Patents

Literature

82results about How to "Reduce noise generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

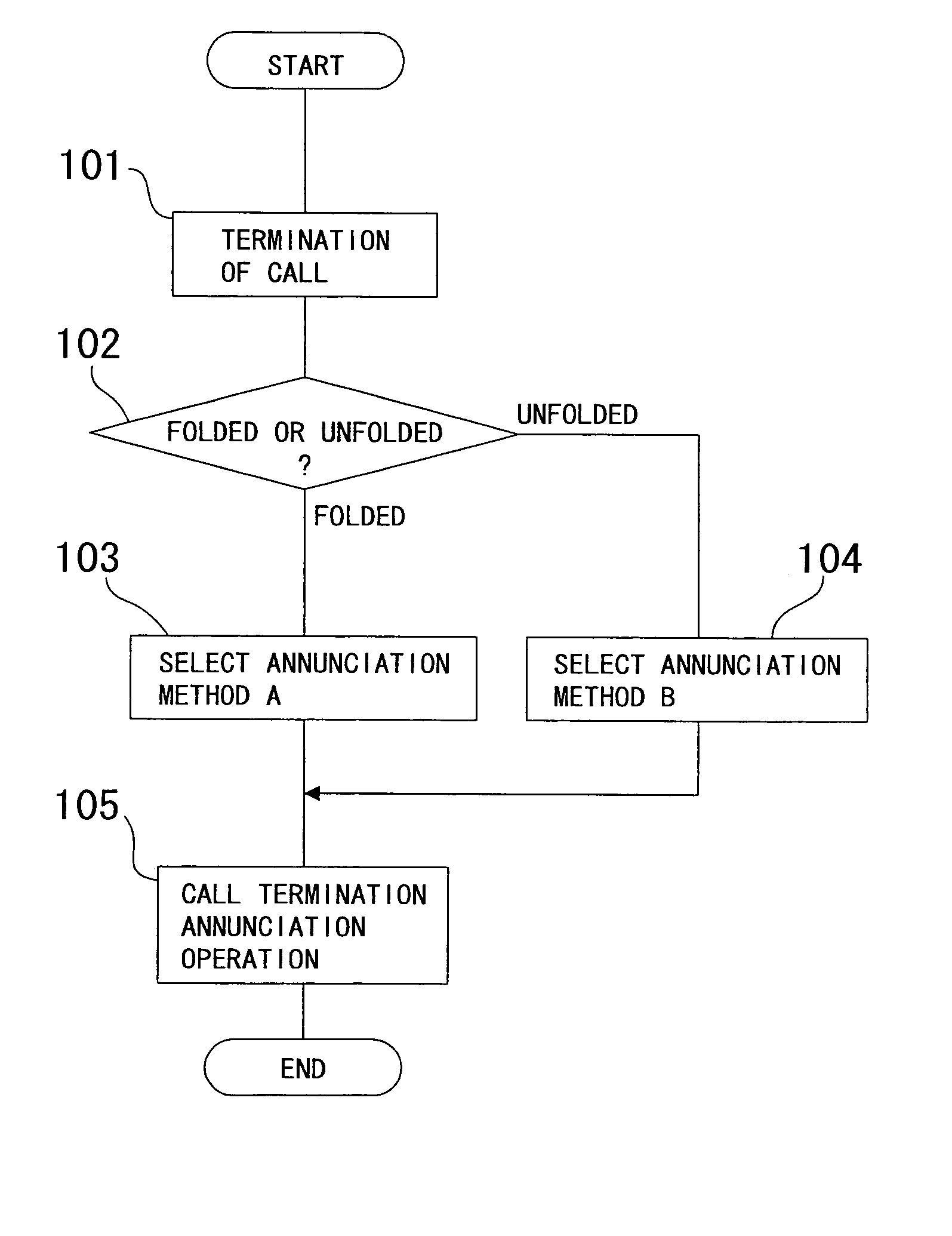

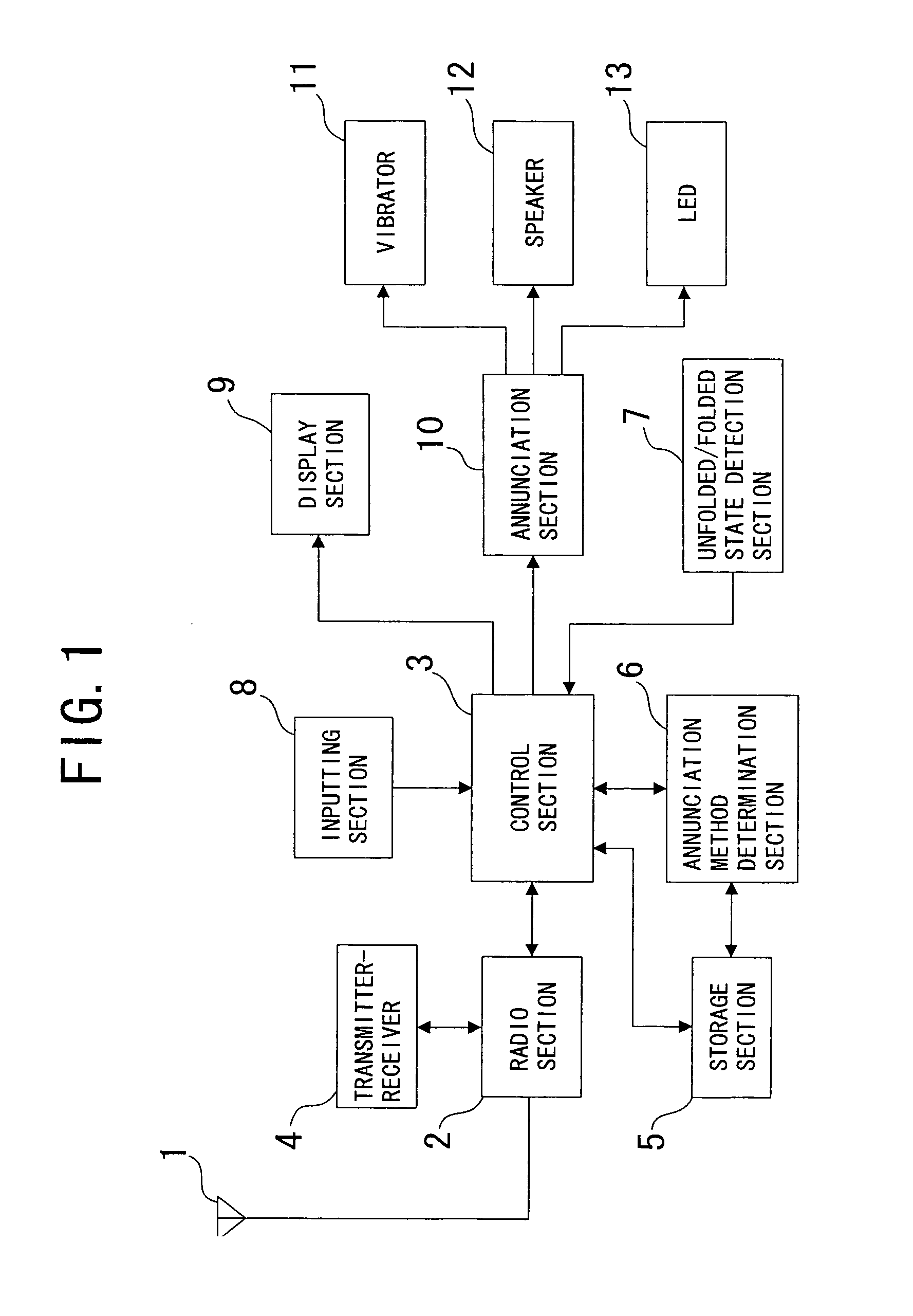

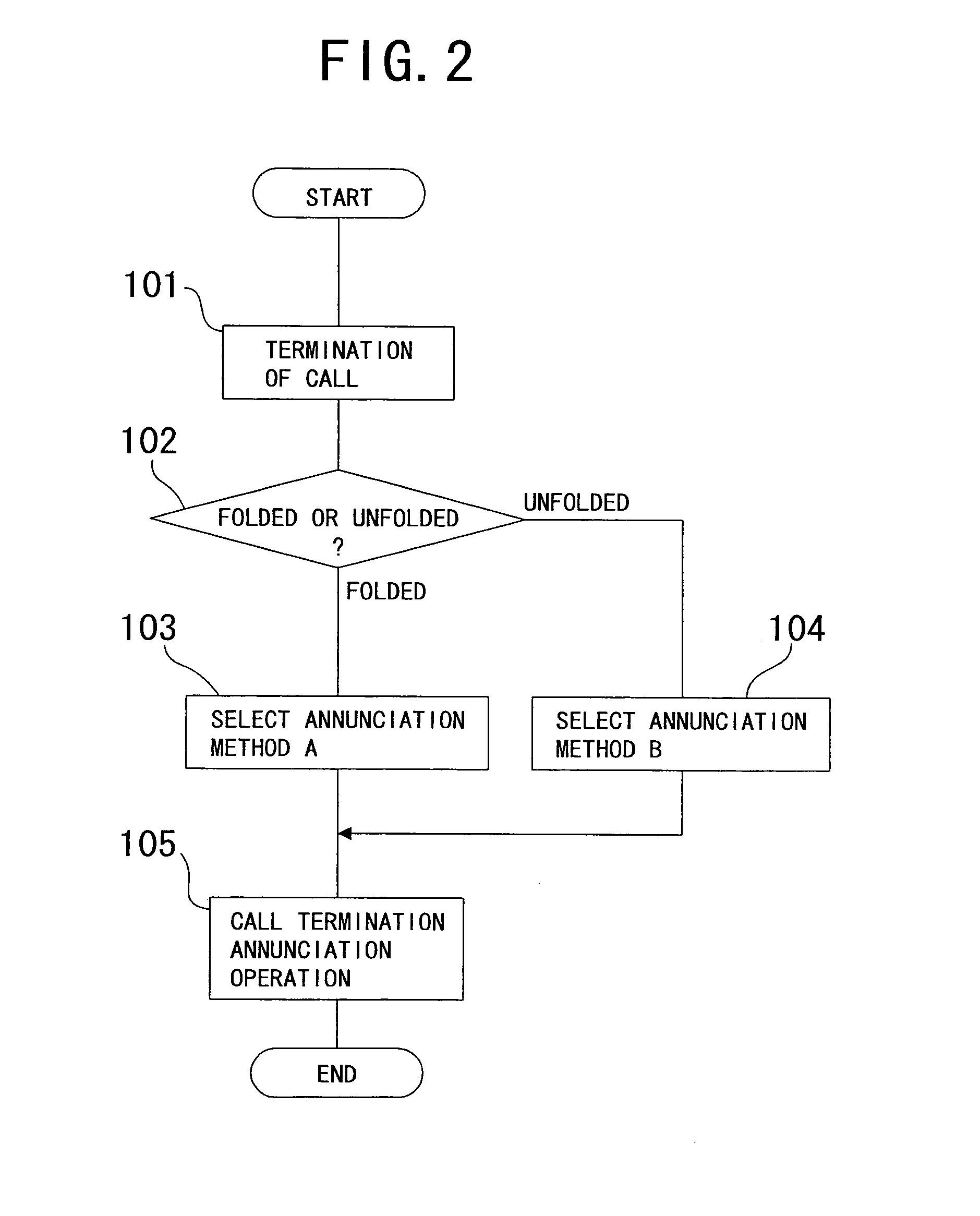

Portable communication terminal apparatus

InactiveUS7096045B2Reduce noise generationReduce power consumptionInterconnection arrangementsTransmissionNoise generationTerminal equipment

A portable communication terminal apparatus is disclosed which can announce termination of a call in various methods with a simple configuration and allows selection of a suitable annunciation method in accordance with a utilization situation of the portable communication terminal apparatus so that an annunciation operation can be performed appropriately thereby achieve reduction of the power consumption and the noise generation. An unfolded / folded state of a body of a foldable portable telephone set is supervised by an unfolded / folded state detection section. When an annunciation operation is to be performed upon termination of a call or the like, an annunciation method determination section selects one of a plurality annunciation methods stored in a storage section in response to the unfolded / folded state of the portable telephone set. A control section controls an annunciation section to drive a vibrator, a speaker or an LED to perform an annunciation operation in accordance with the selected annunciation method.

Owner:NEC CORP

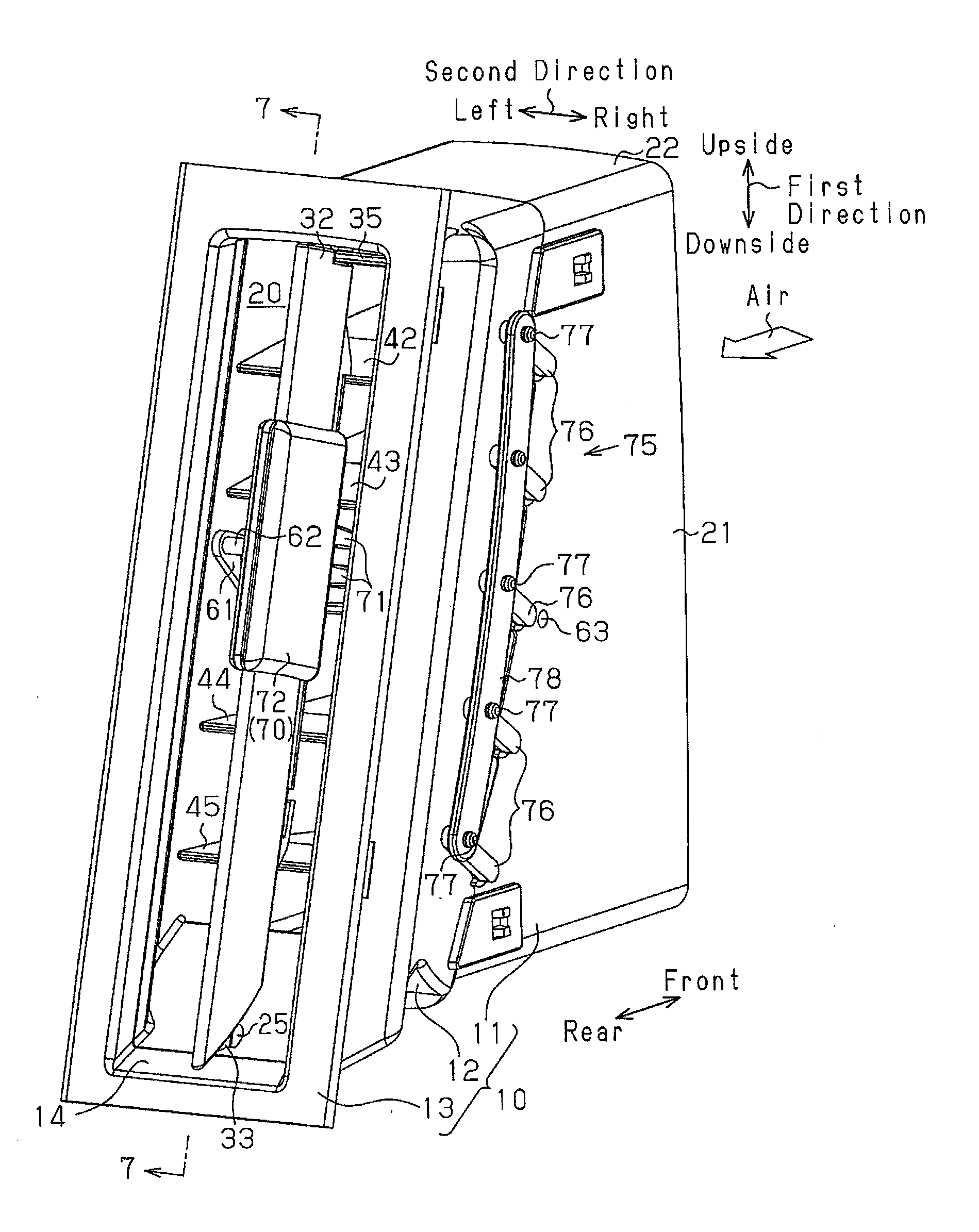

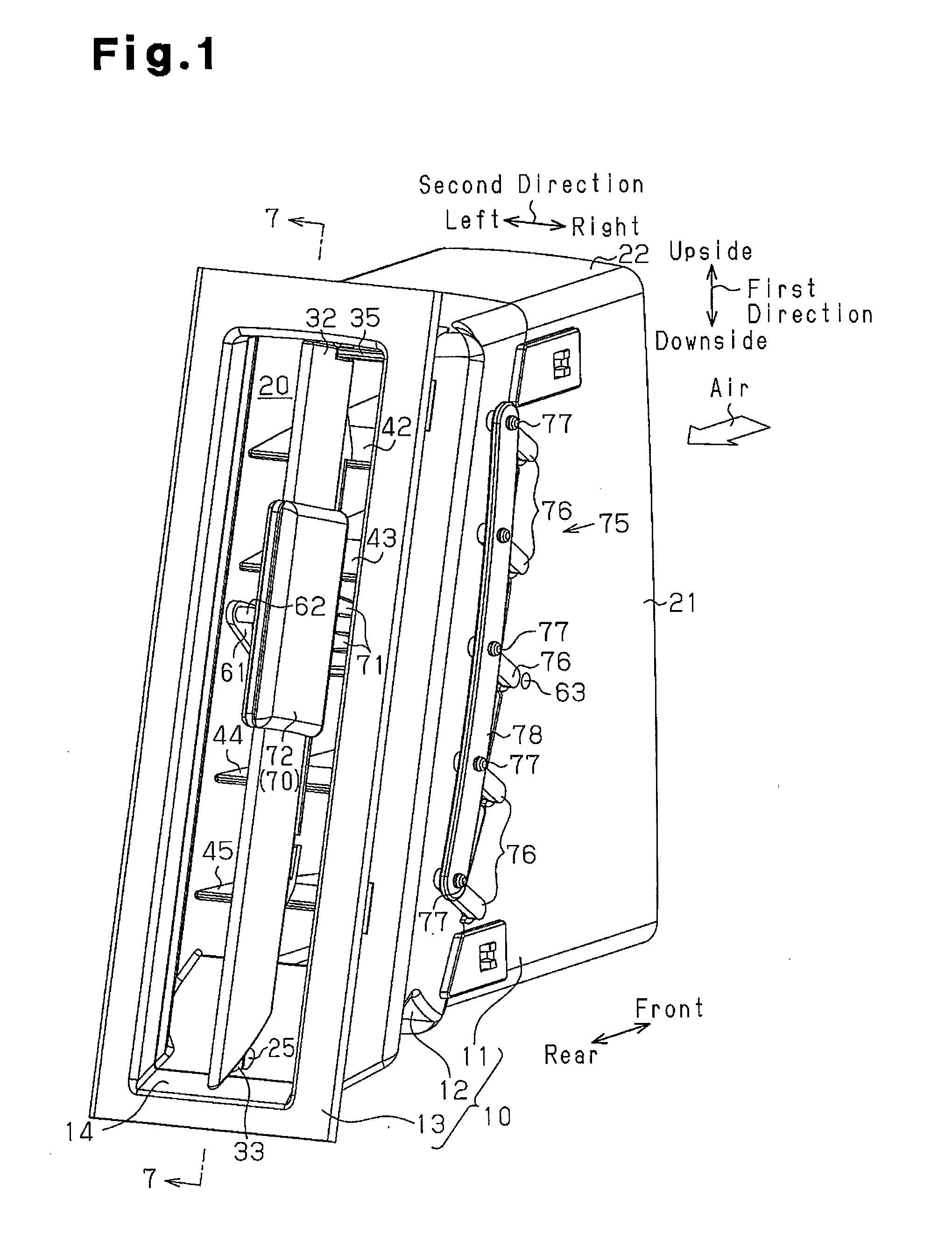

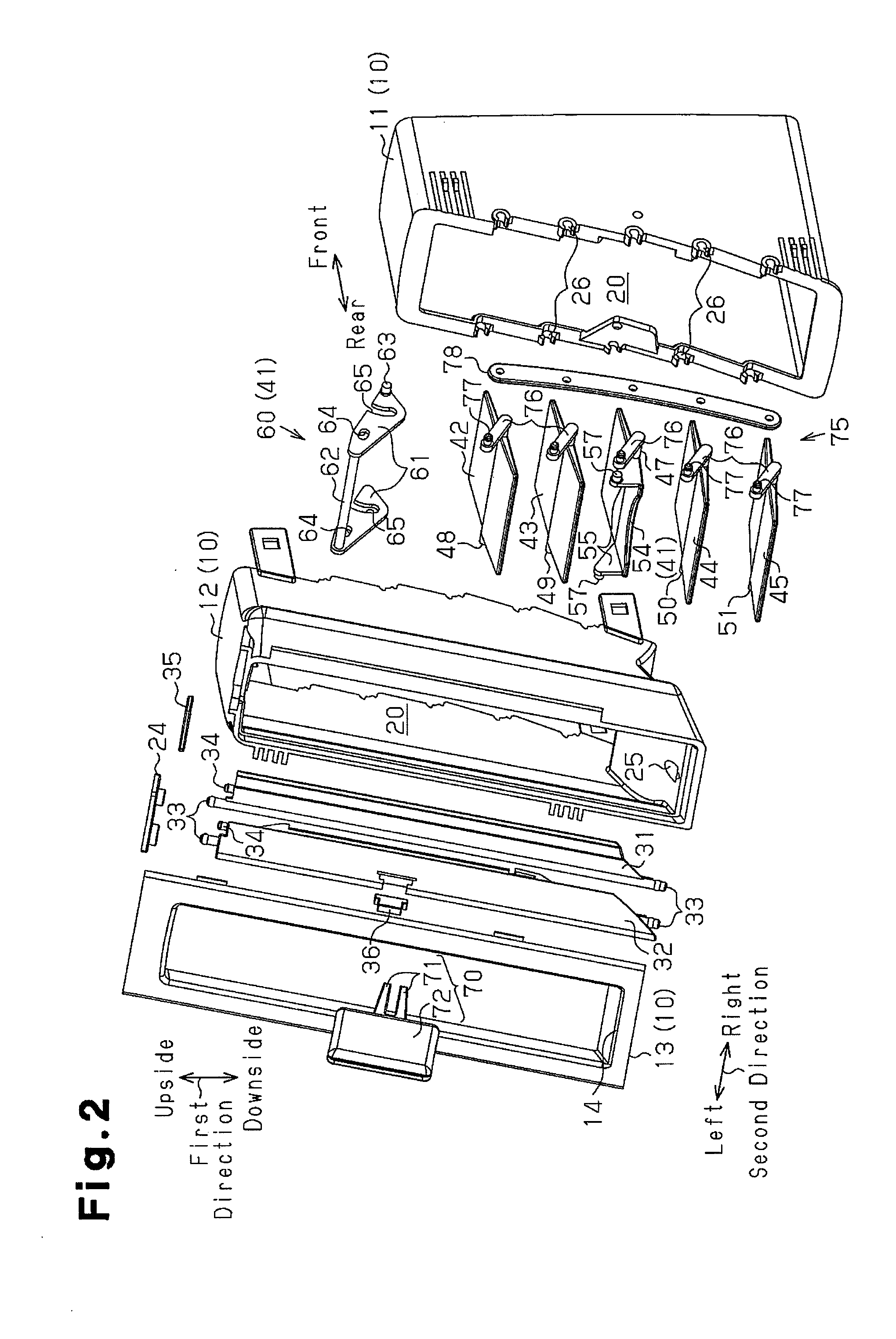

Air conditioning register

ActiveUS20140120826A1Reduce noise generationReduce pressure lossDucting arrangementsLighting and heating apparatusDrive shaftAir conditioning

An air conditioning register is provided that includes a case, a downstream fin, a specific upstream fin extending in a direction perpendicular to the downstream fin, and an operation knob. The specific upstream fin includes a fin main body pivotally supported by the case via an upstream fin shaft and a transmission body pivotally supported by the case via a pivot located further upstream than the upstream fin shaft. The fin main body and the transmission body are coupled to each other. The operation knob is mounted slidably on the downstream fin and includes a pair of fork portions sandwiching a transmission shaft portion of the transmission body therebetween. When the operation knob is operated to slide and thereby the transmission shaft portion is moved, the fin main body of the specific upstream fin is tilted.

