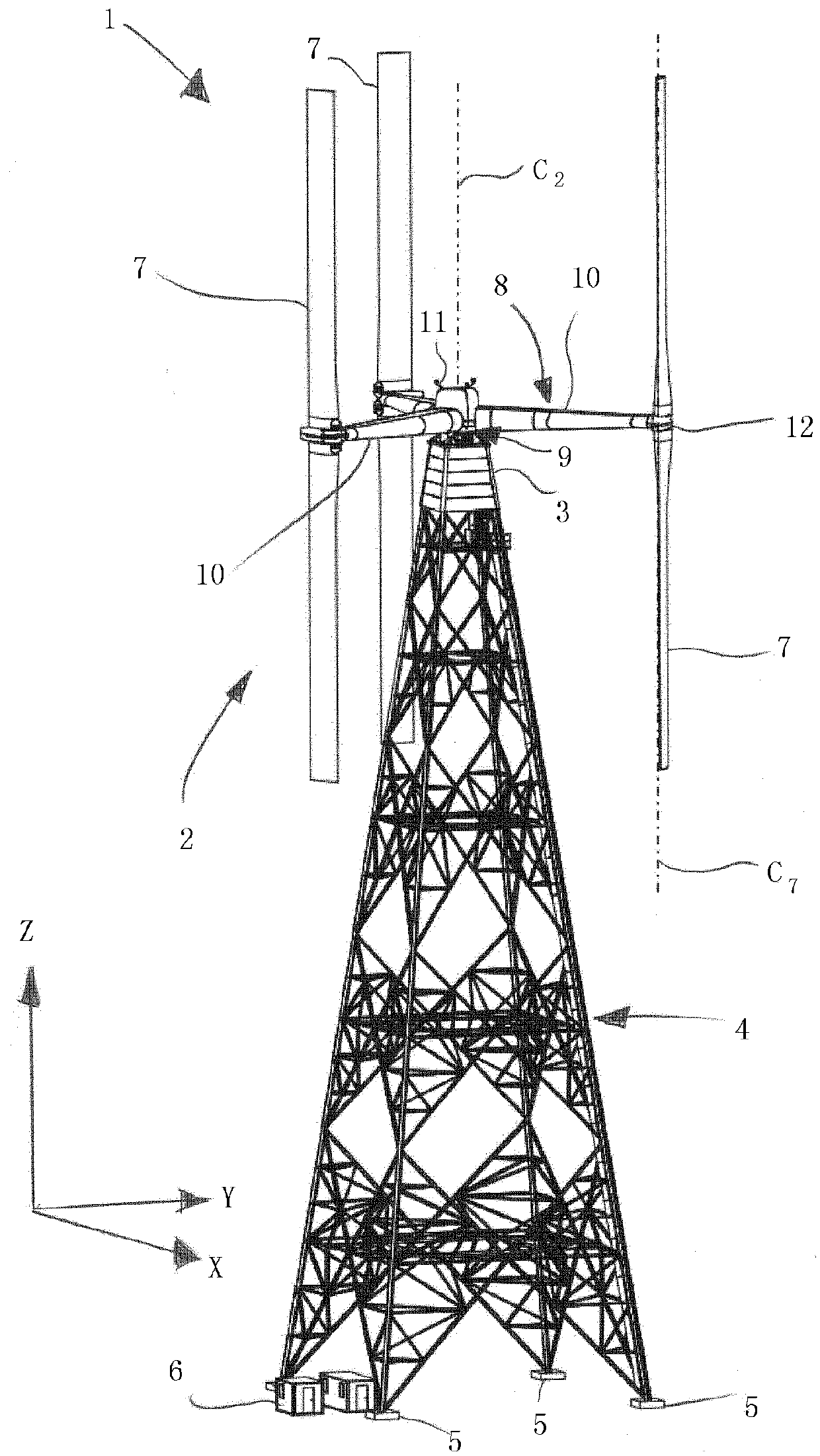

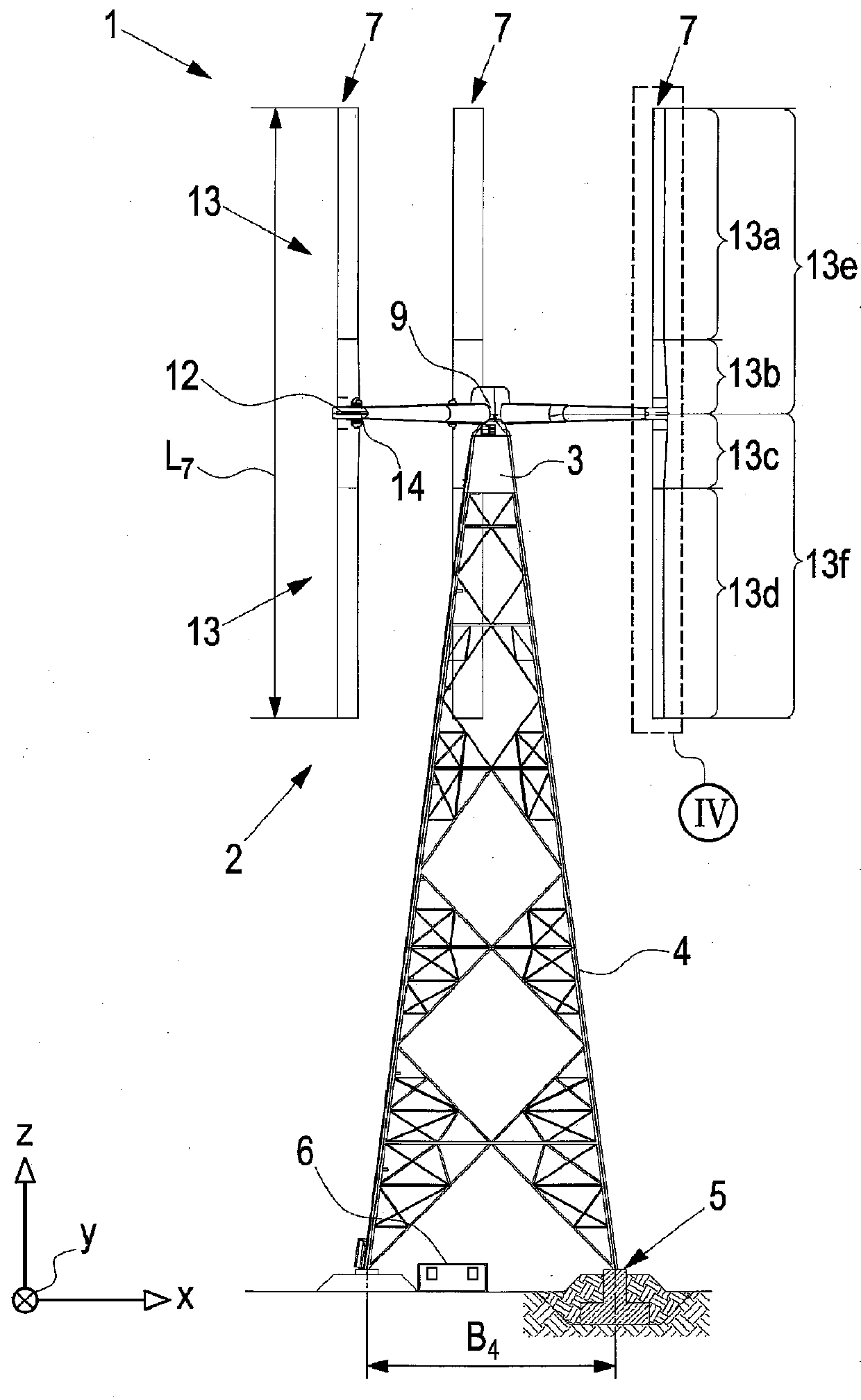

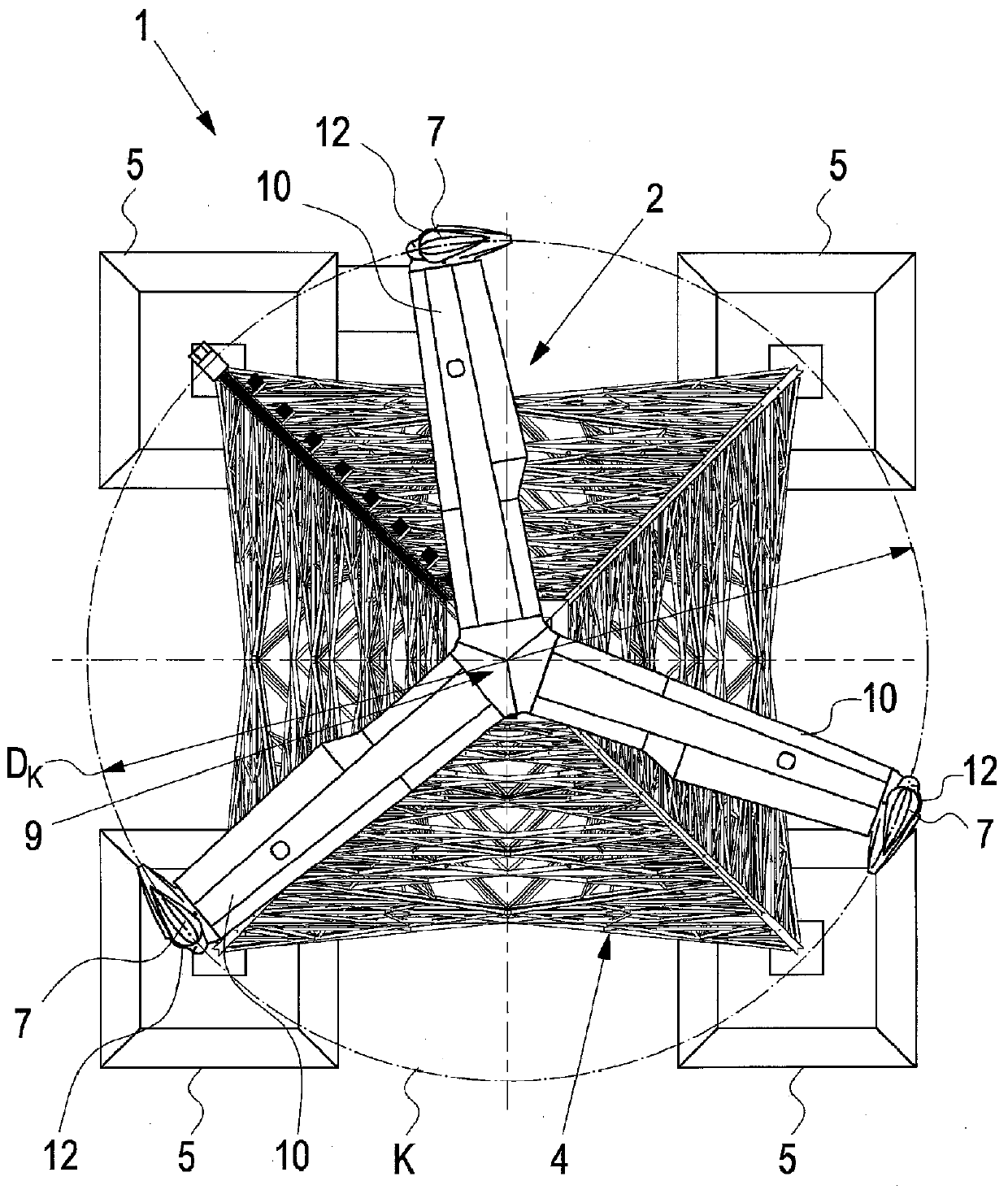

[0096] figure 1 A schematic perspective view of a vertical wind power plant 1 according to the invention is shown. The vertical wind power plant 1 extends along a longitudinal direction X, a transverse direction Y and a height direction Z, which together develop a Cartesian coordinate system. A vertical wind power plant 1 comprises a rotor 2 , a nacelle 3 , a tower system 4 , a foundation 5 and a container-shaped switchgear 6 .

[0097] The rotor 2 comprises a plurality of vertical blades 7 which are fastened via blade hangers 8 at a rotor hub 9 which is movable about a rotor axis of rotation C2 which is oriented vertically, ie runs parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com