Sanitary change-over valve and assembly comprising a change-over valve of this type

A switching valve and hygienic technology, which is applied to indoor sanitary pipeline devices, multi-port valves, control valves, etc., can solve problems such as the inability to adapt the switching valve and the complex space requirements of the switching valve structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

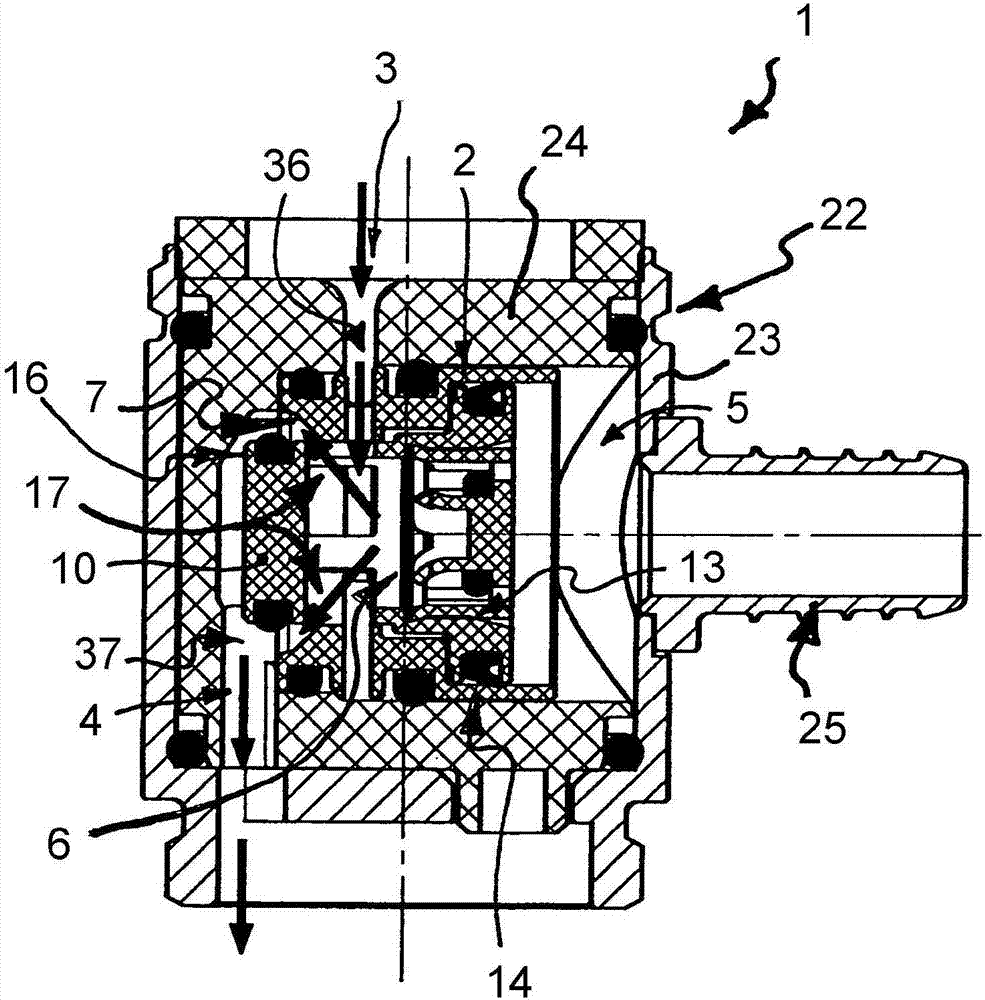

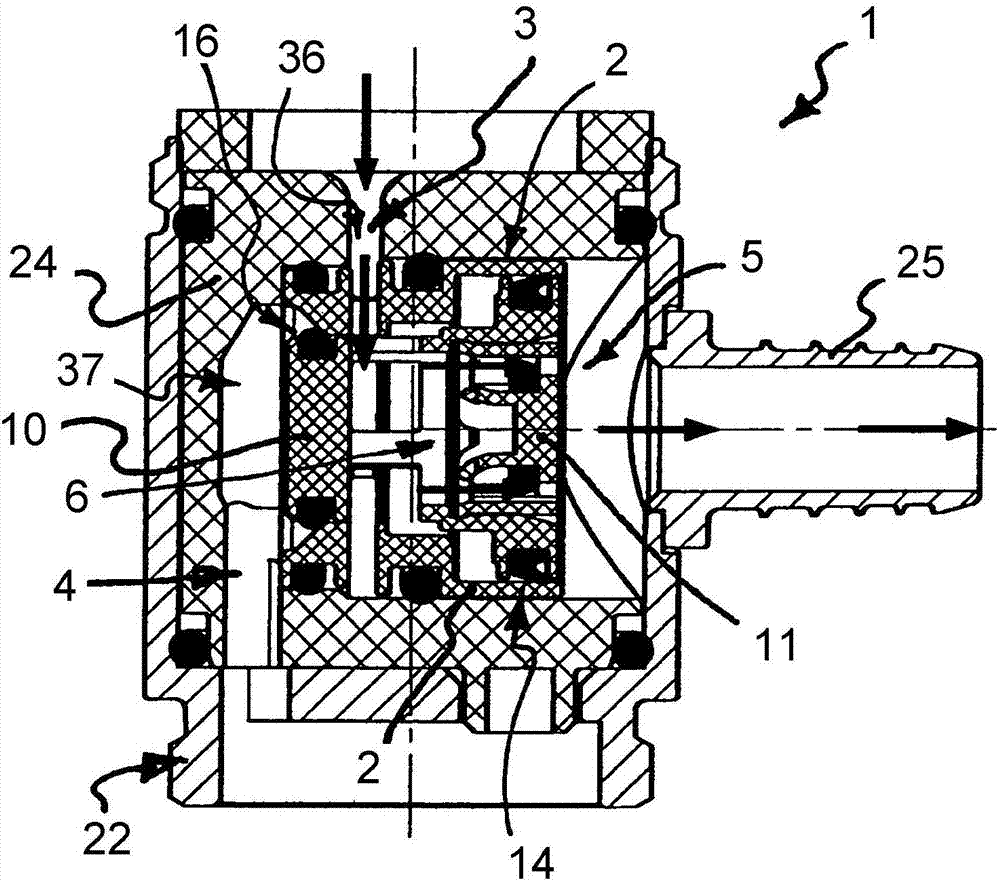

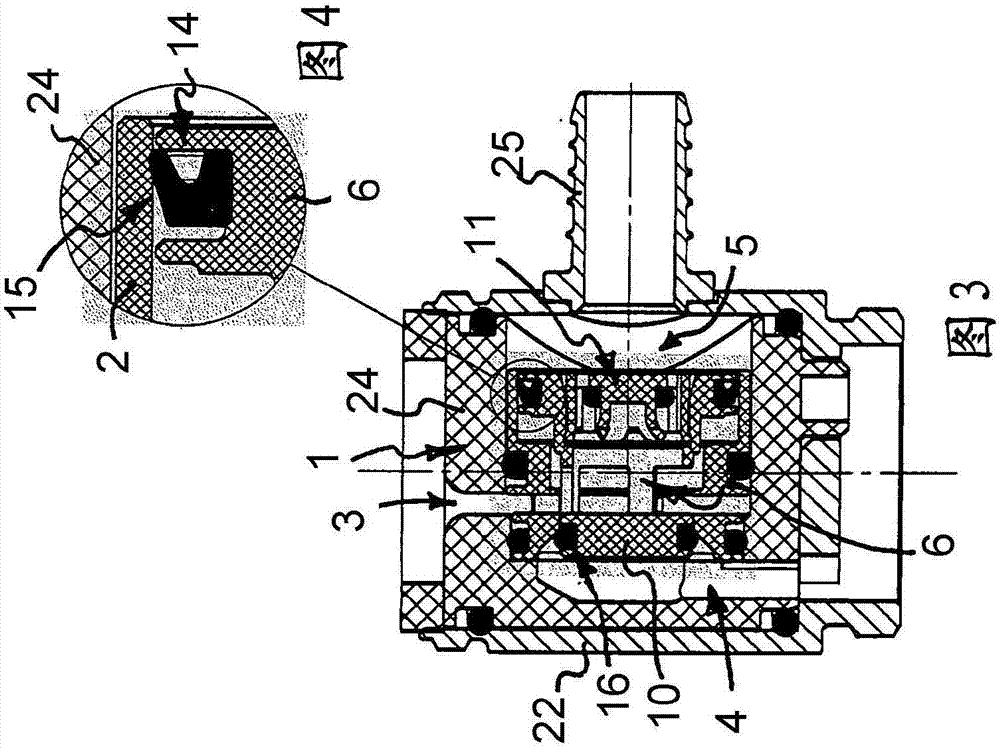

[0061] exist Figures 1 to 39 The hygienic switchover valve 1 is shown in various embodiments and application examples. The changeover valve 1 is intended here to be installed in a water line in order to selectively allow water to flow out of one water outlet or out of the other water outlet when required. The hygienic changeover valve 1 has a valve housing 2 with a valve inlet 3 and two selectively actuatable valve outlets 4 , 5 . A valve piston 6 is displaceably guided in the valve housing 2, which can be moved, for example in figure 1 The first switching position shown in the figure 2 movement between the second switching position shown opposite thereto. in accordance with figure 1 In the first switching position of the water is directed through the flow path through the first valve outlet 4, while the fluid is in accordance with figure 2 The flow path leading through the second valve outlet 5 is reversed in the second switching position of the second valve, once the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com