Owner:TOYODA GOSEI CO LTD

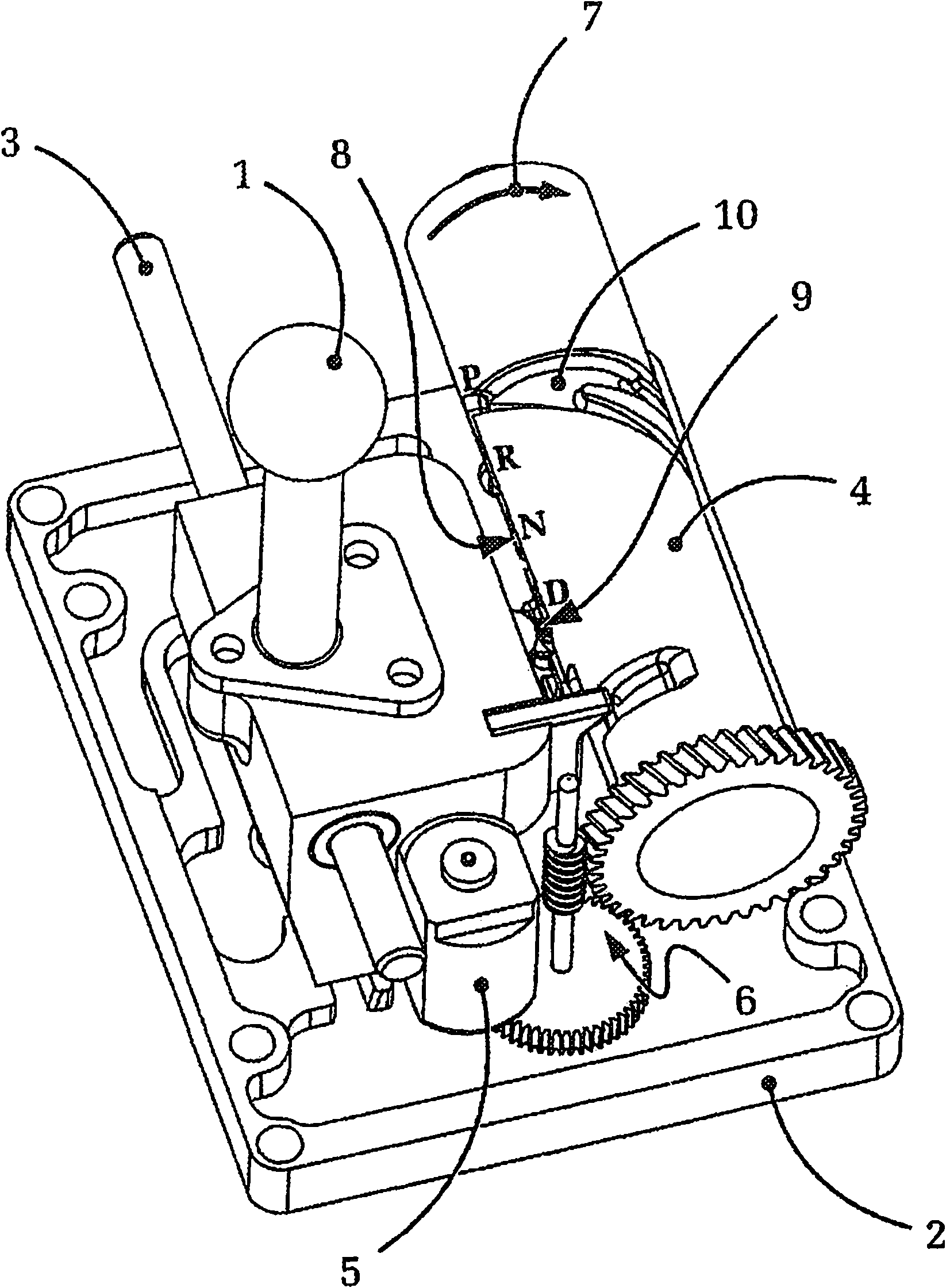

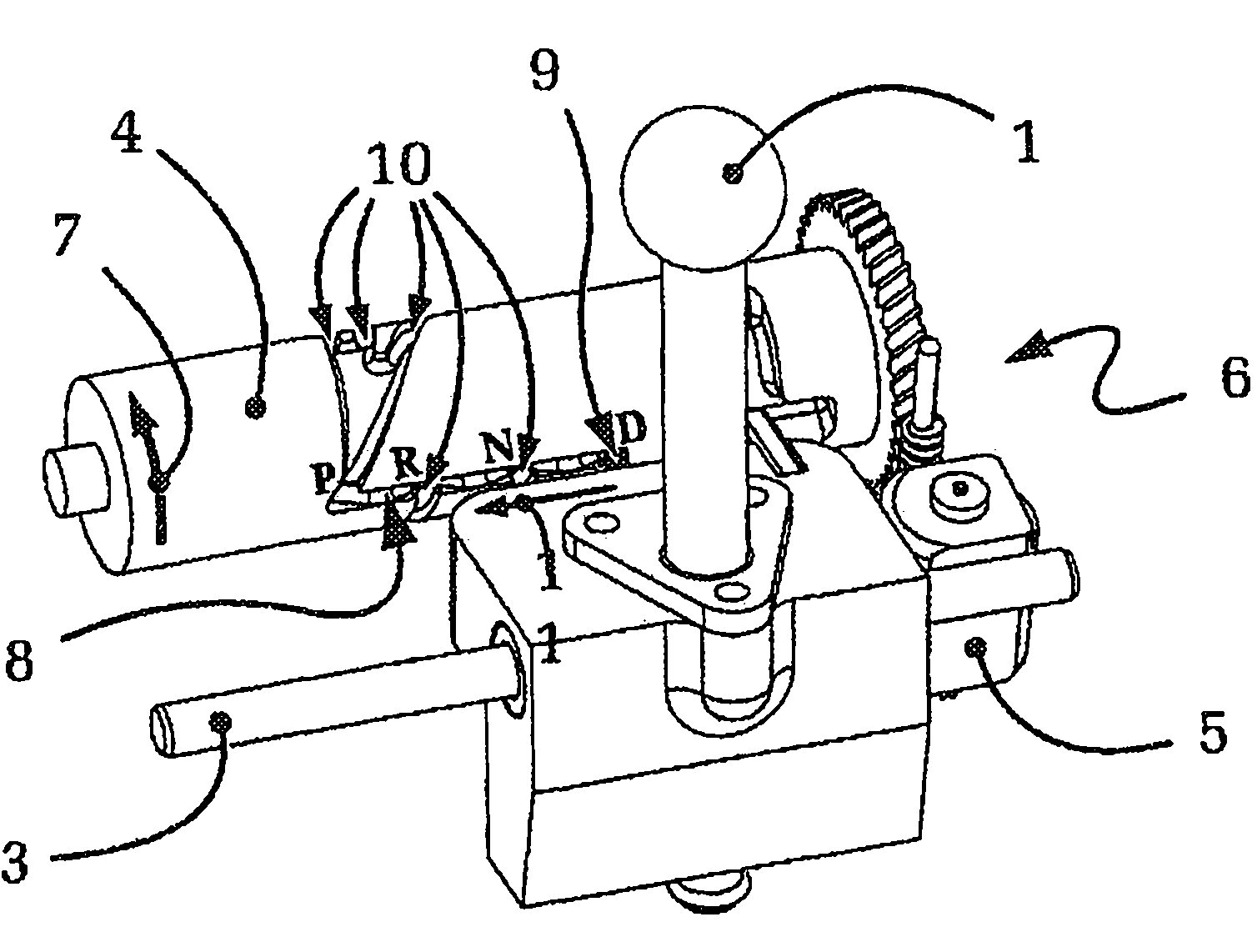

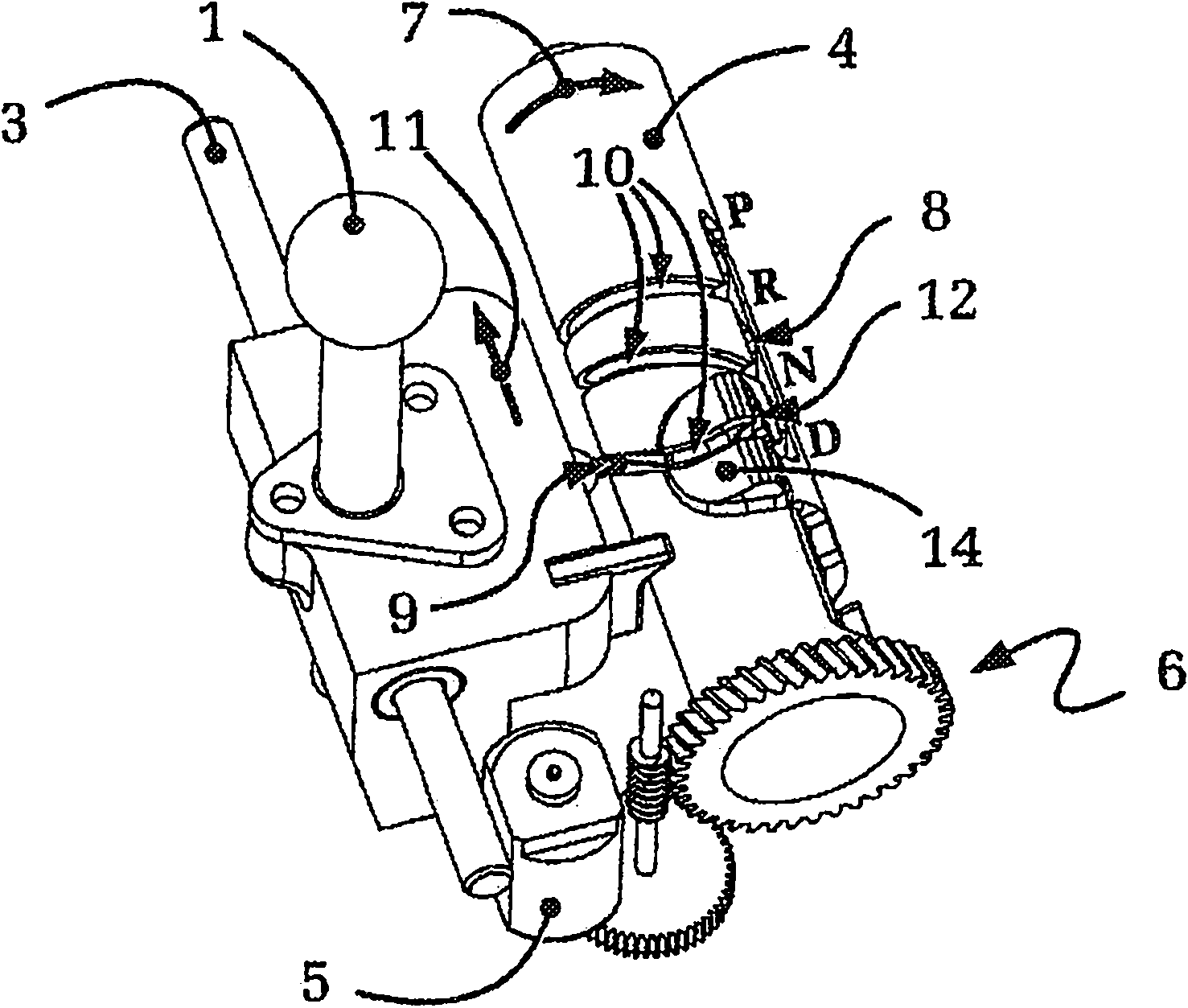

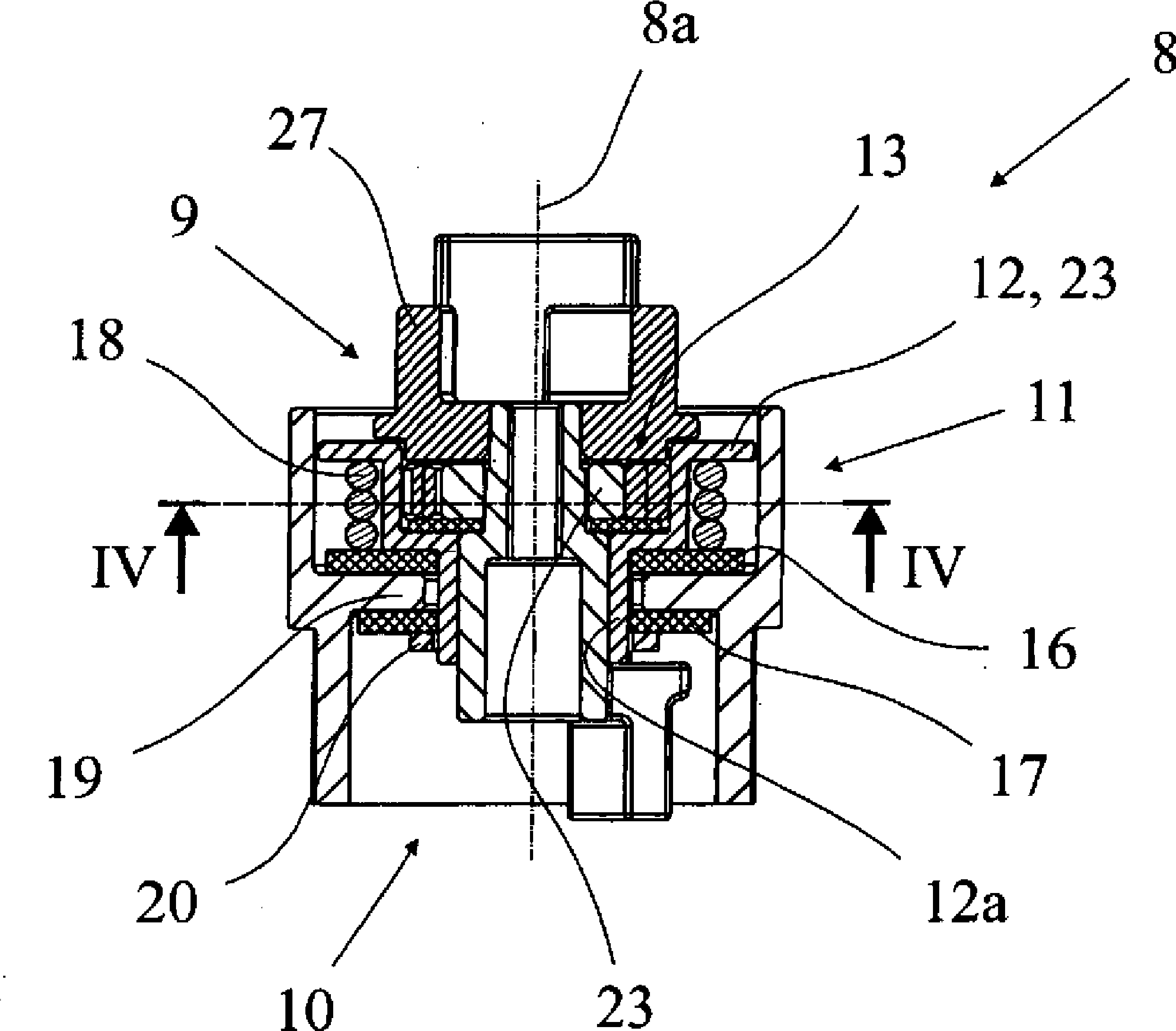

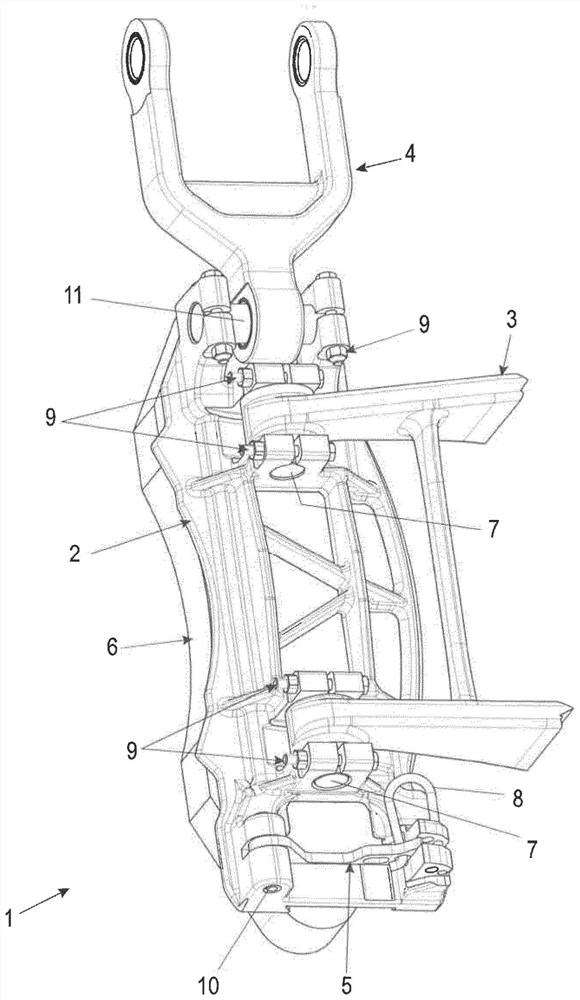

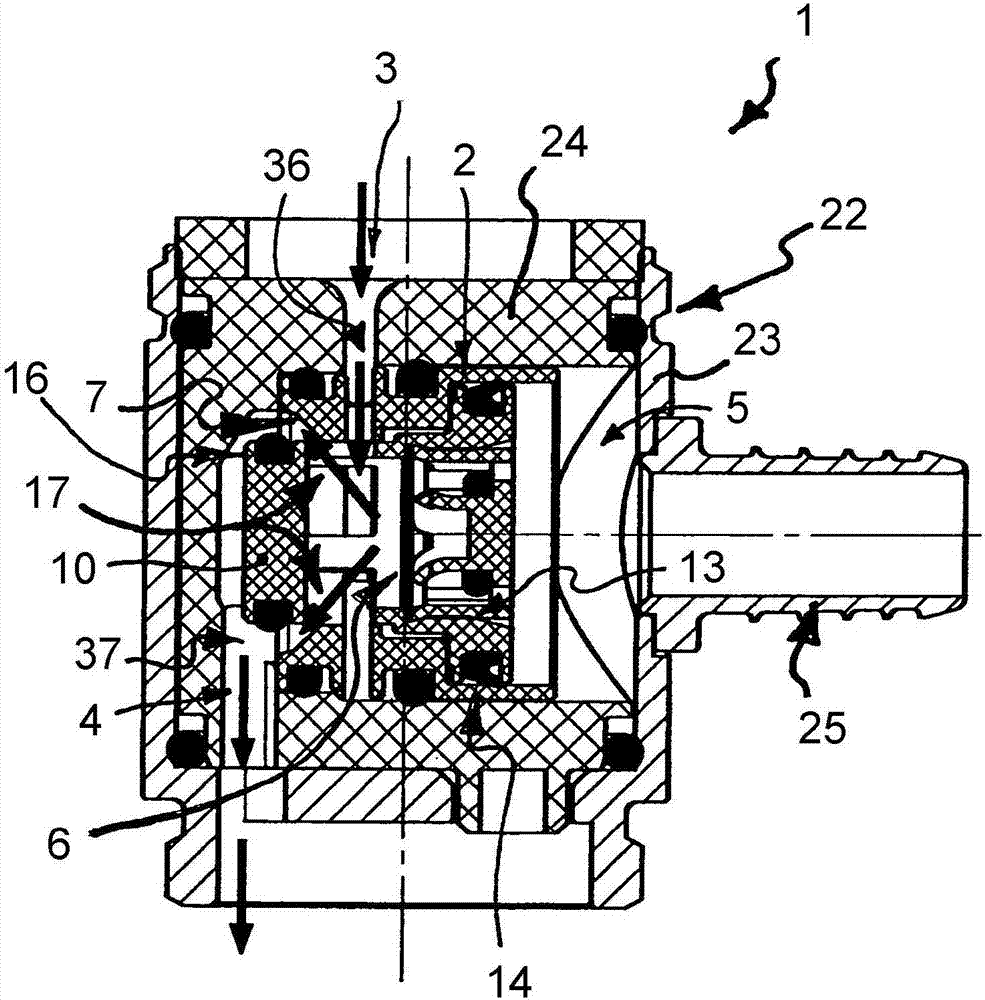

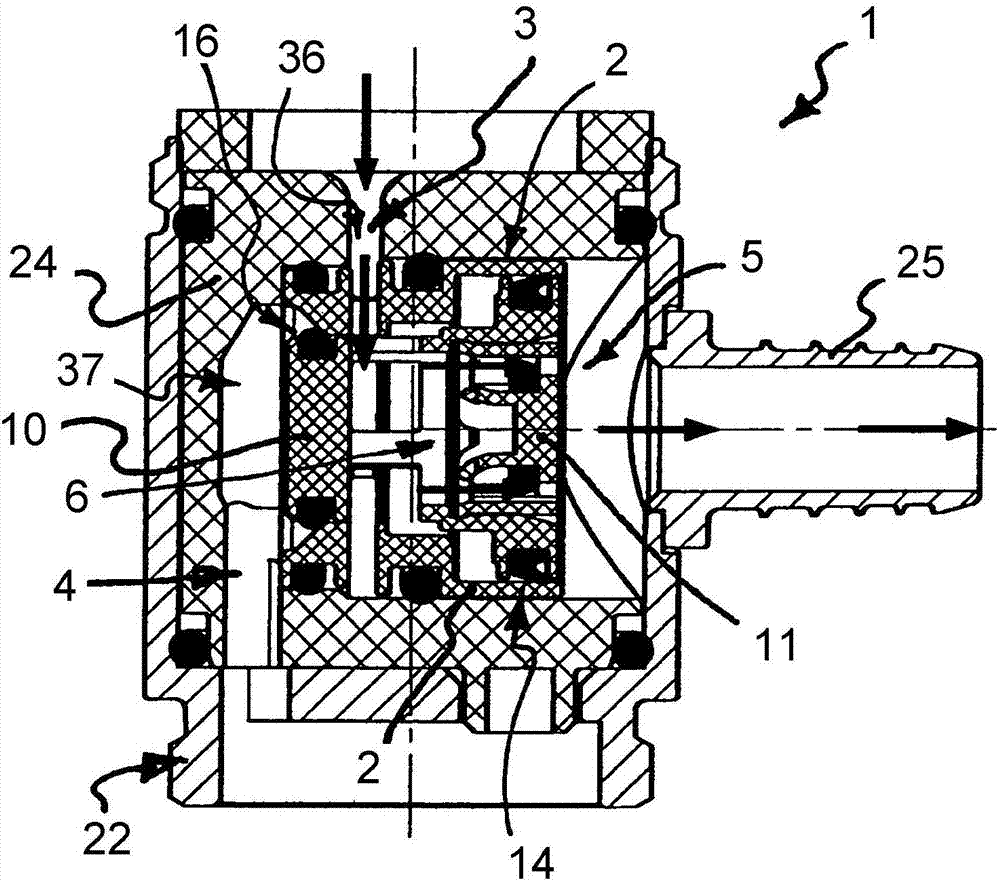

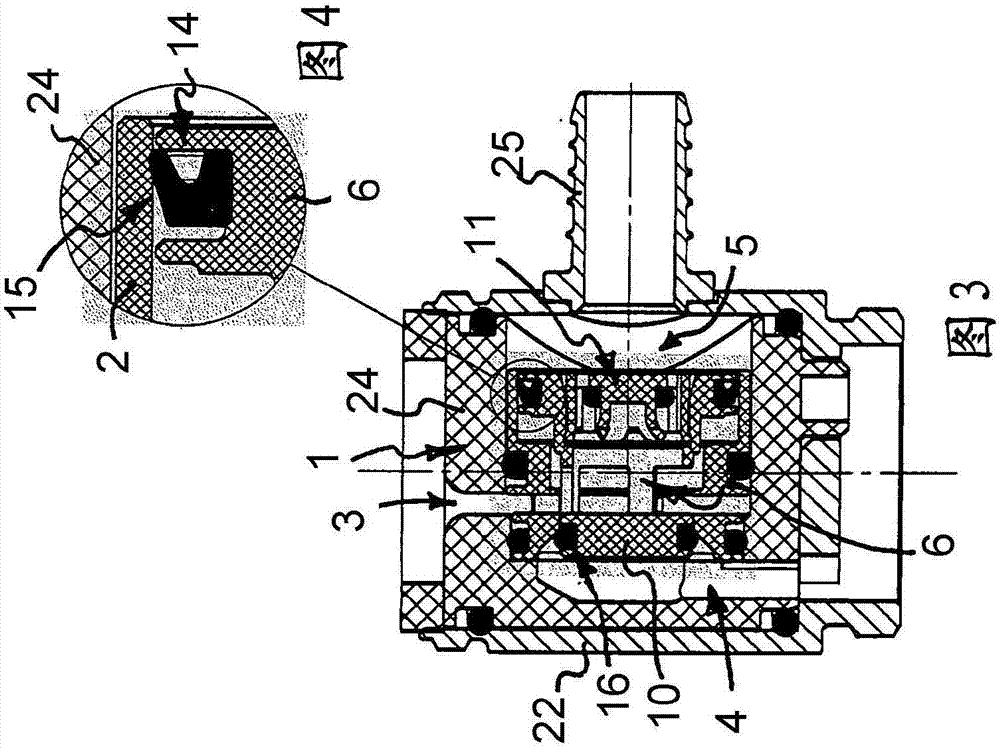

Operating device with gate shafts

InactiveCN101889156ASimple achievabilityMechanically simple and durableGearing controlDriver/operatorEnergy expenditure

The invention relates to an operating device for a gearbox. Said operating device comprises a selector lever (1) with stable selector lever positions and a ratchet device with a ratchet element (9) and index gate (8). Said ratchet element (9) is connected to the selector lever (1). According to the invention, the actuation device is characterised in that the index gate (8) is arranged on a gate shaft (4) that can be rotated by an actuator. Said gate shaft (4) comprises at least one return groove (10) for the ratchet element (9) that is wound in a screw-like manner. Said ratchet element (9) can be guided into the target position from a start position by rotating (7) the gate shaft (4) along the return groove (10). Said selector lever positions can reflect the current shift state of the gear box, also in shift-by-wire-controlled gearboxes. A reliable optical and also tactile signal of the shifting state of the gearbox is obtained for the driver. Said operating device is constructively reliable, has a low energy consumption and minimal noise and is also compact.

Owner:ZF FRIEDRICHSHAFEN AG

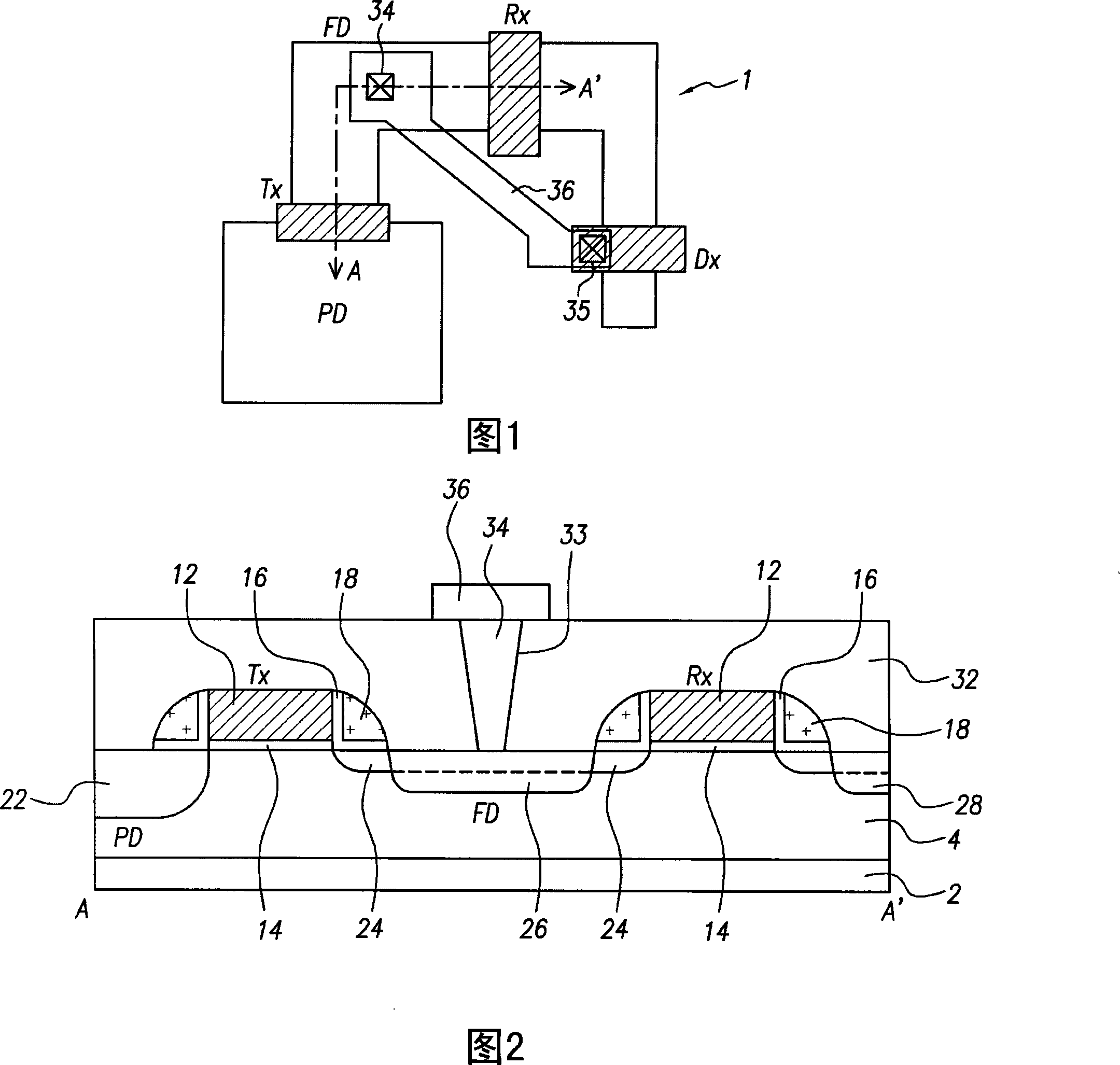

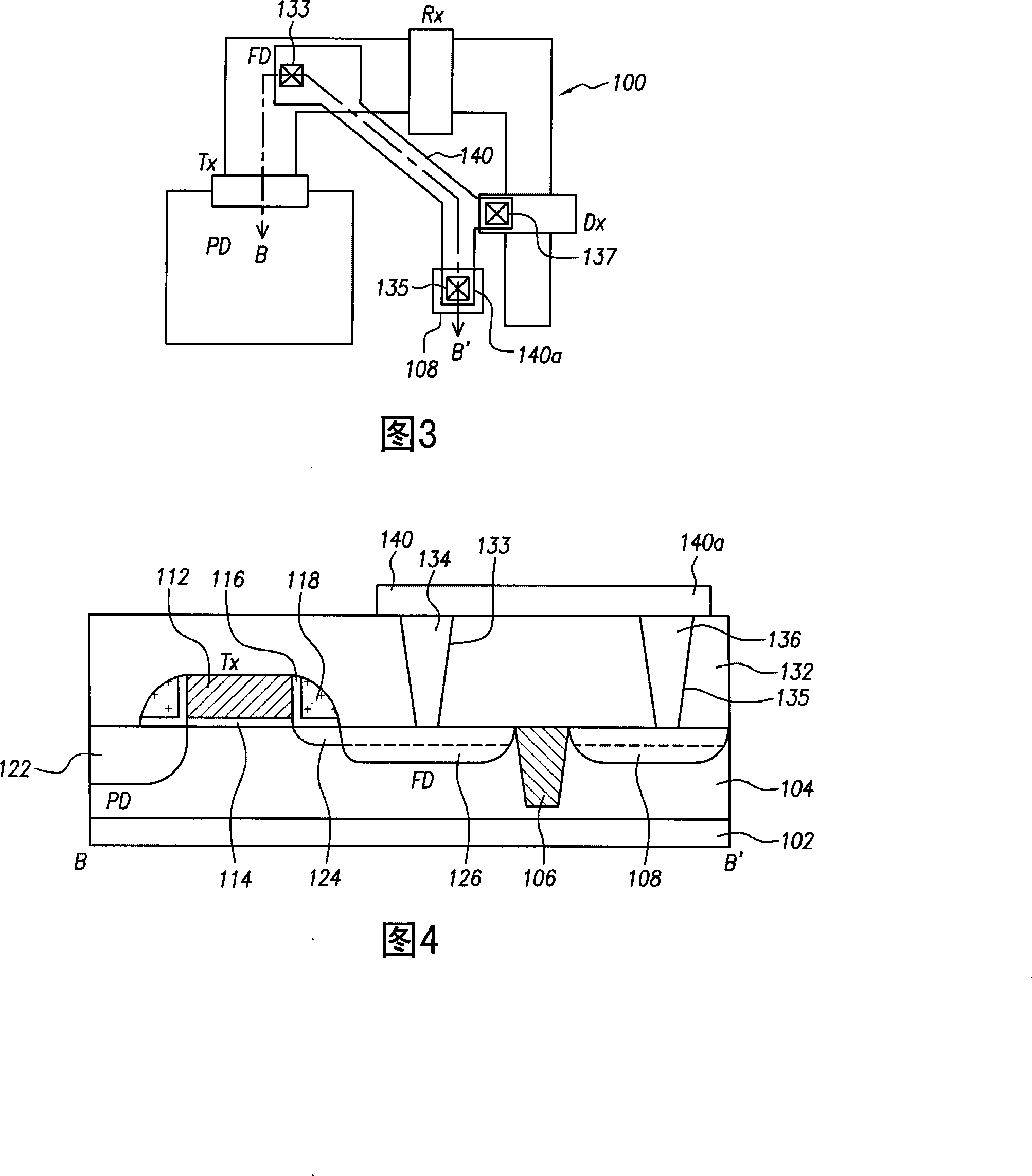

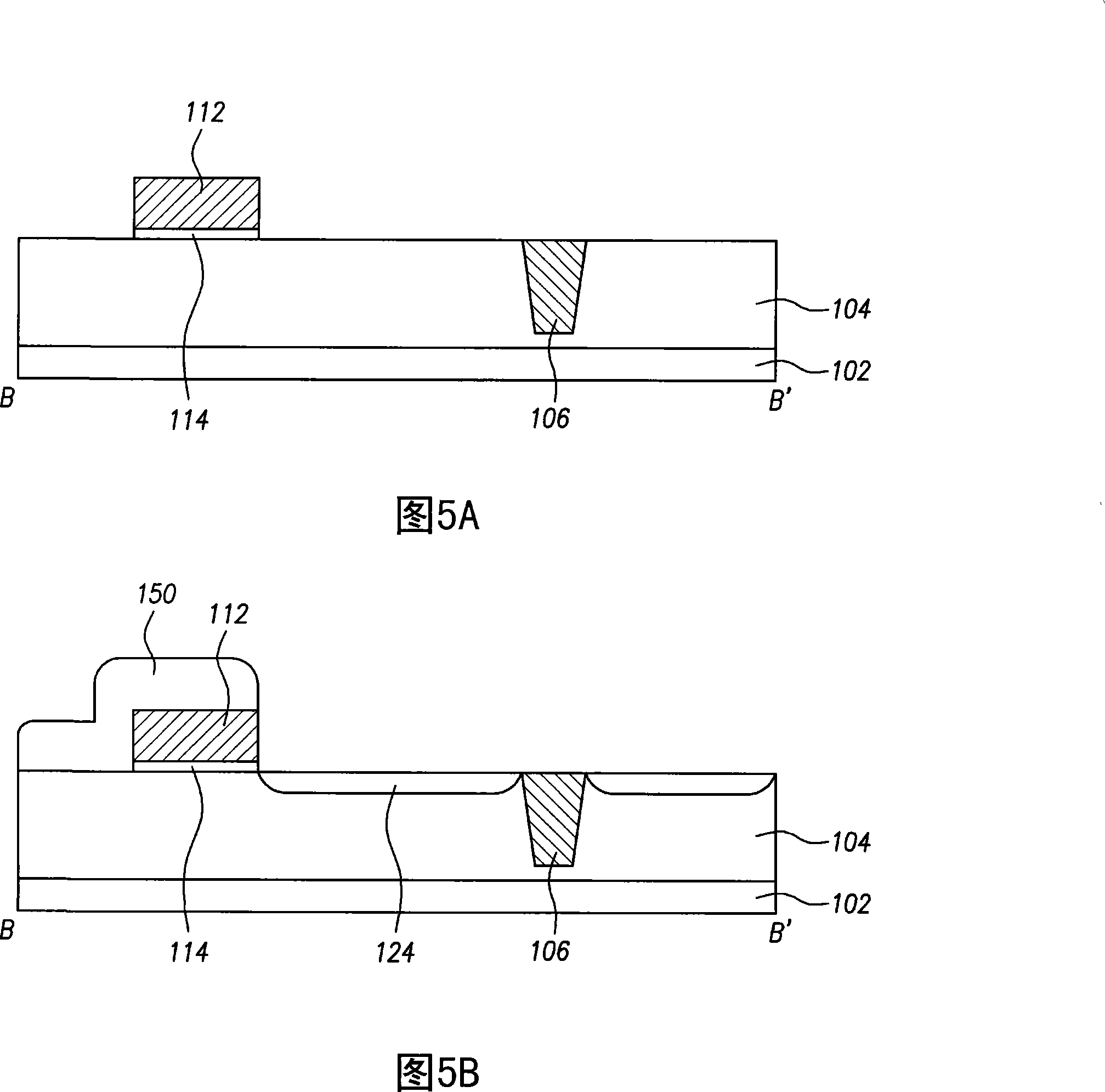

CMOS image sensor and its manufacture method

InactiveCN101211952AEasy to receiveIncrease capacitySemiconductor/solid-state device detailsSolid-state devicesCapacitanceCMOS

A CMOS image sensor and a manufacturing method thereof, the CMOS image sensor comprising: an epitaxial layer formed above a semiconductor substrate; a gate electrode formed above the epitaxial layer; a gate metal formed above a floating diffusion region of the epitaxial layer; The n+ type source region and the drain region are formed in the epitaxial layer; the gate spacer is formed on both side walls of the gate electrode and the gate metal; the insulating interlayer is formed on the gate electrode, the gate spacer and the gate metal Above the epitaxial layer of the layer, the insulating interlayer includes: a first contact hole passing through the insulating interlayer and exposing the source region; a second contact hole passing through the insulating interlayer and exposing the gate metal; a first contact plug formed in the first contact hole and connected to the source region; a second contact plug formed in the second contact hole and connected to the gate metal; and a metal line formed over the first contact plug and the second contact plug to electrically connect the source region to the gate extremely metallic. The present invention can increase the capacitance of the floating diffusion (FD).

Owner:DONGBU HITEK CO LTD

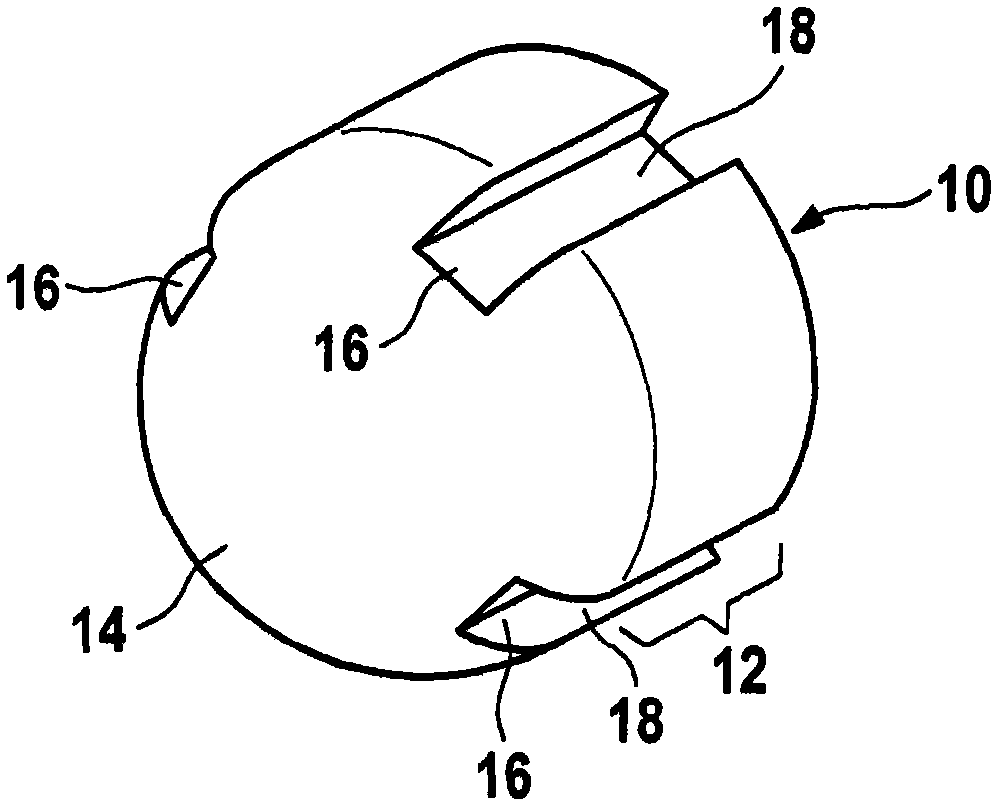

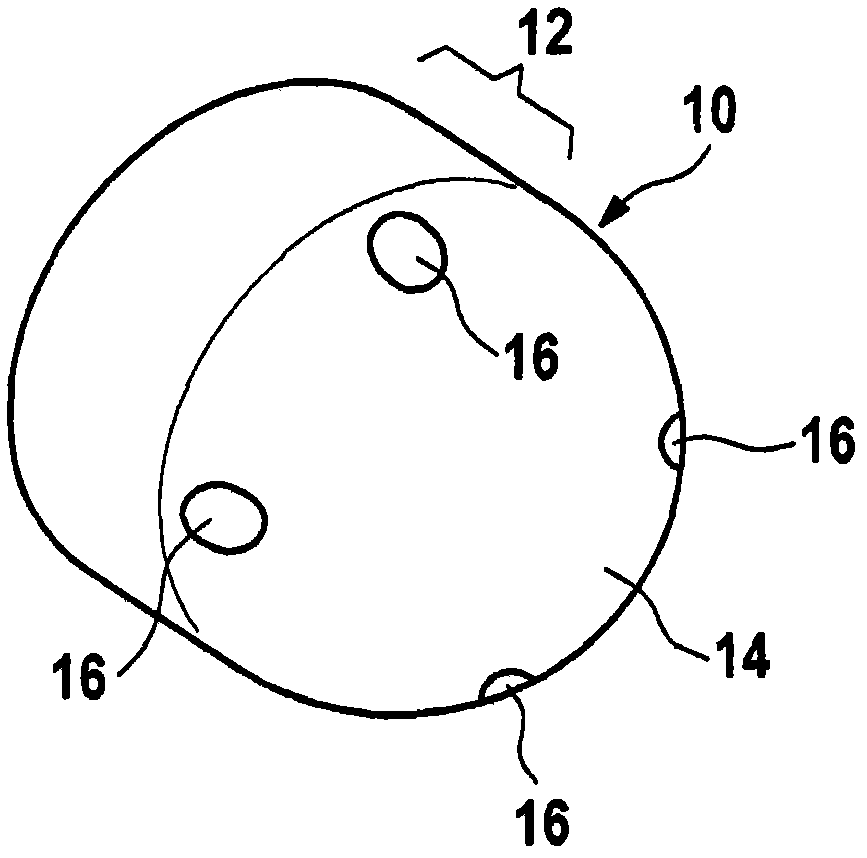

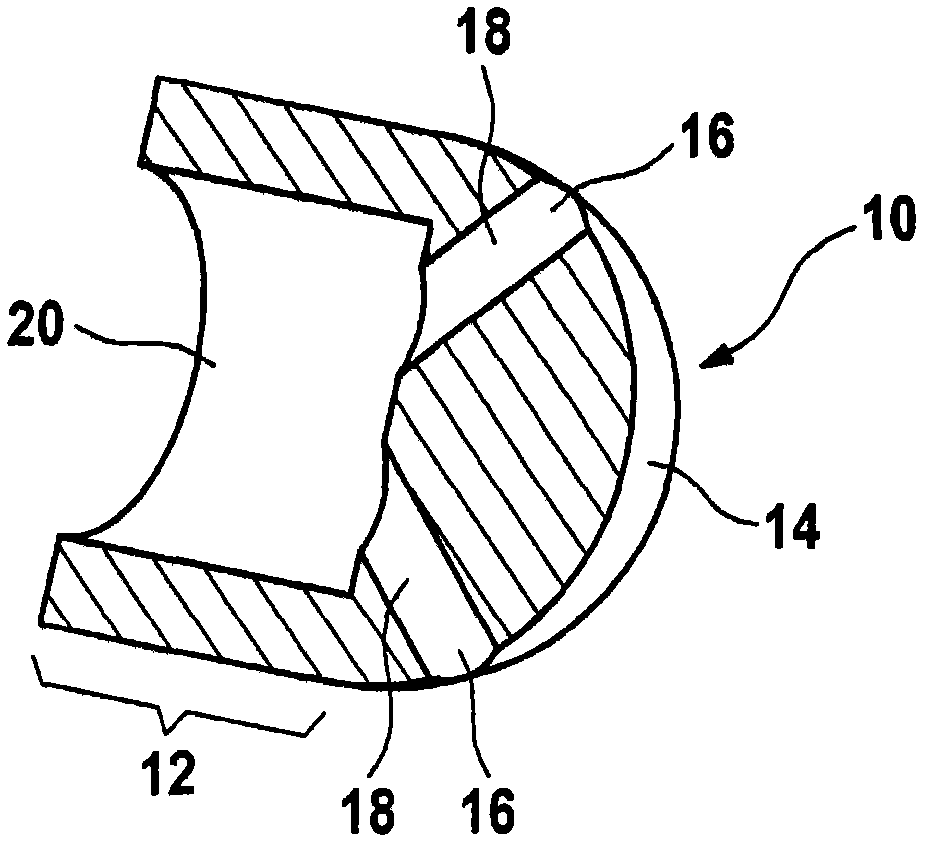

Valve with valve closure body

InactiveCN102072146AReduce manufacturing costEasy to integrateOperating means/releasing devices for valvesPositive displacement pump componentsEngineeringValve seat

The invention relates to a valve for a piston pump, wherein the valve (22) comprises a valve closure body (10) and a valve seat (26) disposed longitudinally facing to the valve closure body (10); the valve closure body (10) comprises a cylindrical guide section (12) and a hemispheric sealing section (14) longitudinally facing to the cylindrical guide section (10) and facing to the valve seat (26); the sealing section is used for selectively closing and opening a hole (30) enclosed by the valve seat (26); according to the invention, the sealing section (14) comprises at least one channel opening (16) which is located out of the hole (30) enclosed by the valve seat (26) under the state that the valve (22) is closed, and extended into a channel (18) in the valve closure body (10) substantially extending along a flow direction.

