Pull-out guide device for furniture parts that are movable relative to one another comprising a roller bearing device

A guiding device and roller bearing technology, which is applied in furniture parts, household appliances, applications, etc., can solve the problems of inconspicuous structural expenditure and no increase, and achieve good working performance and reduce noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

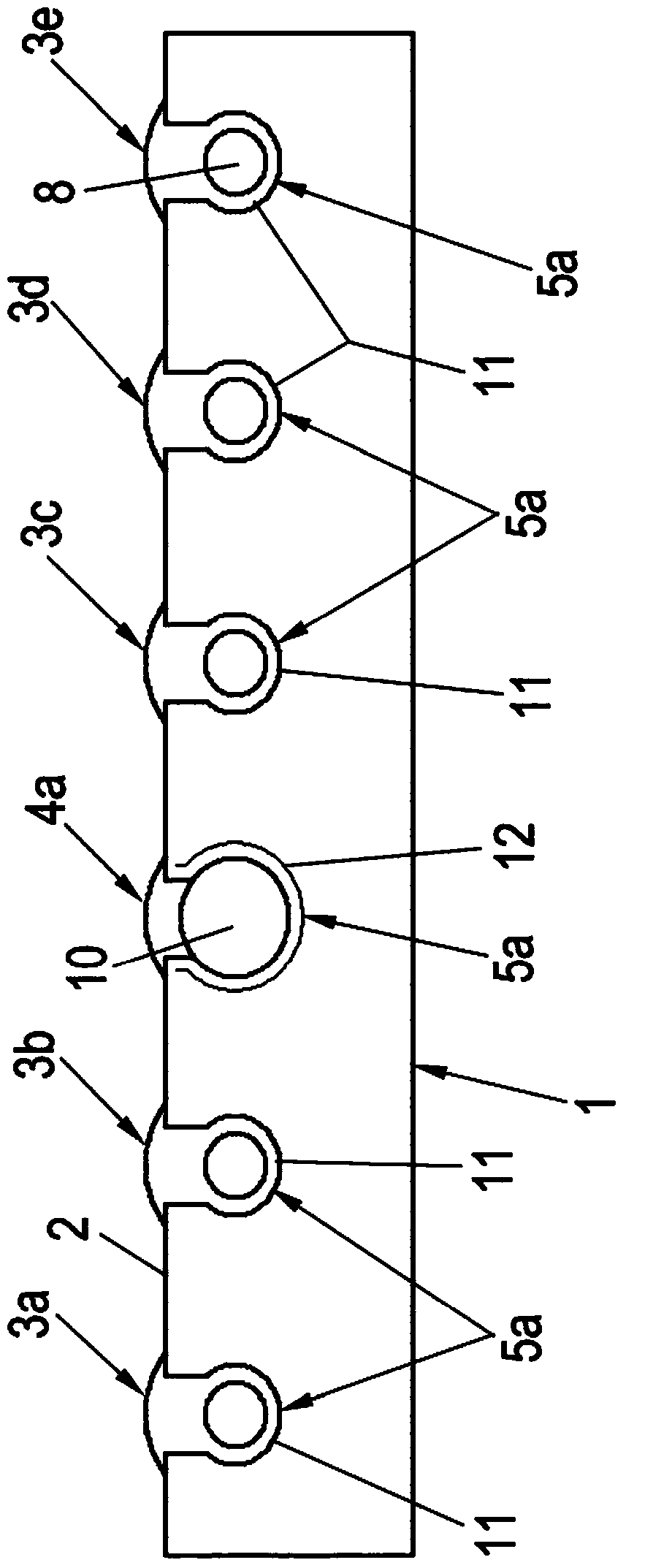

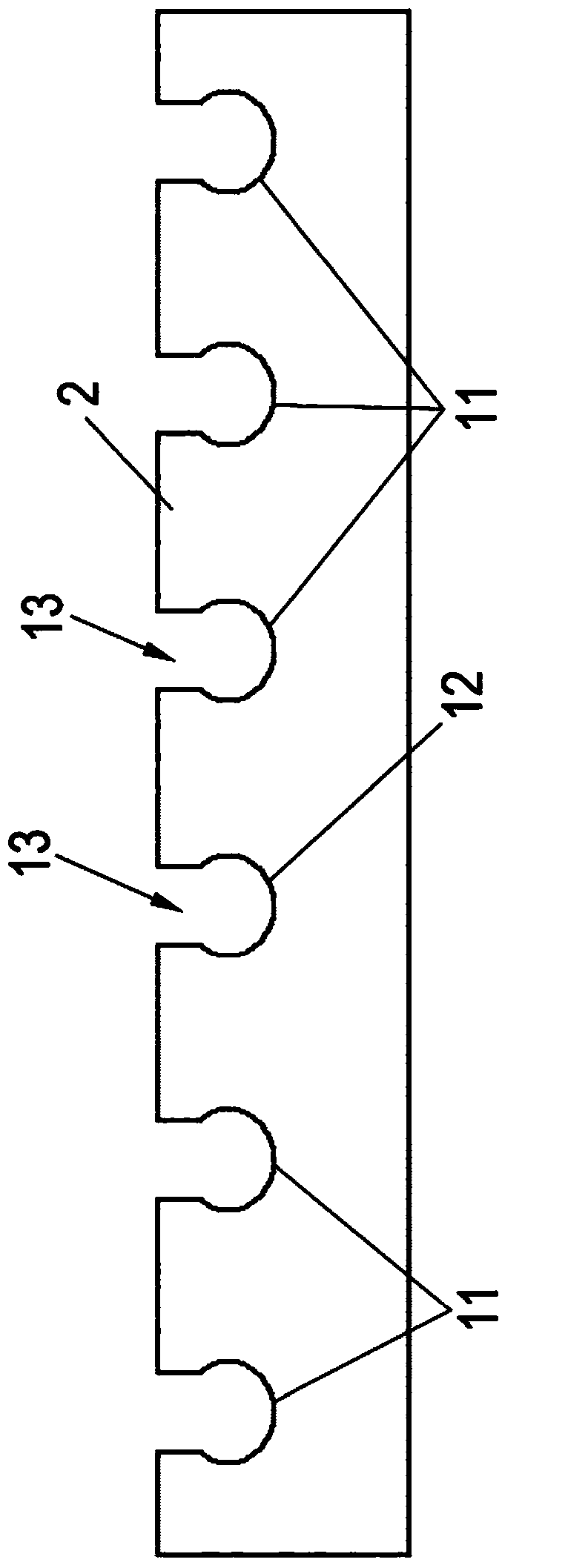

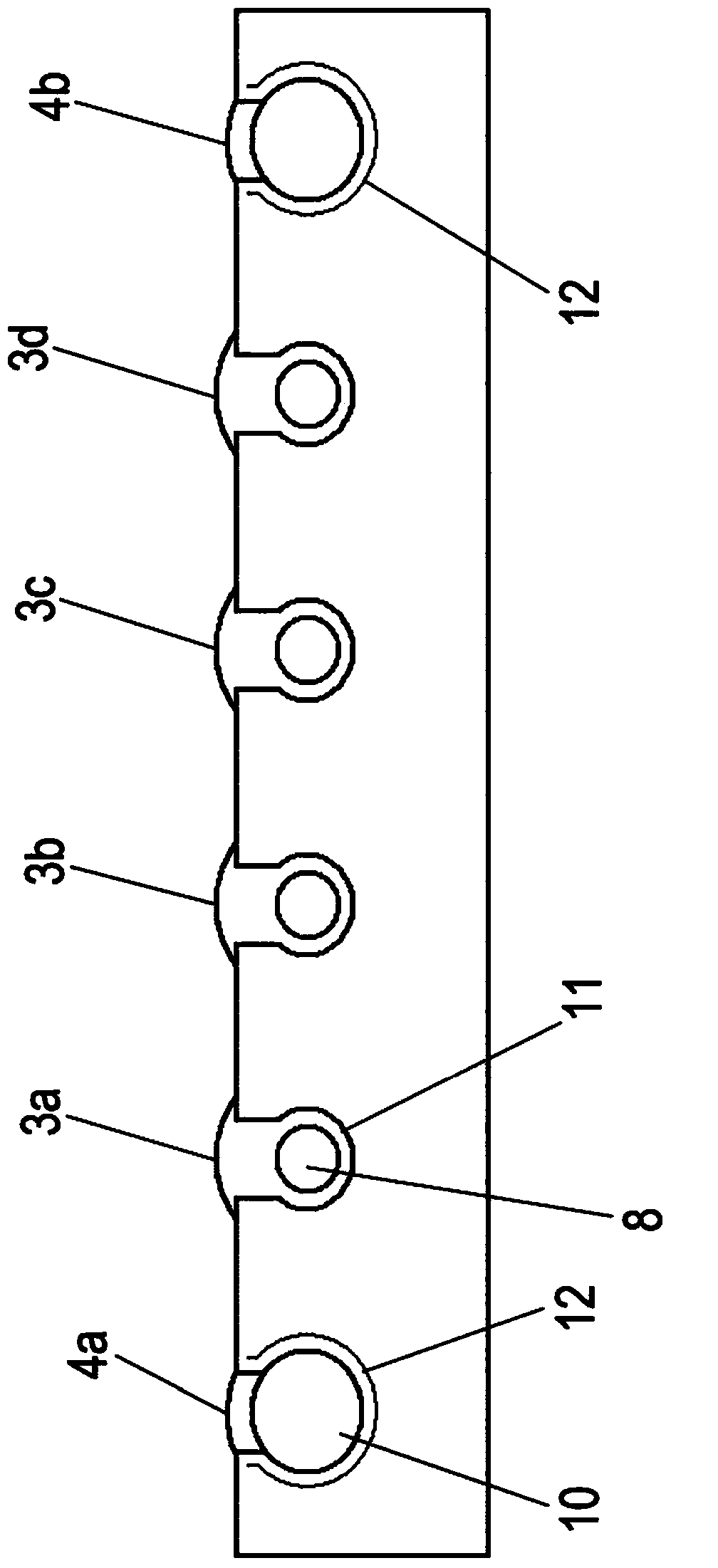

[0039] figure 1 Shown for guides, particularly pull-out guides 100 (see Image 6 ) of the roller bearing unit 1.

[0040] Pull out guide 100 ( Image 6 ) has one or more rails 101 , 102 , 103 preferably linearly displaceable relative to each other, and one or more roller bearing arrangements 1 . The rails 101, 102, 103 preferably form a body rail (for fastening to a furniture body), optionally an intermediate rail and a sliding rail (for fastening to a drawer). A full or partial pull-out guidance is thus achieved. Image 6 The pull-out guide shown in is only to be understood as a preferred exemplary embodiment. The invention also allows the realization of other pull-out guides on which, with Image 6 Design the track or roller bearing arrangement differently as shown in .

[0041] Roller bearing unit 1 ( Image 6 or in an alternate implementation: Figure 1 to Figure 5 ) has at least one roller cage 2 and a plurality of rolling elements 3, 3a, 3b, 3c, 3d, ... and 4, 4a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com