Owner:ROBERT BOSCH GMBH

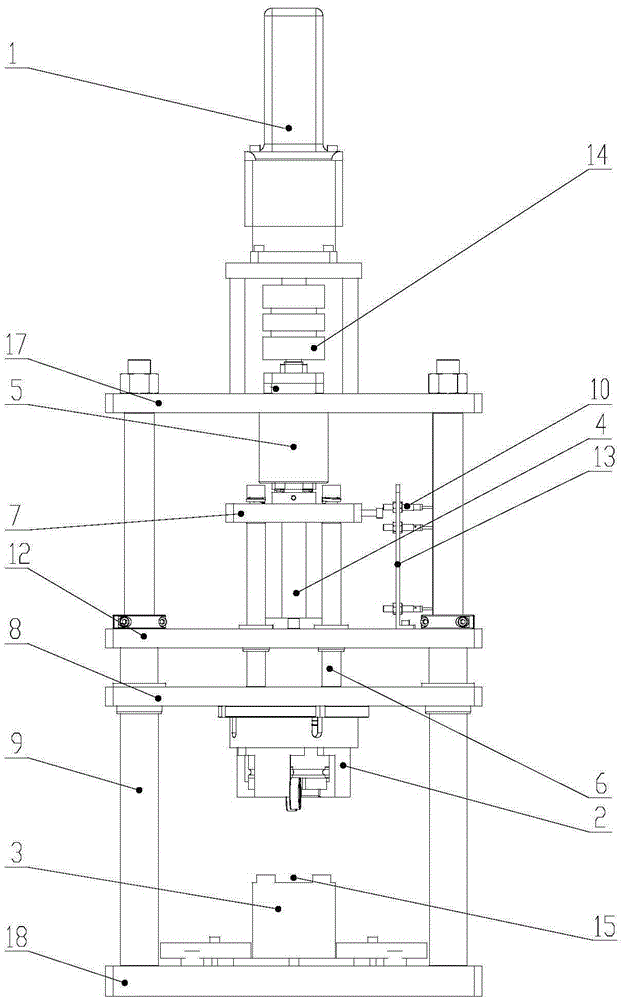

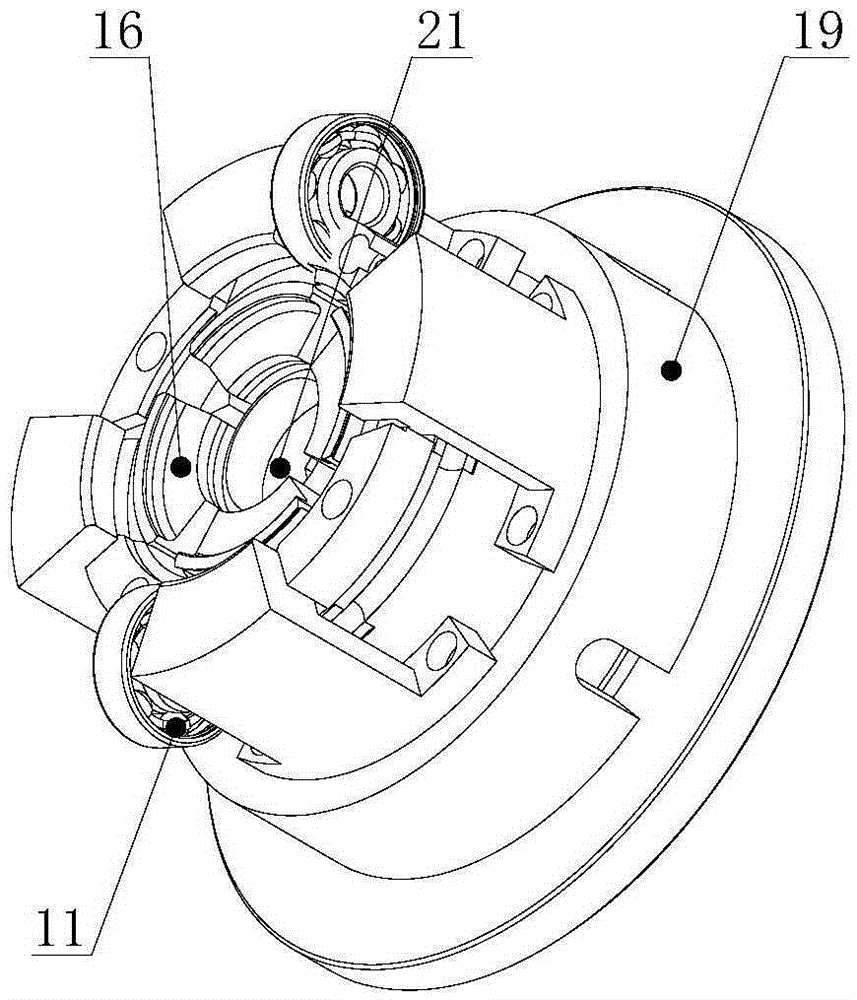

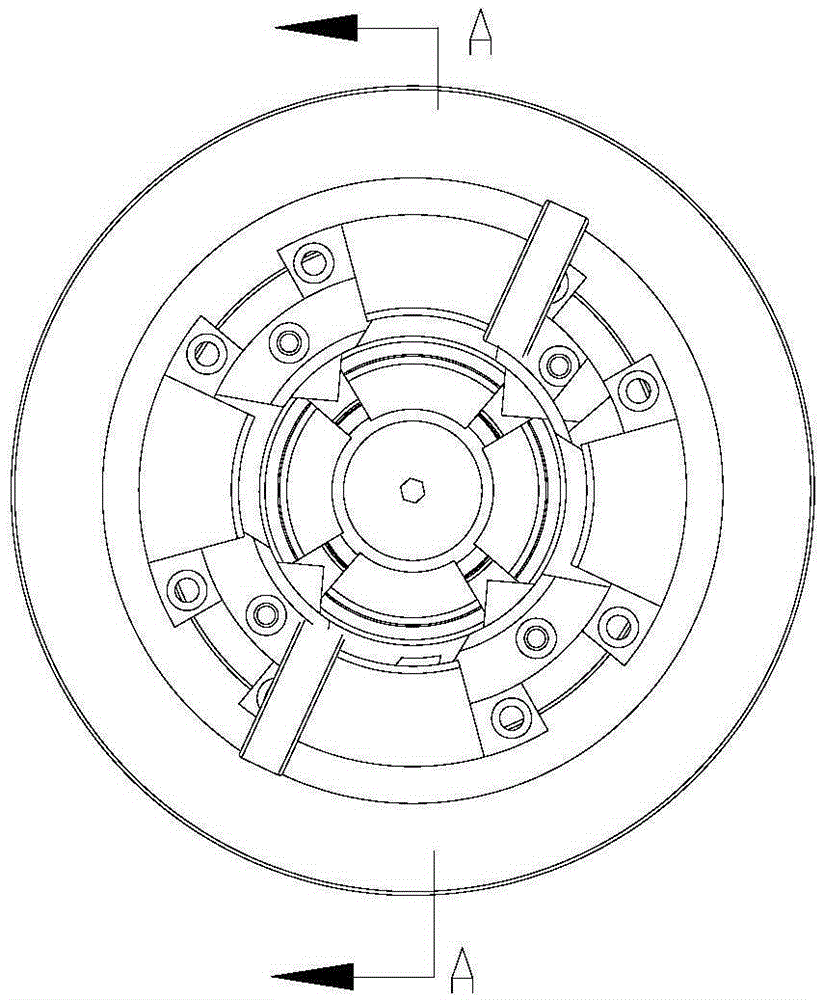

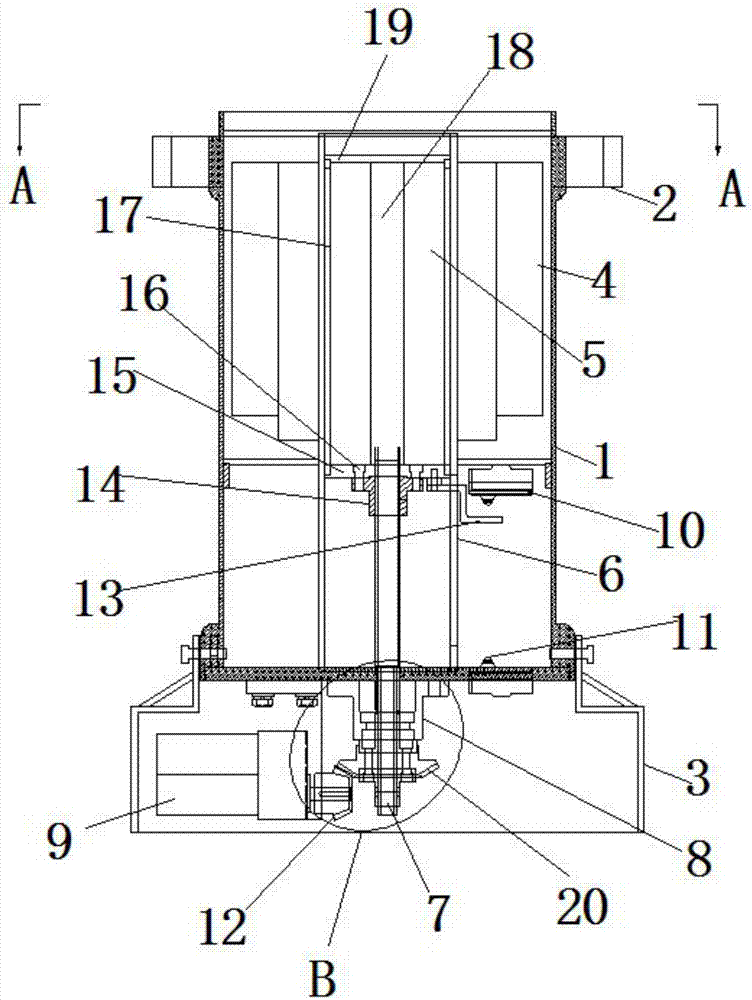

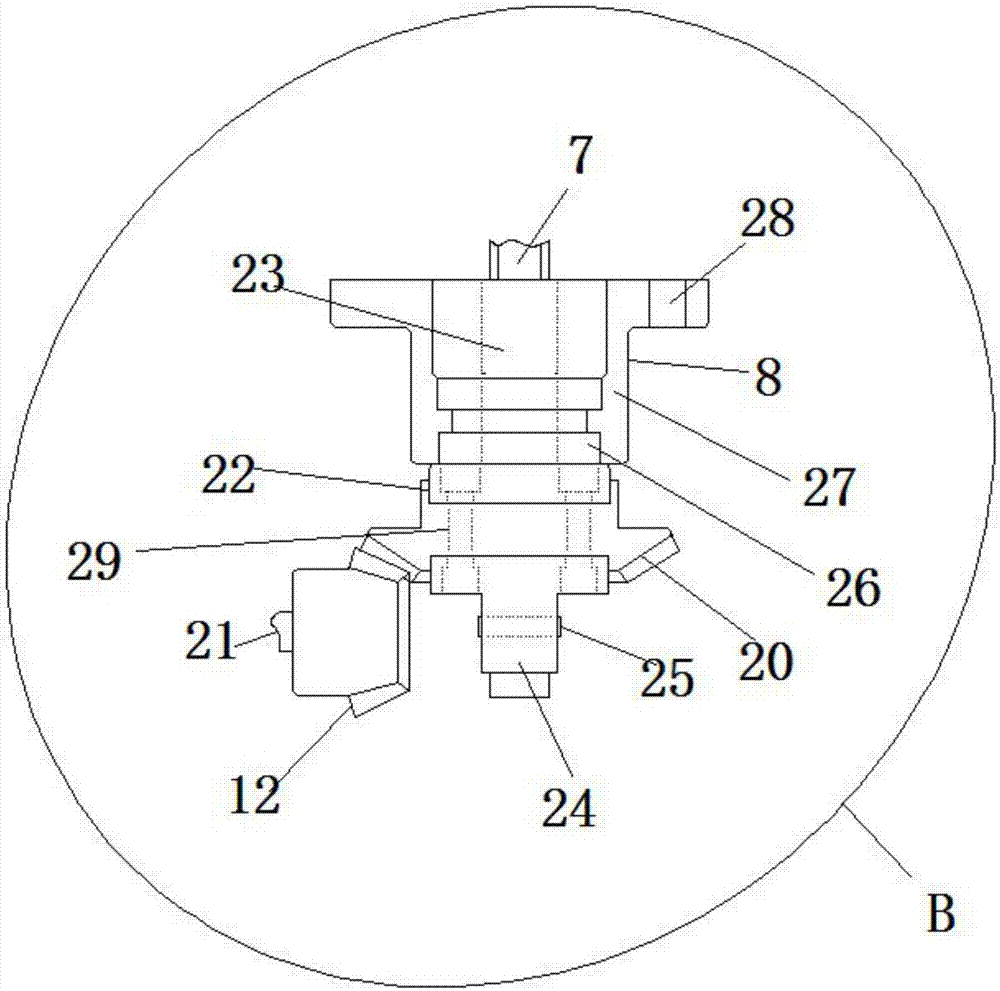

Rivet pressing machine for end cover

InactiveCN105415729AGuaranteed uptimeRealize automatic crimpingPress ramMotor driveElectric machinery

The invention relates to the field of servo motor assembling and machining equipment, in particular to a rivet pressing machine for an end cover. The rivet pressing machine comprises a servo motor, a lifting mechanism, an upper mold and a lower mold. The servo motor drives the upper mold to rise and fall by driving the lifting mechanism. In the falling process of the upper mold, the end cover placed on the lower mold is subjected to rivet pressing. According to the rivet pressing machine for the end cover, compared with the prior art, the servo motor drives the upper mold to rise and fall by driving the lifting mechanism; in the falling process of the upper mold, the end cover placed on the lower mold is subjected to rivet pressing, and the end cover and a stator are automatically connected in a pressed mode; precise control is achieved by adjusting a mold manually, and the product quality is improved; moreover, the noise occurrence rate of bearings is reduced, and operating of the mechanism is stable; the potential safety hazards due to the fact that a cylinder body of an existing air cylinder type rivet pressing machine for the end cover or an existing oil cylinder type rivet pressing machine for the end cover falls off and flies off are effectively avoided, and the safe usability is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

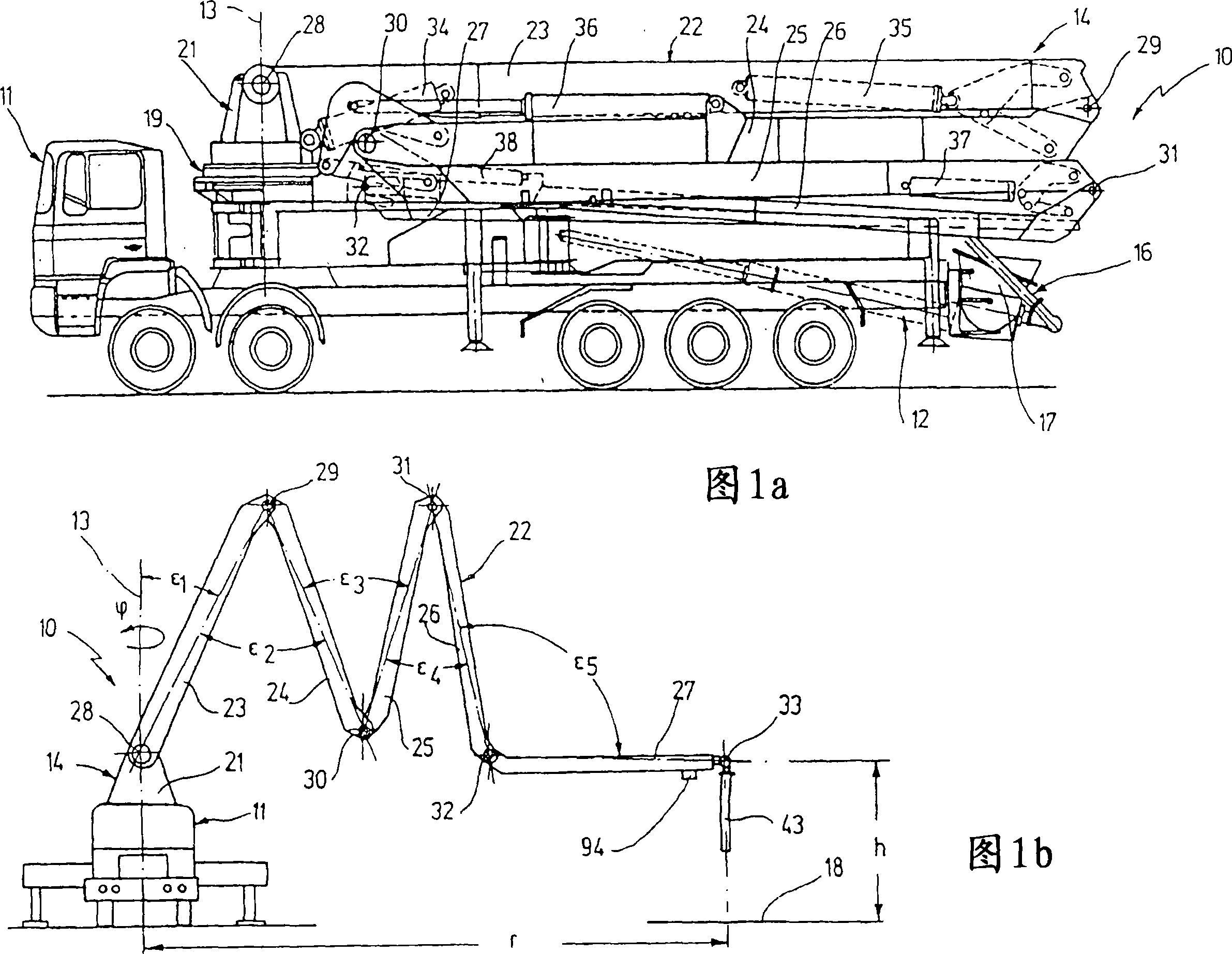

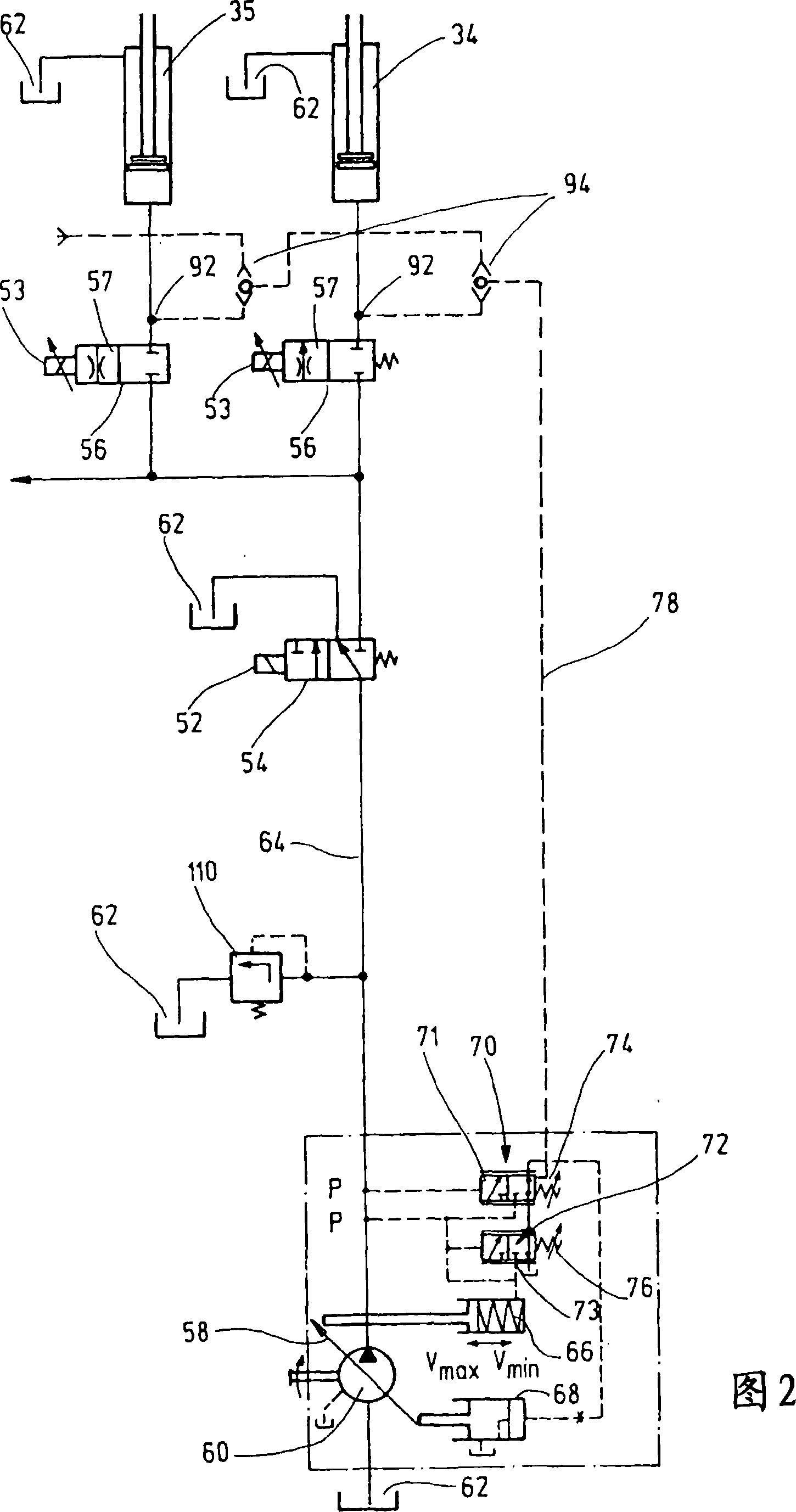

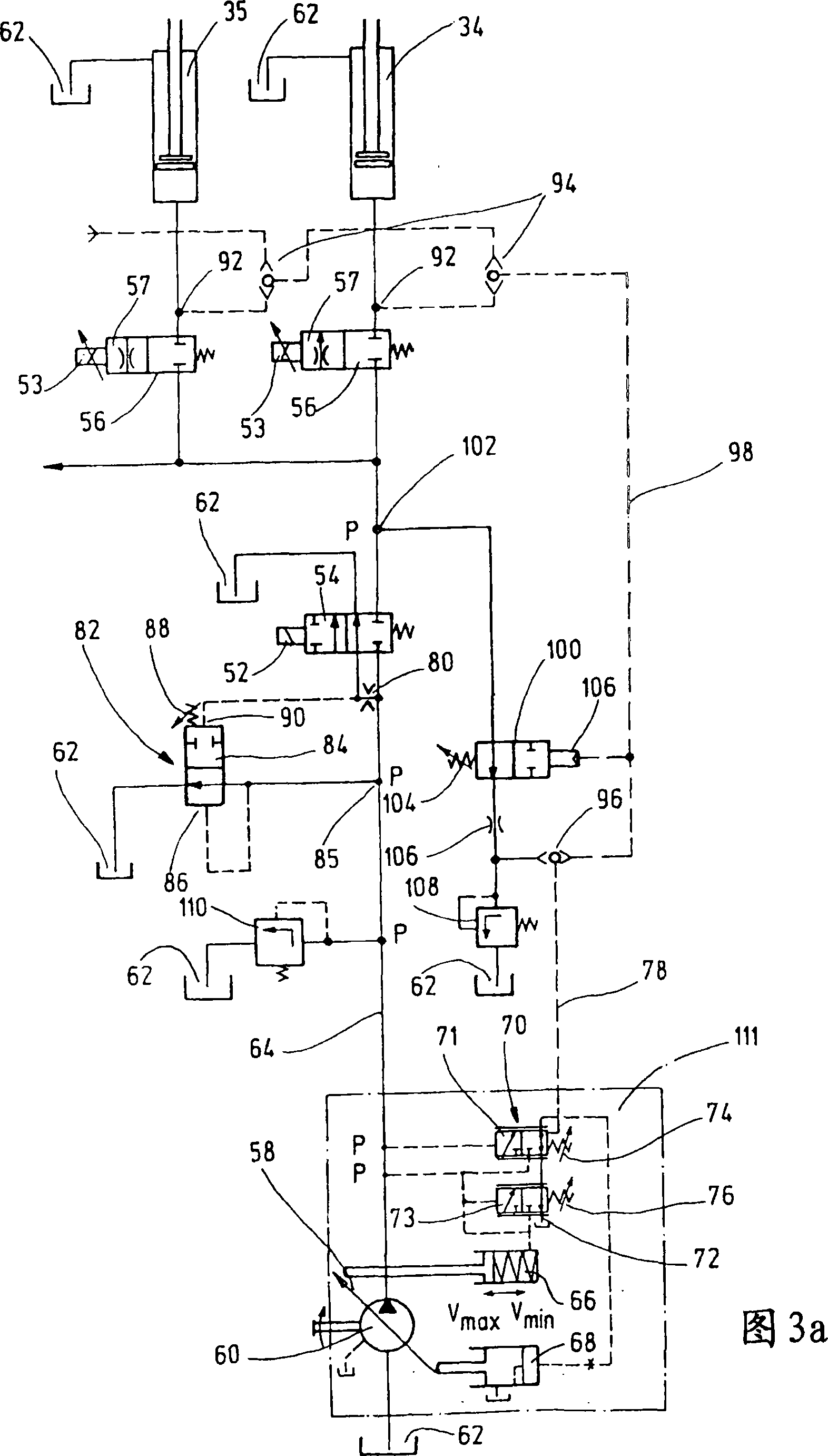

Hydraulic circuit arrangement, in particular for the drive of concrete distributor masts

InactiveCN101069018ANo oil shortageWeak designServomotorsServometer circuitsProportioning valveEngineering

A faucet includes a faucet body, and a switching device including a switching valve mounted on the water outlet pipe of the faucet body, and a control valve adjustably mounted on the switching valve and connected to a shower head. Thus, the valve seat of the control valve is rotated to change and control the water outlet modes of the faucet exactly, thereby enhancing the switching function and working efficiency of the faucet. In addition, the faucet body only needs to provide a single screw bore for mounting the switching device without having to provide two screw bores which have to align with each other, thereby facilitating fabrication of the faucet, and thereby decreasing the costs of fabrication.

Owner:PUTZMEISTER AG

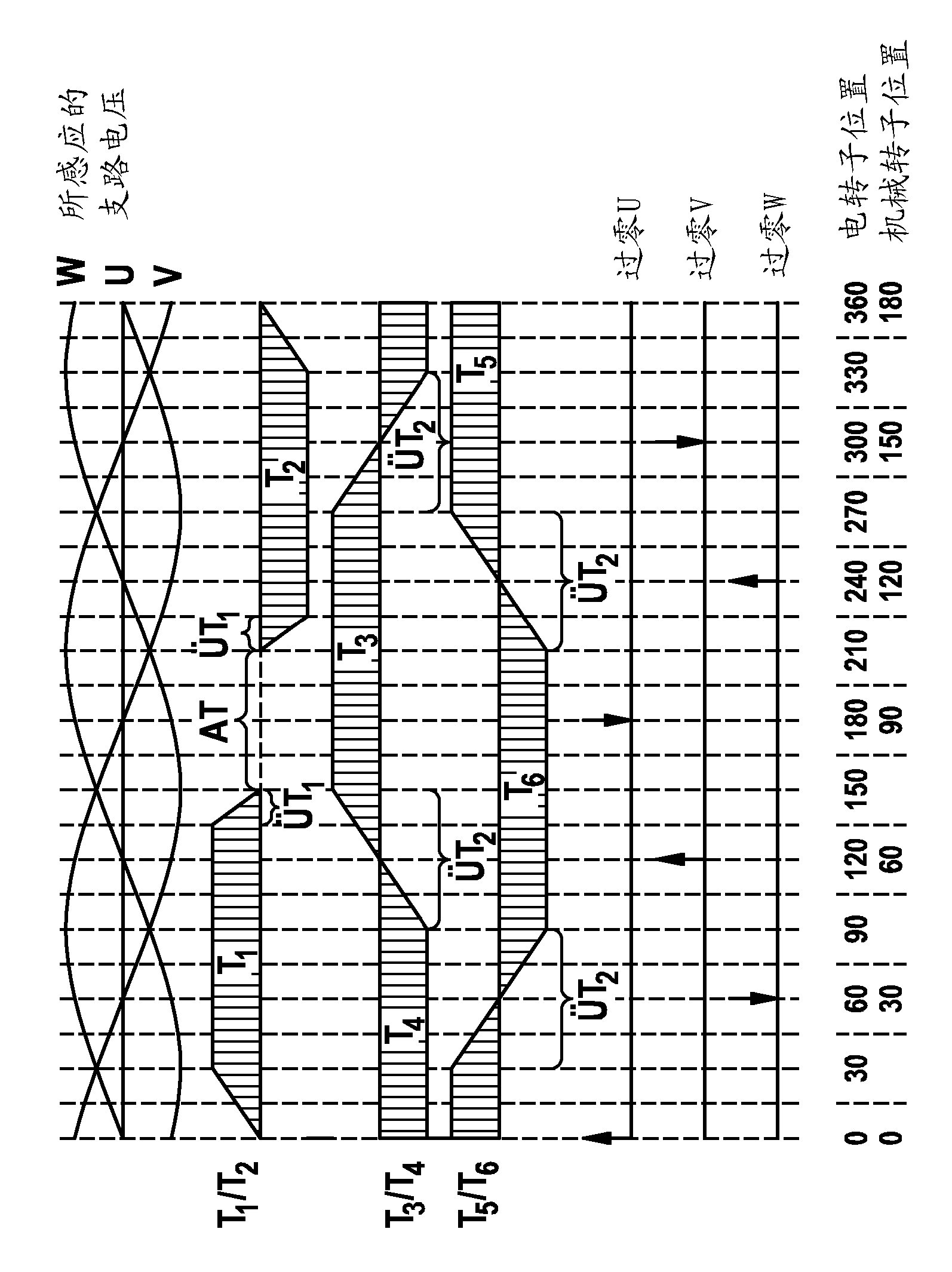

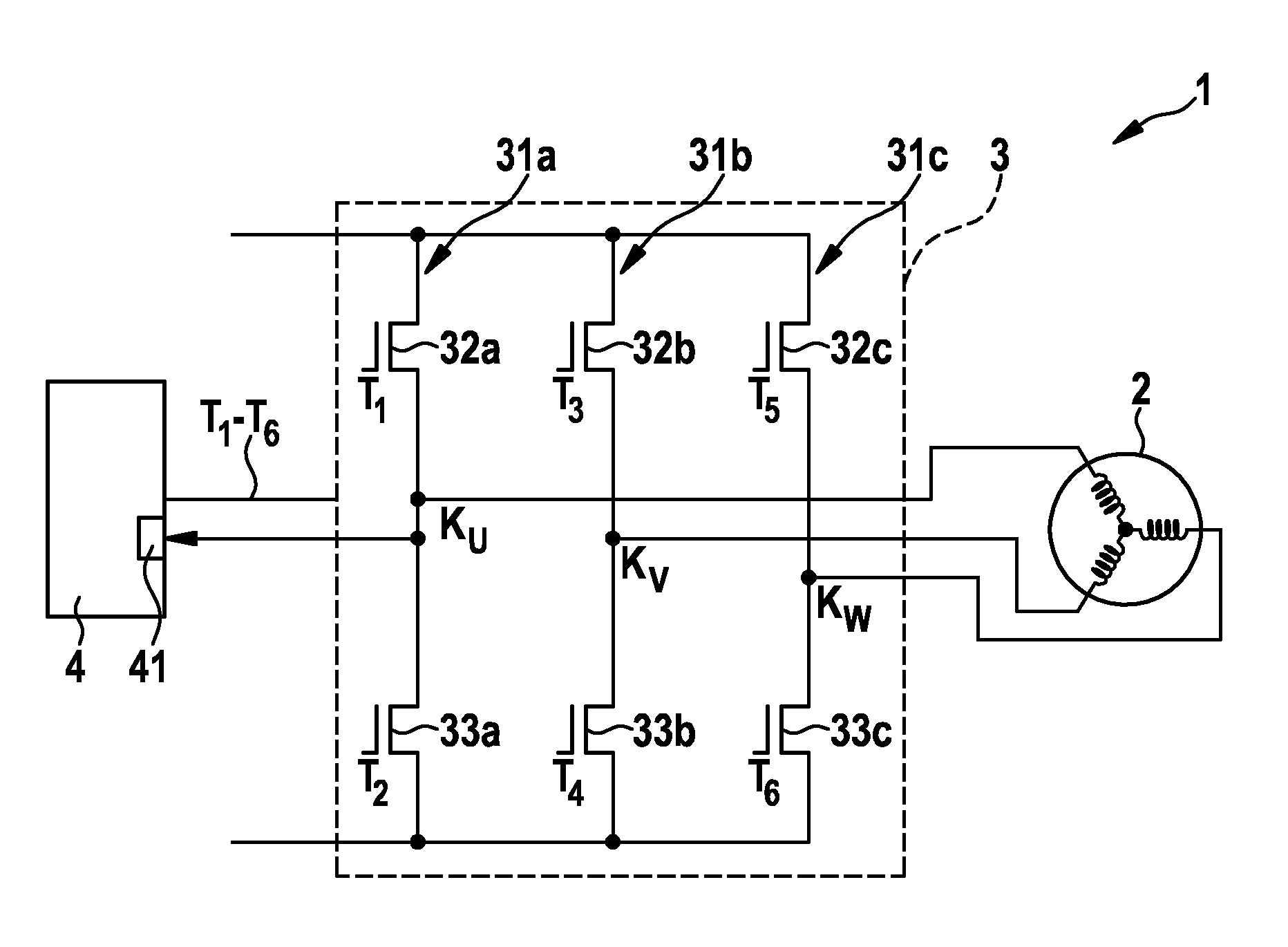

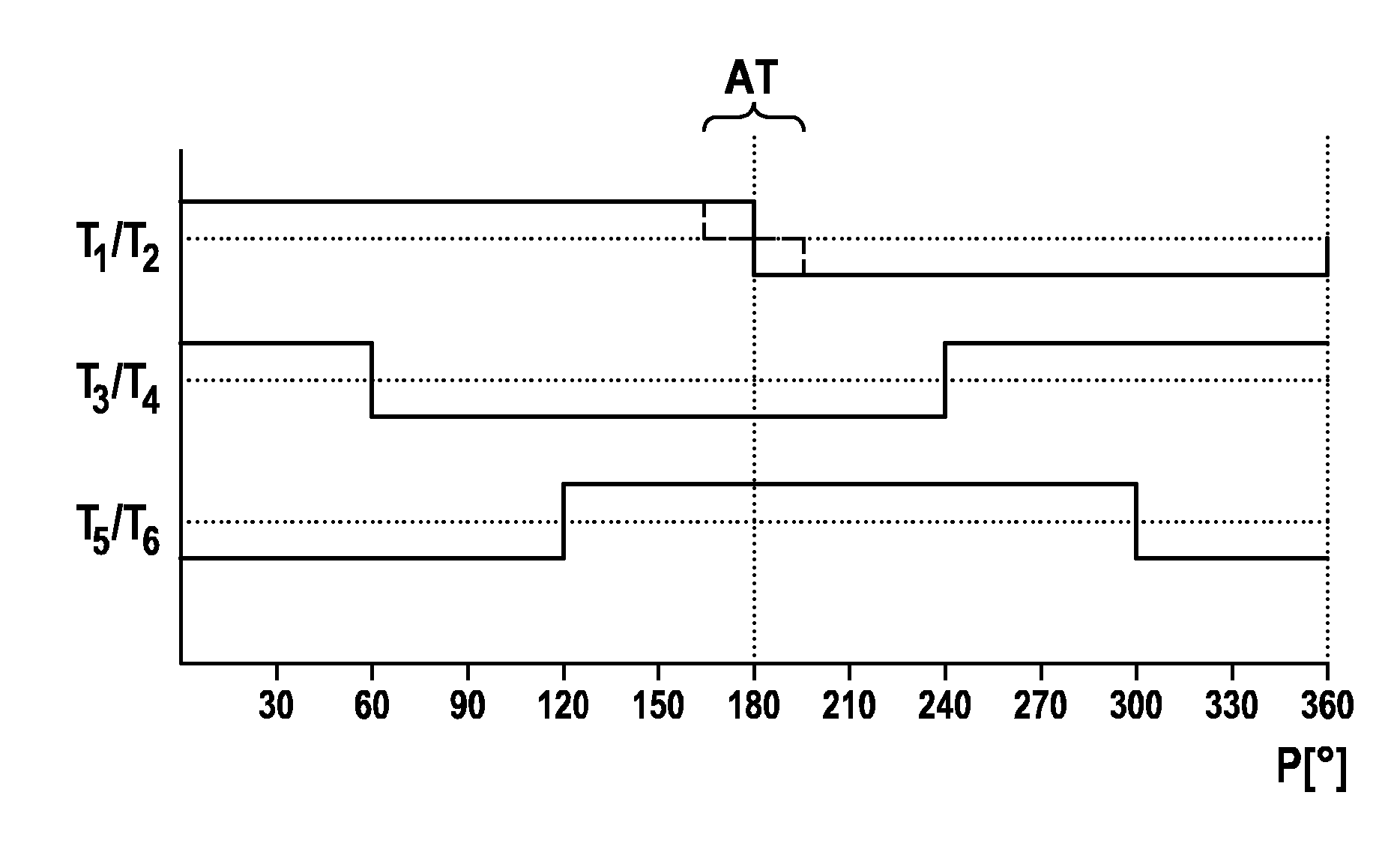

Method and device for controlling a multi-phase electronically commutated electric machine and a motor system

ActiveCN103004081AReduce noise generationReduce noiseSingle motor speed/torque controlCurrent controllersPhase currentsElectric machine

Owner:ROBERT BOSCH GMBH

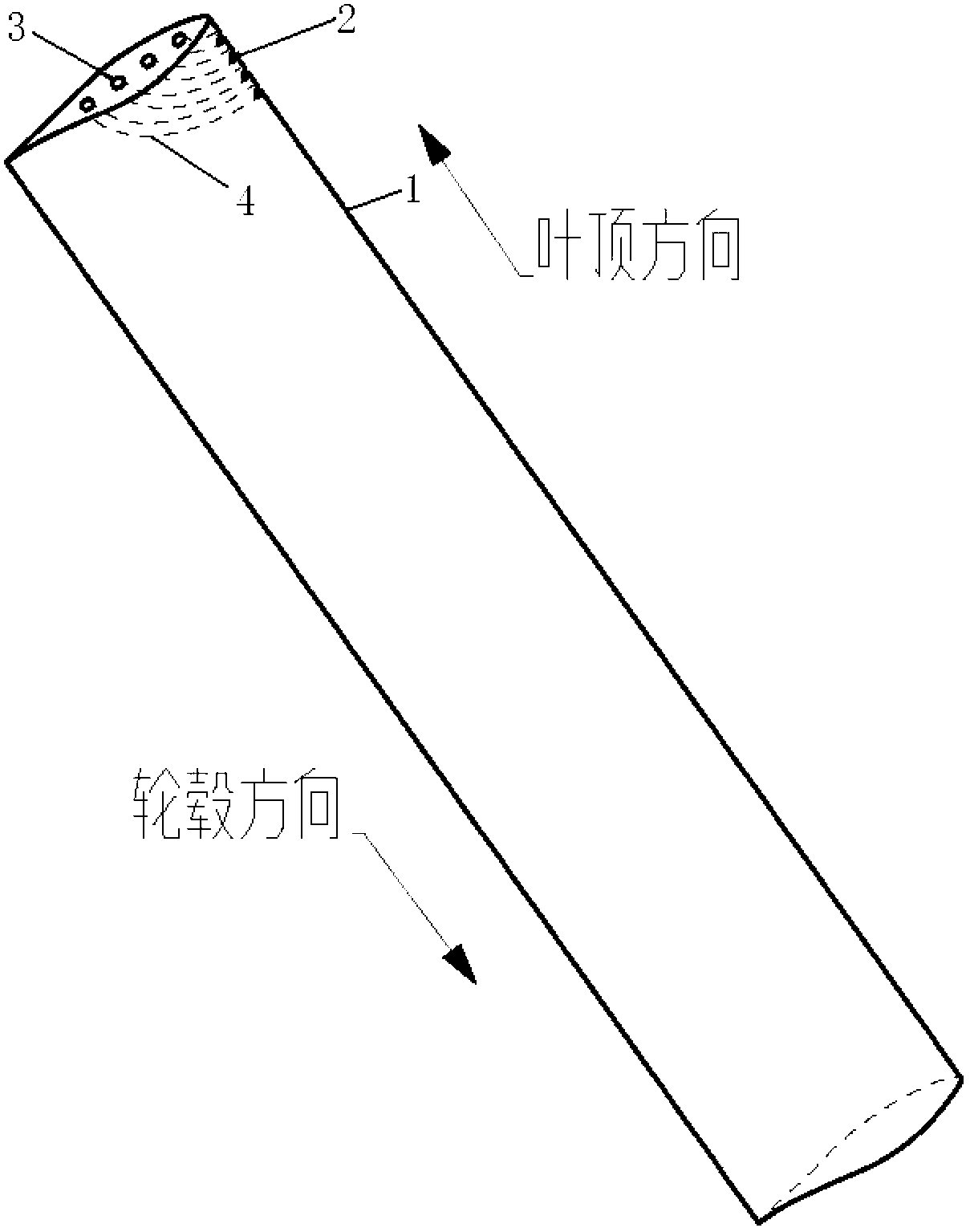

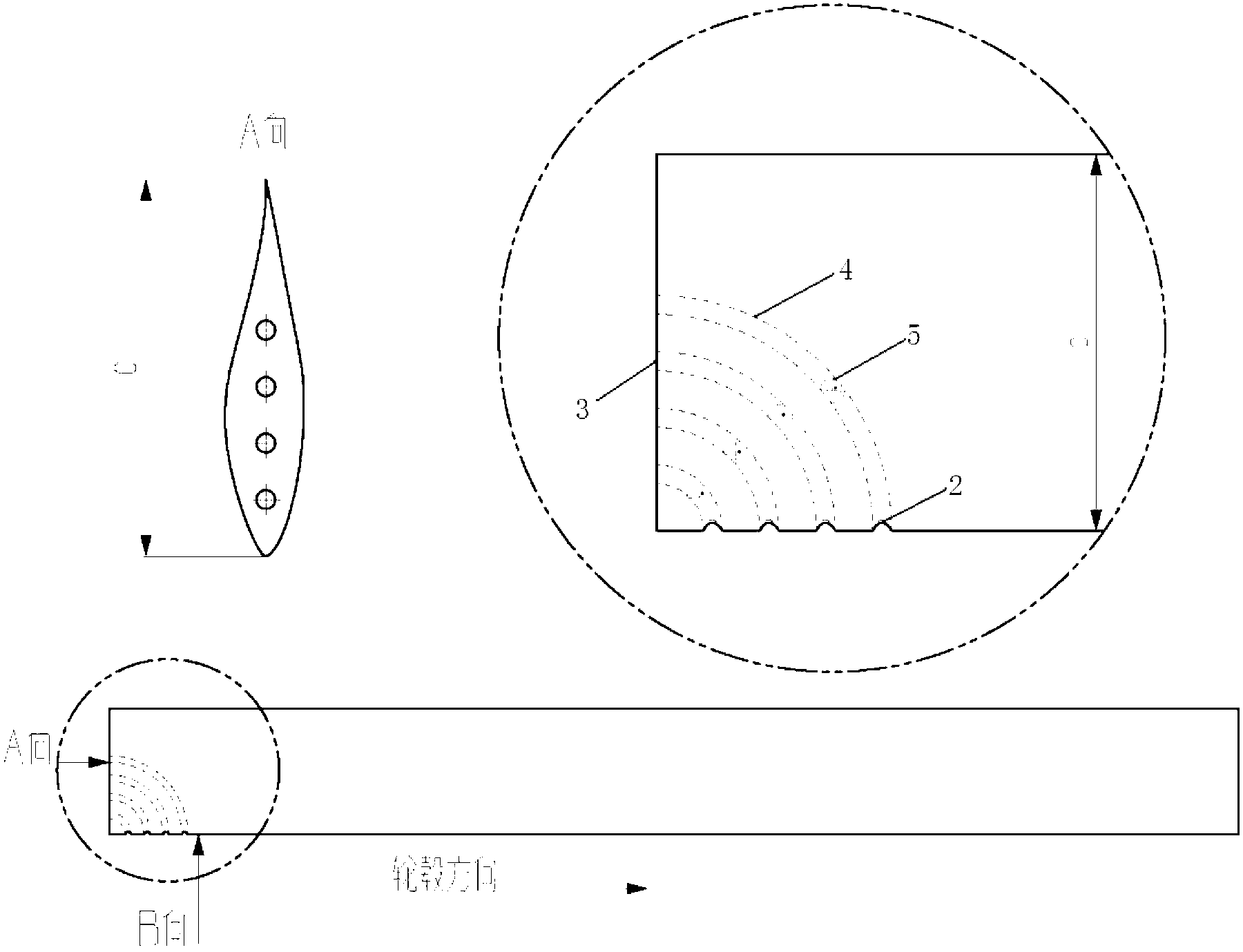

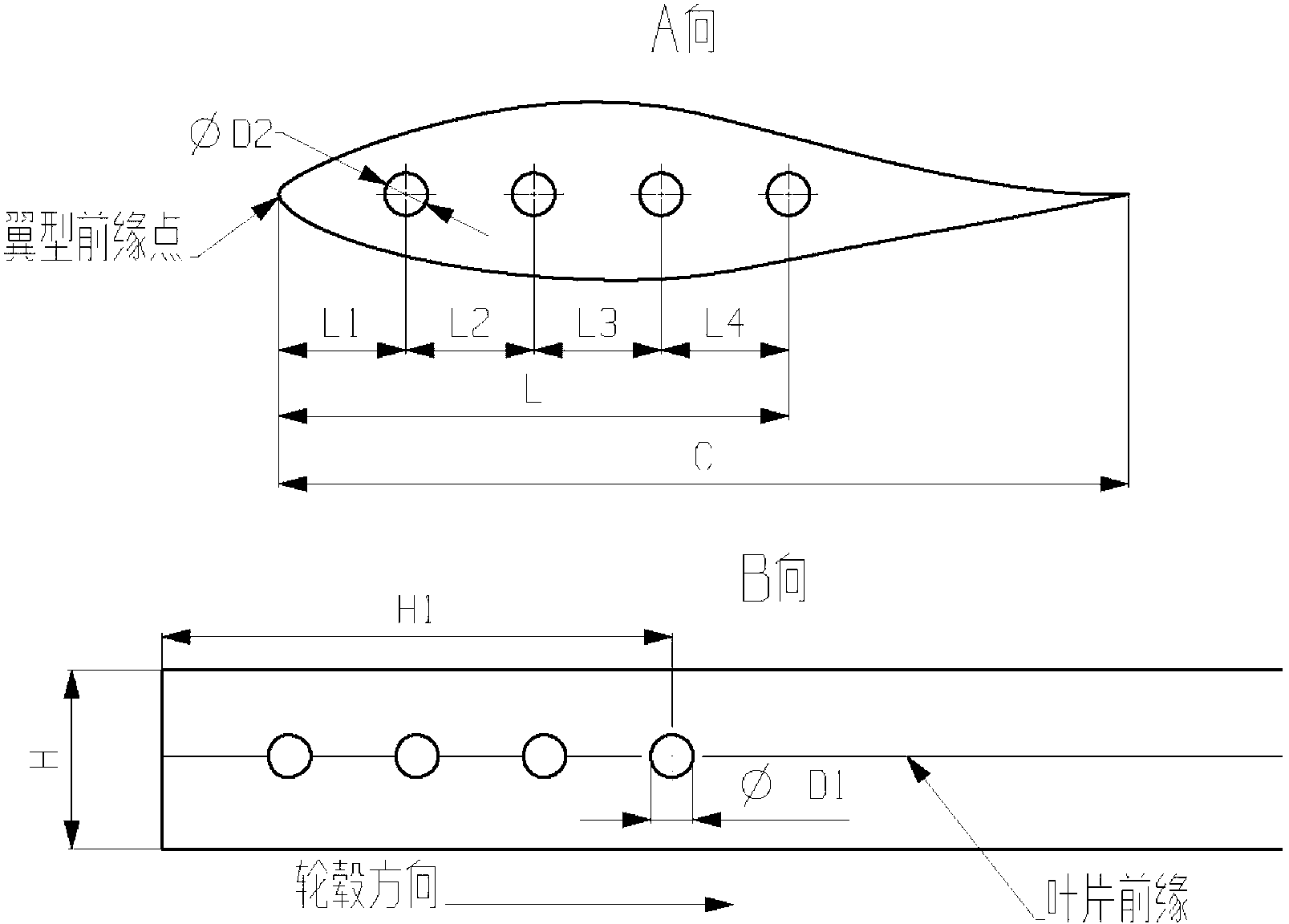

Wind turbine blade with embedded diversion pipe capable of controlling tip vortex

InactiveCN102705176ASimple structureImprove aerodynamic efficiencyWind motor controlMachines/enginesTurbine bladeAirflow

The invention discloses a wind turbine blade with an embedded diversion pipe capable of controlling tip vortex. The wind turbine blade comprises a blade tip device, an air inlet, an air outlet and a diversion pipe, wherein a plurality of air inlets are arranged at the leading edge nearby the blade tip of the blade tip device; a plurality of air outlets are arranged at the blade tip of the blade tip device; the air inlets are communicated with the air outlets by diversion pipes; and the diversion pipes are internally provided with throttling devices for controlling the air flow. The wind turbine blade provided by the invention has simple structure, is used as a blade extension segment connected to the wind turbine blade without changing the main body of the wind turbine blade, and is separately designed according to the actual situation of providing the blade wind turbine, or integrally designed by considering the device and the pneumatic structure portion of the wind turbine blade as a whole, thus maximally controlling the generation of the tip vortex, improving the pneumatic efficiency of the wind turbine and reducing the noise level.

Owner:SHANGHAI JIAO TONG UNIV

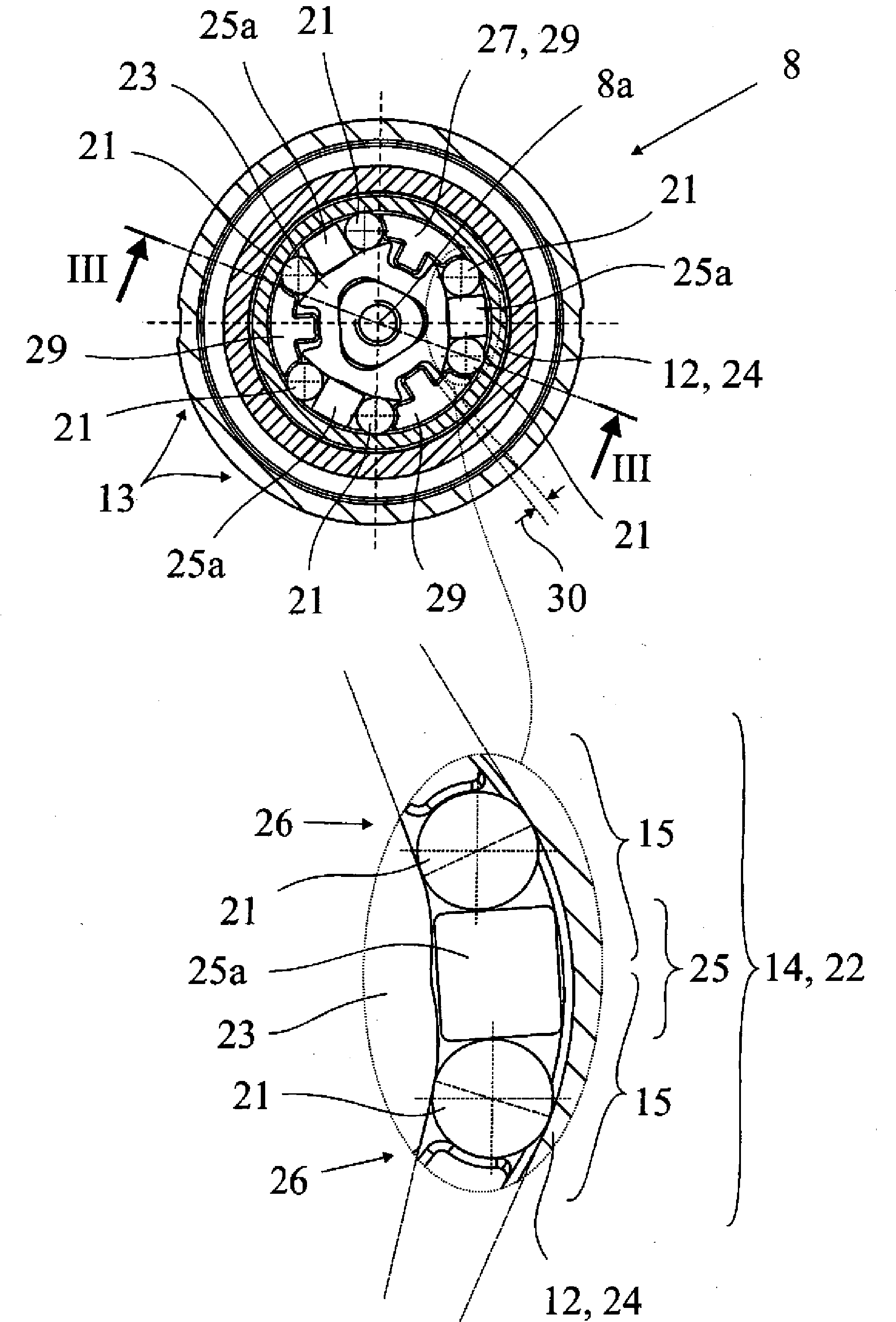

Drive arrangement for an adjustment element of a motor vehicle

InactiveCN104105836AAffect efficiencyReduce noise generationPower-operated mechanismMechanical energy handlingFreewheelCoupling

The invention relates to a drive arrangement for an adjustment element (1) of a motor vehicle, in which a coupling arrangement (8), connected into the drive train, is provided with a drive connection (9) and an output connection (10), said coupling arrangement (8) transmitting each movement introduced at the drive side to the output connection (10) and having a brake arrangement (11) for braking a movement that is introduced at the output side. It is suggested that the braking arrangement (11) has a braking element (12) which can be adjusted counter to a braking force; that, between the output connection (10) and the braking element (12), said coupling arrangement (8) comprises a freewheel arrangement (13) consisting of at least one freewheel pair (14) of clamping-body freewheels (15) which operate in opposite directions; that a movement introduced at the output side always causes the locking of at least one clamping-body freewheel (15), said movement being braked correspondingly by means of the braking arrangement (11); and that a movement introduced at the drive side always causes the release of said clamping-body freewheels (15).

Owner:科堡布罗斯车辆零件两合公司

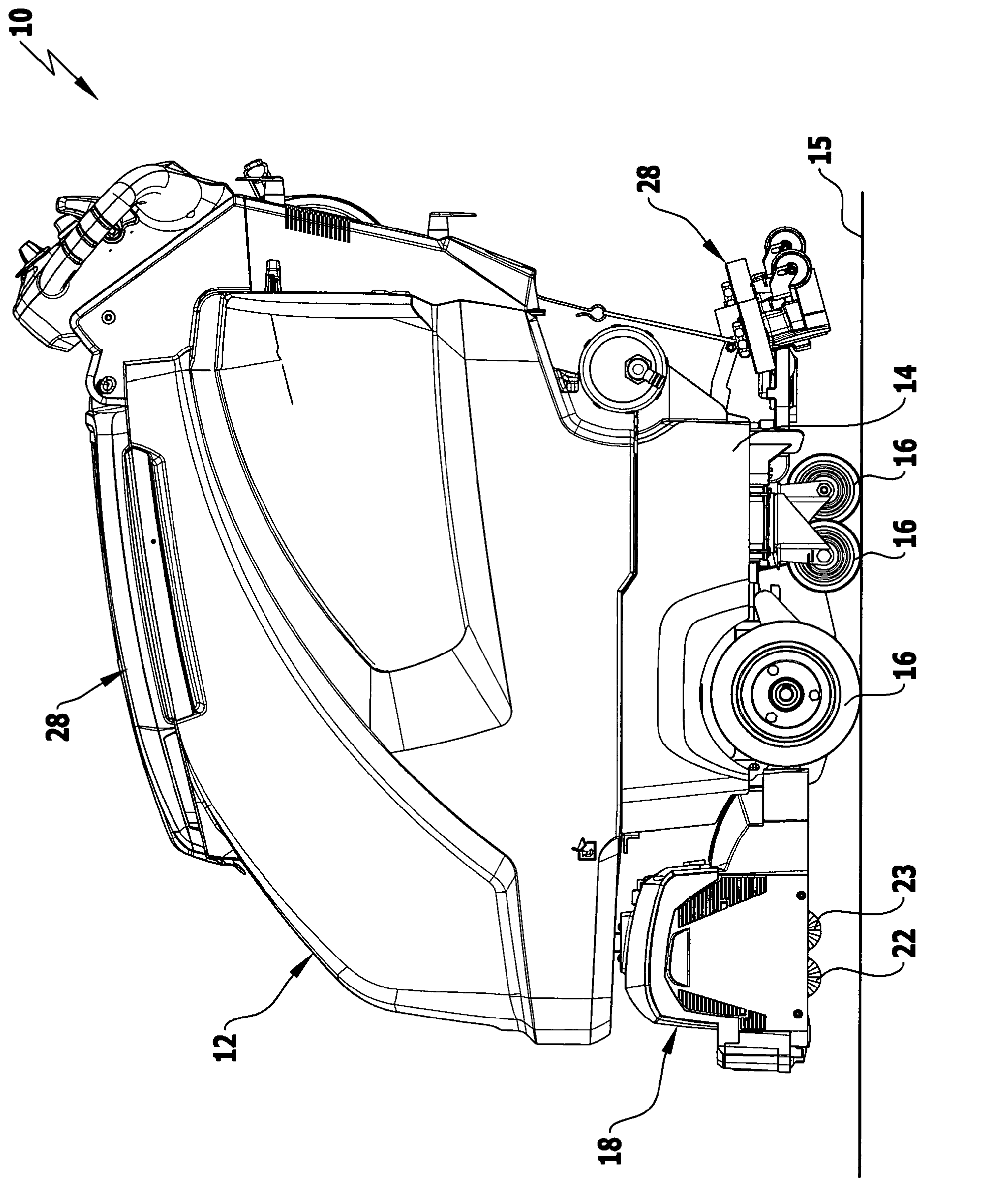

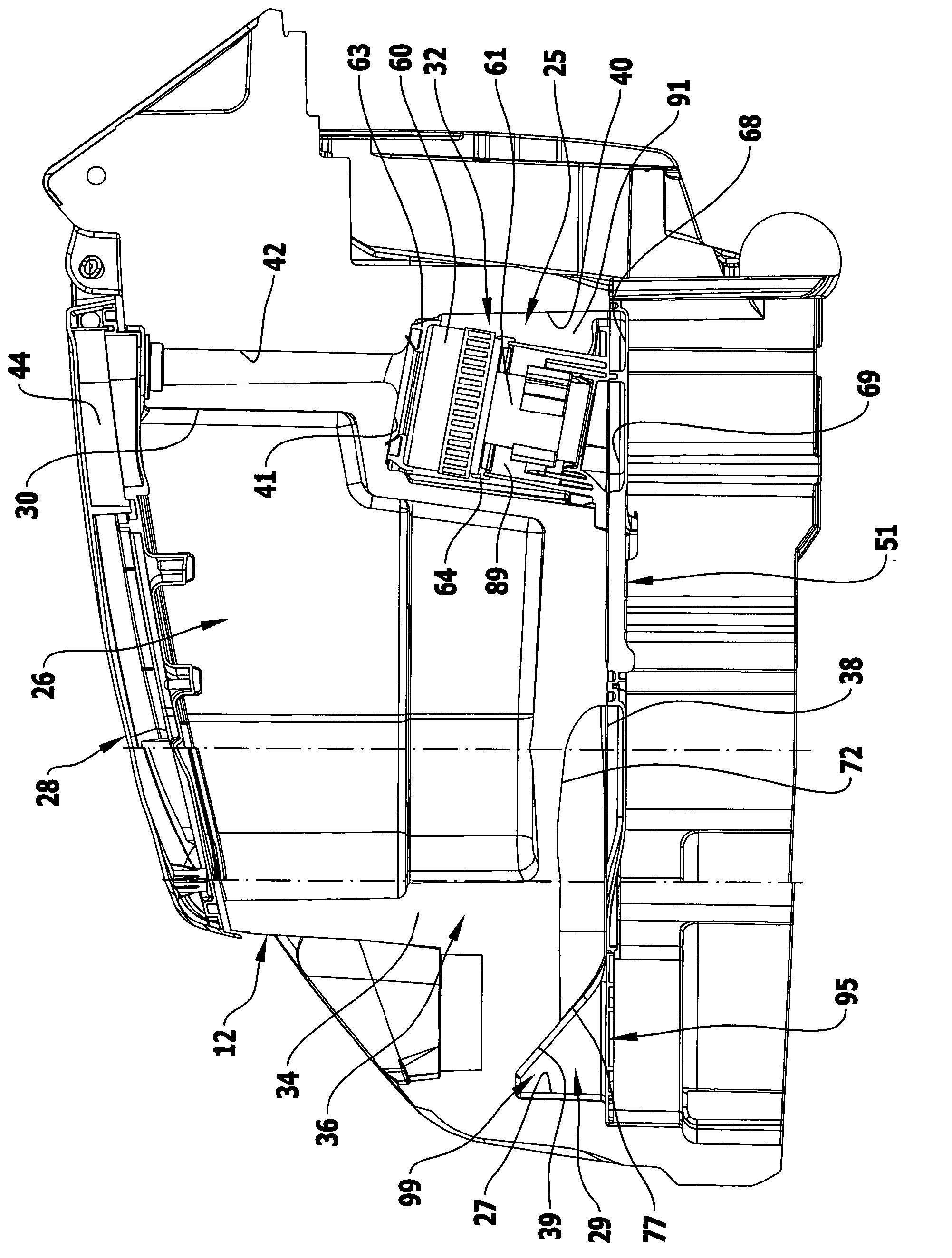

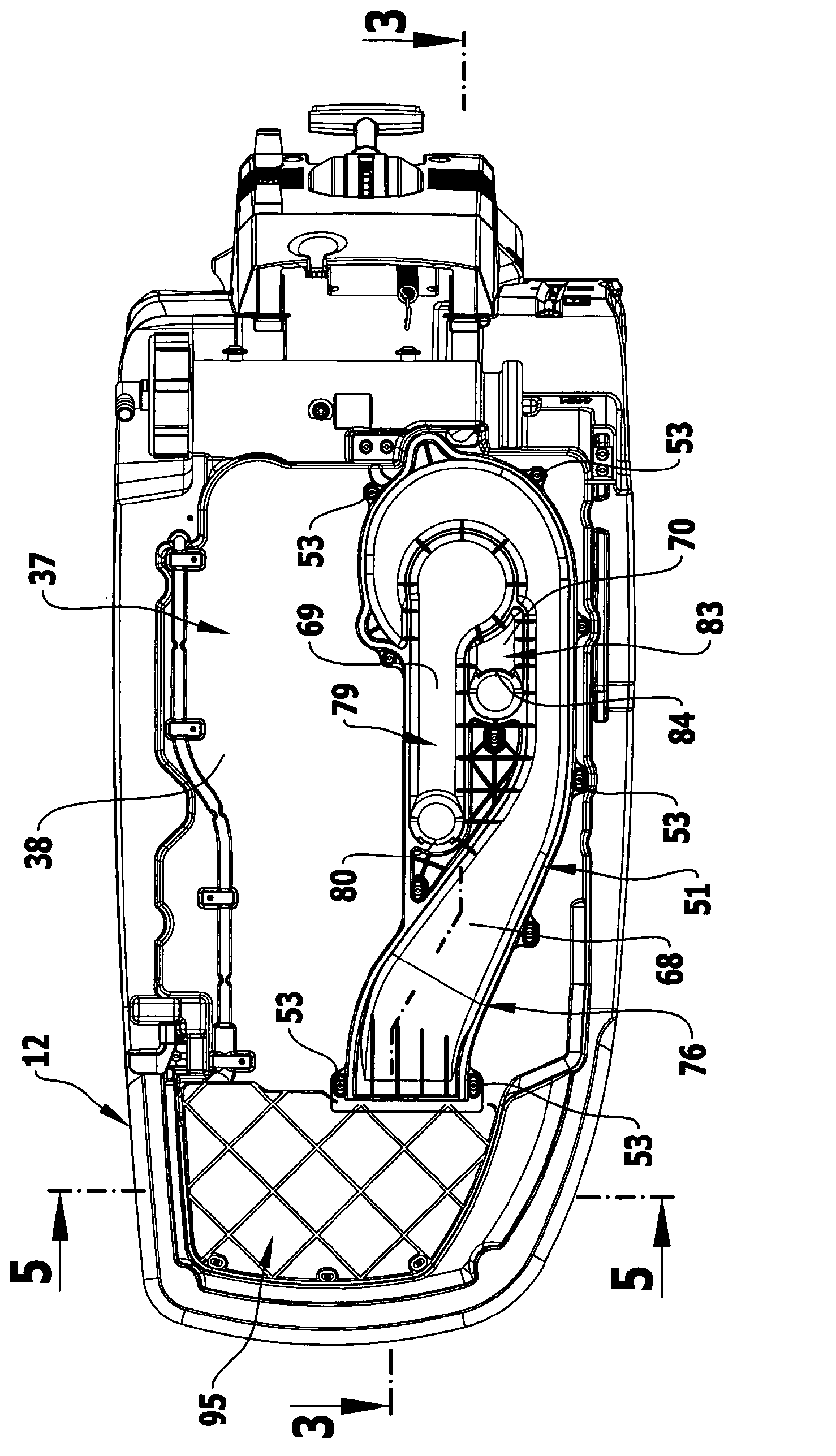

Mobile floor cleaning device having noise insulation

InactiveCN103209630ALow flow resistanceReduce noise generationCarpet cleanersFloor cleanersLiquid tankWaste management

The invention relates to a mobile floor cleaning device (10) comprising at least one cleaning tool (22, 23), a cleaning liquid tank (36), a dirt liquid tank (26) and a suction unit (32). In order to further develop the floor cleaning device (10) such that it has a reduced noise emission, a first recess (30) is formed into the tank wall of the cleaning liquid tank (36) or the dirt liquid tank (26), the suction unit (32) being arranged in said recess which is covered by a first cover element (51). According to the invention, the tank wall and / or the first cover element (51) form at least one air guide channel (76, 79, 83) extending from the first recess (30) to an opening (77, 80, 84).

Owner:ALFRED KARCHER GMBH & CO KG

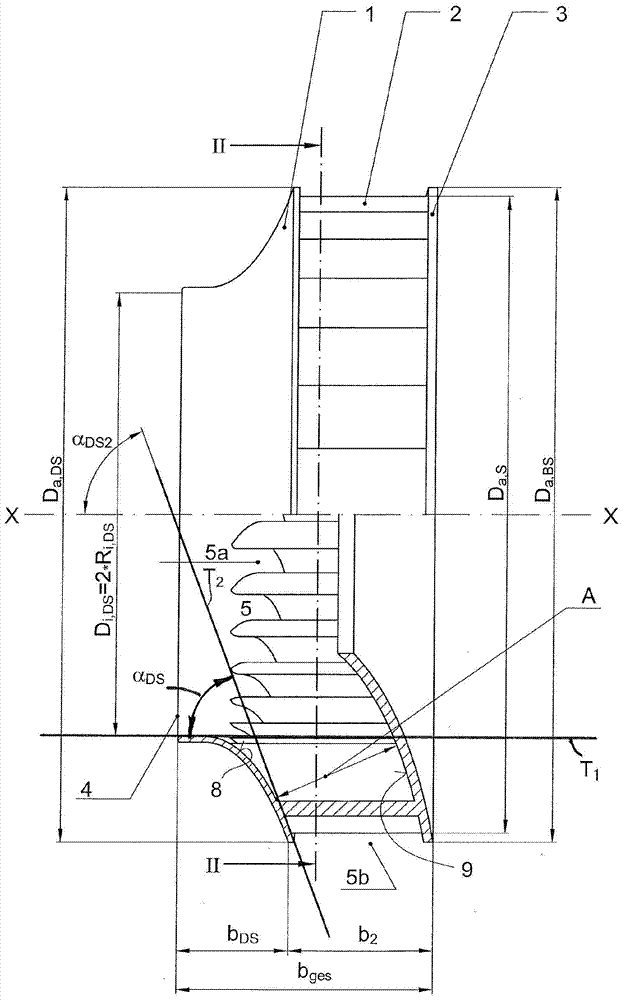

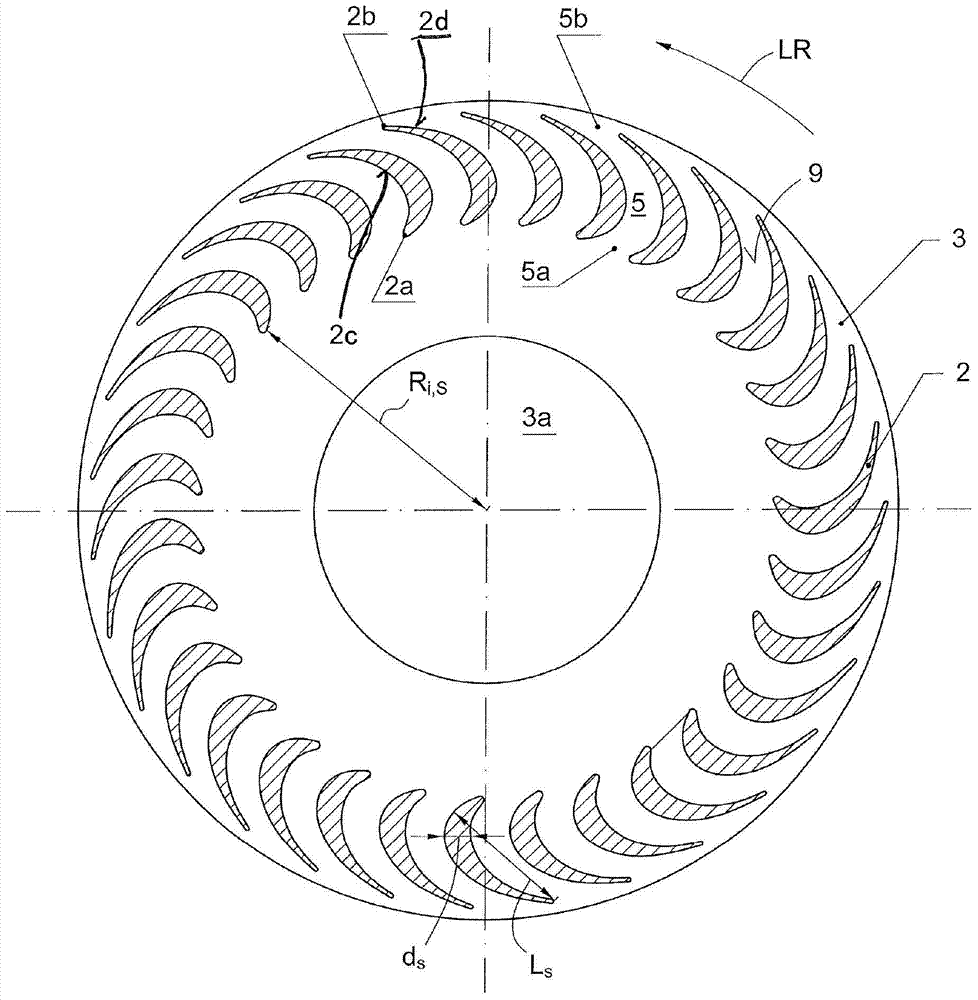

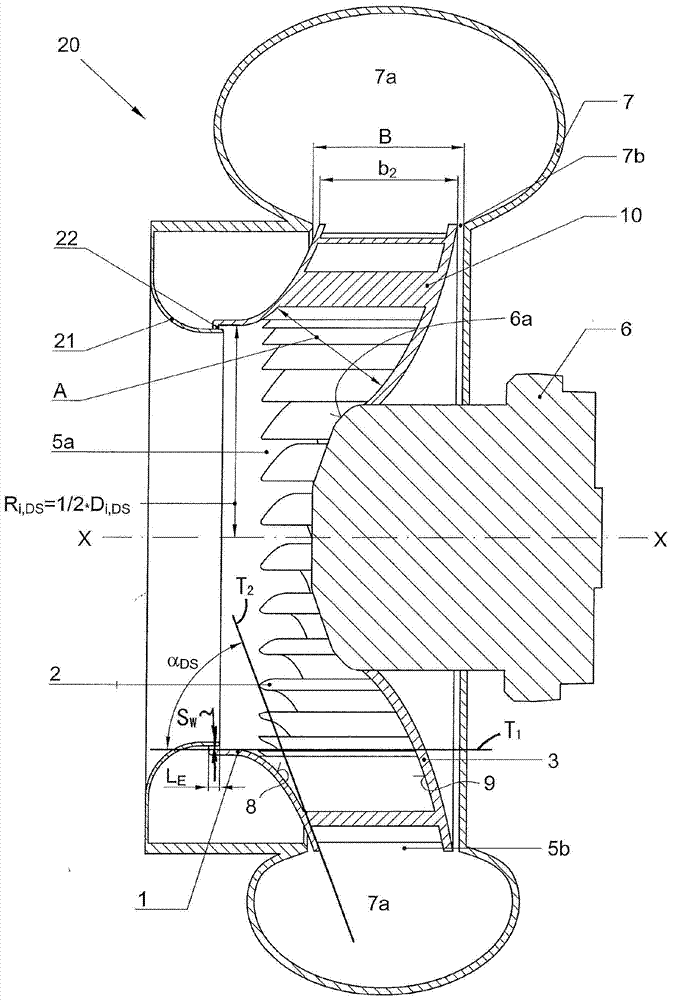

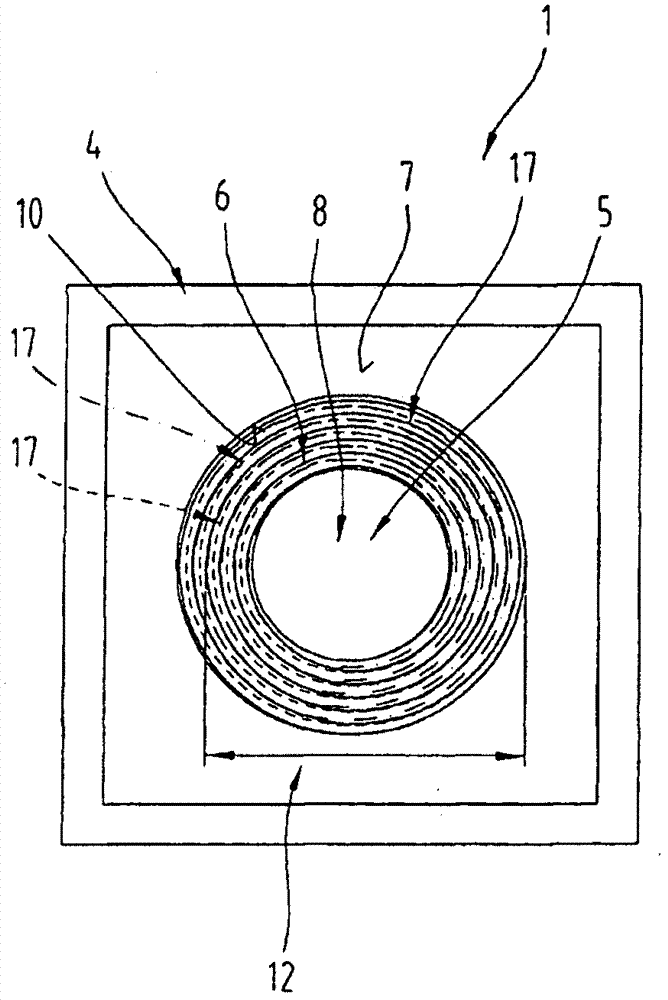

Radial impeller and fan assembly

ActiveCN104728160APrevent or at least reduce vorticesIncrease energy densityPump componentsRadial flow pumpsImpellerEngineering

An impeller has an inlet and outlet. A bottom disc has an external diameter. A top disc concentric to the bottom disc at an axial distance therefrom has a suction opening for the inlet. A plurality of forward-curved blades are arranged between the bottom disc and the top disc. A flow channel has an inner inlet side and an outer outlet side formed between adjacent blades. The channel is curved convexly viewed in the running direction of the impeller. The external diameter of the bottom disc is at least 20% greater than the internal diameter of the suction opening. The top disc forms a guiding surface and an angle is formed between a tangent on the guiding surface at the inlet to the suction opening and a tangent on the guiding surface at the outlet from the flow channel on the air outlet side is at least 30°.

Owner:EBM PAPST MULFINGEN GMBH & CO KG

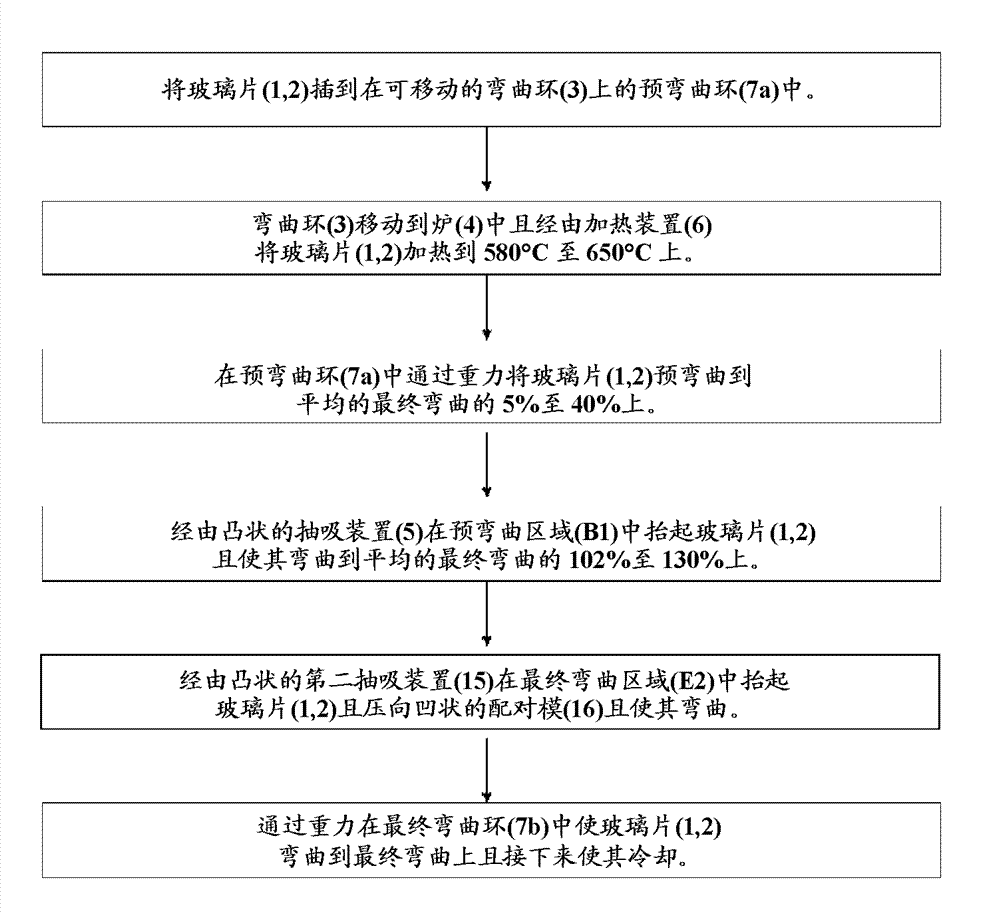

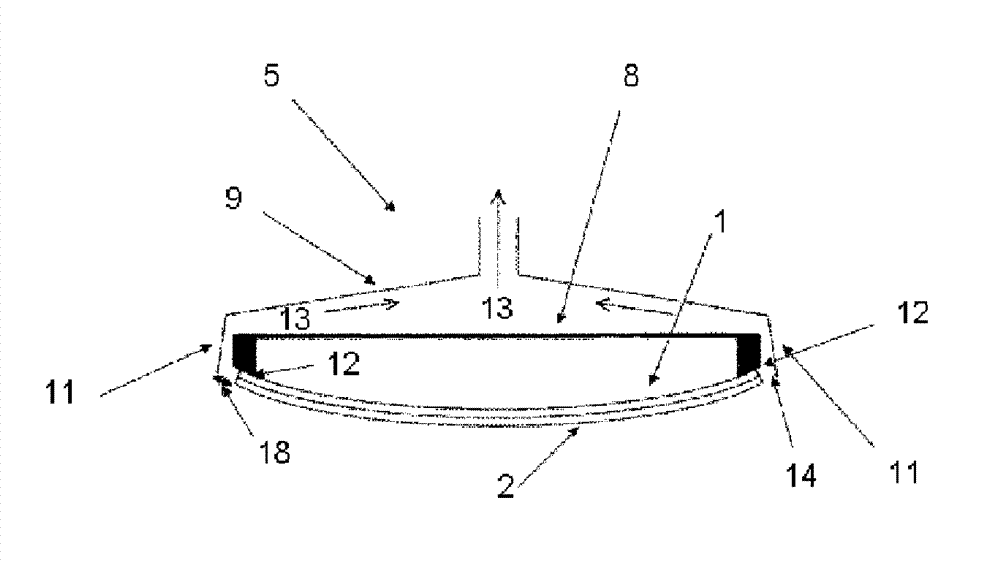

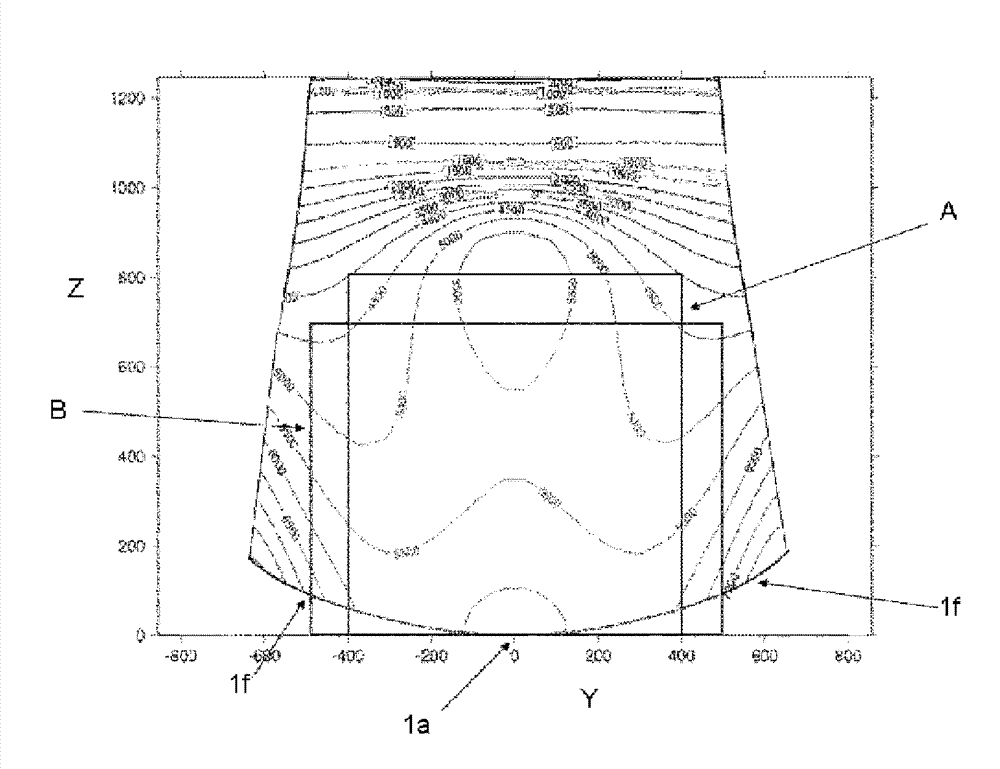

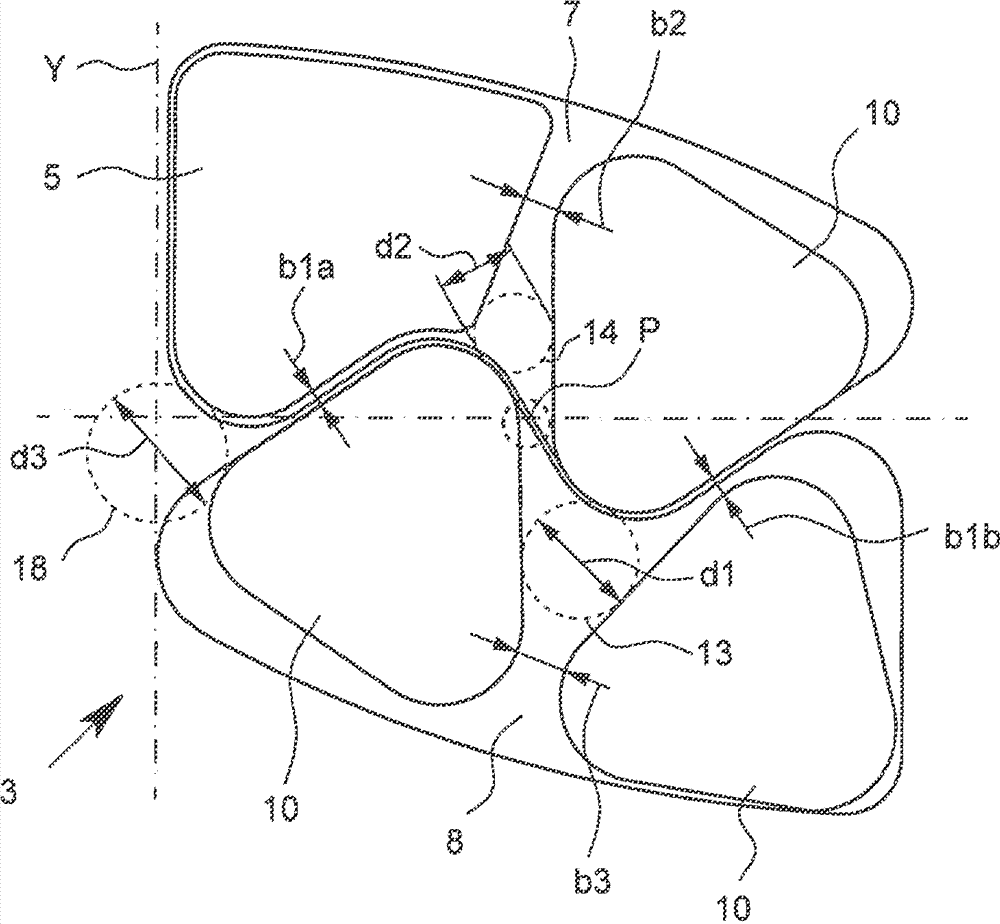

Bent windowpane

ActiveCN103249581AReduce resistanceReduce noise generationWindowsWindscreensShortest distanceShort distance

The invention relates to vehicle glazing, comprising at least one windowpane (1), which has a windowpane height from 900 mm to 1650 mm, an top upper edge (1c), an A-pillar edge (1e), a body edge (1f), and two rectangular surfaces A and B, wherein the surface A has an extent of 800 mm * 800 mm and the surface B has an extent of 1000 mm * 700 mm and surface A and surface B are centrally bounded by the lowest contact point (1a) of the windowpane (1) with the body edge (1f) horizontally with respect to the ground, and the lowest contact point (1a) and the point of the top upper edge (1c) at the shortest distance from the contact point (1a) form a Y0 axis and the points at the furthest distance with respect to the width of the windowpane (1) form a Z0 axis, wherein the windowpane (1) has a. vertical radii of curvature from 18 m to 2 m and horizontal radii of curvature from 10 m to 1.5 in the region of the surface A, b. vertical radii of curvature in the range from 18 m to 3 m and horizontal radii of curvature from 10 m to 0.8 m in the region of the surface B, c. the curvature of the windowpane (1) along Y0 at the boundary with the top upper edge (1c) corresponds to a first tangent (1b), wherein the first tangent forms an angle a (alpha) from -10 DEG to 15 DEG from the top surface (19), the curvature of the windowpane (1) at the boundary of the windowpane (1) with the A-pillar (1e) corresponds to a second tangent (1d), wherein the second tangent forms an angle beta from 28 DEG to 70 DEG from Z0.

Owner:SAINT-GOBAIN GLASS FRANCE

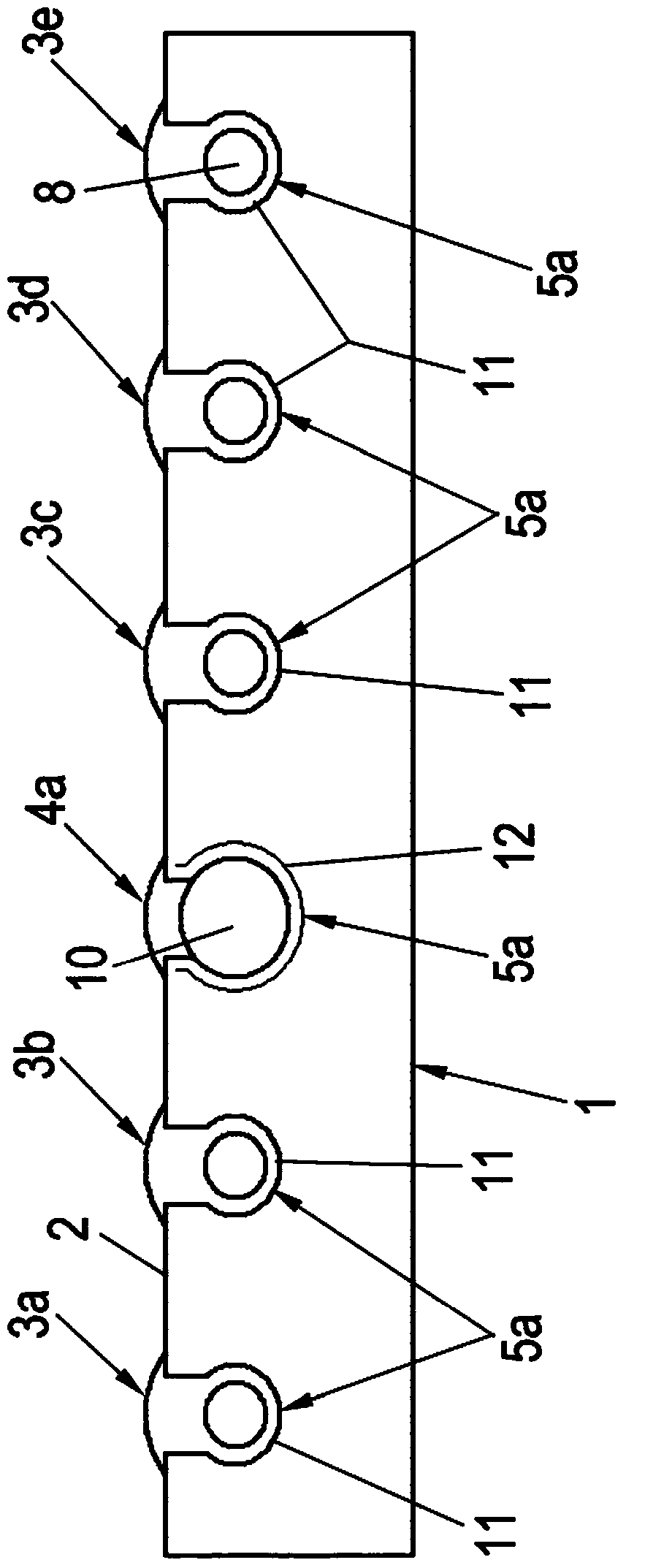

Modular brake lining system and brake lining

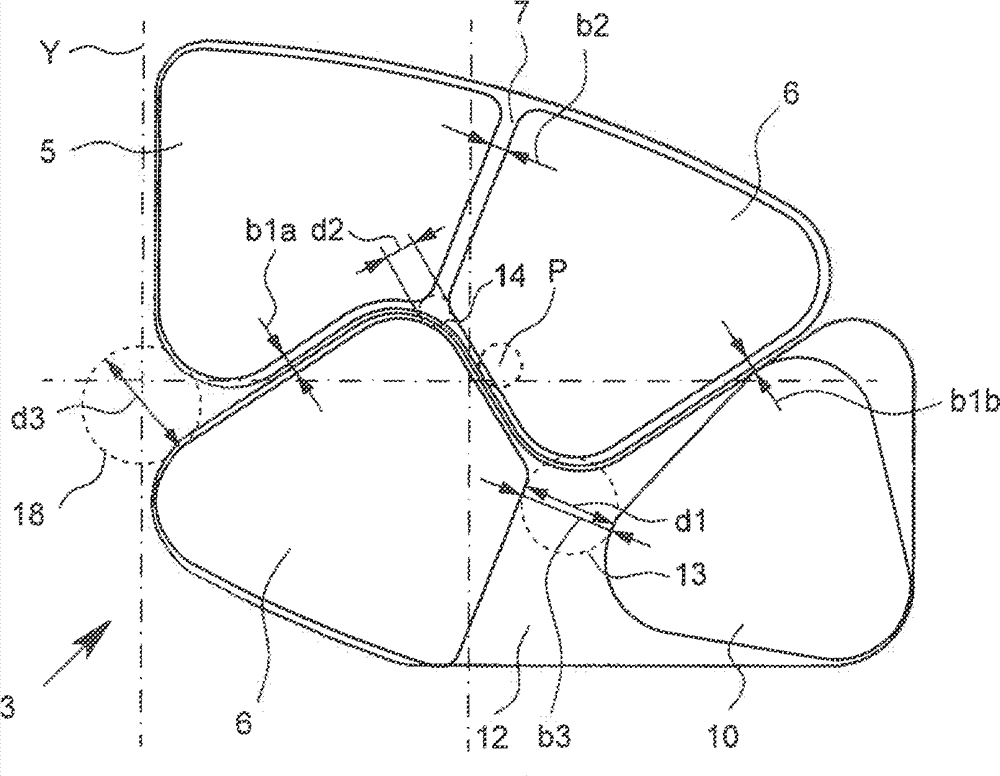

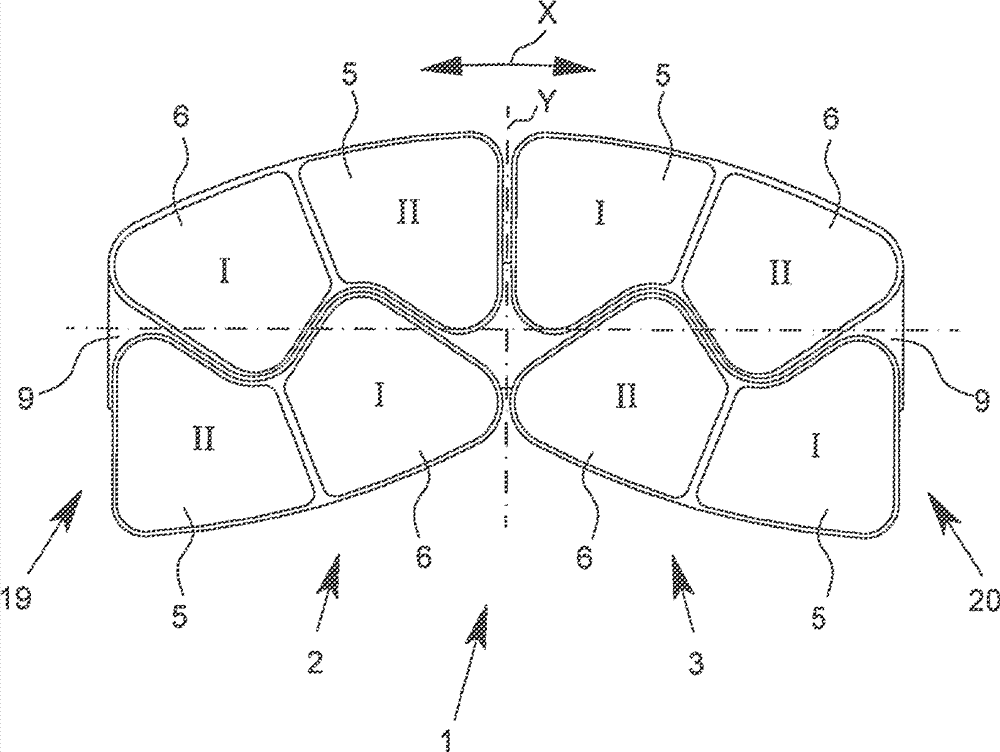

InactiveCN104813061AChange braking characteristicsGood abrasivenessBraking elementsFriction liningTransverse axisBrake lining

The invention relates to a modular brake lining system, in particular for a brake disc (4) of a disc brake, moreover in particular for rail vehicles, having mounting plates (7, 8, 12) held on at least one rear part (9) and having a plurality of different friction segments (5, 6, 10, 11), wherein different friction segments (5, 6, 10, 11) have friction surfaces having different geometries and / or different sizes and / or different coefficients of friction and / or of different friction materials and wherein, as required, different friction segments (5, 6, 10, 11) of the brake lining system can be fastened to the mounting plates (7, 8, 10, 11). According to the invention, by changing the arrangement of the friction segments (5, 6, 10, 11) on the brake lining (1) and / or by changing the number of identical or different friction segments (5, 6, 10, 11), the maximum clearance diameter (d1, d2) of a clearance circle (13, 14) positioned beyond the central transverse axis (Y) of the brake lining (1) tangentially to at least two, preferably at least three, adjacent friction segments (5, 6, 10, 11) is adjustable to a value between 5 and 40 mm.

Owner:BECORIT

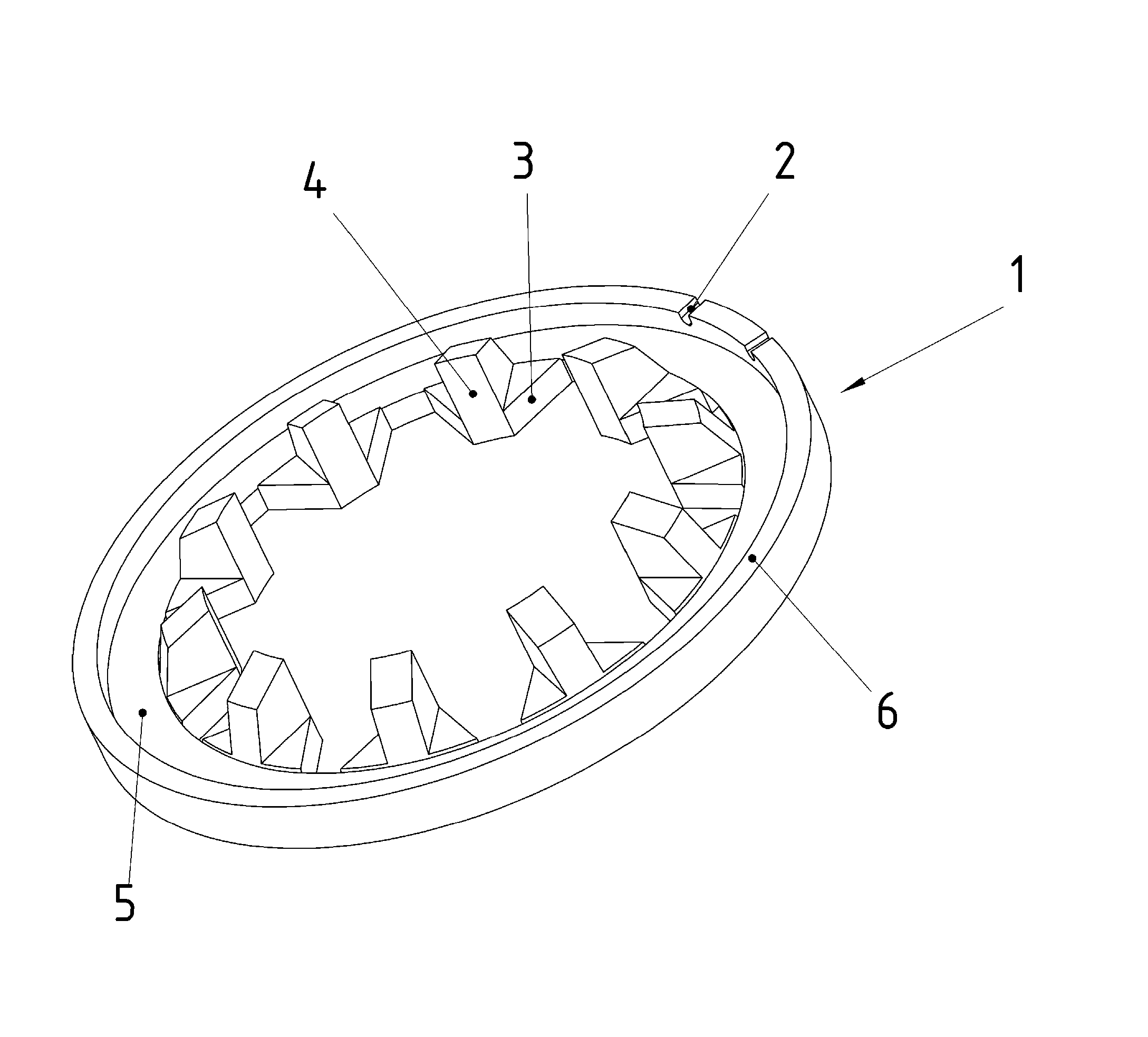

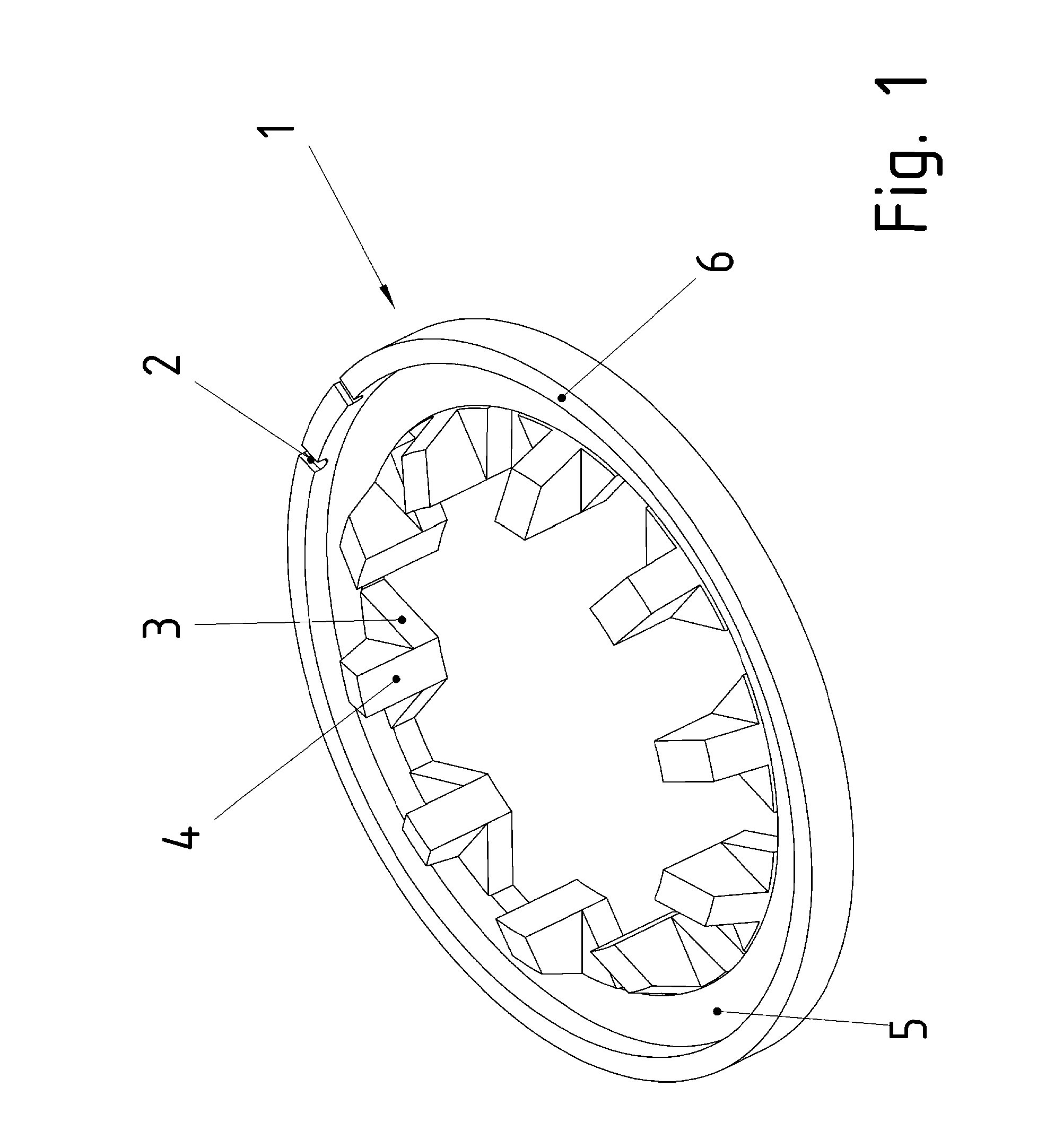

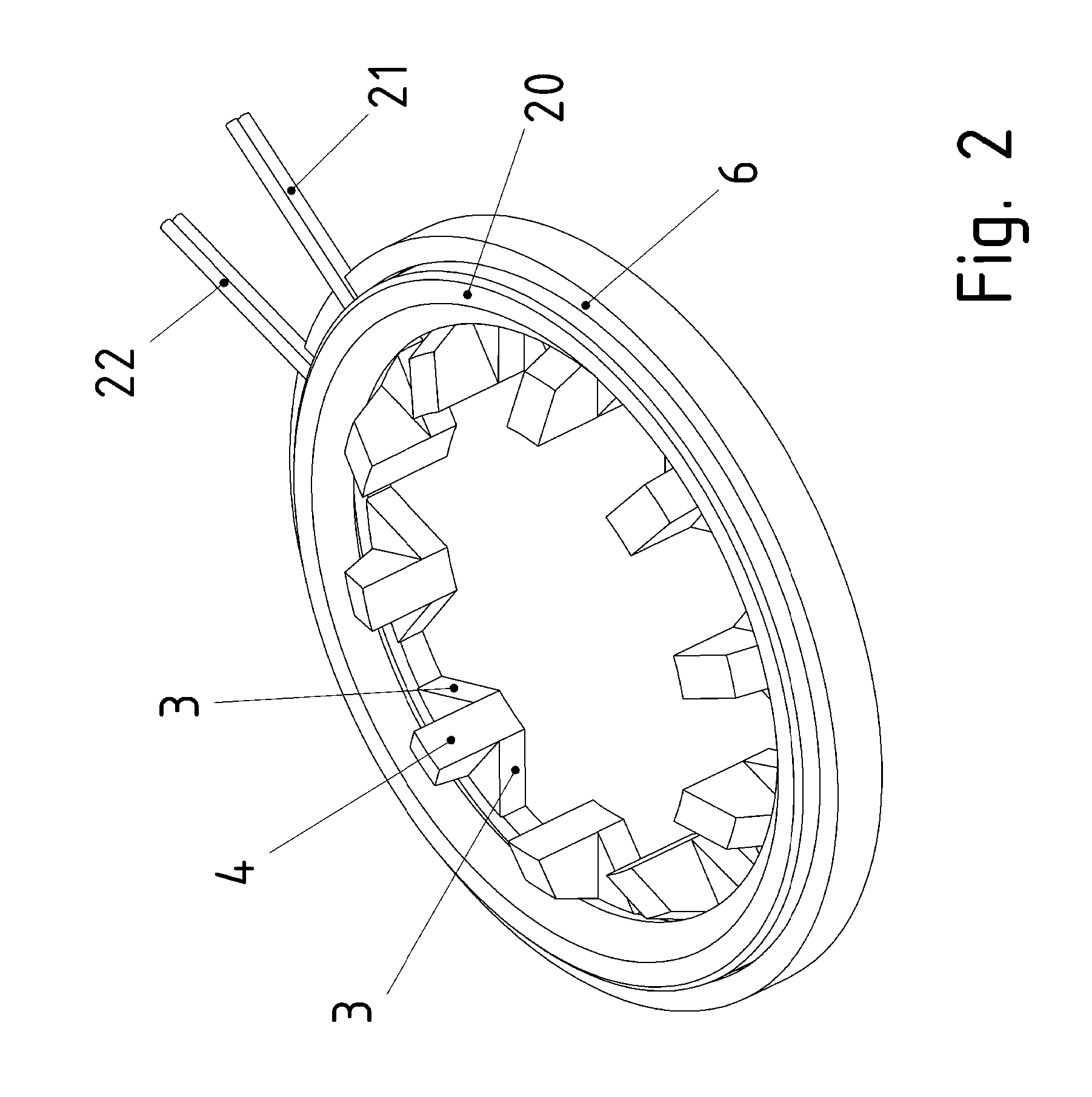

Electric Machine

ActiveUS20140346920A1Good regulation characteristicsIncrease torqueWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machineEngineering

An electric machine, especially a transversal flux machine, the stator being composed of a stack of phase segments, each phase segment having at least one stator segment and one stator winding, especially a single winding, each stator segment having an annular stator bridge, on which pole shoes are premolded, which in particular extend in the radially inward direction, and / or which extend in the direction of the rotor and / or which are situated between the rotor and the annular stator bridge, the pole shoes having the same shape, in particular, the axial width of the pole shoe decreasing with increasing radial clearance, the associated profile being disposed between a first and a second profile, the first profile being a linear function of the radial clearance, the pole back associated with the first profile being a planar area, in particular, the second profile being a circular function, in particular a circular segment function, the pole back associated with the second profile being a cylindrical section area, in particular.

Owner:SEW-EURODRIVE GMBH & CO KG

Open iron core structure of inductance-adjustable resonant reactor

ActiveCN107424810AReduce lossImprove comfort experienceConversion without intermediate conversion to dcVariable inductancesNoise generationEngineering

The invention relates to the technical field of power, in particular to an open iron core structure of an inductance-adjustable resonant reactor. The open iron core structure comprises an outer cylinder, wherein the outer cylinder is a cylinder with two sealed sides, the bottom of the outer cylinder is fixedly connected with the base, a handle is fixedly connected with one side, far away from the base, of an outer wall of the outer cylinder, a line pack is fixedly connected with the top of an inner cavity of the outer cylinder, a guide cylinder is inserted into an inner cavity of the line pack, an iron core is arranged in an inner cavity of the guide cylinder, a screw rod is inserted into the inner cavity of the guide cylinder, and a screw rod sleeve is in threaded connection with one end, near to the iron core, of the lead screw. By the open iron core structure of the inductance-adjustable resonant reactor, the function of adjusting inductance is achieved, a large magnetic sensing force does not exist between irons during the adjustment process, the single iron core which is employed is relatively small in magnetic leakage, the iron core loss is low, the output power of the whole equipment is improved, and the comfortableness of a user is enhanced; and moreover, the whole structure is relatively small in size, the total weight of the whole equipment is reduced, and the noise generation quantity is relatively small during inductance adjustment.

Owner:STATE GRID HUBEI MARKETING SERVICE CENT (MEASUREMENT CENT) +1

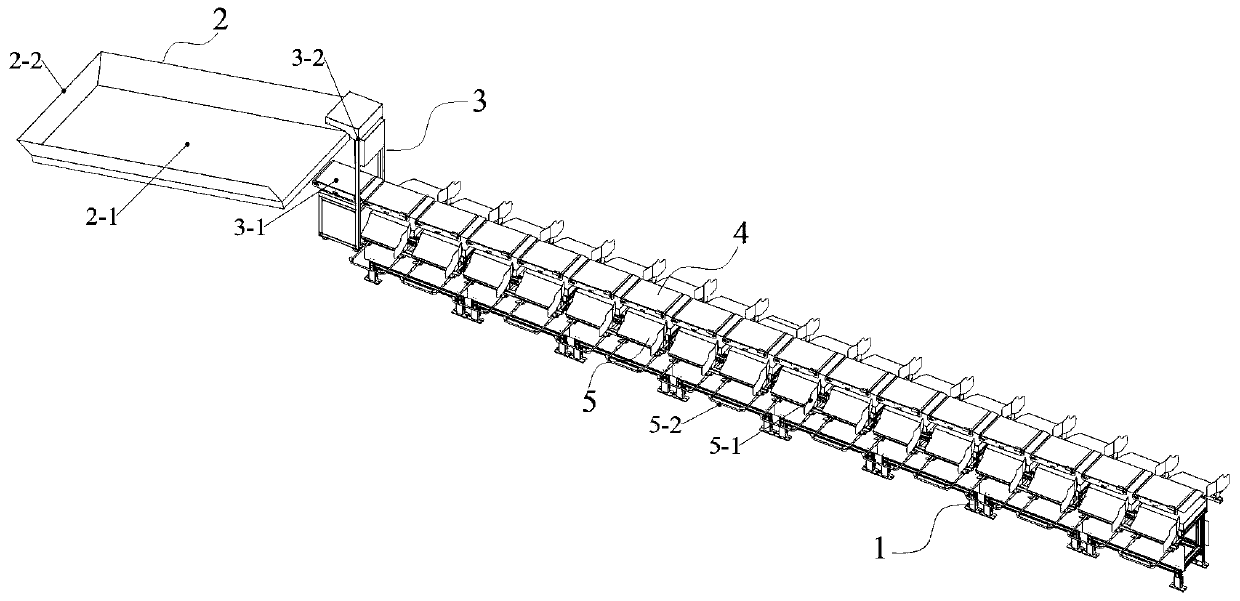

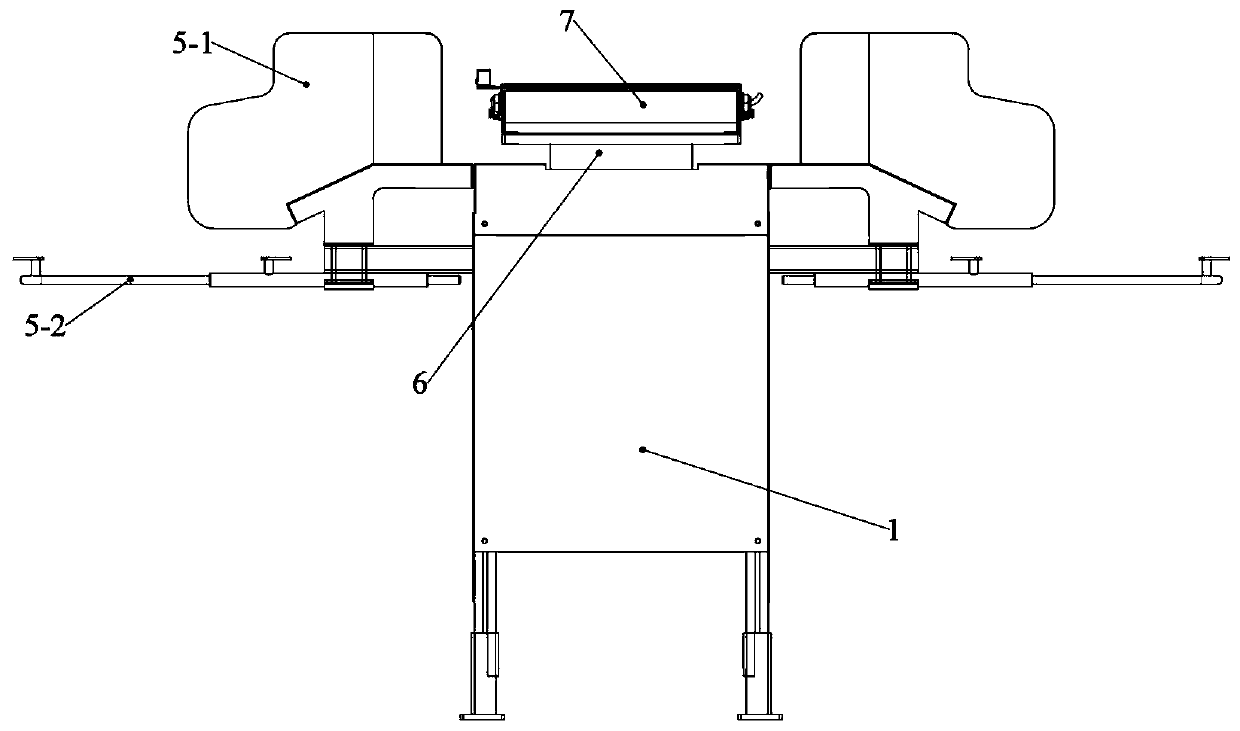

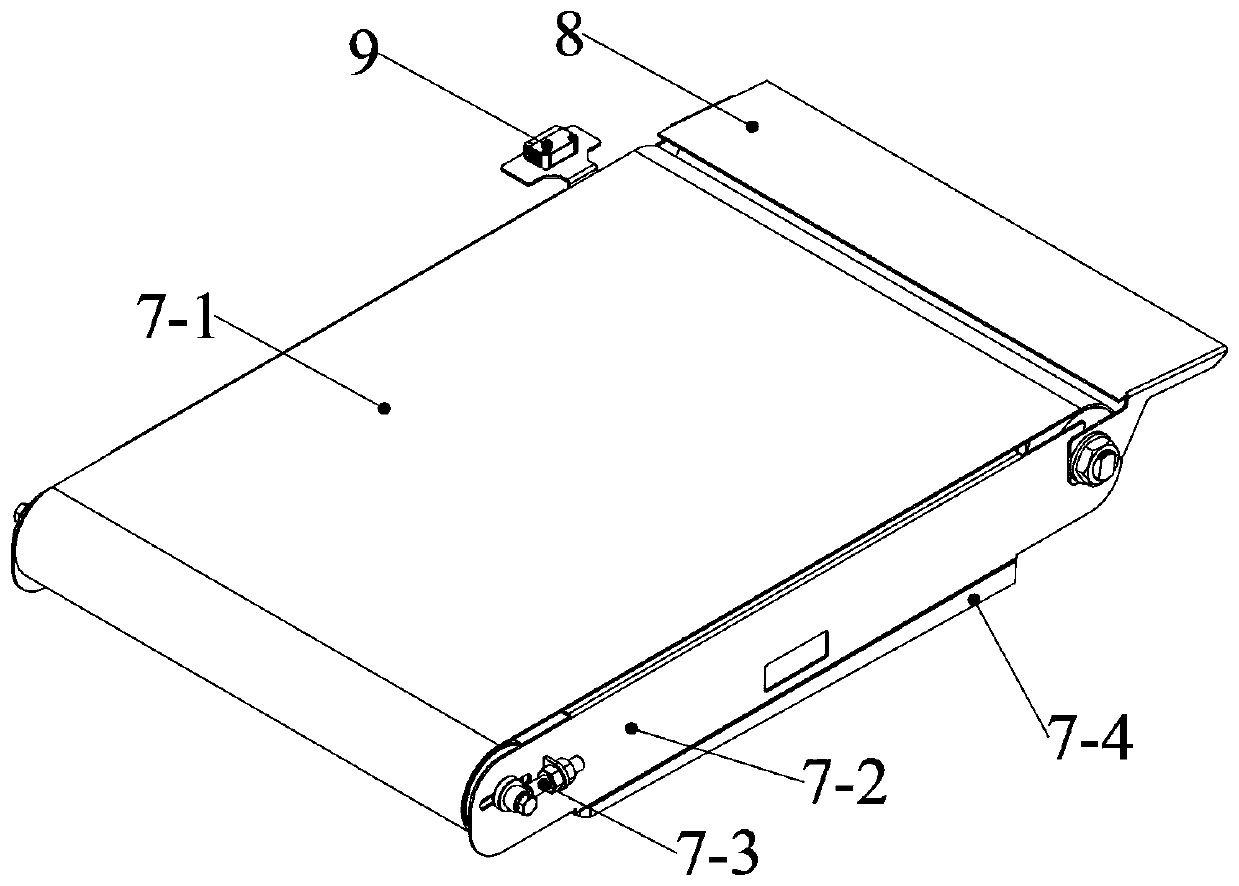

Linear sorting machine based on local rotation and sorting method thereof

PendingCN111332733AImprove adaptabilityReduce the overall heightControl devices for conveyorsSortingAlgorithmControl engineering

The invention discloses a linear sorting machine based on local rotation and a sorting method thereof. A linear sorting machine in the prior art has the defects that a discharging device is complex instructure and large in size; and in addition, a linear sorting machine in the prior art is high in noise. The linear sorting machine based on local rotation comprises a rack and a conveying and sorting device; the conveying and sorting device is installed on the rack and comprises n rotary sorting units arranged in sequence, n is greater than or equal to 2; each rotary sorting unit comprises a steering power element and a sorting conveyor; and the sorting conveyor is mounted at the top of the rack and is driven by the steering power element to steer so as to change the conveying direction ofgoods. According to the he linear sorting machine, the multiple rotary sorting units arranged in sequence are arranged, and the freedom of motion of rotating around the vertical axis is provided for the rotary sorting units, so that the rotary sorting units small and exquisite in size have the functions of conveying goods forwards and conveying the goods into a discharging port through steering atthe same time.

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

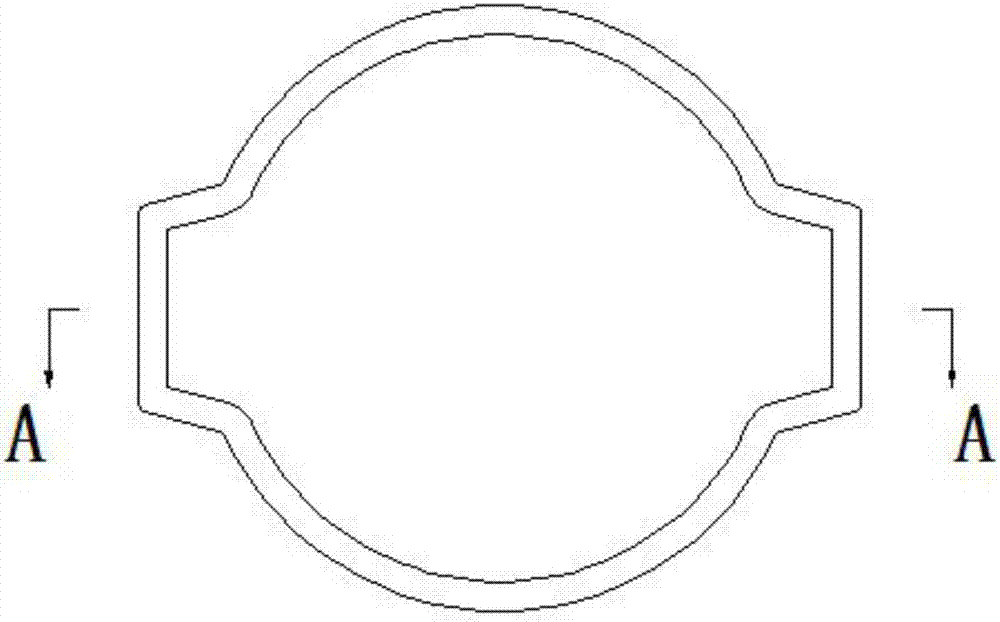

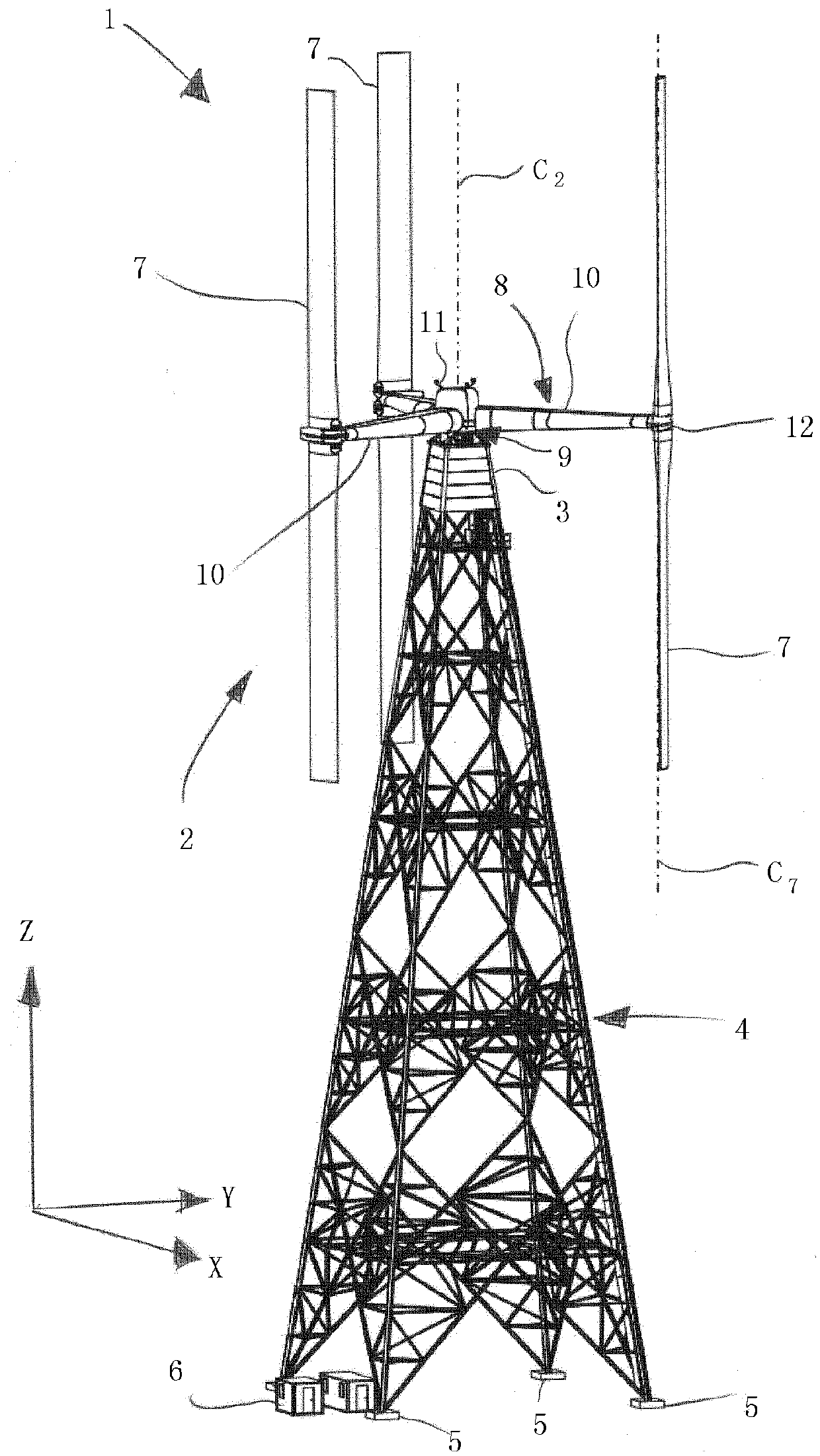

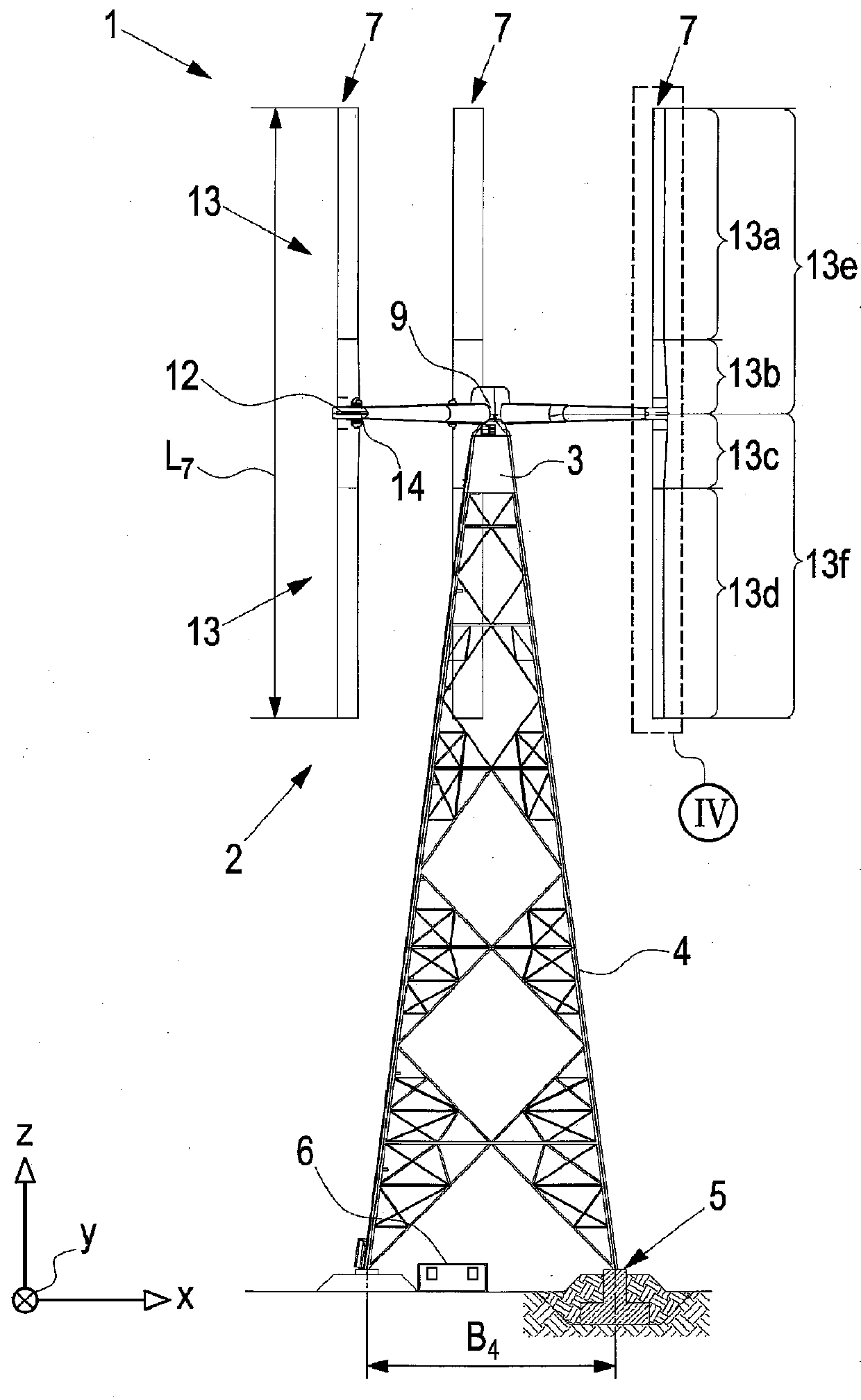

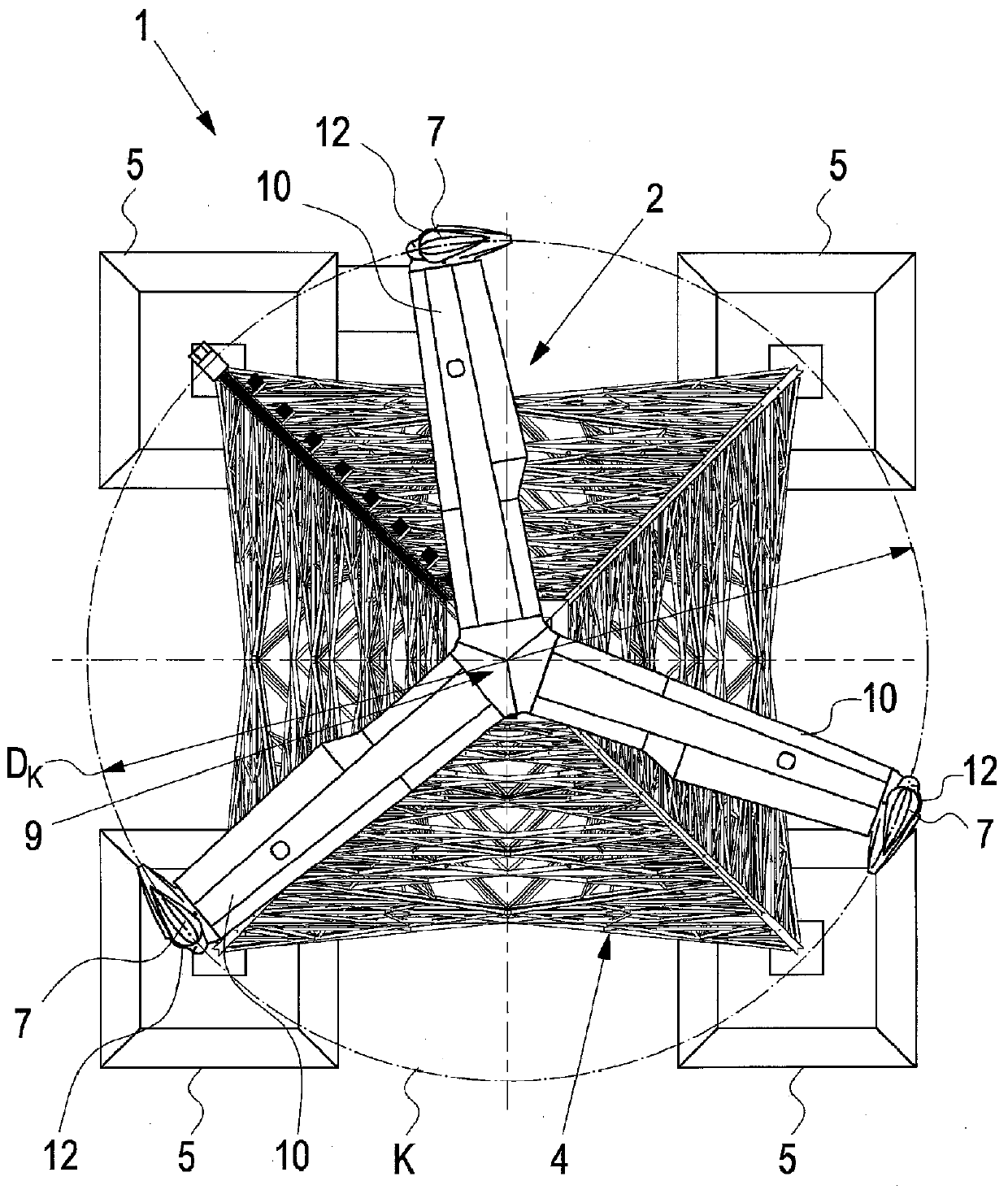

Vertical wind turbine comprising pitch motor with protruding rotor blades, kit for same, and method for operating same

PendingCN110892154APrecise and energy-efficient drivesEasy to adjustWind motor controlEngine fuctionsRotational axisClassical mechanics

Owner:AGILE WIND POWER

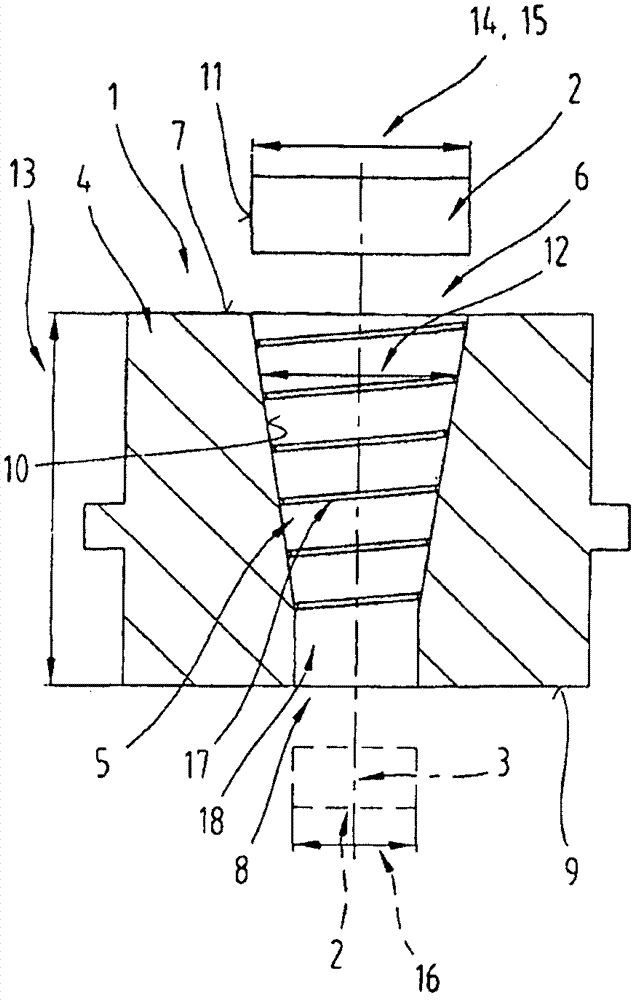

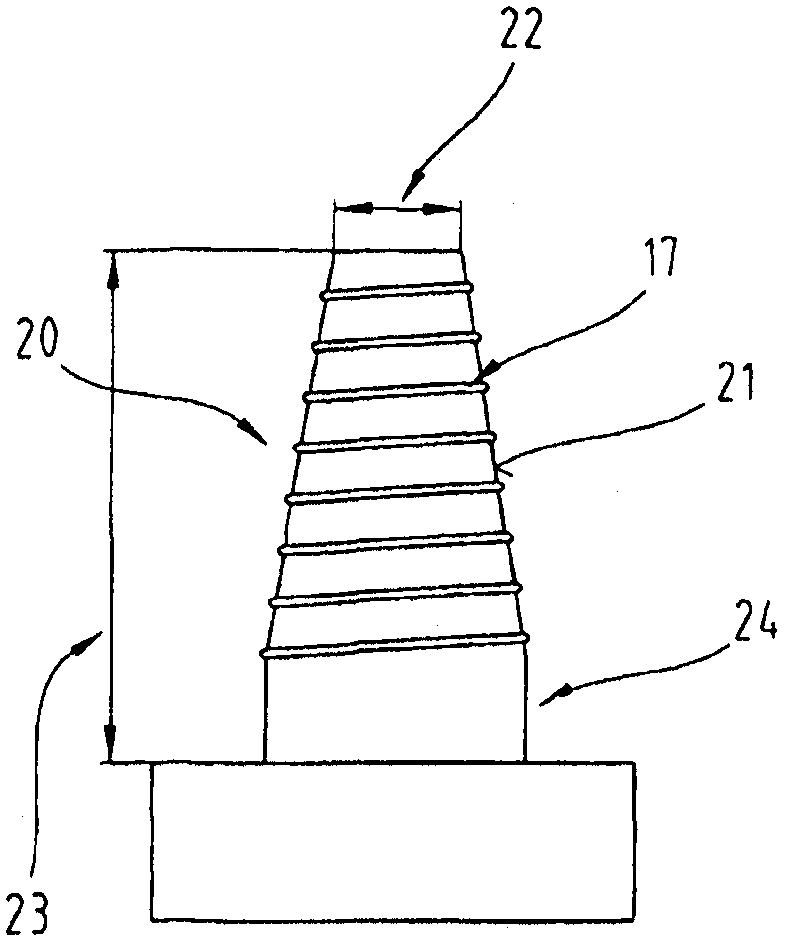

Compacting device

The invention relates to a tool for compacting the surface of a powder-metallurgically produced component (2), comprising a female die (1) and a male die (20), a clearance (5) which extends from a first female die opening (6) to a second female die opening (8) being arranged in the female die (1) and having a wall surface (10) for bearing against the component (2), and the male die (20) having a male die length (23) and a male die surface (21), wherein an inside diameter (12) of the clearance (5) in the female die (1) becomes smaller from the first female die opening (6) in the direction of the second female die opening (8) or an outside diameter (22) of the male die (20) becomes greater over the male die length (23), and wherein a compacting element (17) is arranged on the wall surface (10) of the female die (1) or on the male die surface (21). The compacting element (17) is formed with a thread-like profile.

Owner:MIBA SINTER AUSTRIA

Air extraction device and method for removing particles carried by an air flow

ActiveCN102859201AEasy to separateReduce current consumptionDomestic stoves or rangesPump componentsImpeller

Owner:BERLING

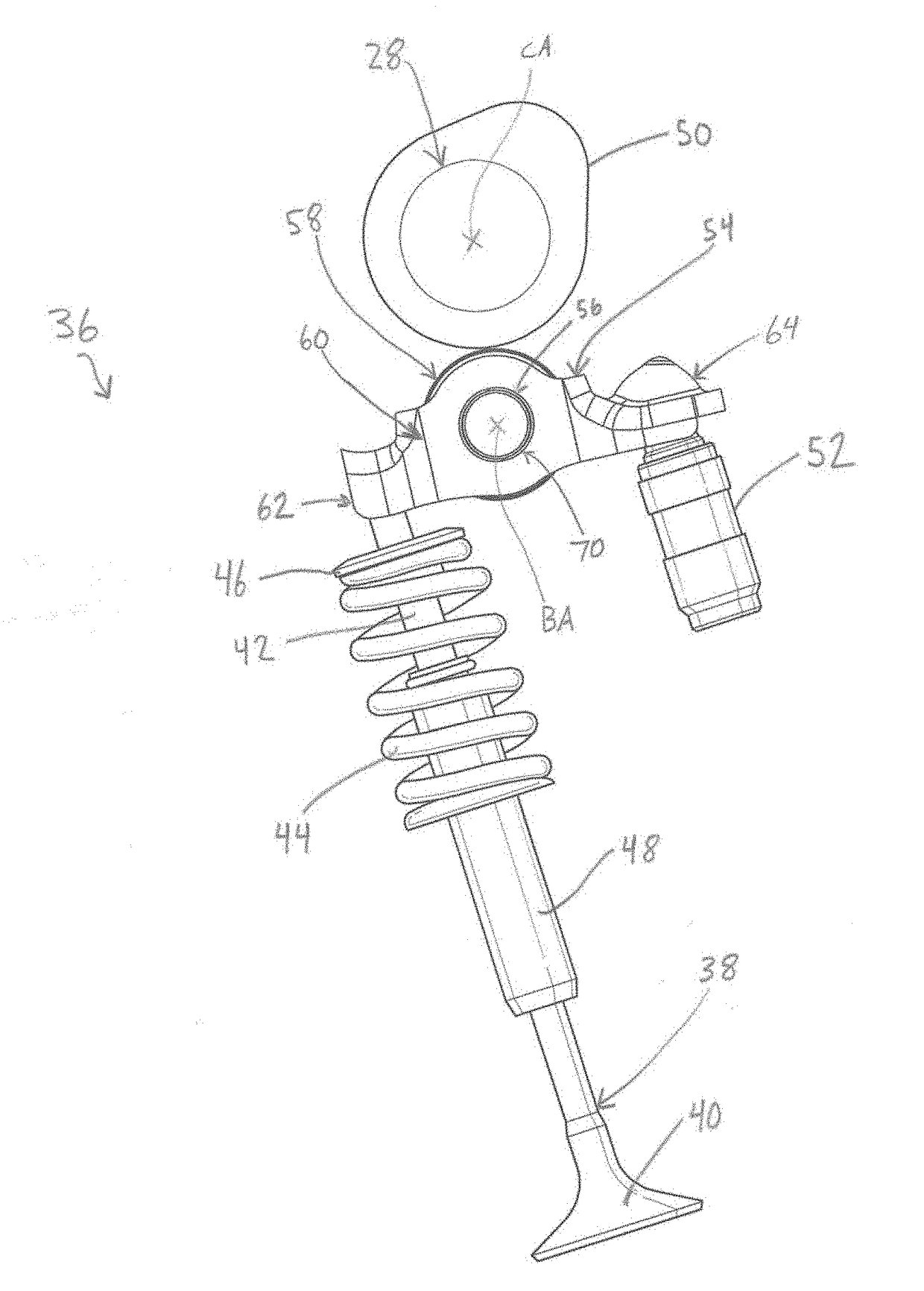

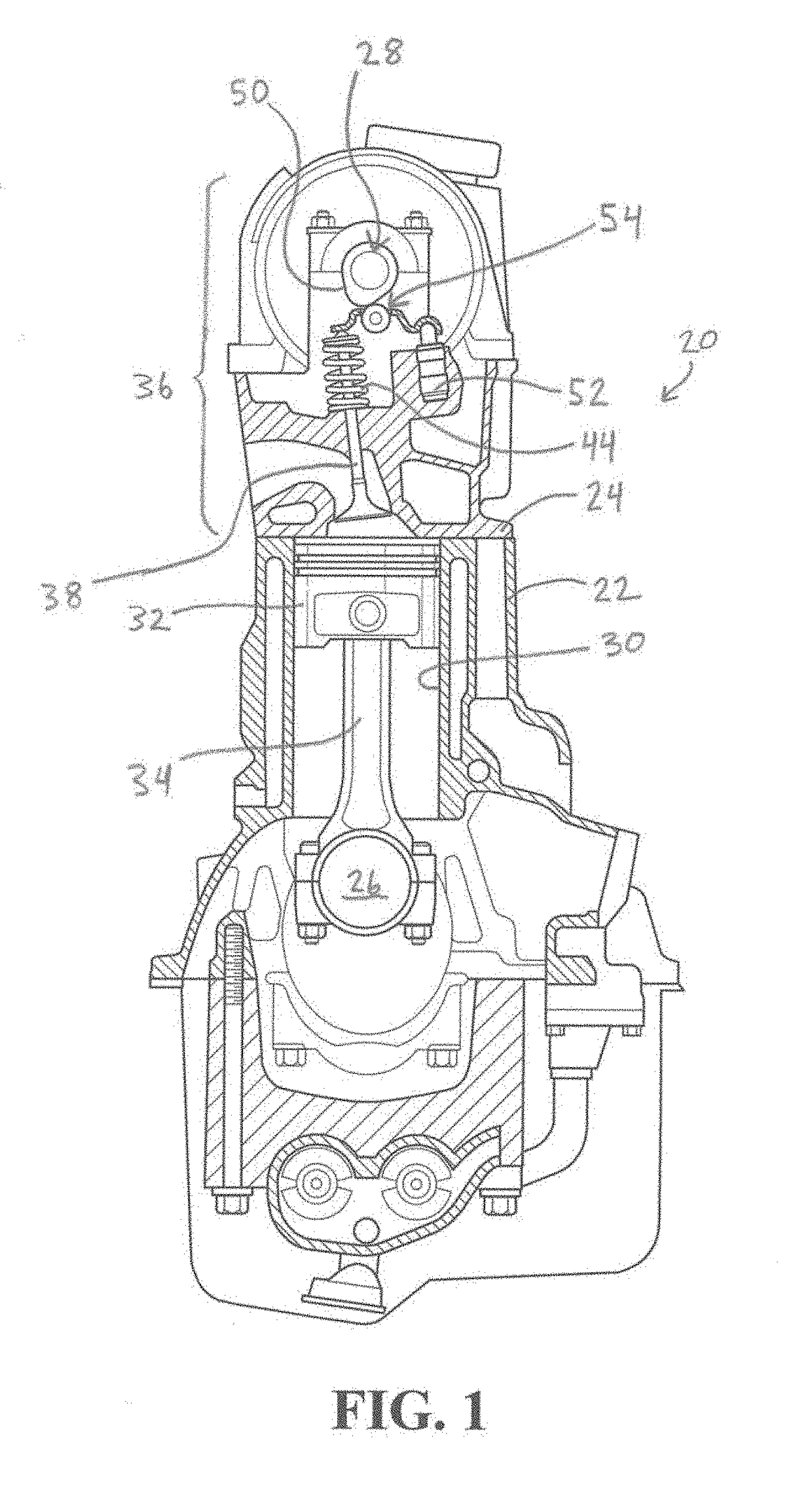

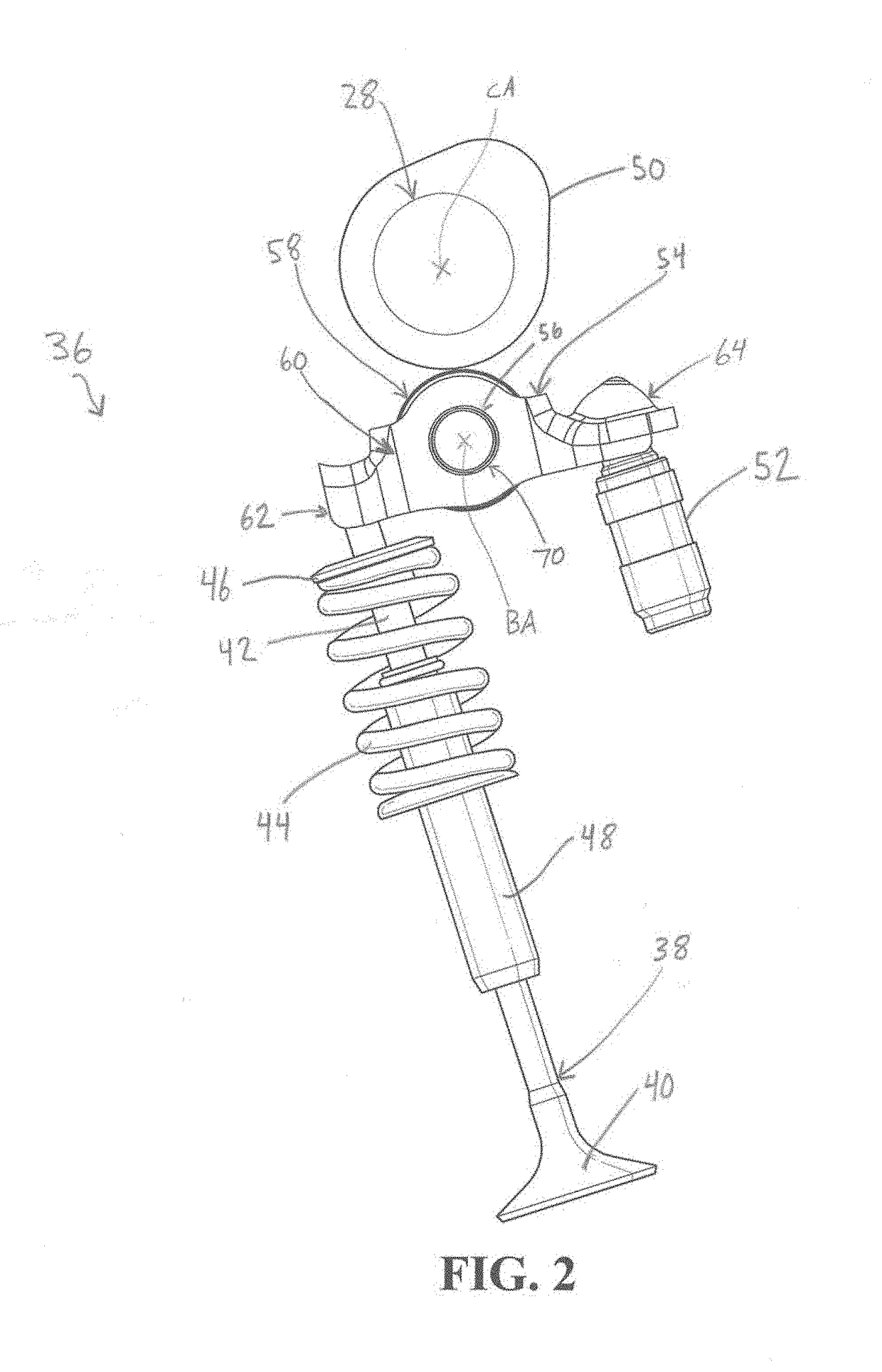

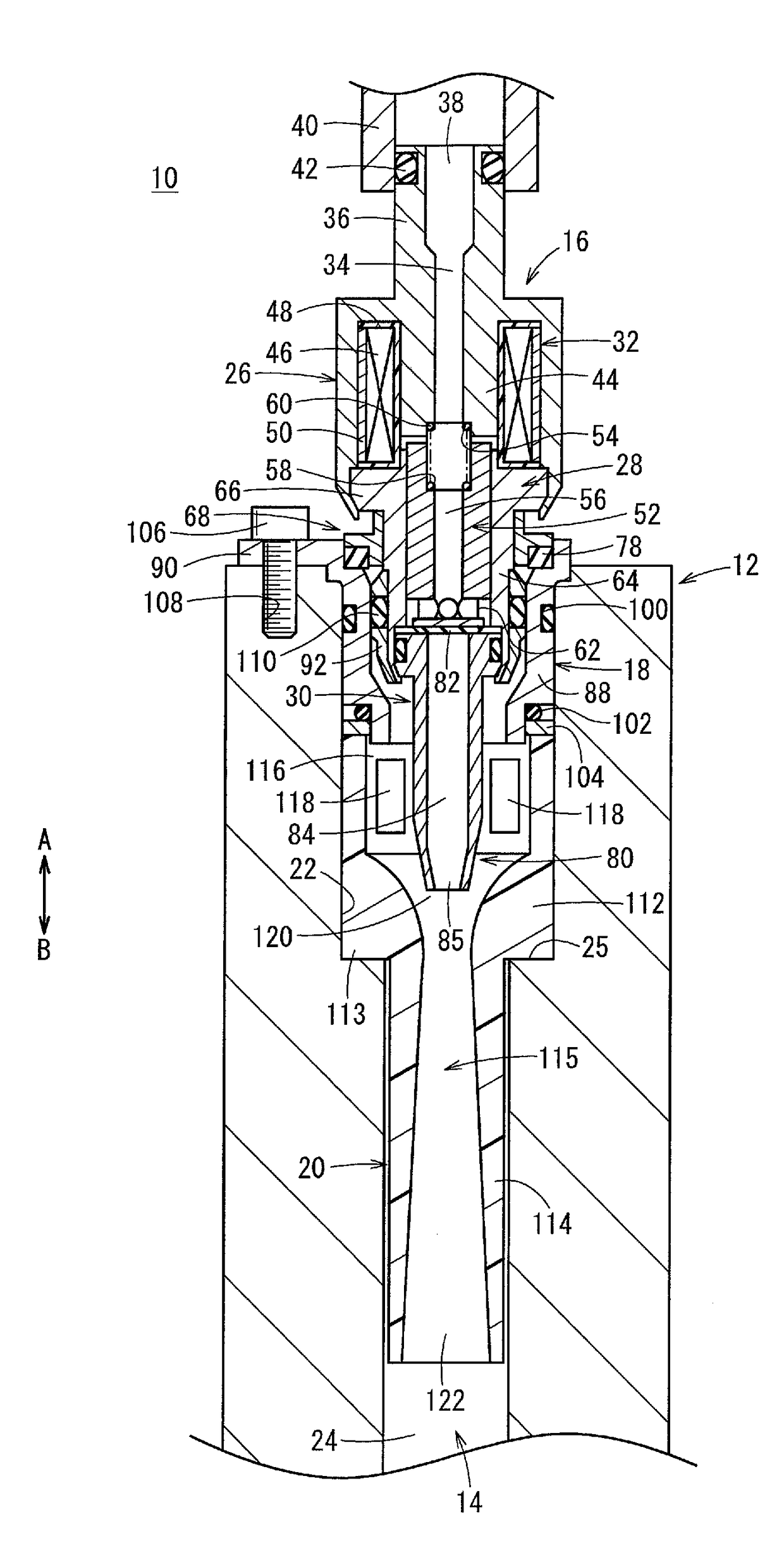

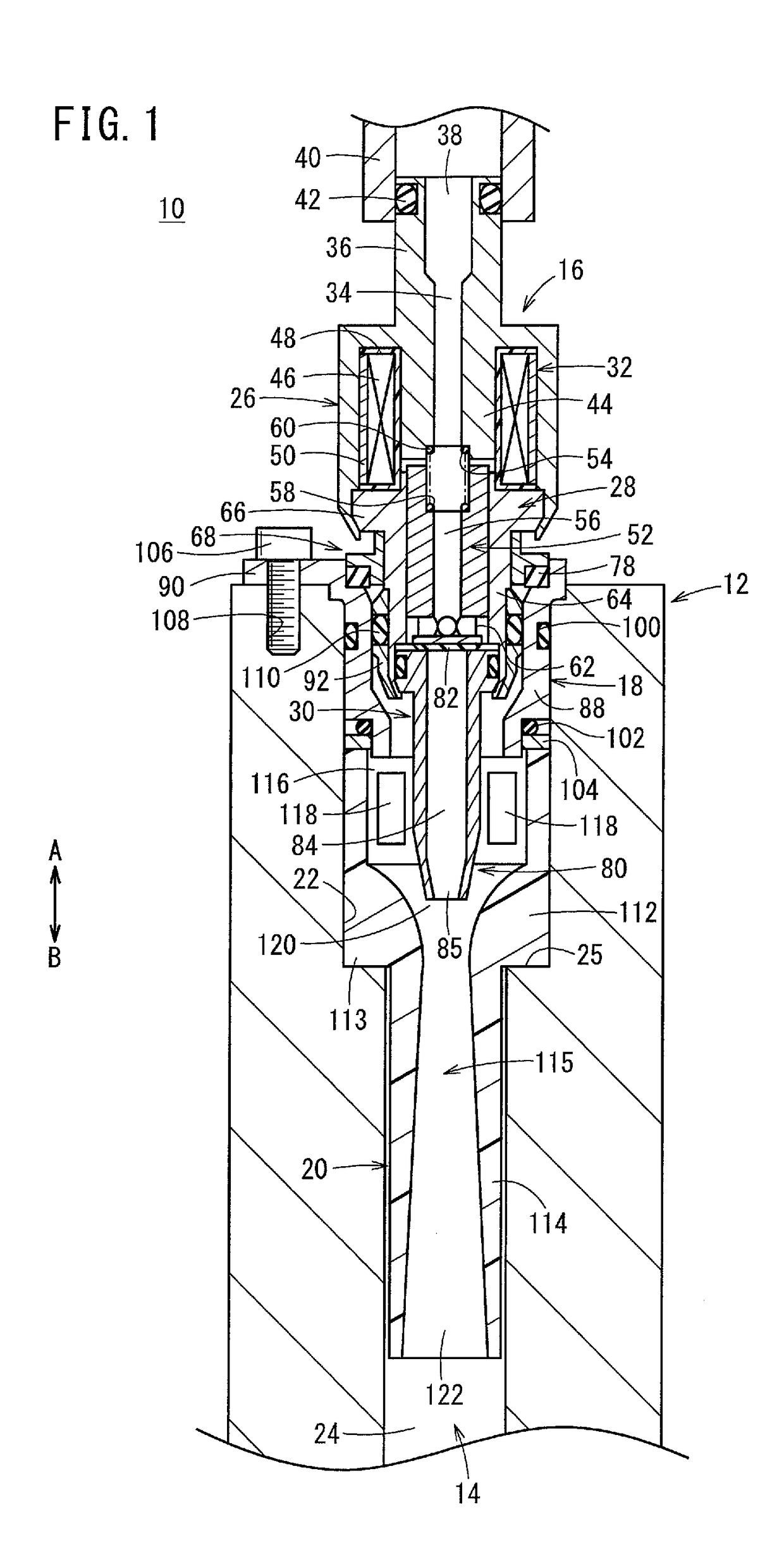

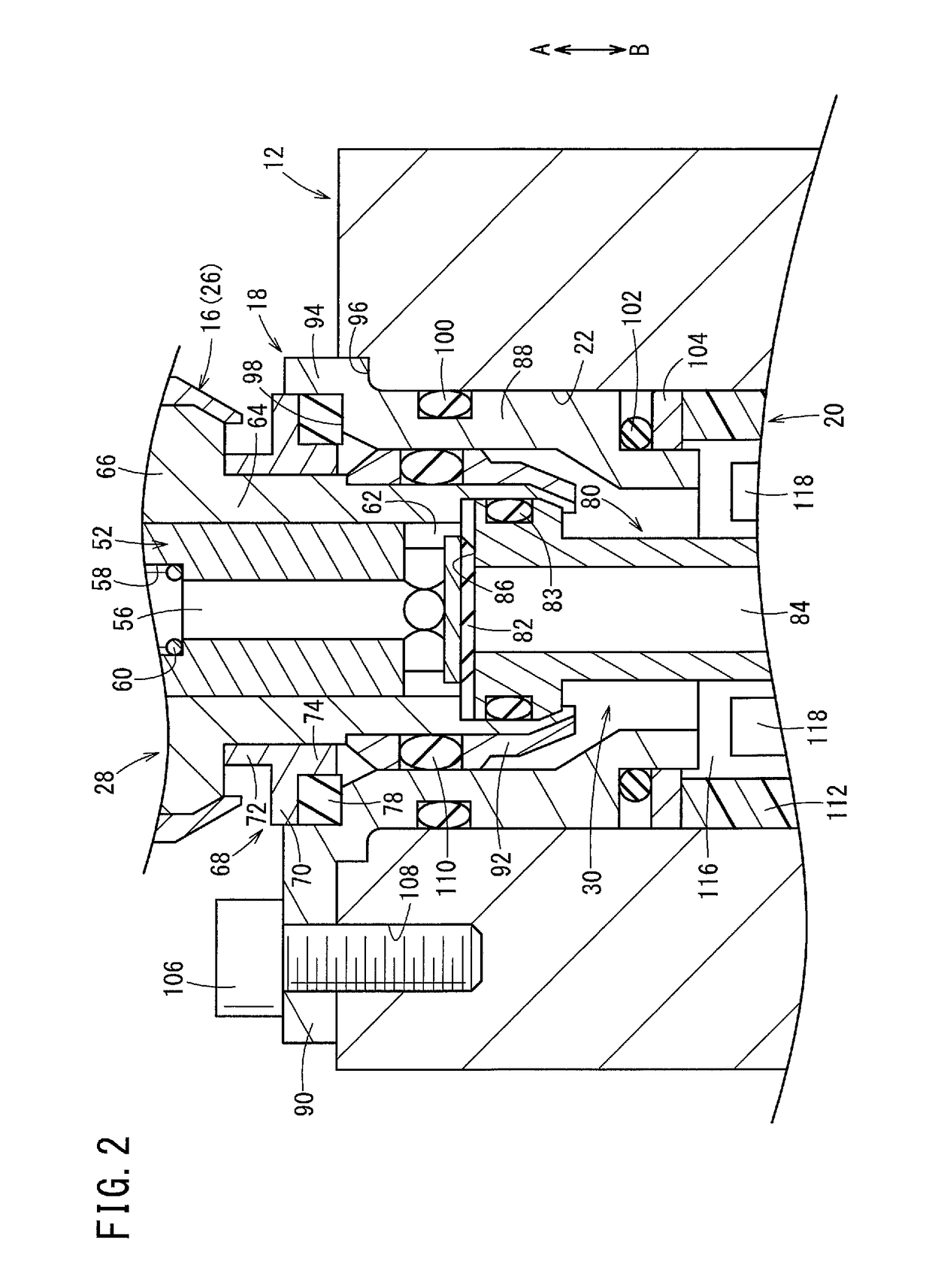

Finger follower assembly for use in a valvetrain of an internal combustion engine

ActiveUS20180156077A1Facilitate alignment of bearingOvercome disadvantagesValve arrangementsMachines/enginesExternal combustion engineBearing surface

A finger follower for use in an internal combustion engine valvetrain having a valve, a lash adjuster, and a camshaft having a lobe. The finger follower includes a shaft, a bearing rotatably supported by the shaft for engaging the lobe. A body is provided with a pad for engaging the valve, a socket spaced from the pad for engaging the lash adjuster, and walls disposed between the pad and the socket. A slot is formed in each wall for supporting the shaft, and each has a respective pair of eccentric arc-shaped bearing surfaces arranged to allow the shaft to rotate within the slots and to move along the slots to facilitate alignment of the bearing with respect to engagement with the lobe independent of alignment of the pad with respect to engagement with the valve and of alignment of the socket with respect to engagement with the lash adjuster.

Owner:GT TECH INC

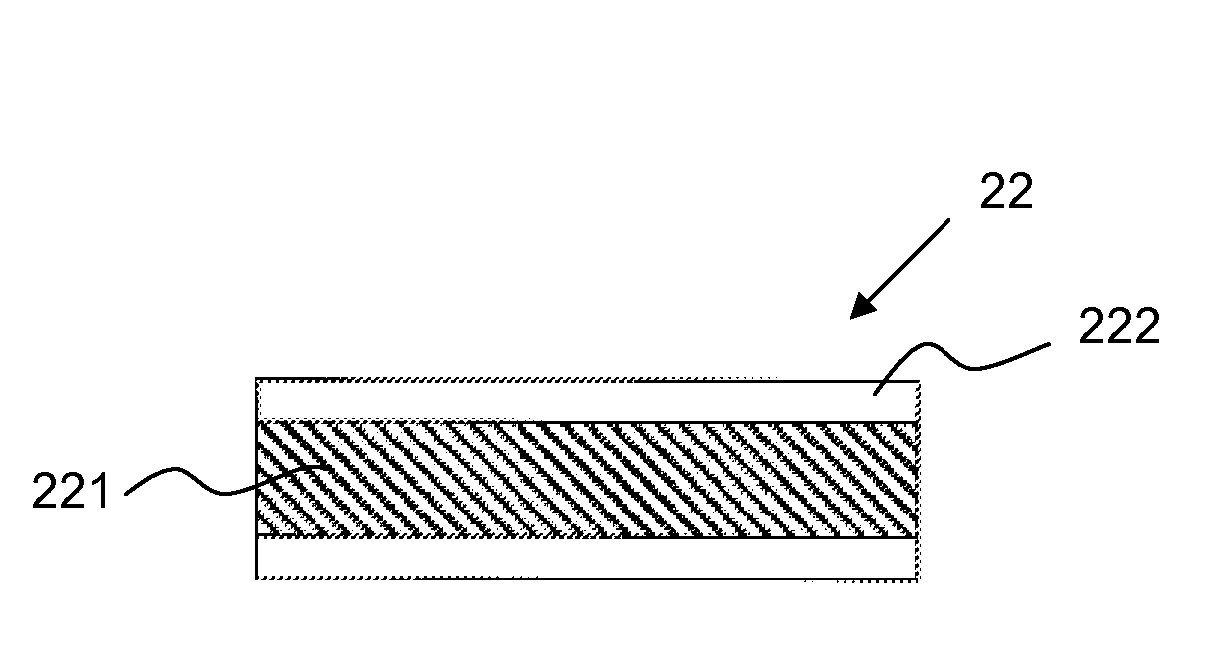

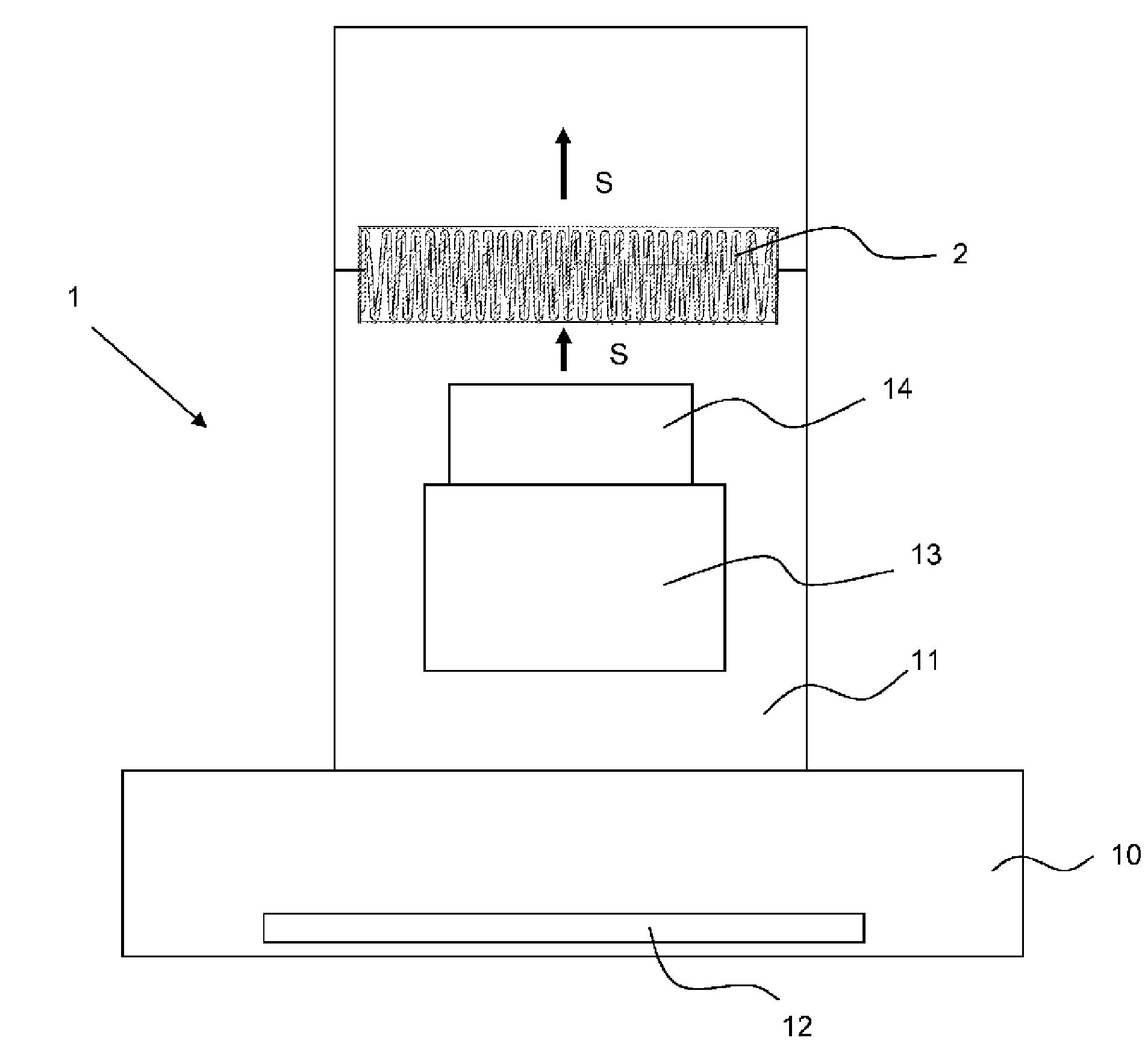

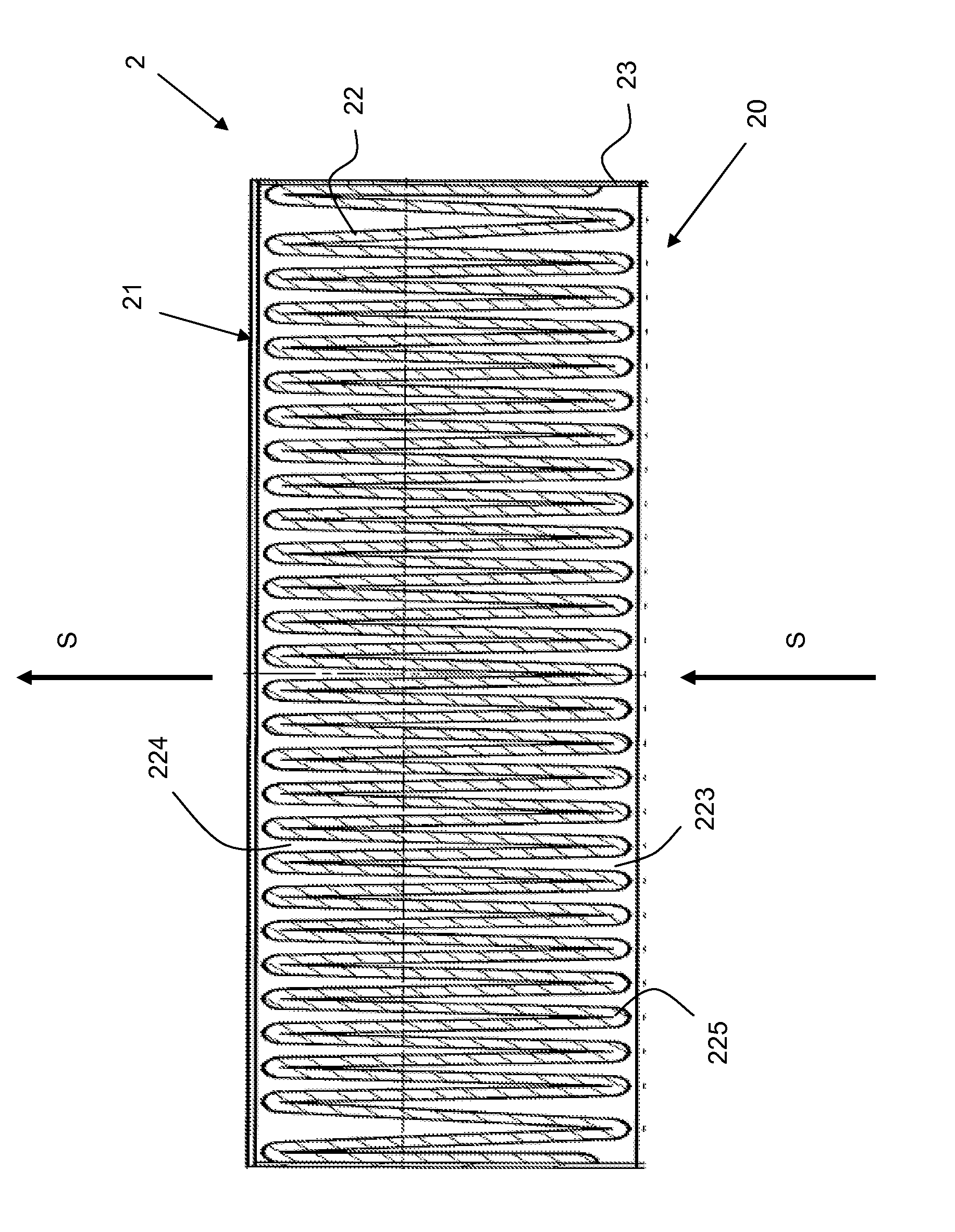

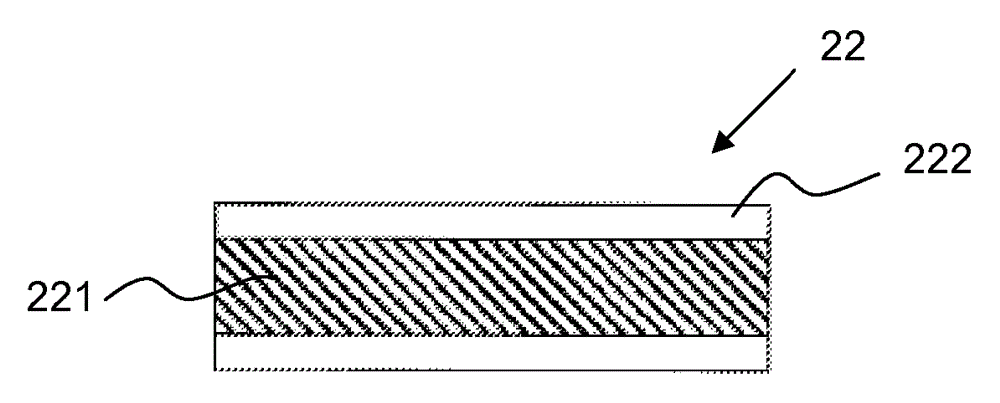

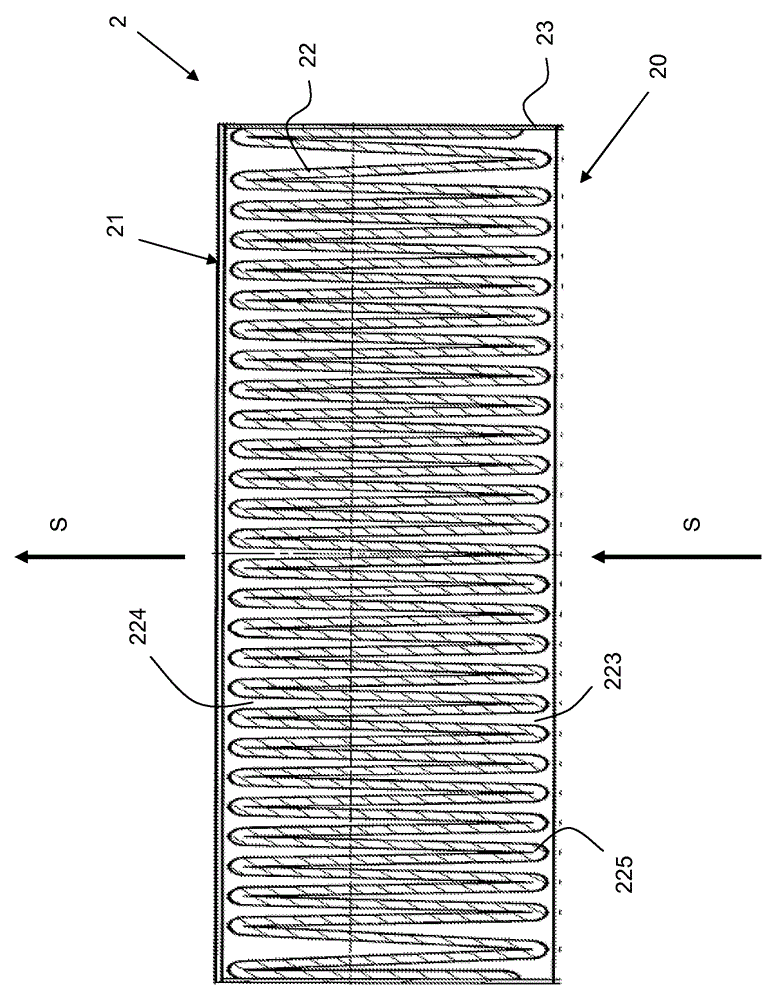

Filter element for an extractor hood and extractor hood

ActiveCN102665865AAvoid flowImprove smellGas treatmentDomestic stoves or rangesStructural engineeringControl theory

The invention relates to a filter element for an extractor hood (1) comprising an odor filter (22) and characterized in that the inflow side (20) of the filter element (2) is provided with recesses (223, 224) which are formed by the odor filter (22) and extend at least over half of the height of the filter element (2).

Owner:BOSCH SIEMENS HAUSGERATE GMBH

Fuel gas circulation apparatus

ActiveUS20170244116A1Reduce transmissionAvoid damageOperating means/releasing devices for valvesJet pumpsEngineeringVibration absorption

In a fuel gas circulation apparatus, a diffuser is accommodated in an attachment hole of a body. An injector is provided upstream of the diffuser through an attachment. A vibration absorption member made of elastic material is provided between a proximal end of a large diameter portion of this diffuser and a distal end of a main body in the attachment, and a ring member is provided adjacent to the vibration absorption member.

Owner:HONDA MOTOR CO LTD

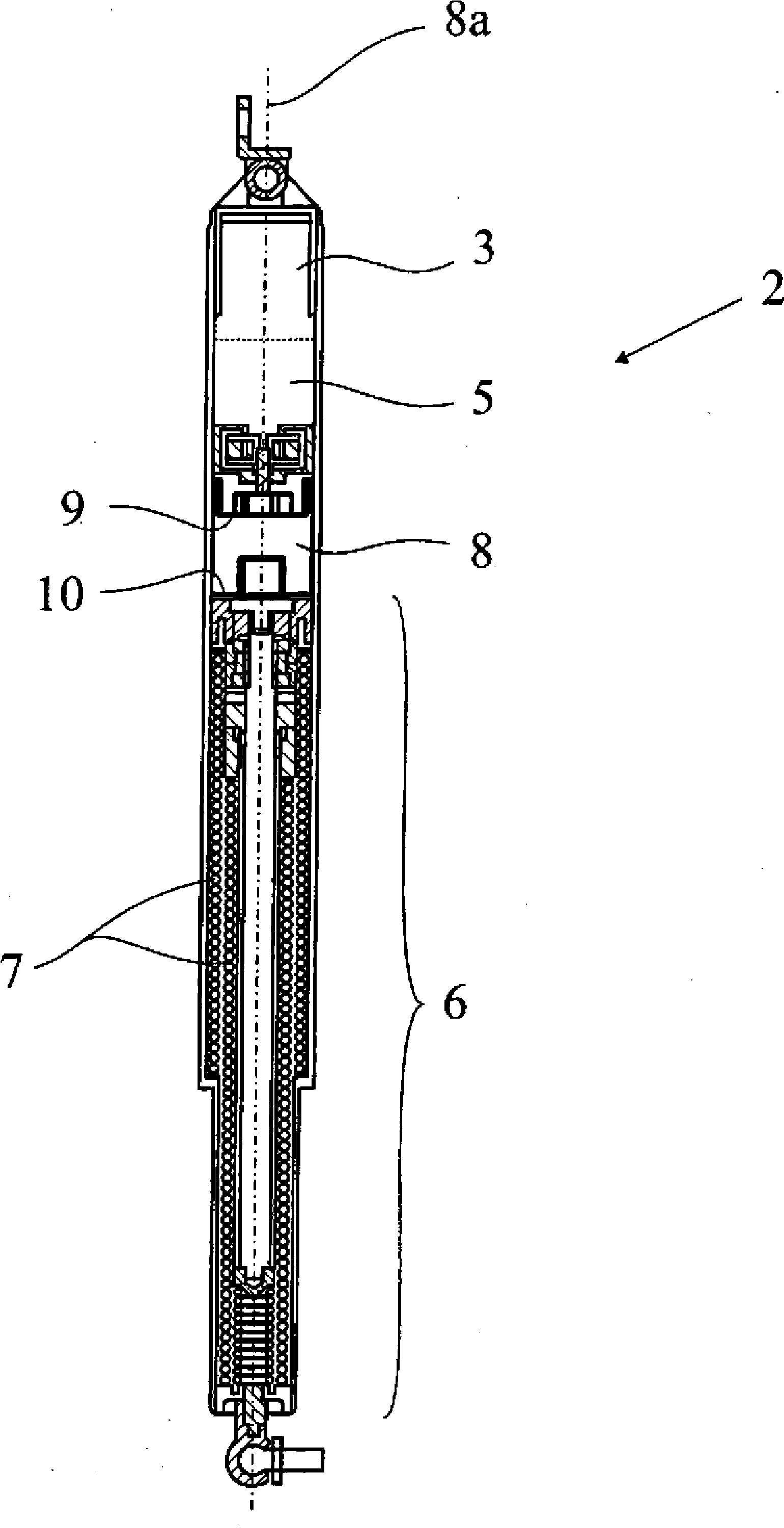

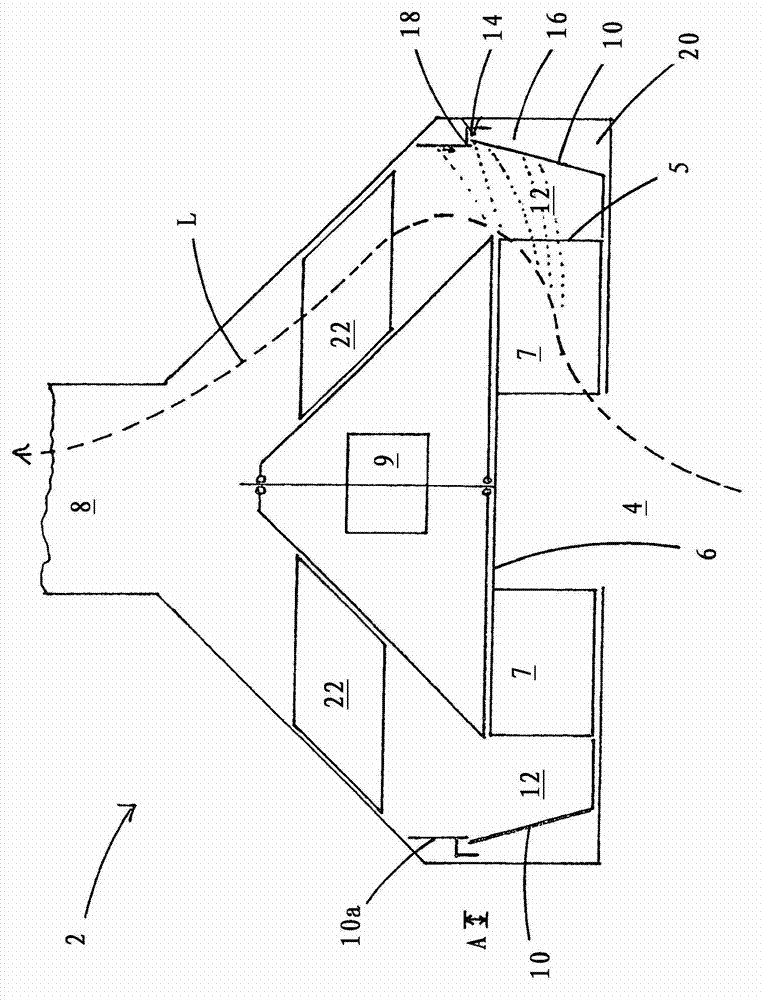

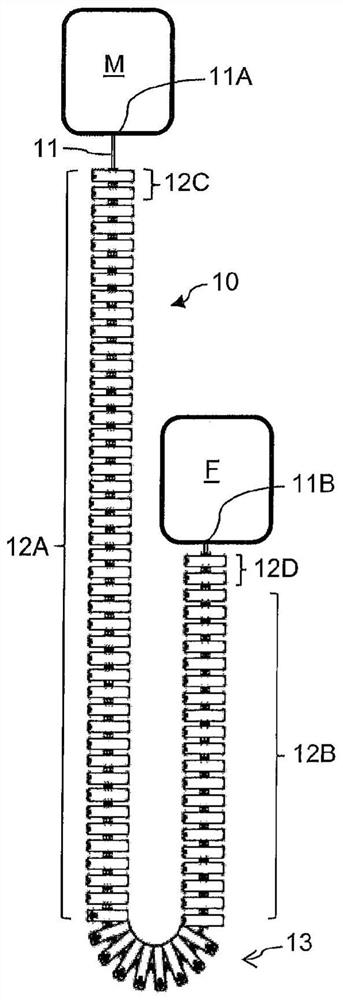

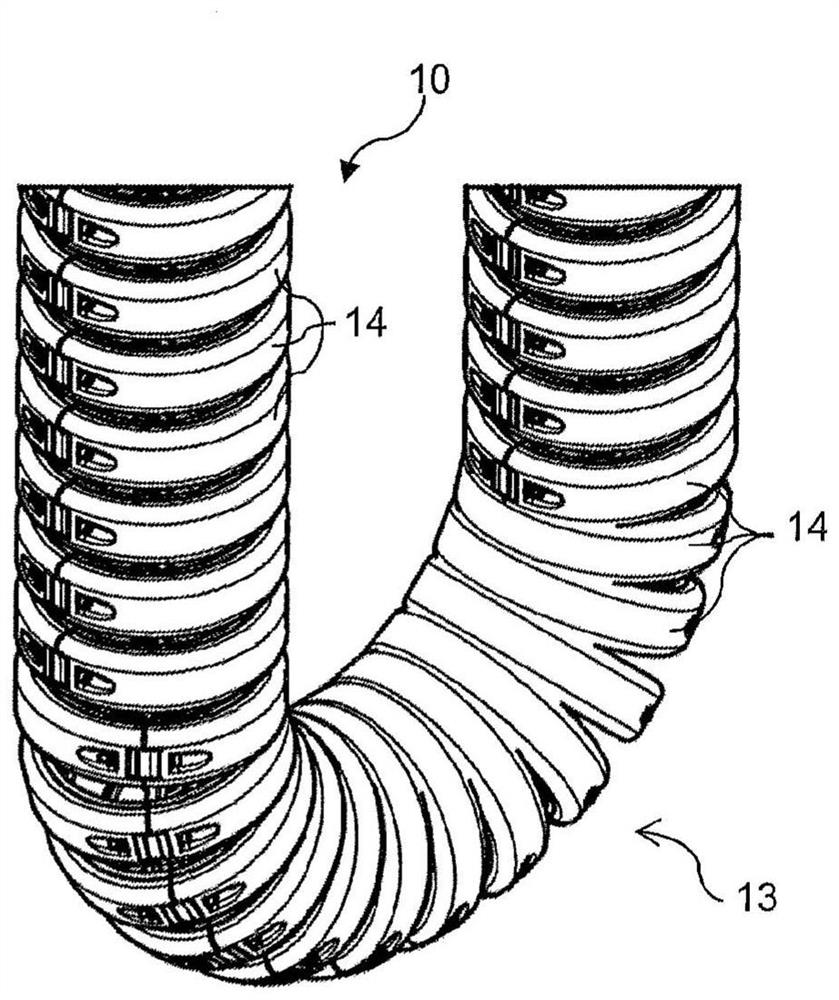

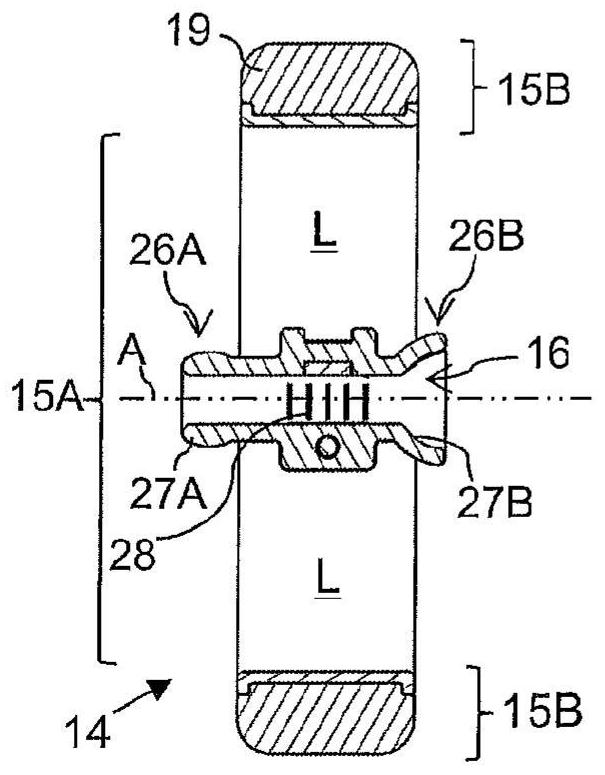

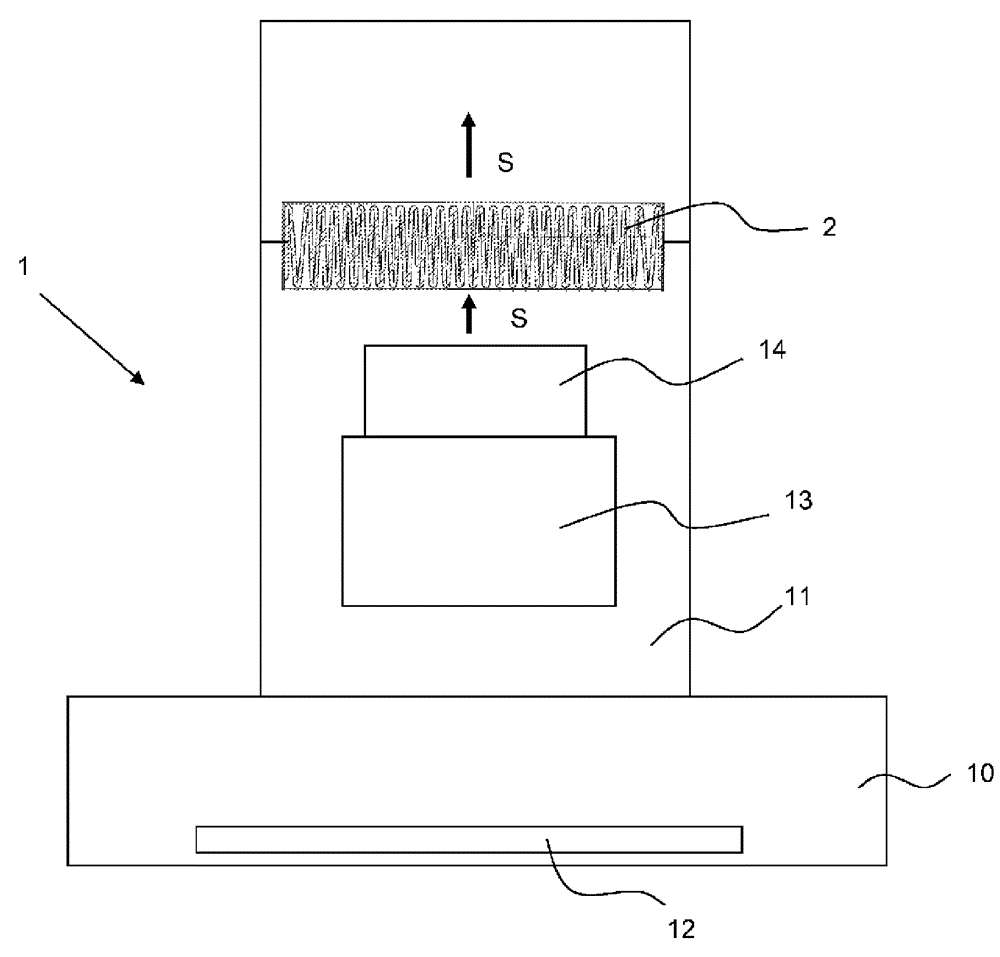

Line routing device for hanging applications, particularly as a service loop for a drill

The invention relates to a line routing device (10) for guiding a plurality of lines, such as cables, hoses, or the like, particularly for hanging applications, such as supplying a vertically traveling power head (3) of a drill (1). The line routing device (10) has a flexible carrying strand (11) and a plurality of guide bodies (14) arranged one behind the other in the longitudinal direction of the carrying strand. According to the invention, adjacent guide bodies (14) can be deflected spatially toward each other and each guide body has a central part (15A) having a center axis (A), which extends coaxially to the carrying strand (11), and an outer part (15B) having at least one circumferential element (17). The outer part (15B) delimits a receiving region (L), which is open in the axial direction, for the lines, radially to the outside.

Owner:IGUS

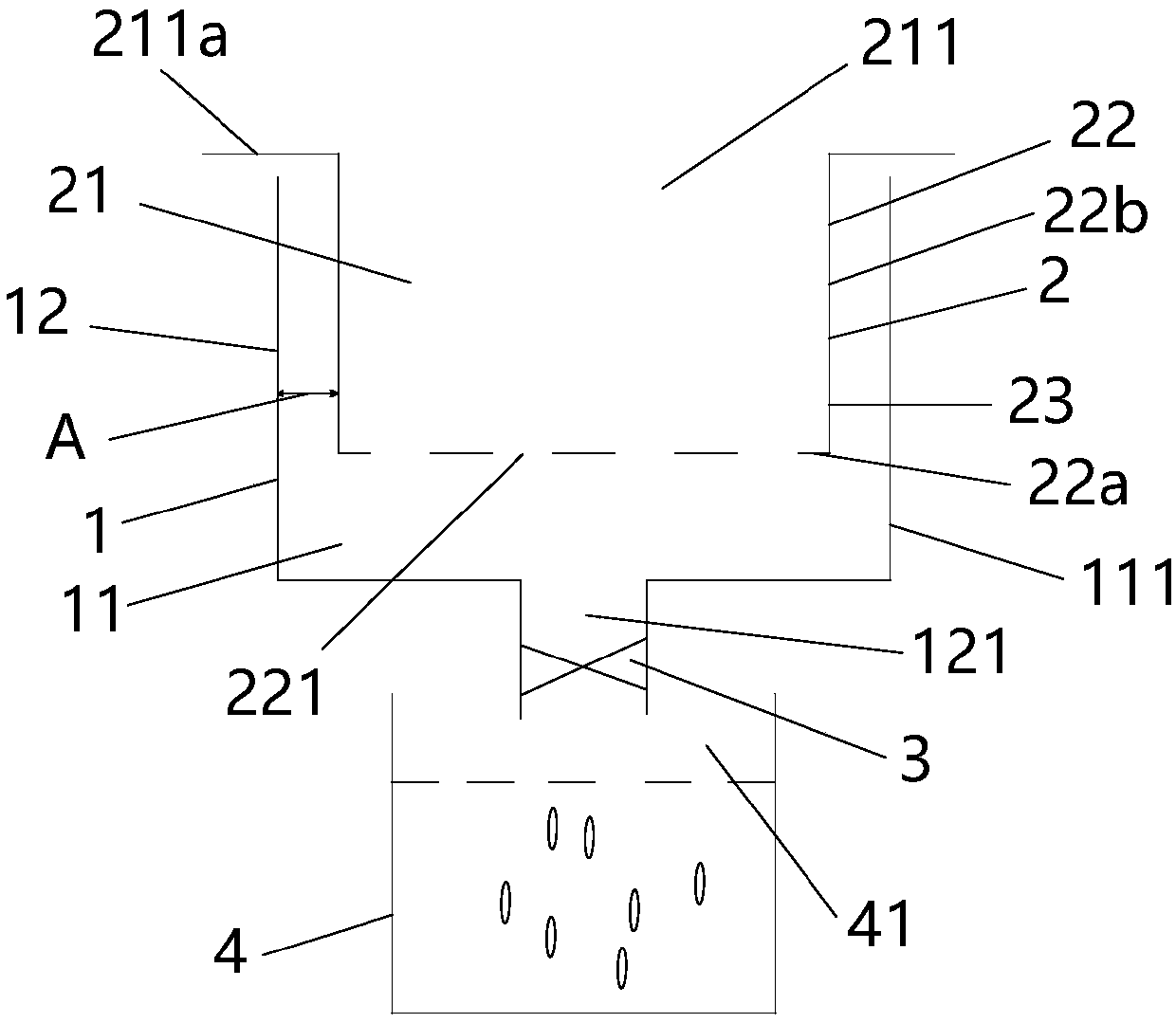

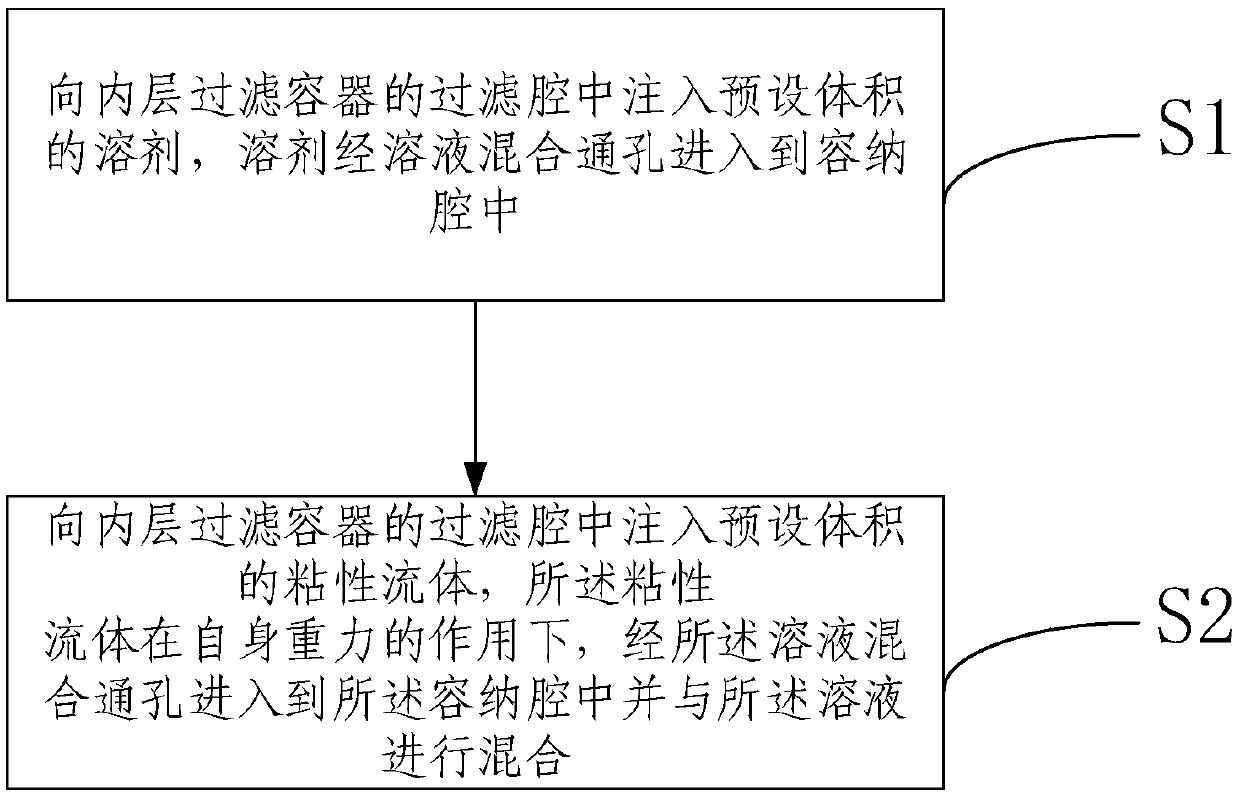

Viscous fluid and solvent mixing device and viscous fluid and solvent mixing method

ActiveCN111346530AReduce noise generationWell mixedFlow mixersTransportation and packagingSolventEngineering

The invention relates to the technical field of solution mixing devices, and discloses a viscous fluid and solvent mixing device and a viscous fluid and solvent mixing method. The viscous fluid and solvent mixing device comprises: a container, wherein an accommodating cavity is formed in the container, the accommodating cavity is used for accommodating a viscous fluid and a solvent, and a liquid outlet communicated with the accommodating cavity is formed in the body of the container; and an inner layer filtering container arranged in the accommodating cavity, wherein a filtering cavity is formed in the inner layer filtering container, a solution mixing through hole communicated with the filtering cavity is formed in the body of the inner layer filtering container, and the viscous fluid andthe solvent enter the filtering cavity and then permeate into the accommodating cavity through the solution mixing through hole so as to be mixed. The mixing device has the advantages of being capable of uniformly mixing without external force, saving energy consumption and being simple in structure.

Owner:GUANGDONG MIDEA WHITE GOODS TECH INNOVATION CENT CO LTD +1

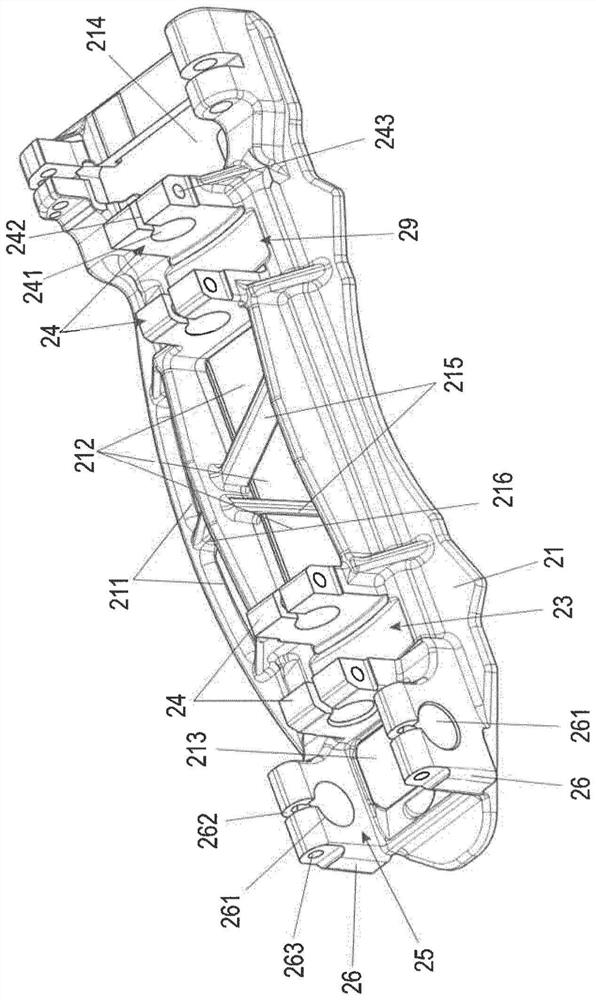

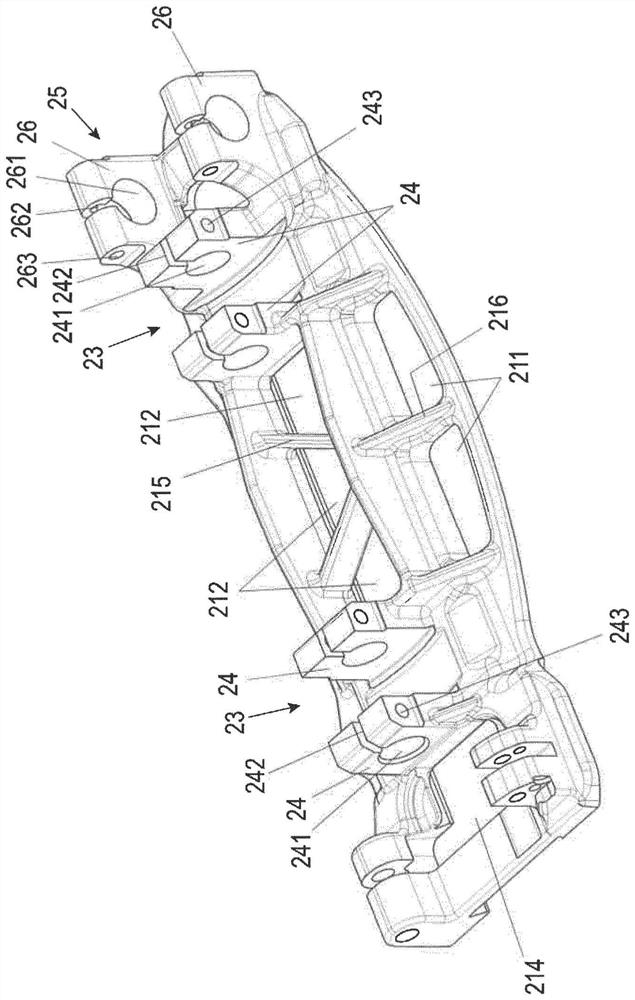

Pad holder for a brake pad holding system of rail vehicle and brake pad holding system

PendingCN112384428AReduce wearReduced noise generationAxially engaging brakesBraking elementsEngineeringBrake pad

The invention relates to a pad holder (2) for a brake pad holding system (1) of a rail vehicle, comprising a pressure plate (21) with a guide channel (22) extending in the longitudinal direction of the brake holder (2), in which a brake pad (6) can be interlockingly slidingly secured perpendicularly to the normal of the pressure plate (21), a locking bar (5) which is pivotably mounted on the pressure plate (21) and used to lock the brake pad (6) in the longitudinal direction of the pad holder (2), said locking bar protruding into the guide channel (22) in a locking position which fixes the brake pad (6) in a functional position, and being removed from the guide channel (22) in a release position, two brake lever bearing points (23) for pivotably mounting a brake lever (3), and a brake hanger bearing point (25) for pivotably mounting a brake hanger (4), wherein the pressure plate (21) has a plurality of window-type recesses (211, 212, 213, 214) which are separated from each other by means of at least one cross piece (). The invention further relates to a brake pad holding system for a rail vehicle.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

Filter elements for fume hoods and fume hoods

ActiveCN102665865BAvoid flowImprove smellGas treatmentDomestic stoves or rangesStructural engineeringFume hood

A filter element for an extractor hood includes an odor filter having depressions provided in an entry side of the filter element and extending at least over half of a height of the filter element. A frame holds the odor filter at its edges and has a height which is smaller at least on one side of the frame than a height of the odor filter.

Owner:BOSCH SIEMENS HAUSGERATE GMBH

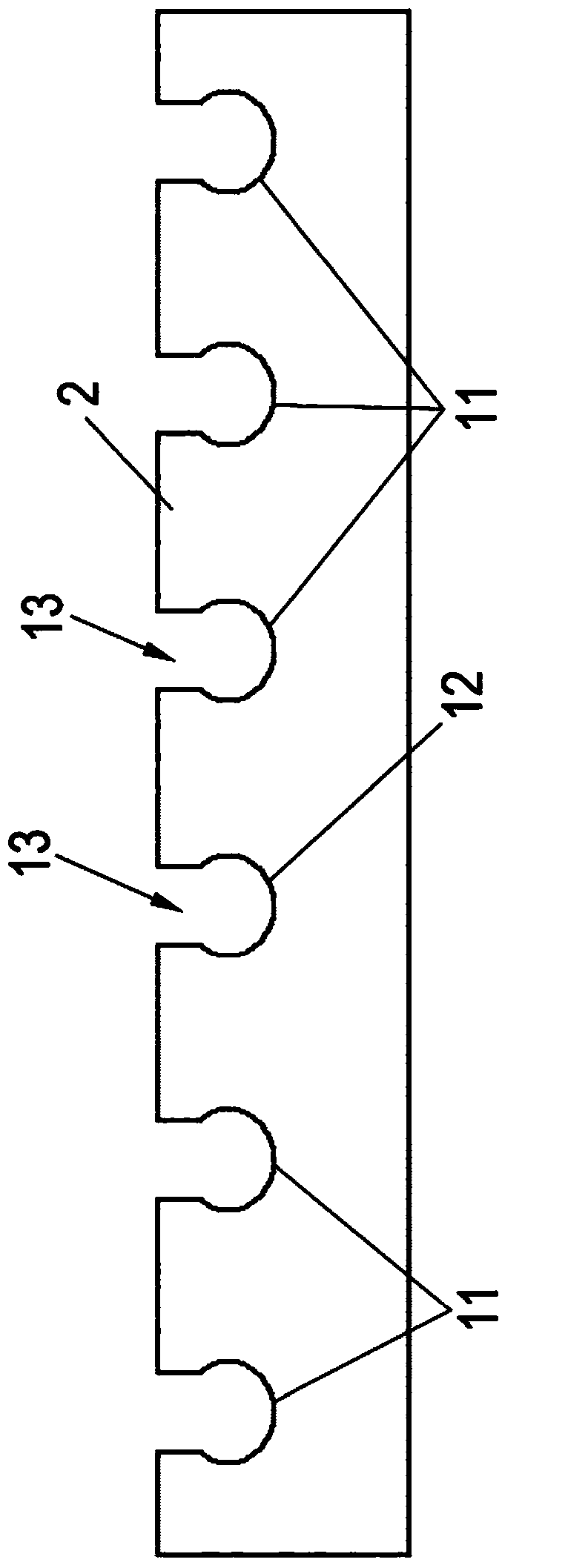

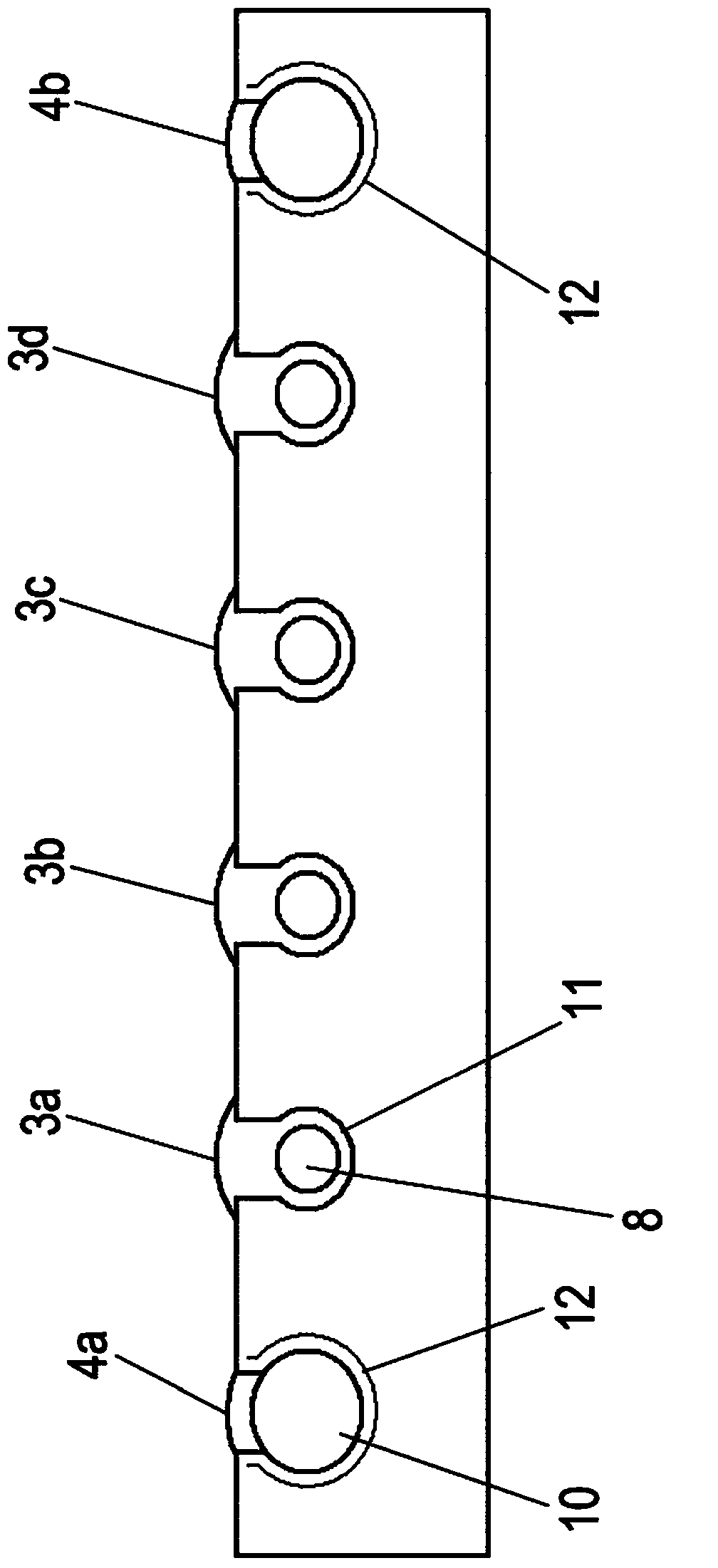

Pull-out guide device for furniture parts that are movable relative to one another comprising a roller bearing device

The invention relates to a pull-out guide device for furniture parts that are movable relative to one another comprising a roller bearing device, having the following: rolling elements (3a, b, c, d,... 4a, b), which are rotatably mounted in at least one rolling bearing cage (2), wherein at least one of the rolling elements (4a, b) is held and rotatably mounted in at least one bearing area of the bearing cage (2) by means of an interference fit, and wherein the bearing area(s) are plastically deformed in the region of the interference fit following the first insertion.

Owner:PAUL HETTICH

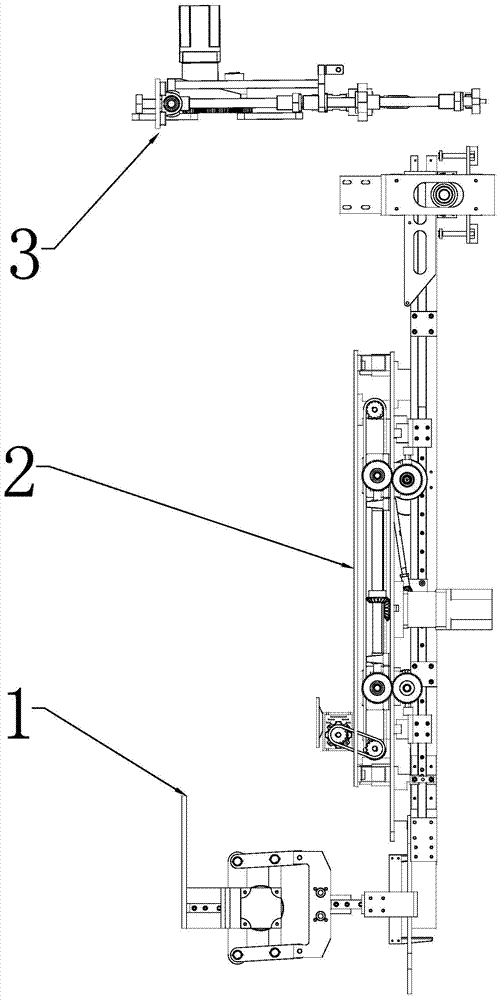

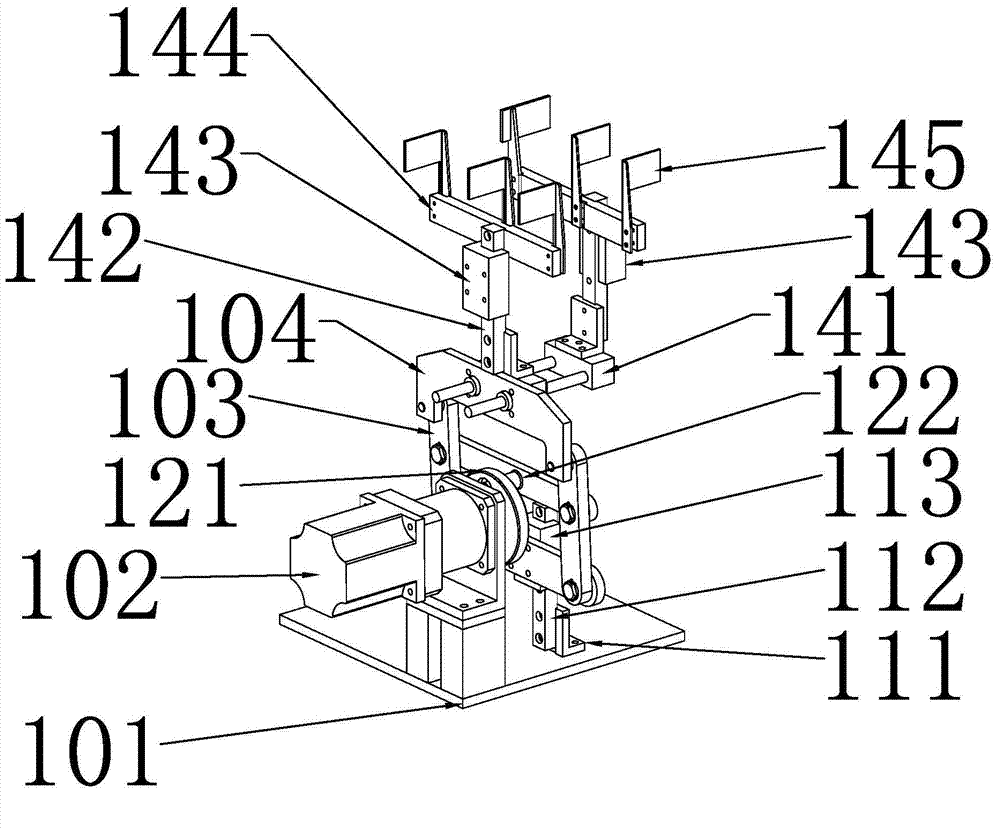

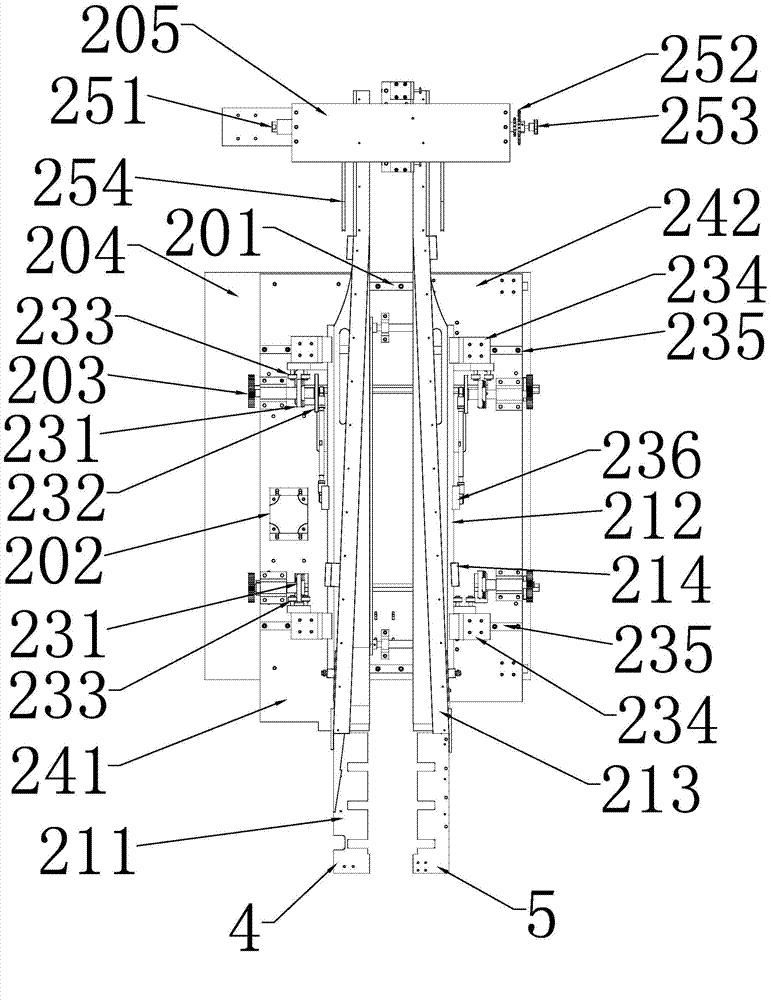

High-speed spring bagging machine

A high-speed spring bagging machine comprises a delivering mechanism, a conveying mechanism and a vertical welding mechanism. The high-speed spring bagging machine is characterized in that the conveying mechanism is provided with a left conveying arm and a right conveying arm, the delivering mechanism is arranged at the front end of the conveying mechanism, the vertical welding mechanism is arranged at the rear end of the conveying mechanism, spaces are reserved between the conveying mechanism and the delivering mechanism and between the conveying mechanism and the vertical welding mechanism, and the delivering mechanism, the conveying mechanism and the vertical welding mechanism are sequentially arranged and fixed to a rack. According to the conveying mechanism, a single motor is adopted for driving a transmission shaft, the welding width of non-woven fabric can be set, the manufacturing and the replacing of a non-woven fabric guiding mold are reduced, meanwhile, the speed for conveying springs is increased, and the yield of bagging the springs is improved. A parallel quadrangle double-crank mechanism is adopted for the delivering mechanism. More springs can be delivered in the spring bagging machine a short time. A single-motor is adopted in the vertical welding mechanism to drive a crank sliding block mechanism, the movement travel is effectively shortened, the design and packaging are simplified, electricity consumption is reduced when the spring bagging machine is used, noise is reduced, and the working environment is improved.

Owner:FOSHAN YULUN MACHINERY

Sanitary change-over valve and assembly comprising a change-over valve of this type

InactiveCN107257895AImplement back and forth conversionImprove back and forth transitionsCheck valvesDomestic plumbingEngineeringCheck valve

The invention relates to a sanitary change-over valve (1) comprising a valve housing (2) which has a valve inlet (3) and two selectively controllable valve outlets (4, 5), a valve piston (6) that can be moved from a first switch-over position, in which the fluid is conducted via a flow path passing through a first valve outlet (4), into a second switch-over position, in which the fluid is conducted via a flow path passing through a second valve outlet (5), as soon as the stretch of the second flow path leading from the change-over valve (1) has been released. The valve piston (6) is designed as a hollow body, through which the fluid is conducted by means of at least one piston inlet (9) positioned on the piston circumference in the course of at least one of the flow paths. The change-over valve according to the invention is characterised in that the fluid conducted by means of the at least one piston inlet (9) is led, in the course of the second flow path, through a first piston outlet provided on the piston end face facing away from the piston head (10), and in that a flow throttle (12), a flow-control valve (11) or a check valve is provided in the first piston outlet.

Owner:NEOPERL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com